- Electrical

- Step 6. Make a finishing screed

- Substrate for IR foil underfloor heating

- Features of laying insulation

- No. 1 - slab laying technology

- No. 2 - installation of roll materials

- No. 3 - mat mounting scheme

- Laying technology: a set of basic rules

- What substrates to choose for electric underfloor heating

- Features of installing laminate on a warm water floor

- Step 1. Selection of tools

- Step 2. Consider all the features of the laying of the laminate flooring

- Step 3. Start assembly

- Characteristics of substrate equipment materials

- Laminate

- What is

- Indicators

- Material characteristics

- How to lay a laminate with your own hands: substrate options and why you need it

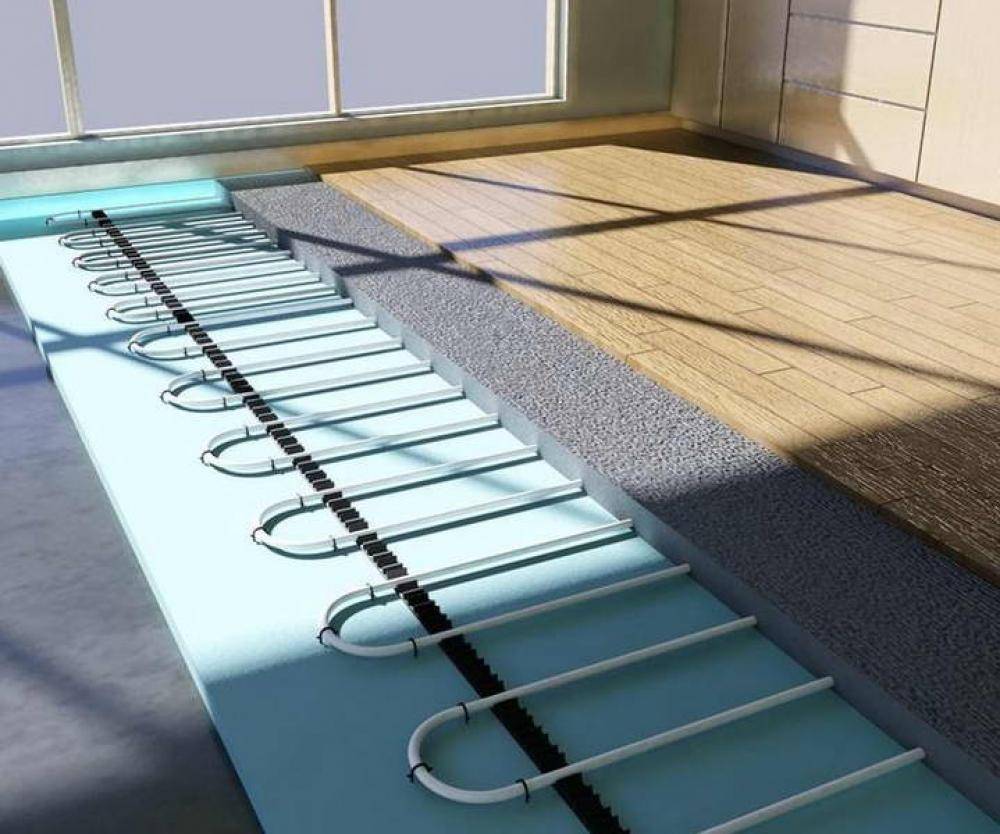

Electrical

Heating occurs due to the energy released by the conductors under the action of an electric current.

By their design, warm floors of this type are film, that is, infrared, and cable, having a heating element in the form of simple flexible cables with conductive elements inside. During the installation of electric floors, complications can arise, so you should take into account all the parameters of the existing wiring in advance, as well as correctly calculate the protective fittings.

In order for the heating to be effective, the calculated power per 1 m 2 must be at least 0.25 kW

When installing a warm floor, it is very important that the substrate for the warm floor is chosen correctly. There are a wide variety of substrates, and each of them is designed to perform specific functions.

Step 6. Make a finishing screed

The recommendation of professionals is to use "dry" building technologies.

Semi-dry screed

Semi-dry screed and warm floor

Wet concrete can leak, takes a long time to cool, and is heavy. All three factors can have negative consequences for the heating system.

The screed is best made from a semi-dry mixture. For its manufacture, the usual proportions of sand and cement (one to three) are taken and thoroughly mixed. This can be done manually or with a concrete mixer.

But water should be added carefully and in small portions. The readiness of the solution is checked simply: squeeze it in a fist

If the mixture holds together and at the same time no water comes out through the fingers, everything is fine, you can work with it. Further, everything is according to the well-known algorithm - the installation of beacons and work with a screed.

Preparation of a mixture of semi-dry floor screed

There are several nuances during work with a screed along the contour of the water supply.

- The first. There are problems with the installation of beacons. Modern metal rails are not suitable, you need to use the old technology. Make beacons from a mixture, pour longitudinal lines from it at a distance slightly less than the length of the trowel. Using the level to catch the horizontal. In order to speed up the setting time of the beacons, you can sprinkle them with dry cement several times. If there is not enough experience with the rule, then you need to put even metal or wooden planks on the beacons.They will not allow the position of the top surface of the beacons to be violated by pressing the rule too hard.

- Second. During the production, try not to step on the joints and fixing of the pipes, they can become loose or completely slip out. This applies to those cases when the pipes are fixed with brackets directly to the insulation boards.

Semi-dry screed with fiberglass. Laying process

Dry screed has sufficient strength for installation of all types of finishing floor coverings, including those made of heavy natural stone. In addition, this method makes it possible to significantly reduce the consumption of building materials and reduce the time of work. You can start further work with the floor after 12 hours. For wet concrete, the time is at least doubled.

Semi-dry floor screed ready

This completes the construction work, you can connect the heating to the adjustment and control system.

