- Manufacturers

- Technical description, low power vibration pump models

- Technical description of this device

- Operating principle

- The second place in the ranking of vibration pumps is LIVHYDROMASH Malysh BV 0.12-40-U5 16 M

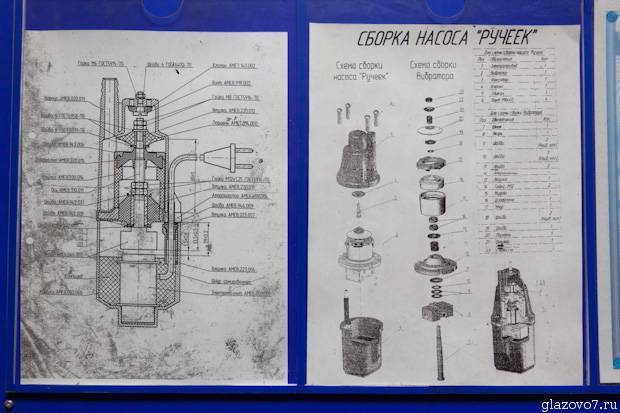

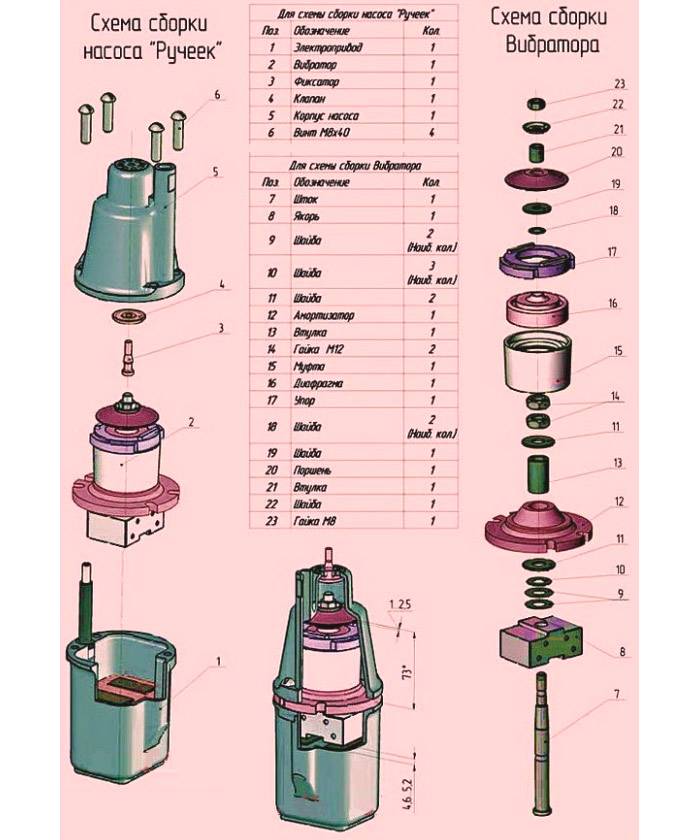

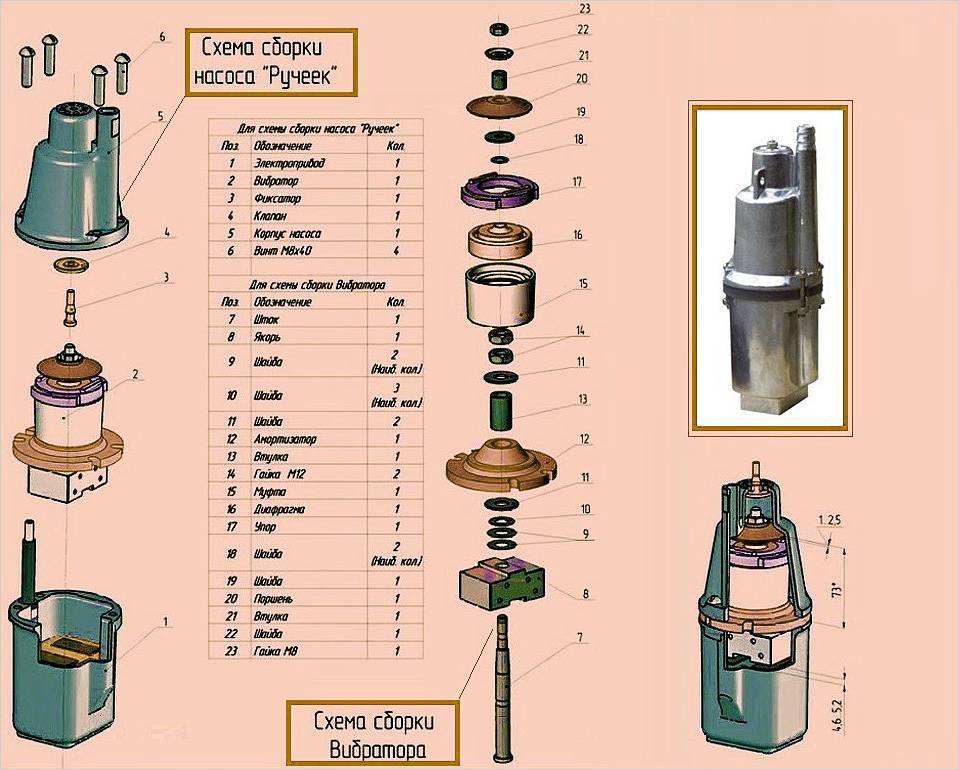

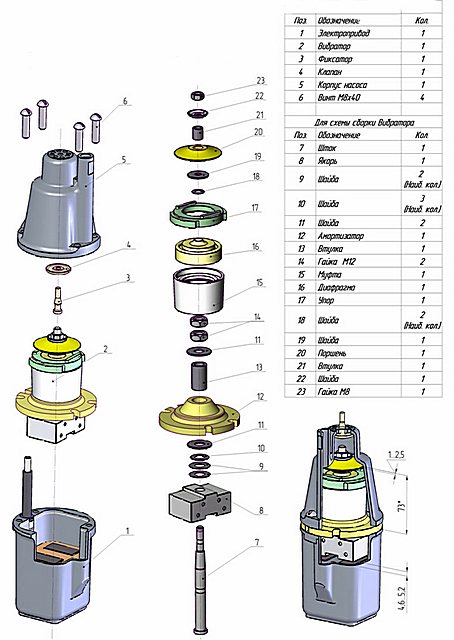

