- Mounting Features

- How to lay water and sewer

- Features of the installation of pressure PE pipes

- No. 5. Pipes for a gas pipeline made of low-pressure polyethylene (HDPE)

- Saddles and their scope

- Gas polyethylene pipes for gas pipelines

- Scope and description

- Advantages of PE pipes

- Flaws

- Assembly on compression (crimp) fittings

- How reliable is the connection

- Assembly order

- Laying a water pipe in the ground from HDPE

- Common mistakes during installation

- Can polypropylene pipes be used for gas?

- Technology of external water supply from polyethylene pipes

- Main advantages and disadvantages

- Installation rules

- What are the permissible deviations in the dimensions of polyethylene pipes?

- Installation rules and useful video

- Advantages of a gas pipeline made of polyethylene pipes

- Installation of a gas pipeline from polyethylene pipes

- Disadvantages of polyethylene pipes

- Advantages of polyethylene gas pipes

- Features according to GOST R 50838-2009

Mounting Features

Polyethylene pipelines are recommended to be laid:

- External networks - underground, since above-ground laying will require additional resources for heat and sun protection of PE products.

- Internal wiring - in heated rooms.

Ground laying of PE bends is carried out on movable and fixed supports, taking into account their linear thermal expansion. Brackets and hangers are used as fasteners.

In underground laying, they use both the trench method and trenchless methods: pulling a pipe into a pipe, puncturing, destroying an old channel while simultaneously replacing it with a new product.

How to lay water and sewer

The diameter of the underground part of the water pipe depends on its length and the pressure of water from the source. The lower the pressure, the larger the cross section of the channel should be.

A trench for a water or sewer network is dug to a depth below the freezing point, but not less than 1 meter.

A cushion of sand or fine gravel is made at the bottom of the ditch to prevent channel deformation.

Next, the pipeline connections are mounted.

The conduit laid and checked for leakage is covered with loosened soil.

When laying sewers, it is important to observe the basic condition: to build a trench with a slope of at least 1 cm per meter of network

Features of the installation of pressure PE pipes

Before installation, polyethylene products are inspected in order to identify defects and contamination. Scratches and other minor damage should not exceed 10% of the minimum possible wall thickness of the elbows.

The bends are cut into segments with a special pipe cutter, which allows you to make even cuts, which is very important when assembling the line. Lines of small sections up to 50 mm, when butt welding or connection through flanges are impractical, are assembled using compression fittings

Lines of small sections up to 50 mm, when butt welding or connection through flanges are impractical, are assembled using compression fittings.

Electrofusion couplings are used for joining long sections of PE pipes with a cross section of 25-110 mm, when installed in a limited space, for tie-ins into existing lines.

No. 5. Pipes for a gas pipeline made of low-pressure polyethylene (HDPE)

HDPE pipes have recently been in no less demand than steel pipes. It should be noted right away that the phrase "low pressure", which appears in the name of the material, refers to the features of the production of pipes, and not to the operating conditions of the gas pipeline. There are polyethylene pipes that can withstand pressure up to 1.2 MPa. What makes us abandon the proven option with steel pipes and use polymer ones? The answer to this question lies in the advantages of the material.

The main advantages of polyethylene gas pipes:

- light weight;

- faster and easier installation without the use of complex expensive equipment that requires special skills;

- strength, ductility and flexibility make it quite easy to bypass possible obstacles in the path of the gas pipeline. The maximum allowable bending radius is 25 pipe radii. Flexibility allows the pipeline to remain intact with small ground movements;

- the ability to withstand pressure up to 1.2 MPa, so that such pipes can be used in almost all sections of the gas pipeline;

- resistance to corrosion, the ability to withstand the effects of aggressive substances;

- high throughput, as the inner surface of the pipe is smooth. With the same diameter as a steel pipe, a polyethylene pipe will have a capacity of about 30% higher;

- HDPE pipes are produced of great length, which makes it possible to do with fewer connections, thereby achieving the integrity and reliability of the structure;

- polymer materials do not conduct stray current;

- low cost when compared with steel or copper counterparts;

- durability of at least 50 years, and under all conditions up to 80-90 years.

