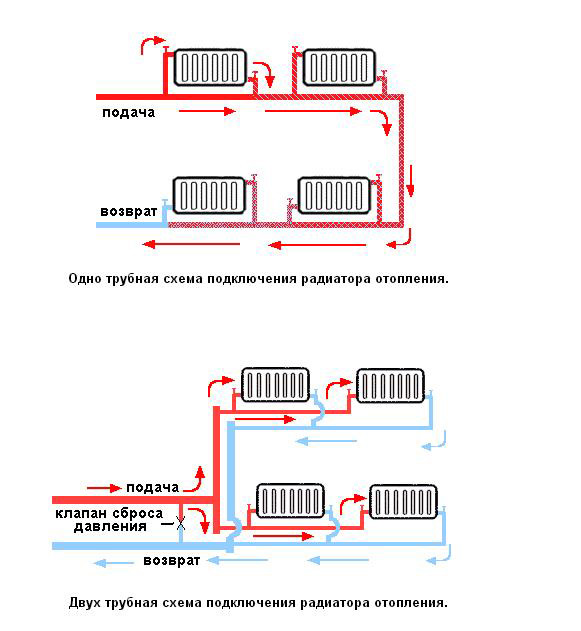

- One-pipe scheme of heating systems

- Other types of connection

- Types of heating systems with gravity circulation

- Closed system with gravity circulation

- Open system with gravity circulation

- Single pipe system with self-circulation

- Two-pipe system with self-circulation

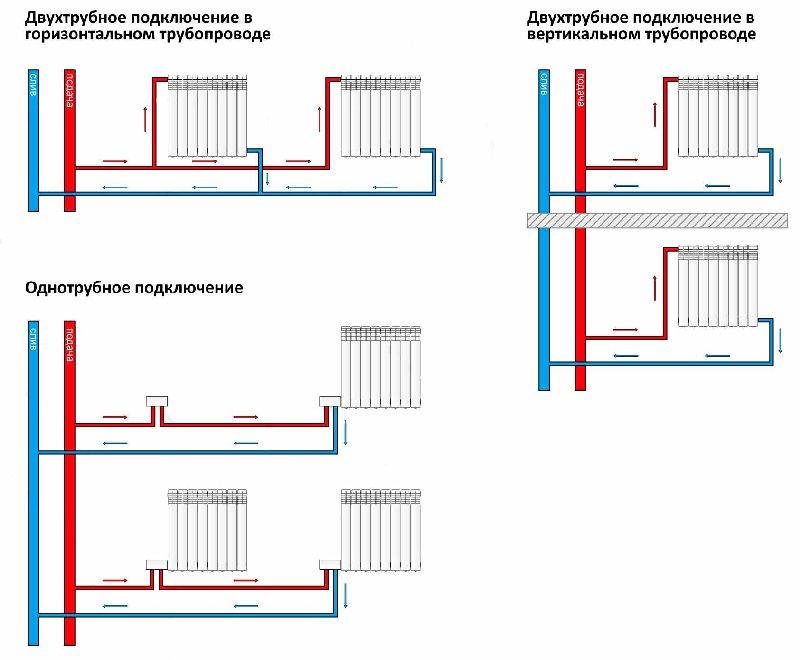

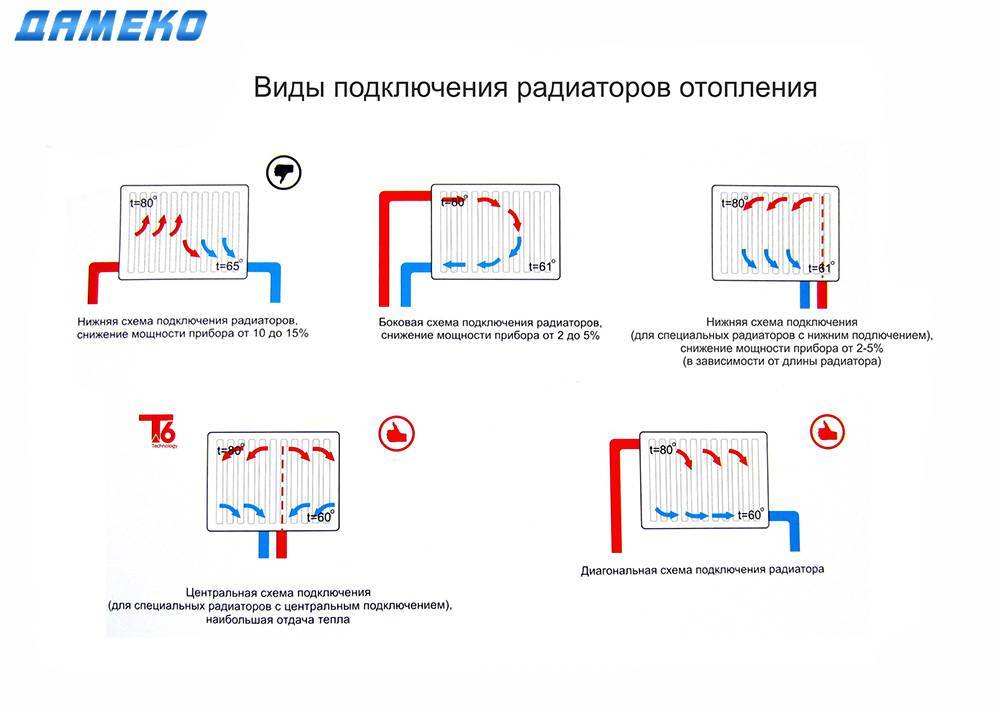

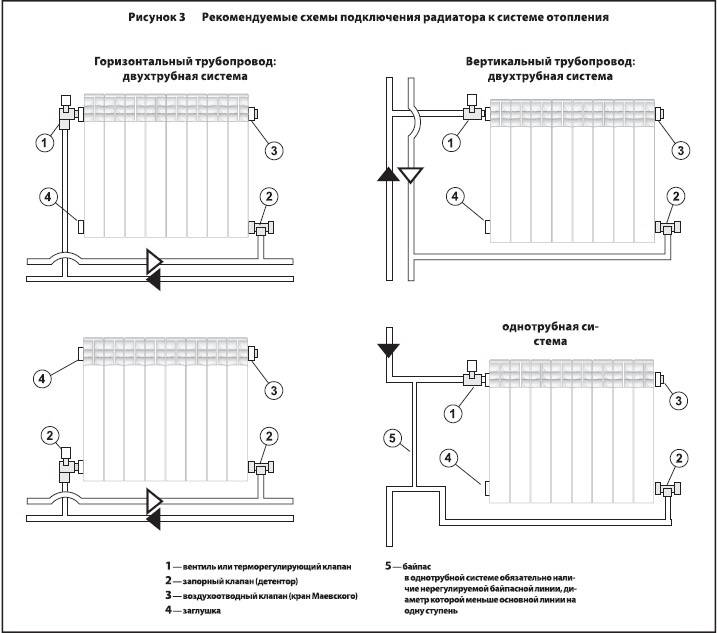

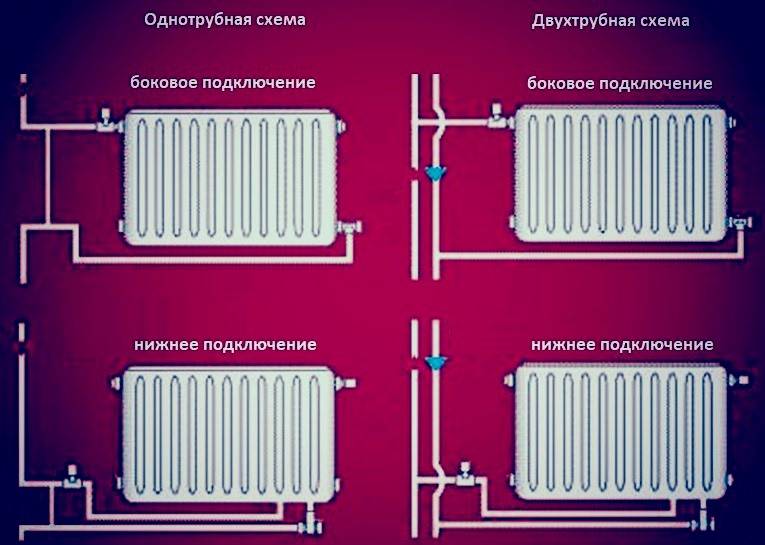