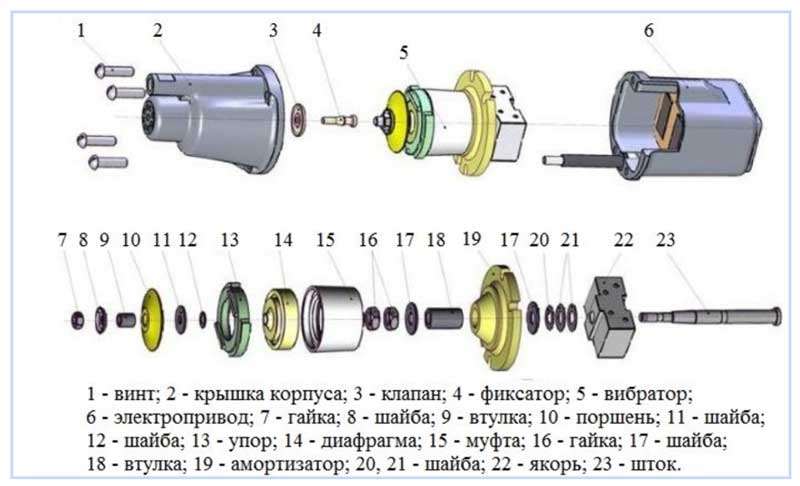

- Disassembly of the pump Kid

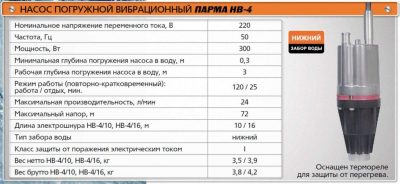

- Specifications

- Kinds

- Selection Guide

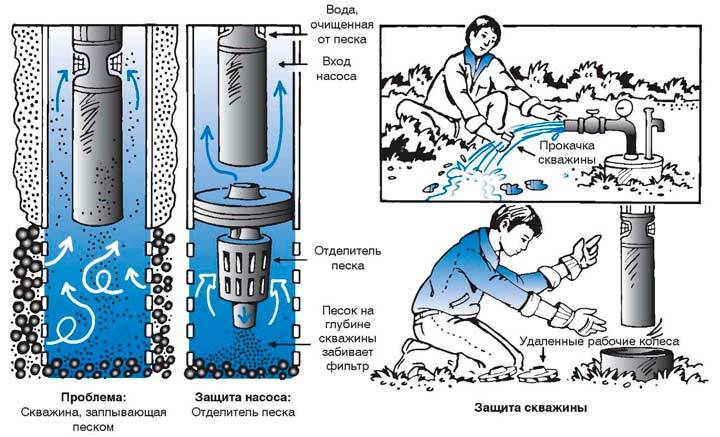

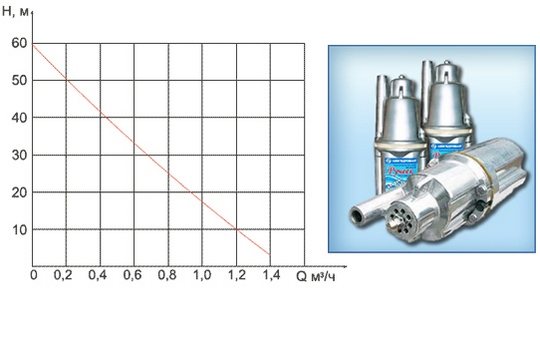

- Parameters of pumps Rucheek

- 2 Do-it-yourself pump repair

- 2.1 How to set up a vibrating electric pump?

- 2.2 How to disassemble the vibration electric pump?

