- Selection and connection of the pump

- Pump connection

- Utility rooms

- How does the pumping station work and what does it consist of

- The nuances of installing a pumping station in a private house

- Choosing a place for the unit

- What equipment is needed for arranging the structure

- First start-up and verification of correct installation

- Selecting an installation site

- How to determine the depth of suction

- Security Considerations

- Convenience and operating conditions

- Pumping station next to the well

- Caisson

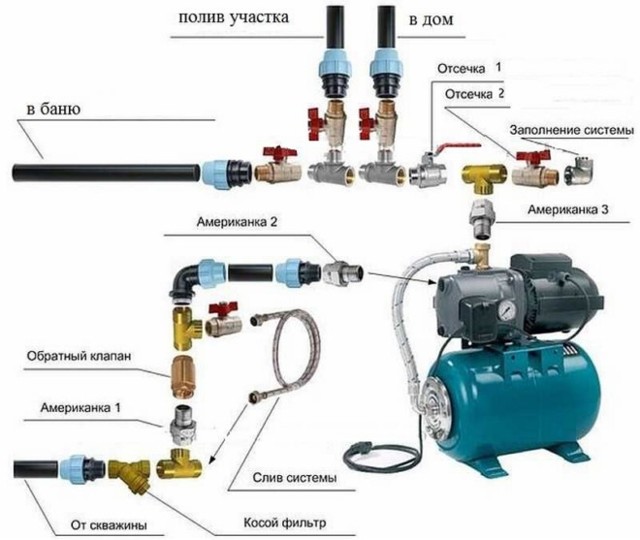

- Connection order: step by step instructions

- Equipment and materials

- Pump equipment

- Hydraulic accumulator

- Water storage tanks

- Automatic systems and elements that ensure control and reliable operation of the pumping station system

- How is the pumping station set up?

