- Ways to install septic tanks Microbe

- Installation of a septic tank Microbe

- Filtration field construction

- Installation of a drainage well

- Pros and cons of polymer sand roofing

- Mounting and connection

- Mounting and connection

- Scope of sewer manholes

- Tips

- Advantages and Features

- Caisson for a well made of concrete rings: advantages and disadvantages.

- Applications of polymer wells

- Reinforced concrete and polymer sand: who wins?

- Weight and transportation to the site

- Features of joining elements and tightness of joints

- Ability to resist moisture

- Resistance to aggressive substances

- Ease of connection to the pipeline

- Warranty period

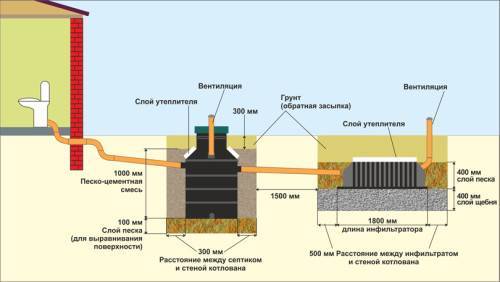

Ways to install septic tanks Microbe

There are two ways to install a septic tank:

- with additional construction of the filtration field;

- with installation of a drainage filtering well.

The choice of an additional structure is based on environmental and soil conditions.

Installation of a septic tank Microbe

The description of the septic tank Microbe 450 and other types, attached to the equipment upon purchase, contains complete information on how to install the device.

To install the equipment yourself, you need:

- dig a pit with a shovel or using special equipment, the dimensions of which are 30–40 cm larger than the dimensions of the installed equipment;

- if the device is mounted on sandy or other types of dry soils, then at the bottom of the pit it is enough to lay out a 10 - 15 cm sand cushion, carefully compacting the sand and leveling the surface to the horizon;

- if moist soils prevail on the site and groundwater is located close to the surface, then at the bottom of the pit it is necessary to build a cement base of approximately the same height and also align it to the horizon;

- after preparation, the septic tank is installed in place and connected to the inlet and outlet pipes;

- then the device is filled with water and the process of filling the installation with a sand-cement mixture begins, which must be done at 2/3 of the height of the equipment;

- the top of the septic tank is insulated. To do this, you can use isolon, polystyrene or any other insulation. This procedure is necessary to ensure the uninterrupted operation of the equipment in winter and the complete elimination of damage to the hull;

- the remaining space is covered with earth so that only the neck of the equipment remains on the surface, through which the device is cleaned and preserved for the winter.

Installation diagram of a septic tank Microbe

Filtration field construction

At a distance of at least 150 cm from the septic tank, it is necessary to build a filtration field. For this, the following steps are performed:

a layer of soil is removed, necessary for laying pipes and crushed stone backfill;

It is important that the laid pipes do not reach the groundwater of 1 meter. Otherwise, the treated water will not soak into the ground properly and the site will flood. a layer of sand is laid at the bottom of the pit and a layer of rubble is laid on top of it

These materials will serve as additional filters for the liquid coming from the septic tank;

a layer of sand is laid at the bottom of the pit and a layer of rubble is laid on top of it. These materials will serve as additional filters for the liquid coming from the septic tank;

Pit prepared for pipe laying

- irrigation pipes are laid, connected to the outlet pipe of the septic tank. The description of the septic tank Microbe attached to the equipment says that the pipes must be laid below the freezing depth of the soil in the region. Otherwise, the piping system will be destroyed with the onset of cold weather;

- manholes must be installed at the junction or branching of pipes. This will allow you to quickly find faults in the pipeline system in case of system inoperability;

Pipe laying and construction of manholes

for air to flow into the system, it is necessary to install a vent pipe. If the house already has a fan riser, then the height of the pipe should be slightly more than the height of the average annual snow cover. If there is no fan riser in the house, then it is required to install a pipe with a height of at least 2 m;

Installation of fan pipes

surface insulation of pipes and backfilling of the earth is carried out.