Substrate for IR foil underfloor heating

If it is planned to equip infrared warm floors, then the main parameters that determine their proper functioning are:

- Proper installation (in strict accordance with the instructions);

- Laying the substrate with the heat-reflecting surface up.

The substrate under the film underfloor heating is made of the following materials and taking into account the recommendations below.

- Magnesite slabs or fiberboard sheets. Before laying them, aluminum foil is laid directly on the pre-arranged screed. And actually the substrate is placed on it. A foil underfloor underfloor heating can be used.

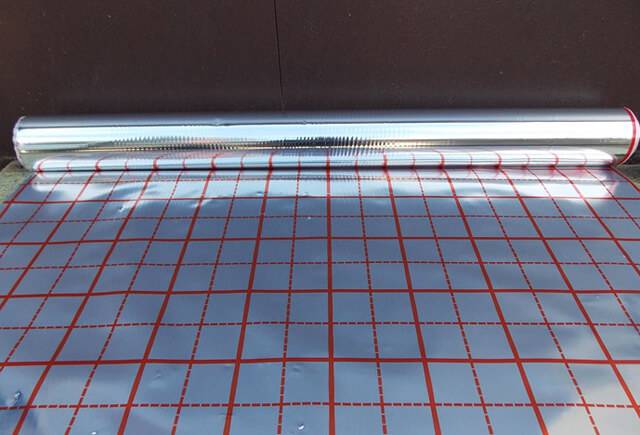

- If a metallized polymer film is used as a substrate, it should be laid with the reflective side up (toward the film floor with IR resistors). The result is a thin, highly elastic, quite flexible and environmentally friendly solution.

- Insulation is laid over the entire area, on which it is planned to lay an IR film floor in the future. The substrate sheets are laid end-to-end, and the seams formed in this case are glued with metallized adhesive tape. That creates the necessary vapor barrier and gives the substrate the required waterproofing qualities.

Find out in detail about choosing the right warm infrared floor.

Features of laying insulation

The substrate mounting scheme depends on the type of materials used. But in any case, it must be placed on the most even surface.

No. 1 - slab laying technology

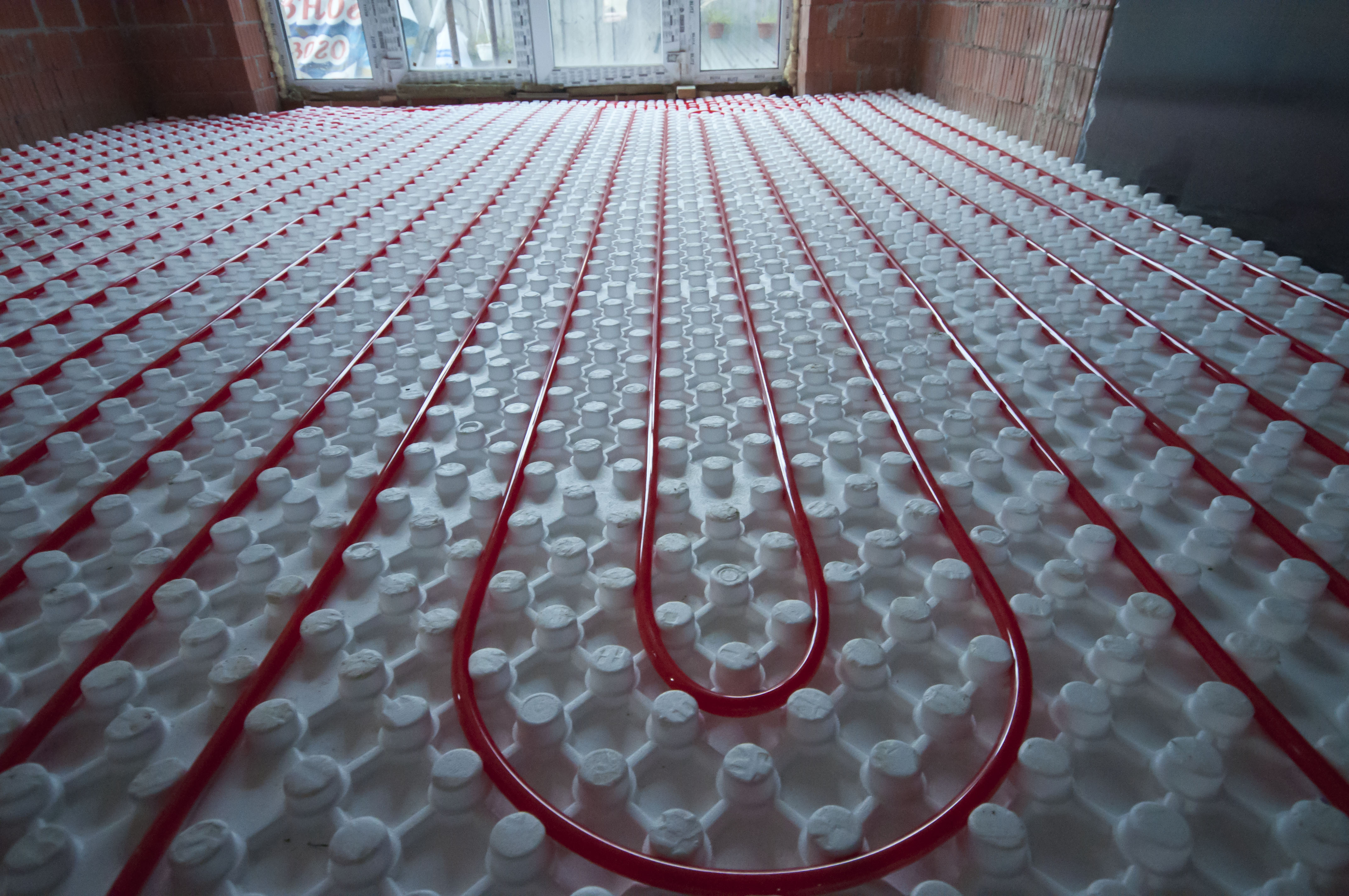

The substrate, constructed from boards with mounting chamfer, is assembled easily - according to the principle of the designer. Plates are easy to fit and measure. You can cut the plates to the appropriate dimensions with an ordinary knife.