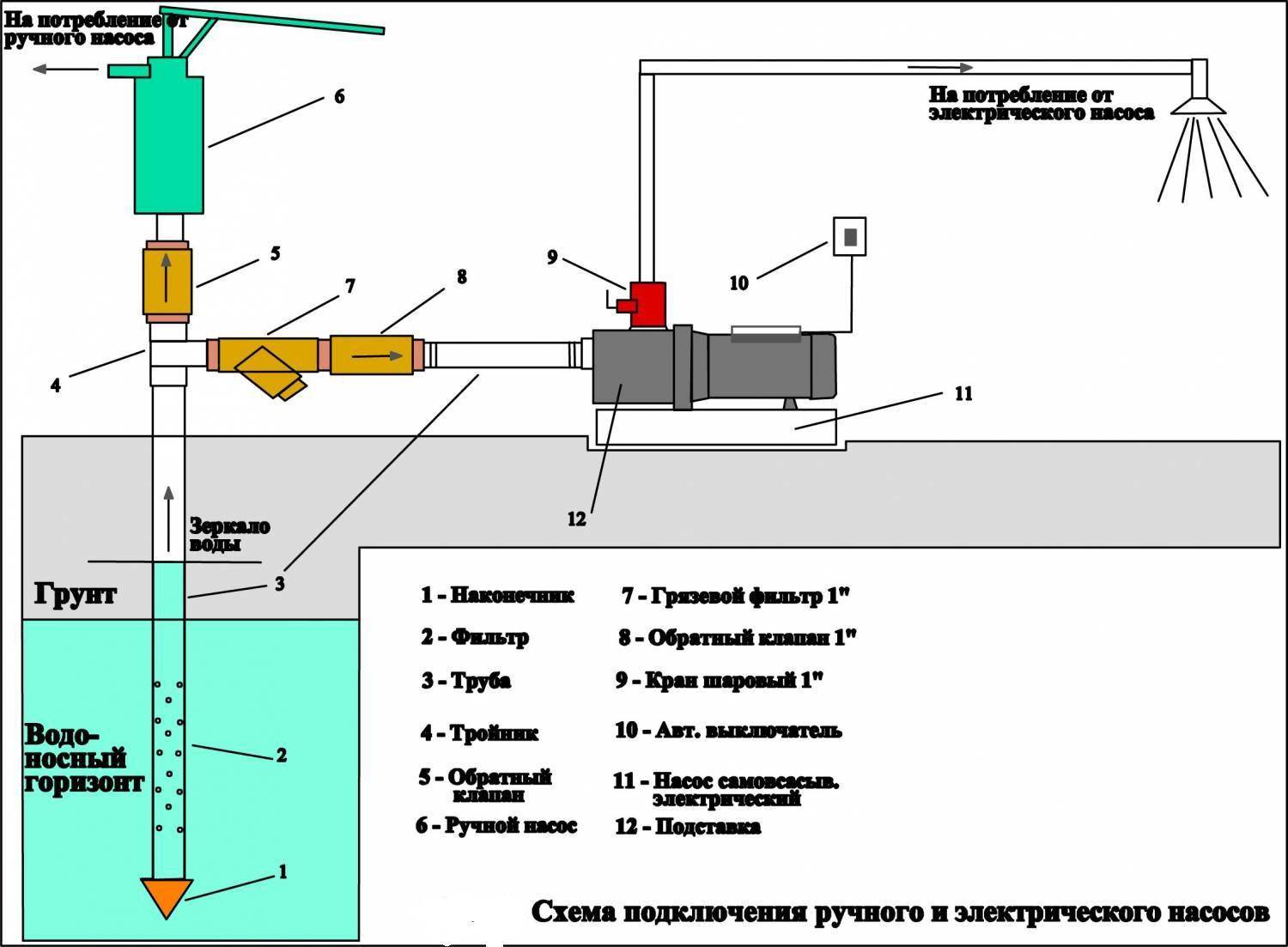

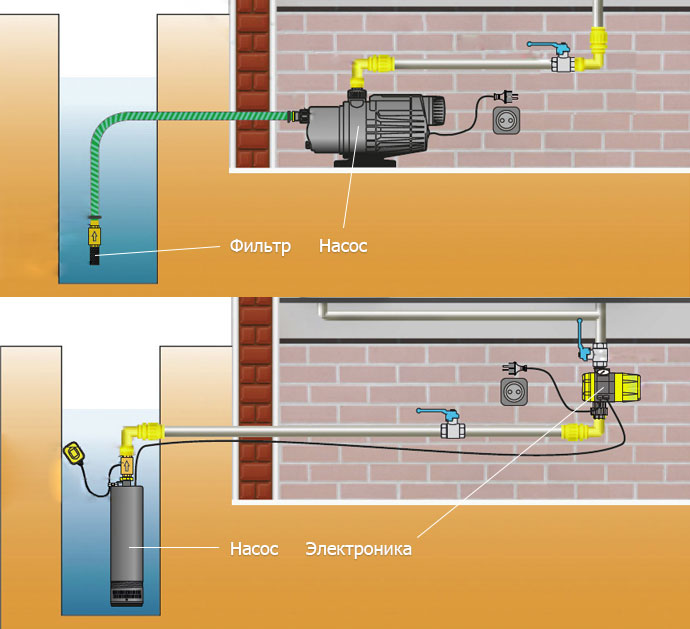

Selection and connection of the pump

The selection of the pump must be done after the well has been drilled. Because its choice should be based on the characteristics of the source. What you need to know to choose the right device:

- well depth and water column height;

- source performance;

- consumption of water by consumers;

- casing diameter.

Typically, either centrifugal or rotary submersible pumps are used. Another option is to use vibration devices. However, despite the cheapness, it is better not to use them, because.they destroy the walls of the well.

When buying a device, you need to pay attention to its power and maximum lifting depth. These characteristics should be with a margin - if the pump works at the limit of its capabilities, it will quickly fail

