- Peculiarities

- Pros and cons of a polymer well

- Tips for choosing and self-assembly

- Nuances of choice

- Installation rules

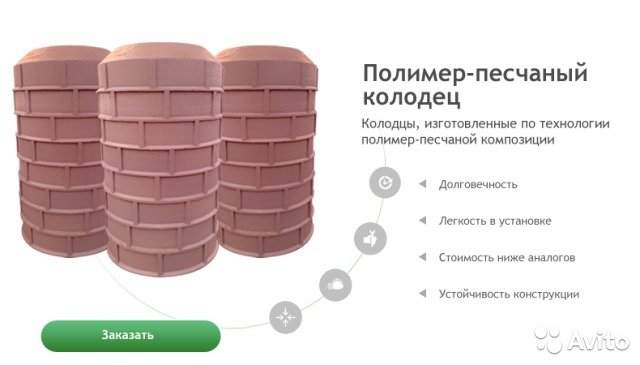

- Features of polymer sand rings

- Preparation method

- Advantages

- Reinforced concrete and polymer sand: who wins?

- Weight and transportation to the site

- Features of joining elements and tightness of joints

- Ability to resist moisture

- Resistance to aggressive substances

- Ease of connection to the pipeline

- Warranty period

- Design features and production standards

- Varieties of polymer wells

Peculiarities

The main secret of a polymer sand well lies in the raw materials used to make it. The basis of the well is a composite material consisting of several polymers with the addition of sand.

The production of this material is carried out with the involvement of resource-saving technologies - casting and pressing takes place using recycled materials. For example, used bottles, packaging and bags made of polyethylene, polypropylene and polystyrene. As a reinforcing base, sandy loam is used - a mixture of sand (80%) and clay (20%) with a particle size of not more than three millimeters.

The components are mixed in a special device (extruder) and turned into a viscous mixture resembling dough.Various products are pressed from this blank - wells, paving slabs, tiles. Moreover, the strength and type of product directly depends on the proportion between sandy loam and polymers.

The heated mass is fed into the mold and pressed with a heavy press until it solidifies completely. Old wells are recyclable. The material is easily crushed, remelted and pressed again.

Experts have compiled an impressive list of advantages of this composite material, for example:

- The resistance of the material to temperature extremes. Polymer sand products can be used at temperatures from -60 to +120 degrees.

- Pronounced frost resistance - the well will withstand up to five hundred complete frosts, followed by defrosting.

- Long service life. The material does not change its physical properties for a hundred years, and the color of the product remains unchanged for about thirty years.

- Special strength. Products do not lose their shape and do not crack under the pressure of the soil or during inaccurate transportation.

- Light weight. For example, a polymer sand ring with a diameter of one meter weighs only 60 kilograms. For comparison, the weight of a similar concrete ring is 700 kilograms.

- High waterproofing properties - products do not absorb moisture and do not let liquids through. For this reason, wells are ideal for water pipes and sewers.

The price of the product is determined by the type of well and its dimensions. For example, a septic tank for two cubic meters costs 20,000-25,000 rubles. A set of eight rings for the well will cost 9,500 rubles. A prefabricated septic tank of two tanks of five cubic meters, designed for a family of three, costs from 58,000 rubles.

Pros and cons of a polymer well

The peculiarity of the joining of elements and the tightness of the resulting tank is not the only advantage.

Each section:

- weighs little, mounted by hand;

- installed at any depth;

- not subject to the destructive action of moisture;

- not afraid of frost, chemicals, sewage;

- more than half a century since commissioning;

- environmentally friendly and low cost.

When calculating the turnkey cost, this technology is the cheapest, as it allows you to save on almost everything. Fasteners are simple, there is no need to hire a team of installers and a truck crane, etc.

But this is only in the case when elements are mounted that are initially incorrectly selected. People cover the well with a thin, light, cheap cover, and then complain that it could not stand the truck loaded with rubble. It is necessary to select elements so that each of them can withstand the required load.

HelpfulUseless

Tips for choosing and self-assembly

In order for the well to serve for a long period of time, it is required:

- choose the right device;

- comply with all installation rules.

Nuances of choice

To choose the right plastic well, you must consider the following factors:

- well model;

- overall dimensions of the device;

- manufacturing material.

