- Polypropylene or metal-plastic pipes: a comparative review and choosing the best option

- What are and what are better

- Which PPR pipes are suitable for which systems

- Which are easier to install

- What are plastic pipe fittings?

- 1 Varieties and characteristics of polypropylene pipes

- Heating system in a private house: an approximate plan of action

- Why choose polypropylene pipes more often: pros and cons

- Comparison of metal-plastic and polypropylene systems

- Criteria for choosing between metal-plastic and polypropylene

- How important is the correct choice of pipes for underfloor heating

- Features of polypropylene pipes

- Pros and cons

- So what to choose?

- What should be considered when choosing metal-plastic pipes for water supply marking, material and pipe dimensions

- Low-quality goods - short service life: the price is responsible for the quality

- The process of installing a polypropylene pipeline

- Characteristics of metal-plastic pipes

Polypropylene or metal-plastic pipes: a comparative review and choosing the best option

Connecting polypropylene pipes is a much more complicated process. It is performed with the help of soldering. In this case, preliminary preparation is necessary (the pipe cut is cleaned, dirt is removed from the surface).The pipes themselves are not deformed, so the bends of the water pipe are made by soldering additional elements. Although the materials themselves are cheaper, installation in the case of polypropylene pipes will be more expensive when compared with metal-plastic products.

Here you can buy polyethylene pipes on favorable terms and at the lowest prices.

As in the previous case, the installation must fully comply with the technology. Only a person with experience in this matter can correctly perform the task. An amateur will not cope with the high-quality installation of a polypropylene water supply system.

Reinforced polypropylene pipes are intended for heating and hot water supply systems, because a simple analogue is deformed when exposed to high temperature. Fastening of products is carried out by a sliding method. The riser is fixed with hinges during installation.