There are also cons:

- polyethylene pipes cannot be used in areas where the temperature drops below -45C. Such a gas pipeline is located at a depth of at least 1 m, at winter temperatures of -40 ° C, the depth increases to 1.4 m, and in some cases, laying HDPE pipes is completely impossible. At low temperatures, performance may deteriorate, and durability may decrease;

- pipes are also not suitable for seismically active areas;

- HDPE pipes will not withstand a pressure of more than 1.2 MPa - only thick-walled steel will help here;

- sensitivity to ultraviolet rays does not allow for above-ground installation - polyethylene pipes are only suitable for installation underground;

- due to the increased level of flammability of polyethylene, such pipes are not recommended for indoor use. Already at + 80C, the material tends to deform and collapse;

- HDPE pipes are not suitable for laying gas pipelines in collectors and tunnels. In such places, a steel analogue is used;

- at the intersection of the gas pipeline with roads and other communications, the pipes must be hidden in a metal case.

It is better not to use polyethylene pipes for installing a gas pipeline indoors, but they are being used more and more often for underground installation.

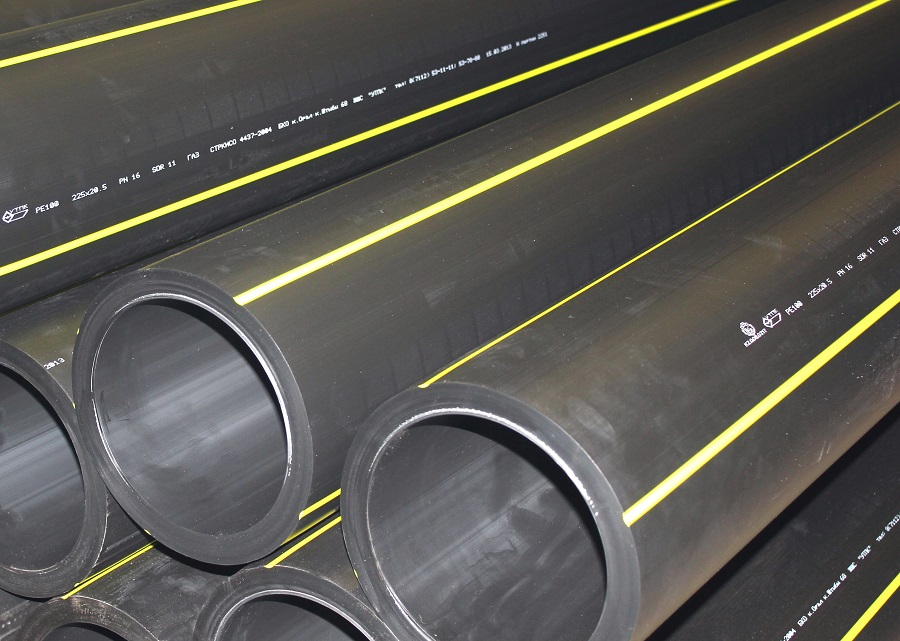

For the production of pipes, special pipe grades of polyethylene are used:

- PE 80 - black pipes with yellow inserts, withstand pressure up to 0.3-0.6 MPa;

- PE 100 - pipes with a blue stripe, withstand pressure up to 1.2 MPa. During their installation, more serious efforts are made, since the material has to be heated to higher temperatures, but the quality of the connection in this case is at its best.

