- What to look for when choosing

- Characteristics of metal-plastic

- Features of metal-plastic pipes

- Product features

- The use of metal-plastic pipes in autonomous and central heating systems

- Materials for sewer pipes

- Cast iron

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Other materials

- Polypropylene pipes

- Marking of polymer pipes

- Polypropylene or metal-plastic - the subtleties of choice

- What is better for a private house

- Polymers and central heating

- Boiler room wiring

- Heating system in the apartment: instructions for its creation

What to look for when choosing

In order to equip a heating circuit that will be efficient and reliable, when choosing pipes, you should pay attention to the following subtleties:

- The inner diameter of the pipes must be greater than or equal to the diameter of the heater pipe intended for connection to the heating circuit.

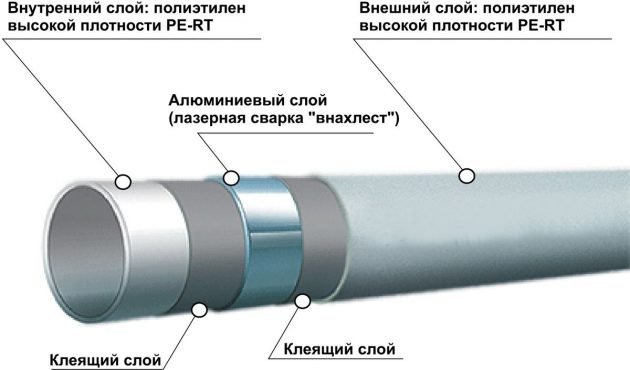

- For the equipment of thermal systems, pipes with an aluminum layer thickness of more than 0.4 mm are suitable - they are able to withstand high temperatures and pressures.

- You need to buy metal-plastic pipes and fittings for them only in specialized stores - this will reduce the risk of acquiring fakes, and buying components from official dealers of well-known companies will completely eliminate this possibility.

- High-quality pipe products always have accompanying documents that describe the technical characteristics, operating conditions, instructions for use, and markings indicating the manufacturer, the outer diameter of the pipe and the thickness of its walls.

- The purchased components must not have obvious defects: surface damage, uneven cuts, delamination on the end parts.

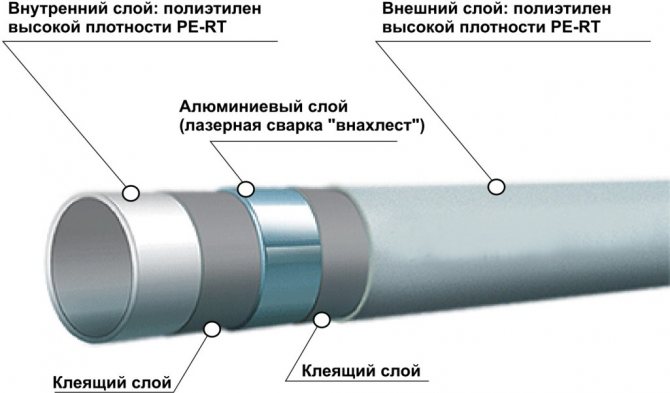

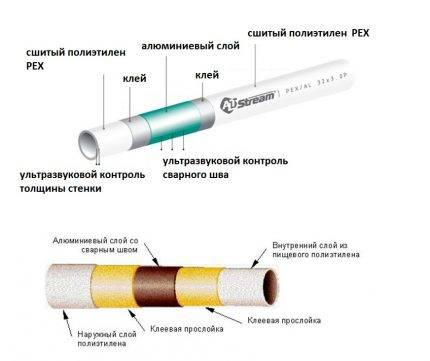

- It is advisable to purchase pipes whose reinforcing layer is butt-welded, and not overlapped. During butt welding of aluminum, a thin neat seam is formed, which does not prevent the pipes from bending and does not deform during their operation. When connecting the aluminum layer with an overlap, the seam is rigid; when the pipe is bent, stress zones, creases, and breaks are formed in such a seam, resulting in a leak. If there is no information about the method of connecting the reinforcing layer in the accompanying documentation, it is enough to look at the cut of the pipe, there will be a thickening at the overlap, which is not noticeable to the naked eye during butt welding.