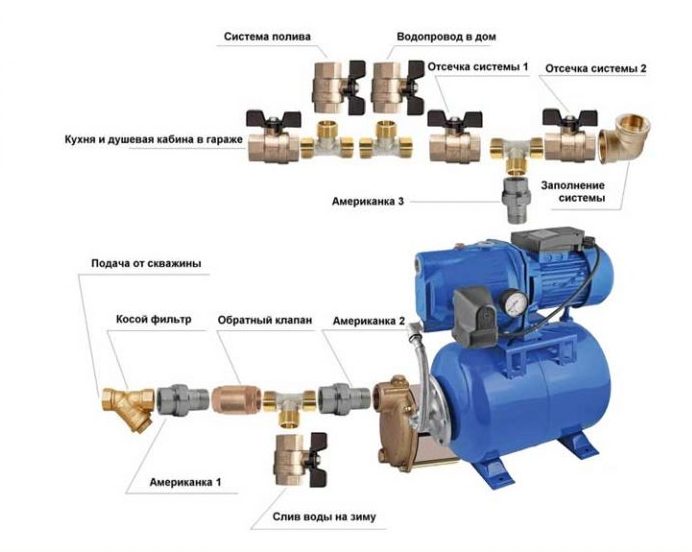

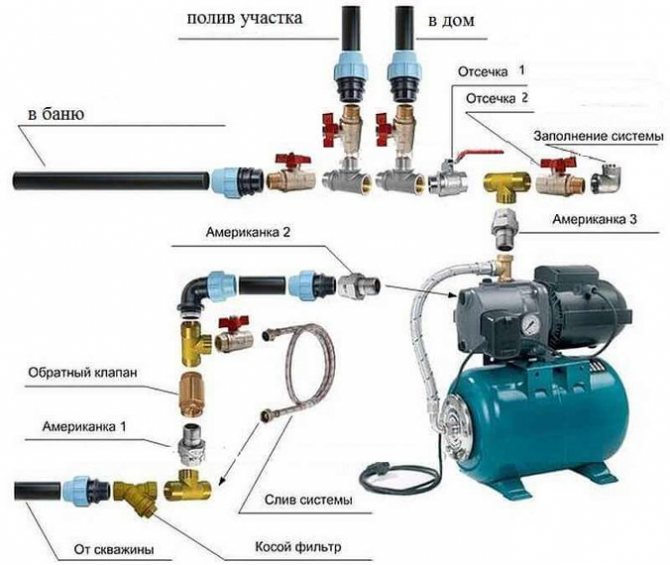

Pump connection

To suspend the pump in the well, you need to use a strong steel cable - if the unit falls into the casing, it will be very problematic to get it. In addition, it is desirable to be equipped with a simple winch - it will be much easier to lower the pump into the casing. Moreover, the mass of the pipe is added to its weight.

- a check valve is connected to the pump;

- a coupling is screwed onto the valve and it is connected to a water pipe;

- the electric cable must be fixed with plastic clamps to the pipe every 2-3 meters;

- the pump is brought into the well and installed at a depth of about 2 meters from the bottom;

- the cable and pipe are threaded through the head and fixed with clamps.

After that, the water supply is connected to the main line and a test run is made. If the water has gone, then everything is done correctly.

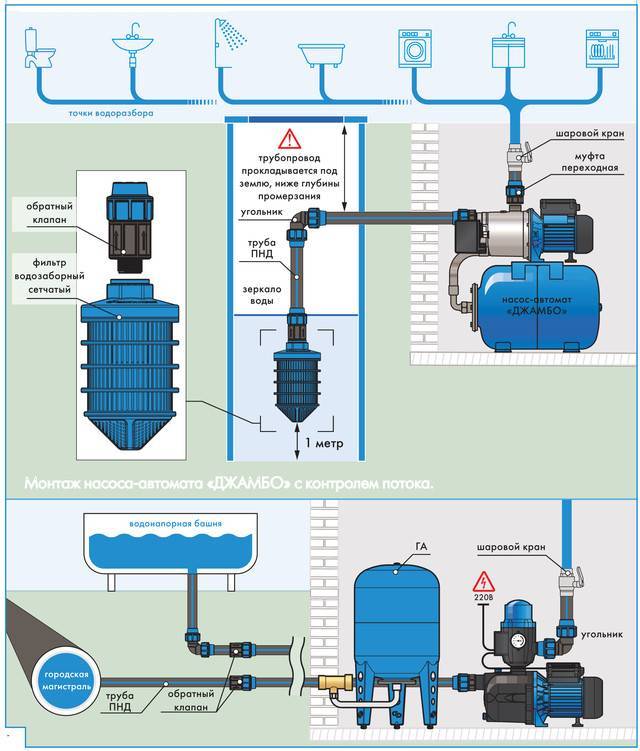

A complete scheme for connecting a well to a country house

Utility rooms

The operation of the pumping station is accompanied by a high level of noise, which makes it almost impossible to install equipment in close proximity to living rooms. If this option is unavoidable, and the installation of pumping equipment is supposed to be in the pantry or in the corridor, then you need to take care of the maximum sound insulation of the room.