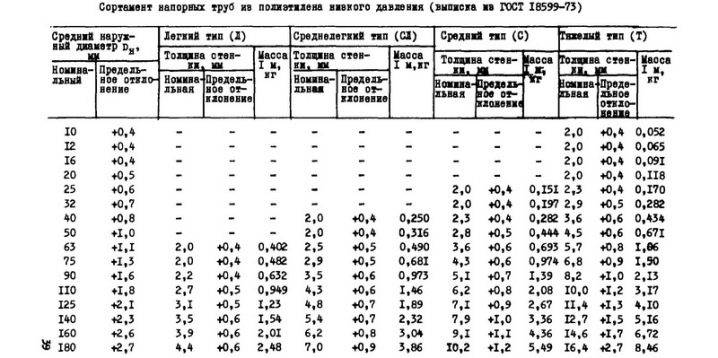

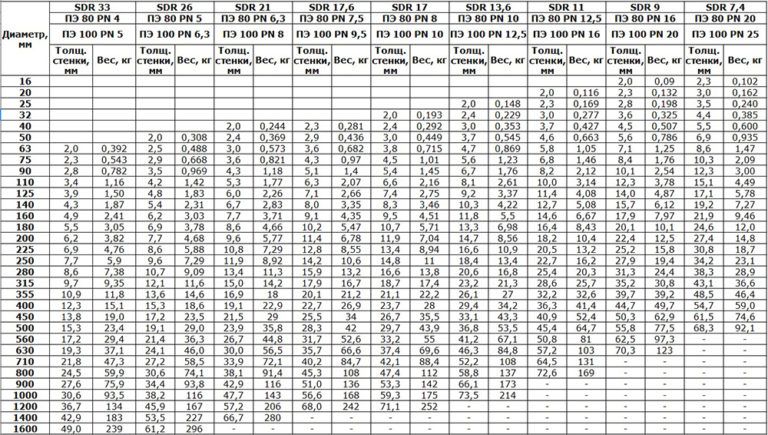

The diameter of HDPE pipes can vary from 20 to 630 mm or more, even pipes with a diameter of 1200 mm are used. When choosing, it is also worth taking into account such an indicator as SDR - this is the ratio of diameter to wall thickness. The smaller this value, the thicker the walls and the more durable the product in front of us. SDR ranges from 9 to 26.

The connection of polyethylene pipes is carried out in one of the following ways:

- butt welding. The edges of individual elements are heated with a special soldering iron until a viscous consistency is reached, which allows you to safely connect two pipes into one;

- electrofusion welding involves mounting the edges of the pipe into a special coupling, to which voltage is applied, due to which heating and connection of two segments occurs. Such a connection is stronger than the pipe itself and can withstand a pressure of 16 MPa.

With an individual connection to the network, butt welding will be enough, and if, for example, gasification of an entire area takes place, then it is better to use electrofusion welding - it is more reliable and tight.

To connect a section of a steel and polyethylene gas pipeline, special elements are used, one side of which is welded to steel, and the other to polyethylene.

Saddles and their scope

In addition to fittings, there is another interesting device that allows you to make branches from an already finished pipeline. These saddles are specially designed couplings. This coupling has one or more threaded holes. They usually put a tap in them, and a new branch of the water supply is connected to it.

Saddles for polyethylene water pipes

Sedeki are put on the pipe, fixed with screws. After that, a hole is drilled in the branch with a drill and a thick drill in the surface of the pipe. When it is ready, a crane is installed, a branch is assembled further. So improve the system with minimal effort and cost.

Gas polyethylene pipes for gas pipelines

Scope and description

Polyethylene gas pipes are produced in bays up to 500 m.

Polyethylene gas pipes are produced in bays up to 500 m.

PE pipes are used for transporting flammable gaseous and liquid substances in the domestic and industrial sector, construction of drainage systems, sewerage systems. They are also used to protect cables (optical fiber, telecommunications, electrical, communication cables) in unstable environments.