- Radiator connection diagrams

- Radiators with bottom connection

- Radiators with side connection

- Option number 1. Diagonal connection

- Option number 2. Unilateral

- Option number 3. Bottom or saddle connection

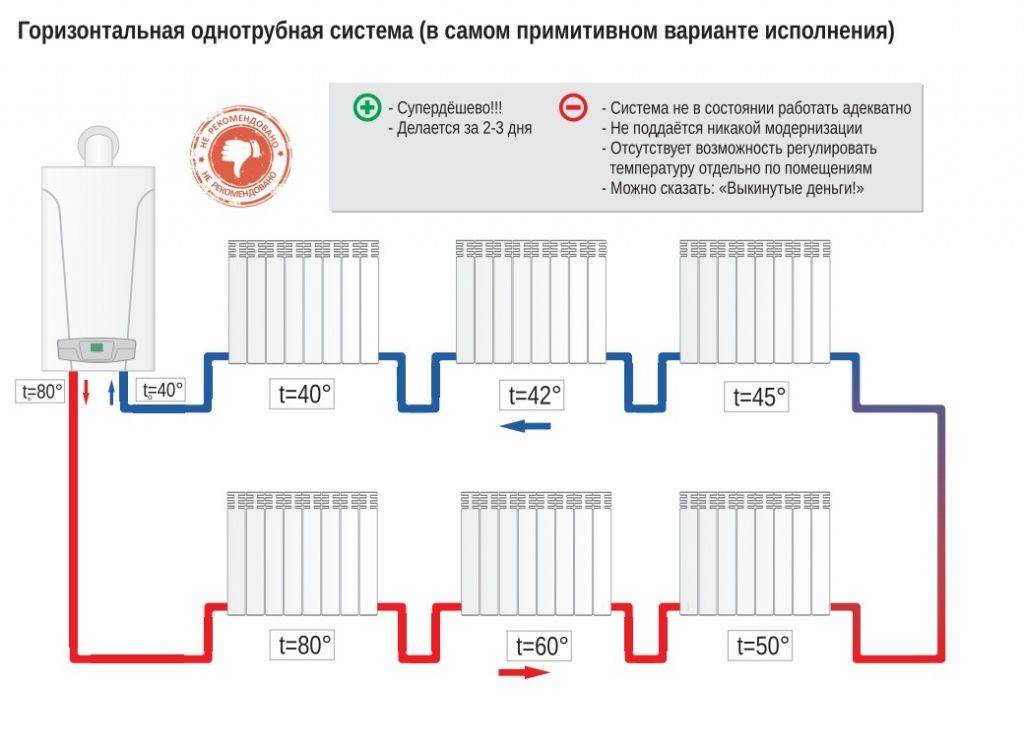

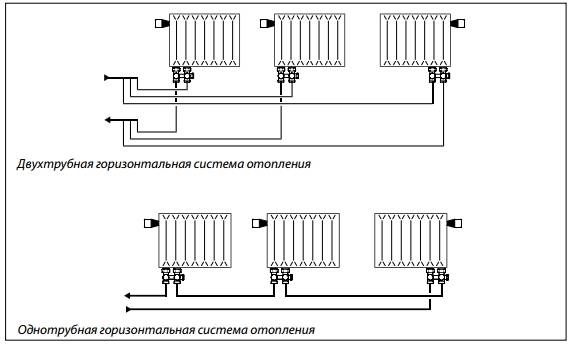

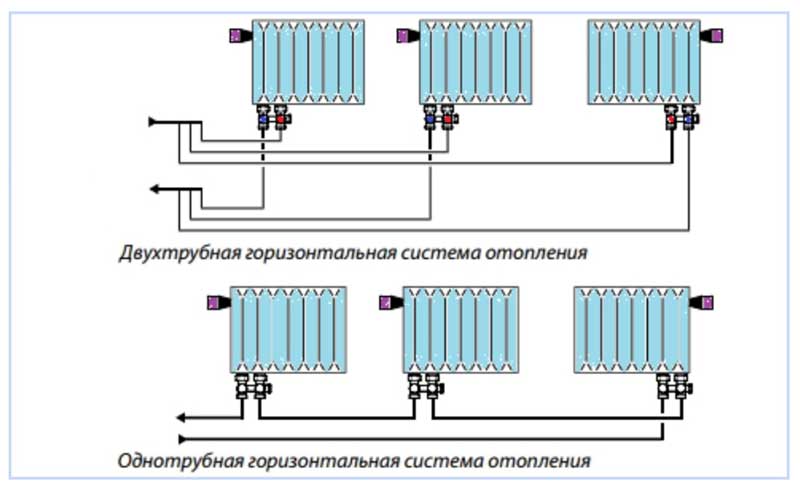

- Classification of one-pipe heating systems

- Bottom and horizontal wiring of the system and its diagrams

- How are sections added?