Characteristics of metal-plastic

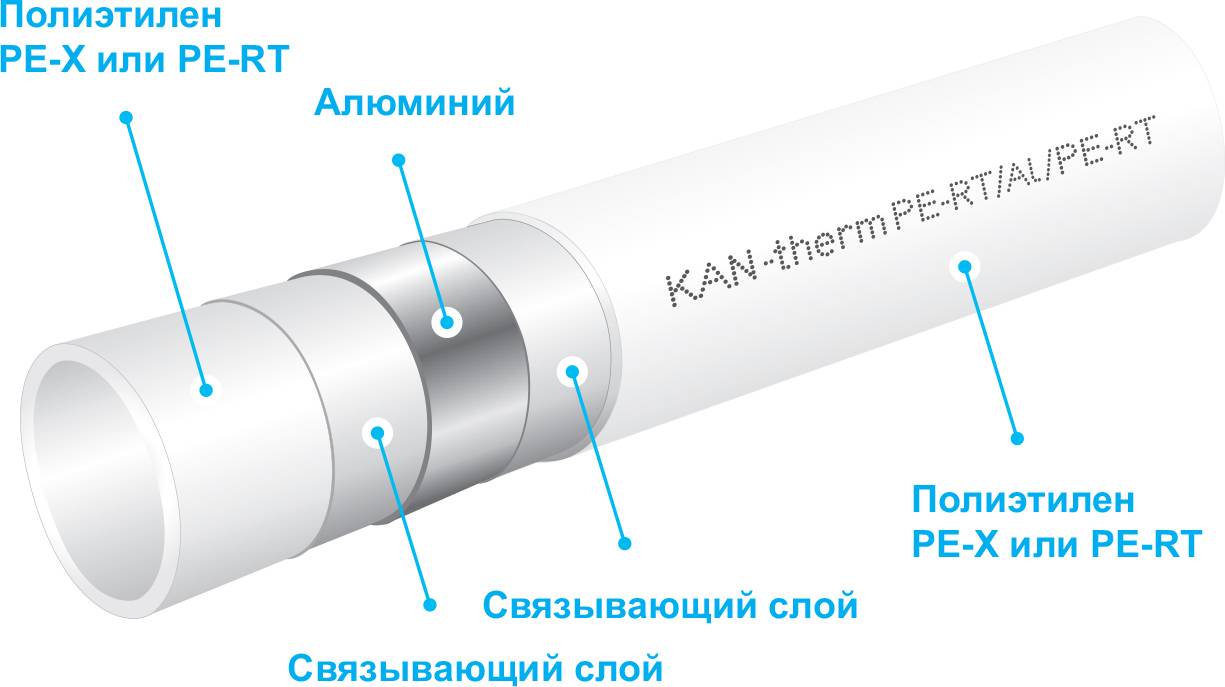

All metal-plastic profiles are three-layer. Therefore, without a professional look, it is immediately difficult to distinguish whether it is reinforced polypropylene pipes or metal-plastic pipes. The design is quite simple: the inner plastic layer, then the intermediate one (reinforced with aluminum foil), the outer one is polymer. For the plastic component, several types of polymer are used, and the material is indicated using lettering:

- PE-AL-PE is read as polyethylene - aluminum - polyethylene.

- PP-AL-PP polypropylene - aluminum - polypropylene.

- PB-AL-PB polybutene - aluminum - polybutene.

Any metal-plastic pipe has the following characteristics:

| Property | Value, units rev. |

| Operating pressure | Up to 2.5 MPa |

| Maximum medium temperature | 95–110 0C |

| Thermal conductivity of reinforcement walls | 0.15W/(m*0C) |

| Operating temperature | up to 120 0C |

| Roughness | 0,07 |

| Life time | 25/50 years |

The design of the metal-plastic pipe

Features of metal-plastic pipes

Products made of aluminum-polyethylene metal-plastic combine the best aspects of plastic and metal. Comparing them with a polypropylene competitor, it should be understood that price per running meter in both cases is approximately the same.

However, metal-plastic fittings are much more expensive than those used in the installation of PPR pipelines.