If it is planned to use a pumping station for a summer residence to pump water from a well only in the summer, then it is recommended to use a portable compact unit.It can be installed in a temporary structure that will protect from rain. The simplest option is a wooden structure in the form of a box. For the winter, equipment and temporary plumbing are dismantled and stored in a warm room.

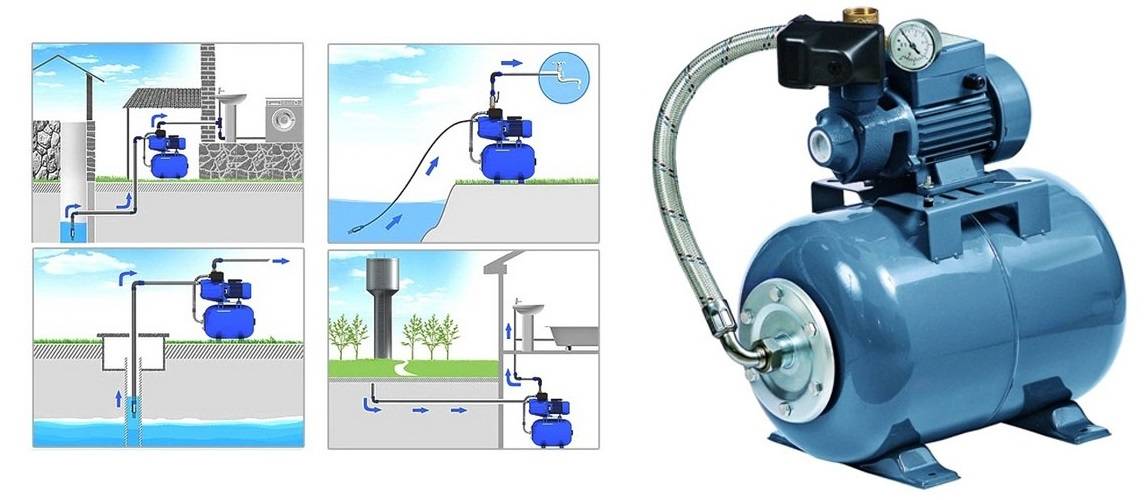

How does the pumping station work and what does it consist of

There are several versions of such devices. All of them differ in the type of pumping unit and accumulator used. If we consider a model with a hydraulic accumulator, then we can talk about a higher degree of efficiency due to the design features:

- membrane tank, divided into two compartments by a partition;

- pressure switch that controls the operation of the device with significant changes in pressure values;

- electric motor;

- the pumping unit itself;

- ground terminals;

- manometer;

- cable.

The basis for the operation of such a device is a pressure switch, which is triggered by significant changes in the pressure value, both up and down. This reduces the number of equipment starts and, thus, reduces the wear rate of the main components. If a model is considered where a storage tank is provided instead of a hydraulic accumulator, then in this case one should not expect high performance, since the liquid moves naturally, without forced action on it.

In addition to everything, the considerable dimensions sometimes make it difficult to install the device, and the storage tank itself is necessarily mounted above the level of the pumping station. And another important drawback of this type of equipment is the likelihood of flooding the premises when water is overflowed from the storage tank.But this happens only in the event of a breakdown of the tank fullness sensor. It is this element that is responsible for starting the equipment.

The main components of the pumping station are also described in the video.

