- How to connect?

- Welded connection

- Connection of polypropylene pipes with metal-plastic options

- Anatomy of polypropylene pipes

- PP material classification

- What does the marking look like?

- Appearance and internal structure

- Types of PP pipes and decoding of markings

- Classification of polypropylene pipes

- Installation

- Metal-plastic pipes - technical characteristics:

- Applications - coverage through technical features:

- Polypropylene pipe connection technology

- With the use of welding

- "Cold" way

- Glue option

- Marking

- Methods for joining pipes made of polypropylene

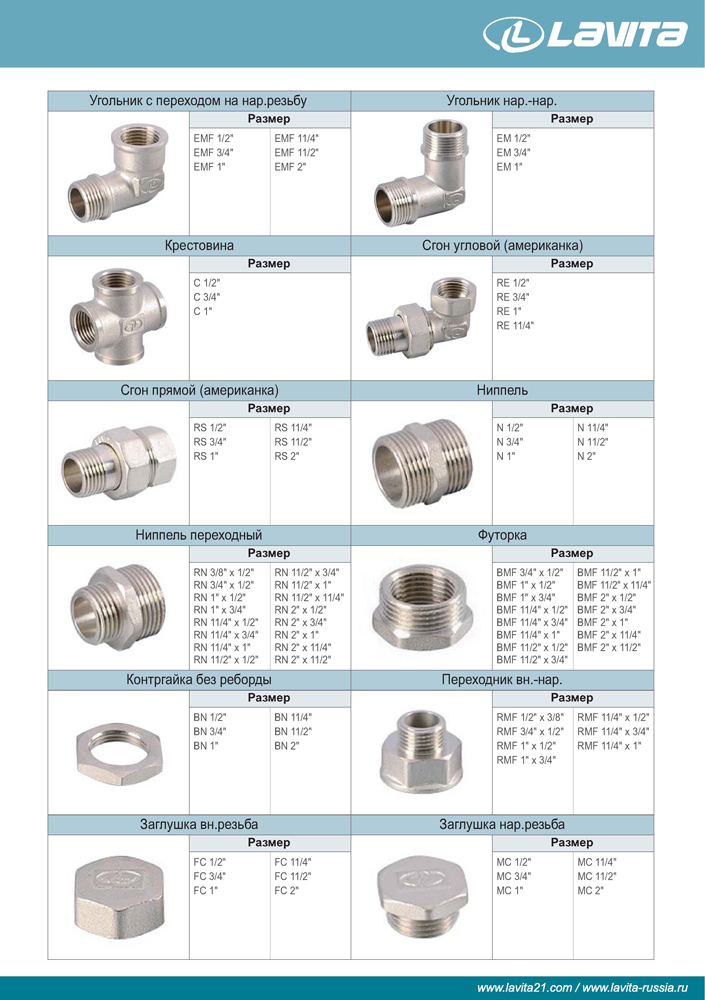

- Threaded fittings

- Diffusion welding

- Welding with electrical fittings

- Butt welding

- Cold welding

- Adhesive connection

- Flange application

- Soldering with solder tape

- About numeric and alphabetic characters in marking

- Rated pressure

- Operating class

- Dimensions

How to connect?

In the case when you need to connect a polypropylene pipe to a metal one, you can use the threaded connection method. To do this, you will need special fittings, one end of which is smooth, and the other end is threaded for a metal pipe. With this type of connection, the diameter of the pipe should not exceed 40 mm.

The thread on the fitting can be either external or internal.A smooth surface on the reverse side is needed for welding a plastic pipe. For tightness, linen tow impregnated with drying oil is mainly used.

The sequence of actions for the threaded mounting method:

- a pipe is cut at a right angle, its end is lubricated with grease, and then a thread is applied using a threading tool;

- remove all chips from the thread and seal the joint with tow;

- a fitting is screwed onto the pipe thread;

- the opposite smooth end of the coupling is welded to the polypropylene pipe.

It is possible to connect polypropylene pipes both by welding and by cold method. More preference is given to the first option, as it is considered the most reliable and durable.

Welded connection

Before welding, polypropylene pipes and fittings for them must be treated with a degreasing solution, and then allowed to dry - only after this procedure can you proceed directly to welding. Similar preparatory work is necessary for any type of PP pipe, with the exception of those reinforced with foil. For a reinforced pipe, the cut is cleaned with a special cleaning tool (shaver), into which the desired end of the pipe is inserted and rotated several times. After stripping, the upper part of the pipe must be degreased.

It is necessary to put a mark on the pipe with a marker, noting the desired distance for pressing it into the fitting. Then the end of the pipe must be put on the mandrel and the fitting inserted into the sleeve of the welding machine. All actions should be done very quickly and clearly. After that, the connected elements are heated for a strictly allotted time.

After the elements to be welded are melted, they must be removed from the nozzles and the pipe must be quickly pressed into the fitting.Some forces are required for the connection, since the elements to be welded must be pressed in tightly and kept in this position for a while. It is not worth clamping the joining elements for more than 20 seconds, since this time is quite enough for them to firmly grasp. After joining, be sure to let it cool down for a few minutes.

Connection of polypropylene pipes with metal-plastic options

In this case, a coupling method is considered a reliable connection method. For installation, you will additionally need two adjustable wrenches, sealant and tow.

The sequence of actions when connecting a polypropylene and metal-plastic pipe:

- the detachable element is disassembled into two parts;

- on the part with an external thread, you need to wind the tow and coat it with silicone sealant;

- tow is also wound on the second fitting, and everything is lubricated with silicone;

- parts of the connection must be twisted together first by hand, and then held out with an adjustable wrench.