Pipes for the gas pipeline are produced from low-pressure polyethylene with high density; available in black with longitudinal orange or yellow stripes and corresponding markings. The classes of polyethylene used are 80 and 100 (SDR 17.6 and 11), the diameter can vary from 20 to 400 mm. Class 80 products are marked in yellow, class 100 in orange. According to DSTU, the inner and outer surfaces are smooth. Polyethylene gas pipes for gas pipelines with a diameter of not more than 110 mm are produced in coils of 50-500 m.

The marking includes the following data: symbol of the product, information about the release batch, date of manufacture.PE-80 tubes withstand up to 4-6 atmospheres and have a wall thickness of about 2.3 mm. PE-100 pipes have walls 3.5 mm thick and can handle pressure from 3 to 12 atmospheres. The number of orange or yellow stripes on the pipe (depending on the class) is at least 3.

Advantages of PE pipes

Polyethylene gas pipes are only suitable for laying a gas pipeline underground.

Polyethylene gas pipes are only suitable for laying a gas pipeline underground.

Polyethylene as a modern material has many advantages over metal counterparts. Here are the most notable ones:

- The warranty period of PE products reaches half a century, which is much longer than the service life of metal counterparts.

- PE pipes weigh 2-4 times less than steel pipes, which simplifies the process of laying them and reduces the time for construction work. Due to the low weight of the products, it is possible to lay a gas pipeline by pulling.

- No need for cathodic protection of structures - virtually no special maintenance required after installation.

- High ductility, material resistance to corrosion, brilliant hydraulics (low pressure loss).

- PE products are not subject to the negative effects of water and other aggressive environments, they are able to withstand soil loads.

- Installation and welding of polyethylene pipes is much cheaper and faster. The joints of such structures do not need additional consumables, such as insulating materials, electrodes, etc. - enough thermistor couplings.

It should also be noted the high elasticity of the material, the almost complete absence of roughness and irregularities on the inner surface of PE pipes. The production of pipes in coils up to 500 m significantly expands the scope of their application in construction, both industrial and municipal.In addition, a gas pipeline made of polyethylene pipes will cost several times less than a similar metal construction. Against the background of the alarming environmental situation in the world, the fact that polyethylene does not emit harmful chemicals into the external environment is also important, and after the end of their service life, such pipes can be completely disposed of - this is safe.

Flaws

Polyethylene gas pipes are only suitable for laying a gas pipeline underground.

Polyethylene gas pipes are only suitable for laying a gas pipeline underground.

Despite the resistance of PE pipes to the effects of chemically active environments, it is not unlimited - polyethylene is characterized by vulnerability to the influence of chlorinated water. Connections become unstable, which limits their use in some areas. With a number of thermal and light effects, the plastic that is part of such pipes begins to release toxic substances. When overheated, PE products release hydrochloric acid, the compounds of which, entering the external environment, can cause severe burns. Colonies of bacteria can form on internal surfaces, which can be dangerous to humans.

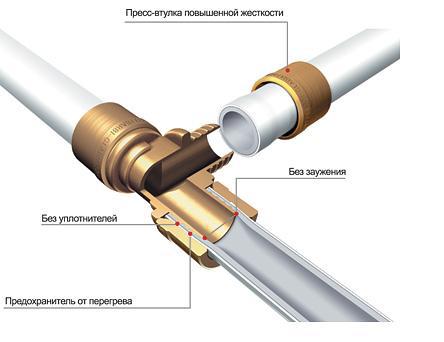

Assembly on compression (crimp) fittings

On one or two sides of the fitting (sometimes on three), a whole system is installed that provides the connection. The fitting itself consists of:

- corps;

- clamping nut;

- collets - a plastic ring with an oblique cut that provides a tight grip on the pipe;

- thrust ring;

- gaskets that are responsible for tightness.

What is a compression fitting for polyethylene pipes

How reliable is the connection

Despite the apparent unreliability, the connection of polyethylene pipes on compression fittings is reliable.Properly made, it can withstand operating pressures up to 10 atm and above (if these are products of a normal manufacturer). Watch the video for proof.