Warming and backfilling

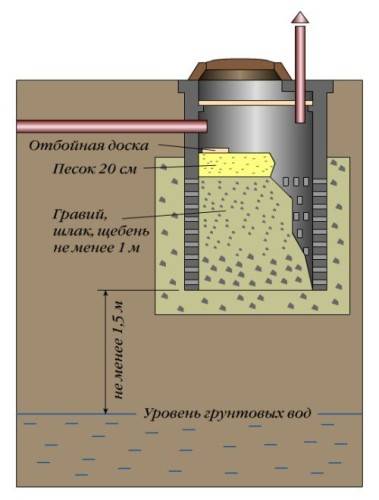

Installation of a drainage well

A filter well can be installed on a personal plot if the following conditions are met:

- the distance to the supply well or well is more than 30 m;

- groundwater is located at a distance of more than 1.5 m from the lower level of the well.

To independently build a drainage filter well, you must:

prepare concrete rings or a finished plastic well with perforations along the walls;

The size of the well depends on the volume of daily discharge of water.

- dig a hole, the dimensions of which are slightly larger than the size of the well rings;

- fill the bottom of the pit with crushed stone, gravel or other backfill with filtration action;

- overlay the walls of the pit with geotextiles to isolate the soil and the filter layer;

- install a well;

- backfill with filter mixture up to the mark of applying the upper perforation point;

- build a fan riser;

- install cover;

- backfill the soil.

Arrangement of a filter well

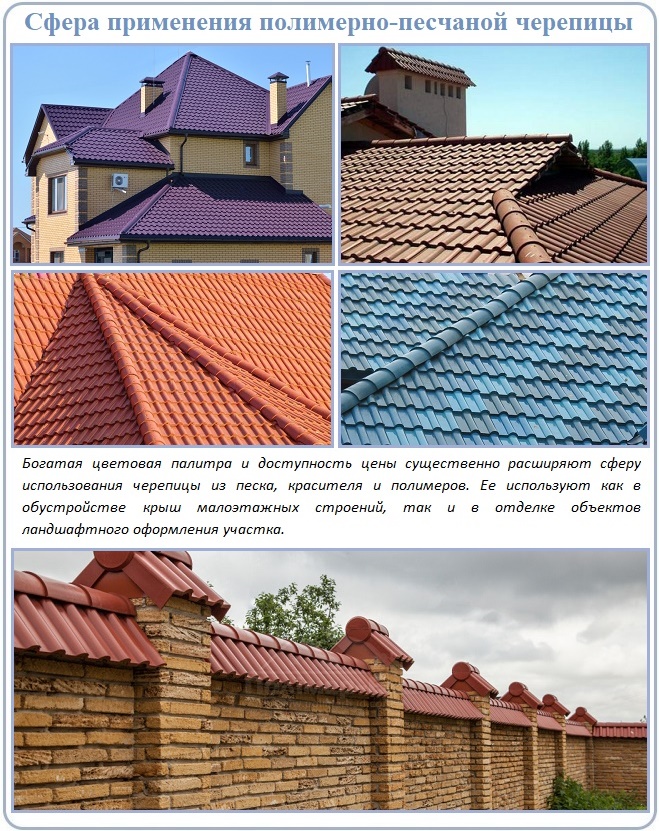

Pros and cons of polymer sand roofing

Made from a mixture of hot polymer, pigment and pure sand, tiles can hardly be classified as artificial materials. Nevertheless, natural components predominate in its composition. The bulk, approximately 60 - 75%, is composed of washed and dried sand aggregate, 1% is a coloring matter.

The remaining share in percentage terms is assigned to the polymer component, designed to bind everything together. It gives shape, provides strength and resistance to all kinds of external phenomena. Thanks to the use of soft and hard plastics, the material acquires unique properties and, as a result, popularity in the roofing business.

To the environmental benefits of manufacturing this type of coating, we can safely add the ability to dispose of polymer waste in the most rational way. Polyethylene packaging, rigid containers, used household items are recycled and receive the source for the production of tiles.

In fact, even a smaller, but close to half part of the final product costs practically nothing, which has a very positive effect on an aspect that is interesting for the buyer - the price. Such a roof will cost much less than its historical ceramic predecessor, and will serve exactly the same.

It is impossible not to note the color advantages of the polymer-sand coating. Its range of colors is noticeably richer, which provides an extensive opportunity for buyers to choose, and for architects and designers to develop amazing ideas.