- Advantages and disadvantages of a one-pipe system

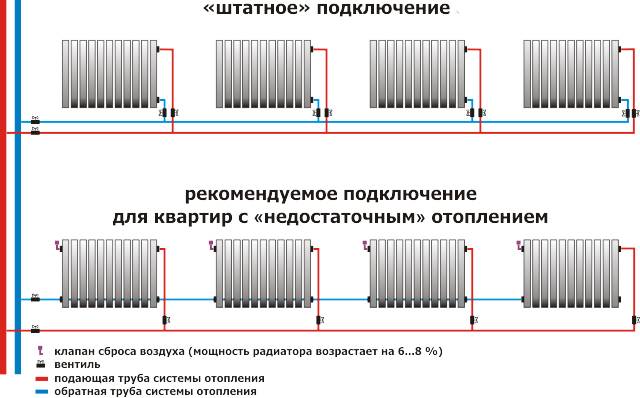

- Feature of the horizontal pipe laying scheme

- Central horizontal heating

- Autonomous horizontal heating

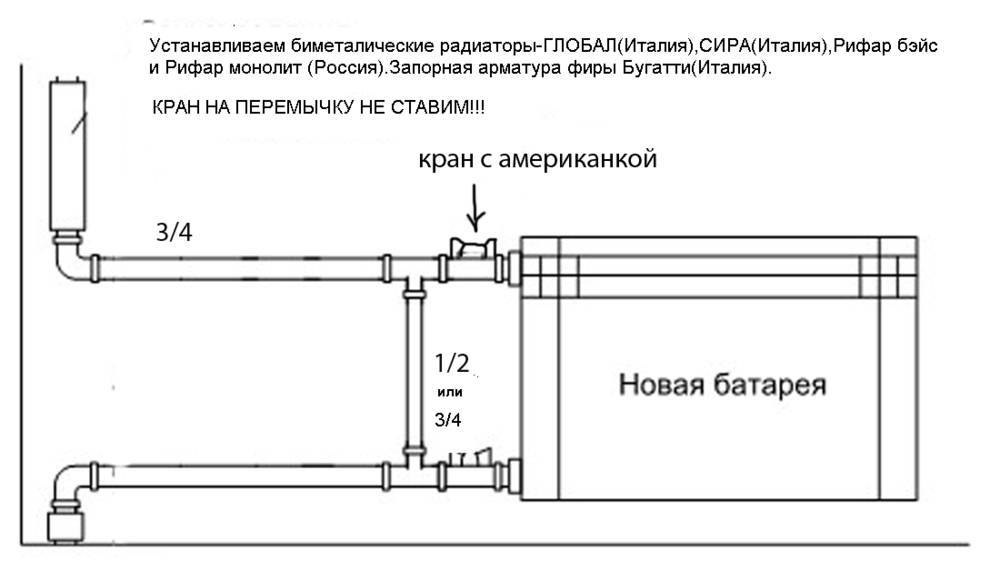

- Connection methods

- Conclusion

One-pipe scheme of heating systems

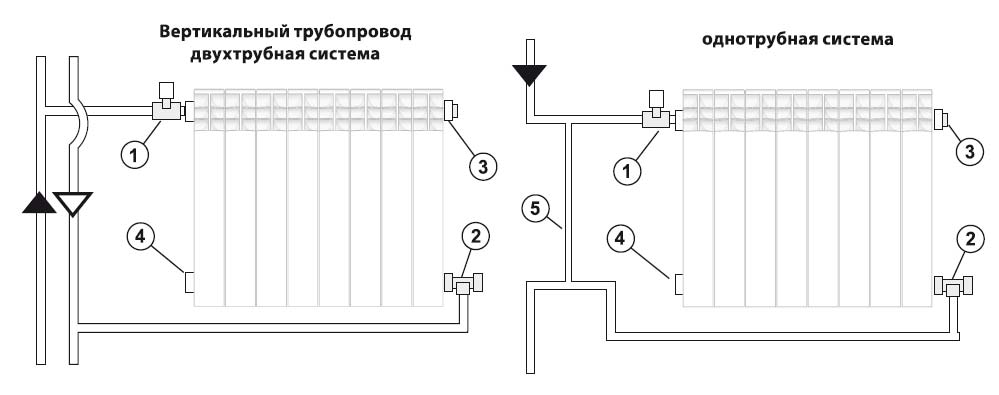

One-pipe heating system: vertical and horizontal wiring.

In a single-pipe scheme of heating systems, the hot coolant is supplied (supply) to the radiator and the cooled coolant is removed (return) through one pipe. All devices are connected in series with respect to the direction of movement of the coolant.Therefore, the temperature of the coolant at the inlet to each subsequent radiator in the riser is significantly reduced after the removal of heat from the previous radiator. Accordingly, the heat transfer of radiators decreases with distance from the first device.

Such schemes are mainly used in old central heating systems of multi-storey buildings and in autonomous systems of the gravitational type (natural circulation of the heat carrier) in private residential buildings. The main defining disadvantage of a single-pipe system is the impossibility of independently adjusting the heat transfer of each radiator individually.

To eliminate this drawback, it is possible to use a single-pipe circuit with a bypass (a jumper between the supply and return), but in this circuit, the first radiator on the branch will always be the hottest, and the last the coldest.

In multi-storey buildings, a vertical single-pipe heating system is used.

In multi-storey buildings, the use of such a scheme allows you to save on the length and cost of supply networks. As a rule, the heating system is made in the form of vertical risers passing through all floors of the building. The heat dissipation of radiators is calculated during system design and cannot be adjusted using radiator valves or other control valves. With modern requirements for comfortable indoor conditions, this scheme for connecting water heating devices does not meet the requirements of residents of apartments located on different floors, but connected to the same riser of the heating system. Heat consumers are forced to “tolerate” overheating or underheating of the air temperature during the transitional autumn and spring periods.

Single-pipe heating in a private house.

In private houses, a single-pipe scheme is used in gravitational heating networks, in which hot water is circulated due to the differential density of the heated and cooled coolants. Therefore, such systems are called natural. The main advantage of this system is energy independence. When, for example, in the absence of a circulation pump connected to the power supply networks in the system and, in the event of power outages, the heating system continues to function. The main disadvantage of the gravitational one-pipe connection scheme is the uneven distribution of the coolant temperature over the radiators. The first radiators on the branch will be the hottest, and as you move away from the heat source, the temperature will drop. The metal consumption of gravity systems is always higher than that of forced systems due to the larger diameter of pipelines.