What are and what are better

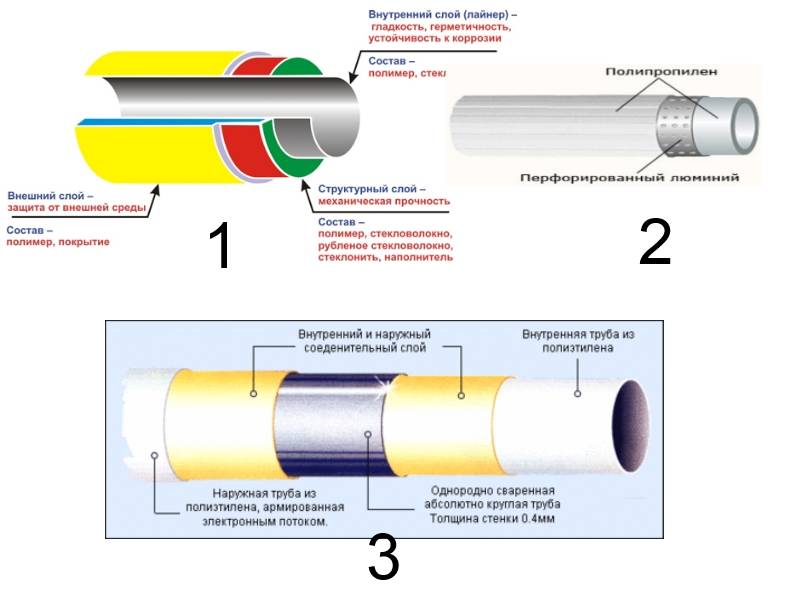

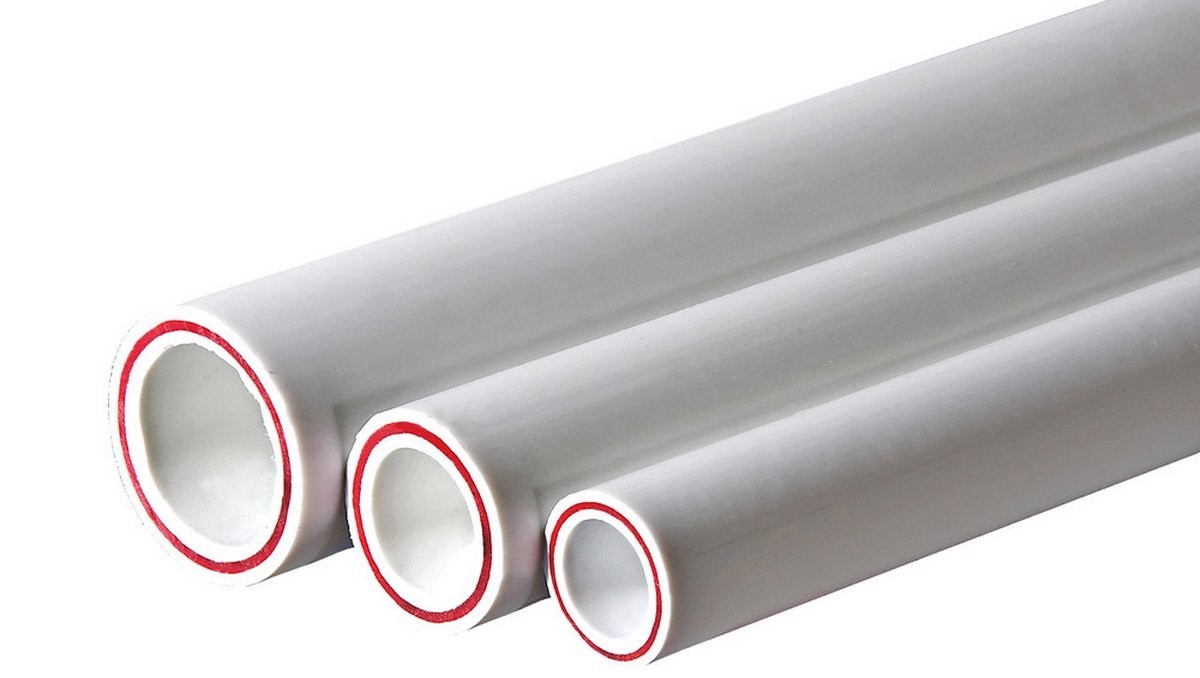

By structure, polypropylene pipes are of three types:

- Single layer. The walls are completely made of polypropylene.

- Three-layer:

- reinforced with fiberglass - fiberglass threads are soldered between two layers of polypropylene;

- reinforced with foil - the design is similar.

Now briefly about why polypropylene pipes are reinforced. The fact is that this material has a high coefficient of thermal expansion. One meter of a single-layer pipe becomes 150 mm longer when heated by 100°C. This is a lot, although no one will heat them that much, but even at lower temperature deltas, the increase in length is no less impressive. To neutralize this phenomenon, compensation loops are installed, but this approach does not always save.

Types of expansion joints for polypropylene pipes

Manufacturers found another solution - they began to make multilayer pipes.Between two layers of pure propylene, they lay fiberglass or aluminum foil. These materials are not needed for reinforcement or any other purpose, but only to reduce thermal elongation. If there is a layer of fiberglass, the thermal expansion is 4-5 times less, and with a layer of foil - 2 times. Compensation loops are still needed, but they are installed less frequently.

On the left is a fiberglass reinforced pipe, on the right is a conventional single-layer

Why is reinforcement made with both fiberglass and foil? It's about the operating temperature range. Those with fiberglass can withstand temperatures up to 90°C. This is sufficient for domestic hot water, but not always enough for heating. Foil-reinforced polypropylene pipes have a wider temperature range - they withstand heating of the medium up to + 95 ° C. This is already enough for most heating systems (except for those in which solid fuel boilers are installed).

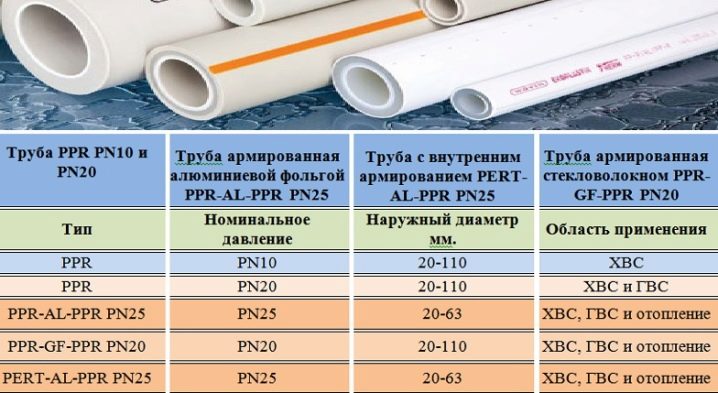

Which PPR pipes are suitable for which systems

Based on the foregoing, it is clear which polypropylene pipes are best for heating - reinforced with foil, if high-temperature operation of the system is expected (from 70 ° C and above). For low-temperature heating systems, products reinforced with fiberglass can be used.

Any PPR pipes are suitable for cold water supply, but the most rational solution is ordinary single-layer pipes. They cost quite a bit, and the thermal expansion in this case is not that big, one small compensator for plumbing in an average private house is enough, but in an apartment, with a small length of the system, they don’t do it at all, or rather they make it “L” -shaped.

An example of a polypropylene plumbing

For laying the DHW system, it is best to take polypropylene pipes with a fiberglass reinforcing layer. Their qualities are optimal here, but can also be used with a foil layer.