This system is good for easy self-assembly. You probably appreciated it already from the video. Just the pipe is inserted, the thread is tightened.

Summer residents, in addition to the ability to do everything with their own urks, like it because, if necessary, everything can be disassembled, hidden for the winter, and reassembled in the spring. This is in case the wiring is done for irrigation. The collapsible system is also good because you can always tighten the digging fitting or replace it with a new one. The disadvantage is that the fittings are bulky and the internal wiring in a house or apartment is rarely made of them - the appearance is not the most pleasant. But for the water supply section - from the well to the house - it is difficult to find better material.

Assembly order

The pipe is cut strictly at 90 °. The cut should be even, without burrs. Dirt, oils or other contaminants are also unacceptable. Before assembly, chamfers are removed from the sections of the connected sections. This is necessary so that the sharp edge of the polyethylene does not damage the sealing rubber ring.

During installation, the connection of polyethylene pipes on compression fittings is tightened by hand

Spare parts are put on the prepared pipe in this order: the compression nut is pulled, then the collet, followed by the thrust ring. We install a rubber gasket in the fitting body. Now we connect the body and the pipe with the parts put on it, applying force - we must insert it all the way. We tighten all the spare parts to the body and connect them with a crimp nut. We twist the resulting connection of polyethylene pipes with force by hand. For reliability, you can hold out with a special mounting key.The use of other tightening tools is undesirable: plastic can be damaged.

Laying a water pipe in the ground from HDPE

In accordance with the type of system, pressure or non-pressure material is selected for laying polyethylene pipes in a prepared trench. Thanks to the first type of pipes, it is possible to continuously maintain the set pressure, a product without pressure cannot boast of this. Pressure - perfect for water supply, the other - for the sewer network.

By following the correct sequence of actions, it is possible to quickly and efficiently carry out work on laying a HDPE pipe into the ground.

It’s worth starting with a schematic indication of where and how the pipes will be placed on the site. To draw up a plan, it is not necessary to have an education with an engineering bias, it is enough to understand the key features of the soil and the available territory.

For proper installation, it is recommended to use special technical documents for the area. Often, they already list the existing communications and land reclamation areas, if any are located nearby. Guided by the specified documentation, you will be able to schematically establish the location of the future pipe laying.

Pay attention to several parameters: the territorial area in order to determine the correct branching and incoming components, as well as the softness and flowability of the soil, which will affect the correct selection of the raw material base

It is also important to know the designation of HDPE products, since there are plenty of their varieties. It has been noticed that for laying networks underground it is worth using PN10

The material fully complies with all standards for a resource with drinking water. HDPE are designed to withstand continuous pressure up to 10 atmospheres. They are endowed with high strength. With the arrangement of sewage, the situation is simpler: it is allowed to use standard products without features

It has been noticed that for laying networks underground it is worth using PN10. The material fully complies with all standards for a resource with drinking water. HDPE are designed to withstand continuous pressure up to 10 atmospheres. They are endowed with high strength. With the arrangement of sewage, the situation is simpler: it is allowed to use standard products without features

It is also important to know the designation of HDPE products, since there are plenty of their varieties. It has been noticed that for laying networks underground it is worth using PN10

The material fully complies with all standards for a resource with drinking water. HDPE are designed to withstand continuous pressure up to 10 atmospheres. They are endowed with high strength. With the arrangement of sewage, the situation is simpler: it is allowed to use standard products without features.

When laying the water supply in the country, pay attention to the recommended immersion depth of the structure - 1.6 m. This is due to the freezing of the soil, which reaches 1.4 m

From which it turns out that by digging a hole smaller in depth, there is a risk of major damage to the pipes.

The ground, below the level of 1.6 m, always contains a positive temperature. In the absence of the possibility of immersing the pipe to a prescribed depth, it is worth thinking about carrying out auxiliary work related to the insulation of the system. It is not advisable to immerse the product below the fixed line, since HDPE cannot cope with physical pressure and will burst.

