- The principle of operation of make-up

- Why is it needed?

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

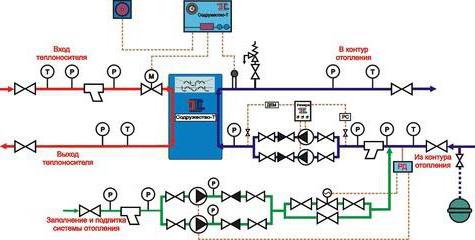

- Automatic filling system

- Signs of a critical shortage of coolant

- Types of make-up valve control

- Up-to-date tips on equipment and maintenance

- Open heating system and what is it?

- Principle of operation, pros and cons

- 5 Principles for safe use

- Where is the best place to install

- Where to put the circulation pump?

- Features of feeding an open heating circuit

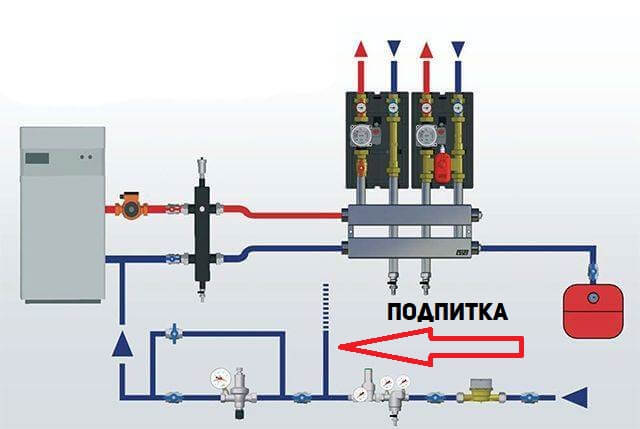

- Ways to feed the heating system from the water supply

- Where to install?

- Mounting

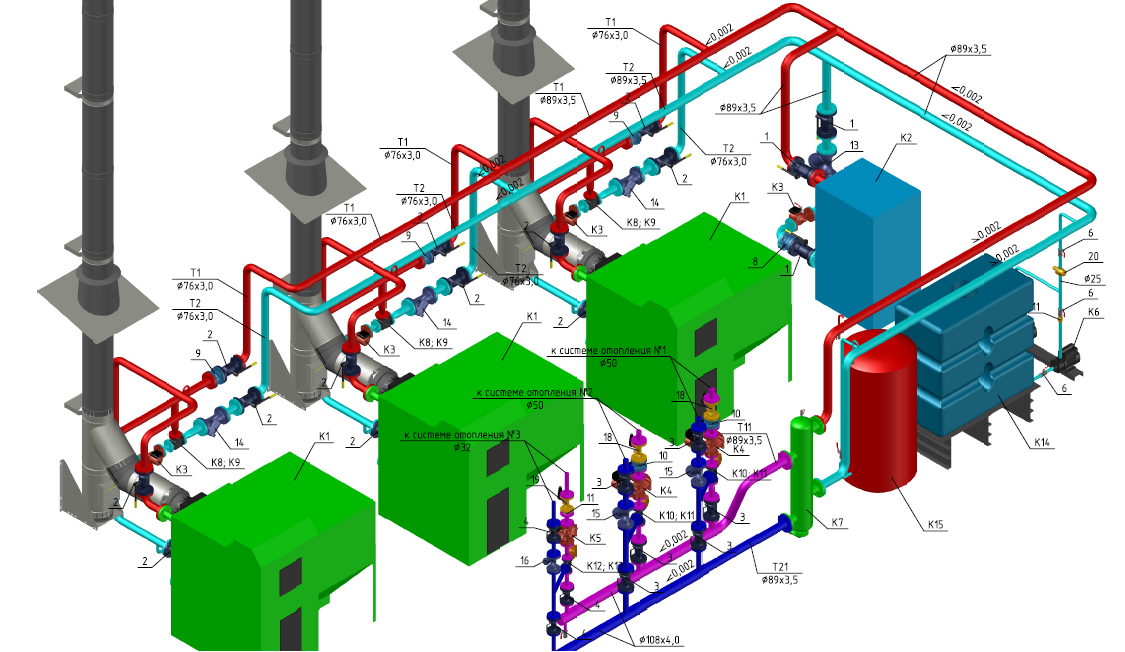

- Feeding a closed-type network: diagrams, instructions

The principle of operation of make-up

The principle of operation of make-up

The principle of operation of make-up

Make-up is needed to restore the volume or pressure in the heating system. When the device adds working fluid, it automatically stops after equalizing the main indicators. Most often, the equipment is connected to a cold water supply, liquid is taken from there. Another option is a storage tank, where you have to manually replenish the stock, and is usually intended for synthetic products.