Polymer wells are made of two types:

monolithic structures are distinguished by a higher strength index under pressure on the walls;

Ready-made polymer well for sewerage

prefabricated structures based on polymer rings for a well of a certain diameter.

Well made of individual polymer sand rings

When choosing a well, it is also recommended to take into account the overall parameters.This issue is especially relevant when using a monolithic structure.

The overall dimensions of the well are determined depending on the purpose of the device and the parameters of the sewer system.

Polymer wells during the construction of the sewer network of a private house can be installed:

to audit the system. They should be located at the junction / branching of individual pipelines, at the junction of pipes of different diameters, as well as at places where large level differences are formed. The dimensions of the manhole depend on the number of lines supplied and the convenience of the user;

Wells for auditing pipeline connections

Manholes can be equipped with branch pipes at the factory. Such designs require careful selection in all respects. Wells are also produced in which the installation of pipes is done independently.

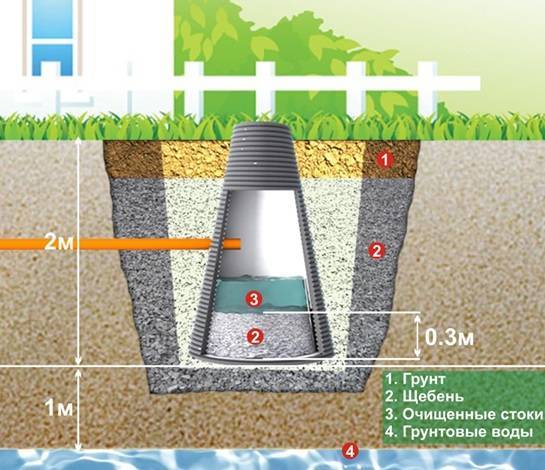

drainage, in which pre-treated effluents are disposed of. The design feature of drainage wells is the absence of a bottom, which is replaced by layers of sand, gravel and other draining materials;

Well for the disposal of treated sewage

the storage well is used as a collection tank for sewage. Such a well is subject to periodic cleaning.

storage well

When choosing the size of drainage and storage wells, the main parameter is the daily amount of drains.

The type of material from which the well is made is also essential:

- PVC wells are mainly used with a large amount of aggressive substances in the drains. Products are also characterized by minimal flammability;

- polyethylene structures are installed in cold climates or with constant use during the cold season. Wells are able to compensate for ground pressure at low temperatures;

- polypropylene wells are installed in areas with high buoyancy of the soil. Structures can withstand higher loads on the walls, are ductile and wear resistant.

Installation rules

Installation instructions polymer well practically does not differ from the installation instructions for wells made of other materials:

- at the preparatory stage, it is necessary to dig a pit and bring trenches to it for laying sewer pipes. The width and length of the pit should be 15–20 cm more on each side than the installed well;

- the bottom of the pit and the summed up trenches is leveled and compacted. Sand and, if necessary, gravel cushions are laid at the bottom. When installing the storage tank with your own hands, the bottom of the pit can be concreted. This will give the tank additional stability;

Pit for installation of a well

- a well is installed and sewer pipes are connected;

Installation and connection of the well

When mounting the collection tank, each individual ring is sealed with bituminous mastic or a special sealant.

How to properly mount a prefabricated polymer sand well, see the video.

- soil is backfilled. Before backfilling, it is recommended to completely fill the container with water. This will give additional rigidity to the structure and avoid deformation during backfilling;

- cover is installed.If desired, the well is decorated.

Closing and masking the sewer well

The use of polymer wells significantly reduces the cost of building a sewer system. Polymer sand structures practically do not require additional maintenance.

Features of polymer sand rings

The desire to build such a well, which for many years will not need repair and reconstruction, is quite understandable. But for its implementation, it is necessary to carefully consider and design the structure and not save on materials and professional installation work.

The price of the described products is higher than that of reinforced concrete analogues, but it justifies itself.

Preparation method

In the manufacture of well rings, polymers are used (plastic with various additives that give the material the required properties) and sand. In production, all components come in the form of a powder.

They are mixed in certain proportions, after which they are pressed under pressure and exposure to high temperatures.