Common mistakes during installation

When installing a pipeline from polyethylene pipes, novice masters often experience the following errors:

- Incorrectly measured pipe sizes. As a result, the consumption of materials increases.

- Leaky connection. Most often this is due to the fact that the pipes were not completely seated in the fitting, and a loose connection formed.

- Nut tightening. They can squeeze out the sealing ring, which in turn will lead to a rapid leak in the pipeline.

In order to prevent adverse consequences, at each stage of work it is necessary to carefully check your actions.

Do-it-yourself pipeline on video:

Can polypropylene pipes be used for gas?

In Western countries, metal pipes are used only for the assembly of industrial pipelines. In the manufacture of water and gas supply systems, plastic elements are used. This is due to the performance characteristics of the material. Gas passes through the plastic pipe without any difficulty. Before the gas pipeline is put into operation, it is necessary to check the tightness of the connections of individual elements in order to prevent violation of the integrity of the system.

To figure out which is better - a pipeline made of metal or plastic, you can compare these two materials. Differences:

- Weight - plastic pipes weigh less than metal parts. Thanks to this, they are easier to mount, they do not require additional fastenings on vertical surfaces.

- Versatility - there are more factors to consider when choosing metal pipes than when using plastic parts.

- Price - tubes made of polymers are cheaper than metal ones.

Metal tubes outperform plastic tubes in terms of strength, durability, resistance to mechanical stress.

Technology of external water supply from polyethylene pipes

When arranging outdoor water supply networks, special points should be taken into account, such as:

- increased rate of linear expansion, which is 15 times more than that of metal pipes;

- great sound effect;

- low fire resistance;

- reduced adhesion to other building materials.

Polyethylene pipes, due to their physical properties, exhibit greater plasticity, which helps to avoid collapse under increased linear load and deformation of the water supply system.

In order to compensate for linear-type expansions for a plastic water pipe, couplings are used during its assembly. The factory product is produced with a margin of length, which reaches 10 mm. The planning of this reserve is connected with the calculation of the occurrence of a technological joint, compensated by the expansion of the pipes.

Main advantages and disadvantages

Like any other product, a PE gas pipe is distinguished by a number of positive qualities that determine their effectiveness. Consider the main advantages of this product:

have resistance to corrosive influences, unlike many metal pipes;

- installation of such pipes is simple. In addition, the speed of installation work of polyethylene parts is higher when compared with metal pipes;

- polyethylene is resistant to aggressive chemicals and does not need additional electrochemical protection;

- do not need to install waterproofing materials, as they themselves have excellent characteristics;

- polyethylene parts comply with all state quality standards;

- smooth walls of such products provide high throughput rates. Unlike metal parts, salt deposits and other particles that narrow the lumen of the pipe do not settle on their walls;

- polyethylene pipelines are environmentally friendly and do not emit harmful substances that can harm human health.

- the service life of polyethylene pipelines is much higher than that of metal counterparts. Under normal operation, it can reach 50 years, and in some cases - more;

- the cost of such products is lower than for metal products, which is a fundamental factor for many construction companies.

- it is also worth mentioning that they are distinguished by low air and gas transmission rates. This is a very important point, given the fact which medium is transported through polyethylene gas pipelines.

Gas PE pipes are produced by extrusion and have high performance characteristics

Now consider the main disadvantages of polyethylene products:

- installation of communications from polyethylene should be carried out only by the underground (closed) method;

- such pipes have good resistance to temperatures, however, with sudden temperature changes, their use is not recommended. This is especially true for low temperatures;

- in addition, there are restrictions on the depth of laying such pipelines - at least 1 m;

- under the roadbed or other engineering structure, the laying of a gas pipeline from polyethylene pipes is carried out using special protective cases. Such cases are usually made of steel;

- installation of HDPE pipes must be carried out by specialists who have permission to do this and have construction skills in this area.

