- Design features and principle of operation

- Pumps for watering from a well

- Livgidromash Malysh-M BV 0.12-40 10m

- Grundfos SBA 3-35 A

- Technopribor Brook-1, 10 m

- Main selection factors

- Popular brands of equipment

- Operation and care

- Summing up

- Overview of the best brands

- How to decide on the type of pump

- Submersible or surface pump for a well

- What you need to know about pump performance

- Pump head

- pump efficiency

- Which pump is suitable for pumping water

- Mechanized pump

- Hand pump

- Best Inexpensive Drainage Pumps

- Whirlwind DN-300 68/2/6

- Leberg GP250 UT000008999

- Stavr NPD-810

- Parma ND-250/5PV

- Which brand of drainage pump to choose

Design features and principle of operation

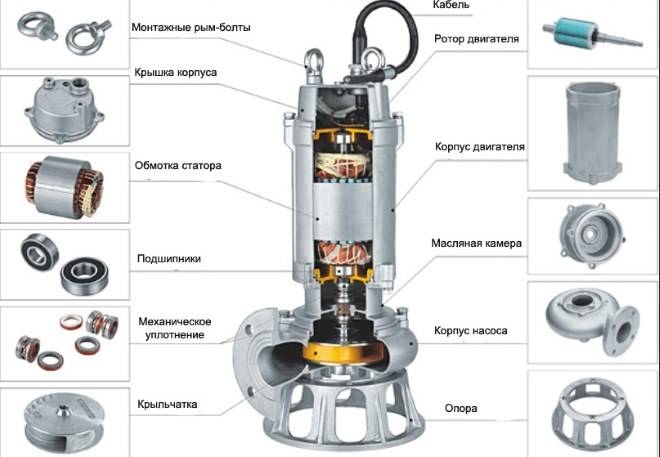

The drainage type centrifugal pump is a compact device, the main structural elements of which are:

- housing made of durable and wear-resistant materials - cast iron, stainless and ordinary steel, plastic (the choice of material depends on the purpose and technical characteristics of the device);

- an electric motor that drives the working shaft;

- an impeller, on the outer surface of which curved blades are fixed (the rotation of the impeller is provided by a drive shaft, on which such a wheel is fixed).

Drain pump device

A submersible drainage pump, which is in operation in the thickness of the liquid medium it pumps, is additionally equipped with a strainer that protects such a pump from solid particles that exceed the allowable size from entering its internal chamber.

The dimensions of the internal chamber of drainage pumps used for pumping groundwater from basements and cellars, as well as pumping dirty water from wells or ground tanks, are calculated in such a way that solid inclusions contained in the pumped liquid can freely pass through it.

The bottom of the drain pump should be easy to remove to clean the impeller.

As elements of additional equipment that protect drainage pumps from the consequences of emergency situations, as well as allowing them to organize their operation in automatic mode, the following can be used:

- temperature switches that automatically turn off pumping equipment in case of overheating;

- sensors that protect the electric pump from idle operation.

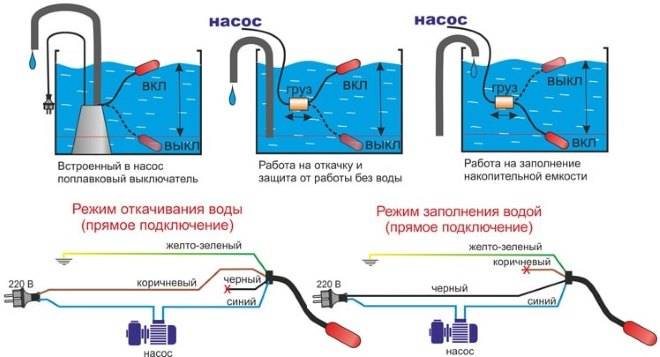

Idling sensors are float switches that automatically stop the operation of the equipment if the level of pumped water falls below a critical level. A floatless pump not equipped with such sensors requires constant attention from users to monitor its operating conditions.

When installing such sensors, it is important to correctly determine the depth of their immersion. This is necessary so that the pump turns off and on exactly at those moments when it is required.