Video about the device of a single-pipe heating scheme in an apartment building:

Other types of connection

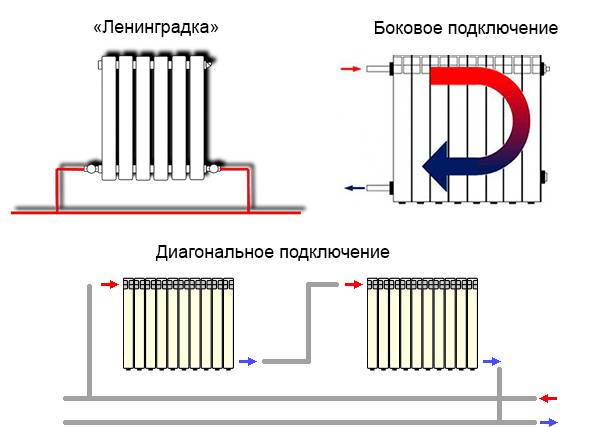

There are more profitable options than the bottom connection, which reduce heat loss:

- Diagonal. All experts have long come to the conclusion that this type of connection is ideal, regardless of which piping scheme it is used in. The only system where this type cannot be used is the horizontal bottom single pipe system. That is the same Leningrad. What is the meaning of diagonal connection? The coolant moves inside the radiator diagonally - from the top pipe to the bottom. It turns out that hot water is evenly distributed throughout the entire internal volume of the device, falling from top to bottom, that is, in a natural way.And since the speed of water movement is not very high during natural circulation, the heat transfer will be high. Heat loss in this case is only 2%.

- Lateral, or one-sided. This type is very often used in apartment buildings. Connection is made to the side branch pipes on one side. Experts believe that this type is one of the most effective, but only if the coolant circulation under pressure is installed in the system. In city apartments, this is not a problem. And to ensure it in a private house, you will have to install a circulation pump.

What is the advantage of one species over others? In fact, proper connection is the key to efficient heat transfer and reduced heat loss. But in order to properly connect the battery, you need to prioritize.

Take, for example, a two-story private house. What to prefer in this case? Here are some options:

Two and one pipe systems

- Install a one-pipe system with side connection.

- Carry out the installation of a two-pipe system with a diagonal connection.

- Use a single-pipe scheme with lower wiring on the first floor and with upper wiring on the second.

So you can always find options for connection schemes. Of course, you will have to take into account some nuances, for example, the location of the premises, the presence of a basement or attic

But in any case, it is important to correctly distribute the radiators among the rooms, taking into account the number of their sections. That is, the power of the heating system will have to be taken into account even with such a question as the correct connection of radiators. In a one-story private house, it will not be very difficult to connect the battery correctly, given the length of the heating circuit

If this is a Leningrad one-pipe scheme, then only a lower connection is possible. If the two-pipe scheme, then you can use a collector system or solar. Both options are based on the principle of connecting one radiator to two circuits - coolant supply and return. In this case, the upper piping is most often used, where the distribution along the contours is carried out in the attic.

In a one-story private house, it will not be very difficult to connect the battery correctly, given the length of the heating circuit. If this is a Leningrad one-pipe scheme, then only a lower connection is possible. If the two-pipe scheme, then you can use a collector system or solar. Both options are based on the principle of connecting one radiator to two circuits - coolant supply and return. In this case, the upper piping is most often used, where the distribution along the contours is carried out in the attic.

By the way, this option is considered optimal both in terms of operation and during the repair process. Each circuit can be disconnected from the system without turning off the latter. To do this, a shut-off valve is installed at the point of pipe separation. Exactly the same is mounted after the radiator on the return pipe. One has only to close both valves to cut off the circuit. After draining the coolant, you can safely do repairs. In this case, all other circuits will work normally.

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of the coolant, there are at least four popular installation schemes.The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is required to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the pipe diameter, etc. You may need the help of a professional when doing the calculations.

Closed system with gravity circulation

In the EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet been widely used. The principles of operation of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands, water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container is a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs, and the gas squeezes the water out of the tank.

Otherwise, closed-type systems work like other natural circulation heating schemes. As disadvantages, one can single out the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a capacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantages of an open system is the possibility of self-manufacturing containers from improvised materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the ingress of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing the system is also a frequent "guest" in open circuits. Therefore, radiators are installed at an angle, Mayevsky cranes are required to bleed air.

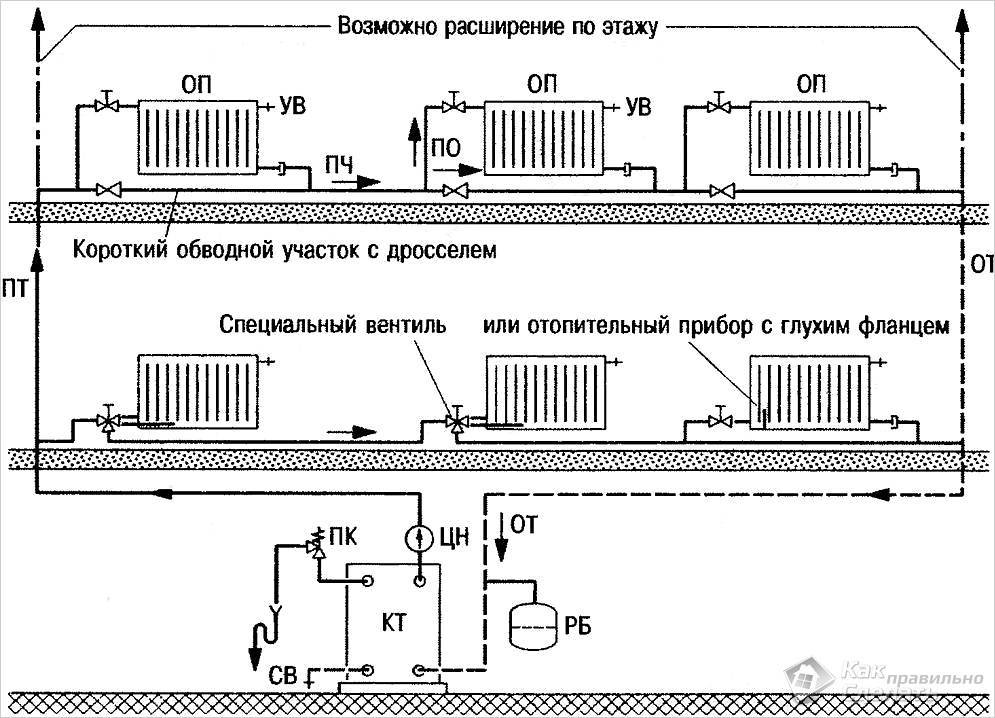

Single pipe system with self-circulation

This solution has several advantages:

- There is no paired pipeline under the ceiling and above the floor level.

- Save money on system installation.

The disadvantages of such a solution are obvious. The heat output of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a single-pipe heating system of a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often redone (by installing pumping equipment).