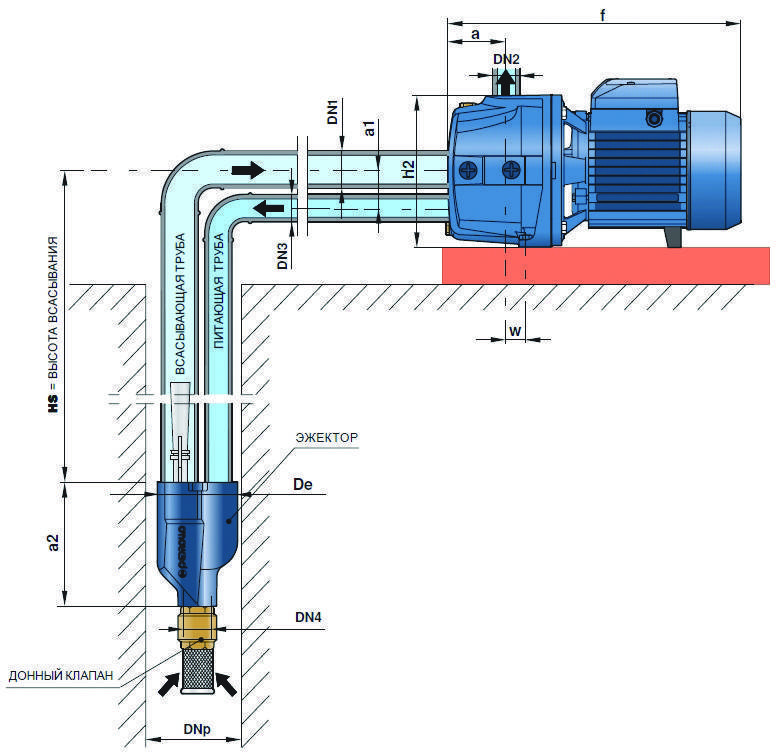

Pumping station with a hydraulic accumulator and an external ejector allows you to raise water from a depth of 8 meters or more

If you want to connect the pumping station to the well with your own hands, the scheme will also differ depending on the type of pumping unit: with and without an ejector. Moreover, the first option exists in two variations: with a built-in (it has a higher performance) and a remote ejector. A design feature with a built-in ejector is the ability to suck water when creating a vacuum. But at the same time, there is an increased noise level. Somewhat less efficient versions with a remote ejector. The most simple and inexpensive devices in terms of cost are ejectorless.

This is interesting: Do-it-yourself head for a well: device and installation procedure

The nuances of installing a pumping station in a private house

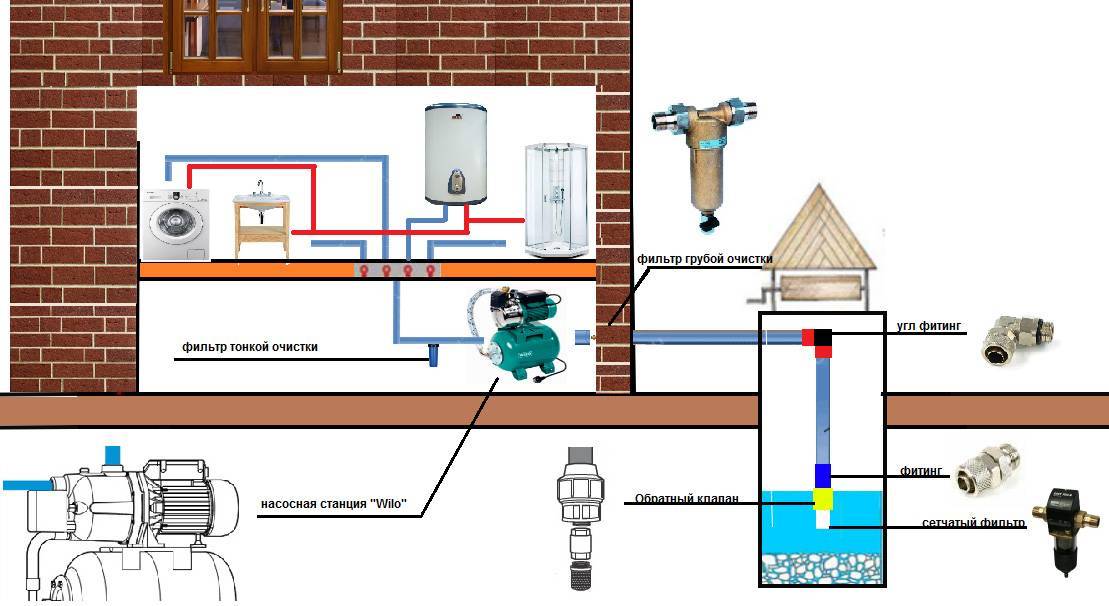

There are several classifications of pumping stations according to the water intake mechanism. There is a pumping station with a remote ejector. The ejector is placed in the well, which makes it possible to place the station in the house due to the absence of a high noise level.

There is a pumping station with a built-in ejector: it is capable of pumping water from a depth of 8 m, low sensitivity to water pollution by debris, but the operation of this installation is accompanied by a high noise level.