Mixing sand and polymer powder

As a result of hot pressing, sand-polymer rings for wells acquire the desired shape and a strong, low-porous structure.

Added to the mass of pigments allow you to get products of different colors

Advantages

Most clearly, the advantages of a particular material are manifested when it is compared with analogues used in the construction of the same structures. For example, it is easy to see the advantages and disadvantages wooden house walls in comparison with brick or stone ones. We will compare polymer-sand well rings with reinforced concrete, which are still in the lead in the construction of all types of wells.So:

The weight. Everyone who has ever taken part in the construction of reinforced concrete wells knows that it is impossible to do this work manually, since concrete rings are very heavy and bulky.

Special equipment is required not only for their installation in the mine, but also for delivery to the site, loading, unloading, moving. The weight of products made of polymers does not exceed 60 kg, which makes it possible to abandon trucks and manipulators, saving on their rent and payment for the work of loaders.

To center the rings and fix them, they are equipped with interlocks.

In addition, soil movement and strong groundwater flows can cause displacement of concrete rings with rupture of joints, leading to their depressurization and even destruction.

Docking of polymer sand rings is carried out by means of their tight connection with each other by the "groove-comb" system. Thanks to strictly maintained dimensions, they fit perfectly one on top of the other, creating a sealed, non-displacement structure. To be sure, before installation, you can coat the grooves with mastic or silicone sealant:

Ease of installation. The light weight and the presence of interlocks greatly simplify the installation of a well made of polymer sand rings.

It is noticeably easier in comparison with reinforced concrete products and its connection to the water or sewer system: holes for pipes are made easily and quickly with ordinary household tools and do not require subsequent treatment with anti-corrosion compounds.

The photo shows - the sealing of the input is carried out using rubber o-rings

Moisture resistance. The main disadvantage of concrete is the porosity of the material.Water penetrates into the pores, which, when frozen, increases in volume and disrupts the structure of the material, causing cracks to appear in it. Over time, they grow, the number increases, and the rings lose their original strength.

Cracks in concrete require sealing, as they violate the tightness of the well

This does not happen with polymer-sand products, since they have a dense, low-porosity structure due to particle sintering during hot pressing. The minimum degree of water absorption allows the material to withstand up to 500 freeze and thaw cycles without compromising structural strength.

Resistance to aggressive environments. The well is likely to be exposed to chemicals dissolved in groundwater, which accelerate the destruction of the concrete structure. If it is sewer or storm, then its inner surface is subjected to even more aggressive influence.

Polymer sand ring for the well thanks to its composition is not afraid of either chemicals or reactions occurring during the decomposition of biomass.

All of these properties clearly indicate that the competitiveness of parts made of polymer sand mixture is very high. And first of all thanks to ease of installation, undemanding maintenance and exceptional durability.

Reinforced concrete and polymer sand: who wins?

For a long time, reinforced concrete remained the only material for the production of wells. But its properties are far from ideal. Let's compare them with similar characteristics of polymer-sand raw materials.

Weight and transportation to the site

Reinforced concrete materials differ in significant weight.The meter ring has a mass of about 500 kg, which means that for its transportation to a construction site, special equipment is needed both for loading and unloading (crane) and for transportation (truck). Even if this is found, then such voluminous equipment will not always “squeeze” into the narrow construction space, especially in the city, where there are residential buildings nearby.

Due to less bulky components, polymer wells are easier to install, because large-sized equipment and many workers are not needed.

In diameter, polymer sand wells are not thicker than 1.1 meters, so they can easily fit into a regular trailer for a car

In turn, polymer-sand wells are much lighter. The mass of any structural fragment (ring, hatch, etc.) is up to 60 kg. This weight can be lifted by two people without using a crane. Yes, and the summer resident will be able to transport to the site with an ordinary trailer for a car. Another plus: it is easily mounted in a hard-to-reach place (for example, in the basement), because the owner of the site himself can roll up the rings and throw them into the mine.

One person can assemble a whole well from elements and mount it in the ground, because the weight of each element does not exceed 60 kg

Features of joining elements and tightness of joints

In reinforced concrete rings, the edges cannot be made absolutely even, therefore, during installation, you have to fiddle a lot with the tightness of the joints. And anyway, over time, they are washed away by water, as well as the walls. And if the well stands on moving ground, where groundwater has very strong flows in the spring, then the rings can move, breaking at the joints.