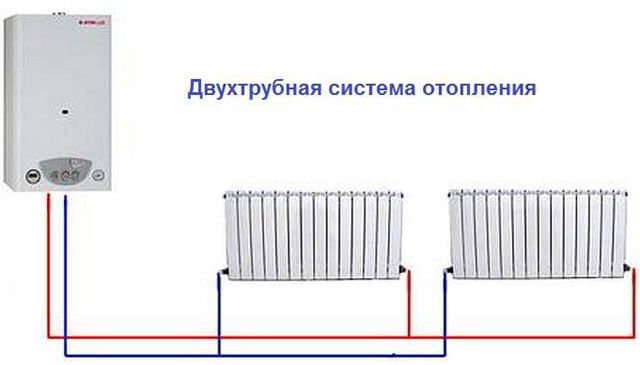

Two-pipe system with self-circulation

The two-pipe heating system in a private house with natural circulation has the following design features:

- Supply and return flow through separate pipes.

- The supply pipeline is connected to each radiator via an inlet.

- The battery is connected to the return line with the second eyeliner.

As a result, a two-pipe radiator type system provides the following advantages:

- Uniform distribution of heat.

- No need to add radiator sections for better warm-up.

- Easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe schemes.

- Lack of strict rules for installing a two-pipe system. Small deviations regarding slopes are allowed.

The main advantage of a two-pipe heating system with lower and upper wiring is the simplicity and at the same time the efficiency of the design, which allows you to level errors made in the calculations or during installation work.

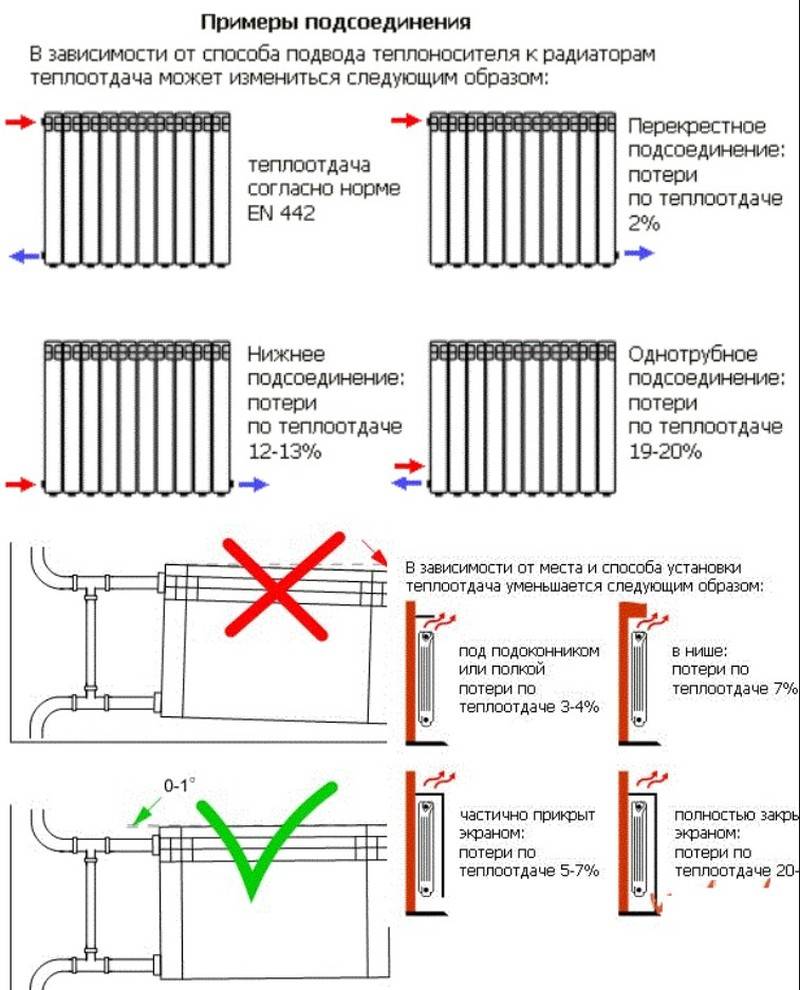

Radiator connection diagrams

How well the radiators will heat up depends on how the coolant is supplied to them. There are more and less effective options.

Radiators with bottom connection

All heating radiators have two types of connection - side and bottom. There can be no discrepancies with the lower connection. There are only two pipes - inlet and outlet. Accordingly, on the one hand, a coolant is supplied to the radiator, on the other hand it is removed.

Bottom connection of heating radiators with one-pipe and two-pipe heating systems

Specifically, where to connect the supply, and where the return is written in the installation instructions, which must be available.

Radiators with side connection

With a lateral connection, there are much more options: here the supply and return pipelines can be connected to two pipes, respectively, there are four options.

Option number 1. Diagonal connection

Such a connection of heating radiators is considered the most effective, it is taken as a standard, and this is how manufacturers test their heaters and the data in the passport for thermal power - for such an eyeliner. All other connection types are less efficient at dissipating heat.

Diagonal connection diagram for heating radiators with a two-pipe and one-pipe system

This is because when the batteries are connected diagonally, the hot coolant is supplied to the upper inlet on one side, passes through the entire radiator and exits from the opposite, lower side.

Option number 2. Unilateral

As the name implies, pipelines are connected on one side - supply from above, return - from below. This option is convenient when the riser passes to the side of the heater, which is often the case in apartments, because this type of connection usually prevails. When the coolant is supplied from below, such a scheme is used infrequently - it is not very convenient to arrange pipes.

Lateral connection for two-pipe and one-pipe systems

With this connection of radiators, the heating efficiency is only slightly lower - by 2%. But this is only if there are few sections in the radiators - no more than 10. With a longer battery, its farthest edge will not heat up well or even remain cold. In panel radiators, to solve the problem, flow extensions are installed - tubes that bring the coolant a little further than the middle. The same devices can be installed in aluminum or bimetallic radiators, while improving heat transfer.

Option number 3. Bottom or saddle connection

Of all the options, the saddle connection of heating radiators is the most inefficient. Losses are approximately 12-14%.But this option is the most inconspicuous - the pipes are usually laid on the floor or under it, and this method is the most optimal in terms of aesthetics. And so that the losses do not affect the temperature in the room, you can take a radiator a little more powerful than required.

Saddle connection of heating radiators

In systems with natural circulation, this type of connection should not be done, but if there is a pump, it works well. In some cases, even worse than the side. Just at some speed of movement of the coolant, vortex flows arise, the entire surface heats up, and heat transfer increases. These phenomena have not yet been fully studied, therefore it is not yet possible to predict the behavior of the coolant.