Based on the type of pumping station, installation is possible in 3 places:

- Basement: free access for maintenance and repair, it is possible to make high-quality sound insulation.

- A separate building, which is located above the wellhead or next to the well, but the construction of such a building entails additional costs, because this building must also be heated.

- A caisson is a structure with the bottom located below the freezing level.

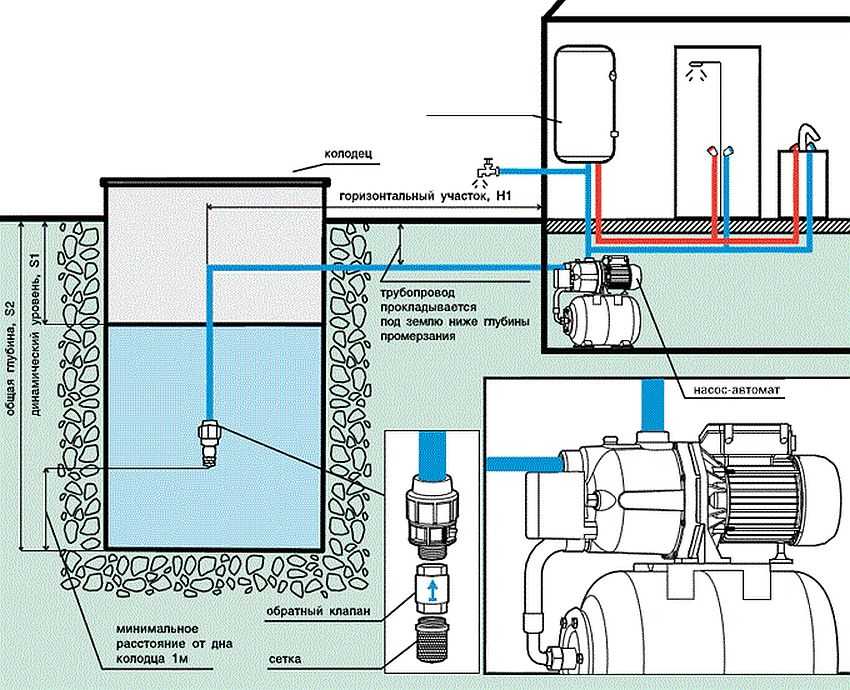

According to the method of supply, water goes through a storage tank with a volume of up to 100 liters, which is installed in the attic of the house and serves for accumulation. It is distributed by gravity through the pipes of the house, but the water pressure is weak. The float valve controls the liquid level. This type is economical, because the pump is turned on only to fill the tank. With the help of a hydraulic accumulator or a membrane tank that regulates pressure, it is possible to place the system in the basement of a building, the water supply is about 20-30 liters. According to the source of water, there are surface pumps.

It is better to install the pumping station in a dry place

A pump capable of lifting water from 9 m is located on the surface in a warm room, the intake takes place using a pipe or hose attached to it and immersed in the source. The pump must be protected from moisture. There are submersible pumps - they have a waterproof case, they are placed entirely in water in a source with a depth of more than 10 m. Submersible pumps are borehole and well. Pumps for wells are centrifugal, have high performance, their minus is that they are extremely sensitive to various water contaminants. The well pump is easy to install, unpretentious to water quality, but has low power.

Choosing a place for the unit

You can install a pumping station with your own hands in one of three places:

- in the basement of a private house;

- in a separate building;

- in a caisson.

If your house has a dry spacious heated basement, then you can use one of its premises for installing a pumping unit. The room must be well insulated and soundproofed. The station can be mounted on a stand away from walls to protect structures from vibration.

If the area of \u200b\u200bthe house does not allow allocating a separate room for the unit, you can build an insulated extension to the house or build a separate structure. Of course, this will incur additional costs, but this is the only way you can properly install and protect the equipment. By the way, it is better to build a building where heating networks pass in order to heat this building as well.

The installation of the caisson is carried out near the head of the well. This option is good because placing the unit away from home will protect residents from noise during its operation. If you install the caisson with your own hands, do it right - its bottom and the pumping station itself should be located below the freezing point of the soil. To ensure uninterrupted water supply even in winter, the caisson must be carefully insulated.