How float switches work

Centrifugal equipment is mainly used as a submersible pump for dirty water.The main element of its design is an impeller with blades, which, moving the pumped dirty water through the inner chamber, creates a centrifugal force that increases the pressure of the liquid medium, due to which the latter is pushed out through the pressure pipe. At the same time, an air rarefaction is created in the middle part of the working chamber of the centrifugal electric pump, which ensures that a new portion of the pumped out dirty water is sucked into such a chamber.

Centrifugal pumps are considered the best in terms of working with polluted waters for a number of reasons.

Due to its high reliability, this pump does not require frequent maintenance.

Electric pumps of this type have high performance and the ability to form a liquid medium flow with good pressure, which is especially important for devices through which muddy and dirty water is pumped.

On the market you can find many different models, which allows you to optimally select a centrifugal pump, based on the nature of the tasks for which it is purchased.

The versatility of such pumping equipment allows it to be used not only for drainage, but also as a pump for pumping water from a well or well, as well as for its further transportation through a pipeline system to water intake points.

Cast Iron Centrifugal Drainage Pump

Pumps for watering from a well

These devices do a good job of providing water supply to small private houses. They are used to take clean water from a well, barrel and well. The presence of solid particles leads to breakage of devices. The advantage of such pumps is a large immersion depth and a good head

Experts VyborExpert carefully studied the characteristics of each of the 10 considered models. After comparing them, 3 winners were chosen

Livgidromash Malysh-M BV 0.12-40 10m

The well pump "Livgidromash Malysh-M BV 0.12-40 10m" of the submersible type perfectly copes with the supply of water from wells, wells and ponds. He is fixing the water supply for a small house. In order to avoid breakage, the incoming water must be clean with a maximum temperature of 35°C. It uses a vibratory mechanism that provides minimal energy consumption (240 W) and good performance (1.5 cubic meters / hour).

The maximum immersion depth and head of the irrigation unit are 3 and 60 m. The absence of rotating parts and the use of an aluminum-silicon alloy provide reliable protection and extend its service life. The tightness of the collapsible parts of the device keeps the bolts securely tightened. Due to the upper water intake, the engine of the device is protected from overheating and the possibility of suction of mechanical impurities.

Advantages:

- Light weight - 3.4 kg;

- Compact dimensions - 9.9 x 25.5 cm;

- Easy installation;

- No special maintenance required;

- Protection class IPX8;

- The optimal length of the power cord is 10 m.

Flaws:

No dry run protection.

Grundfos SBA 3-35 A

The Grundfos SBA 3-35 A model with a single-stage suction system descends to a depth of 10 m. An 800 W electric motor at a speed of 2800 rpm provides a throughput of 3000 l / h and a liquid lift of 35 m. This pump is used for watering the garden from the tank, clean ponds, as well as for pumping it with a temperature of up to 40 ° C from wells and wells.It adjusts the pressure in the water supply network and provides liquid supply for private small houses.

This unit has protection against overheating and is equipped with a flow switch. It has a floating stainless steel suction filter with a 1 mm perforation and a non-return valve. It draws in a clear liquid that is below the water table. High protection of internal elements is provided by a reliable housing made of stainless steel and composite materials that are not prone to corrosion.

Advantages:

- Long cable - 15 m;

- Average dimensions - 15 x 52.8 cm;

- Small weight - 10 kg;

- Quiet operation - 50 dB;

- Protection against operation in the absence of liquid.

Flaws:

High price.

In the reviews, the owners of the product write a lot of positive feedback about its quiet operation and the presence of a suction floating filter.

Technopribor Brook-1, 10 m

The model "Technopribor Brook-1, 10 m (225 W)" with a vibration mechanism is equipped with a 225 W motor that provides a 60 m rise in water. When lowered to a depth of 1 m, its productivity is 1050 l / h. Using the maximum capacity of 60 m, the liquid volume is reduced to 432 l/h. The unit has proven itself in the intake of clean water from ponds, wells, wells and tanks.