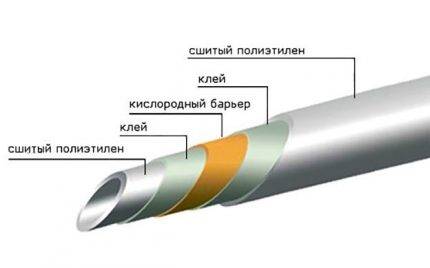

A metal-plastic pipe (PEX-AL-PEX) consists of two layers of "cross-linked" polyethylene and a reinforcing aluminum layer 0.2–0.3 mm thick, which are interconnected with glue

A metal-plastic pipe (PEX-AL-PEX) consists of two layers of "cross-linked" polyethylene and a reinforcing aluminum layer 0.2–0.3 mm thick, which are interconnected with glue

“Crosslinking” of polyethylene occurs during its production at the molecular level. There are no seams or stitches of threads in sight. There are three main manufacturing technologies for this plastic, indicated in the marking of pipe products PEX-A, PEX-B and PEX-C.

These nuances of production do not make much difference to the final characteristics of the pipe.

Here, it is more important that the manufacturer adheres to the PEX technology itself.

A thin layer of aluminum between the inner and outer layers of PEX serves to:

- partial compensation of thermal expansion of the pipe;

- formation of a diffusion barrier.

Cross-linked polyethylene is initially designed for high operating temperatures up to +95 °C. However, when heated, it begins to expand slightly. To compensate for this expansion, an aluminum tab is made between the two polyethylene layers.The metal takes over most of the stress that occurs in the polyethylene through the adhesive layer, preventing the plastic from expanding and deforming too much.

But the main task of aluminum in metal-plastic is not to compensate for stress in polyethylene, but to prevent oxygen from entering the pipe from the air in the room.

But the main task of aluminum in metal-plastic is not to compensate for stress in polyethylene, but to prevent oxygen from entering the pipe from the air in the room.

Among the advantages of metal-plastic pipelines, it is worth highlighting:

- no stray currents;

- constancy of flow section;

- lower noise compared to metal analogues;

- lack of expansion of plastic (sagging pipes) as a result of heating water in them;

- ease of installation of the pipeline system.

The symbiosis of metal and plastic is able to withstand a short-term increase in the temperature of the water inside up to +115 °C. And plus 95 degrees Celsius is the norm for him.

Metal-plastic pipes are ideal for hot water systems, "warm floors" and heating. It is thanks to them that the aggressive effect of oxygen on various hydraulic pumps, as well as heating boilers and radiators, can be minimized.

Among the negative sides of metal-plastic pipes are:

- aging of polyethylene under direct sunlight;

- the need for a grounding device for plumbing with a metal case, because plastic is a dielectric;

- the need to pull the fittings one year after the commissioning of the pipeline system.

Metal-plastic pipes must be covered behind the finish from direct sunlight, otherwise their service life will be drastically reduced. A tightening of the fittings is required due to the temperature deformations of the pipeline, from which it is simply impossible to completely get rid of.

And the main drawback is that metal-plastic cannot be frozen.Due to such sudden changes in temperature, it can be trite at the seams.

Product features

Even if you have some experience installing a plumbing, sewerage or heating system, and you know everything about pipe sizes in inches and millimeters, it would still not be superfluous to find out something else.

The work of replacing water pipes in an apartment or a private house is within the power of every man.

However, do not forget that this activity is not as simple as it might seem at first glance.

Inside the apartment, it is allowed to install one of several types of pipes, namely:

- copper (how to solder copper pipes for plumbing read here),

- metal-plastic,

- steel,

- galvanized,

- cast-iron (read about the tie-in into the cast-iron water supply in this article),

- pvc,

- polypropylene (plastic fittings for plumbing are described on this page).

Each of these materials has its own advantages and disadvantages.

In this article we will talk about polypropylene and metal-plastic pipes.

The use of metal-plastic pipes in autonomous and central heating systems

The use of metal-plastic pipes for the installation of heating networks allows you to save time, effort and money and equip a pipeline that has all the positive qualities of metal and plastic.