Classification of one-pipe heating systems

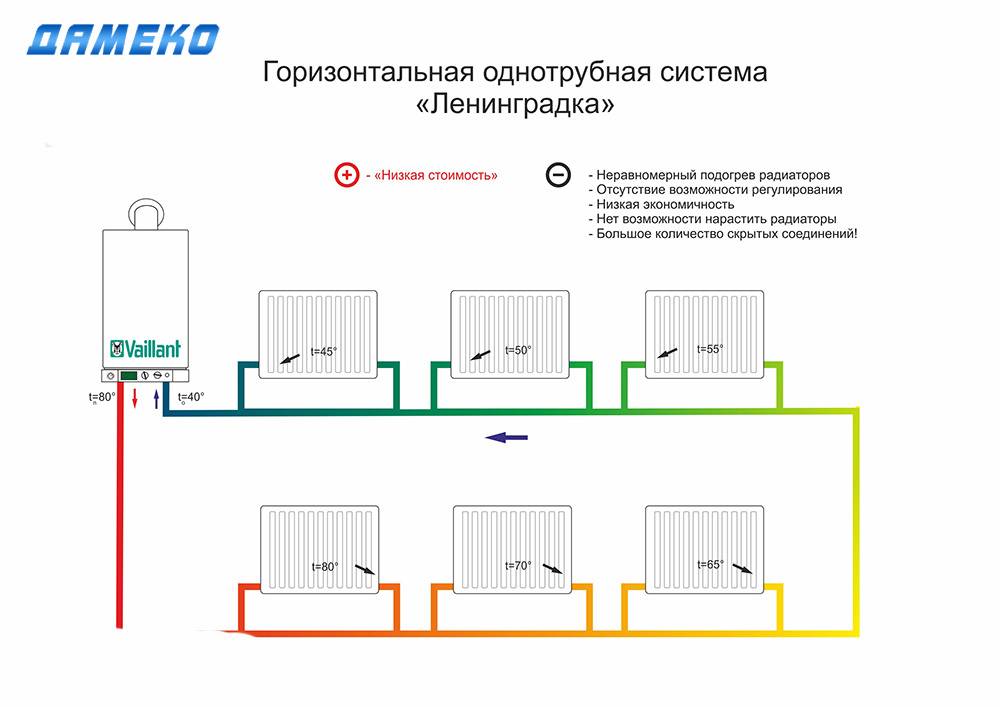

In this type of heating, there is no separation into return and supply pipelines, since the coolant, after leaving the boiler, goes through one ring, after which it returns to the boiler again. Radiators in this case have a serial arrangement. The coolant enters each of these radiators in turn, first into the first, then into the second, and so on. However, the temperature of the coolant will decrease, and the last heater in the system will have a temperature lower than the first one.

The classification of single-pipe heating systems looks like this, each type has its own schemes:

- closed heating systems that do not communicate with air. They differ in excess pressure, the air can only be discharged manually by means of special valves or automatic air valves. Such heating systems can work with circular pumps.Such heating may also have a lower wiring and a corresponding circuit;

- open heating systems that communicate with the atmosphere using an expansion tank to release excess air. In this case, the ring with the coolant should be placed above the level of the heating devices, otherwise air will collect in them and the water circulation will be disturbed;

- horizontal - in such systems, the coolant pipes are placed horizontally. This is great for private one-story houses or apartments where there is an autonomous heating system. Single-pipe type of heating with lower wiring and the corresponding scheme is the best option;

- vertical - the coolant pipes in this case are placed in a vertical plane. Such a heating system is best suited for private residential buildings, consisting of two to four floors.

Bottom and horizontal wiring of the system and its diagrams

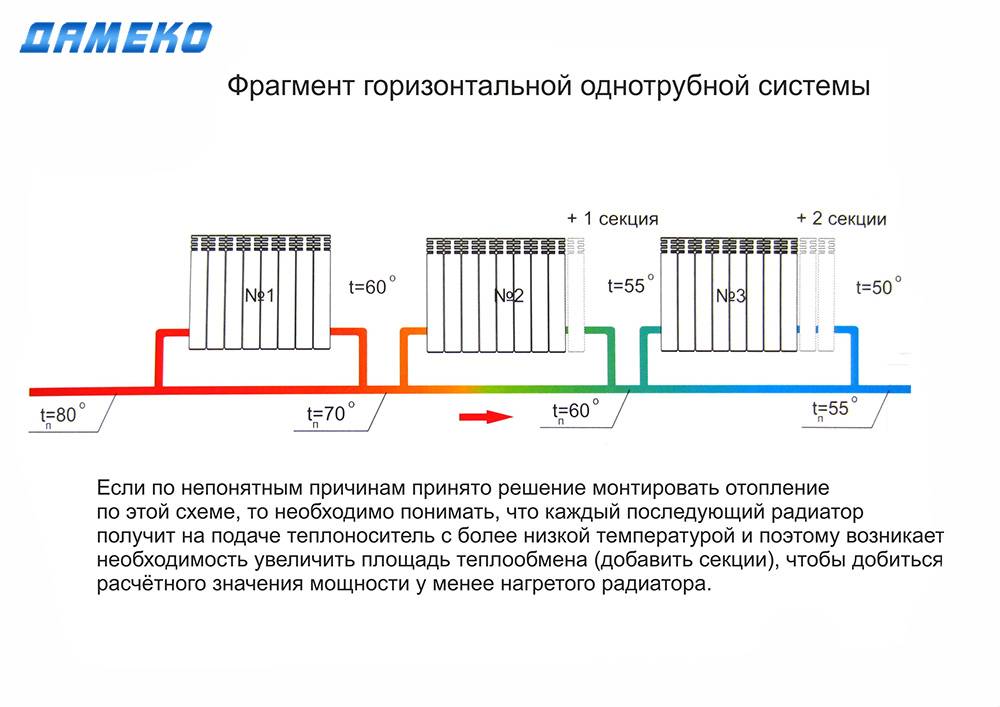

The circulation of the coolant in the horizontal piping scheme is provided by a pump. And the supply pipes are placed above or below the floor. A horizontal line with a lower wiring should be laid with a slight slope from the boiler, while the radiators must be placed all on the same level.

In houses with two floors, such a wiring diagram has two risers - supply and return, while the vertical circuit allows for more. During forced circulation of the heating agent using a pump, the temperature in the room rises much faster.Therefore, to install such a heating system, it is necessary to use pipes with a smaller diameter than in cases of natural movement of the coolant.

On the pipes that enter the floors, you need to install valves that will regulate the supply of hot water to each floor.