Anatomy of polypropylene pipes

Most polypropylene (PP) pipes are the same only at first glance. A more detailed examination of them will make it possible to notice differences in material density, internal structure and wall thickness. The scope of pipes and the features of their installation depend on these factors.

PP material classification

The quality of the welded polypropylene seam and the performance of the pipes are largely determined by the manufacturing technology of the PP.

There are such types of parts, based on the material of their manufacture:

- PRN. Single-layer products made of homopolypropylene. Are applied in industrial pipelines and systems of cold water supply.

- RRV. Single-layer products made of PP block copolymer.Are applied at installation of floor heating networks and cold pipelines.

- PPR. Single-layer products made of PP random copolymer. Are applied in systems of water supply and home heating with water temperature up to +70 °C.

- P.P.S. Flame-retardant type of pipes with operating temperature up to +95 °С.

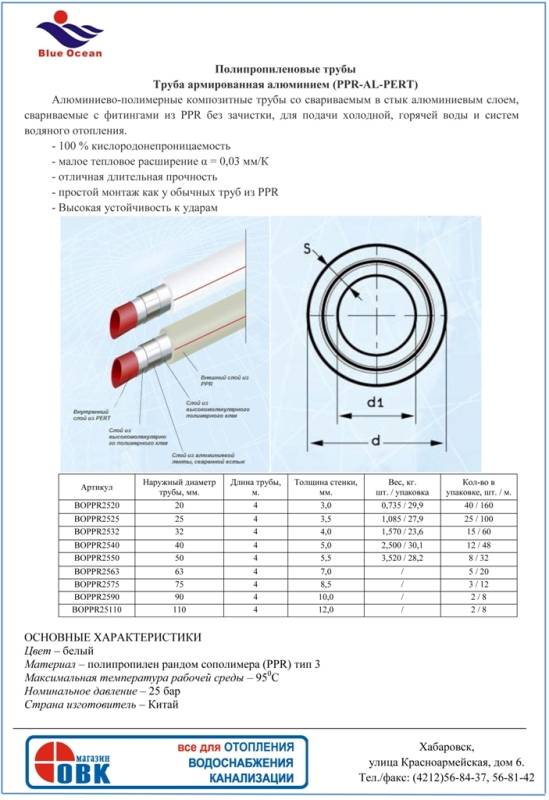

There are also multilayer reinforced parts made of PP.

When heated to 80 degrees, reinforced PP pipes lengthen by 2-2.5 mm / m, and ordinary single-layer pipes - by 12 mm / m

They have an additional inner aluminum shell, which dramatically reduces thermal elongation, facilitating wiring installation and operational safety.

The disadvantage of these products is the need to remove the upper polymer layer and aluminum before soldering to the depth of penetration of the pipe into the fitting.

We examined in more detail the types of PP pipes according to the material of manufacture and fittings in our other article.