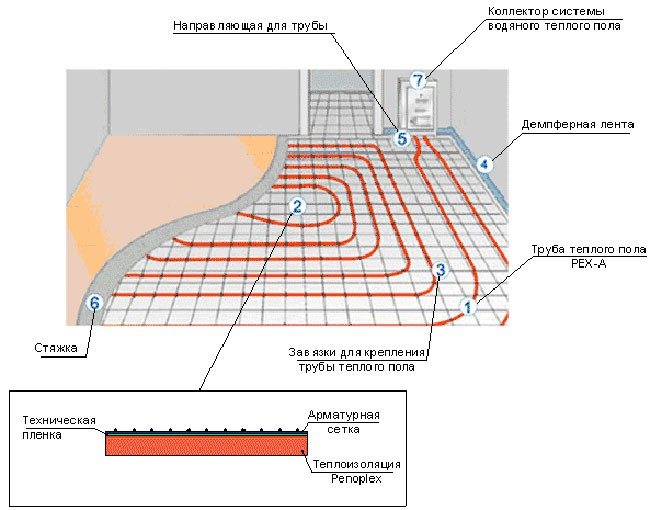

The ease of laying the substrate is convenient because during installation at any time you can change the configuration of the contours and the length of the pipelines. So that the plates of the material do not move relative to each other during installation and operation, their joints are glued with construction tape.

In order to prevent the formation of heat-conducting bridges, the contour seams between adjacent plates are glued with foil tape

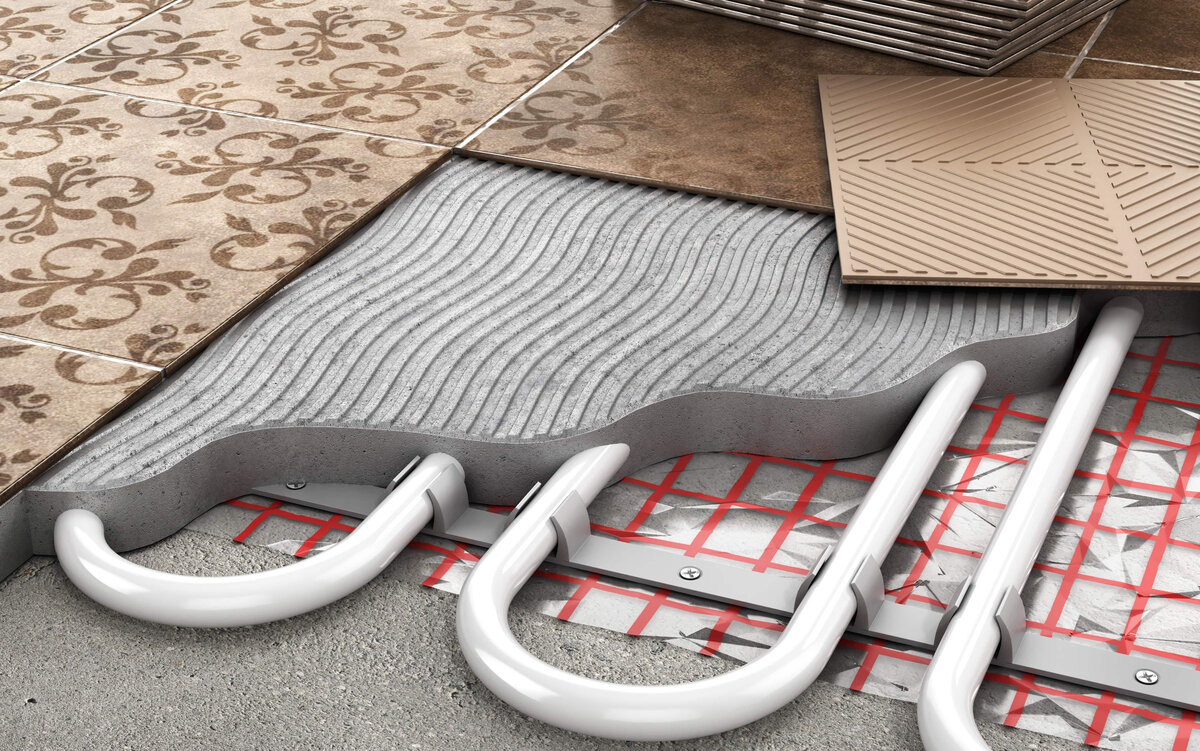

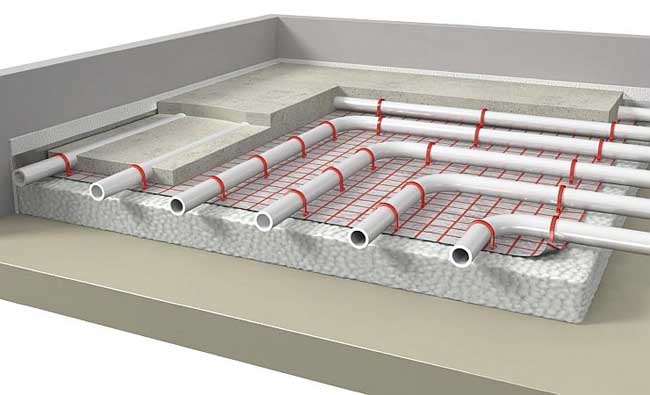

The sequence of actions when laying insulating boards:

- Styrofoam plates are laid on a cleaned and leveled base, fixing them with special plastic brackets, anchor dowels or planting them on an adhesive composition.