Consider some wiring diagrams for a single-pipe heating system:

- vertical feed scheme - can have natural or forced circulation. In the absence of a pump, the coolant circulates by means of a change in density during the cooling down of the heat exchange. From the boiler, water rises to the main line of the upper floors, then it is distributed through the risers to the radiators and cools in them, after which it returns to the boiler again;

- diagram of a single-pipe vertical system with bottom wiring. In the scheme with the lower wiring, the return and supply lines go below the heating devices, and the pipeline is laid in the basement. The coolant is supplied through the drain, passes through the radiator and returns down to the basement through the downcomer. With this method of wiring, heat loss will be much less than when the pipes are in the attic. Yes, and it will be very simple to maintain the heating system with this wiring diagram;

- scheme of a single-pipe system with an upper wiring. The supply pipeline in this wiring diagram is located above the radiators. The supply line runs under the ceiling or through the attic. Through this line, the risers go down and radiators are attached to them one by one. The return line goes either along the floor, or under it, or through the basement. Such a wiring diagram is suitable in the case of natural circulation of the coolant.

Remember that if you do not want to raise the threshold of the doors in order to lay the supply pipe, you can smoothly lower it under the door on a small piece of land while maintaining the general slope.

How are sections added?

After you have empirically determined that the reason for the cool temperature in the house is not at all the clogging of the radiator, you should find a store near your home (so that you do not have to travel to distant lands and thereby waste your time) a store that sells heating equipment. You need to buy the same sections that your radiator is equipped with - cast iron, aluminum, or bimetallic.

It should not happen that you choose the wrong sections - because of such an error, you simply will not be able to add them, that is, the money spent will be thrown away, so be careful. The section extension procedure is carried out in the same sequence of actions for all types of heating radiators.

For docking sections, you need a connecting nut - nipple

We proceed directly to increasing the number of sections. The first step is to unscrew the futorka with a radiator key from the side to which you plan to add one or more elements. After you have untwisted the futorka, a nipple (connecting nut) is applied to the docking area of the sections. The following important feature must be taken into account: the threads at different ends of the nipple are different, and in order to properly install new sections, you must be guided by the following rules:

- The right part of the nipple should be directed to the side where the connection with the new element will be made;

- Accordingly, the left one is towards the sections of the heating radiator already present.

In order to prevent further battery leakage, intersectional gaskets should be put on the nipple (they can be rubber, paranitic, or gel)

At the same time, you need to put them on carefully and carefully - this will serve as a guarantee that the gasket will be located as evenly as possible, without unwanted distortions. Next, you need to tighten the thread. This action should also be carried out without sudden movements, in a leisurely rhythm, and carefully

If you want to qualitatively build up a heating radiator, then there can be no question of any rush

This action should also be carried out without sudden movements, in a leisurely rhythm, and carefully. If you want to qualitatively build up a heating radiator, then there can be no question of any rush.

An intersectional gasket is required to prevent leakage

It is highly undesirable to damage the metal thread - because of this, not the most harmless problems may appear, the solution of which will have to additionally spend your own time and financial resources.

The enlarged radiator must be placed back on the bracket and the connection to the central heating pipe must be renewed. To do this, you need to arm yourself with a wrench of the appropriate diameter and tow, which is necessary for wrapping pipe threads when screwing the radiator.

It is not difficult to add sections to a heating radiator, for this you do not need to work in a team of heating installers for 10 years. But without a serious approach, the availability of elementary tools and the removal of this process of your personal time is indispensable.However, you can also resort to the second option for solving the problem of insufficient heating of the premises - to become a client of a company providing such services, whose employees will do everything themselves, quickly and efficiently.

Advantages and disadvantages of a one-pipe system

Single-pipe heating has gained wide popularity in the field of private construction.

The main reasons are the relatively low cost of the structure and the ability to mount it on your own, without the involvement of specialists.

But the single-pipe heating system has other advantages:

- Hydraulic stability - the heat transfer of other elements of the system does not change when individual circuits are turned off, radiators are replaced or sections are increased;

- The device of the highway costs a minimum number of pipes;

- It is characterized by low inertia and warm-up time due to a smaller amount of coolant in the line than in a two-pipe system;

- It looks aesthetically pleasing and does not spoil the interior of the room, especially if the main pipe is hidden;

- Installing the latest generation of shut-off valves - for example, automatic and manual thermostats - allows you to fine-tune the operation of the entire structure, as well as its individual elements;

- Simple and reliable design;

- Simple installation, maintenance and operation.

When connecting control and monitoring devices to the heating system, it can be switched to a fully automatic mode of operation.

Integration with the Smart Home system is possible - in this case, you can set programs for optimal heating modes depending on the time of day, season and other decisive factors.

The single-pipe heating main can be completely hidden by finishing.Such a device not only does not spoil the appearance of the room, but also becomes its detail - an interior item.

The main disadvantage of single-pipe heat supply is the imbalance in the heating of heat-releasing batteries along the length of the main.

The coolant cools as it moves along the circuit. Because of this, radiators installed far from the boiler heat up less than close ones. Therefore, it is recommended to install slowly cooling cast iron appliances.

The installation of a circulation pump allows the coolant to warm up the heating circuits more evenly, however, with a sufficient length of the pipeline, its significant cooling is observed.

Reduce the negative effect of this phenomenon in two ways:

- In radiators remote from the boiler, the number of sections is increased. This increases their heat-conducting area and the amount of heat given off, allowing the rooms to be heated more evenly.

- They draw up a project with a rational arrangement of heat-releasing devices in rooms - the most powerful ones are installed in nurseries, bedrooms and "cold" (northern, corner) rooms. As the coolant cools, the living room and kitchen go, ending with non-residential and utility rooms.

Such measures minimize the disadvantages of a one-pipe system, especially for one- and two-story buildings with an area of \u200b\u200bup to 150 m². For such houses, single-pipe heating is the most profitable.

Feature of the horizontal pipe laying scheme

Scheme of horizontal heating in a two-story house

In the vast majority of cases, a horizontal two-pipe heating system with bottom wiring is installed in one or two-story private houses.But, besides this, it can be used to connect to centralized heating. A feature of such a system is the horizontal arrangement of the main and return (for a two-pipe) line.

When choosing this piping system, it is necessary to take into account the nuances of connecting to various types of heating.

Central horizontal heating

To draw up an engineering scheme, one should be guided by the norms of SNiP 41-01-2003. It says that the horizontal wiring of the heating system should ensure not only proper circulation of the coolant, but also ensure its accounting. To do this, two risers are equipped in apartment buildings - with hot water and for receiving cooled liquid. Be sure to calculate a horizontal two-pipe heating system, which includes the installation of a heat meter. It is installed on the inlet pipe immediately after connecting the pipe to the riser.

In addition, hydraulic resistance is taken into account in certain sections of the highway.