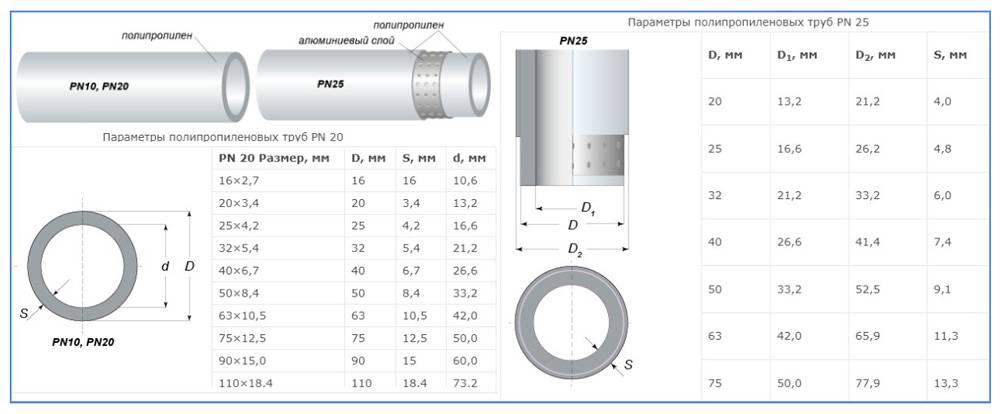

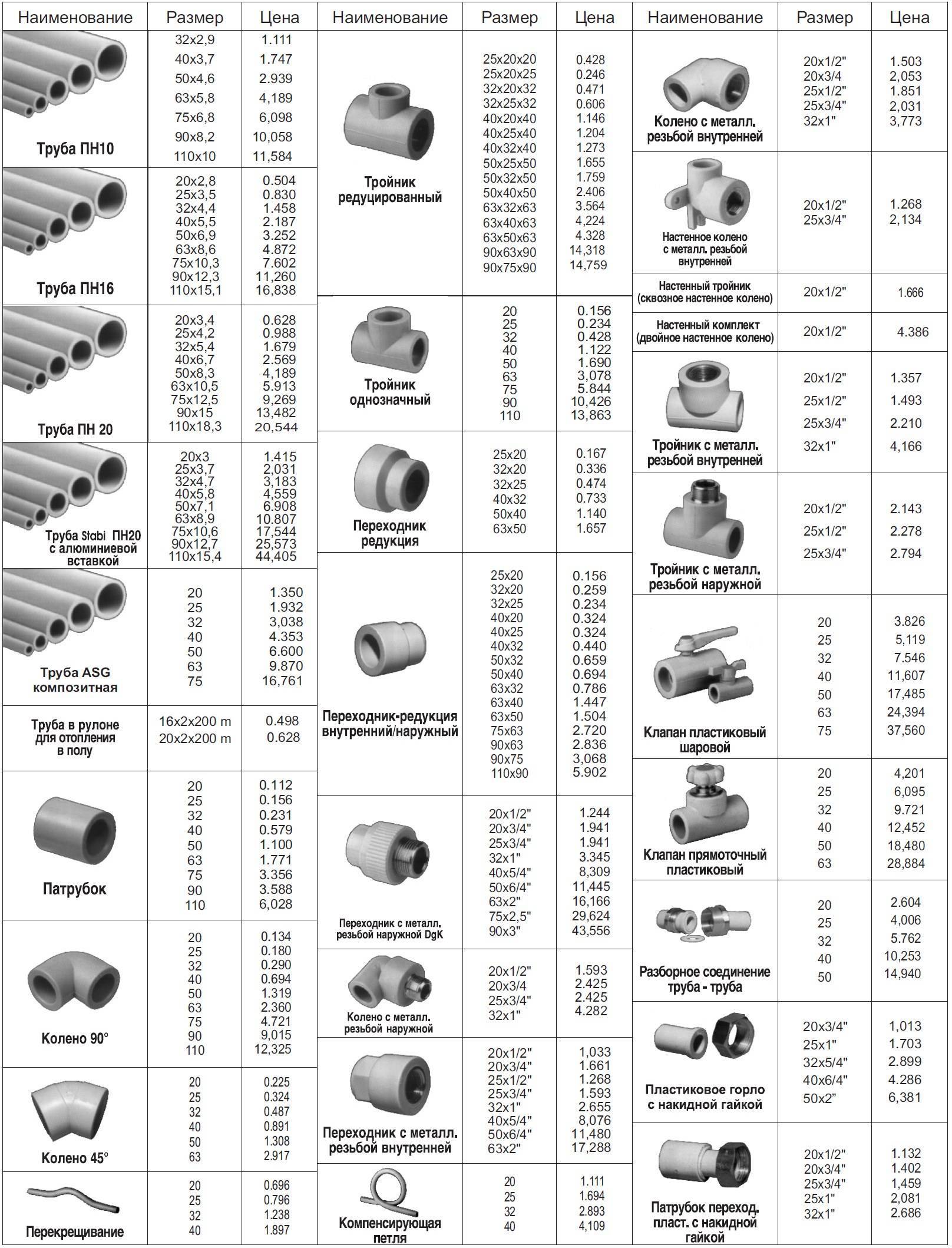

What does the marking look like?

You can choose the required pipes and fittings for plastic wiring in the construction market yourself. You just need to know the labeling conventions.

The indicators may be in a different sequence and in a foreign language, but store managers should know any decoding

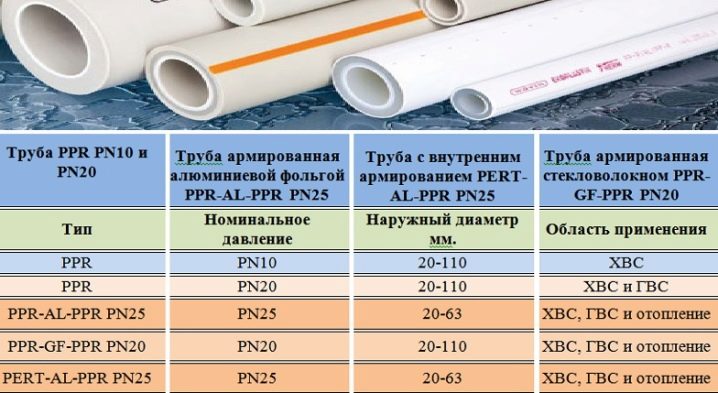

To determine the scope of polypropylene products, the main indicator is PN. This is an indicator of the nominal pressure in kgf / cm2 (1 kgf / cm2 \u003d 0.967 atmospheres), at which the service life does not change. The base temperature of the coolant in the calculation is assumed to be 20 °C.

In the domestic sector, 4 main types of PP pipes with different PN indicators are used:

- PN10 - for cold water supply;

- PN16 - for cold and for warm water supply;

- PN20 - for hot water and heating systems;

- PN25 - for heating systems, especially central type.

Products with PN25 often have a large linear length, so they are almost always reinforced with aluminum foil or strong fiberglass for less expansion when heated. We recommend that you take a closer look at the marking of PP pipes for heating.

Appearance and internal structure

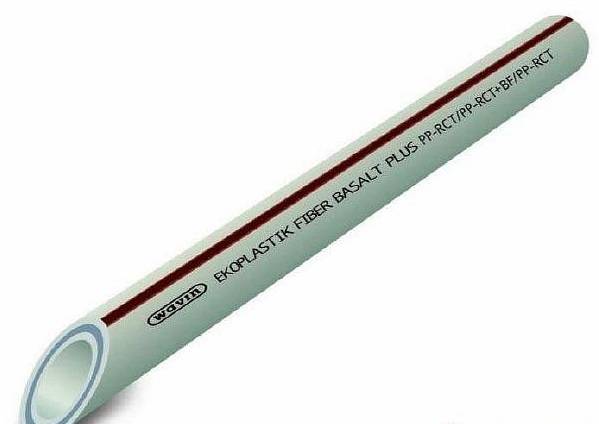

High-quality PP pipes have a perfectly round shape on the cut. The thickness of the walls and the reinforcing material must be the same around the entire circumference, there should be no breaks in aluminum or fiberglass.