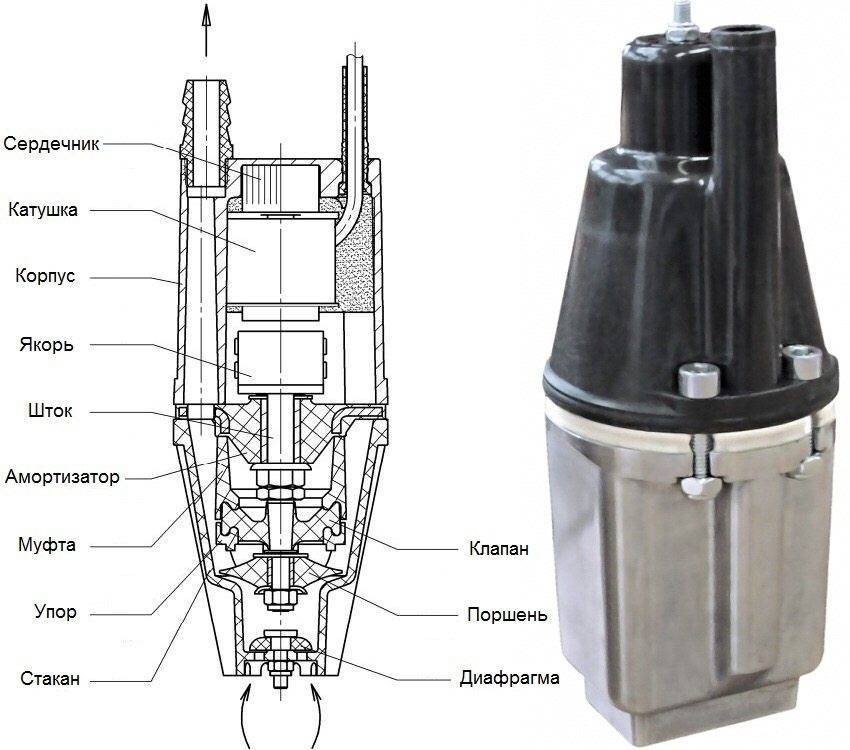

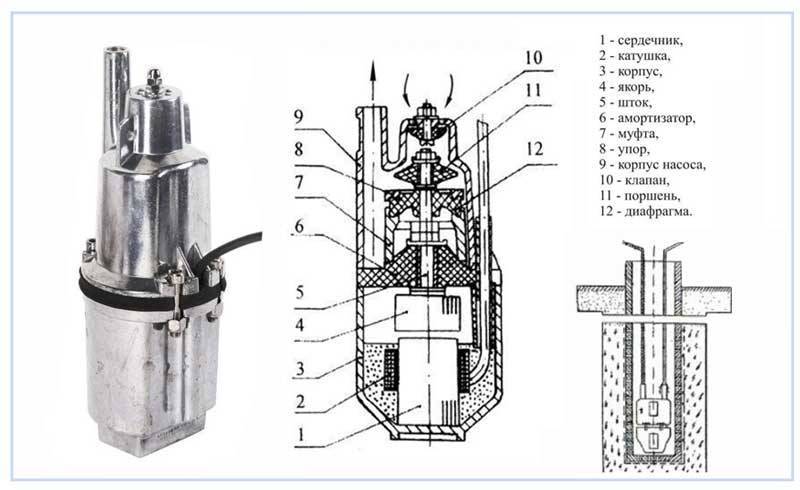

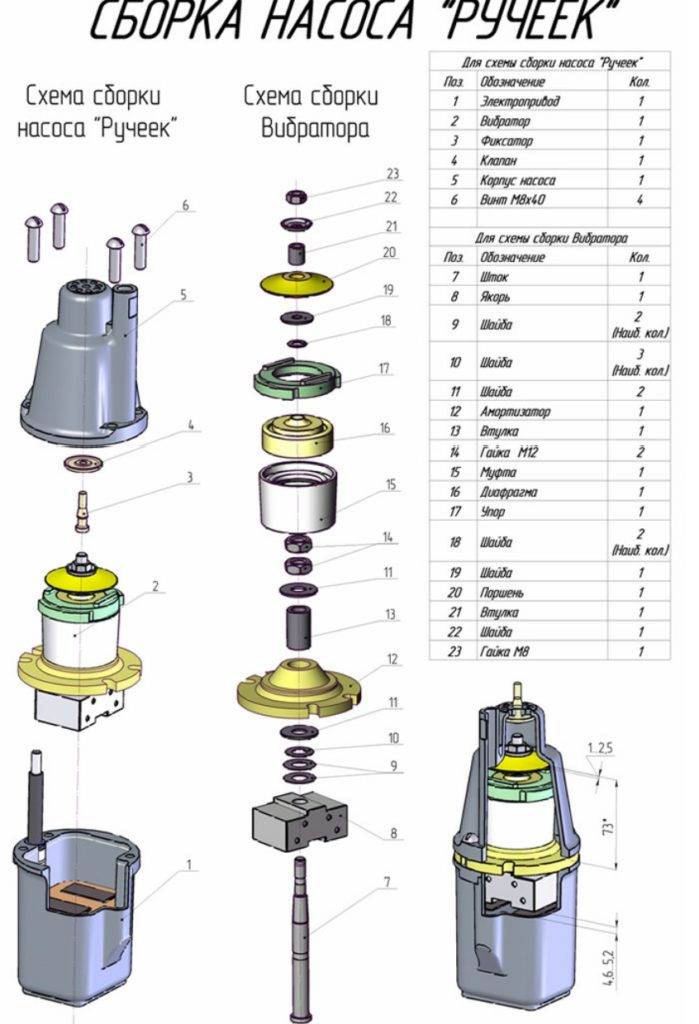

- The device of water pumps "Brook"