To obtain such a result, it is necessary, first of all, to understand the differences in the operation of central heating and individual:

- In a central heating system, a powerful heat generating device heats a large amount of water.The heated coolant enters houses and apartments with a temperature of 40 to 95 degrees, but with preventive measures, the water supplied to the pipes can have a temperature of up to 150 degrees. The pressure is usually in the range of 4-5 atmospheres, but since an extensive and branched heating network is serviced, water hammer occurs in the pipeline - pressure surges when it exceeds the norm by 2-3 times. For metal-plastic, 95 degrees is the operating temperature limit, and water hammer is the threat of instant destruction of the walls, especially at turns and knots. Therefore, the installation of metal-plastic pipes in rooms receiving coolant from a centralized system is undesirable. However, the above problems can be solved by equipping the pipeline with pressure stabilizers and temperature controllers.

- In an autonomous system, a small volume of coolant circulates, the temperature and pressure can be adjusted directly on the heat generating device. Therefore, in houses, apartments, commercial and other buildings with individual heating, metal-plastic can be used without restrictions.

Materials for sewer pipes

Now that the requirements are presented, it is necessary to consider each of the materials and evaluate how it corresponds to them. And although a fairly wide range of products made from different raw materials are used for sewer pipes, only three options are most common: cast iron, polyvinyl chloride and polypropylene. In addition to them, you can see ceramic, steel, asbestos-cement pipes, but they come across much less frequently.

Ceramic sewer pipes

Cast iron

Without a doubt, if cast iron is not the best sewer pipes, then it is certainly the most durable and durable.Their service life is measured in almost centuries, and this is supported by well-known practice, and not by theoretical calculations. As for the rest of the properties, the resistance to all factors is high, with installation there may be difficulties associated with connections and heavy weight, which is extremely inconvenient during work. The surface has irregularities, sooner or later leading to clogging. Another disadvantage is the high cost.

Cast iron pipes for sewerage

Polyvinyl chloride (PVC)

The strength and durability of these pipes is at the level, at least according to experts, since they have been used relatively recently.

Let's take a look at the rest of the features:

- Resistance to temperature - with an increase above 70 degrees - deformation, at negative temperatures - brittleness.

- Fire resistance is absent, moreover, during combustion, it releases phosgene gas, which is officially classified as a chemical weapon.

- Immune to ultraviolet and aggressive reagents.

- Installation is simple, the inner surface is smooth.

- The cost is affordable.

Summarizing all of the above, we can say that it is better to use PVC for internal sewage, and for the external one, choose another material that is more suitable for this role.

PVC sewer pipes

Polypropylene (PP)

Fittings for PP pipes

Looking ahead, we can say that at the moment, the best sewer pipes are still polypropylene. Such a conclusion can be drawn by evaluating them according to all the above parameters, where for each of them they are rated at five. Strength and durability are high, the pipes are resistant to a complex of influences, the only thing is that with constant heating a slight linear expansion is possible.Installation of PP pipes is easy and without the use of any particularly expensive and complex devices, the inner surface is not something that does not retain deposits - it repels them, and after a few years, it will be almost as clean as when installed. The cost is quite acceptable.

Other materials

Going through the rest of the materials, we can say the following:

- Steel. Strong and resistant to most factors, easy to process, but suffers from corrosion and has a large weight that can create serious installation difficulties.

- Ceramics. It is resistant to chemicals, fire, corrosion, strength and durability. Installation is difficult, if the grooves are clogged, it cannot be carried out. Also, ceramics are fragile and cannot withstand mechanical shock loads, and all protective properties depend on the presence of glaze. Today, ceramics can be found, perhaps, in old reclamation structures; it has already been replaced by more modern and practical materials from other areas.

- Asbestos cement. The material has almost disappeared, and has many more minuses than pluses: fragility, fragility, inconvenience during installation, and many others.

Sewerage from PP pipes

When choosing a material for the construction of a sewer, it is necessary to carefully and seriously evaluate and calculate all the minuses and pluses of any option, without bypassing the final cost of the project. To date, sewerage from plastic pipes made of polypropylene is probably the best option, both in terms of practicality and economy.