To trim the top layer of plastic and foil on reinforced pipes, you need to purchase a special tool - a shaver. It is inexpensive and easy to operate

The reinforced pipe traditionally consists of three layers: inner and outer polypropylene and medium aluminum or fiberglass. Pipe surfaces must be smooth, without sags and recesses.

The color of the material can be green, white or gray, but the quality and characteristics of the pipes do not depend on this at all.

Types of PP pipes and decoding of markings

Manufacturers produce several types of polypropylene pipes, which differ in wall thickness and the presence of an additional reinforcing layer of aluminum foil or fiberglass.

Each type of product has standardized external and internal dimensions of various diameters, its purpose and appropriate marking.

The main technical characteristics are the operating temperature of the coolant and the nominal internal pressure in the pipe. The service life of the pipeline directly depends on these parameters.

Marking includes:

- letters "PN" - designation of nominal pressure;

- the numbers "10, 16, 20, 25" - they correspond to the value of the nominal working pressure in atmospheres (kgf / sq.cm).

Classification of polypropylene pipes

| Type of pipe | Characteristics and purpose | Max. working temperature | Rated working pressure |

|---|---|---|---|

| PN10 | Thin-walled, for cold water and underfloor heating | up to 20°С up to 45°С (for floors) | 10.2 atm. (1MPa) |

| PN16 | Universal, for cold and hot water supply | up to 60°С | 16.3 atm. (1.6MPa) |

| PN20 | Universal, for cold and hot water supply | up to 95°C | 20.4 atm. (2 MPa) |

| PN25 | Reinforced, for hot water supply and heating systems | up to 95°C | 25.5 atm. (2.5 MPa) |

Pipes are available in four colors

Advantages and disadvantages of the Leningradka heating system. Why is it undesirable to use it in multi-storey buildings, what wiring scheme to choose for a one-story house.

Examples of the implementation of a two-pipe heating system, depending on the direction of movement of the coolant: dead-end, direct-flow, natural and forced circulation.

Installation

Soldering sewer and heating polypropylene pipes RVC is no more difficult than any other plastic pipes. There are certain rules by which you need to connect the system. Step-by-step instructions on how to mount a sewer frame:

To get started, you need to prepare a tool. This is a welding machine for polypropylene joints (inverter or hand-held soldering iron), pipe cutters, connections (American fitting, gaskets, fitting, etc.);

The first step is to clean up the connections. The pipe cutter is pressed against the desired section of communication and cuts it to the desired dimensions

Please note, depending on how you will solder the joints, you may need to cut and clean one side, and thread on the other;

After you need to make a chamfer, it is made at an angle of 15 degrees;

To evenly connect the pipes to each other, a trimmer is used. Before soldering communications, make sure they are perpendicular to the floor.

To do this, you need to install them in the centralizer and connect;

Welding is carried out at a certain temperature. Many plastic welding manufacturers indicate in the instructions what temperature will be optimal;

It takes a certain time to weld polypropylene pipes for diffusion to take place, but at the same time the plastic does not overheat. After it is warm, it is left in a vice to cool.

The heating technology of polypropylene pipes may be different depending on their purpose. Sometimes nozzles are mounted on the equipment, for example, electrical couplings. They will help to warm the connection at the right point, while not touching other parts of the craft.

Installation of polypropylene pipes

Thus, it is possible to carry out not only self-made installation, but also repair of cracked pipes or eliminate system depressurization. Then welding or soldering of reinforced polypropylene pipes is carried out using special sealants.

Metal-plastic pipes - technical characteristics:

- outer diameter 16-63 mm;

- wall thickness 2-3 mm;

- aluminum layer thickness 0.19-0.3 mm;

- the weight depends on the diameter, for example, one meter of a metal-plastic pipe with a diameter of 16 mm weighs 105 grams, and if the diameter is 63 mm, then the weight of one meter is 1224 grams;

Metal-plastic pipes withstand pressure:

- operating pressure 10 bar (at 95 °C);

- operating pressure 25 bar (at 25 °C);

- bursting pressure 80 - 94 bar (at 20 °C);

Metal-plastic pipes withstand temperatures:

- constant load +95°С;

- short-term load — up to +110°С;

- at a temperature of -40 ° C freeze;

- with manual bending, the minimum bending radius is 80-125 mm (depending on the outer diameter);

- when bending with a pipe bender - 45-95 mm (depending on the diameter);

- coefficient of linear expansion 1/°C - 0.26 x 10-4;

- thermal conductivity of metal-plastic pipes (the amount of heat that the material is able to pass through a square meter per second) W / m * K - 0.43;

- oxygen diffusion 0 g/m3 (does not let air through);

- service life: a) 25 years at 95°C; b) 50 years at 20°C;

- throughput is 1.3 times higher than that of steel.

The advantages of pipes made of metal-plastic

For anyone who decides to purchase this material, operational characteristics are much more important than technical ones. First the positives:

- ecological cleanliness;

- resistance to the formation of rust, stones or other deposits;

- the ability to maintain a newly acquired shape after bending;

- the possibility of profiling to wrap around the structural elements of the building;

- easy and quick assembly that does not require many tools;

- minimum waste;

- flexibility allows you to save on connection elements;

- low resistance to fluid flow due to the absence of roughness;

- compatibility with other materials;

- light weight for easy transportation;

- high levels of sound insulation;

- antistatic;

- resistance to condensate and freezing (metal-plastic withstands triple freezing);

- do not change the quality of the transported liquid;

- high maintainability;

- aesthetic appearance without painting.