Please note that the presence of compensators is required

Which are easier to install

When deciding which polypropylene pipes are better, pay attention to such a parameter as the complexity of installation. All types are connected by welding, and for turns, branches, etc.

fittings are used. The welding process itself is identical for all types, the difference is that in the presence of aluminum foil pre-treatment is required - it is necessary to remove the foil to the soldering depth.

It looks like external reinforcement of a polypropylene pipe with foil

In general, there are two types of aluminum reinforcement - external and internal. With the outer, the foil layer is close to the outer edge (1-2 mm), with the inner, the reinforcing layer is approximately in the middle. It turns out that it is filled with almost the same layer of polypropylene on both sides. In this case, the preparation for welding also consists in removing the outer layer of propylene to the entire depth of welding (and the foil too). Only under these conditions can the required strength of the seam be achieved. All this preparation takes a lot of time, but the most unpleasant thing is that in case of an error we get a very unreliable connection. The most dangerous option is when water seeps into the foil. In this case, polypropylene will sooner or later collapse, the connection will flow.

Foil-reinforced pipes must be welded correctly

Based on these data, it can be concluded that, if conditions permit, it is better to use single-layer or fiberglass-reinforced polypropylene pipes.Adherents of aluminum reinforcement say that the foil further reduces the amount of air that enters the system through the walls. But the foil is often made perforated and it does not necessarily go in a continuous strip, covering the entire diameter of the pipe. Often it has a longitudinal gap. After all, its task is to reduce the amount of thermal expansion, and even strips of more stable material cope with this task.

What are plastic pipe fittings?

The choice of parts is wide, but the best ones are already using the new European brass standard - brand No. 602. There are many varieties, for cross-linked polyethylene, in our opinion, the tension sleeve is ideal.

Compression fittings are also a cool thing, you can safely tighten them - plumbers say that not a single one has ever burst, unlike Chinese ones, where when tightened, the nut cracks in half.

Elbows, tees, threaded tees - for every taste. Out of competition - compression fittings with press technology.

Water outlets are an interesting engineering solution. Short ones - they are installed in the water pipes of solid brick houses, as well as from heat blocks and in concrete.

Elongated - for frame construction, where there are sip panels or drywall.

There are also brass and plastic fittings.

We are sure that plastic products, by definition, should be cheaper than metal-plastic and brass elements, therefore we consider the state of the market to be not entirely fair. A well-known brand can value a plastic fitting even more expensive than a brass fitting.

It is impossible to explain what the logic is, so think for yourself - decide for yourself.

The result - there is no bad material, from the ones we are considering, in the article. There are circumstances under which he is selected and skillful professional hands. This will depend on the service life. So there is still no unequivocal answer to which plastic pipe is better.

Let your house always be warm and clean water!

Read also:

1 Varieties and characteristics of polypropylene pipes

According to the design features, the assortment of polypropylene fittings of products is divided into two main groups, which include single-layer and three-layer pipes. The first option is a monolithic pipe made only from polypropylene. The second option is a more complex pipe-in-pipe fitting. Its walls are made of two layers of polypropylene, between which there is a reinforcing layer. Moreover, both ordinary fiberglass and foil are used for reinforcement.

Both types of polypropylene pipes have almost identical physical characteristics:

- Working pressure - up to 2.5 MPa.

- The maximum temperature of the pumped medium is 70-95 °C (depending on the grade of polypropylene and the presence of reinforcement).

- Operating temperature: up to 120 °C.

- The thermal conductivity of the reinforcement walls is 0.15 W m/°C.

- Roughness - 0.015.

Polypropylene pipes are single-layer and three-layer

The difference between a single-layer version and a multi-layer counterpart lies only in the resistance to expansion under the action of high temperature. And if a single-layer pipe has an expansion coefficient of 0.15, then for a three-layer version it is 0.3-0.07. Moreover, the smallest value is typical for a fiberglass-reinforced pipe.

According to the type of structural materials used, the range of polypropylene reinforcement can be divided into four groups:

- PPH is a cold water version made from polypropylene homopolymer.

- РРВ - pipes for hot and cold water, made of polypropylene block copolymer.

- PPR - fittings for hot water and heating systems, made from polypropylene random copolymer.

- PPS is a heat resistant variant made of flame retardant polypropylene.

By geometry, the range is divided into 34 standard sizes with a throughput diameter from 10 to 1600 millimeters. However, in everyday life, PP pipes with a diameter of 10 to 40 millimeters are used. The rest of the size range is more exotic than the norm.