There are no rubbing surfaces and rotating parts in the irrigation pump, so it is characterized by uninterrupted long-term operation. The device is equipped with a thermal relay that protects the engine from overheating. The upper fence is used here, this contributes to the constant cooling of the electromagnet system. For convenience of use of the device the long cord of 10 m is provided.

Advantages:

- budget cost;

- Unpretentiousness in service;

- Small weight - 3.6 kg;

- Compact dimensions - 10 x 28 cm;

- The best indicator of pressure in the rating.

Flaws:

There are often fakes.

Main selection factors

If it is intended to use the pump in a private courtyard, then it is usually installed at the stage of arranging the sewer system. Therefore, when choosing, take into account the length of the pipes through which the pumped-out effluents will be transported. It is this parameter that will help determine the required power of the equipment. But besides him, this parameter is also affected by:

- Pipeline location;

- Estimated volumes of pumped wastewater.

However, the brand of the manufacturer, as well as the cost, are considered no less important. It should be noted here that savings when buying a pump is unacceptable. You should not buy cheap models, because the period of trouble-free operation depends on their quality. Therefore, it is better to choose expensive equipment from a trusted manufacturer than to change it every year.

Popular brands of equipment

Grundfos models

One of the most famous companies involved in the production of drainage equipment is Grundfos. Its equipment is represented by several Unilift series:

- KP;

- AP;

- CC.

Moreover, submersible pumps for dirty water of this manufacturer are assembled exclusively from parts that are manufactured at the factories of the concern.

Their quality is subject to strict control at every stage of assembly. The electric motors in the equipment are also the development of the company's specialists and are assembled here. In addition, the pumps are equipped with high-tech electronic equipment, which has a positive effect on performance and minimized energy consumption.

The company does not forget about the external design of its products. All units of the manufacturer have an aesthetic appearance and are assembled using high quality materials.

Calpeda Model

You can also trust Calpeda equipment. It produces several series of dirty water pumps:

- GM10;

- GXR;

- GMV.

The equipment from this manufacturer is distinguished by high reliability and performance, it is completely safe to operate and economical.

At each stage of assembly, the pumps undergo strict control, which guarantees high quality products. All work is carried out exclusively at factories in Italy. For any model of equipment, the manufacturer gives a guarantee of three years.

There are, of course, other companies that make submersible pumps for dirty water. Their products differ in quality and value. For example, budget options are offered by Aquatica and Dnipro-M. The cost of their equipment is no more than $50.

Operation and care

In order for the submersible pump to work for a long time and efficiently, the following should be observed:

- Select a model in accordance with the manufacturer's recommendations;

- Comply with all operating requirements set out and attached instructions.

Since equipment of this type is located in water, it is almost impossible to check whether the case has warmed up or whether extraneous noise has appeared. Therefore, the operation of such units must comply with the requirements of the manufacturer.

Watch a video about Aquatica products:

Particular attention must be paid to the oil level in the chamber that protects the engine from water ingress. The check is carried out every 15 days. At the same time, the oil is changed after 200 hours of operation, and it is added as needed.

In this case, the oil is changed after 200 hours of operation, and it is added as needed.

Another important factor in the operation of a submersible pump is the correct connection to the power source. It is recommended to use a circuit breaker or a magnetic starter for this, corresponding to the motor power. Only if all these requirements are met, the pump will serve you for a long time.

Summing up

Having learned what the equipment used for pumping dirty water is and familiarizing yourself with its technical characteristics, you can easily choose the right model.

Overview of the best brands

The modern market opens wide horizons for the selection of fecal pumps equipped with grinders. Italian, German, Spanish and other equipment is offered to customers, and each manufacturer puts up an impressive range of models for sale.

Imported products, which are present in large quantities on the modern market. The main suppliers of fecal pumps are German, Italian, Spanish companies

grundfos. Among the best manufacturers, the first place in the ranking is the company. The Germans have succeeded in the development and production of pumps for various purposes. Not without German ideas in the production of fecal equipment with a grinder.

Their Grundfos Seg model, made for professional use, is well suited for ordinary private households. Despite the cast-iron body of the device, it is easy to transport from one place to another.