Installation rules

When installing cylindrical products made of polyethylene, the laying depth must necessarily exceed the corresponding soil freezing value by about 20 cm. If we take the Moscow region, this value reaches about 1.5 m.

The trench should have a bottom whose width exceeds the diameter of the pipe by 40 cm. If welding will take place directly in the recess, then it is made wide enough so that the special apparatus can fit freely.

To maintain the integrity of the pipes, the bottom of the trench is well leveled, then covered with solid inclusions. Next, a sand cushion is made, the layer thickness of which is 10-15 cm. With trenchless pipe laying, the organization of the base and backfilling are not needed.

After the installation is fully completed, backfilling must be done. First, a layer of sand is placed, which closes the pipe about 15-30 cm above its top point. The trench is then filled with any suitable material, such as rocks or building debris. When laying a PE water pipeline under roads, backfilling is done only with sand, each time compacting its layer.

What are the permissible deviations in the dimensions of polyethylene pipes?

GOST 32415 standards provide for maximum permitted deviations from the required diameter and ovality parameters of pressure pipes.

| D, x1000 mm | Add. deviation >х10-1, mm | Ovality, mm x10-2not > |

| 0,025 | 3 | 120 |

| 0,032 | 3 | 130 |

| 0,040 | 4 | 140 |

| 0,050 | 4 | 140 |

| 0,063 | 4 | 150 |

| 0,075 | 5 | 160 |

| 0,090 | 6 | 180 |

| 0,110 | 7 | 220 |

| 0,125 | 8 | 250 |

| 0,140 | 9 | 280 |

| 0,160 | 10 | 320 |

| 0,180 | 11 | 360 |

| 0,200 | 12 | 400 |

| 0,225 | 14 | 450 |

| 0,280 | 17 | 980 |

| 0,315 | 19 | 1110 |

| 0,355 | 22 | 1250 |

| 0,400 | 24 | 1400 |

| 0,500 | 30 | 1750 |

| 0,560 | 34 | 1960 |

| 0,630 | 38 | 2210 |

| 0,710 | 64 | — |

| 0,800 | 72 | — |

| 0,900 | 81 | — |

| 1,000 | 90 | — |

| 1,200 | 108 | — |

Table of maximum permissible deviations according to GOST 32415

Note! According to GOST 18599 2001, pressure pipes made of polyethylene with a diameter of more than 180 mm are manufactured and supplied in lengths up to 25 m. Products with a smaller diameter can be supplied in coils

Installation rules and useful video

The key rules for installation work are to follow a series of actions: before operating the water supply network, it is worth checking the system to avoid leaks by filling the pipe with pressurized water. In the event of leakage from the coupling or fitting, the accessories must be tightened and the pressed fitting must be replaced.

The occurrence of errors is not excluded if the connection rules are violated, namely:

- the distance between the fasteners is not respected;

- the heating time is violated or extra efforts are applied during welding;

- rigid fasteners were installed, which did not take into account the linear expansion of the raw material base.

HelpfulUseless

Advantages of a gas pipeline made of polyethylene pipes

Compared with other types, a polyethylene gas pipeline has a number of advantages, this applies to:

- long service life, because, subject to proper installation, the gas supply line will last at least fifty years;

- high resistance to chemical attack, as well as aggressive environment;

- the absence of gas leaks, because the walls of the PE pipe are resistant to the influence of the working environment;

- low weight of pipes, which greatly simplifies the installation process;

- elasticity, which allows you to bend polyethylene pipes for gas and give them the necessary shape;

- no need to use additional protective equipment;

- environmental friendliness of the design and its low cost.

Another factor contributing to the popularity of PE pipe gas supply systems is that they do not require waterproofing during their installation, which significantly reduces the cost of materials and work.

During the laying process, pipes of two modifications PE-100 and PE-80 are used, which have different technical characteristics. If for PE-100 the pressure indicators are in the range of 3-12 atmospheres, and the wall thickness is 3.5 millimeters, then for PE-80 the first indicator is 3-6 atmospheres, and the wall thickness is up to three millimeters.