Two types of heating make-up have been developed:

- Manual. Designed for small closed circuits where small pressure surges occur.A manometer is used to detect leaks in a timely manner. When the pressure drops, opening the corresponding tap supplies water, thereby compensating for losses. The liquid flows between the pipes either independently or with the help of a special pump. Budget solutions have an overflow pipe in the expansion tank, when the water reaches this mark, the liquid supply is stopped. The only disadvantage of such a device is the need for constant supervision and experience in performing the procedure.

- Automatic. The equipment independently processes data from the pressure gauge. When the critical point is reached, the working fluid supply valve opens. As with manual control, the pressure in the cold water supply is sometimes not enough, so pumps are installed. When water losses in the heating system are restored, the valve closes. The advantage over the manual method is the automation of the process. When leaving home for a few days, there is no need to worry that the boiler will overheat or fail. The disadvantage is the increase in electricity costs.

The need for recharge does not always arise. So that the equipment does not stand idle, it can be used for other purposes. It is able to fill the pipeline with water or synthetic coolant. The equipment will come in handy at the beginning of the heating season, when the entire system is pressure tested. And also the device is suitable for flushing pipes, discharging water or filtering it from coarse particles.

Why is it needed?

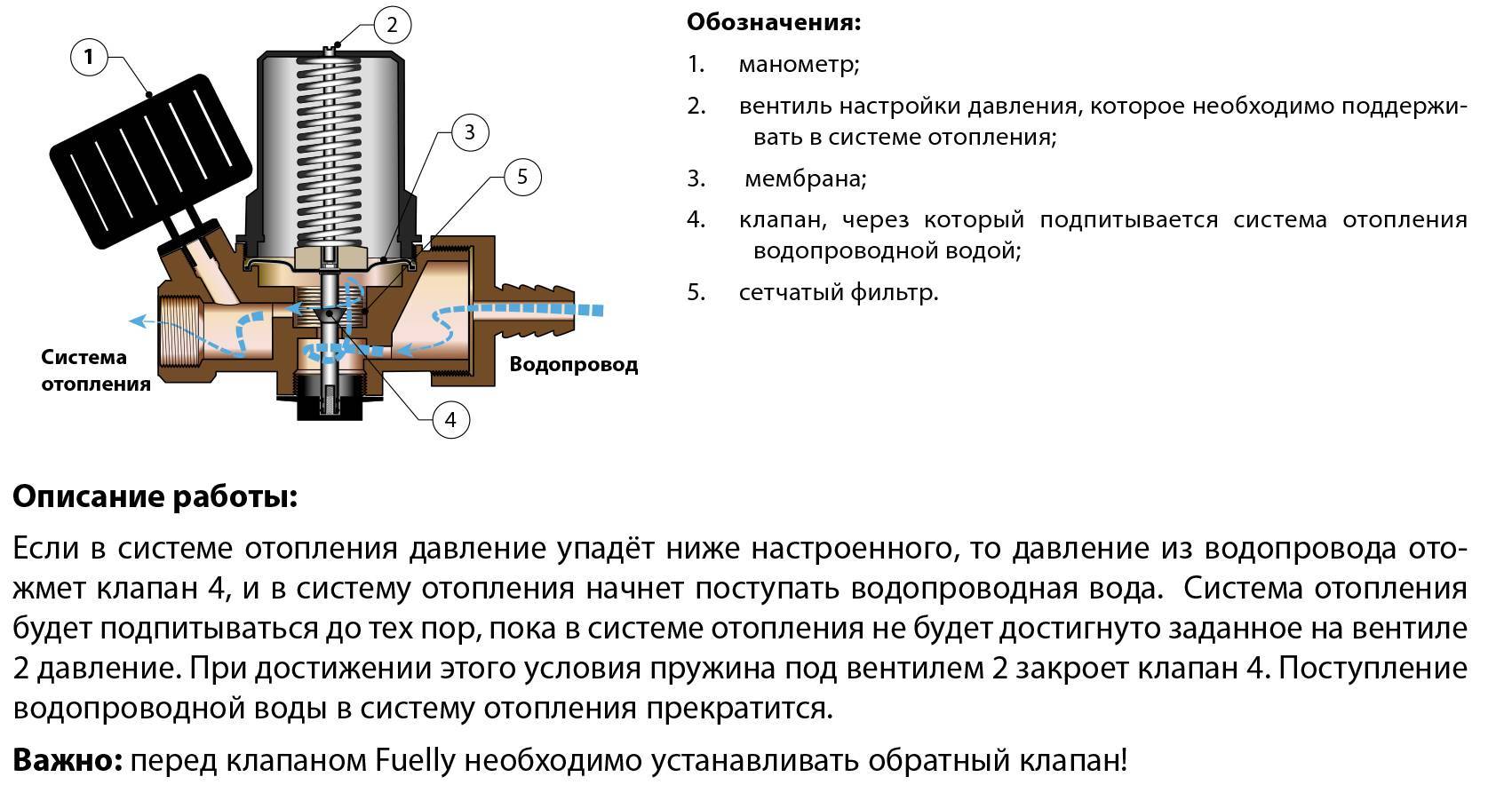

The make-up valve is necessary to maintain the minimum pressure of the heating system within the specified parameters, pumping water from the water supply system. Normal pressure for heating is from 1.5 to 3 bar, water supply - from 2.5 to 6 bar.In the event of a pressure drop for any reason, the make-up valve will automatically restore it.