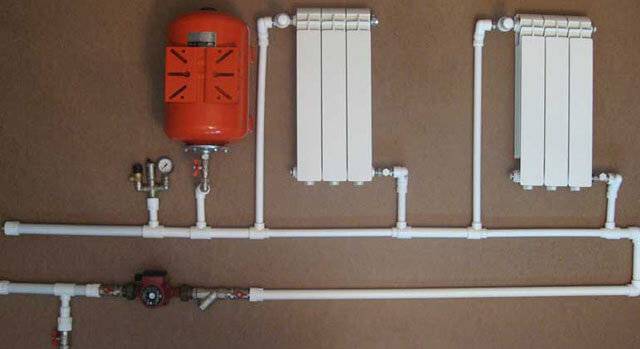

Heating system in a private house: an approximate plan of action

Installation of a heating system in a private house, by analogy with the previous option, also needs careful planning and preliminary preparation. Note that in this case, the option with two-pipe wiring is more preferable. First, you should decide on the type of heating element (boiler).

As a rule, they are:

- solid fuel;

- gas;

- electric

Solid fuel boilers are quite difficult to maintain, and it is better to entrust the connection of the heating system to them to professionals. The use of gas boilers is relevant if there is a gas pipeline connected to the house. Compared with the previous options, the installed electric boiler in this case is the safest.

An important factor in the situation with the installation of heating in a private house will be the type of movement of the coolant in the system.

The generally accepted division into circulations is:

- natural (gravitational);

- forced (pumping).

In the first case, it is imperative to provide for the presence of an air vent and an expansion tank in the heating system circuit in order to prevent sudden pressure drops. At the same time, it is recommended to install the expansion tank in a warm room to prevent freezing of the coolant.

It should also be borne in mind that with a relatively simple installation, systems with natural circulation of the coolant have some disadvantages. So, they are put into operation for a long time, and their total length should not exceed 30 m.

After you have managed to decide which polypropylene pipes for heating are better, you can proceed to the next step: connecting them to radiators.

To do this, choose one of the existing methods:

- lower;

- side;

- diagonal.

The option with a bottom connection (this scheme is also called "Leningrad") involves connecting both the supply and discharge pipes to the bottom of the radiator. For multi-storey buildings, such a system is not recommended. But it can be effective in a private house, especially since, if desired, the lower wiring can be hidden in the space under the floor.

In the case of a side connection, the supply and return pipes are located on the same side of the radiator, one on top, one on the bottom. This scheme is most often found in apartment buildings and is quite effective.

Why choose polypropylene pipes more often: pros and cons

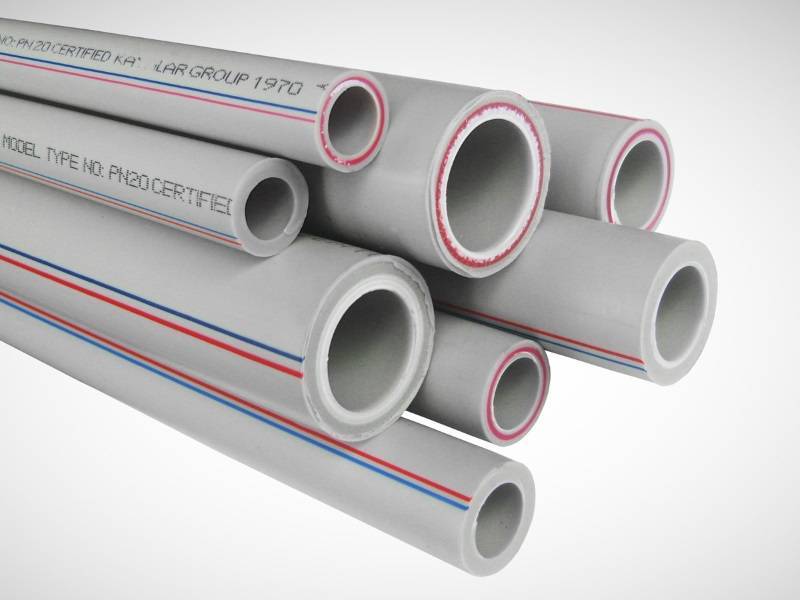

Polypropylene pipes are recommended to buy by many experts. They are good for laying for a water supply system through which drinking water will flow. They are resistant to corrosion and do not evaporate harmful substances into the air.

Also, the advantages of polypropylene pipes are:

- constant pipe temperature of about 95 degrees with the possibility of up to 110 degrees Celsius;

- diameter allows you to lay a pipeline from 16 to 125 millimeters;

- the ability to withstand pressure up to 20 atm;

- reliable against leaks and mechanical shocks;

- resistance to sudden changes in temperature;

- low cost.

Choose those pipes that you think are suitable for a particular room.

Comparison of metal-plastic and polypropylene systems

The choice of pipes depends on the conditions of use of the pipeline, the possibilities for performing installation, the budget of the project.