- A foil layer is laid on top of the stacked and docked plates.

- The top layer is lined with a reinforcing mesh, on which pipes are subsequently mounted.

If the concrete screed of the base floor is poured with significant deviations from the level or has gross cracks and irregularities, or the concrete slabs are laid with violations, it is better to build a frame before laying the substrate. For this, wooden logs are assembled from a dry and even beam with a section of 50x50, 50x100 or 100x100 mm.

Logs are placed at an equidistant distance of 60 cm, cuts of mineral wool or foam boards are laid between them

A distance of 60 cm between the lags is considered the best option, since with such a “step” no additional crate is required. The main thing is that the logs are located in the same plane and lie strictly in level.

Thermal insulation boards must be tightly packed between wooden joists. If there are gaps - they must be blown out with mounting foam.

In laying plates made of extruded polystyrene foam, it is necessary to observe some nuances:

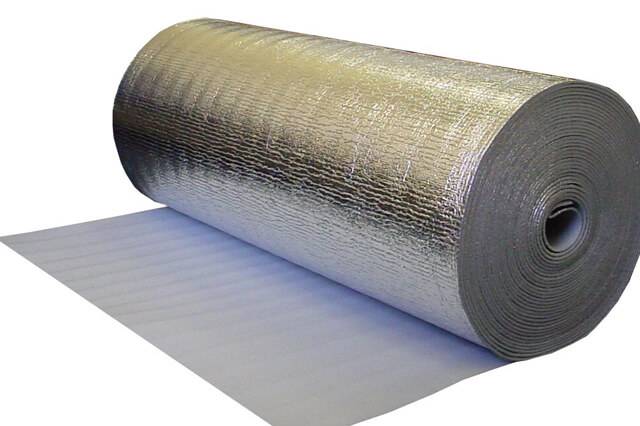

No. 2 - installation of roll materials

The laying of the roll material is carried out on a carefully leveled base and fixed to the base base using tile adhesive or double-sided tape. Cutting strips of the required size is performed with ordinary clerical scissors.

To compensate for the thermal expansion of the screed, it is recommended to place the foil layer with a slight overhang on the wall.

The foil material is placed with the metal side up so that the metallized surface best reflects heat.

When laying rolled materials, they are guided by the marking of printed mounting markings. It determines the distance between the contours and facilitates pipe laying. Typically, rolled materials at the edges have allowances for a foil polymer film to allow the connection of adjacent sheets.

When laying cuts, special attention is paid to expansion joints. To do this, the joints of the laid strips are glued with one-sided construction or metallized adhesive tape.

If a cork coating is used as a substrate, then before laying it, it is necessary to take care of reliable vapor and waterproofing.