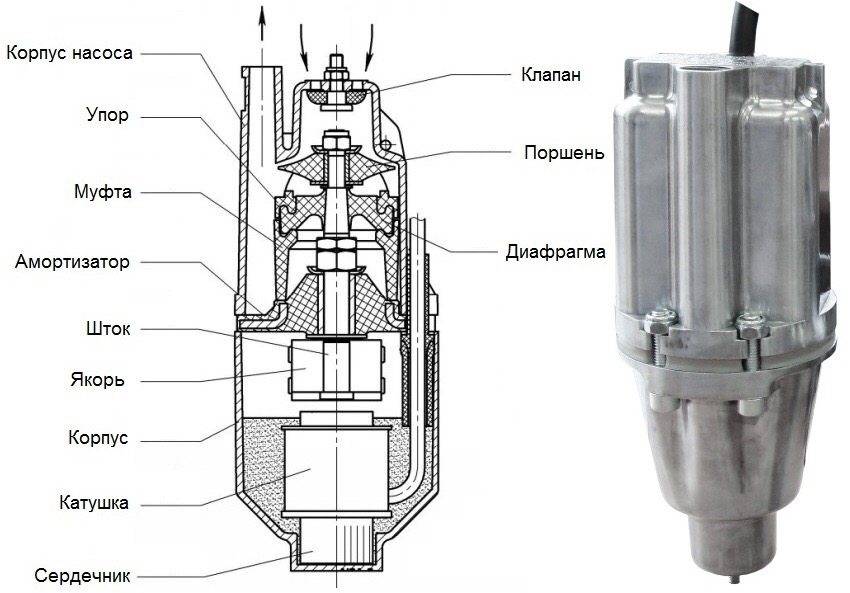

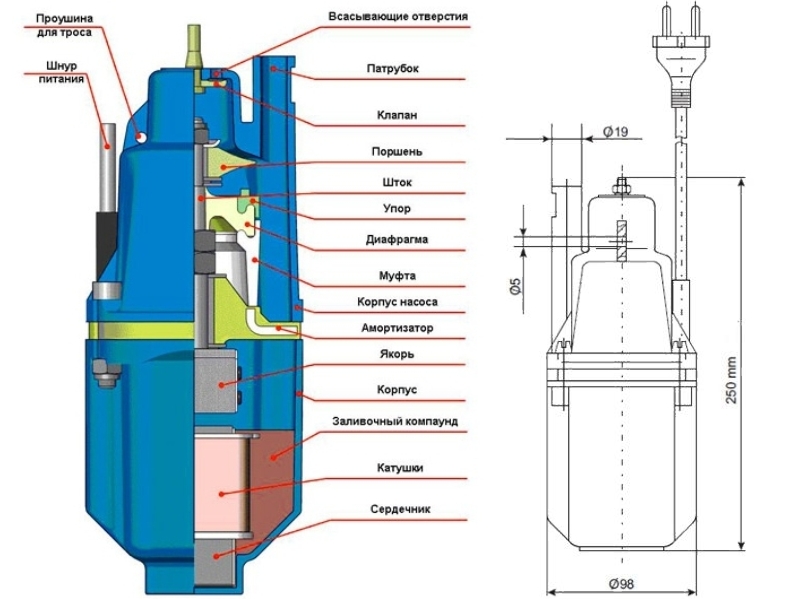

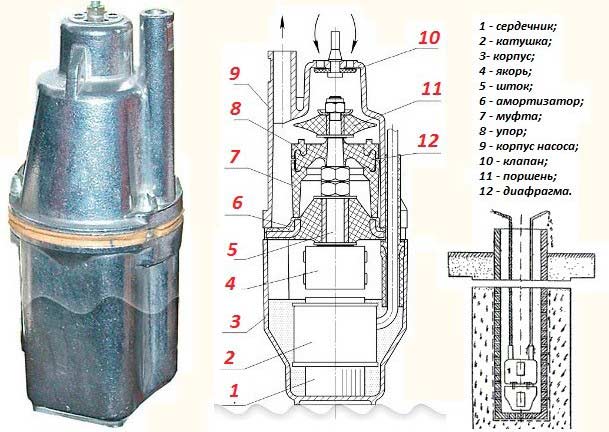

- Device and principle of operation

- Operating rules

- Equipment

- The principle of operation and advantages of the submersible pump "Brook". Do-it-yourself repair instructions

- Technical characteristics of the pump "Brook"

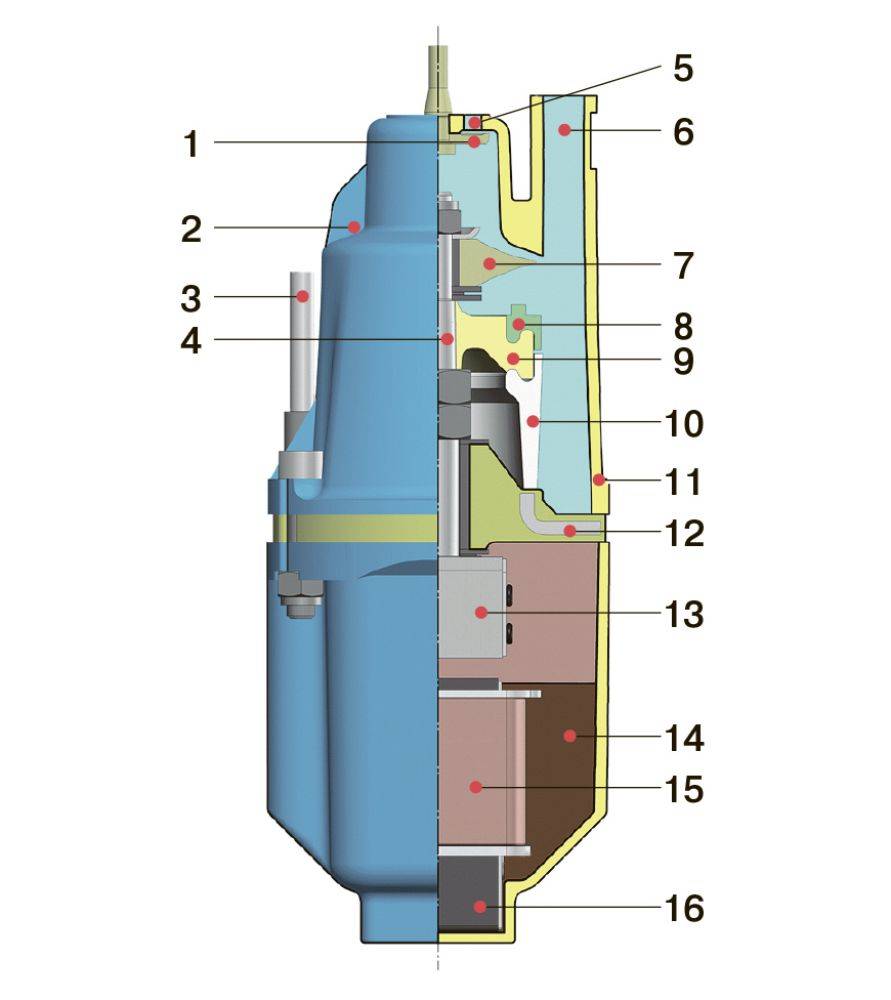

- Brook pump device

- Principle of operation

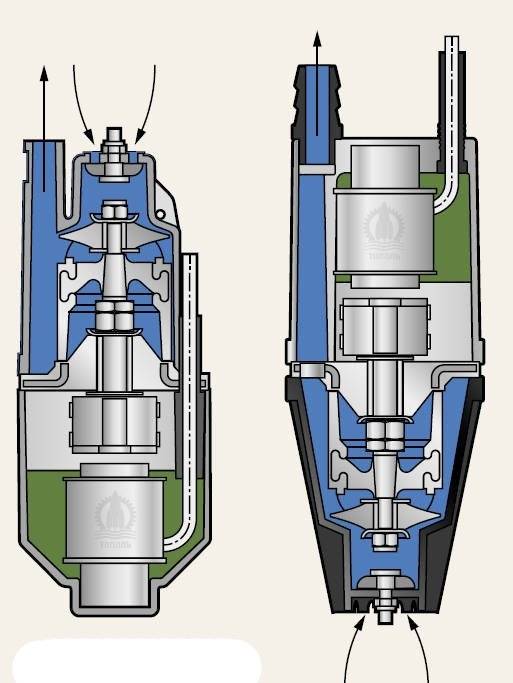

- Submersible vibration pump - principle of operation

- Technical information and principle of operation

- Repair features

- Disassembly Difficulties

- Diaphragm wear

- Winding repair

- Solenoid filling damage

Manufacturers

In the domestic market, the most common manufacturers are "Baby", "Brook", "Aquarius". Foreign manufacturers PATRIOT, QUATTRO and GRUNDFOS also enjoy a good reputation.

| City or country | Manufacturer |

| Livny bavleny Klimovsk | Baby |

| Kursk Kirov | Aquarius |

| Bransk Chelyabinsk | Rodnichek (Zubr and Topol firms) |

| Mogilev (rep. Belarus) | Brook |

| USA and China | PATRIOT |

| city of Bjerringbro (Denmark) | GRUNDFOS |

| China | QUATTRO |

All models have approximately the same design, the difference in names is associated with marketing principles.