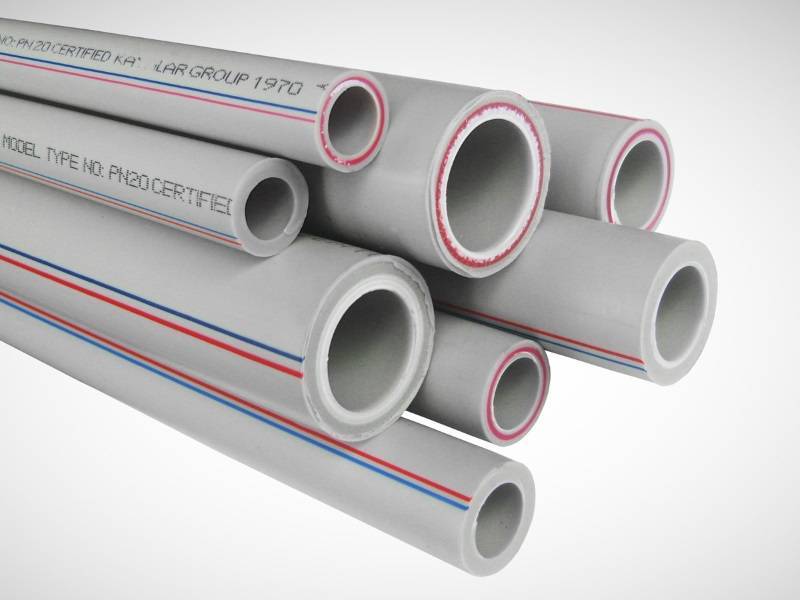

Polypropylene pipes

For the manufacture of PPR pipes, random is used (this is polypropylene of the third type).

This modified material has a huge number of positive properties, thanks to which products made from it can be used not only in cold, but also in hot water supply.

This modified material has a huge number of positive properties, thanks to which products made from it can be used not only in cold, but also in hot water supply.

In addition, PPR has increased resistance to various chemical compounds.

Therefore, it is very often used in the arrangement of technological pipelines.

Polypropylene belongs to the category of materials related to thermoplastics.

This means that it becomes soft and begins to melt only at high temperatures (+170 degrees Celsius).

High-quality PPR products are able to withstand nominal temperatures ranging from 75 to 80 degrees.

The most they can withstand is temporary jumps up to +95 degrees Celsius.

This is the reason that many experts do not recommend using them when installing a heating system.

Polypropylene pipes cannot be bent.

Therefore, if you need to make a turn or bend, you can not do without a fitting.

The elements of the system are fixed using a welding machine specially designed for this purpose.

Advantages of PPR pipelines.

- Water tightness of all connections.

Due to this property, these products are successfully used in concealed plumbing systems. - They are not subject to corrosion processes.

This contributes to a long service life. - Increased mechanical wear resistance.

- During the entire period of operation of the pipeline, its internal diameter remains unchanged.

Scale and other deposits do not form on smooth walls. - Excellent soundproof qualities.

The sound of water in these pipes is inaudible at all. - They are easy and quick to install.

This does not require special knowledge and skills.

Joints are welded in a minimum period of time. - Polypropylene is an environmentally friendly material.

It is completely harmless to human health.

After use, it is recycled without damaging nature. - PPR does not interact with chemically active substances.

It is not able to change the taste, smell, color and composition of water. - Good thermoplasticity.

Thanks to this quality, the pipes, after freezing and subsequent thawing, take their original shape and size, while not bursting or deforming. - The cost of production is available to the general population.

Cons of polypropylene products.

- If the pipes are not reinforced, they cannot be used to install a system through which a well-heated liquid will pass.

- Significant temperature increase in size.

This fact must be taken into account when arranging hot water supply.

In this case, pipes are not recommended to be hidden under finishing materials.

Since when expanding hollow objects, they will be damaged. - The inevitability of the use of a large number of fasteners when installing the wiring.

And this will lead to an increase in the cost of construction. - Pipes cannot be connected to each other without a special soldering device, you still need to be able to manage it.

- It is unacceptable to assemble the system at low temperatures.

The modern market offers another option for such pipes - reinforced.

They have improved technical characteristics.

Such products can transport liquid, the temperature of which is from +95 to + 120 degrees Celsius.

Marking of polymer pipes

Polymer pipes are marked according to the type of polymer (RE,

RE-X, RR etc.), according to the outer diameter and nominal

pressure (PN).

External pipe diameters (in mm) for internal wiring are presented

next row: 10; 12; 16; 25; 32; 40; 50 etc.

In addition to diameter, pipes are marked by wall thickness.