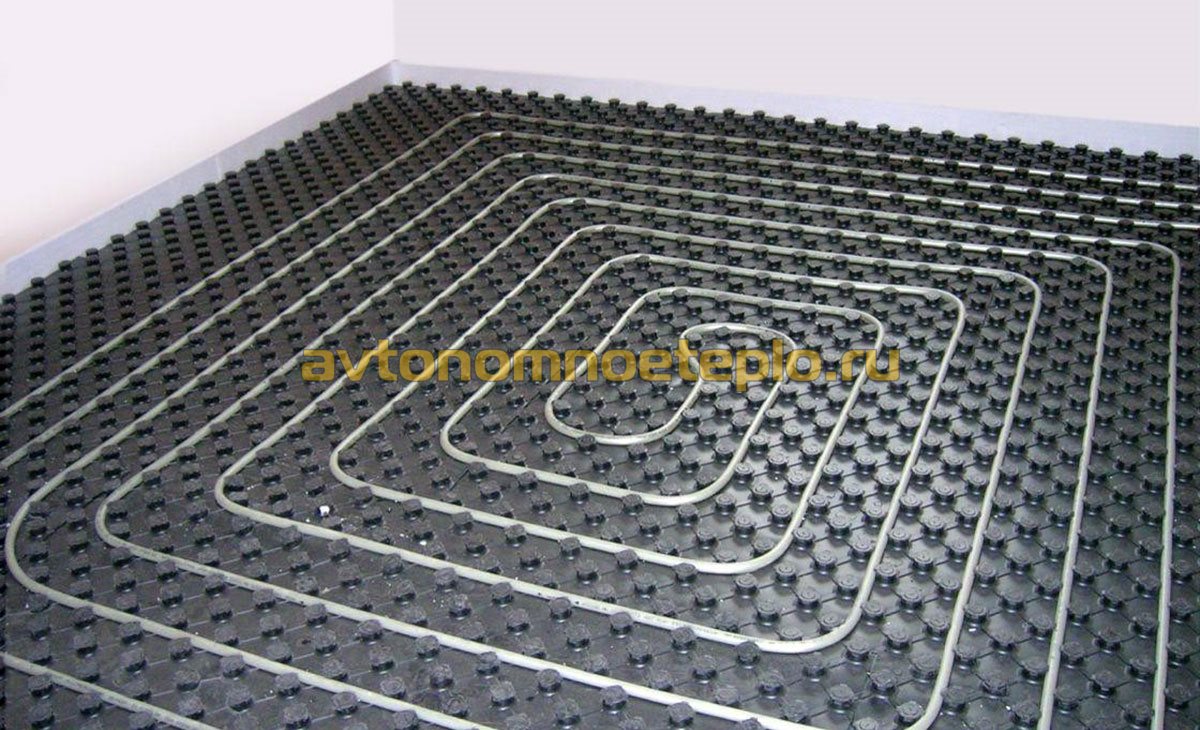

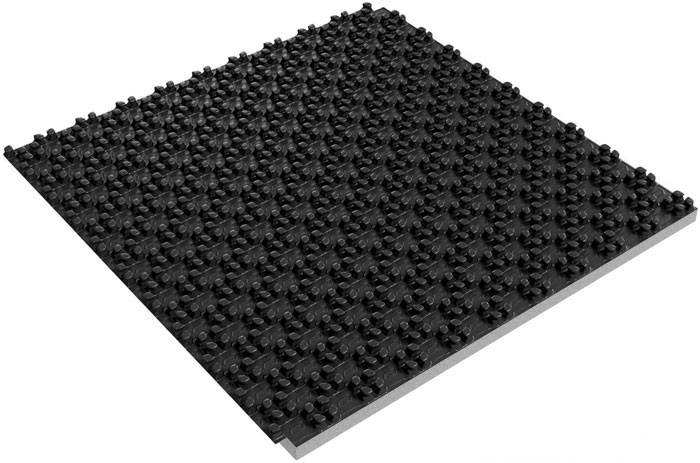

No. 3 - mat mounting scheme

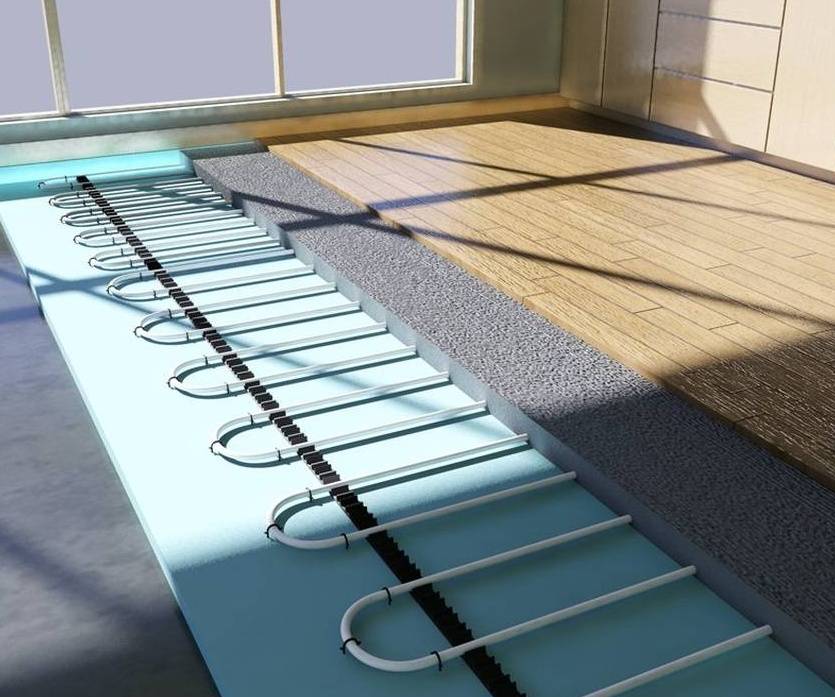

The stage preceding the laying of mats is the arrangement of film waterproofing. After laying it around the perimeter of the room, strips of damper tape are glued along the bottom of each of the walls.

Mats are laid on the prepared base, fastening the plates together by means of a locking system. To securely fasten plates of small thickness and light weight, an adhesive method is used and plastic harpoon brackets are used.

Some manufacturers, for ease of installation, complete with mats, apply edge strips, with which it is convenient to mark the exit areas from the heating zone

An important point: when laying mats, it is not allowed to use metal fasteners, since it can damage the integrity of not only the heat insulator, but also the waterproofing.

The choice of the optimal base for the thermal insulation substrate depends on your capabilities. Yes, a good underlay is not cheap. But it will significantly increase the functionality of the equipped water floor system.

Laying technology: a set of basic rules

Installation of the substrate is not difficult, the work can be done independently. The main thing is to follow simple and clear rules.

The laying order depends on the form of the underlay: roll insulation, individual modules or puzzle plates, fixed together by a lock connection

General requirements for mounting the substrate:

- Accurate calculation. It is necessary to determine in advance the amount of material, taking into account the standard sizes of the lining. It is optimal if the insulation is placed with a minimum number of joints.

- Subfloor preparation. The base must be flat. You should not particularly rely on the ability of a dense material to mask irregularities - any product will eventually take the form of a base.

- Waterproofing. Underlays made from natural components (cork underlay, chipboard, OSB) require preliminary laying of a hydro-barrier. It is enough to lay dense polyethylene.

- Laying. Rolled, sheet material is rolled out without stretch, an overlap on the walls is required. The placement of the plates takes place close to the vertical surfaces, protected by 10 cm with a damper tape.

- Docking. Cloths of roll insulation are overlapped and fixed together with construction tape. Slabs and mats are grouped end to end.

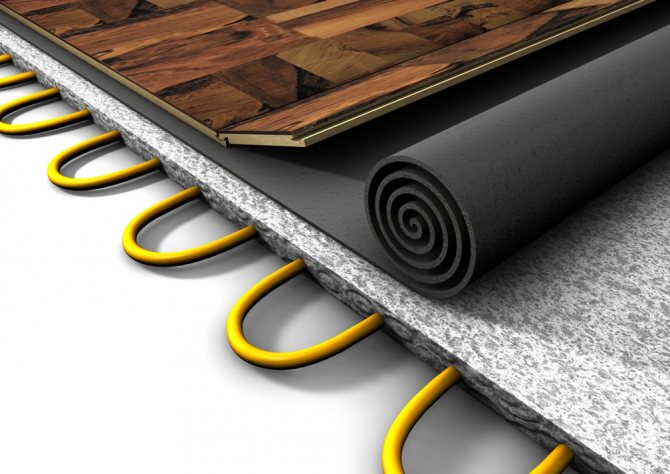

When arranging a warm floor for a laminate, it is necessary to take into account the direction of the panels - they are placed with a rolled substrate mutually perpendicular.