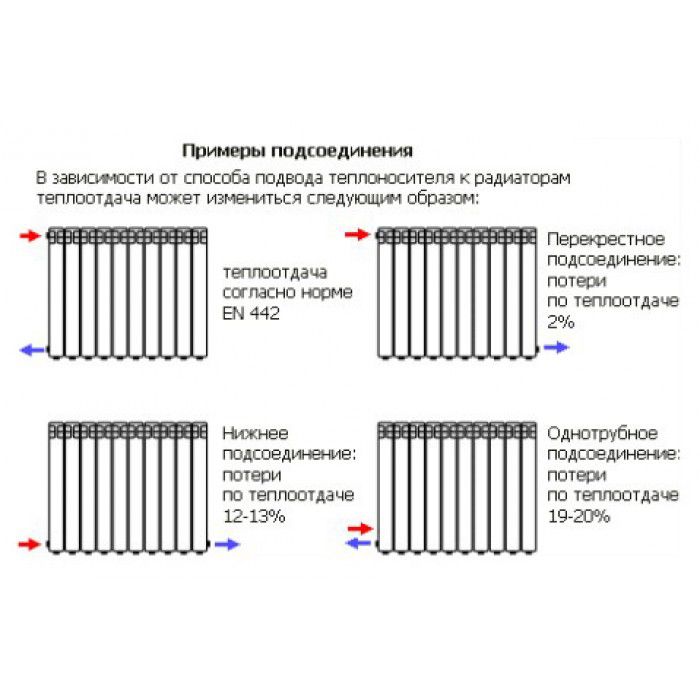

By standards, the valve is mounted on a pipe where ordinary water circulates. That is, on a pipe that is connected to a water supply system. It is worth remembering about this, since purified water is used for the heating system (it leaves less plaque from the inside of pipes and batteries).

At the same time, the usual tap water was not filtered. It would be rational to put a small filter at the inlet and replace it periodically. So you will save pipes and joints from the rapid accumulation of deposits.

The make-up valve is installed only in the heating system, where the heat carrier is water. If antifreeze is flooded, then non-metered dilution of the “anti-freeze” can contribute to precipitation, and this, in turn, will have a bad effect on the entire heating system.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Filling instructions heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices.They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a manual pump for filling the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

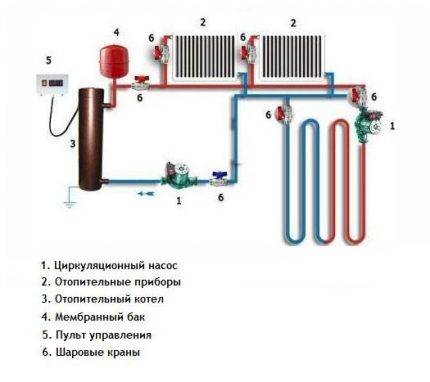

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system.Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Signs of a critical shortage of coolant

Not all owners of private houses monitor the technical condition of water heating, it works - and all right. When a latent leak forms, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is tracked by the following signs:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipe overheats, turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way, in addition, the gurgling of water in the riser is heard.

- On the gas heater (open circuit), there are frequent starts / burner starts - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall models of gas boilers automatically stop when they fall below the threshold of 0.8 bar.

- Floor-standing non-volatile units and solid fuel boilers continue to properly heat the remaining water in a closed system until the volume released by the coolant is filled with air. The circulation will stop, overheating will occur, the safety valve will work.

We won’t explain why we need to recharge the system - this is an obvious measure to keep the heating working. It remains to choose a method of replenishing the heating system.

Types of make-up valve control

There are two types of heating system make-up valve:

- mechanical;

- auto.

A mechanically controlled device can be mounted in compact heating systems due to the fact that the tank membranes influence the increased pressure there. In this case, the volume of liquid can be made smaller by yourself, simply by opening the water supply tap.

However, in order to carry out these works at the right time, a little experience is required. Due to the fact that it is necessary to regularly adjust the pressure values \u200b\u200binside the heating system and the volume of liquid. If there is a lot of coolant, then emergency situations will arise with a high probability. An automatic type valve must be installed in large heating systems where there are many circuits.