Comparative characteristics of the main parameters of pipelines made of metal-plastic and polypropylene.

| options | metal-plastic | polypropylene |

|---|---|---|

| wall thickness, flexibility | the walls are thin, the products are elastic, easy to bend and take the desired configuration | the walls are thick, due to which the products almost do not bend |

| likelihood of clogging | absent in any condition and water temperature | absent in any condition and water temperature |

| diameter | from 16 to 63 mm | from 16 to 125 mm |

| maximum pressure in water pipes | 25 atmospheres | 25 atmospheres |

| maximum pressure in heating systems | 10 atmospheres | 7 atmospheres |

| Maximum temperature | 110 degrees | 95 degrees 110 degrees for PN25 |

| thermal conductivity | low | low |

| frost resistance | missing | missing |

| resistance to temperature changes | low, the product delaminates, becomes unusable | high |

| mounting | the connection of components by the threaded method using seals does not provide impeccable strength, there is a possibility of leakage | Welded connections provide high strength of the entire structure without leakage |

Criteria for choosing between metal-plastic and polypropylene

When deciding on the choice of products for the installation of a water supply system, one should proceed from the following criteria:

The purpose of the future design. To meet the needs for cold water, it is advisable to choose polypropylene pipes. They are cheaper and won't leak. Metal-plastic pipes and reinforced polypropylene pipes are suitable for supplying hot water.

Material quality. This affects the efficiency and service life of the water conduit.

When buying pipes, it is important to evaluate their appearance, familiarize yourself with the markings, technical documentation and certificates.

Technical specifications. Pipes must comply with the requirements of operation.

Installation of a structure from both types of pipes is not extremely difficult

If necessary, you can do it yourself with basic skills and tools. The system of metal-plastic pipes should be assembled in such a way that there is free access to the threaded joints.

The cost of metal-plastic pipes and accessories for them exceeds the cost of a similar project using polypropylene.

Thus, most often, when arranging a cold water supply system, both materials are chosen.

For a hidden conduit, it is recommended to use polypropylene. For hot water supply - metal-plastic or reinforced polypropylene.

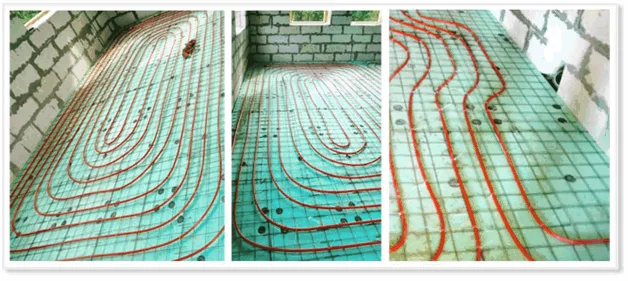

How important is the correct choice of pipes for underfloor heating

The water heating system, when the channels through which the coolant circulates, are laid on the floor and warm water circulates through them, is at first glance simple and understandable.Another thing is how to install the pipeline on the prepared surface, correctly lay the loops of the water circuit, ensure a strong connection of the pipes and, accordingly, connect the finished lines to the distribution equipment. There are many questions that need to be answered and, accordingly, competent engineering decisions should be made.

Different tasks can be assigned to a warm floor at home. Some prefer to use a similar heating option in limited areas of residential premises. Others set large-scale tasks for underfloor heating - heating the entire living area of the object. The pipe for the warm floor in this case plays an almost decisive role. The quality of the pipe, its strength and reliability are the main conditions for the efficient operation of the heating system, especially when it comes to the long length of the water circuits.

Currently, the market for consumables for heating systems is quite diverse. In the distribution network, you can see consumables specially designed for installation in the floor, differing in the method of manufacture and composition. At first glance, only the cost of materials can be decisive in terms of choice, but in fact, the issue of choosing a water line should be taken more carefully. There are a number of criteria according to which consumables for underfloor heating circuits should be selected.

Among the most important criteria, the following aspects should be noted:

- the cross section of the water channel should not exceed 16 mm, taking into account the thickness of the screed;

- all consumables must be marked accordingly, designed for use in low-temperature heating systems;

- the ability of the pipe to withstand significant drops in the working pressure of the coolant in the system;

- technological stability of the material to high temperatures;

- resistance of the pipeline to mechanical stress and the reaction of the material to heating;

- ease of use, including routine and emergency repairs.

In most cases, today preference is given to working with metal-plastic and polymer pipes, which are based on cross-linked polyethylene. Such materials have already been tested in practice and serve as the main elements of pipelines of heating systems for more than one year and in a variety of conditions.