All the advantages of metal-plastic pipes are obtained due to the unique design. The inner polyethylene layer makes it possible to bend the product. Aluminum provides rigidity and prevents oxygen diffusion. The absence of oxygen prevents rust from forming in boilers and radiators.

Flaws

When choosing and buying metal-plastic pipes, negative characteristics are just as important to consider as positive ones:

- with a hidden pipeline, threaded fittings cannot be used;

- metal-plastic does not tolerate ultraviolet rays;

- when freezing with water, the system will certainly burst, although they are suitable for installing an external pipeline. In this case, high-quality insulation is necessary.

Metal-plastic pipes are supplied in bays. The length of the pipe in the bay varies from 50 to 200 meters. You can buy any length, starting from a meter.

Applications - coverage through technical features:

- internal systems of cold and hot water supply, heating of apartments, houses and cottages;

- floor heating systems, sports grounds, swimming pools;

- transportation of gaseous and liquid substances (including caustic and poisonous) in industry, agriculture and transport;

- compressed air supply;

- air conditioning systems;

- protection of electrical wires and cables;

- construction and repair of river and sea vessels, railway cars;

- systems of watering, irrigation, collection of water from wells and wells.

A sufficiently long service life and an optimal ratio of cost and quality have allowed metal-plastic pipes to establish themselves as a successful alternative to metal and plastic products. After all, metal-plastic combined the positive qualities of both of these materials.

Increasingly, when creating plumbing and heating systems in residential buildings, metal-plastic pipes are used.

However, in order to make the right choice, it is important to know not only the features of the structure and operation of pipes consisting of a composite material, but also the pros and cons of these products.

Polypropylene pipe connection technology

Docking and connection of polypropylene pipes can be performed by exposing their ends to high temperature, by installing connecting fittings, or by gluing.

The device for welding polymer products can be rented at the construction center

With the use of welding

It is impossible to connect polypropylene pipes with your own hands without the so-called "iron" - a welding machine powered by the mains.

Without the necessary skills in working with the device, it is worth practicing before performing basic manipulations. Trial docking will make it possible to determine the pressure force and “catch” the optimal holding period. Therefore, materials should be purchased with a small margin.

- In places of future docking, cuts are made on the pipes, the ends are carefully cleaned. At the ends, with a marker, marks are made indicating the depth of immersion of the ends into the heating device. The soldering iron itself is heated to 270 ° C.

- The ends of the pipes and the connection elements are put on the nozzles of a hot soldering iron strictly perpendicularly.

- After holding for 10-15 seconds for the melt, the heated elements are removed from the nozzles and connected to each other, slightly pressing down, but not turning.

- The docked parts are left for several minutes in a fixed position until completely cooled.

If everything is done correctly, then a monolithic joint is formed at the place of soldering without depressions and "sagging".

The installation process is clearly shown in the video:

When welding pipes with a diameter exceeding 40 mm, socket soldering is used. But it is better to entrust this work to a specialist who knows the intricacies of the process and has professional equipment.

Tip: To create strong knots, the elements are heated from the inside, and the pipes are heated from the outside. When joining heated parts along the inner surface of the pipes, a small tubercle may form, reducing the permeability of the pipe. This can be prevented by blowing the structure.

"Cold" way

This method involves the use of compression fittings. To connect polypropylene pipes with fittings, in addition to the main elements, only a crimping key is needed.

Tightness is achieved due to the rubber seal, which is clamped with this key.

- After making cuts at the ends, check the perpendicularity of the edge. With the help of a fine-grained skin or a wire washcloth, the ends are cleaned of burrs.

- A coupling nut is put on the end of the pipe, directing it with a thread towards the fitting. After it, a compression ring is put on, placing it with a long bevel to the fitting.

- A fitting is strung on the prepared end, inserting it all the way against the inner surface of the socket.

- Tighten the coupling nut, check the system for leaks.

If a leak is detected during a test run of water, all joints are sealed, and the connection is tightened.

Glue option

Unlike the welding method, which involves hot exposure, gluing polypropylene pipes is carried out in a cold mode. The method is based on the dissolution of the outer surface of plastic elements under the action of chemical compounds.

Glue is applied only to pre-cleaned and degreased ends

The key to the strength of the joints is the correct choice of composition. In the manufacture of adhesive compositions, manufacturers add substances to them that act as a component of polymer pipes. Therefore, when choosing an adhesive, it is worth giving preference to compositions designed to work with polypropylene products.

The composition is applied in a thin layer, after which the parts are docked and fixed in a stationary position for 10 seconds.

The tightness of the joints of the glued elements is checked after 15-20 minutes, and the strength test of the pipeline is after a day.

- Volgorechensk Pipe Plant (Gazpromtrubinvest)

- Izhora Pipe Plant (ITZ)

- Royal Pipe Works (KTZ)

- Chelyabinsk Pipe Insulation Plant (ChZIT)

- Kstovo Pipe Plant

Add company

- We carry out calculations for the pipe deflection independently

- Features of insertion into gas pipes

- Dealing with condensate from chimneys

- Ways to fix leaking pipes under pressure

- How to make a fungus on a chimney pipe with your own hands

TrubSovet .ru We know everything about pipes

2015–2017 All rights reserved

When copying materials from the site, be sure to place a back link to

Marking

To find out the characteristics of the material from which pipes are made, you need to look at the markings with which they are marked.Deciphering the letter index:

- PP is the designation of ordinary polypropylene;

- PP-R - polypropylene random polymer;

- PP-RC is the designation of type 3 random copolymer;

- PP-RCT is an improved type random copolymer.