Installation of HDPE pipes

HDPE gas pipes can be supplied in coils or lengths up to 12 meters. It is allowed to operate both types of pipes at temperatures from -15 to +40 degrees, since it is within these limits that they retain their properties. Therefore, polypropylene pipes are used in heating systems, which are more resistant to high temperatures.

Installation of a gas pipeline from polyethylene pipes

When installing the gas pipeline, it is necessary to adhere to safety rules in order to avoid leaks during further operation. Polyethylene pipes are connected using fittings, and it is necessary that the entire structure is airtight, so the tie-in is carried out by butt welding, or electrofusion welding.

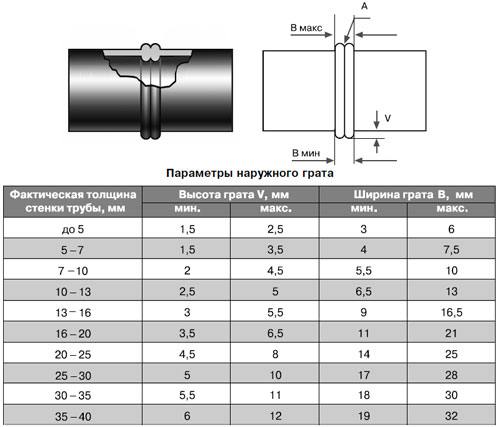

During the welding process, the parts must be stationary both during heating and cooling. The nozzles used for welding are put on pipes, after which the parts are heated and connected.

After the tie-in is completed, solidification occurs for 5-7 seconds, and after another twenty minutes, the system can already be put into operation.The seam formed after welding is very strong, but only if it is even and the height of the indent is the same everywhere.

In order to ensure the reliability of the gas pipeline and minimize the chance of leakage of the transported substance, frequent connections should be avoided and fixed to the walls every half a meter.

Disadvantages of polyethylene pipes

However, the disadvantages of low-pressure polyethylene products when used for laying a gas pipeline must also be taken into account, among them:

- the need for installation only underground;

- operating temperature restrictions;

- requirements for the depth of occurrence, which must be at least a meter;

- the need to use metal cases when laying a gas pipeline under roads and communication lines.

In addition, tie-in and installation of gas networks from HDPE pipes is carried out by specialists with special permission.

Advantages of polyethylene gas pipes

Polyethylene pipes for gas supply have a number of undeniable advantages, due to which they firmly occupy a leading role in this area.

Their main advantages are as follows:

- Long service life, which, with proper use, can reach several decades.

- Low gas permeability and, as a result, a high level of safety.

- Lightness and lack of significant loads on the structure.

- Reliability in use, resistance to aggressive media and corrosion.

- Strength and flexibility, the ability to bend during laying.

- No need for special enclosures, chemical, electrical and other protective equipment.

- Wide operating temperature range (-15°C to +40°C).

- No need for waterproofing.

- The low cost of the pipes themselves, as well as elements for their installation.

- Easy and cheap transportation and installation.

- Excellent environmental performance.

Features according to GOST R 50838-2009

GOST R 50838-2009 sets standards for gas pipes made of polymers. Manufacturers are required to adhere to prescribed rules and regulations in order to ensure the release of quality products.

In accordance with state regulations for HDPE gas pipelines, a number of characteristics are important and must be within acceptable limits. Finished structures are evaluated immediately according to three indicators:

- SDR;

- Wall thickness;

- section diameter.

For production, two modifications of polymers are used - PE-80 and PE-100. Pipes are made in lengths of 12 m or in reels of 100 or 200 m.

For external differences of pipes for laying gas communications, special color designations are used. Pipes must have a pronounced distinctive color:

- be completely yellow;

- painted in a different color, but have continuous yellow stripes along the entire length.