Nominal pressure is usually expressed in bar: 1 bar = 0.1

MPa. Rated pressure means constant

internal water pressure at 20°C, which the pipe can reliably

withstand for 50 years (for example, PN=10, PN=12.5 or

PM=20).

To assess the level of these parameters, we can recall that the working

water pressure in the plumbing system is not more than 0.6 MPa (6

bar). The maximum pressure that the pipe can withstand

short time, several times higher than the nominal. At a temperature

above 20°С the period of non-failure operation of polymer pipes at a constant

pressure decreases or may remain the same - 50 years,

but subject to lower operating pressure.

Polypropylene or metal-plastic - the subtleties of choice

Homeowners involved in the heating device, when choosing, are guided by the price of materials and the cost of installation work, which in total gives the total cost. This factor plays an important role, which is quite natural given the current incomes of citizens. In this regard, PPR is better than metal-plastic, since it will cost at least half the price. If you take high-quality materials produced by well-known brands, then metal-plastic will be three times more expensive.

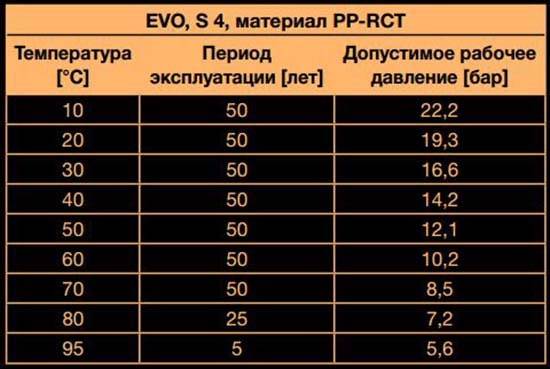

It is impossible not to touch upon the technical characteristics of metal-plastic and polypropylene. The most important are the working maximum allowable pressure and temperature of the water in the pipeline.These parameters are interrelated, for example, a PP-R pipe can withstand a pressure of 10 bar at a coolant temperature of 60 °C, and at 95 °C the pressure drops to 5.6 bar. The higher the operating temperature, the shorter the service life of polypropylene, as shown in the table:

For comparison, let's take the no less eminent Belgian brand Henco, which offers the highest quality pipeline metal-plastic reinforced with a single layer of aluminum. Its performance characteristics are as follows: at a temperature of 95 ° C, the maximum working pressure is 10 bar, and for some pipe modifications - 16 bar. The given indicators of technical characteristics should be taken into account when choosing a material

It is also important to understand where it will be used:

- heating of a private house;

- centralized heating system of the apartment;

- boiler room;

- warm floor.

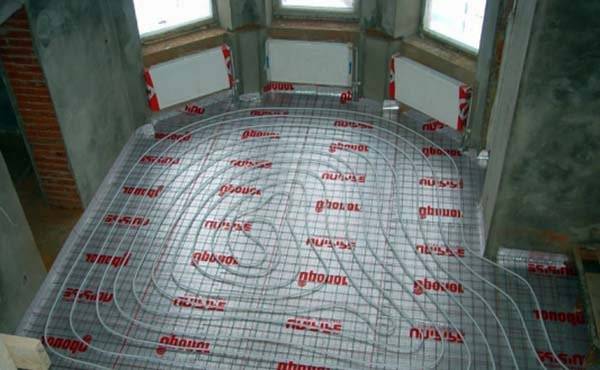

For water heated floors, polypropylene is not used, only metal-plastic or cross-linked polyethylene

Although some manufacturers (Valtec, Ekoplastik) have begun to produce polypropylene pipes for underfloor heating, metal-plastic remains the leader in this area. It is better in all respects, including heat dissipation. PPR heating circuits transfer heat worse “due to” the large thickness of the pipeline walls.

What is better for a private house

Owners of cottages with several floors are advised to turn their attention to metal-plastic. As a rule, such houses are built by developers with high requirements for the interior and the reliability of all engineering systems. Polypropylene manifolds and wiring will definitely not be able to meet these requirements due to the difficulties with the hidden gasket.Metal-plastic can be safely carried out under the floor and in other problem areas.

Polymers and central heating

A feature of district heating is that the parameters of the coolant are unknown and can often reach maximum values. Despite this, many plumbers offer apartment owners to put polypropylene on central heating, lay it in the furrows of the walls. Such decisions are risky, the material may not withstand the pressure drop or temperature jump and leak at the junction.