The electric motor of the device is endowed with a sensitive system of protection against overheating and short circuits. There is a regulator of speed of rotation of a rotor of the electric motor.With a maximum operating power of 0.9 kW, it gives a pressure of at least 15 meters. Dives to a depth of 10 meters.

The Grundfos brand is famous for producing a wide range of garden pumps. The line of submersible pumps presented to the buyer is dominated by models for pumping clean and dirty water.

Gilex. German equipment attracts the buyer with technology, but pushes it away with a high price. It was the affordable cost, combined with good quality, that brought Dzhileks Fekalnik to second place.

The development of Russian engineers also belongs to the category of professional equipment. The effectiveness of the action and quality indicators in the work were appreciated by many users of this equipment.

"Dzhileks Fekalnik" is made of stainless steel. It can be submerged to a depth of 8 meters. The power of the device is 0.4 kW, and the productivity is 160 l / min. A reliable hermetically sealed housing, equipped with a thermal protection system, also attracts simple maintenance.

Herz. The next best representative of liquid pumping devices is another German invention, this time from Herz. Model WRS25/11 is in high demand due to its reliability, durability and wear resistance. A feature of the model is the design for use in extreme conditions.

Fecal pumps of the German manufacturer Herz attract with excellent performance, practicality and a wide range that allows you to choose equipment for pumping any volume.

The development from Herz provides a capacity of up to 260 l / min., creates a pressure of up to 14 meters and can dive to a depth of 8 meters.The weight of the pump is 31 kg due to the cast iron body and steel working parts. The motor winding has insulation class "B".

Vortex. The well-deserved fourth position in the ranking of the best is occupied by the Whirlwind fecal pump. The FN-1500L model showed good results in operation. Efficient pumping and efficient shredding of large debris. Fully automatic control of the water level in the working chamber - switching on and off when the set parameters are reached.

Device for pumping faeces brand "Whirlwind". The pump equipped with a grinder is manufactured by a Russian company. The technique has received clear recognition from users. Demand for Whirlwinds exceeds supply

The pump is capable of lifting a column of liquid up to 18 meters. The productivity of the device reaches the value of 24 cubic meters / hour. Throughput on crushed particles - 15 mm. Maximum power - 1.5 kW. Material - a steel blade of a chopper knife and a cast-iron casing of the pump itself.

A fecal pump with a self-sharpening chopper from Italian manufacturers is designed for operation in extreme conditions. The design allows diving to a depth of 20 meters. During operation, a pressure of up to 40 meters is created. Productivity indicator - 16 cubic meters / hour.

A powerful device from an Italian manufacturer is the Calpeda GMG fecal pump with a grinder, which is endowed with a self-sharpening mechanism. Equipment, the service life of which depends only on the natural wear of parts

This is how the rating of the best pumping equipment from the group of fecal systems looks like. Of course, this list should be taken only conditionally. The range of pumping equipment is very large, and only five models are not able to show the situation in full.But in the case of choosing a pump for everyday life, it is quite logical to focus on the designated list.

How to decide on the type of pump

If you want to organize the water supply of a country house or summer cottage by digging your own well, you should also take care of the method of extracting water from it. The easiest way to solve this problem is with an electric pump. Before purchasing a suitable model, it is necessary to formulate the technical requirements for the unit, which will be discussed in this section.

Submersible or surface pump for a well

For domestic use, two main types of pumps are produced: submersible and surface. Their choice is largely determined by the depth of the well and the level of the water table relative to the surface of the earth.

Surface pumps are installed on specially equipped sites or in utility rooms. For fluid intake, they are equipped with a suction pipeline with a check valve that prevents spontaneous emptying of the system. At the moment of start-up, the impeller rotating at high speed creates a vacuum that sucks water from the well, which is then pushed out at high pressure through the discharge nozzle.

Surface pump installed near the well.

The theoretically possible suction head of such pumps cannot exceed 10.3 meters. In real conditions, depending on the design features and the quality of the pump, it reaches 5-9 meters. To reduce the distance to water, such units are installed in the immediate vicinity of the mouth of the well or inside it on rigid supports or a floating raft.