Models from different manufacturers differ in body shape

Technical description, low power vibration pump models

Vibratory pumps have a simple design without rotating parts. The membrane pumping mechanism is powered by an electromagnet connected to an alternating current line with a frequency of 50 Hz. The core of the electromagnet transmits vibrations, in the amount of 100 times / sec, to the pin, which makes the membrane vibrate.

The membrane is the wall of the water chamber. The chamber has an opening for water suction and a discharge pipe. When the chamber expands, water is drawn in, then the check valve closes, and the liquid is squeezed out into the discharge pipe. And so 100 times per second. The user feels the vibration of the body, for which the pump is called vibration.

You can increase or decrease the pump performance by adjusting the vibration amplitude, that is, the length of the pins driven by the core. For shock absorption, the joints are made of rubber products. With intensive work, they wear out and the cuffs need to be replaced.

The basic models of the Brook pumps did not have overheating protection. Now any vibration pumps have a "dry run" blocking and from overheating. At the lower water intake to the hole, a filter is necessarily installed to protect against sand, which is easily replaced.

Pumps Malysh M have an upper intake, Malysh-3 has a lower one, and Malysh-K is used as a drainage pump. The pump overheats when running for more than 2 hours. The break must be at least 20 minutes.

Belarusian vibration pumps Rucheek are produced with upper and lower water intake. Lots of modifications. Depending on the location of the suction, the brands Brook B 10 - 40 (the number is the length of the supply cable), Brook H 10 - 40 are produced. Submersible pumps work in wells and wells.

Technopribor Corporation produces pumps Rucheek-1 with an upper water intake and Rucheek 1M with a lower suction. The devices are equipped with automatic switches and comply with safety standards.

Technical description of this device

Specialists refer to a pump of this type as a classified group of a submersible pump, which quickly and successfully functions due to multiple oscillatory movements of the diaphragm, which instantly responds to any change in pressure of this device.

This unit operates exclusively from two hundred and twenty watts, for sixty minutes, while consuming about two hundred and fifty watts in total. First of all, everything depends directly on the maximum power of a particular brand of technical device.

It completely lacks various moving elements and unnecessary bearings, thanks to this characteristic it functions effectively, because the necessary parts are disabled with the help of friction and their immediate reinstallation is required.

The water intake is located on top, which gives an important positive effect in the quality cooling of the entire working system. In real operation, the working system does not experience excessive heat, and therefore does not face daily overloads.

The second, but important, advantage of the upper fence is the complete absence of suction from the bottom, due to which clean water is not contaminated and it can be drunk daily by all residents of a country house or summer cottage without worrying about the general state of their health and the health of children.

Operating principle

The operation of the "Rucheyok" pump is based on vibrations, due to which the pressure changes in the injection chamber. It looks like this:

- After the pump is connected to the mains, the coil creates a magnetic field.

- Due to the acting magnetic forces, the vibrator is attracted.

- This entails bending the piston inwards and bringing it closer to the pressure chamber.

- The process contributes to the formation of a rarefied atmosphere in the suction chamber and a decrease in pressure there.

- Water begins to flow through the check valve, filling the suction chamber.

- At the next cycle of alternating current, the magnetic field disappears, the rod takes its original position.

- The piston presses on the water in the suction chamber, the check valve does not let it out, so it moves into the discharge chamber.

- The next cycle starts the process in a new way and the water from the chamber moves into the pipeline.

With a rhythm frequency of 100 times per second, the work of the piston on the rod creates vibration. Therefore, due to the principle of operation of the internal mechanism, the Brook pump is classified as a vibration type.

The second place in the ranking of vibration pumps is LIVHYDROMASH Malysh BV 0.12-40-U5 16 M

It is very similar to the Soviet counterpart, which is in first place in the ranking. It has an extremely low price. Due to this, absolutely everyone can afford this pump.There are no supernatural technical characteristics, but at the same time the pump has 100% reliability and maintainability due to a simple design.

The motor is not powerful - only 240 watts, but it can work in a horizontal position, which is extremely important when organizing an irrigation system. It tolerates abrasive impurities well and has a powerful winding that enhances the reliability of the pump. Peak flow 25 liters per minute

Most often it is used for arranging cottages. For a full-fledged water supply system, it is only suitable if water consumption is negligible. However, for the irrigation system - exactly what you need.

Peak performance 25 liters per minute. Most often it is used for arranging cottages. For a full-fledged water supply system, it is only suitable if water consumption is negligible. However, for the irrigation system - exactly what you need.

Of the negative sides, it is worth noting the complete absence of an automation system, protection and a float switch. The water level must be monitored independently. It emits a significant amount of noise, so you will have to additionally purchase sound insulation, otherwise there will be a strong hum and significant vibrations.

Disassembly of the pump Kid

Before, how to repair a pump "Baby", it needs to be taken apart properly.. The main thing in this matter is not to damage the whole parts, and remember the procedure in order to properly assemble the mechanism after repair. Before disassembly, drain the water from the pump and turn it off.Next, you need to use a sharp object or a marker to apply marks on the two halves of the case in order to properly dock them during assembly.

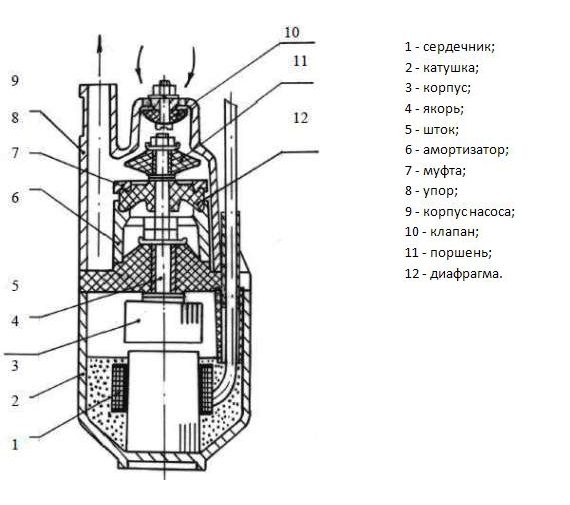

Then the body of the "Kid" is clamped in a vice in a vertical position, just below the butt joint of the upper and lower parts. All fixing bolts are unscrewed, and the upper part of the mechanism case is removed. Next, we unscrew and remove the fixing nut from the vibrator bushing, and remove all the parts put on the rod. The main components of the vibration pump:

- Piston.