Industrial pipelines, agricultural systems are made from PP-RC pipes.

Marking by characteristics:

- PN10 is the designation of parts that can withstand pressure up to 10 atmospheres. The maximum allowable temperature is 45 degrees. Such material is suitable for the manufacture of cold water pipes.

- PN16 - the pressure of a liquid or gas can reach up to 16 atmospheres. Temperature regime - up to 60 degrees. Suitable for assembling underfloor heating systems.

- PN20 - withstand pressure up to 20 atmospheres. Permissible temperature - 95 degrees. Central heating pipelines are made from such elements.

- PN25 - consist of plastic with a layer of aluminum or fiberglass. Withstand pressure up to 25 atmospheres and temperature - 95 degrees.

In the manufacture of a pipeline for hot and cold water supply or a heating circuit, products marked PN25 are more often used.

Methods for joining pipes made of polypropylene

The choice of docking method depends on what kind of connection we want to get - detachable or not. The decision may be influenced by the presence of a special tool and work skills. Consider the most commonly used methods.

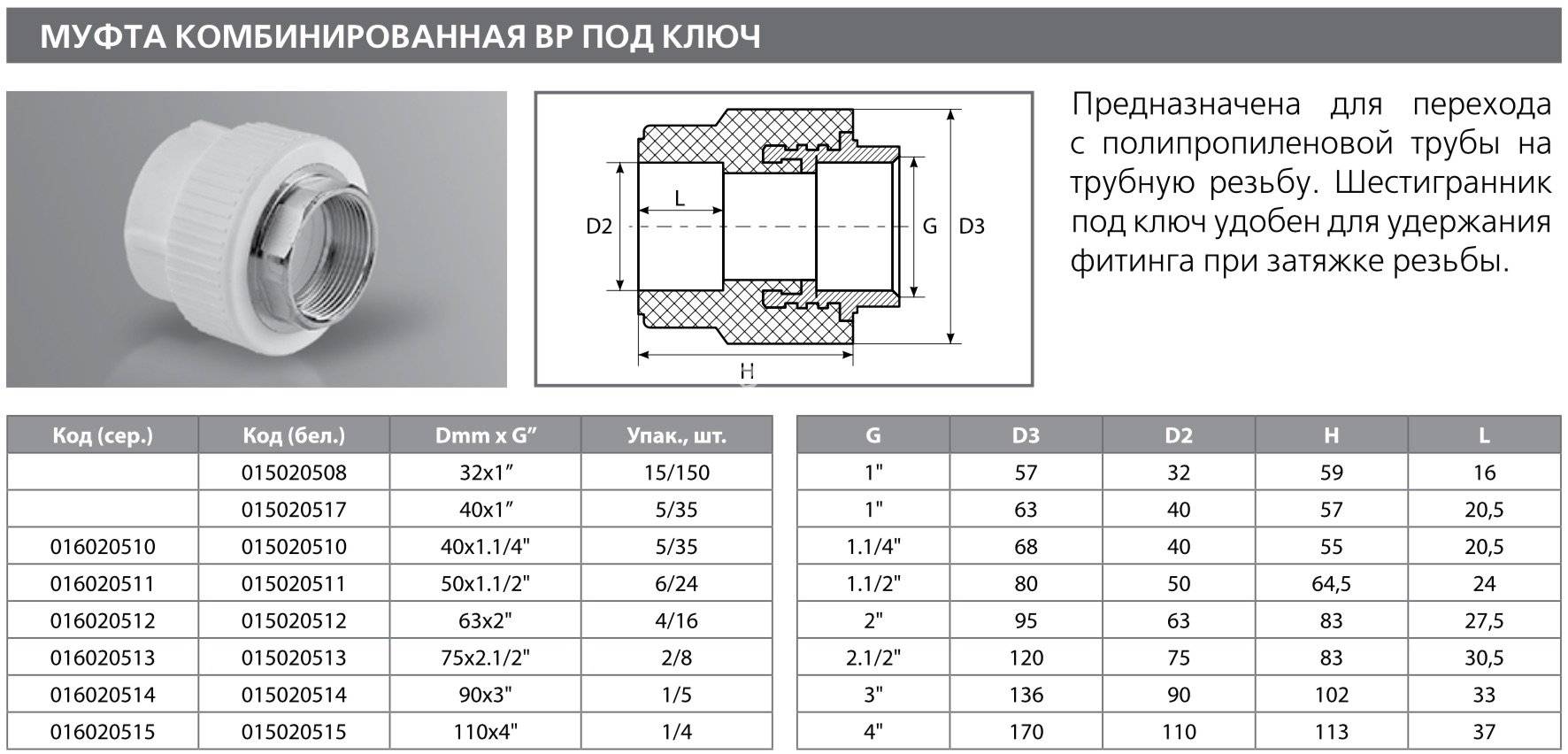

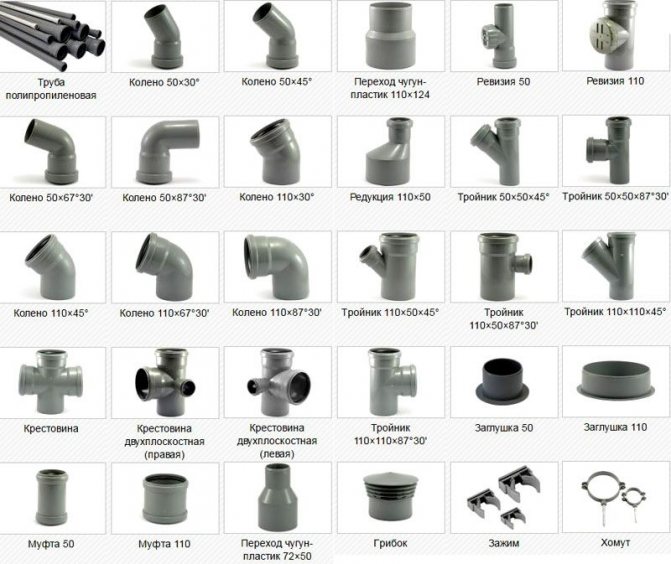

Threaded fittings

If you are thinking about how to make a detachable connection of polypropylene pipes, use threaded fittings. Working with such fittings is considered the simplest and allows you to achieve a good result.