With the “groove-ridge” system, both structural elements are connected as tightly as possible, so the joints do not require additional sealing, except for lubrication with silicone

Polymer-sand elements are joined according to the “groove-ridge” system, thanks to which they are not afraid of soil movements. Such a connection absolutely does not let water through, and it is enough to coat all the grooves for insurance with silicone sealant or bitumen mastic.

Ability to resist moisture

Moisture is the main enemy of reinforced concrete structures. The concrete surface has large pores, and in winter, frost from the ground penetrates into them, expands and causes microcracks that will increase every year.

Due to the technology of "sintering" of particles, polymer sand rings have a water absorption level of only 0.03%. The well is able to withstand over five hundred freeze-thaw cycles (from -65˚ to +160˚С) without any structural damage.

Resistance to aggressive substances

Together with water from the soil, aggressive substances enter the surface of the wells, destroying the structure of concrete, and if the well is a sewer well, then the biomass decomposition reactions will “spoil” it from the inside. To make these processes run weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of an aggressive environment. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

Ease of connection to the pipeline

When connecting a well with home water supply system you have to drill holes or openings in it. In reinforced concrete, this is very difficult to do. Often a professional tool is required.

You can cut openings and holes for pipes in polymer sand wells with ordinary household tools, and the edges do not need to be processed with anything.

In the polymer ring, all openings are created with household tools. At the same time, it is not necessary to lubricate the edges of the cut piece with any compounds, because corrosion of plastic is not terrible.

Warranty period

For reinforced concrete products, manufacturers give a guarantee of about 50 years, but indicate that these parameters relate only to the main technical characteristics. Those. The ring will definitely not fall apart and will not become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out illiterately.

With polymer sand wells, such incidents are excluded. Therefore, manufacturers give a guarantee of up to 100 years, although plastics decompose in nature for over 400 years, and the sand that is part of the raw material is eternal.

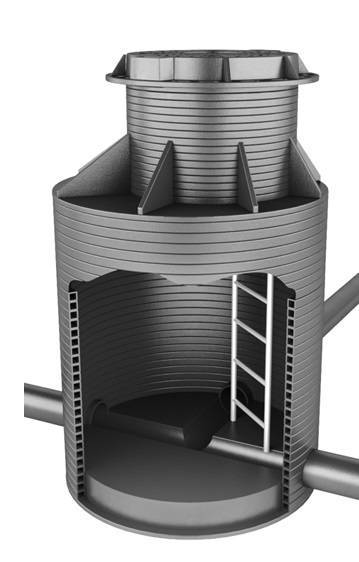

Design features and production standards

Regardless of the type of material used, the design of sewage wells is the same. The structure is a cylindrical shaft deepened into the ground, at the bottom of which there is a kinet - a tray for two or three pipes with sewage.

To regulate the length of the structure allows the use of extension cords and retractable shafts. To gain the required length of the structure, they are connected to each othercreating a strong and tight connection.

Often, sliding extension models are also used to build up the structure. Acting as connecting elements, in parallel with this they also serve as a continuation of the wall of the structure.

The upper part of the well is equipped with an overlap with a hatch.When installing plastic wells, it is quite logical to choose hatches from the same polymers, thanks to which it is possible to ensure equally long durability of the entire structure.

The dimensions of the plastic models correspond to the dimensions of the cast-iron counterparts. When choosing a hatch, they are guided by its functionality. Depending on the degree of withstand load, hatches are divided into 4 categories:

- The "A15" standard applies to green areas and walkways. It can withstand up to one and a half tons.

- "B125" is installed on sidewalks and in park areas and parking lots, where the load weight does not exceed 12.5 tons.

- "S250" is used in the construction of sewers, the laying of which is carried out under city roads. Products withstand loads up to 25 tons.

- "D400" the most durable structures, capable of withstanding up to 40 tons, are designed for highways.

Hatches of the “A15” standard can be installed directly on the well shaft, and their counterparts of the “B125”, “C250” and “D400” categories can be installed on an unloading ring or a retractable telescopic pipe.