If desired, and with financial capabilities, you can bet on copper pipes, but in this case, the warm floor will become golden for you, in the truest sense of the word. Underfloor heating, in which the pipe is the main working element, can have a different length. Doing underfloor heating throughout the house, using expensive consumables, is a thankless task. Copper piping is suitable for installing a water circuit in a bathroom or kitchen. Using copper lines for other purposes is a waste of money.

Each type of main water circuits used in floor heating systems has its own technological characteristics. Accordingly, pipelines in such a situation have different technical parameters and differ in installation conditions.

What are the options when choosing the optimal consumables for underfloor heating? Let's figure it out in more detail

Features of polypropylene pipes

Polypropylene is also a building polymer, only more traditional. Polypropylene is known for its strength.If we compare it with cheaper plastic samples, then the material in question will surely surpass them both in density and in the nature of the reaction to the operating temperature of the carrier.

That is why polypropylene pipes began to be used as a basic raw material for advanced water supply systems, heating, etc.

A polypropylene pipe consists of a single piece of plastic, molded in the form of a round oblong blank. As a rule, this is an ordinary pipe, only with thickened walls. Polypropylene products are characterized by a wall thickness of 1 cm, while metal-plastic and other polymers form pipes with walls in the range of 2-5 mm.

Polypropylene expands slightly, but still reacts to excess heat. That is why ordinary polypropylene samples were additionally reinforced with fiberglass or foil. This is done according to a system that is similar to the system for the production of metal-plastic pipes.

Only lighter materials (fiberglass or foil) are used as a reinforcing layer. Accordingly, the wall thickness of the pipe with reinforcement also increases significantly.

Pros and cons

Since polypropylene and metal-plastic pipes are in many ways similar to each other and are derived from a class of polymers, they often have many properties. However, there are also some differences.

Consider the unique advantages of polypropylene pipelines:

- Extremely low pipe weight;

- Low price (except for reinforced samples);

- The ability to use welding fittings and diffusion welding during installation;

- Pipes do not need pre-treatment, turning or stripping (except for reinforced samples);

- Withstand high pressure;

- They do not conduct electricity, they can be used as grounding.

High-pressure metal-plastic pipes, in section

The main and most important plus of polypropylene is that it is pure plastic without impurities. It is exceptionally easy to work with him. No need to clean or calibrate anything.

The pipe, even with thick walls, is cut with ordinary pipe cutters. Stripping is either not needed at all, or is performed by several turning rotations. And the whole process takes a matter of seconds.

Plus, polypropylene pipes can be connected using welding fittings, or chemicals, which is very convenient. Welded joints are the main advantage of plastic pipes, they are easy to produce, but at the same time, the quality of the joint and its tightness remain almost the best in its class.

Main cons:

- The cost of reinforced polypropylene is almost equal to the cost of metal-plastic, with a difference in performance not in favor of the first;

- Less strength;

- Pipes cannot be bent by hand, they may crack;

- Polypropylene tolerates defrosting and freezing cycles worse.

Polypropylene products suffer from the same diseases as standard plastic ones. Unfortunately, without a significant modification, which is metal-plastic, it is impossible to get rid of them.

So what to choose?

So which pipes should you choose? After all, both options have a lot of pluses, and the minuses are not that much noticeable, especially when compared with less common counterparts.

We recommend that you evaluate your pipeline design against several criteria.Acting in this way, you will be able to complete the overall picture and still decide.

Consider the following factors:

- Potential loads on the water supply.

- Should it be further disassembled?

- Is the pipe being laid down the street?

- Working pressure level.

- How complicated is the wiring, do the pipes need to be bent.

After answering all these questions, look again at the list of properties of each material above. And you will surely find the answer.

In short, polypropylene, due to its cheapness and practicality, is ideal for standard plumbing and domestic hot water systems in private homes.

You can also lay it down the street, but with great care.

Metal-plastic is more expensive, but it is not afraid of high temperatures, it is represented by various models, has many working diameters, and does not burst under prolonged loads. It can be used both inside the house and outside. At the same time, mainly collapsible pipelines are assembled from metal-plastic.

A big plus is that you most likely will not need corner fittings at all, since the pipe can also be bent with a pipe bender, which has a positive effect on the stability of the entire system.

What should be considered when choosing metal-plastic pipes for water supply marking, material and pipe dimensions

Information about the product and its operating conditions is contained in the marking. As a rule, it includes the following data:

- manufacturer;

- pipe name;

- material;

- outer diameter and wall thickness (usually indicated in millimeters, but sometimes in inches);

- maximum working pressure and temperature;

- icons indicating permission to use for water supply;

- date of manufacture, batch number;

- certificates;

- barcode;

- other information.

For ease of measurement, marks are applied every 0.5 or 1 meter, depending on the diameter.