- Focused diaphragm.

- Electro coupling.

- shock absorber.

- Anchor.

All of the above parts are strung on the central rod, and washers and locknuts are installed between them.

Specifications

The brook pump, in terms of technical characteristics, occupies a worthy place among other vibration-type units, and surpasses them in some parameters. Some models have a water lifting height of 40 m. Pumps are more practical in operation, where the technical characteristics of the lifting height reach 60 m. The maximum immersion depth is 7 m. 100 mm.

Among the technical characteristics of the unit, the key place is occupied by productivity, which is calculated in the number of liters pumped by the pump in 1 hour. According to these parameters, all models of "Brook" are divided into three groups:

- with low productivity when the volume is 360 l/h;

- average performance is characterized by indicators of 750 l / h;

- a pump with high performance is capable of pumping 1500 liters of water in 1 hour.

The power of various models of "Brook" varies from 225 to 300 W, all operate on a voltage of 220 V. The current frequency is 50 Hz.Duration of continuous work reaches 12 hours.

Additional technical characteristics of interest to the consumer:

- Pump type - submersible vertical.

- The body is made of aluminium.

- The number of check valves - 1 pc.

- Weight about 4 kg.

- The length of the cable is different. There are Brook models equipped with 10,16,25,32 and 40 meter cables.

- Hose diameter from 18 to 22 mm.

- "Brook-1" is characterized by an upper water intake, it enters the "Brook-1M" model from below.

Comment! Pumps with a top water intake are more practical, the risk of large solids entering them is significantly reduced compared to models where water enters the casing from below.

Kinds

This is due to the principle of water intake from the reservoir (reservoir):

model with the upper position of the non-return valve (upper water inflow).

Creek-V-10, V-15, V-25, V-40. The pump is constantly in the water and the situation with overheating does not threaten it;

with the lower position of the valve (lower water inflow).

Creek-N-10, N-15, N-25, N-40. It is possible that the pump, having pumped out the maximum water, will be in the air, which threatens with inevitable overheating. To avoid this, it is equipped with a thermal relay that protects it from overheating.

In terms of design and technical characteristics, both types of pumps differ little from each other. Numerical indicators for all modifications indicate the length of the supply cable - from 10 to 40 meters.

Selection Guide

The following manufacturers are considered the leaders in sales among vibration models:

Each manufacturer has models for different purposes. These can be pumps lower water intake or with the top, more powerful or weaker, with or without additional protection.The principle of operation is the same, the main difference is the depth of immersion, the method of water intake, and performance.

Other well-known companies like Grundfos or Karcher can also be found on the market. They were not included in the list, as they are more focused on the production of pumps of a different principle of operation: screw, centrifugal, vortex and others.

Vibration pump "Aquarius" is characterized by increased power and lifting height

Parameters of pumps Rucheek

All models of electric pumps for water have almost the same parameters and technical characteristics and differ from each other only in the length of the cord (from 10 to 40 m), standard indicators have the following values:

- Submersible pumps Brook are designed to lift water from water intake tanks from depths from 1 to meters to the surface. For wells with a diameter of less than 100 mm. deep vibrating pumps are not recommended.

- The power of electric pumps does not exceed 300 W.

- The most important parameter of the device is performance, in electric pumps Brook it is 430 liters of pumped liquid per hour, with a surface location, the intake increases to 1500 l / h.

- Electric pumps should not be submerged under water by more than 3 meters - exceeding this value leads to an increase in fluid pressure on the check valve, its spontaneous opening and, as a result, to incorrect operation of the electric pump.

- Horizontal water supply at a small immersion depth can be carried out at a distance of up to 100 m.

- In order to avoid overheating of the electromagnetic coil winding, electric pumps should not be used for pumping warm water with a temperature of more than 35 C.

- Vibratory pumps have a limited run time of up to 2 hours, after which they require a cooling down break of about 20 minutes. The total working time should not exceed 12 hours per day.

- The pump can operate with turbid water up to 0.01% of mechanical impurities, its rubber parts, when in contact with oil refinery products or large solid particles, change their physical properties and can be mechanically damaged.

- Water pumps are sensitive to changes in supply voltage, which affects their technical characteristics. Its excess leads to the beating of the metal core on the magnetic circuit and premature wear of the electric pump, with a decrease in the supply voltage by 10%, the head of the device drops significantly (up to 60%).

2 Do-it-yourself pump repair

Very often, submersible vibration pumps stop working, having a minor breakdown, which you can fix on your own, and sometimes very quickly, without the intervention of paid specialists. Therefore, you should know how to determine the malfunction and how your own electrical appliance behaves in this case.

A characteristic feature of the repair of the fixture is that after replacing the damaged elements, their additional adjustment is necessary. For example, after replacing the rubber valve system, the pump does not deliver rated power or refuses to pump at all. In this case, a simple adjustment of the valves helps, setting them in the correct position, determining the correctness of their opening and closing.

2.1 How to set up a vibrating electric pump?

Before the user is filled with determination to disassemble a non-working product, a number of simple manipulations should be performed to establish a preliminary diagnosis:

- fix the pump in a container with water, freeing the outgoing pipe. After turning on the device in the mains, check the voltage level, which should be in the range from 200 to 240 V.

- when normal, turn off the pump and drain the water. Then blow with your mouth into the outlet pipe. A properly tuned apparatus can be blown through, but with strong blowing it is locked with the stroke of the working piston inside. Conversely, with the suction of air, the latter must pass freely inside.

With an incorrect setting, when air is not blown through the pump, but passes with suction, the pump can operate at a reduced voltage of less than 200 V.

The principle of operation of pumping equipment dictates the control of three important parameters of reassembly with the specified order:

- Axial matching of piston and seat. Sliding the inlet cup on the gasket makes it very difficult to achieve this when assembling the pump, but misalignment will not allow the pump to work in principle.