What substrates to choose for electric underfloor heating

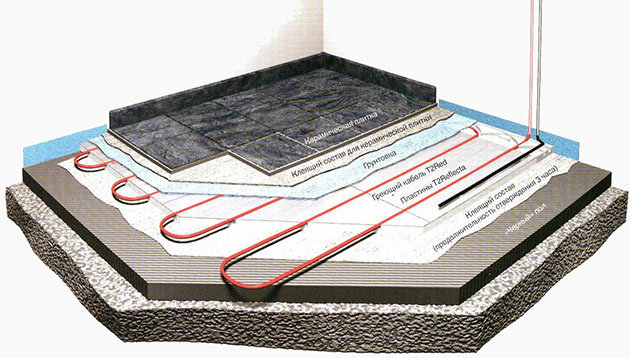

Quite thin types of substrates are best suited for electric underfloor heating, for example, pressed cork, Foiloplast, ТМpro, Polyfom, Thermodom and other foamed polymeric materials.

By the way, foamed polymers are able to withstand significant loads, due to which they are increasingly in demand in construction work. Expanded polystyrene foam is used to produce a thicker substrate.

Such a substrate can even withstand a concrete screed, since it is designed for heavy loads. Expanded polystyrene is actively used when laying underfloor heating with electric heating elements, whether it be flexible hoses or film floors.

In cases where preliminary leveling of the base for underfloor heating is required, chipboard OSB and chipboard, as well as plywood, can be used as a substrate.

Two initial factors should determine which substrate grade to choose:

- Finished floor type. The substrate is chosen the stronger, the heavier the coating. Under the laminate, you can put a simple foam underlay (read: “Why do you need a lining under the laminate and which one is better”), and under the tile - a substrate made of materials with special strength.

- Room type. It matters whether the building is new or the repair is carried out again in the old building. Based on what type of electric floor will be chosen, and what features the load-bearing floor has, the thickness of all layers of the heating system, together with the floor covering, can vary from 10-15 mm to 3-4 cm.

All these nuances should be taken into account when calculating the height of door and window openings. During the repair process, it is desirable to take into account all the parameters in order to minimize the height of the warm floor. This will allow you not to run into problems with mismatching the height of the doors with the opening, and so on.

If something goes wrong, the door leaf and vertical trim will need to be cut a few centimeters at the bottom. The most unfavorable outcome is that you will need to raise the lintel of the doorway or redo the entire underfloor heating system.

Features of installing laminate on a warm water floor

In order for the material to be used for a long time in the future, it is necessary to make high-quality installation. To do this, you can not miss a single point and act in stages. If there are difficulties with the installation, it is better to resort to the help of specialists.

Step 1. Selection of tools

Almost all the necessary tools are at hand in every home. If something is missing, then getting the materials at hand is not difficult. The list of essential tools includes:

- building level;

- jigsaw or circular saw, in their absence, a hacksaw is also suitable;

- a hammer;

- rubber percussion instrument;

- tamping bracket and timber;

- tape measure, ruler, corner and pencil for recording measurements and drawings;

- stationery knife;

- drill and drill-column.

These materials will be necessary for the installation of the laminate.

Step 2. Consider all the features of the laying of the laminate flooring

Installation on such a coolant requires taking into account some nuances

If you do not take them into account, then you can make mistakes during installation. Let's look at the following:

- before carrying out installation work, the concrete screed must finally harden. You also need to first check the operation of the entire floor heating unit to be sure of its serviceability. This will help dry the screed to the end;

- laminate can not be installed immediately.It must lie in the room where further installation will be carried out for at least two days, so that the coating gets used to the conditions of the room. This will test the resistance to the indoor climate of the room. The film must be removed and the humidity in the room maintained no more than 70 percent;

- the direction of the coating must be perpendicular to the laid pipes of water heating. So the heat can safely exit through the joints of the panels and enter the room freely. In relation to the light source, namely the window, it is also required to observe the perpendicularity of the masonry.

Features must be taken into account without fail even before installing the laminate flooring. This step is preparatory to the process of direct installation of the floor.

Step 3. Start assembly

Floor installation goes through the following steps:

- level the surface of the concrete screed, if there are roughness and bumps, this will require a building level. There should be no extra space or gaps. Cracks must be patched to avoid direct contact between the warm water floor and the laminate;

- remove small construction debris with a vacuum cleaner from the surface and proceed with the primer;

- to lay the substrate under the boards in one or two layers, the main thing is to ensure that it is not damaged or deformed. All sheets are laid end to end. This is necessary to protect the material from direct exposure to heat;

- they begin to lay the laminate from the far left corner of the room with small gaps from the walls, following the location of the boards according to a well-thought-out plan;

- then the rest of the panels are fixed in a vertical direction in a locking way: it is enough to connect the elements and snap the fastener between them. Boards are laid at an angle of 15 degrees;

- cut the last panel of the row to length and immediately lay the next row from the sawn part. For trimming, an electric jigsaw is best;

- after the installation of the first and second rows is completed, they must be raised at the same angle and connected to each other;

- at the location of the pipes, it is necessary to cut holes in which the heating pipes will be located, observing the distance and gaps;

- as soon as the installation of all rows is completed, marks must be left on the walls for future skirting boards.

It is impossible to start the heating unit immediately after installing the laminate. This contributes to the instant occurrence of defects. The material should lie down for at least two or three days before launch. After that, you can start, but gradually, starting with low temperatures. If the surface reacts without consequences, then you can slowly increase the degree of heating.

Characteristics of substrate equipment materials

In some cases, the inhabitants of houses try to use for thermal insulation any materials that are at hand or have a low cost.

Consider the characteristics of the substrate made of various materials:

- Polyethylene foil, self-adhesive - thickness 8 mm. It features high reflectivity, hydro and sound insulation.

- Polyethylene one-sided, laminated - thickness 8 mm. It has good thermal insulation and water resistance.