This is important, since the horizontal wiring of the heating system will only work effectively while maintaining the appropriate pressure of the coolant.

In most cases, a single-pipe horizontal heating system with a lower wiring is installed for apartment buildings. Therefore, when choosing the number of sections in radiators, one must take into account their distance from the central distribution riser. The further the battery is located, the larger its area should be.

Autonomous horizontal heating

Heating with natural circulation

In a private house or in an apartment without a central heating connection, a horizontal heating system with a lower wiring is most often chosen. However, it is necessary to take into account the mode of operation - with natural circulation or forced under pressure. In the first case, immediately from the boiler, a vertical riser is mounted to which horizontal sections are connected.

The advantages of this arrangement for maintaining a comfortable temperature level include the following:

- The minimum cost for the purchase of consumables. In particular, a horizontal single-pipe heating system with natural circulation does not include a circulation pump, a membrane expansion tank and protective fittings - air vents;

- Work reliability. Since the pressure in the pipes is equal to atmospheric pressure, the excess temperature is compensated with the help of an expansion tank.

But there are also disadvantages to be noted. The main one is the inertia of the system. Even a well-designed horizontal single-pipe heating system of a two-story house with natural circulation will not be able to provide rapid heating of the premises. This is due to the fact that the heating network begins its movement only after reaching a certain temperature. For houses with a large area (from 150 sq.m.) and with two floors or more, a horizontal heating system with lower wiring and forced circulation of the liquid is recommended.

Heating with forced circulation and horizontal pipes

Unlike the above scheme, for forced circulation, it is not necessary to make a riser.The pressure of the coolant in a horizontal two-pipe heating system with bottom wiring is created using a circulation pump. This is reflected in the improvement of performance:

- Rapid distribution of hot water throughout the line;

- The ability to control the volume of coolant for each radiator (only for a two-pipe system);

- Requires less space for installation as there is no distribution riser.

In turn, the horizontal wiring of the heating system can be combined with a collector. This is true for long pipelines. Thus, it is possible to achieve an even distribution of hot water throughout all rooms of the house.

When calculating a horizontal two-pipe heating system, it is necessary to take into account the rotary nodes, it is in these places that the greatest hydraulic pressure losses are.

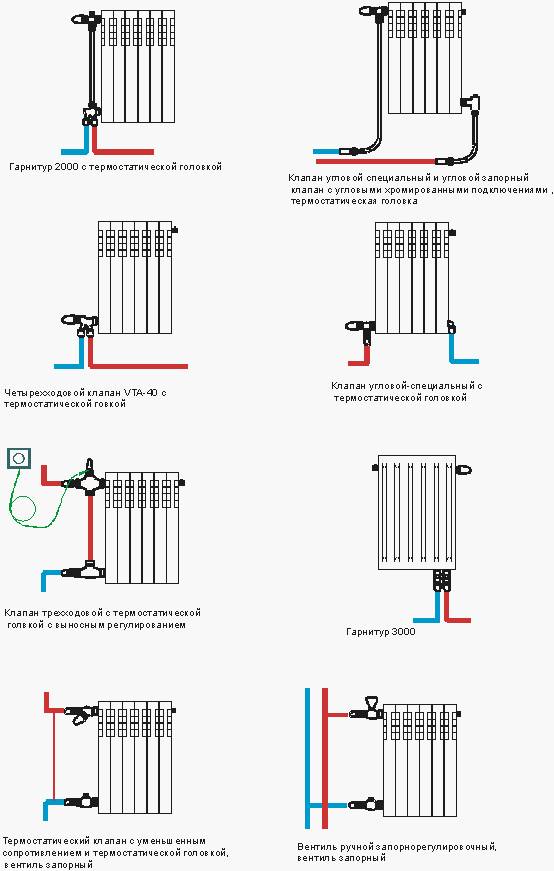

Connection methods

You can connect radiators to pipes in different ways, depending on the installation location and the laying of pipes in the room and, of course, the heating scheme:

When the connection method is selected (see diagram), you must:

- Wipe all joints and pipes with sandpaper and degrease them.

- Attach the radiator. This can be temporary fixing or installation, depending on the complexity of the location of the pipes of the heating system according to your scheme.

- We screw in the adapters, which, by turning, can be adjusted to the direction of the pipes to which the elements are connected. If, for example, they are located on the floor, then the adapter is screwed down with a thread, if the pipes go deep into the room, then the direction of the adapter changes. So the main thing is to look carefully at the layout of a single-pipe heating system.

- Pipe adapters, preferably made of domestically produced polypropylene, as experts advise, are attached to the main pipe with a soldering iron.

- We install the valve from above and the plug from below, as shown in the diagram, or vice versa.

Conclusion

Working with polypropylene pipes is not particularly difficult. Previously, any installation of the heating system has a ready-made scheme and thermal calculations. With the help of the drawn up scheme, you will be able not only to calculate the required number of pipes for your heating circuit, but also to correctly place the heating devices in the house.

The use of polypropylene pipes at home allows you to reinstall the radiator at any time. The presence of appropriate shut-off valves will ensure that you turn the radiators on and off at any time. However, during the installation process, certain rules and instructions should be followed.

- avoid using a combination of individual pipe fragments made of different materials during installation.

- Excessively long piping without the proper number of fasteners can sag over time. This applies to small heated objects, where there is a powerful autonomous boiler, respectively, the water in the pipeline has a high temperature.

When installing, try not to overheat the pipe, fittings and couplings. Overheating leads to poor soldering quality. Molten polypropylene boils, obscuring the internal passage of the pipe.

The main condition for the durability and quality of the pipeline of the heating system is the strength of the connections and the correct piping. Feel free to install taps and valves in front of each radiator.By installing an automation system and adjusting the heating mode, with the help of taps you can mechanically turn on and off the heating in the room.

Oleg Borisenko (Site Expert).

Indeed, the configuration of the room may require a combined connection of radiators. If the design of the radiator allows, then several radiators can be mounted in one circuit by connecting them in different ways - side, diagonal, bottom. Modern threaded fittings, as a rule, are high-quality products with consistent thread parameters. However, to ensure the tightness of threaded connections, various seals are used that differ in characteristics. The sealing material must be selected depending on the design features of the heating system and its location (concealed, open), since sealants can be designed to adjust (tighten) threaded joints, or they can be a one-time use that does not allow deformation after curing. Select a sealant for sealing threaded connections will help the material of this article:

- Do-it-yourself project and calculation of a brick fireplace

- How to lay and insulate heating pipes in the ground?

- Why do you need a plinth for heating pipes?

- Choosing ribbed registers, radiators and heating pipes

- How to hide a heating pipe?