- Product Comparison Baby and Brook

- Mounting

- Vibration Pump Kid

- Pump operation

- Features of the model of the vibration pump Kid

- Overview of the range of pumps and their differences

- Base model: features and specifications

- Other modifications of the pump "Kid"

- Technical parameters of models

- Specifications and features of models

- Conventions

- Basic model Baby

- Malysh-M

- Kid-3

- Kid-K

- Pump Kid: technical characteristics, design and principle of operation

- The device of the pumping unit

- Vibrator

- Electromagnet

- Frame

- The principle of operation of the pump Kid

- Operation features

- Dry run protection

- Working with a hydraulic accumulator

- What to do to work longer

- Pump Maintenance Malysh

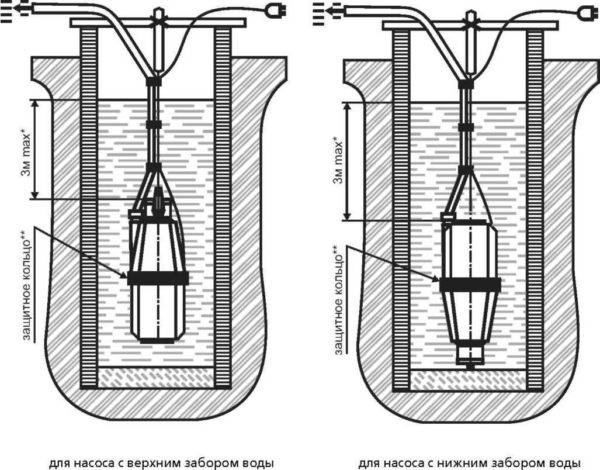

- Installation in a well or well

- Connecting hoses and pipes

- Preparation and descent

- Installation in a shallow well

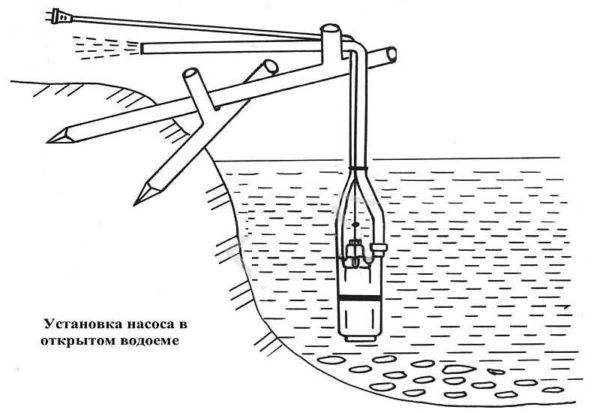

- Installation in a river, pond, lake (horizontal)

- What is the baby for?

- Tips & Tricks

- Pump Maintenance Malysh

Product Comparison Baby and Brook

The Brook pump has a slightly different structure, on the contrary, it has an electric motor located at the bottom, and suction holes at the top. This almost completely eliminates the ingress of impurities, and also provides better cooling.

When comparing two models of submersible pumps "Brook" and "Kid", it is noted that the shock absorbers in the design are made of natural rubber, which gives reliability and stability in operation. Studies and experimental experiments have shown that both units work remarkably well in a complex for water supply equipment for summer cottages and country houses.

When choosing a submersible pump, you can additionally compare popular models and brands of manufacturers

The performance indicator directly depends on the quality of the selected reservoir:

- River;

- Artificially punched well;

- Well, swimming pool.

It is important to consider how much it costs, how often the pump will be used and what additional protective devices will be used. When dealing with constant flooding in the area or in the cellars, it is important to take into account automatic shutdown in case of overloads, the possibility of a vertical or horizontal location of the pump, performance - the amount of power and pressure, on which the pumping time or filling the tank for a certain time directly depends

The main thing is to clearly assess the technological situation when installing the selected models, determine the depth and level of water during seasonal changes, assess the condition and quality of the soil. The main indicator of the popularity of these models is their ease of use: anyone can handle them, both install and perform minor repairs. And their low cost frees from the need for additional security measures.

Mounting

Vibrating do-it-yourself pump It is quite easy to implement, especially if you have instructions at hand. Begin the installation of the pump by determining the depth of its immersion.Then you need to pick up a flexible plastic or rubber hose with an inner diameter of about 18 millimeters. You should not take hoses with a smaller diameter, as this will create an extra load on the pump. Metal or plastic pipes are also suitable for water supply. But they must be connected to the pump by means of a hose, the minimum length of which should be two meters.

When the hose is selected, it must be connected to the outlet of the device using a clamp. When using the pump in winter, frost must be prevented and the liquid must be able to drain. To do this, a small hole (about 1.5 mm) is made in the hose next to the pump housing. In the summer, this hole is easily closed with electrical tape. After connecting the hose, it is necessary to fix the nylon cord on the pump lugs. As a rule, this cord, about 10 meters long, is included with the pump. In the event that there is a need to increase the length, then you can use the wire and attach it to the nylon cord. It is worth remembering that the wire or metal cable is not attached directly to the device, as this may damage the mounting holes.