- Polyethylene foam (Tepofol) - only 2 mm thick. Average thermal insulation parameters;

- Foil polystyrene of various thicknesses, with printed markings.High heat-insulating, hydro and soundproofing characteristics;

- Tuplex backing, proprietary 3 mm thick. It has the maximum parameters of heat, hydro and sound insulation;

- Underlay made of polystyrene and lavsan coated, 3 mm thick.

The smaller the thickness of the thermal insulation, the lower the thickness of the entire layer cake becomes. Accordingly, the height of the flows in the room is slightly reduced. The thickness of the screed over a water-heated floor can vary within 50-60 mm.

The listed materials are the set that is presented in the trading network today. The cost of materials may vary. Here, the amount of material used in the work and the intensity with which floor heating should be carried out are taken into account.

Less commonly used is cork, which is made from crushed oak bark. There is one important aspect here - such material is environmentally friendly. However, if moisture gets in, it can become a place for the development of the fungus. This material is supplied in rolls.

The cheapest option is foil polyethylene. Of all the materials listed, foil polyethylene is the most common today. Despite the fact that the material is characterized by a high degree of thermal insulation and fairly moderate waterproofing, foil polyethylene does not have sufficient rigidity and strength.

In order to achieve quality when installing underfloor heating, try to use foil polystyrene

Do not pay attention to the cost of the material, it is high, but the obvious benefits more than offset your costs, making the water floor durable and efficient.

Laminate

Laminate - dense

fibreboard, with a thickness

6 - 15 mm. It is not as capricious as parquet, and unlike it, it is less

subject to deformation.

The main advantages of laminate:

- easy to install and can be laid

yourself; - is inexpensive;

- many options for color shades reminiscent of different types of wood. aesthetic

appearance; - the ability to quickly dismantle, with

need only separate boards; - comfortable, pleasant to walk on

barefoot; - inert, able for some time

retain heat, the thinner the thickness, the higher the thermal conductivity.

In spite of

positive aspects, this flooring also has disadvantages:

- low thermal conductivity;

- deformed under high temperature

and moisture, so it is not suitable for a room with high humidity. Designed

exclusively for living rooms; - cheap options when heated

formaldehyde is released above the norm, which is dangerous to health; - warms up 20% slower than ceramic hob;

- maximum

heating temperature 27 degrees.

Although today, manufacturers produce models of laminated boards suitable for water floors, as they have an increased level of thermal conductivity and heat resistance. This is evidenced by a special marking on the packaging.

The service life of this floor covering is up to

15 years.

Peculiarities

use of laminated boards for various types of floors.

| Warm water floor | Film floor |

| Laminated boards for underfloor heating can only be laid if there is a dry screed. Otherwise, the floor after drying will move and creak. Laminate must have a moisture-repellent impregnation. | Laminate with a porous structure, and having a non-resistant binder impregnation to temperature changes cannot be put on the film, it will crack. |

When choosing a laminate

for underfloor heating, it must meet the following requirements:

- class not less than 32;

- must have low porosity;

- be equipped with a substrate intended for mounting

floor covering on a warm floor; - heating - no more than 30 degrees.

What is

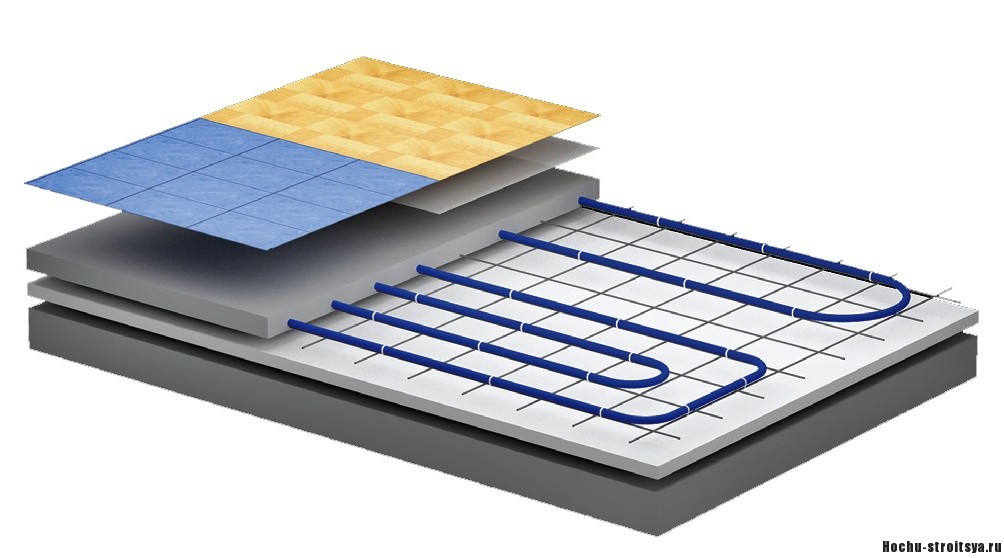

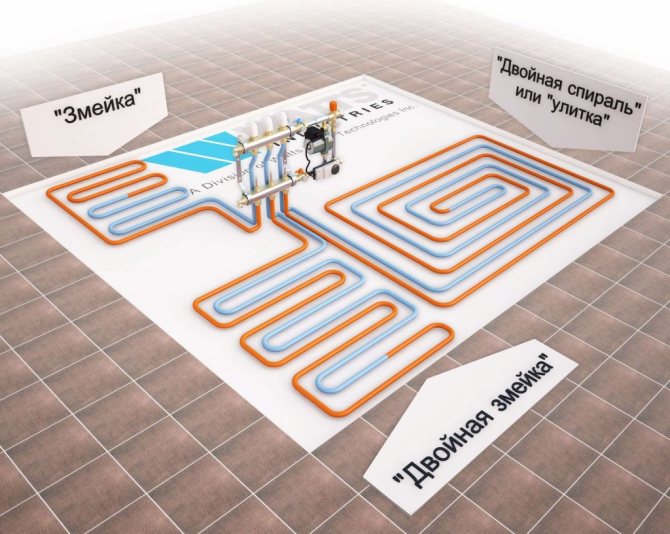

In addition to the correct installation of the main elements of the equipment, it is also necessary to properly configure them. A significant role in this is played by the substrate under the water-heated floor, the efficiency of heating the room will depend on the correct installation of which. The choice of finishing and flooring will depend on the method and type of contours to be laid. Even a small detail can deprive a number of advantages, even if expensive pipes, auxiliary devices, a high-quality mixing and pumping station, and the heating boiler itself were used during the installation.