The advantages of polymer-sand piece coating recognized by builders and consumers include:

- Lightness. The average mass of 1 m² of such a roof varies between 21 and 30 kg, which is approximately half the mass of ceramic and sand-ceramic coatings. This means that you can save on the construction of the foundation for laying, because. it doesn't have to be that powerful.

- No pores. The polymer binder completely fills the space between the grains of sand, preventing water from penetrating into the thickness of the material. The roof does not “swell” and does not become heavier during the rainy season, caverns and cracks do not appear in it during the first frost.

- Impact resistance. Polymer-sand tiles do not tend to chip and beat as easily as ceramic counterparts. The percentage of "battle" in the process of transportation and laying is much less, which once again has a positive effect on the overall construction budget.

- resistance to negative influences. The material withstands 500 freeze/thaw cycles without loss of strength. Firmly reflects chemical and biological attacks, resists UV, does not lose color.

- Manufacturability. There is no need to drill holes in the tiles for fixing, the fasteners are laid during manufacture.There are upper hooks, with the help of which the roof elements cling to the crate, and side locks, with the help of which a monolithic coating is formed. Easily cut with a saw.

- Maintainability. By analogy with all piece roofing options, if necessary, only damaged petals are replaced, and not all of the material. Dismantling the tile and installing a new one is not difficult.

- Insulation. Despite the almost complete absence of pores, the polymer-sand roof has high sound-proofing qualities, which is explained by the specific properties of the polymer binder component. Due to the low thermal conductivity, there is no condensation on the surface.

In a house with the roof we are describing, summer heat is not felt, cold is not felt in winter. Excellent insulating performance makes it possible to reduce the thickness of the insulation, use not the most effective and, therefore, expensive insulating materials in the formation of a roofing pie.

To the list of advantages, we add the simplicity and low cost of producing tiles from a polymer-sand mixture. The ready-to-work line can be placed in a garage or similar small space. It is only necessary to provide the area chosen for organizing a mini-factory with powerful exhaust ventilation, because. production of products from polymers is a rather dangerous process.

Mounting and connection

The process does not represent complex technological steps. It is quite possible to do the work with your own hands, without involving specialists. CM. below in the video.

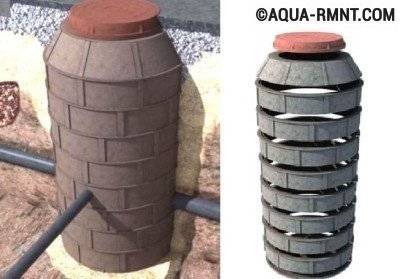

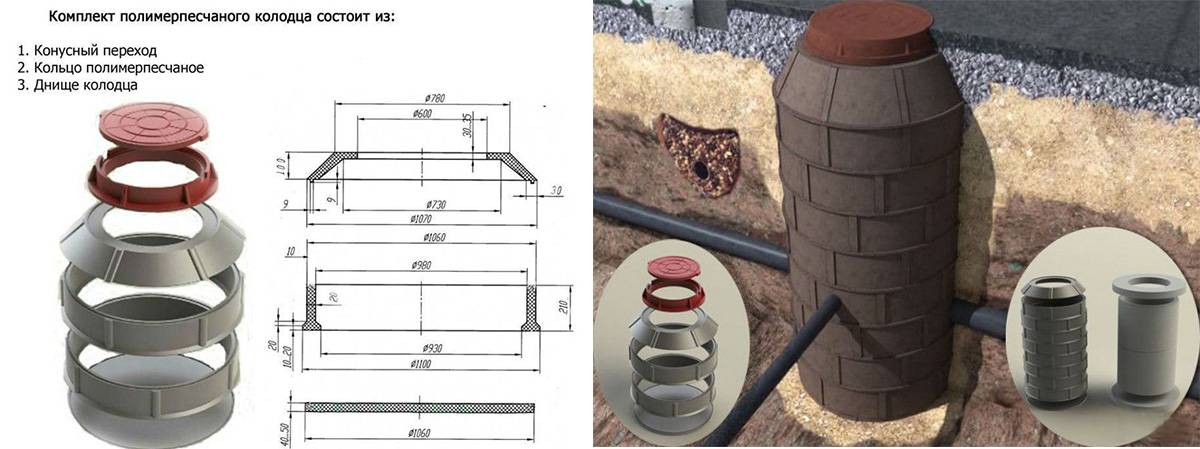

So, the installation of stacking rings for a polymer sand well is carried out in the following sequence:

- At the first stage, a foundation pit is dug to install a structure and lay water supply or other communications.The depth of the trench is below the freezing level of the soil.