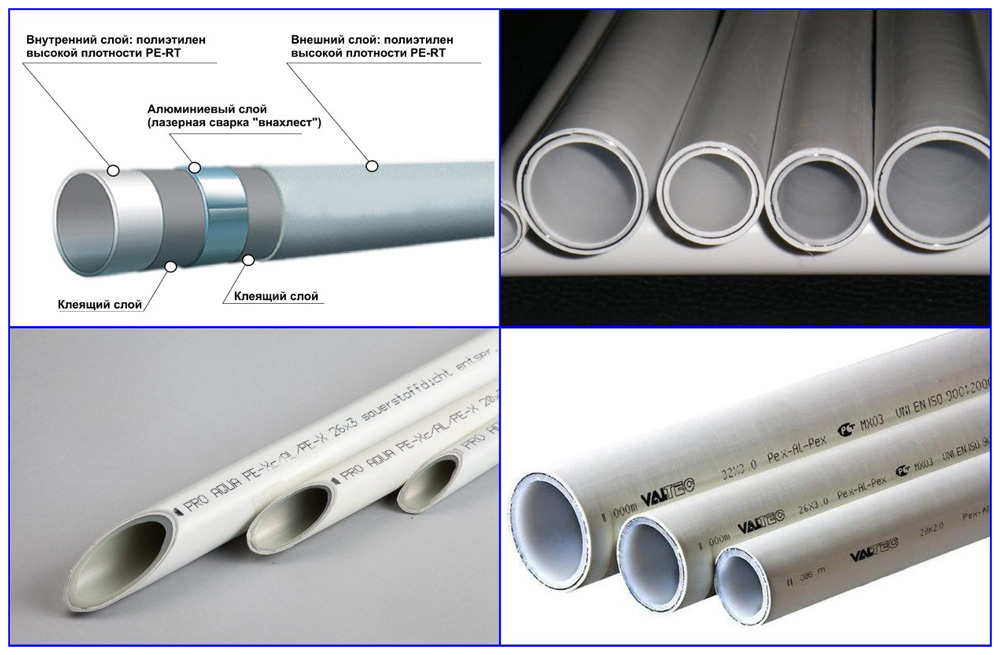

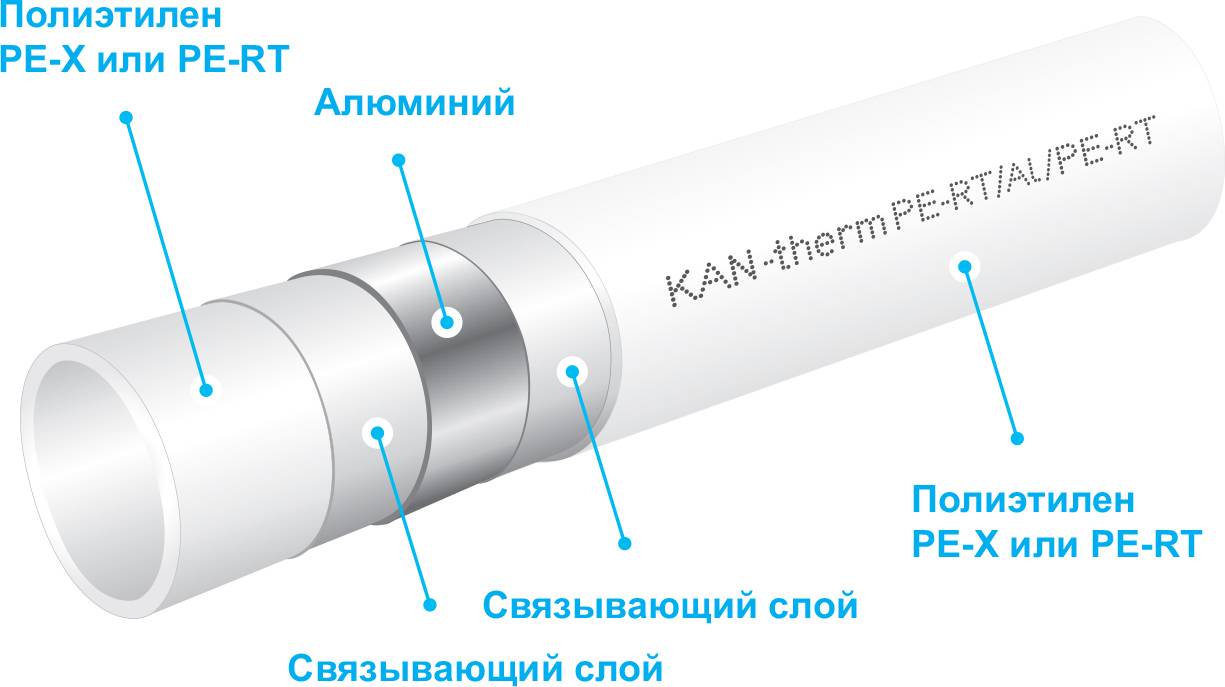

The pipe material is designated as follows: inner layer - intermediate layer - outer layer. Adhesive layers are not indicated in the marking, but the quality of the pipe directly depends on the properties of the adhesive.