Having threaded the cable into the ears, it is fixed. In this case, the fasteners must be at a distance of at least 10 centimeters from the body of the device so that they are not sucked in. The cut edges must be melted so that the cable does not unravel. Before installing the pump, you should calculate in advance what is the distance from the outlet to the water intake. This is the only way to find out how long the cable is needed to connect the vibration pump. Included with the pump "Kid" is a cord with a length of 6 to 40 meters. Usually its length is indicated in the instructions.

As a result, the pump should go: a hose, a nylon cable and an electric wire. In several places they are connected with each other with adhesive tape. The interval between connections should be 1-2 meters. The first such connection should be located at a distance of no more than 20 centimeters from the pump housing. When the pump is running, it is quite common for there to be vibration that causes the device to come into contact with the walls of a narrow well or casing in the well. As a result, the case is damaged and this can lead to breakage of the entire device. To prevent this, put a rubber ring on the pump before submerging it. It will absorb possible impacts and provide additional protection to the body.

After everything is connected to the pump, it must be lowered into the water and hung evenly so that there is no contact with the walls and the gaps are the same on all sides. At the top of the well, it is necessary to install a bar to which the suspension will be attached, preferably from an elastic and at the same time durable material. Such a suspension will reduce the vibration that occurs when the device is in operation. The suspension can be made from a piece of rubber hose or a medical tourniquet. The upper end of the cable is connected to the suspension so that tension is created.

The electrical wire lies freely on the bar without any tension. The pump is now ready for operation. Before use, it does not need to be lubricated or filled with water. If the device has 1 protection class, then the socket needs to be grounded. You can turn on the device immediately after it has been immersed in a well, well or pond.If the device has a lower water intake, then the distance from the body to the bottom should be up to one meter. Pumps with a top water intake can be submerged below, but at the same time its casing must not come into contact with the bottom. This may cause damage during operation.

In order for the pump to work longer, it is recommended to purchase a mechanical filter for it in order to avoid internal contamination of the device. If small particles often get inside the pump, the piston and check valve will quickly wear out, and the hose will clog, causing a critical increase in water pressure. Most often, for vibration pumps, a conventional cylindrical gasket made of fibrous polyethylene or other porous material is used as a filter.

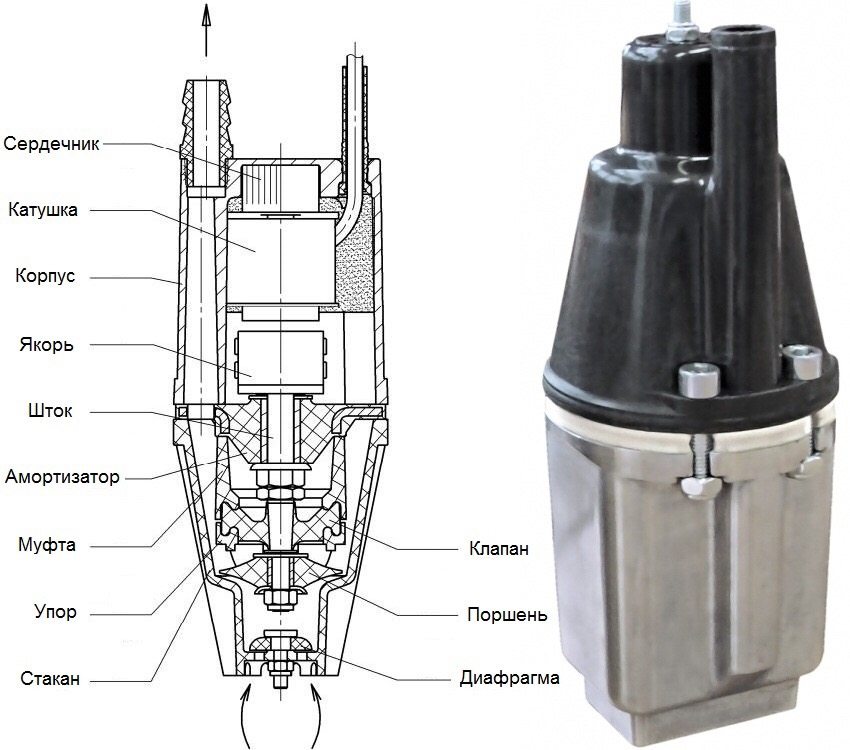

Vibration Pump Kid

Summer residents face the problem of water supply. Water supply to the site with the help of additional equipment will be an excellent solution. Using the Malysh pump in small volumes, they solve the tasks. It is arranged as follows.

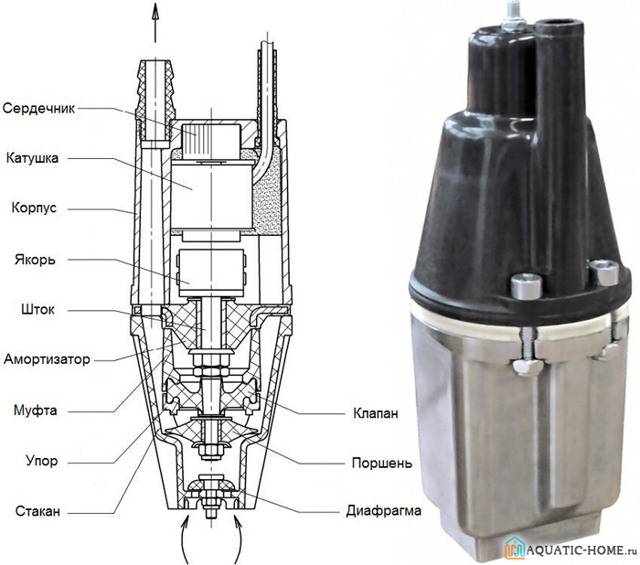

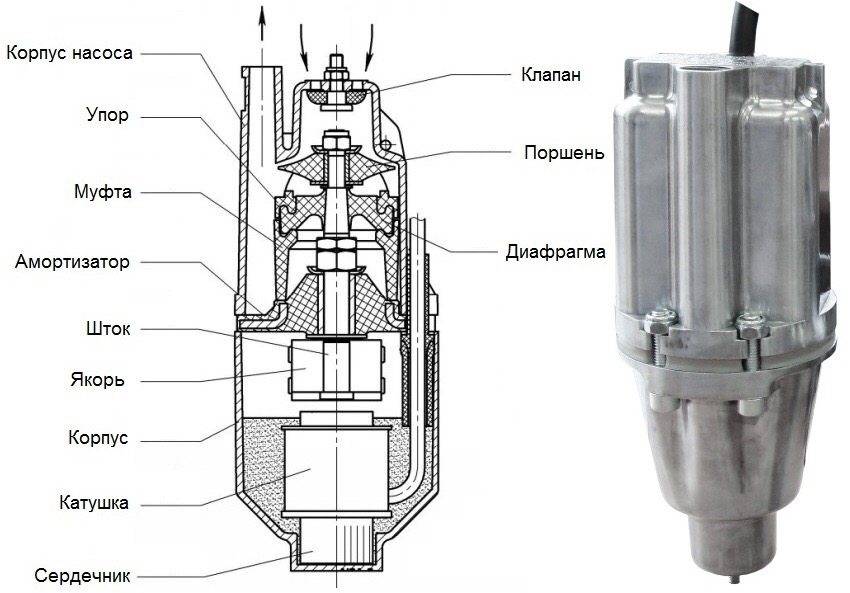

The general design includes a core, a coil, a body of the entire unit, a shock absorber, a rod, a piston, a check valve, a coupling. By the way, the application is only available in places with clean water. If it is contaminated, then the wear of the product occurs in the shortest possible time. This is due to the manufacture of the piston from rubber materials. Don't worry about the rest of the structure. Even the electrical part is isolated by a clutch from the general water intake mechanism. Everything was done with high quality and without additional problems. Even external factors do not affect the product. After all, the body is made of a metal alloy that completely excludes corrosion.

Pump operation

The principle of operation of this product is quite simple.At the very beginning, electricity is supplied to the unit. Under the influence of energy, the electromagnet in it is activated. Thus, he attracts an anchor to himself. When the polarity is reversed, the core moves to the side, which leads to the filling of the tank with water. In one second, the number of oscillations reaches 100 times. Such movements create a pressure of water from the rod to the piston and further through the hoses into the house. And in order to prevent a reverse return, a check valve is connected to the case.

Features of the model of the vibration pump Kid

The fence is carried out in the lower way. Network connection via a standard socket. The maximum immersion reaches 5 meters. Consumes only 250 watts. In hour pumps up to 450 liters. Works continuously for two hours. Total weight 3.5 kg. The package includes a hose, filter, connection wire. The price for the product is 2100 rubles. The manufacturer also produces modifications with the prefix M and the number 3. They have almost similar characteristics, but still differ.

Overview of the range of pumps and their differences

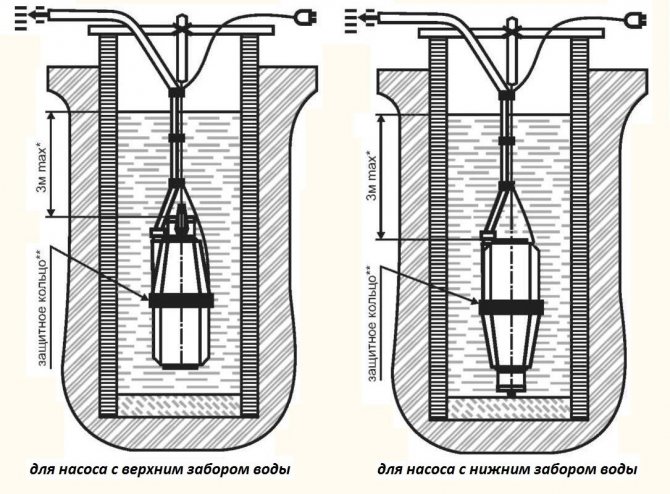

There are three main models of a submersible pump, which have slight differences in technical parameters, as well as a different (upper or lower) water intake system, and therefore their scope is somewhat different.

Modifications of submersible pumps with the Malysh logo are available with a lower and upper water intake option. Depending on the model, they can work in wells with an internal diameter of 80 to 110 mm

Modifications of submersible pumps with the Malysh logo are available with a lower and upper water intake option. Depending on the model, they can work in wells with an internal diameter of 80 to 110 mm

Base model: features and specifications

The classic pump Kid is produced with a lower water intake, thanks to which it:

- most effectively supplies water from open reservoirs located at large distances,

- copes well with draining flooded lower floors and basements of buildings,

- can pump water to the lowest possible level.

At the same time, with the lower location of the nozzles that perform the suction of the liquid, sand particles may enter the unit, which can cause damage to the device. Therefore, it is not recommended to use it in heavily polluted water bodies without installing special filters.

The pump Malysh in the basic version is produced with a lower water intake. To prevent debris from entering the tank, it is recommended to install it at a distance of at least a meter from the bottom of the reservoir (+)

The pump marked "K", in fact, is the same "Kid", but with built-in additional thermal protection.

A thermal switch is installed in its case, which turns off the device in case of overheating. The model is convenient in that the device can be left to work unattended for a sufficiently long period of time without worrying that it will burn out.

A device marked “P” informs that its body is made of plastic, if there is no marking, then it is made of aluminum. It is worth noting that the aluminum case, although it costs a little more, is more durable and reliable.

It is not uncommon for the plastic case to not withstand the load and cracks appear on it. Therefore, the desire to save money can lead to the opposite result, and you will have to buy a new device.

Other modifications of the pump "Kid"

Other models "Kid-M" and "Kid-3" differ from the classic pump in the upper water intake.At the same time, if the first one is identical in technical characteristics with the base model, then the second one has significant differences. The parameters of all devices are shown below.

The power and performance indicators of the Malysh-M pump are the same as those of the base model, but it is produced with an upper water intake, so it is suitable for installation in dirty water sources

The power and performance indicators of the Malysh-M pump are the same as those of the base model, but it is produced with an upper water intake, so it is suitable for installation in dirty water sources

Units with an upper suction pipe are usually used to supply water from wells and wells.

They can be used in places where pumps with a lower water intake are at risk of failure: in heavily polluted water bodies, because during operation they do not raise debris and silt from the bottom that clog the system.

In models with an upper intake, the engine cools better, due to which the pump does not overheat.

Technical parameters of models

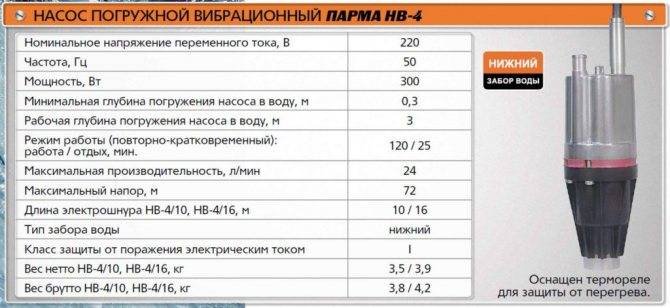

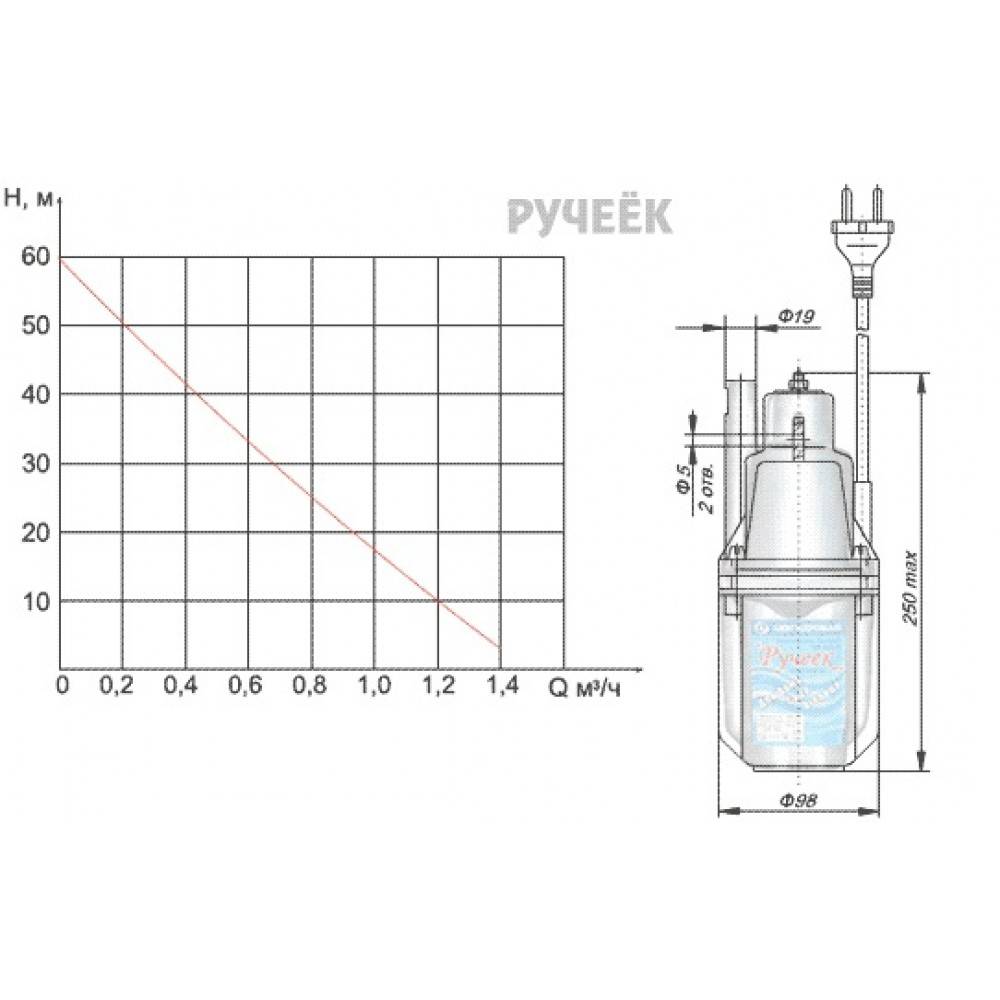

The pumps operate from a conventional 220 V network and can be submerged to a depth of up to three meters. When working in marginal wells (with a small volume of water), deeper lowering is possible.

The productivity of all models is 430 l / h, while “Kid” and “Kid-M” have a head of 40 m (maximum - 60 m), “Kid-3” - 20 m (maximum - 25 m). When working without pressure, productivity increases to 1500 liters.

The dimensions and power of the devices also have different indicators. So, the power of the basic model and modification with the letter “M” is 240 W, length - 25.5 cm, weight - 3.4 kg.

The power of the Malysh-3 pump is only 185 W, its length does not exceed 24 cm, and its weight is 2 kg, so it is usually used to draw water from shallow wells and wells with an internal diameter of 8 cm or more.

When buying a pump, you must first familiarize yourself with its technical characteristics and choose a model in accordance with the diameter and depth of the well (+)

When buying a pump, you must first familiarize yourself with its technical characteristics and choose a model in accordance with the diameter and depth of the well (+)

Another parameter that you should know when buying a device is the electrical protection class. By default, all pumps that do not have this indicator have protection class 2.

The first class is indicated by the Roman numeral I. At the same time, class 2 devices are equipped with reinforced insulation, they are equipped with a cord with two cores. Class 1 devices are additionally equipped with a three-core cable with grounding.

Specifications and features of models

In the line of pumps of this brand there are several models with top and bottom suction. All of them are used to take water from a well or a shallow well, as well as from open reservoirs, and supply it in a horizontal direction to a distance of 100-150 meters. What makes them convenient both for water supply at home (see Pumps for water supply for the home: how to choose), and for watering the garden.

Conventions

When studying the pump before buying, you should pay attention to the markings and be able to decipher the alphanumeric designations. How to do this, we will tell using the example of the device BV 0.12-40 Malysh-K (p) Ikl:

How to do this, we will tell using the example of the device BV 0.12-40 Malysh-K (p) Ikl:

- BV - household vibration;

- 0.12 - nominal flow in liters per second;

- 40 - head in meters at nominal flow;

- Malysh-K - the name in which the letter K indicates the presence of built-in thermal protection;

Plastic and aluminum models

Ikl - the first class of protection against electric shock. The absence of such a designation indicates the second class.

Basic model Baby

This is the simplest modification with a lower water intake, designed to work in a source with a diameter of at least 100 mm. It has no filter, no overheating protection, no pressure switch. But all this can be purchased and installed separately, as well as a hose with a diameter of 18-22 mm for supplying pumped water to the consumer.

Deep pump Kid features the following:

| Characteristic | Unit rev. | Meaning |

| Rated power | Tue | up to 280 |

| Max head | m | 40 |

| Performance at max. pressure | l/hour | 430 |

| Time of continuous work | hour | 2 |

| Operating pressure | MPa | 0,4 |

| Max. immersion depth | m | 5 |

| The weight | kg | 3-3,5 |

Malysh-M

In terms of its parameters, this unit does not differ from the base model, the difference lies in the upper location of the water intake valve. The performance of the Malysh-M pump is the same as that of the Malysh.

Top suction port

Kid-3

The diameter of the Malysh-3 pump allows it to be used in narrower wells - from 80 mm. This is a more compact version of the basic model, with a reduced power rating to 165 W and a head of up to 20 m. It is ideal for installation in low flow sources.

The kit includes a network waterproof cable 30 meters long.

Kid-K

This is the most advanced modification with built-in thermal protection and lower water intake. Automation protects the device from overheating, disconnecting it from the network in time when the engine temperature rises. Unlike other devices, rewinding the Malysh-K pump as a result of winding combustion is not required.

Pump Kid: technical characteristics, design and principle of operation

Each pumping equipment has certain unique features. These features primarily include:

- principle of operation;

- internal organization.

Of course, to purchase or use the device, it is not necessary to study all the nuances. However, with self-assembly of pumping equipment, the study of unique features is an integral part of all work on installing the product.

Malysh units are one of the most common and reliable devices

The device of the pumping unit

The Baby pump is a standard device with the corresponding elements in the design. In total, there are three main components of the device:

- electromagnet;

- frame;

- vibrator.

Each constituent element in the design is necessary to ensure the full operation of the pumping mechanism.

Internal design of the vibrating unit

Vibrator

At the heart of this detail, as a rule, there are three components at once:

- shock absorber;

- stock;

- anchor.

Between themselves, the anchor and the rod form a single connection, in which the elements are attached due to the action of strong pressure. The shock absorber, regardless of the type of pump, is mounted directly on the rod and performs its corresponding role.

The main structural elements of the unit

Electromagnet

This component of the device is the most complex mechanism than other parts of the pump. At the base of the part is a small core with two copper coils. In addition, the case at the location of the core is pre-treated with a compound to ensure complete safety.

Frame

The shell of each pumping device, as a rule, is made of durable materials.To ensure the durability of the equipment, as well as its stable performance, a rubber valve is mounted in the housing.

Different types of housings of different models

The principle of operation of the pump Kid

The device of the Malysh series works in the same way as other types of pumping equipment. The main function is performed due to the ability of the device to convert all AC power into mechanical vibrations, which are subsequently transmitted directly to the piston and armature.

Schematic diagram of the operation of the pumping unit

As a result of such an impact, the piston begins an intense vibration, due to which the process of fluid circulation starts. Water begins to actively flow from the hydraulic chamber to the outside, entering the pressure compartments.

Operation features

Some models of submersible vibration pumps for wells have overheating protection. This is a very useful feature that prevents the motor from burning out. During prolonged operation or in case of violations of operating conditions, the built-in thermal relay (protection against overheating) opens the power circuit, turning off the pump. After a while, the relay returns to its original state and work resumes.

Another option for protective rings

If your pump has turned off due to overheating, it is advisable to immediately find out the cause. Shutdown can be caused by lack of water, increased voltage. If so, start the equipment only when everything returns to normal. Another possible reason is a clogged suction pipe. This can only be dealt with by taking out the pump, disassembling and cleaning it, which is contraindicated during the warranty period. Although, if your pump is clogged, you have already violated the rules of operation - it is suitable for pumping only clean water.

Dry run protection

Since many Malysh models cannot be lowered below three meters from the water surface, with a low flow rate, there is a threat that the water will run out, and the pump will continue to work and, as a result, will burn out. To avoid this situation, you can install a water level sensor. This is a float sensor, which is also called a “frog”. It works very simply:

Float water level sensor

- when it is raised up, the contacts are closed, power is supplied;

- when the water level drops, the float also drops, the contacts in the sensor open, breaking the power circuit;

- water is gradually drawn in, the float rises higher, at a certain level the contacts close again, the pump starts to work.

Such a sensor costs - less than 1 tr, it is installed simply - in the gap of the supply cable, but the benefits from it are great.

Working with a hydraulic accumulator

In general, vibration submersible pumps are not designed to work in conjunction with a hydraulic accumulator. They cannot create high enough pressure. But ... under certain conditions they work. The assembly scheme is standard: a pump, a pressure switch, a pressure gauge, a hydraulic accumulator, all this is assembled through a five-pin fitting. For normal operation, a check valve is installed at the end of the submerged hose (so that water does not flow back into the well). Another condition is that the accumulator must be of significant capacity (100 or 150 liters).

Water supply scheme of a private house with a submersible vibration pump Malysh

Having assembled this circuit, you need to configure the pressure switch. It is asked the less, the better, otherwise the Kid will not have enough power. But even with a little pressure, everything will work on the strength of a couple of years, but rather - a year and a half.

What to do to work longer

Pumps like the Kid cost very little, but they also do not last long - about 2-3 years. In their production, inexpensive materials are used to reduce costs. If, immediately after the purchase, some activities are carried out, as well as regular “technical inspections”, you can significantly extend the service life. So what can be done:

- The screws fastening the body should immediately be replaced with longer ones, supplemented with locknuts. If this is not done, the bolts become loose and break the stem.

- Once a month, inspect the pump, disassemble and rinse when pumping contaminated water.

- When operating with a hydraulic accumulator, set the minimum pressure.

- Install dry run protection.

- Apply voltage through the stabilizer.

Some of the activities are costly. For example, a stabilizer costs about the same or even more than this pump, but it can be used with other types, and all of them will work better with a stable voltage. But changing the bolts is the key point that needs to be done.

Pump Maintenance Malysh

In order for the pump to serve for a long time and properly, it is necessary to observe the operating and storage conditions recommended by the manufacturer. In this case, the manufacturer guarantees its normal operation for two years. The pump does not require complex maintenance and care, and simple rules will not be difficult to follow.

After the first installation of the device in the well, you need to let it work for one to two hours, and then take it out and carefully inspect the body and components for faults. If everything is normal, then the vibration pump can be replaced and used further, leaving it immersed in water for a long time.

Periodically, at least once every three months, and if possible, then every hundred hours of operation, it is also necessary to inspect the unit. If at the same time traces of friction are found on the body, it means that it was installed incorrectly and, during operation, came into contact with the walls of the water intake.

To avoid this, it is necessary to set it evenly and put an additional rubber ring on the body.

If the inlet holes become clogged, they must be carefully cleaned without damaging the rubber valve. For cleaning, it is best to use a tool with a blunt end.

If the pump is not used in winter, it must be pulled out of the well, washed and dried well. During storage, the unit should be placed away from heaters and protected from direct sunlight.

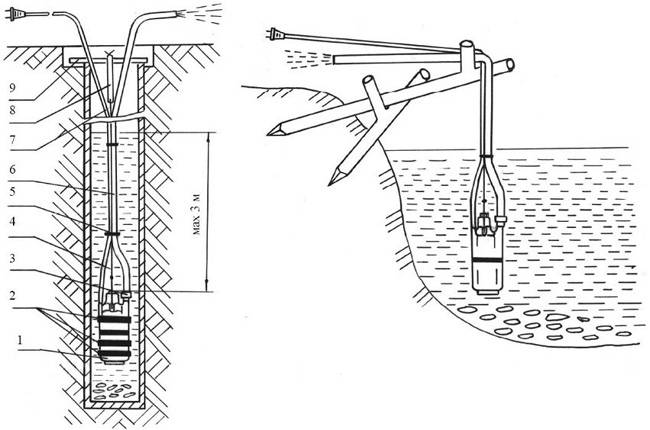

Installation in a well or well

The submersible pump Kid is suspended on a synthetic cable. A metal cable or wire is quickly destroyed by vibration. Their use is possible if a synthetic cable is tied below - at least 2 meters. There are eyelets in the upper part of the case for its fixing. The end of the cable is threaded through them and carefully fixed. The knot is located no lower than 10 cm from the pump housing - so that it is not sucked in. The cut edges are melted so that the cable does not unravel.

The cable clings to a special eye

Connecting hoses and pipes

A supply hose is put on the outlet pipe of the pump. Its inner diameter should be slightly smaller (by a couple of millimeters) than the diameter of the pipe. Too narrow a hose creates an additional load, due to which the unit burns out faster.

It is allowed to install flexible rubber or polymer hoses, as well as plastic or metal pipes of suitable diameter. When using pipes, the pump is connected to them with a piece of flexible hose at least 2 meters long.

Installation diagram of a submersible vibration pump

The hose is secured to the nozzle with a metal clamp. Usually a problem arises here: the hose jumps off from constant vibrations. To prevent this from happening, the outer surface of the pipe can be processed with a file, giving it additional roughness. You can also make a groove for the clamp, but do not get carried away too much. It is better to use a stainless steel clamp with notches - it gives additional rigidity to the mount.

It is better to take a collar like this

Preparation and descent

The installed hose, cable and electric cable are pulled together, installing constrictions. The first is placed at a distance of 25-30 cm from the body, all the rest in increments of 1-2 meters. The straps can be made from sticky tape, plastic ties, pieces of synthetic twine, etc. The use of metal wire or clamps is prohibited - when they vibrate, they fray the sheaths of the cord, hose or the twine itself.

A crossbar is installed on the head of the well or well, for which the cable will be attached. The second option is a hook on the side wall.

The prepared pump is gently lowered to the required depth. Here, too, questions arise: at what depth to install the Malysh submersible pump. The answer is twofold. Firstly, from the water surface to the top of the hull, the distance should be no more than the immersion depth of this model.For the “Kid” of the Topol company, this is 3 meters, for the PATRIOT unit - 10 meters. Secondly, there must be at least a meter to the bottom of the well or well. This is so as not to disturb the water too much.

Tie with plastic, nylon cords, adhesive tape, but not with metal (even in a sheath)

If the Malysh submersible pump is installed in a well, it should not touch the walls. When installed in a well, a rubber spring ring is put on the body.

Having lowered the pump to the required depth, the cable is fixed on the crossbar

Please note: all weight must be on the cable, not on the hose or cable. To do this, when fastening, the twine is pulled, and the cord and hose are slightly loosened.