- A pillow is made of sand with a thickness of 200 mm. The spilled sand is carefully compacted, and a layer of concrete up to 300 mm is poured on top.

- After the concrete has hardened, the bottom of the well is installed.

- Before mounting the ring, all joints are treated with a special sealant and mastic.

- As you move, holes are drilled for the output / input of water or sewer pipes.

- Each pipe outlet in the place where the hole is cut is sealed with a rubber seal and sealant.

- Plumbing is connected.

- At the end, the top ring is laid with a hole for a cover or hatch.

- After completion of work, the empty space is covered with soil and compacted around the entire perimeter.

Mounting and connection

The process does not represent complex technological steps. It is quite possible to do the work with your own hands, without involving specialists. CM. below in the video. So, the installation of stacking rings for a polymer sand well is carried out in the following sequence:

- At the first stage, a foundation pit is dug to install a structure and lay water supply or other communications. The depth of the trench is below the freezing level of the soil.

- A pillow is made of sand with a thickness of 200 mm. The spilled sand is carefully compacted, and a layer of concrete up to 300 mm is poured on top.

- After the concrete has hardened, the bottom of the well is installed.

- Before mounting the ring, all joints are treated with a special sealant and mastic.

- As you move, holes are drilled for the output / input of water or sewer pipes.

- Each pipe outlet in the place where the hole is cut is sealed with a rubber seal and sealant.

- Plumbing is connected.

- At the end, the top ring is laid with a hole for a cover or hatch.

- After completion of work, the empty space is covered with soil and compacted around the entire perimeter.

Scope of sewer manholes

Manholes for sewerage

The sewer manhole cover performs a dual function - it protects people from falling into underground sewer labyrinths, and also prevents debris and foreign objects from clogging the mine.

Products are used wherever it is necessary to close access to manholes:

- storm sewer;

- domestic waste water;

- electrical cable;

- telephone line;

- gas pipes;

- heating main;

- water pipes.

Depending on the expected load, the material and method of opening are selected. In private areas, locks that are easier to use are installed, since the likelihood that the device will be removed is small. On your own site, you can install a less durable sewer manhole design, since the potential load on it will be small.

Tips

For self-assembly of a polymer well on the site, you need to follow simple instructions, then you won’t have to make much effort:

- dig a pit suitable for the size of the selected well;

- its bottom must be leveled with a sand cushion;

- this is followed by the installation of the bottom of the structure;

- installation of polymer sand rings, including the treatment of joints with sealant or bituminous mastic - the first ring is laid with a ridge down, and an adapter similar to a cone is put on the last one;

- after that, the hatch or cover is installed.

To install the well, you will need a metal cable to secure the structure. During seasonal ground movements, additional fastening of the well to the foundation with cables will prevent the tank from floating up.

There are several additional details, such as ladders (they are used for quick access to the well), covers (they help prevent debris from getting inside), a garbage container (large debris collects on the inside of the well).

It should be noted that these designs are not used for the construction of a water supply well. This is due to the fact that direct contact of polymers with drinking water is unacceptable, as it has toxic properties. Despite this, the scope of use is very wide: sewer and drainage systems, well caisson construction and more.

Technological openings for communications can be made both before the installation of the well, and after the fact. The easiest way to do this is with a regular crown.

It should be noted that the reviews of polymer wells are excellent. Users note for themselves high reliability, durability, ease of use and quality. When compared with reinforced concrete, cast iron or other analogues, many people prefer polymeric ones. The ability to choose the color of the sunroof also attracts people, because it is very convenient to make it more invisible in the grass, on the ground or paving slabs.