- The piston must be at some distance from its seat. The value of this gap should not exceed 0.5 mm, but be greater than 0. You can adjust the gap using shims. The correct distance allows air to pass into the water outlet, and with a greater blowing force, the piston closes the channel.

- It is necessary to observe the parallelism of the piston disk with its seat - their axes must also be parallel.

Cases of non-parallelism:

- large clearance between piston bushing and rod.Such a problem can not only affect the adjustment, but also cause vibration of the operating unit. How to reduce a large gap? It is enough to replace either the sleeve or the stem, and a popular method is to seal the stem with improvised material, such as foil.

- bent stem. In this case, the problem is unlikely to be corrected, but parallelism may be achieved by expanding the spacer to 180.

A properly replaced structural element and a properly assembled submersible electric pump gives a jet of at least 30 cm in height and operates without interruption with a voltage of up to 240 V. Reducing the voltage changes the sound of the pump and may reduce performance.

2.2 How to disassemble the vibration electric pump?

It greatly facilitates disassembly by placing the unit in a vice. By clamping the housing protrusions with sponges, the coupling bolts will give in faster, but they need to be loosened in turn and little by little. Similarly, collection is carried out after repair.

Assembly of the vibration pump Brook

If the pump has been submerged for a long time, most likely the tie bolts will not give in quickly - apply a penetrating lubricant and make slots in the bolt heads. In extreme cases, you should carefully cut off the heads of the bolts to disconnect the body parts of the fixture.

The device of water pumps "Brook"

All pumps of the Rucheek model range are household pumps. They are not intended for pumping large volumes of water and are used only in individual wells and wells with a diameter of more than 100 mm and a depth of not more than 40 m.

At the same time, their capacity is quite enough to meet household needs and water garden plantings on a personal plot.

Device and principle of operation

Structurally, all models practically do not differ from each other: they are all submersible, vibration type.

The main elements of the pump are located in the housing:

- An electromagnet consisting of a core and two coils;

- Anchor;

- A piston rigidly connected to the armature, which, when moving, pushes the liquid out of the chamber into the outlet pipe.

The only distinguishing design characteristic of the Brook pumps is the location of the water intake pipe. For all models except Rucheek-1M, it is located in the upper part of the case.

This arrangement reduces the likelihood of solid impurities entering the unit - sand and silt in the water. It also eliminates overheating of the engine, which is located in the lower part and is always cooled by the pumped water.

Operating rules

In order for the device to work for a long time and reliably, the instruction pump manual The brook must be observed strictly. As well as installation rules.

The device is lowered vertically into a well or well using a cable threaded through special eyelets on the body;

The photo shows the attachment of the safety cable.

- To ensure that the unit does not come into contact with the walls of the well or casing pipe during operation, a protective rubber ring must be put on it. As a rule, it comes with a pump;

- Before installation in the source, the supply cable must be fixed on the supply pipeline so that it does not sag. This is easy to do with your own hands using plastic clamps.

During operation every two hours of continuous operation device must be switched off 15 minutes.In general, it is designed for 12 hours of operation per day, therefore, with a round-the-clock need for water, it is advisable to have two pumps or equip the system with a storage tank (hydraulic accumulator).

Equipment

The kit of each pump of any model, in addition to itself, includes clamps for fixing hoses, a shock-absorbing rubber ring and a cleaning filter. The length of the power cable depends on the recommended immersion depth of the particular model. It can be 6, 10, 16, 25, 32 or 40 meters.

The cost of components is included in the price of the device. But all other necessary elements of the system (check valve, hose, accumulator) are purchased separately.

With a hydraulic accumulator and a pressure switch, such a device turns into a mini-pumping station

In addition, a sensor is built into the pump itself, which automatically turns it off in case of overheating, which can happen during prolonged operation or a decrease in the water level in the source.

The principle of operation and advantages of the submersible pump "Brook". Do-it-yourself repair instructions

The Rucheek pump was developed in Soviet times more than forty years ago. It was made at the Mogilev OAO Olsa in Belarus. This device competed with any models of this class. This was due to simple reasons:

- Its size and shape of the cylinder are convenient for use in places unsuitable for other devices, such as a well, the bottom of a deep well, flooded garages and basements, the shore of a reservoir;

- Easy to use: does not require filling with water before operation, does not need lubrication of the mechanism;

- Long service life associated with high quality indicators, long-term developments in process technology;

- Good water pressure;

- The minimum power consumption is about 225 watts per hour.

It was invented for use in summer cottages and today it has a very wide distribution. The pump is of good quality, relatively inexpensive, and its power is quite enough to serve a small family and a plot of six to twelve acres.

It was invented for use in summer cottages and today it has a very wide distribution. The pump is of good quality, relatively inexpensive, and its power is quite enough to serve a small family and a plot of six to twelve acres.

Breakdowns are rare, repair work is not difficult, spare parts are readily available and not expensive. On average, the pump can last from five to eight years.

submersible vibration the pump is intended for water intake from a well shaft more than a hundred millimeters wide and up to forty meters deep. The pump weighs about four kilograms.

submersible vibration the pump is intended for water intake from a well shaft more than a hundred millimeters wide and up to forty meters deep. The pump weighs about four kilograms.

The "Pen" pump involves taking water from above, which of course is a plus from the ingress of various contaminants into the device.

Technical characteristics of the pump "Brook"

The pump has a small power consumption of two hundred twenty to three hundred watts. This is comparable to an aquarium pump filter for three hundred to five hundred liters. If necessary, it can be easily powered by a battery or generator. The pump is powered from a household network. For wells up to forty meters deep, the capacity will be up to 40 liters per hour. If the fence is superficial and the depth of the fence is not more than one and a half meters, the fence capacity will be up to one and a half cubic meters per hour. A working time of up to twelve hours is provided and often used.

Brook pump device

Attaching the pump is not always necessary. In a vertical position, it weighs on a cable.

The pump has a practical metal housing and is very durable. To prevent collision with the walls of the well shaft, a rubberized cushioning ring is put on it.

Principle of operation

The principle of operation of the pump is based on the vibrational movements of the armature with the membrane, produced by the action of a magnetic coil. Electromagnetic voltage creates magnetic fields that cause a change in the internal pressure of the pump. The pressure oscillation of the diaphragm causes the water to rise.