Threaded fittings are a combination of metal and plastic.The plastic part is attached to the polypropylene by welding or soldering through a plastic sleeve. The second end of the element is made of metal, it is threaded, through which it is attached to another piece of pipe or plumbing equipment.

For work you will need:

- Required fittings.

- gas key.

- Cap coupling and key for its installation.

- Sealant.

To prevent leaks at the points of attachment of threaded fittings, flax fiber, fum-tape are wound on the thread. Threaded fittings are installed when connecting plastic pipes with metal ones.

Diffusion welding

This type of butt welding, obtained due to the melting of the material of the parts and the diffuse mutual penetration of molecules. Suitable for joining diameters from 16 to 40 mm. Additionally, a sleeve is used, which provides a layer of plastic to obtain a seam. For thick-walled pipes, diffuse butt welding is used.

Welding with electrical fittings

An electrical fitting is a connector made of polypropylene, in its design it has a metal heater, the contacts of which are brought out.

After the fitting is put on the pipe, the metal contacts are attached to the apparatus, the element is heated, and the fitting through it.

Butt welding

Based on the occurrence of diffusion during heating of polypropylene. To work, you will need a disk unit equipped with a centering device to ensure the alignment of the pipes. It is performed for welding segments with a diameter of more than 60 mm with a wall of 4 mm.

The technology of work includes operations:

- The pipe joints are simultaneously heated to the required temperature with a disk soldering iron.

- Press the ends of the pipes to each other, make sure that their axes coincide, there is no skew.

- Withstand until the material cools down.

Each welding machine is supplied with an instruction, which contains tables indicating the heating and cooling times for a certain wall thickness. Thick-walled pipes produce a reliable seam. Such pipelines can be buried in the ground, immured in the wall.

Cold welding

It is carried out when the material is melted from the chemical action of the adhesive. It is applied to the joined areas, pressed, held for 10-15 minutes. After stabilization of the substance, we obtain a sealed joint. The strength of the connection is low. It is used in pipelines for supplying liquid for cooling and other connections, low responsibility.

Adhesive connection

A thin layer of glue is applied to the cleaned surface, the parts are pressed tightly against each other, and held for 10 seconds. The joint reaches its highest strength in a day

It is important to choose the right adhesive composition, it must be designed for polypropylene

Flange application

Flanges are used when pipes made of various materials are joined, for example, polyethylene with polypropylene. Rubber seals are used for tightness.

Soldering with solder tape

Using a soldering tape, you can connect the elements without a soldering iron, which greatly simplifies the work. The algorithm of actions is as follows:

- We clean the surfaces of parts, degrease.

- We wrap the place of soldering with tape.

- We heat the place where the tape is applied until it melts.

- We put on the joined part.

- We wait until the joint cools down.

- Remove excess solder.

We get a reliable sealed joint. This method is used for soldering small pipes.

Having some plumbing skills, you can do the installation of an internal plumbing or heating system with your own hands. To get a good result, you should read the instructions and recommendations of specialists. The choice of tool, compliance with the technology of work will serve as a guarantee of obtaining high-quality repairs.

Errors when welding polypropylene pipes:

About numeric and alphabetic characters in marking

Many letters and numbers are applied to this material. Manufacturers usually open official websites, where, among other things, there is information on the label and the information that it indicates. But it is best to translate these explanations into a language that everyone can understand.

Pressure. The unit of measurement is kg\cm2. Designated as PN. Indicates how long the pipe has been operating normally while maintaining certain characteristics.

The thicker the wall, the higher this indicator is likely to be. For example, they produce grades PN20, PN25. Such options are needed for supplying hot water, heating systems.

Sometimes red or blue stripes are also applied. This will make it clear what kind of water future pipelines are intended for.

The marking of polypropylene pipes for heating includes data related to materials and structure. Large tables are compiled to describe this parameter. But it is enough to be aware of the basic designations in order to perform the correct installation of heating in an ordinary building.

- Al - aluminum.

- PEX is the designation for cross-linked polyethylene.

- PP-RP. It is high pressure polypropylene.

- PP - Common varieties of polypropylene material.

- HI - fire resistant products.

- TI is a thermally insulated version.

- M - designation of multilayer.

- S - icon for single-layer structures.

The marking of polypropylene pipes for water supply can also indicate data related to:

- The presence or absence of certificates.

- Issued batch numbers, serial designation and time, and so on. Such designations can consist of 15 characters or more.

- Manufacturers.

- Wall thicknesses and sections.

Thanks to this information, each buyer himself will choose a material for water supply that satisfies all his needs.

Rated pressure

The letters PN are the designation of the permitted working pressure. The next figure indicates the level of internal pressure in bar that the product can withstand during a service life of 50 years at a water temperature of 20 degrees. This indicator directly depends on the wall thickness of the product.