In conclusion, I would like to note that wells made of polymer-sand composite have a number of advantages over analogues made of both reinforced concrete and other materials. Thanks to this, they have become widespread not only among the owners of private houses, but also in various areas of construction.The design will be an excellent solution and an alternative to the usual and expensive reinforced concrete product.

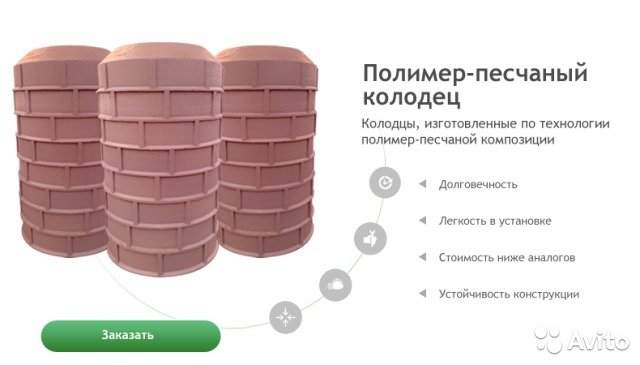

Advantages and Features

A polymer-sand composite is a heterogeneous continuous material obtained using nanotechnology and consisting of two or more components.

A polymer-sand composite is a heterogeneous continuous material obtained using nanotechnology and consisting of two or more components.

Technologically, there are two main ones:

- reinforcing element,

- matrix.

The matrix uses a high pressure polymer.

In simple terms, this is recycled household plastic (including plastic bottles and stretch film).

Sand is used as a reinforcing element.

Among the main properties of the polymer-sand composite are:

- Increased strength and resistance to mechanical stress.

- Complete rejection of water and high anti-corrosion.

- Light weight of the finished product.

- Resistance to aggressive and acid-base environments.

It is allowed to use at a temperature regime from minus 60 to plus 60 degrees, which is suitable, practically, for any region (insulation of sewer pipes of external sewerage).

Unlike reinforced concrete, the polymer has no moisture absorption even at the microscopic level, which eliminates the freezing of absorbed water and the destruction of the structure at sub-zero temperatures.

Also, the polymer has very little expansibility with temperature changes.

This means that the rigidity and geometry of the entire structure will remain unchanged under any adverse conditions.

The material is non-flammable and does not spread flame.

It does not emit toxic vinyl chloride, which allows it to be used in residential areas.

Unlike cast iron, manholes made of polymer-sand composite, the possibility of sparks is completely excluded.

Such hatches are safer for silo pits and septic tanks, where the formation of combustible gases is possible.

It has a high degree of resistance to decay, which increases the durability of polymer-sand products by 1000 times compared to other materials.

This technology is relatively new, but according to manufacturers, the service life should be at least 100 years.

Therefore, it can be used in any type of repair and construction work - from the production of parts for wells (read about drainage and viewing here), to the isolation of the basement of the house and production of paving slabs.

Caisson for a well made of concrete rings: advantages and disadvantages.

Before installing the caisson on the well, a hole is dug, then an even base of the bottom is made, then reinforced concrete rings are installed, a concrete cover is placed on the rings, and a hatch crowns this whole structure.

Advantages:

Cheap

And then there are the disadvantages:

- Heavy weight - you will need a truck and a manipulator for installation in a pit.

- Mandatory processing of rings with bitumen (waterproofing) - since concrete has a porous structure and passes water through itself. The waterproofing must dry, i.e. in one shift it will not be possible to install a caisson.

- Over time, the upper part of the caisson of concrete rings is destroyed under the influence of temperature fluctuations.

Applications of polymer wells

One of the main disadvantages of reinforced concrete wells was susceptibility to external factors. Temperature fluctuations destroyed, first of all, the cement screed between the rings, therefore, there was no longer any talk of tightness.Water penetrated into the well through cracks, and in the end, the rings in the mine could simply part - the mine was destroyed, and additional resources were required for restoration. But if it was still possible to repair a water well, then it was much more difficult to restore a cesspool or a septic tank. Even if it is completely drained, working in such a well is difficult, and even dangerous!