What equipment is needed for arranging the structure

To equip an artesian well with your own hands, you will need:

- water lifting equipment;

- cap;

- hydraulic tank;

- additional equipment for pressure, level, water flow control;

- frost protection: pit, caisson or adapter.

When buying a submersible pump, it is important to correctly calculate the required power. The model is selected according to performance and diameter. You can’t save on this equipment, because

the performance of the entire water supply system of the site depends on it

You can’t save on this equipment, because. the performance of the entire water supply system of the site depends on it.

The best option is a model in a high-strength hermetic case, equipped with sensors, filter units, and automation. As for brands, Grundfos water-lifting equipment deserves special attention.

Typically, a submersible pump is installed at a height of about 1-1.5 m from the bottom of the hydraulic structure, however, in an artesian well, it can be located much higher, because. pressure waters rise above the horizon.

The immersion depth for an artesian source should be calculated based on the indicators of static and dynamic water levels.

To keep artesian water crystal clear, the production pipe must be protected from debris, surface water and other adverse environmental factors. This structural element is used to securely fasten the submersible pump cable.

The head consists of a cover, clamps, carabiner, flange and seal. Models of industrial production do not need to be welded to the casing, they are fastened with bolts that press the cover against the seal, thus ensuring a complete seal of the wellhead. Features of mounting homemade heads depend on the design of the devices.

The hydraulic accumulator is an important unit of an autonomous water supply system. It is necessary to ensure the normal operation of the water supply, protect the pump from constant on-off and prevent water hammer. The battery is a water tank, additionally equipped with pressure sensors and automation.

When the pump is turned on, water first enters the tank, and from it is supplied to the draw-off points. The water levels at which the pump turns on and off can be controlled using pressure sensors. On sale there are hydraulic tanks with a capacity of 10 to 1000 liters. Each well owner can choose the model that best suits their system.

The well must be protected from freezing. For these purposes, you can make a pit, install a caisson, an adapter. The traditional option is a pit. It is a small pit, the walls of which are reinforced with concrete or brickwork. From above, the structure is closed with a heavy lid with a hatch. It is undesirable to install any equipment in the pit, because even with good waterproofing, the walls still let moisture through, the design is not airtight.

A more modern and technological analogue of the pit is the caisson. This design is best purchased at a specialized store. Industrial production caissons are pre-designed to accommodate all the necessary equipment. Plastic models are well insulated and airtight. Metal caissons often need additional insulation.

For a single-pipe artesian well, an arrangement using a pitless adapter is suitable. In this case, the function of the protective structure is performed by the casing pipe itself. The adapter can only be installed if the column is made of metal. There are serious difficulties with the operation of a plastic pipe, and the service life of the structure may be short-lived.

First start-up and verification of correct installation

For the initial start-up, the pump must be filled with water. To do this, provide a special filling funnel, cut off from pump shut-off valve. A more convenient option for initial filling is to pump the pumping station with a manual piston pump connected at the outlet of the station.

The pump is controlled by a pressure switch.

It is connected to the hydraulic system and has a spring-loaded diaphragm (bellows) that transmits water pressure to the electromechanical part of the relay. The relay ensures that the contacts close when the pressure falls below the set pressure (switch-on pressure) and open when the switch-off pressure is reached. Usually, the lower pressure value is directly adjusted by adjusting the compression force of the corresponding spring. The second adjustment is responsible for the pressure difference between turning the pump on and off.

You can determine which pressure values are set by looking at the pressure gauge on the supply pressure line. If there is no flow (closed taps), turn on the station and wait for it to turn off. The pressure gauge will show the cut-off pressure. Open the tap (more convenient - near the station), slowly release the pressure. At the time of switching on the station, fix the switch-on pressure. If the measured values do not suit you, remove the cover of the pressure switch and adjust the pressure values by turning the corresponding nuts.

During the initial installation of the station and during its operation, it is necessary to maintain the actual values of the parameters in the operating range specified in the station passport. It is not recommended to force the pump to work, as they say, for wear by increasing the pressure on the relay. This mode usually reduces the time between starting and stopping the pump.With a significant overestimation of the set pressure, the pump can switch to the mode without turning off at all, which means that the pump power is not enough to create the set pressure.

A simple tire pressure gauge is used to determine the available pressure. