- Which brand of submersible pump is better to choose

- Surface pump for a well 30 meters

- Video - Hand pump for a well without a foundation

- Types of pumps for wells

- The principle of operation and installation rules for surface pumps

- Types of submersible pumps for wells

- Centrifugal pumps for wells

- Vibratory Pump Applications

- Specifics of submersible pumping equipment

- Vibration pump + well: yes or no?

- Guidelines for choosing a centrifugal pump

- A few words about popular models

- Surface pumps for wells

- What should be a good pump

- Well pump selection options

- Aquifer characteristics

- Water requirement

- pressure

- The degree of entry into the casing

- What to look for when choosing a pump?

- Vortex

- Centrifugal

Which brand of submersible pump is better to choose

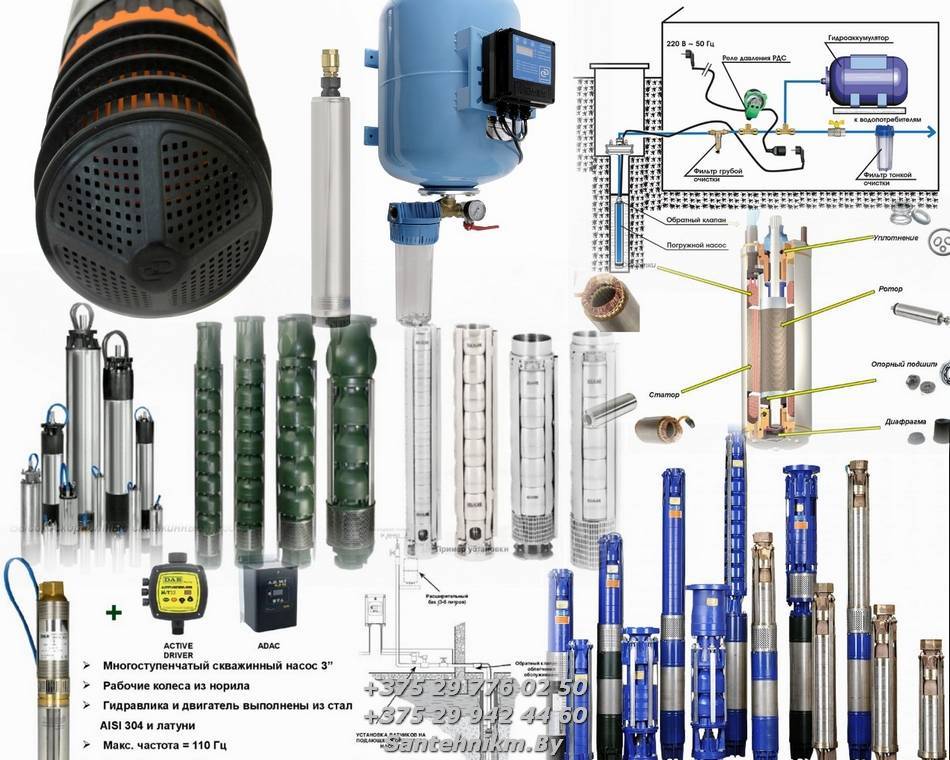

There is a wide variety of submersible pumps on the market. However, not every manufacturer can offer customers guaranteed quality. Specialized service, a company guarantee can only be provided by reputable companies with a good reputation. Focusing on the numerous reviews of ordinary consumers and the opinion of experts, a review was compiled, which included the TOP-10 manufacturing companies, professionals in their field.

Gilex LLC. The Russian campaign is the leader among domestic manufacturers. Market launch date 1993.It produces a wide range of high-level pumping equipment. The company's specialists carefully analyze market demand, which helps to create equipment that is most adapted to the specific needs of people. A wide network of company branches successfully operates on the territory of the Russian Federation and neighboring countries.

OJSC Technopribor. Belarusian manufacturing company. Founded in 1974. Production facilities are located in Mogilev. High-quality, affordable, inexpensive products have been leaving the assembly line of the enterprise for decades.

Most of all, the company paid attention to the development and production of pumping equipment. Reliable, affordable household models, such as the well-known "Brook" series, are very popular among the population.

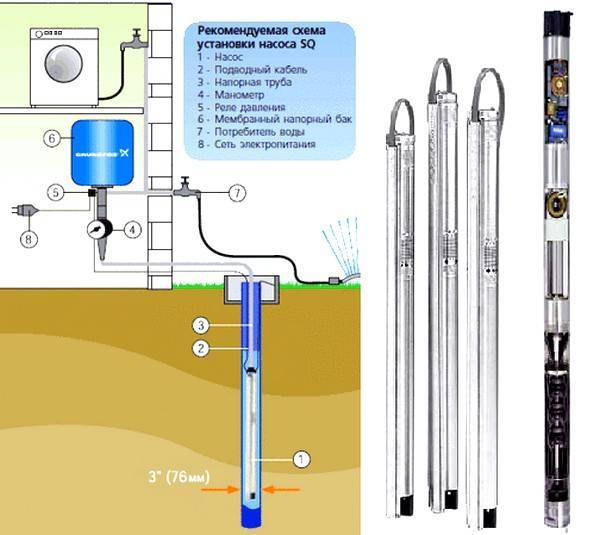

Grundfos

A large manufacturer of pumping equipment from Denmark. Founded in 1945. Literally after 5 years, the company has already launched its first 5000 pumps on the market, which made a splash among consumers. Since 1952, a mass production line has been launched. Grundfos borehole models in stainless steel and ceramics are world market leaders.

OOO Promelectro. Kharkov enterprise, founded in 1995. Engaged in the development, manufacture of household submersible pumps "Aquarius", the BTsPE line. The brand has earned a good reputation in the Russian market. Each unit of production is quality, reliability, long service life. Provides high performance when working in an autonomous water supply system.

Hammer. Well-known German company. Date of foundation 1980. The main activity is the production of power, measuring equipment, garden power tools.Pumping stations, submersible pumps of various modifications of the company have a high reputation among Russian consumers. The introduction of new developments, the modernization of lines, the high German quality of components are the three pillars on which the company's popularity invariably rests.

Karcher. An authoritative German brand that specializes in the production of cleaning and cleaning equipment. Founded in 1935. The trading company has been successfully maintaining high German quality throughout the years, quickly introducing new developments. Successfully engaged in the sale of household and professional appliances, with more than 120 subsidiaries in 70 countries.

Bison. Russian manufacturer-supplier. Date of foundation 2005. It supplies the market with a wide range of inexpensive hand and mechanized tools, materials and electrical equipment. The brand is known for innovative developments, a wide area of service and warranty customer service. The products are characterized by stable characteristics, high reliability, long service life.

ALKO. The German manufacturer is one of the leading European brands of garden equipment and machinery. Founded in 1931. Over the years, the company has expanded, introduced and developed its range of products. Today, the brand has a huge volume of products: climate and ventilation components, garden equipment, elements for cars. The priority direction is occupied by garden equipment and tools.

Vortex. Russian manufacturer, a recognized leader among pumping equipment and power tools. The priority direction of production is pumping stations, borehole and drainage models.The first batch of equipment under the brand name Whirlwind rolled off the assembly line in 1974 at a plant in Kuibyshev. Today, the manufacturer has its own facilities in China, where almost all equipment is produced.

Belamos. Russian trademark that produces pumping equipment for heating and water supply systems. Date of foundation 1993. In a short period of time, the exporter of foreign equipment has become the largest manufacturer of pumping equipment for various purposes: for heating systems, water supply, borehole, drainage, fecal, etc.

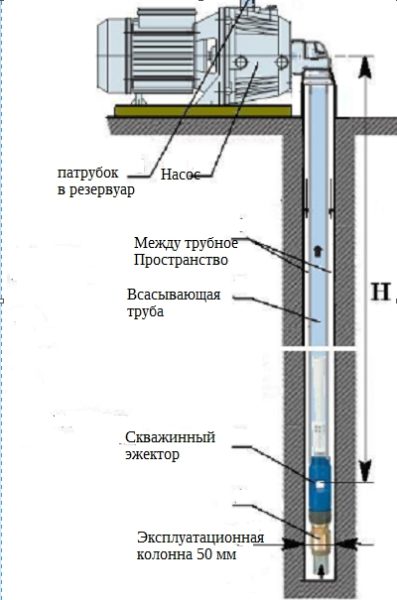

Surface pump for a well 30 meters

With increasing depth, the pressure increases, so for a static level of 30 m, you will need a pump more powerful than the DP-100.

Surface pump with remote ejector LEO AJDm110/4H

The maximum suction height is 40 meters, which guarantees a certain power reserve for lifting water from a depth of 30 meters.

The manufacturer LEO launches a new type of flexible shaft pumps for deep wells.

It is installed at the wellhead. A flexible shaft is produced with a length of 25, 45 meters - the depth from which water can be pumped out. This type of pump is more semi-submersible than surface. They are mounted on a production string with a diameter of 50 mm. Can be an alternative to a hand pump.

The hydraulic part consists of 2 hoses inserted one into the other. A flexible shaft is passed inside, connected to a screw-type pump head.

screw pump

Despite its small size, the maximum capacity is 1.8 m3/h and the head is 90 meters. The hose is lowered into the well to a predetermined depth, the flexible shaft is connected to the shaft of the electric motor gearbox.The advantage of the pump is that the electric motor is at the top. In case of clogging of the pump, the flexible shaft is disconnected, the hose is pulled out, and washed.

Let's make a table of the top 10 surface pumps that are most in demand among buyers.

Table 2. The best surface pumps.

| brand | Type of | Pressure, bar | Head, m | Consumption, m 3 / h | Water level depth, m |

|---|---|---|---|---|---|

| Grundfos MQ 3-35 | multi-stage, self-priming | 7.5 | 44 | 4.1 | 8 |

| AJDm110/4H | with external ejector | 9 | 100 | 2.2 | 30-40 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming with built-in ejector | 7 | 37 | 4.8 | 8,5-9 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming, vortex | 8 | 38 | 8 | |

| APM 100, 150, 200 (Speroni) | with remote ejector | 7 | 64 | 1,8 2,7 | 10-40 |

| BG and BGM (3, 5, 7, 9, 11 (Lowara) | self-priming with integrated ejector | 9 | 46-60 | 2-4 | 8-9 |

| JET 112 T by DAB | self-priming with integrated ejector | 6-8 | 50 | 2-3 | 8-9 |

| Calpeda NGLM 4/A | self-priming with integrated ejector | 8 | 50 | 2-4 | 9 |

| JMC 100 | centrifugal self-priming | 7.5 | 44.5 | 3 | 8 |

| Gilex Jumbo 70/50 N / 3702 | self-priming | 8 | 50 | 4.2 | 9 |

| The best pumping stations for deep water lifting | |||||

| Grundfos JPD 4-54 PT-V | with remote ejector | 6 | 54 | 27 | |

| ELITECH CAB 800/24E | with remote ejector | 6 | 45 | 2.4 | 25 |

| Gilex Jumbo 50/28 Ch-18 | with remote ejector | 3 | 28 |

Here, stations and pumps with a built-in ejector or an external version are selected. To automate the process of extracting water from wells, it is recommended to purchase a hydraulic accumulator with a pressure switch for these pumps. Usually they buy a ready-made pumping station. The manufacturer has calculated the optimal tank volume for this type of pump.

In order for the pumping equipment to work smoothly, it is necessary to choose the right pump.In addition to the static, dynamic level, well flow rate, average consumption per person per day, it is necessary to determine the total height of water rise from the mirror to the highest point of supply. Do not forget the horizontal section, 6% -10% of which must be added to the height of the lift. So determine the required pressure.

Self-priming surface pumps without a built-in ejector are best installed in basements or caissons. The shorter the distance to the water surface, the lower the hydraulic losses. Turns and narrowing of water lines also increase hydraulic resistance. Purchase a storage tank for irrigation, so you will create a supply of water if the daily well flow rate is low.

Video - Hand pump for a well without a foundation

One more type of pump could be considered - the compressor. It is used to lift water from a well using an airlift. The method has not found wide distribution. Submersible, semi-submersible and deep pumps are often used, but their device is more complicated, the cost and repair is also expensive. The best option for shallow wells is a surface pump.

Types of pumps for wells

All models are divided into:

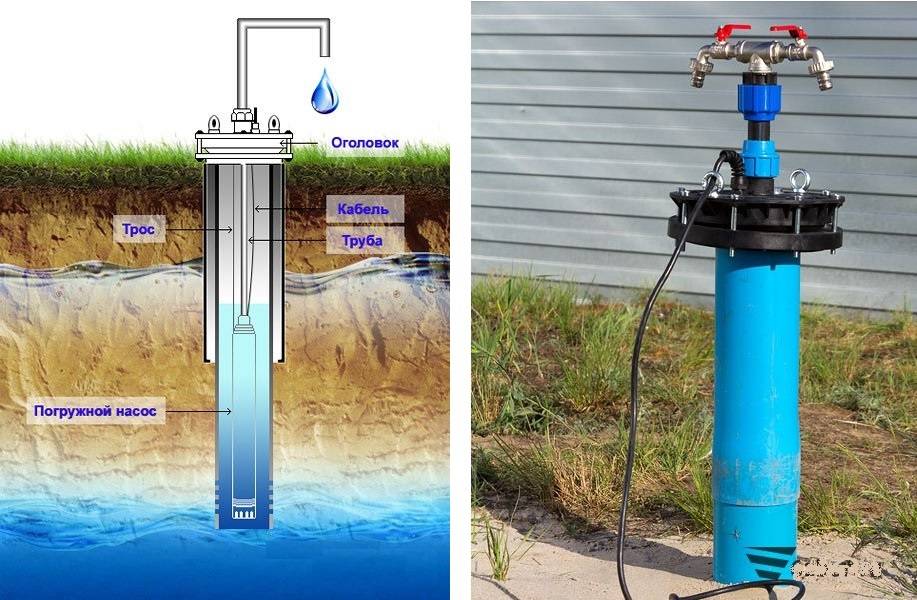

- Submersible pumps. Devices are partially or completely immersed in water.

- Surface. They are used when the water level is not lower than 9 meters. Their installation can be carried out on the ground and a floating platform, but a prerequisite is that water does not get inside the engine.

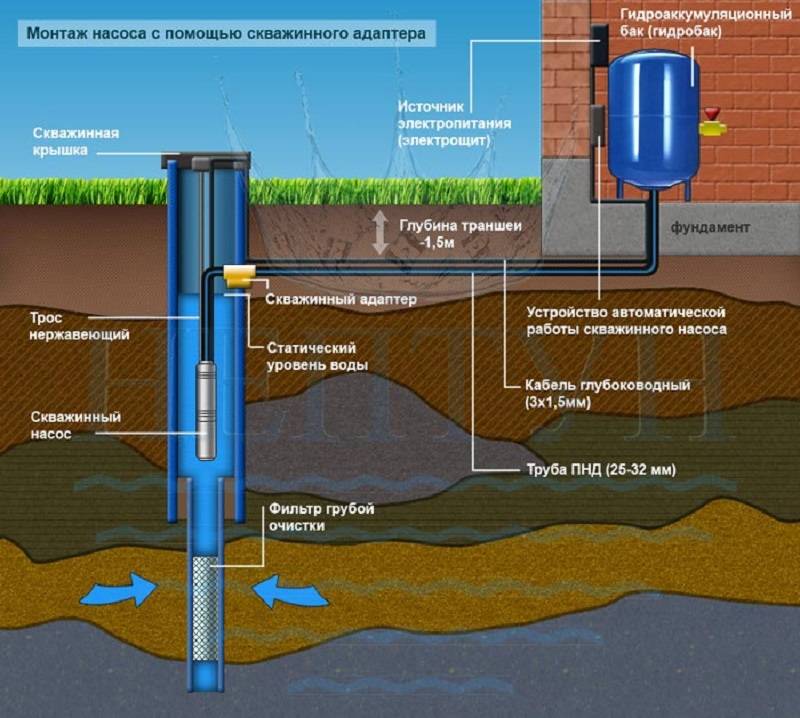

The principle of operation and installation rules for surface pumps

Installation of a surface pump

The operation of the well pump is as follows:

- A pump is mounted on the rotating shaft of the electric motor, on which there are holes for supplying and taking water.

- The intake is carried out by a sleeve or hose with a check valve. The element must be of good quality, otherwise depressurization of the unit may lead to the fact that the engine will not start.

- To increase the depth of water intake over 9 meters, you can use an external ejector, which is lowered under water along with a hose. In this case, when the pump is running, part of the water falls into the ejector, the pressure in the hose rises, which increases the pressure. But the strong noise generated by the installation does not allow using this option all the time.

- Installing a surface pump is very easy. The unit is placed near the well, a hose is lowered into the water, the device is connected to the network.

- It is better to install the pump in a heated room or in an insulated container.

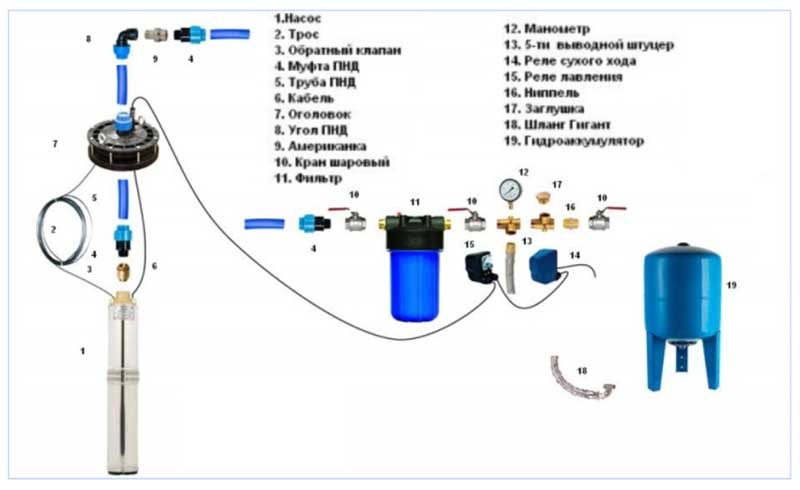

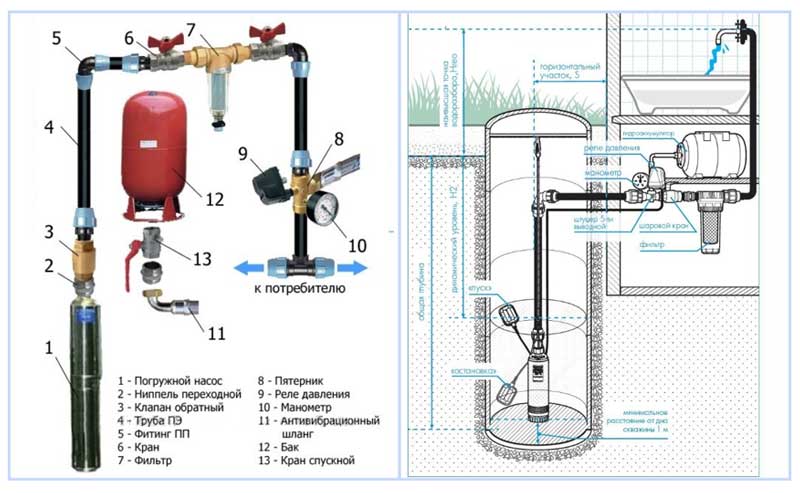

Types of submersible pumps for wells

Manufacturers produce three types of submersible equipment:

- Centrifugal. These are the most expensive devices. Designed to lift water from a depth of more than 100 meters.

In its composition, sand can exceed 180 g / m. A feature of the units is greater power and increased productivity. - Vortex. With their help, water with an impurity content of up to 40 g / m3 can be pumped, and the depth of the wells is from 30 to 100 meters.

- Screw. The price of such devices is the smallest. They serve to organize water supply from wells, the depth of which is up to 15 meters or open reservoirs. The maximum presence of abrasive particles is 40 g/m.

For wells, deep-well pumps with high power are used.

Deep pumps

The optimal dimensions of such devices allow them to be installed in narrow wells. The length of the elongated pump cylinder is from 50 centimeters to 2.5 meters, and the outer diameter is about 10 centimeters.

If the question arises which pump to choose for a well of 15 meters, then a deep pump is the best solution. It is well suited for shaft wells, deep sand or artesian wells, process tanks. They are made using high quality stainless steel.

Centrifugal pumps for wells

Centrifugal pump

The features of the unit are:

- The design of the device includes an engine shaft on which a wheel is located, consisting of two plates connected by blades.

- The centrifugal force of the pump captures the water with the blades, and then throws it into the supply pipe. Centrifugal pumps are the most common type of equipment for wells. This is the most versatile mechanism.

- Their main purpose is to pump clean water. This indicates that there should not be even a small amount of sand in the water.

- The cost of centrifugal pumps depends on the number of stages and some design features.

- For domestic needs, single-stage pumps are most often used, however, if more water pressure is needed, multi-stage pumps should be chosen, where there are several operating wheels on one shaft.

Vibratory Pump Applications

Vibration pumps are used for the following purposes:

Vibration pump device

- Pumping water from the tank. It can be used to drain a freshly dug well or clean it out if necessary.

- Raising water from a tank for domestic use.

- Water supply from an open source such as lakes, pools, rivers, etc.

- Water supply from a pre-filled container, which can include a cistern, tank, etc.

- Pumping water from a flooded room, basement, trench, etc.

- Pumping water from a well can also be done using a vibration pump, but reviews on the use of this unit in such conditions vary greatly. Some speak positively about the operation of the pump, using it for years, while others talk about a damaged well and collapse of the foundation.

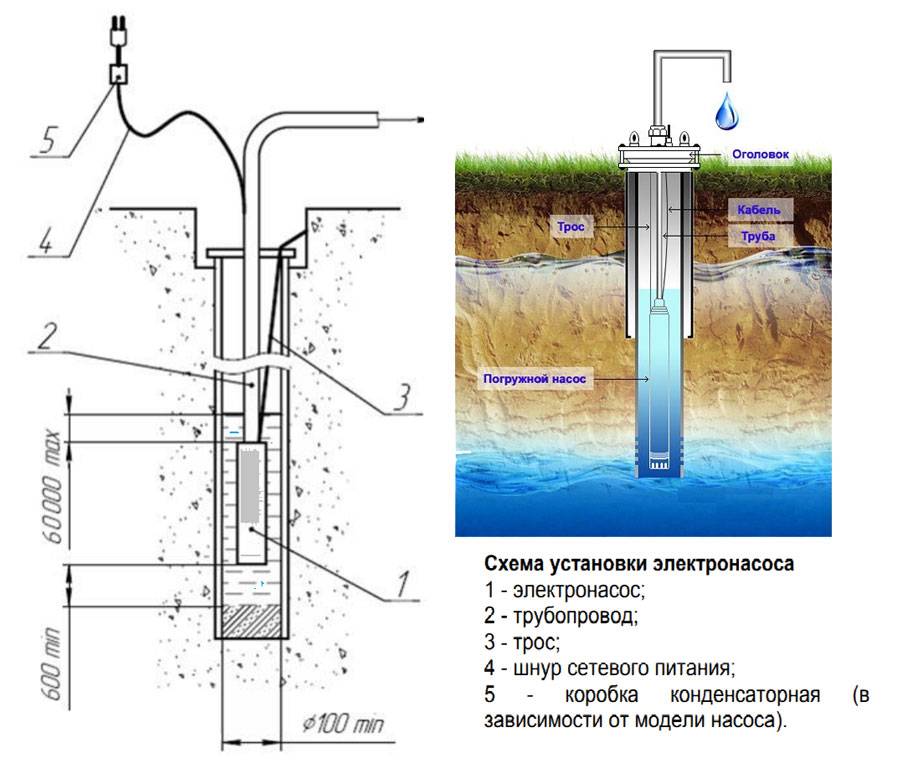

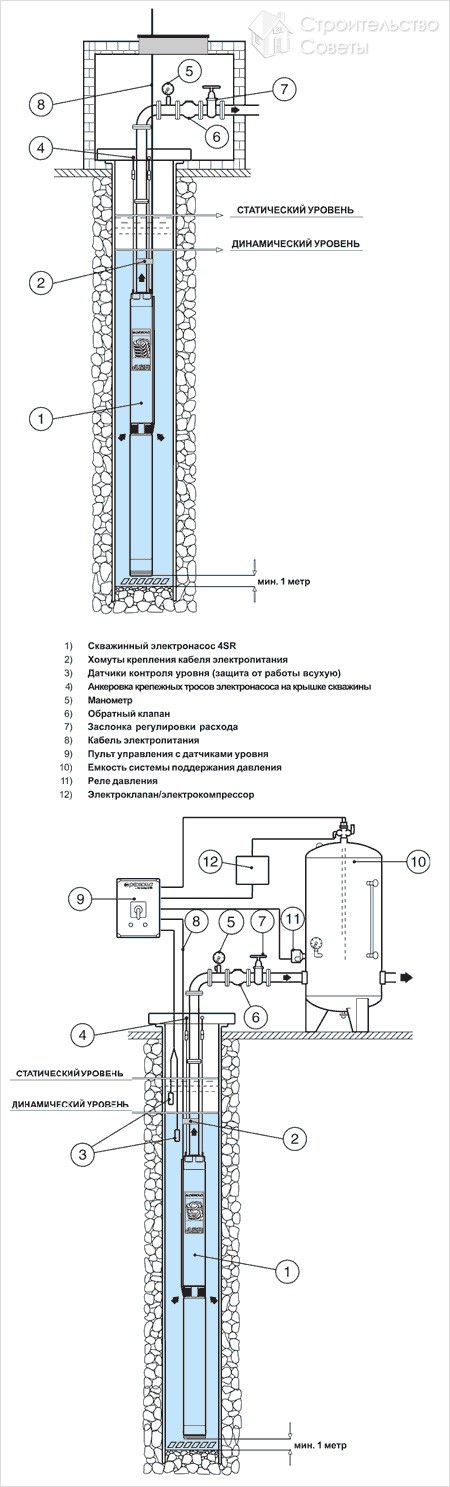

Specifics of submersible pumping equipment

According to the type of device, centrifugal and vibration pumps are distinguished. In the first, a rotating disk with blades is used to supply water, and in the second, a special membrane that transfers water with the help of numerous vibrations. These design features are important because they affect well integrity in different ways.

Vibration pump + well: yes or no?

Is it possible to install a vibration pump in the well? These models are relatively inexpensive, easy to operate, and have performance that is suitable for a significant number of wells.

Many experts categorically object to the use of any vibration technique in the well shaft. However, owner reviews report that pumps of this type are used quite successfully without any damage to the structure. So, which pump - vibration or centrifugal - is better for a well?

The objections of experts are well founded. Prolonged vibration exposure almost always negatively affects the state of surrounding objects. The well is no exception.

Vibrations from the pump located next to the filter affect the condition of the casing and the surrounding soil, which are gradually destroyed. Vibration can cause a significant acceleration of the processes of silting and sanding.

But it doesn't happen right away.Typically, wells successfully resist vibration for some time. Therefore, with the help of such a pump, it is possible to pump the well, and clean it, and successfully operate it without visible damage.

But destruction from vibration still occurs, although not too quickly. The constant use of a vibration pump can significantly reduce the life of the structure.

If necessary, the use of vibration models is quite acceptable, but only as a temporary option. But at the first opportunity, such a pump should be replaced with a safer centrifugal device.

Guidelines for choosing a centrifugal pump

To do this, you need to carefully study the technical passport of the centrifugal device and find out several important points:

- what is the performance of the pump;

- whether its dimensions are suitable for the well;

- from what depth can he raise water;

- what are the features of its installation and operation;

- how and under what conditions warranty service is carried out, etc.

Usually consultants give quite professional recommendations when choosing such equipment. It should be remembered that many manufacturers indicate limiting rather than average characteristics for pumps, so you need to take into account some margin of operational life.

Directly in the marking of a domestic pump or in the technical passport of a foreign one, two numbers that are important for choosing are indicated. The first (in example 55) is the flow in l/min, the second (75) is the maximum head in meters

A few words about popular models

If the decision is made to use a vibration pump, most likely, “Kid” or “Brook” will be bought.These models are distinguished by good performance, resistance to breakdowns and quite affordable price.

They are easy to clean or repair with your own hands. But for permanent use, vibration technology is not suitable, it must be replaced as soon as possible.

Vibration pump "Kid" is a popular, but not very suitable choice for a well, since the vibrations of the device can cause its destruction

Among the popular brands of submersible centrifugal pumps, it is worth noting "Aquarius" and "Vodomet". They are very similar, but according to user reviews, Aquarius noticeably wins in quality and durability, although it costs more.

However, the Water Cannon also has its adherents. If you are lucky enough to get a well-assembled model, it will show quite decent results.

Submersible centrifugal pumps of the Aquarius brand have established themselves as reliable and durable equipment for the well, capable of coping with increased loads

Special well pumps will cost a substantial amount, but such costs will fully justify themselves over time. As an example of such a technique, it is worth noting the 3STM2 and 4STM2 models manufactured by TAIFU.

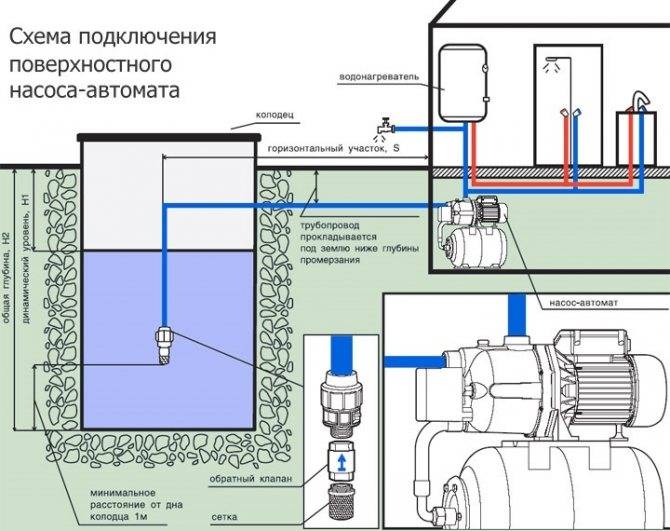

Surface pumps for wells

Equipment of this type is not designed to be lowered into a well. It is an electric motor equipped with a device for pumping liquid. Suction occurs by creating a vacuum in the working chamber of the device. It must be taken into account that surface pumps can lift water from a depth not exceeding 10 m. Based on this, their area of application is extremely limited, and the quality of the resulting water is rather low.

Install surface-type equipment in the following places:

- on a floating platform, if the casing goes into a sealed tank;

- under a canopy in the immediate vicinity of the source;

- in a specially designed booth to protect the device itself from mechanical damage and precipitation;

- in a residential or utility room by connecting the pump to the well with pipes located underground or on props.

To install a surface pump, there is no need for special education or the use of professional tools.

This work is carried out in the following sequence:

- A platform is being set up on which the pump will stand. The equipment itself is serviced and its performance is checked. The device is rigidly fixed on the platform.

- The pipeline is being assembled. For this, steel, brass or plastic pipes with a diameter of 25-32 mm are used. Metal is connected by thread, and plastic by couplings or welding.

- The pipeline is connected to the pump. The productivity of his work on pumping water from the well is checked.

Before the storage tank, the pipeline is made permanent from rigid products or temporary from a flexible hose, which is untwisted and twisted as needed.

What should be a good pump

The flow rate of a local source is an important indicator when choosing a device. For high performance, a large power unit is required. Depth is the determining factor. A model designed for 40 m will supply water from 50 m, but will quickly fail.

The level of drilling quality should also be taken into account. If the work was carried out by a professional team, the shaft can withstand heavy loads and is resistant to external influences.For do-it-yourself pits, it is better to buy centrifugal models designed specifically for wells for installing a submersible pump.

When choosing equipment for pumping water, special attention is paid to the dimensions of the device. They must be selected in accordance with the internal section of the casing

The pump must pass freely into the pipe. If the unit is in contact with the walls, it is better to look for an option with smaller dimensions.

Finding a pump model that fits a 4" casing is easier than a 3" one. This factor must be taken into account when drawing up a plan for installing a submersible pump in a well.

Deep pump mechanisms have different power supply schemes. Single and three-phase devices are allowed to be used in a water mine.

Well pump selection options

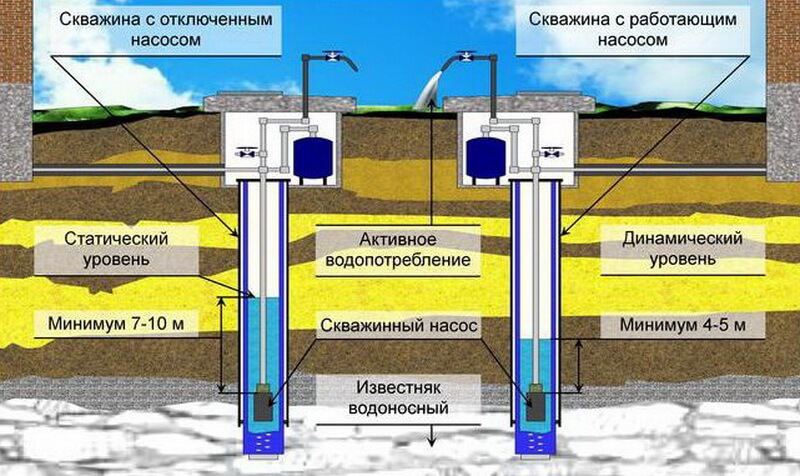

Aquifer characteristics

The characteristics of the aquifer include:

1. depth - dynamic, changing depending on various factors, and static;

2. debit - the amount of liquid entering the intake per unit of time;

3. the type of soil in which the water is located.

After the work is completed, a passport is drawn up indicating all the necessary data.

Water requirement

In the case of a private house, the need for water is calculated - it should not exceed the debit. When determining it, the number of residents and plumbing fixtures, as well as the mode of operation + the amount of liquid for irrigation, are taken into account.

This parameter, depending on the situation, differs significantly, therefore, with an eye to the norms, it is better to determine it based on consumption habits - under similar conditions, the throughput may need both 2 and 20 m3 / h.

pressure

A mandatory parameter is the head, which can be considered in atmospheres or meters of water column - the ratio between these values is approximately: 1 to 10.

In its simplified calculation, the following are summarized:

1. Geometric lift height (vertical distance from the pump to the highest point of disassembly);

2. Losses on horizontal sections (10 m equals 1 m)

3. Free pressure at the mixer (from 2 or 3 m).

The degree of entry into the casing

The device should enter the casing pipe with a clearance of 1 ... 3 cm. The most common diameters of the latter are 10, 13 and 15 cm. Accordingly, the pumps are produced at 3", 4", more than 4".

What to look for when choosing a pump?

Before the final choice, you should pay attention to several key technical characteristics of pumping equipment. One of these characteristics is performance.

It is measured in l / min or in cubic meters. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum

One of these characteristics is performance. It is measured in l / min or in cubic meters. m / h and means the volume of pumped water per minute or hour. For a family of 2-3 people, this figure should reach 45 l / min or 2.5 cubic meters. m/h minimum.

This indicator can be calculated independently. Sum the water consumption of all points of intake (consumers) in the house and multiply by a factor of 0.6. The number 0.6 means that no more than 60% of all water intake points are used at the same time.

The coefficients for calculating the performance are presented in l / min and in cubic meters. m/hour.For calculations, select only the values of those fence points that are in the house

The maximum pressure is an important indicator. It depends on the pressure force whether the pump will pump enough water for your needs. To calculate it, it is necessary to sum up the dynamic and static water levels. Then add 10% of the amount received.

There are more complex formulas that take into account the distance to the house and the number of water intake points. If you do not want to carry out complex calculations yourself, then seek the advice of a specialist.

The statistical water level or depth to the mirror is the distance between the actual water level and the top of the well. If this distance does not exceed 10 meters, then a surface pump should be selected.

Some experts believe that this figure should be in the range of 2-7 meters. In other cases, focus on the submersible. Note that the latter is more durable, almost silent, and also powerful.

Surface pumps are quite heavy and noisy. They are ideal if a well or well up to 10 meters deep

Also important is the height of the water column or the dynamic level - this is the distance from the water's edge to the bottom of the well. It is necessary to take into account the depth of the well or well, since this parameter is also prescribed in the passport for the pump. These indicators should ideally match

It is worth taking into account the height of the pump itself in relation to the well

The power of the equipment is fixed in W and means how much electricity the pump will “pull”. Do not purchase a pump with a power reserve, otherwise you will simply overpay for electricity.

Pay attention to the body material, it must have corrosion protection. Details are also important.

Check, at least visually, the quality of the assembly, the wheels. It is best if they are "floating" and made of durable technical plastic.

The key working tool of a centrifugal hydraulic pump is the wheel. Most often it is made of an alloy of non-ferrous metals, stainless steel or cast iron.

We have provided more tips on choosing the right pump model for the well in the following article.

In the case of a centrifugal pump there is an impeller with blades that pump water. In powerful devices, there may be several such wheels.

The wheel is powered by an electric motor. Centrifugal force displaces water to the edge of the wheel from its center. Thus, a zone of high pressure is formed and the liquid flows through the pipes to the points of water intake (kitchen, bath, watering). Then the pressure is reduced and the process starts again.

Some centrifugal pumps have a hydraulic accumulator. This is a tank with a membrane element. It is used to maintain the necessary pressure in the pipes through which water, with the help of a pump, flows from the well and into the house. It is indispensable for wells and wells with a depth of 10 to 30 meters.

Another important element is the check valve. The principle of its operation is that the water does not have the opportunity to move in the opposite direction, that is, from the house through pipes to the well.

It is also worth considering what kind of water the pump can pump. If the water in the well is mixed with lime, clay or sand, then this must be announced before purchase. Otherwise, the pump will clog and fail prematurely.

Before buying, find out the location of service centers and the availability of parts (at least key ones) for the selected pump model.

If you want to install the pump yourself, then be sure to carefully read the instructions for the device and consult with specialists.

Given these characteristics, you can easily select the right pump model.

Vortex

In vortex submersible pumps, the intake and expulsion of water occurs with the help of a single impeller with blades, which is located in the upper part of a vertically suspended casing near the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side face of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to work in an environment with sand particles.

Vortex-type devices have good pressure characteristics (liquid lifting height reaches 100 m) and average pumping volumes (about 5 cubic meters / hour).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Whirlwind, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump - design and appearance

Centrifugal

Centrifugal devices have achieved such distribution due to the following properties:

- Their coefficient of performance (COP) is the highest of all analogues, in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel, and is pushed out through the side pipe. This allows you to make multi-stage centrifugal devices in which the ejected fluid is fed to the axle of the next wheel, which further increases its pressure.Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters / h.

- Centrifugal type units are less affected by fine sand particles on the working mechanism, they are widely used in sand wells, choosing a model to work with a suitable particle size indicated in the passport.

- A significant advantage of centrifugal types is the high level of automation, the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) supply their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save electricity during the operation of the electric pump (up to 50%), but also to significantly increase its service life.

If we list all manufacturers of centrifugal pumps that represent their products on the domestic market, the list will be quite voluminous, so we will limit ourselves to the world's leading manufacturers listed above. Of the domestic brands, Aquarius, Dzhileks Vodomet, Whirlwind, Belamos, Caliber, Unipump received the greatest fame.

Rice. 8 Centrifugal submersible pumps - design and materials of manufacture using the example of Grundfos SBA