Polymer wells come in a monolithic design - this guarantees the strength of the structure and its reliable tightness. Their main task is to connect sewer lines with each other. But the design features and versatility allow the use of polymer wells in the following cases:

- Year-round monitoring and maintenance of important nodes on water pipes, comfortable repair and replacement of parts at such nodes;

- The possibility of installing sewer branches at different levels, thanks to internal differences;

- Influence on the flow rate in the sewer water system;

- As inspection purposes, control over the quality of wastewater is possible (for example, for supervisory and environmental organizations)

In general, the scope of polyethylene wells is much wider than that of their reinforced concrete counterparts, therefore, a greater demand is also natural. The laying depth for such wells is different - it is taken into account depending on the depth of the wastewater, the type of soil, the depth of freezing, and the transport load. Many manufacturers carry out an individual calculation of such loads and are ready to provide the customer with an almost unique well, made taking into account the specifics of the area and installation conditions.

Reinforced concrete and polymer sand: who wins?

For a long time, reinforced concrete remained the only material for the production of wells. But its properties are far from ideal. Let's compare them with similar characteristics of polymer-sand raw materials.

Weight and transportation to the site

Reinforced concrete materials differ in significant weight. The meter ring has a mass of about 500 kg, which means that for its transportation to a construction site, special equipment is needed both for loading and unloading (crane) and for transportation (truck). Even if this is found, then such voluminous equipment will not always “squeeze” into the narrow construction space, especially in the city, where there are residential buildings nearby.

Due to less bulky components, polymer wells are easier to install, because large-sized equipment and many workers are not needed.

In diameter, polymer sand wells are not thicker than 1.1 meters, so they can easily fit into a regular trailer for a car

In turn, polymer-sand wells are much lighter. The mass of any structural fragment (ring, hatch, etc.) is up to 60 kg. This weight can be lifted by two people without using a crane. Yes, and the summer resident will be able to transport to the site with an ordinary trailer for a car. Another plus: it is easily mounted in a hard-to-reach place (for example, in the basement), because the owner of the site himself can roll up the rings and throw them into the mine.

One person can assemble a whole well from elements and mount it in the ground, because the weight of each element does not exceed 60 kg

Features of joining elements and tightness of joints

In reinforced concrete rings, the edges cannot be made absolutely even, therefore, during installation, you have to fiddle a lot with the tightness of the joints.And anyway, over time, they are washed away by water, as well as the walls. And if the well stands on moving ground, where groundwater has very strong flows in the spring, then the rings can move, breaking at the joints.

With the “groove-ridge” system, both structural elements are connected as tightly as possible, so the joints do not require additional sealing, except for lubrication with silicone

Polymer-sand elements are joined according to the “groove-ridge” system, thanks to which they are not afraid of soil movements. Such a connection absolutely does not let water through, and it is enough to coat all the grooves for insurance with silicone sealant or bitumen mastic.

Ability to resist moisture

Moisture is the main enemy of reinforced concrete structures. The concrete surface has large pores, and in winter, frost from the ground penetrates into them, expands and causes microcracks that will increase every year.

Due to the technology of "sintering" of particles, polymer sand rings have a water absorption level of only 0.03%. The well is able to withstand over five hundred freeze-thaw cycles (from -65˚ to +160˚С) without any structural damage.

Resistance to aggressive substances

Together with water from the soil, aggressive substances enter the surface of the wells, destroying the structure of concrete, and if the well is a sewer well, then the biomass decomposition reactions will “spoil” it from the inside. To make these processes run weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of an aggressive environment. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

Ease of connection to the pipeline

When connecting a well to a domestic water supply system, you have to drill holes or openings in it. In reinforced concrete, this is very difficult to do. Often a professional tool is required.

You can cut openings and holes for pipes in polymer sand wells with ordinary household tools, and the edges do not need to be processed with anything.

In the polymer ring, all openings are created with household tools. At the same time, it is not necessary to lubricate the edges of the cut piece with any compounds, because corrosion of plastic is not terrible.

Warranty period

For reinforced concrete products, manufacturers give a guarantee of about 50 years, but indicate that these parameters relate only to the main technical characteristics. Those. The ring will definitely not fall apart and will not become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out illiterately.

With polymer sand wells, such incidents are excluded. Therefore, manufacturers give a guarantee of up to 100 years, although plastics decompose in nature for over 400 years, and the sand that is part of the raw material is eternal.