Surface pump installed inside the well.

Option to install a surface pump inside the well.

The advantages of such models:

- relatively low requirements for the tightness of the structure and the quality of the materials used;

- affordable price;

- simple maintenance.

There is a way to take water with a surface pump from a depth of 25-40 m using a lowering ejector. At the same time, the piping of the unit becomes more complicated and a significant part of the power spent on the operation of additional equipment is lost.

Pumping station with a remote ejector.

Submersible pumps are lowered directly into a well or other body of water used as a source of water. They do not have problems with suction and the risk of jet rupture, but there is a possibility of picking up soil particles or plant debris. They are usually equipped with a receiving mechanical filter. The body of such units is made of expensive stainless steel, and all current-carrying elements are placed in a sealed casing.

Strengths of such equipment:

- no problems with filling and suction;

- simple start;

- compact dimensions.

During the operation of the submersible pump, it is necessary to monitor the condition of the receiving grate and prevent dry running in the event of a drop in the liquid level.

What you need to know about pump performance

The performance of the pump shows the maximum amount of water pumped by it per unit of time. It is expressed in m3/h or l/min. At the factory, it is determined under ideal conditions for the equipment. In reality, the flow rate is highly dependent on the hydraulic resistance of the system, which is usually shown in the performance curve attached to the data sheet.

When choosing a unit for a well, they are guided by the number of residents and plumbing fixtures, including the needs for watering the garden.Sometimes the fluid replenishment rate associated with the carrying capacity of the aquifer plays a decisive role. To smooth out peak loads when using not the most powerful models, pressure tanks with a supply of water or hydraulic storage tanks, which are part of pumping stations equipped with the manufacturer, help.

Pump head

The head of the pump is expressed in meters of liquid column. It is equal to the maximum height to which it can be raised, although the consumption in this case will be minimal. With a stable pumping mode, pressure is spent not only on overcoming the difference in elevation, but also on the hydraulic resistance of pipelines and fittings installed on them.

pump efficiency

The efficiency of a pump, like any other mechanism, shows the ratio of useful work to the amount of energy expended. The higher it is, the more economically the equipment is operated, the less will be the payment to power engineers. This indicator depends not only on the design of the machine pumping liquid, but also on the chosen water distribution scheme in your home. Usually, for submersible units, it is somewhat higher than for surface units, since they do not have to expend suction forces.

Which pump is suitable for pumping water

When choosing which equipment suits you best, you need to take into account its features. The water pump can be manual or mechanized (automatic):

Mechanized pump

The mechanized pump can be surface or submersible

- the surface pump is located near the water;

- the submersible pump is installed directly into the water.

When using a surface pump, a rigid pipe is installed in the water, and a flexible garden hose is used to drain. The surface pump is easier to monitor and easier to repair.

To carry out heat removal, it is necessary to equip the pump with a fan and fins. The surface unit is unable to remove the liquid completely and stops working when a large volume of air enters the intake pipe. Another limitation is that the maximum intake depth is 9 m. It is better to use such a pump for pumping water once.

Fecal pumps UNIPUMP

A submersible pump can pump out almost all the water. Only a few millimeters remain. And by equipping a drainage pit, you can get a completely dry floor. It works quietly, easily tolerates air ingress. Due to the fact that it is in water, it does not require cooling. Such pumps are equipped with floats, which allows them to be left in the pit, and they can automatically turn on and off. They can take water from great depths. But submersible equipment is much more expensive, which is explained by the need to use a sealed hull, non-corrosive materials and a float mechanism.

Submersible pumps according to their purpose are:

- for wells;

- for wells;

- fecal;

- drainage.

Drainage pumps pump out small solid waste along with the liquid. To avoid damage to the mechanical parts of the pump on the lower cut of the pipe, a filter made of mesh with small cells. The filter is made of a material that is not subject to corrosion. The filter will not allow solid particles to enter the inside of the pump.

Hand pump

A hand pump for cottages is indispensable, especially in the absence of electricity.Suitable for pumping small volumes of water, eliminating flooding of a small depth in the basement and for taking water from 8-9 m.

Mechanized pump

This is a piston device. The piston creates a vacuum, and the water rises. Such a unit is usually used as a backup equipment.

Best Inexpensive Drainage Pumps

Such models belong to the price category up to 2500 rubles. They are equipped with low power engines and reliable particulate filters. The mesh size is optional, so the devices are used for pumping not only clean, but also contaminated water.

Whirlwind DN-300 68/2/6

4.8

★★★★★

editorial score

89%

buyers recommend this product

See review

The model is equipped with a thermal protector that regulates the temperature of the electric drive and turns it off when it reaches a critical point, which reduces the risk of rapid wear. The filter passes particles up to 5 mm in diameter, preventing clogging of the hose and increasing pump performance.

The power of the unit is 300 W, the volume of pumped liquid per minute is 183 liters. Small dimensions and low weight guarantee easy storage and transportation of the device for installation at various sites.

Advantages:

- compactness;

- overheat protection;

- offline work;

- light weight;

- shockproof body.

Flaws:

noisy.

Whirlwind DN-300 68/2/6 easy to use lightweight and compact pump. It is worth buying for pumping clean or slightly polluted water - a great helper in the household.

Leberg GP250 UT000008999

4.8

★★★★★

editorial score

88%

buyers recommend this product

See review

The main features of the model are long service life and comfort in use.It is provided by a low noise level of the pump during operation, which allows it to be installed in a residential area or operated at night. The fiberglass body and technopolymer reinforcement make the device lightweight and impact resistant.

Ball bearings do not require lubrication throughout the life of the unit, and a transport handle with a latch ensures comfort when carrying the device. Additional features include overheating protection provided by a thermal relay.

Advantages:

- low noise level;

- Ease of use;

- durability;

- automatic operation;

- long network cable (10 meters).

Flaws:

shallow immersion depth.

Leberg GP250 functions properly when installed both in pools or wells with clean water, and in small reservoirs. A one-stop solution to water supply problems at an affordable price.

Stavr NPD-810

4.8

★★★★★

editorial score

86%

buyers recommend this product

See review

The universal mounting connector and the included coupling with adapter make it easy to use the pump with both detachable and already installed hoses on the job site.

The engine power of the device is 810 W, the maximum immersion depth is 6 meters. This ensures stable pumping of water from shallow wells or wells at a rate of up to 208 liters per minute.

Advantages:

- simple installation;

- powerful engine;

- float switch;

- long service life;

- corrosion resistance.

Flaws:

fragile body.

Stavr NPD-810 can be used for efficient pumping of both clean and contaminated water.Quick installation and high performance make it suitable for intensive use.

Parma ND-250/5PV

4.7

★★★★★

editorial score

85%

buyers recommend this product

See review

The user of the device has two modes of operation - manual and automatic. When the first one is activated, the pump runs constantly. Automatic mode involves turning off the engine when the liquid level drops below the set threshold. This provides an effective solution to everyday or unforeseen tasks.

The maximum productivity is 6000 liters per hour. The cable length is 10 meters. The insulated power connector is reliably protected from moisture and dirt, so that the unit can be used not only indoors, but also outdoors.

Advantages:

- optional mode of operation;

- ease of transportation;

- overheat protection;

- long cable;

- high protection class.

Flaws:

low performance.

Parma ND-250/5PV will be an excellent acquisition for pumping liquid during flooding or providing water supply to an irrigation system.

Which brand of drainage pump to choose

Today, the drainage pump market offers a wide selection of different models from domestic and foreign manufacturers. At the same time, the quality of the devices is quite high, and the reliability is high even for budget units. The main difference between the models from each other is the performance and purpose for a certain concentration of pollution.

However, some manufacturers qualitatively differ from others in the variety of the model range and the versatility of their products.So, not every pump can be operated for pumping heavily polluted media, but manufacturers, given this fact, produce various modifications of the same model.

We have compiled a small list of the best drainage pump manufacturers based on positive reviews:

- GILEX

- Belamos

- PATRIOT

- GARDENA

- AL-KO