The neck is a transitional element between the shaft and the hatch. Its main purpose is to accept and compensate loads from the outside that can damage the mine and the pipes leading to it. For this reason, it is a corrugated or telescopic design.

The telescopic part of the shaft can be extended, taking the most convenient position for inspecting the condition of the wall surface and providing access during repair work.The relief ring is threaded at both ends, making the connection as tight as possible.

Holes are provided in the walls of the structure for supplying the inlet and outlet pipes.

Depending on the size of the structure, wells are of two types:

- Less than one meter in diameter with an unattended shaft. Compact inspection structures are installed when arranging at a shallow depth.

- Over one meter in diameter. The design allows you to easily maintain the equipment and, if necessary, repair the structure.

The well itself is made of the same material that is used in the production of ordinary sewer pipes. It can be structured or two-layer polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP).

No less popular are models made of corrugated plastic. This solution simplifies the task of adjusting the height of the tank and allows you to partially compensate for the load on the bottom, thereby significantly extending the service life of the structure.

Both manhole options are available with single or double walls. To resist the compression of the soil from the outside, the products are equipped with stiffeners.

Varieties of polymer wells

First of all, all polymer wells differ in size, which directly affects the daily disposal of sewage. In addition, wells can be either with free access or without access at all. As for polymer wells with free access, they imply unhindered inspection or repair, and for those that are produced without access, maintenance is possible only from above.

Also, polymer wells differ from each other in texture and purpose. They may be the following:

- Smooth single-walled;

- Smooth double-walled;

- Corrugated single-wall;

- Corrugated double-walled;

- Combined.

According to their purpose, they are:

- Prefabricated manholes - designed for maintenance and technical inspection of storm or utility sewers.

- Sewer - used to control and gain access to sewer pipes.

- Storm type - serve to collect storm drains.

- Sedimentary type - used to treat wastewater from precipitation.

- Drainage - are used in the corresponding system as connecting and rotary elements.

- Differential - used to change the level of the pipeline. In turn, they come with a vertical, stepped and cutting tip pipe.

- Caissons - designed for installation of pumps, locking equipment or electrical devices in the depths of the earth.

- Collector - serve to connect sewer, storm water or drainage systems.

- Telecommunication - serve to control the junction of cables and other equipment. Such wells are prefabricated and welded.

Polymer wells, depending on the functions performed, are divided into the following types:

- Swivel;

- Lookouts;

- Stormwater;

- Mud;

- Cumulative.

Each of these types has its own characteristics.

When choosing a polymer well, you should pay close attention to its purpose immediately before buying

Rotary wells serve to clean pipes and are installed on lapels, inspection wells provide access to hydraulic communications, and storm wells are needed to drain rainwater. Accumulative polymer wells completely replace cesspools and prevent the penetration of an unpleasant odor into the site, and mud wells purify water from dirt and sediment.

In order to determine the number of polymer wells for a particular sewer system, it is necessary to strictly follow SNiP.

In addition, when purchasing a polymer well, you must also take care of the following functional details:

- Polymer hatches, which are mainly used for private households and places with rarely passing traffic;

- Lids - used to protect the well from the penetration of dirt and debris;

- Necks - used to narrow the top of the well, which are central, as well as offset;

- Stairs - used for quick access to the well;

- Anti-freezing funnels - serving to prevent the penetration of cold air inside;

- Garbage containers - necessary for collecting garbage on the inner surface.

In addition, polymer wells are:

- From polyethylene - they are used for such sewer systems as stormwater, household and common alloy. Such wells are characterized by good tightness, corrosion resistance, ease of installation and long service life.

- FROM polypropylene - are very popular. The rings of these wells have different diameters, and the pipes are double-layer and single-layer.As for double-layer pipes, they have an external corrugated layer, which significantly increases the protection of the product from adverse conditions. In addition, corrugated pipes are distinguished by a longer service life, environmental safety, durability and ease of installation.

- Polymer-sand - this type of material appeared on the construction market relatively recently, so it has not yet become popular. Such wells are made from a composite material, which includes plastic and sand. Such wells are distinguished by high tightness, which is achieved due to the special connection of the elements.