PN10. This designation has an inexpensive thin-walled pipe, the nominal pressure in which is 10 bar. The temperature maximum that it can withstand is 45 degrees. Such a product is used for pumping cold water and underfloor heating.

PN16. Higher nominal pressure, higher limiting fluid temperature - 60 degrees Celsius. Such a pipe is significantly deformed under the influence of strong heat, therefore it is not suitable for use in heating systems and for supplying hot liquids. Its purpose is cold water supply.

PN20. The polypropylene pipe of this brand can withstand a pressure of 20 bar and temperatures up to 75 degrees Celsius. It is quite versatile and is used to supply hot and cold water, but should not be used in a heating system, since it has a high coefficient of deformation under the influence of heat.At a temperature of 60 degrees, a segment of such a pipeline of 5 m is extended by almost 5 cm.

PN25. This product has a fundamental difference from the previous types, since it is reinforced with aluminum foil or fiberglass. In terms of properties, the reinforced pipe is similar to metal-plastic products, is less susceptible to temperature effects, and can withstand 95 degrees. It is intended for use in systems of heating, and also in GVS.

Operating class

When choosing polypropylene products of domestic production, the purpose of the pipe will tell you the class of operation according to GOST.

- Class 1 - the product is intended for hot water supply at a temperature of 60 °C.

- Class 2 - DHW at 70 °C.

- Class 3 - for underfloor heating using low temperatures up to 60 °C.

- Class 4 - for floor and radiator heating systems that use water up to 70 ° C.

- Class 5 - for radiator heating with high temperatures - up to 90 ° C.

- HV - cold water supply.

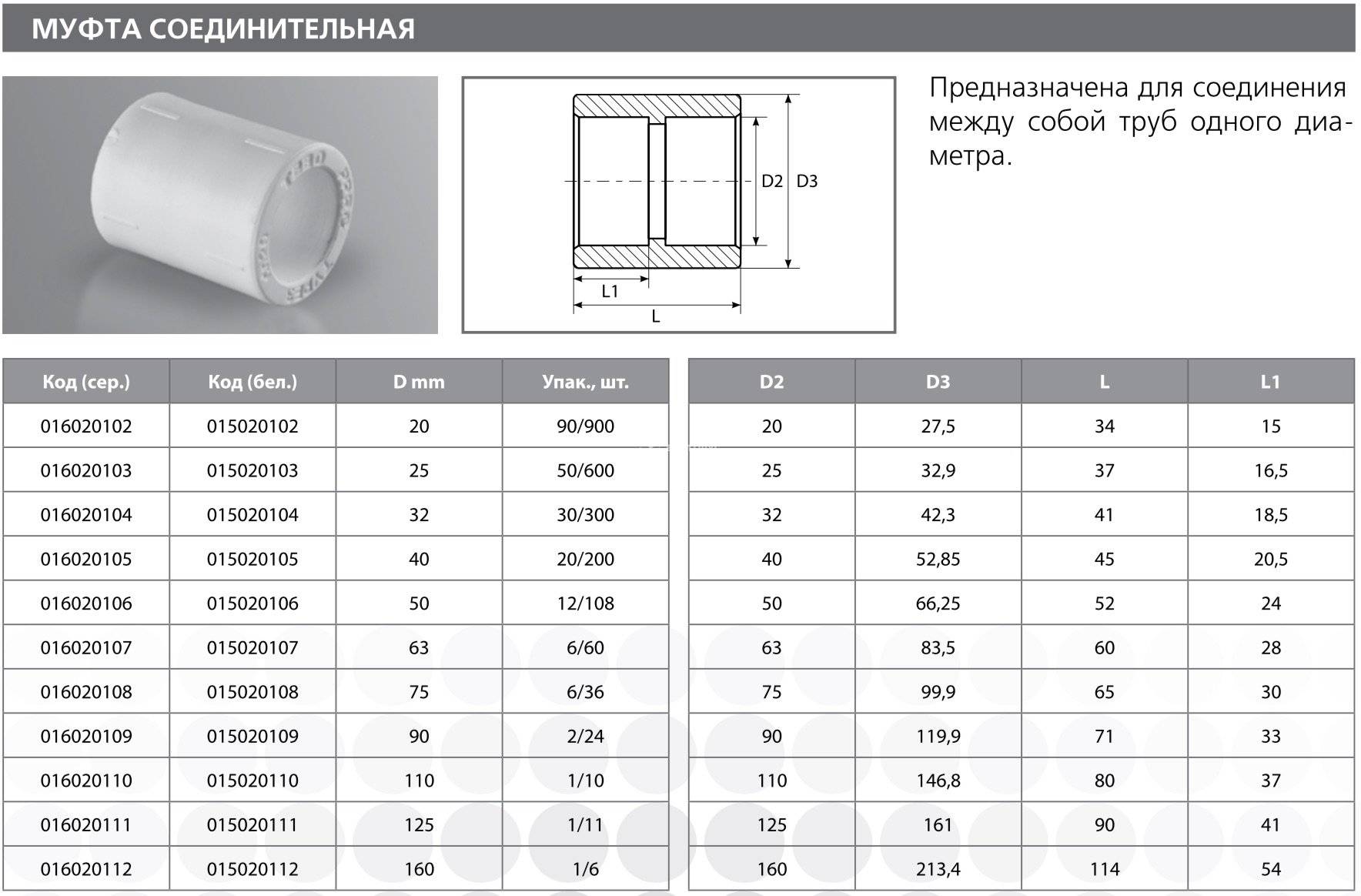

Dimensions

The dimensions of polypropylene pipes vary widely. Values for external and internal diameters, wall thicknesses can be found in the following table.