In modern models of boiler equipment, an automatic valve (also called a pressure reducing valve) is included as standard. To be more precise, this device is part of automation. Separately, it is possible to install a make-up reducer only if the entire circuit depends on electrical energy.

Automatic feeding valve for Huch EnTEC Fuelly heating system

Up-to-date tips on equipment and maintenance

Whichever power plant you choose, remember that, first of all, it must be safe and easy to use, made of high-quality materials. If the heating system is small, give preference to a device with the simplest possible design. The central caliper with moving parts and the internal compensation piston must necessarily be made of materials with a low adhesion coefficient: the risk of limestone formation in the assembly must be minimized.It is no secret that they are the main reason for the poor performance of the device.

Pay attention to whether the product has a replaceable cartridge: this will greatly facilitate and speed up the process of revising the assembly for you. Periodic maintenance of the make-up device will help to avoid malfunctions in the entire heating system.

Periodic maintenance of the make-up device will help to avoid malfunctions in the entire heating system.

To clean or replace the entire cartridge, proceed as follows:

- Isolate the installation.

- Unscrew the control knob located at the bottom.

- Unscrew the adjusting screw as far as it will go and remove the cover.

- Remove the cartridge with pliers.

- After the necessary manipulations, assemble the device again.

It remains only to re-configure the equipment and continue to enjoy the uninterrupted operation of the heating system in your home!

(1 vote, average: 5 out of 5)

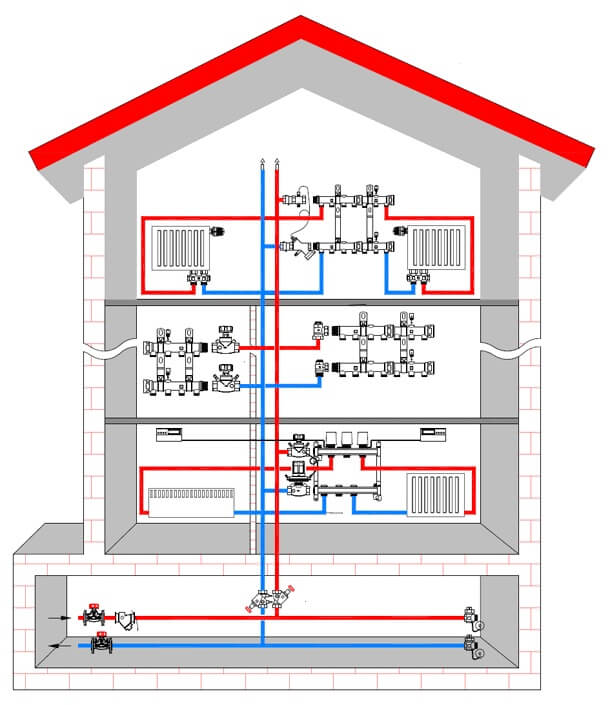

Open heating system and what is it?

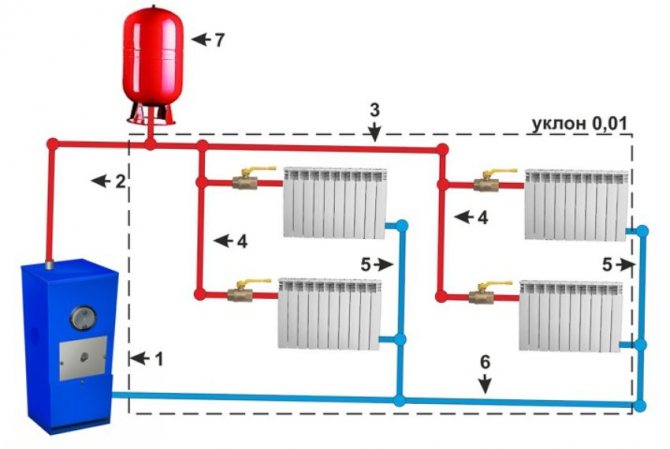

Open-type heating does not have high pressure, which is artificially injected. An open expansion tank is installed in the network. It is needed to compensate for the thermal expansion of the liquid, it is mounted at the highest point of the circuit. Compensation capacity simultaneously serves as an air vent.

Principle of operation, pros and cons

An open-type heating system can only work with a liquid heat carrier in the form of water. The principle of operation of a network with a natural coolant current is based on the laws of thermodynamics. The flow of liquid through the pipes occurs due to the different density of heated and cooled water, as well as the slope of the pipelines. The excess of the expanded liquid is fed into an open-type expansion vessel. This helps to stabilize the pressure.

Advantages of open heating:

- The main advantage is reliability and durability.

- A simple layout of an open heating system ensures ease of installation.