Installation in a shallow well

With a small depth of the well, when the length of the cable is less than 5 meters, to neutralize vibrations, the cable is suspended from the crossbar through a springy gasket. The best option is a piece of thick rubber that can withstand the load (weight and vibration). Springs are not recommended.

Mounting options for submersible vibration pumps with upper and lower water intake

Installation in a river, pond, lake (horizontal)

The Malysh submersible pump can also be operated in a horizontal position. Its preparation is similar - put on a hose, fasten everything with ties. Only then the body should be wrapped with a rubber sheet 1-3 mm thick.

Vertical installation option in open water

After the pump is lowered under water, it can be turned on and operated. It does not require any additional measures (filling and lubrication). It cools down with the help of pumped water, which is why switching on without water has an extremely bad effect on it: the motor overheats and can burn out.

What is the baby for?

This pump can be used in a wide variety of areas, including farms, suburban areas, and various farms. This device is rightfully considered universal, and therefore is used for the following purposes.

- Arrangement of watering / irrigation systems in areas, in plantings and in fields. In addition, the pump can be used to fill artificial reservoirs with water or, on the contrary, to pump it out.

- Pumping from various utility rooms and basements. Due to its compactness, ease of connection and use, the unit is ideal for this.

- Water supply from a source (a well, a well can act as such) into special containers or water pipes. So, for a small area, the pump is able to provide water to all water intake points.

The connection of the pump can be either upper or lower - it all depends on the specifics of its application. The second option is more effective if application is required in a well / well whose diameter is more than 10 centimeters. Even with the help of a pump, you can pump out liquid from small containers (that is, again, pumping water out of basements during flooding). The disadvantage of the lower intake can be considered the fact that various particles or dirt can get into the water, and therefore a filter must be installed at the inlet.

As for the equipment with the upper fence, the garbage cannot get inside here; moreover, it is characterized by effective cooling, due to which the risk of overheating is minimal. You can, for example, leave the pump running and go about other things - a great option for providing autonomous water supply.Even with the help of such pumps, water can rise from wells / wells.

Tips & Tricks

According to reviews, the Baby pump is able to work for very long years and without interruption, especially if you follow some recommendations. Despite its rather unpretentious characteristics, this pump does an excellent job of pumping water. More than enough for wells. Among the recommendations for the use of this pump, one of the most frequently encountered was the recommendation for monitoring mains voltage. This is due to the fact that when power surges occur, the device must be immediately turned off. The best solution would be to supply voltage through the stabilizer.

You should pay attention to the quality of the water that the pump pumps. It often happens that the device breaks due to sand or other debris getting into it.

Moreover, even pumps with an upper intake will not always guarantee that debris particles will not fall. Therefore, it is better to immediately install a filter on the pump, which will allow the device to last much longer. In addition, due to the filter, the water will come in better quality, since there will be no impurities in it.

When the inlets on the device become clogged, they must be carefully cleaned so as not to damage the rubber valve. That is why it is best to use tools for cleaning, the ends of which are blunt. In the event that the pump will not be used in winter, it should be removed from the well. Then rinse thoroughly and dry. It is best to store the pump away from heating appliances and preferably out of direct sunlight.

The vibration submersible pump is not designed to work with a hydraulic accumulator, as it cannot create high pressure. However, there are certain conditions when they can work together in one bundle. For this, a standard scheme is used in the form of a pump, a pressure switch, a pressure gauge and a hydraulic accumulator. All this must be assembled using a five-pin fitting. In order for this design to work normally at the end of the hose immersed in water, it is necessary to install a check valve. It will prevent water from flowing back into the well. Also a prerequisite is a significant capacity of the accumulator (at least 100-150 liters). The pressure switch is set as low as possible so that the pump has enough power.

How to repair the pump "Kid" with your own hands, see the following video.

Pump Maintenance Malysh

In order for the pump to serve for a long time and properly, it is necessary to observe the operating and storage conditions recommended by the manufacturer. In this case, the manufacturer guarantees its normal operation for two years. The pump does not require complex maintenance and care, and simple rules will not be difficult to follow.

After the first installation of the device in the well, you need to let it work for one to two hours, and then take it out and carefully inspect the body and components for faults. If everything is normal, then the vibration pump can be replaced and used further, leaving it immersed in water for a long time.

Periodically, at least once every three months, and if possible, then every hundred hours of operation, it is also necessary to inspect the unit.If at the same time traces of friction are found on the body, it means that it was installed incorrectly and, during operation, came into contact with the walls of the water intake.

To avoid this, it is necessary to set it evenly and put an additional rubber ring on the body.

If the inlet holes become clogged, they must be carefully cleaned without damaging the rubber valve. For cleaning, it is best to use a tool with a blunt end.

If the pump is not used in winter, it must be pulled out of the well, washed and dried well. During storage, the unit should be placed away from heaters and protected from direct sunlight.