The principle of operation of the pump is based on the vibrational movements of the armature with the membrane, produced by the action of a magnetic coil. Electromagnetic voltage creates magnetic fields that cause a change in the internal pressure of the pump. The pressure oscillation of the diaphragm causes the water to rise.

The membrane sucks water through the check valve into the mechanism and pushes it out through the outer fitting. Water is distributed to users through a hose attached to a fitting. Due to the minimalist design, the vibrating mechanism can be cleaned from clogging by unscrewing four screws.

The membrane sucks water through the check valve into the mechanism and pushes it out through the outer fitting. Water is distributed to users through a hose attached to a fitting. Due to the minimalist design, the vibrating mechanism can be cleaned from clogging by unscrewing four screws.

Submersible vibration pump - principle of operation

Uninterrupted long-term operation is ensured by the fact that there are no rubbing and rotating parts. The Brook pump has restrictions in the field of domestic use. It is not used for industrial purposes, as it has little power. In the farm, devices with more power and a storage tank are used.

Uninterrupted long-term operation is ensured by the fact that there are no rubbing and rotating parts. The Brook pump has restrictions in the field of domestic use. It is not used for industrial purposes, as it has little power. In the farm, devices with more power and a storage tank are used.

"Trickle" is convenient for use in a well with low power. Where, when the well is empty, a powerful pump goes to idle or turns off, then the Brook, when the thermal protection is activated, continues pumping the well at a speed of five to seven liters per minute. Often after the work of the Brook, an increase in well capacity by fifty percent is observed.

"Trickle" is convenient for use in a well with low power. Where, when the well is empty, a powerful pump goes to idle or turns off, then the Brook, when the thermal protection is activated, continues pumping the well at a speed of five to seven liters per minute. Often after the work of the Brook, an increase in well capacity by fifty percent is observed.

Applicable:

- for the delivery of water from a well for consumption;

- for the delivery of water for irrigation;

- for filling the heating system;

- when pumping out a pool or reservoir.

"Trickle" is used to clean wells clogged with silt. Also, the pump can be used to pump out drainage water. It is mainly used, of course, for pumping drinking water, but due to various situations that arise in summer cottages, it can be used as a drainage device. Even a special device is commercially available that protects the pump when working with contaminated water.

This is interesting: Do-it-yourself balcony on the roof of the house: we understand in detail

Technical information and principle of operation

The technical characteristics of the water pump Brook can be described as quite worthy for a device of this level.

Submersible vibration devices of this type are designed for the supply of water from wellshaving a depth of 40 m and a width of 100 mm. Some modifications can be operated at a depth of up to 60 m.

Weight (without hose and wires) - about 4 kg.

Type of water intake: upper and lower (Brook-1 and Brook-1M).

Submersible vibration pump Brook - characteristics:

| Water flow rate m3/h Max | Maximum head, m | Power, W | Voltage, V | Current frequency, Hz | Cable length, m | Weight, kg | Hose diameter, mm |

| 0,43 -1,50 | 40-60 | 225-300 | 220 | 50 | 10, 16, 25, 32, 40 | 4 | 18-22 |

Maximum run time: 12 hours

With a well depth of up to 40 m, the capacity of the device is about 430 liters per hour, when water is taken from the surface (up to 1.5 m), this figure increases to 1.5 m3 per hour.

The dependence of the performance of the pump Stream on the depth of water intake

The design of the pump consists of the following elements:

- Electromagnet.

- U-shaped core.

- vibrator.

- Corps.

And it works like this:

- With the help of electromagnetic voltage, a magnetic field is created, leading to a change in pressure inside the unit, which causes all its parts to turn into alternate movement.

- The movements of the diaphragm of the device raise the water under pressure.

- Due to the absence of bearings and rotating parts in the design of the pump, it functions stably and uninterruptedly for a long period of time.

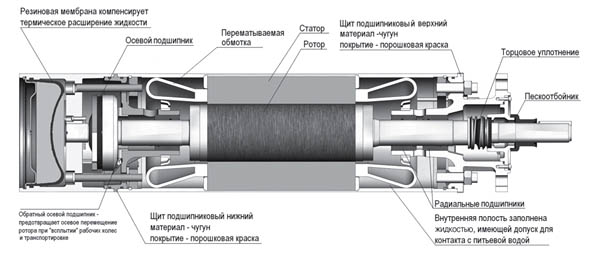

This photo shows a more detailed device of a submersible pump Brook

Repair features

At a low cost, repairs are often neglected, simply by purchasing a new one. But this is not entirely correct.

At a low cost, repairs are often neglected, simply by purchasing a new one. But this is not entirely correct.

The device in most cases is excellently repaired and the cost is low.

Therefore, the logical decision would be to purchase a new pump, giving the old one for repair. You will have two working devices, which guarantees uninterrupted water supply in the event of failure of one of the devices.

Since the device is simple, you can repair the brook pump with your own hands by replacing a couple of gaskets or cleaning important parts of the device from sand and dirt.

Disassembly Difficulties

The first difficulties arise when trying to disassemble the device. The fixing bolts on the case are covered with a dense layer of rust until it is completely impossible to unscrew them with a screwdriver.

Do not try to unscrew tightly rusted bolts. It is recommended to carefully cut the heads of the fasteners with a grinder.

Pump internals - motor

To avoid damage to the motor during this procedure, use a small diameter disc and be sure to secure the pump in a vise. When fixing it, it is convenient to use dense rubber gaskets or a shock-absorbing elastic band.

Diaphragm wear

The rubber elements of the pump can fail as a result of wear or foreign objects. There are special repair kits that should be used in such cases, replacing failed valves and diaphragms as needed.

Alternative use of rubber caps from medical vials. Rubber pharmacy caps successfully replace the failed valve of this pump. Proven by practice.

Winding repair

The winding of the electromagnet can cause a malfunction of the device. If you do not have an engineering specialty, it is better to send the device in for repair to restore the winding.

Solenoid filling damage

Such malfunctions are eliminated with the help of auto-sealant.

Such malfunctions are eliminated with the help of auto-sealant.

Filling instructions are very simple.

Shallow grooves are cut on the surface of the electromagnet using a grinder for better fastening.

Then glue is applied to the product.