- The operation of the heating circuit does not need to be adjusted. After filling the network with water, it is enough to turn on the boiler, the system starts working.

- In networks with gravitational fluid current, there are no noises and vibrations.

- An open heating system with a circulation pump is called universal, because in case of power outages, it is possible to switch to work with a gravitational fluid flow if the pump is installed on bypasses.

- An efficient heating system allows you to constantly maintain a comfortable temperature in the room.

There are also many disadvantages of open networks:

- Open circuits are not used in large houses, since the system is in static equilibrium at a distance of more than 30 meters from the boiler.

- The main disadvantage is the inertia of the network. With a significant amount of coolant, the system starts up for a long time.

- Networks are assembled from pipes of different diameters, including large sections, so you will need various spurs and adapters.

- For the gravitational flow of the liquid, the return pipeline is laid at a slope. It is not always possible to do this.

- The expansion tank is mounted at the highest point of the network (usually in the attic), so the room has to be additionally insulated so that the coolant does not freeze.

- It is necessary to periodically check the water level in the tank, as it evaporates. The problem is solved by a float valve or a layer of oil on the surface of the water.

- During operation of an open heating system with a pump, noise and vibrations are observed.

- In an open tank, the coolant is constantly in contact with air, which is why it is saturated with oxygen. This leads to corrosion of metal elements.

5 Principles for safe use

During operation, it is very important to correctly fill the water and partially refuel. You need to follow simple guidelines:

- 1. When topping up the system, open the valve ¼ of the lever travel and top up slowly. Such actions will prevent the formation of air pockets and temperature fluctuations.

- 2. If refueling is carried out from scratch, then it must be done with the pump turned off and the heat generator not working.

- 3. It is necessary to determine the pressure in the expansion tank, and also check all radiators by turning the Mayevsky taps to release air.

- 4. If the system is equipped with modern electronics, you should carefully study the instructions and points regarding refueling. In some cases, you need to enable special mode.

- 5. Excess pressure is easily released through the air vent.

The feed valve is necessary to maintain a stable level of coolant in the heating system. The selection and installation of this part is not difficult. Compliance with simple rules of operation will ensure proper and long operation of the equipment.

Where is the best place to install

The "zero" point of any heating network is considered to be the point of insertion into the expansion tank circuit. It is here that, theoretically, it is supposed to connect the valve for automatic feeding of the heating system.However, in practice, the installation of such equipment in this place may, unfortunately, not be the best option. The fact is that expansion tanks in heating systems are often mounted directly next to the boilers.

In this case, the incoming return water will mix with water from the water supply and enter the boiler too cold. This can lead to malfunctions of the heating unit or even to its breakdown. Therefore, the automatic make-up unit is usually simply carried a little further than the expansion tank and cut into the return line.

It is also possible to connect such equipment to a hot water supply. In this case, the node, of course, can be placed next to the expansion tank and boiler.

In any case, experts do not recommend installing make-up equipment at the supply. This can damage valves and filters. After all, the water in the supply pipe flows very hot.

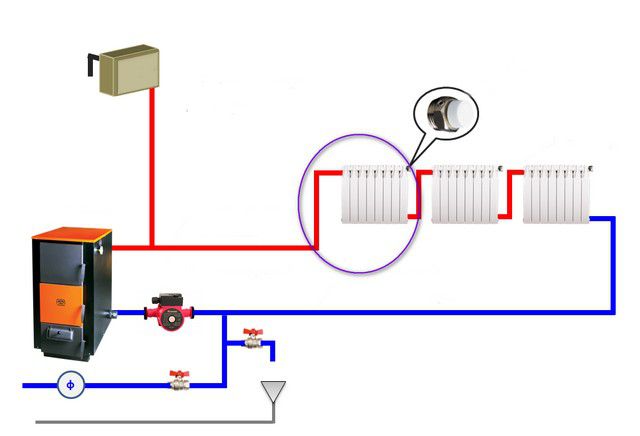

Where to put the circulation pump?

Most often, the circulation pump is installed on the return line, and not on the supply. It is believed that there is a lower risk of rapid wear and tear of the device, since the coolant has already cooled down. But for modern pumps this is not necessary, since bearings with so-called water lubrication are installed there. They are already designed specifically for such operating conditions.

This means that it is possible to install a circulation pump in the supply, especially since the hydrostatic pressure of the system is lower here. The installation location of the device conditionally divides the system into two parts: the discharge area and the suction area. The pump installed on the supply, immediately after the expansion tank, will pump water out of the storage tank and pump it into the system.

The circulation pump in the heating system divides the circuit into two parts: the injection area, into which the coolant enters, and the rarefaction area, from which it is pumped out

The circulation pump in the heating system divides the circuit into two parts: the injection area, into which the coolant enters, and the rarefaction area, from which it is pumped out

If the pump is installed on the return line in front of the expansion tank, then it will pump water into the tank, pumping it out of the system. Understanding this point will help to take into account the features of hydraulic pressure at various points in the system. When the pump is running, the dynamic pressure in the system with a constant amount of coolant remains constant.

It is important not only to choose the optimal place for the installation of pumping equipment, but also to install it correctly. We recommend that you familiarize yourself with the nuances of installing a circulation pump

The expansion tank creates a so-called static pressure. Relative to this indicator, an increased hydraulic pressure is created in the injection area of the heating system, and a reduced one in the rarefaction area.

The rarefaction can be so strong that it reaches the level of atmospheric pressure or even lower, and this creates conditions for entry into air system from surrounding space.

In the area of pressure increase, air can, on the contrary, be pushed out of the system, sometimes boiling of the coolant is observed. All this can lead to incorrect operation of heating equipment. To avoid such problems, overpressure must be ensured in the suction area.

To do this, you can use one of the following solutions:

- raise the expansion tank to a height of at least 80 cm from the level of the heating pipes;

- place the drive at the highest point of the system;

- disconnect the accumulator branch pipe from the supply and transfer it to the return line after the pump;

- install the pump not on the return, but on the supply.

Raising the expansion tank to a sufficient height is not always possible. It is usually placed in the attic if there is the necessary space.

At the same time, it is important to follow the rules for installing the drive in order to ensure its trouble-free operation.

Detailed installation recommendations and connection of the expansion tank, we have given in our other article.

If the attic is not heated, the drive will have to be insulated. It is quite difficult to rearrange the tank to the highest point of the system with forced circulation, if it was previously created as natural.

Part of the pipeline will have to be redone so that the slope of the pipes is directed towards the boiler. In natural systems, the slope is usually made towards the boiler.

An expansion tank installed indoors does not need additional protection, but if it is installed in an unheated attic, care should be taken to insulate this device

Changing the position of the tank nozzle from supply to return is usually not difficult to perform. And it is just as easy to implement the last option: to insert a circulation pump into the system on the flow line behind the expansion vessel.

In such a situation, it is recommended to choose the most reliable pump model, which can endure contact with the hot coolant for a long time.

Features of feeding an open heating circuit

Features of feeding an open heating circuit

Features of feeding an open heating circuit

The open system has an expansion tank. It is installed in the highest part of the "highway". It helps to cope with the thermal expansion of water, compensating for pressure in heating.To determine the liquid level, a control tube is brought out of the tank into the kitchen or into the bathroom. A stop valve is installed at the end of this tube, it will help to avoid leakage of excess water.

During the control time, the valve opens. If the water is flowingthen everything is fine. Otherwise, the water level must be replenished immediately.

The gravity heating system has three main elements:

- a ball valve is necessary to transfer the coolant from the water supply to heating;

- the filter helps to eliminate dangerous impurities;

- the non-return valve protects against mixing of drinking water and liquid from the heating system.

Ways to feed the heating system from the water supply

The easiest way is to do it yourself. It is enough just to lay a section of pipes that will connect the return line and the central water supply. A shut-off valve and a filter are also mounted here.

The scheme of the heating system is quite simple. The feed pipe is mounted to the check valve in front of the pump, because it is on this part that the pressure and temperature are lowest. But despite its simplicity, such a system has its drawbacks.

Disadvantages of manual feeding:

- The volume of liquid in the pipes requires constant control of the owner. You will have to constantly look into the expander of the open system and follow the pressure gauge if the tank is closed.

- The amount of make-up water also needs to be adjusted.

With open systems, it is better to add water directly to the expansion tank. This will make maintenance easier as you don't have to constantly climb into the attic to check. This can be achieved by welding 3 auxiliary pipes to the tank.

Where to install?

Masters recommend attaching a make-up valve for the heating system near the expansion tank. And this is logical, because the tank always works, and, of course, immediately after the pressure drops due to the operation of the tank, it is automatically adjusted by the valve.

Pressure instability is short-lived and will not affect system performance.

It is not necessary to install the automatic feeding valve of the heating system on the return circuit near the boiler. Otherwise, a dose of cold liquid may cause malfunctions.

It is not necessary to carry out the installation of the device on the supply circuits. Otherwise, too hot water can damage the elements of the assembly itself.

Mounting

Installing a make-up valve involves:

- Installation work should begin with the preparation of the assembly, having packed all the threaded connections: on the one hand, a polypropylene American 20x1 / 2 is installed, on the other hand, an end sleeve 20x1 / 2.

- Now you need to solder the mounting taps, install a standard pressure gauge and connect the assembled unit to any point in the heating system.

- Now the question arises of how to adjust the heating system feed valve. After all, in order to put the assembled system into operation, it needs to be adjusted to the required pressure. To do this, there is a pressure adjusting screw on the top of the device. It must be unscrewed completely and slowly twisted then back. The rising pressure is controlled by a manometer.

- Having set the required pressure, it is necessary to securely fasten the screw with a lock nut. The lower handle of the locking device overlaps, and when unscrewed, it opens.

After the make-up valve has been adjusted, the system can be considered ready for operation.

Installation of the make-up valve for the heating system

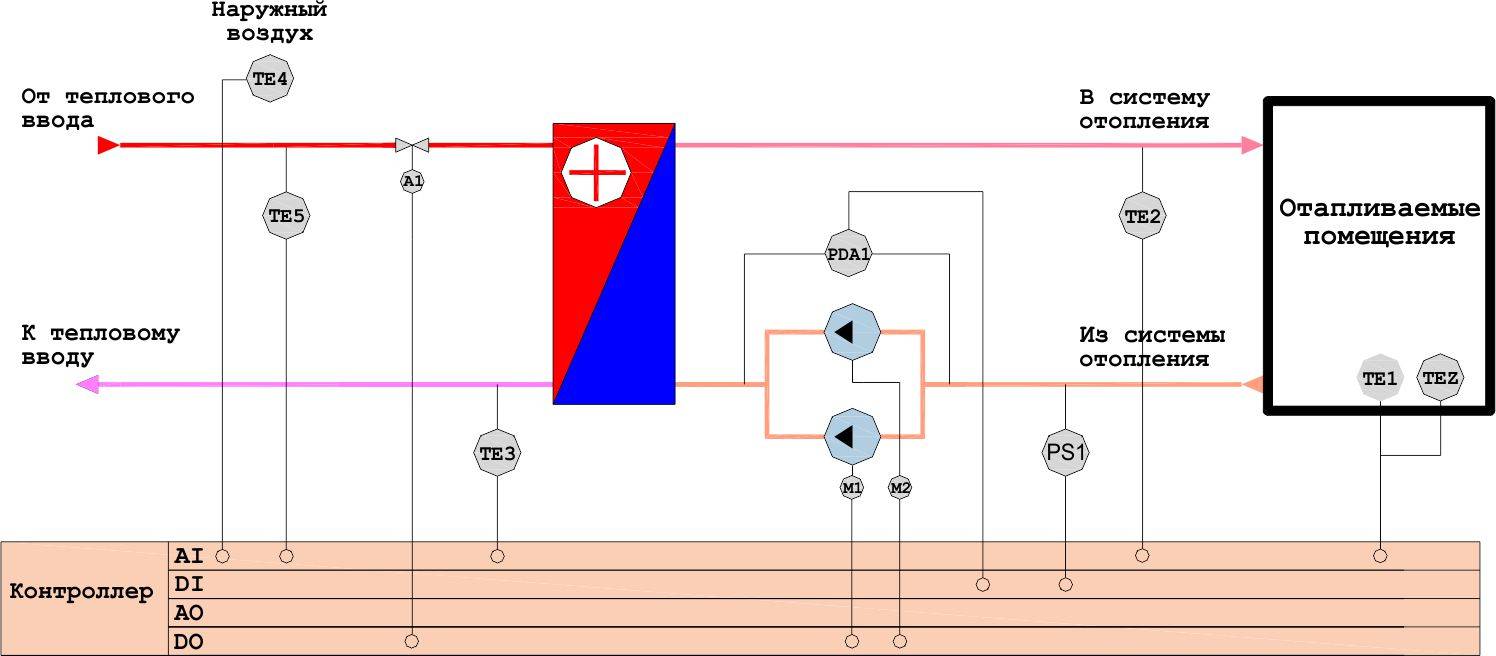

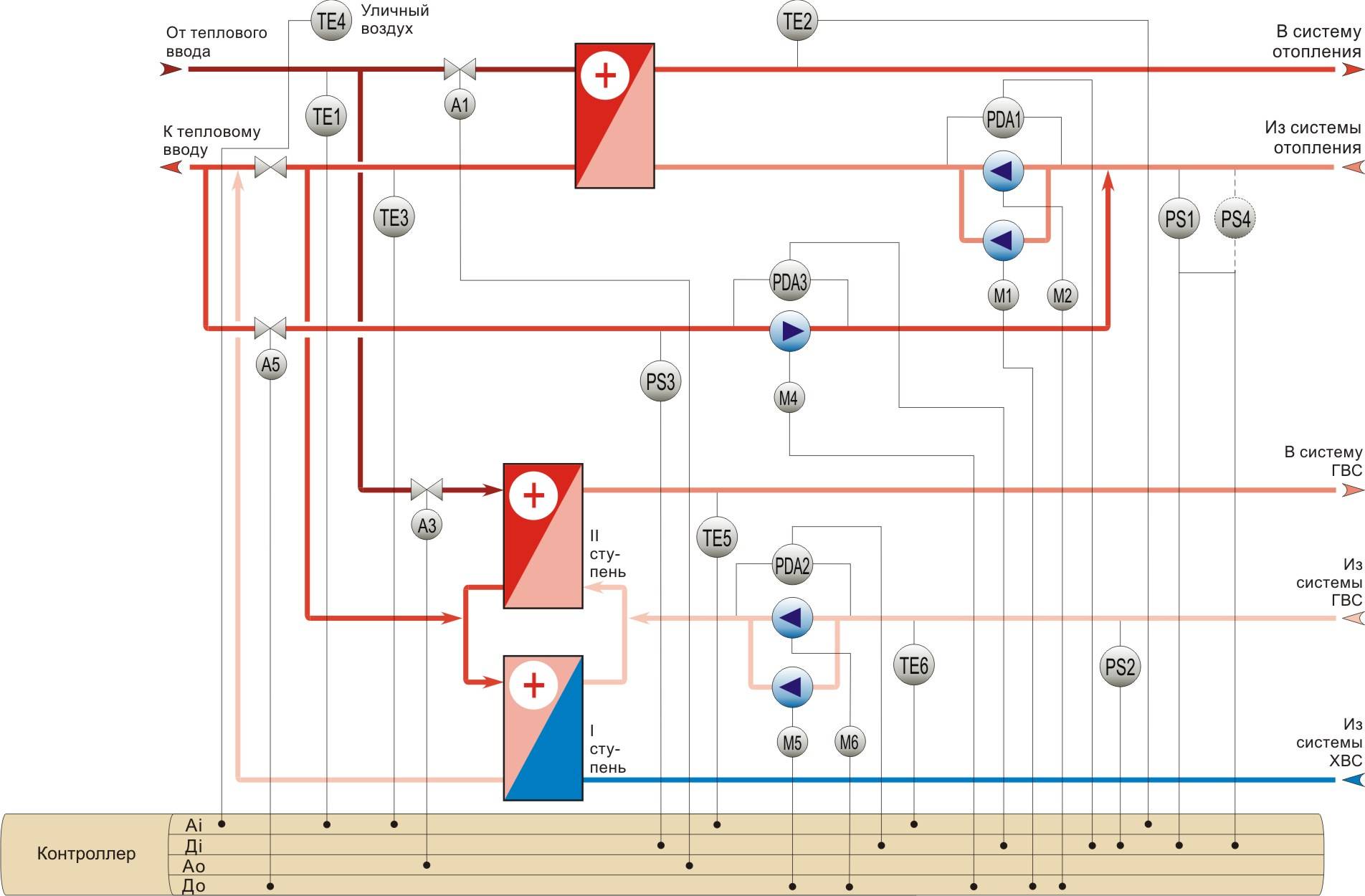

Feeding a closed-type network: diagrams, instructions

If the line is closed, then the pressure in it, as noted above, is increased, therefore, the previous scheme will not work in this case. Here it is necessary to install exclusively an automatic make-up valve. The principle of operation of such a valve is described above, but we will consider a simple scheme for its installation, which can be done by hand. It consists of several elements (in the following order): tap -> pressure gauge -> feed reducer.

By the way, it is the gearbox that is the main element of this system. It consists of several elements below.

The device and features of a closed heating system

Earlier we talked about how a closed heating system is arranged, in addition to this article, we advise you to read this information, see all the details here

- Stopper platform restricting the flow of fluid from the feed pipe.

- Adjustment unit, which includes a membrane and a special rod with a spring. The block itself is located on top of the device.

- Check valve - we have already considered its function.

Video - Make-up reducer

First, the minimum pressure in the network is set using the adjustment unit. During this time, the working fluid will contact the diaphragm, preventing the stem from dropping. And after the pressure drops below a predetermined mark, the spring will press on the rod and it will still fall. As a result, the damper will be opened, and water from the pipeline will begin to flow into the heating network. And when the pressure returns to normal, the rod will return to its original position, stopping the supply of coolant.

The reducer should be installed on the "return" pipe directly at the entrance to the boiler, since it is here that the pressure is minimal.If the system is equipped with a circulation pump, then the feeding unit should be marked already in front of it, otherwise, when it (the pump) is operating, the pressure may “jump”, which, in turn, leads to false activation of the gearbox.

Note! The volume of passage ranges from 6 to 12 liters per minute, a more specific figure depends on the set value. As a conclusion

As a conclusion

Feeding the heating system helps to avoid utility emergencies. Moreover, it supports the required working fluid pressure in the system. As for the feed valves specifically, automatic devices allow you to control these processes remotely.