The best solution for an apartment is metal-plastic with press connections, it is better to put PP-R on the water supply. Judge for yourself: apartment wiring cannot be called complex or too long, so you won’t feel a big difference in price. But metal-plastic will give you reliability and durability, plus it can be hidden in a wall or floor, making the interior of the rooms more attractive.

Boiler room wiring

Piping of boilers and other heat-power equipment can be done with both polypropylene and metal-plastic. But there is a peculiarity here - the presence of a large number of turns and connections. It is difficult to do the wiring with your own hands from any polymer pipes, except that there is 1 wall-mounted heat generator in the boiler room, which works only for heating. But even here it is necessary to do everything beautifully so that the pipes do not pass at random.

An example of a beautiful wiring from PP-R, the manifold is also welded from polypropylene tees

If a solid fuel boiler is used to heat a private house, then polymers can be used to tie it, but carefully. This means that some sections will have to be made of metal, for example:

- a piece of pipe from the heat generator to the safety group when it is installed separately;

- a section where an overhead temperature sensor is attached to the return flow, working with a three-way valve.

Heating system in the apartment: instructions for its creation

Sometimes there are situations when it may be necessary to replace the heating pipes in the apartment. Despite the complexity of such events, subject to the rules and following a strict installation algorithm, it is quite possible to carry out this work on your own, without resorting to the help of specialists.

Initially, you need to consider the type of system that should eventually be installed. Not only the final cost, which is determined by the number of radiators, pipes and mounting hardware, but also the quality of heating depends on whether it will be single-pipe or two-pipe. So, when installing a two-pipe system a large number of radiators may be required, and if more than 8 are planned to be installed, pipes with a cross section of 32 mm will be optimal in this case.

Installing a single-pipe system will be cheaper, however, with this wiring configuration, it is likely that the coolant temperature in each radiator will be lower than in the previous one. To minimize this effect, it will be necessary to install thermostats to regulate the power of each of the radiators.

Mounting fittings (fittings, clamps, couplings of plugs, tees, adapters) should be selected in accordance with the selected heating scheme.

Having previously stripped the foil of aluminum-reinforced polypropylene pipes, you can begin to connect them using a special welding machine

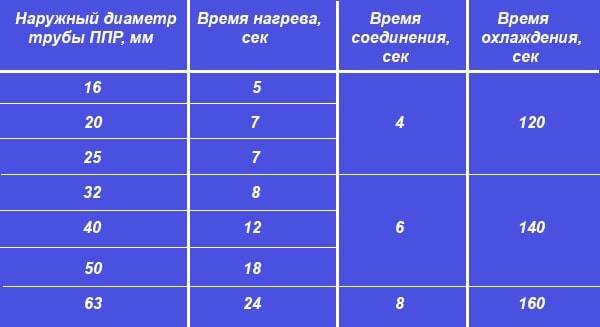

At the same time, it is important to observe the required time interval, as a rule, different for each type of pp pipes for heating. So, for melting pipes with a cross section of 25–32 mm, 7–8 seconds will be enough.

To achieve efficient and high-quality operation of the system, it is necessary to strictly adhere to the following action plan:

Coordinate remedial measures with the relevant utilities to be able to cut off the water and carry out its discharge.

If possible, notify tenants whose apartments are located on the floor below and above

However, if it is not possible to completely replace the riser due to circumstances, you can use special adapters from cast iron to plastic pipes.

Dismantle the old communications of the heating system, observing extreme caution and accuracy. It is advisable not to neglect safety precautions and wear goggles and a respirator

The fact is that with prolonged use, cast iron becomes very brittle, and with careless or sudden movement, its fragments can get into the pipe and disrupt the movement of the coolant.

Proceed with the installation of the new system by installing new heating radiators along the specified perimeter.

Assemble polypropylene pipes and connect radiators to them (for more details: "How to connect a heating radiator to polypropylene pipes - methods used by fittings").

Check the system for integrity and tightness

In this case, attention should be paid to the fact that if the newly installed system is a two-pipe system, then when checking, the coolant must move in the opposite direction.And the pressure in the case of a test should be about 1.5 times higher than the usual initial one.