Incorrectly laid pipes and cheap insulation can make even expensive equipment unnecessary and ineffective. In this case, the heating of the device will not be aimed at heating the floor, but, for example, the lining.

When designing a circuit, it must be taken into account that the main coolant (hot water) will give at least 65% of the heat to the floor covering, thus heating the surface evenly and heating the room.

Indicators

Such indicators can only be achieved through the correct installation of the main pie, which includes substrates and waterproofing material.For the correct filling of this layer, it is recommended to use only high-quality materials, which are characterized by the presence of a heat-reflecting effect. At the same time, the level of thermal conductivity is considered to be minimal. Underfloor heating reflects heat and directs upward, thereby giving off heat to the floor. Efficiency will also depend on the integrity and evenness of the concrete screed, the installation of the water circuit and the substrate itself. The heat-insulating layer is laid directly on the subfloor, which is pre-prepared.

The first and main layer of the substrate consists of thermal insulation, which creates a kind of thermos. At the same time, waterproofing does not allow condensation to form and get into the underground.

I would also like to note that the usual water devices can be laid on wooden and concrete floors. If the pipe is damaged, condensate will begin to accumulate. At the same time, even an insignificant leak will certainly lead to flooding of the lower floors and basements. For the installation of a warm floor, a wide substrate is required. But the quality of the constructed cake will directly depend on the quality of the materials used.

Material characteristics

To create it is recommended to use a material with a high thermal conductivity and a sufficient level of rigidity. Manufacturability also plays an important role, since the practicality of the further use of materials and devices depends on this. A high-quality substrate for a water-heated floor will be expensive, but it will significantly increase the performance of the device and the endurance indicator.

Main characteristics:

- Fire resistance.

- The ability to reflect heat.

- Practicality.

- Environmental friendliness of the materials used.

- Ease of installation.

- Indicators of thermal insulation and waterproofing.

- Ability to resist possible deformation.

- Resistant to climate and temperature changes.

Subject to the above parameters, you can create an ideal substrate design for warm water floors.

When choosing materials, it is necessary to pay attention only to the types that best correspond to the given characteristics. Expanded polystyrene is often used, as it is better than others in terms of parameters.

How to lay a laminate with your own hands: substrate options and why you need it

Underlayment is a must if you are using floating laminate flooring. You can learn how to lay a substrate with your own hands from numerous videos on the Internet.

A laminate underlayment is needed to ensure the following qualities:

moisture insulation. The basis of any laminate is pressed paper.

This means that the coating is more sensitive to moisture, which can cause the panels to swell and warp. It is especially important to install a layer of moisture insulation if you are laying a laminate on a concrete floor; soundproofing. If the underlay is not installed, the concrete or wood floor under the laminate may creak and make other sounds;

The floor in the room is covered with a foil substrate and is completely ready for the installation of the laminate

thermal insulation.

The underlay layer keeps the cold from the concrete or cement coating from affecting the temperature of the laminate.If you use an underfloor heating system and think what to put under the laminate so that the heating efficiency does not decrease, for this there are special options for substrates that conduct heat well; leveling small irregularities. Remember that the substrate can only hide very small irregularities, to eliminate more significant height differences, there are methods described above.

There are several common substrate options, each with its own advantages and disadvantages.

One option is cork panels.

They are environmentally friendly and safe for health, they are made from oak bark pressed using a special technology. Cork masks small irregularities very well, boasts a high level of heat and sound insulation, as well as a long service life. The disadvantages of the cork substrate include the fact that it does not tolerate moisture and is quite expensive.

The subtleties of installing a cork substrate can be found in the video below. The correct laying of the laminate with your own hands, as you probably already understood, largely depends on the quality of this stage of work.

As can be seen from the properties of the material, it is not well suited for arranging the floor in the bathroom, kitchen or any other room with a high level of humidity. In addition, the cork does not interact well with the floor heating system. But for laying in the living room, nursery or playroom, it is an excellent option.

A much cheaper version of the substrate is polyethylene foam. If you are unfamiliar with how to properly lay underlayment under a laminate, you will love PE foam as it is very easy to operate.

In addition, it perfectly resists the effects of aggressive chemicals, and pathogenic bacteria and fungi do not multiply on its surface. Another advantage of the material is increased moisture resistance, so it is recommended to make a substrate from it in rooms with a high level of humidity. Also, polyethylene foam has a low weight.

Fragility is the main drawback of the material. It quickly loses its shape and performance properties, so be prepared for the fact that the substrate from it will have to be changed quite often.

The substrate, laid under the laminate, provides a high level of heat, sound and waterproofing

The best option that combines durability, relatively low price and good performance is expanded polystyrene. It is quite easy to install, responds well to the underfloor heating system and masks small irregularities in the base. Another drawback of the material is that panels from it can lose shape over time.

There are also a variety of combination options. For example, if the question arises as to whether it is possible to lay a laminate on penoplex, the answer will be in the affirmative. The only point is the rather high cost of the material.

In recent years, a substrate made of pressed needles has also become popular. This material is absolutely environmentally friendly, it passes air well, but it is thicker than other substrate options, and it is very expensive.

The main qualities of the substrate for pressed needles laminate are safety and environmental friendliness.