The intermediate layer of aluminum foil is designated AL. As for the rest of the layers, there are different options on the market. Due to the lower water temperature, less stringent requirements are applied to metal-plastic pipes for cold water supply compared to hot ones.

The most common metal-plastic pipe PEX-AL-PEX with an inner and outer layer of cross-linked polyethylene. If another letter is added to their designation, then it indicates the crosslinking method: a - peroxide chemical method, b - silane chemical method, c - physical radiation using an electron gun, d - nitrogen chemical method.

It is impossible to unambiguously judge by the method of polyethylene crosslinking which metal-plastic pipes are better for plumbing. The fact is that it determines the heat resistance and strength of the material, and with an increase in one indicator, the second simultaneously decreases. In addition, the advantage in parameters is not always necessary and justified by the difference in price. Therefore, the specific choice depends on the priorities of the consumer. Metal-plastic pipes for water supply are very popular.

In another commonly used PERT-AL-PERT pipe, the inner and outer layers are made of high temperature resistant polyethylene. According to its characteristics, it is only slightly inferior to PEX-AL-PEX.

In practice, metal-plastic pipes for water supply are mainly used with an outer diameter of 16 (the most popular size) and 20 mm with a wall thickness of 2 mm and a diameter of 26 and 32 mm with a wall thickness of 3 mm. Large diameters are rarely used.

Low-quality goods - short service life: the price is responsible for the quality

When buying, pay attention to the quality of workmanship. The pipe must be without delaminations, with a constant thickness of aluminum foil along the entire circumference, not counting the seam. Mandatory marking with precise and indelible inscriptions at the same distance from each other

Mandatory marking with precise and indelible inscriptions at the same distance from each other.

Choose only quality materials

Choose only pipes specially designed for water supply, the rest may contain plastic that is unsafe for health, and even the presence of a certificate of conformity sometimes does not guarantee against the specific smell and taste of water. When using non-certified products, you may also encounter increased bacterial growth.

Cheap pipes made of HDPE polyethylene are not very durable. They quickly break down under the influence of ultraviolet rays and can lose their shape at temperatures above 75 degrees.

WATCH VIDEO

To avoid buying obviously bad goods or outright fakes, it is better to contact reliable dealers and give preference to products from reputable manufacturers: Nanoplast, Valtec, Oventrop, Henco, Wirsbo, TECE, Rehau, Golan, KAN, Viega and some other companies. Metal-plastic pipes for water supply are often used in construction.

The process of installing a polypropylene pipeline

The installation of polypropylene pipes is carried out using fittings in two ways: by fitting on a thread and by welding. Welding requires a special soldering iron. The principle of operation of which is to heat and soften the edge of the fitting and pipe. Heated joints are connected and soldered together when cooled.

Installation of polypropylene pipes

Reinforced profiles require special joint preparation. To form a monolithic joint, the edges are cleaned from metal and the second layer of plastic.

Threaded connections are used to create detachable joints, connect polypropylene pipes to metal networks, supply to mixers and counters. Threaded fittings on both sides end with a socket and a drive. The thread can be internal or external.

For turns and branches, angles, tees and couplings are used. All connections are welded to achieve a monolithic connection.

Characteristics of metal-plastic pipes

When deciding which types are better, polypropylene or metal-plastic, you need to thoroughly understand their technical characteristics. So, the first in the foreshortening of consideration is a pipe made of metal-plastic.

When examining the MP of the workpiece in the section, a composition consisting of five layers is visible. These are: cross-linked polyethylene, glue, aluminum foil, a second layer of glue, and another layer of cross-linked polyethylene.

Any metal-plastic product is durable and reliable in use, and their service life lasts for more than a dozen years. In this indicator, they are much better than other analogues. This pipe rolling does not overgrow inside, and does not layer.

It does not form corrosion, and salts are not deposited.The material that is used for the manufacture of these products is absolutely oxygen-proof, anti-toxic and resistant to the aggressive influence of the chemical environment.

Describing the characteristics of this pipe, one cannot ignore the fact that the polyethylene used in its production does not include harmful impurities. For this reason, it is quite suitable for organizing the supply of drinking water.

Experts are unequivocal in their opinion that MP water supply networks are in many ways better than their "brothers" from other materials, including analogues from polypropylene.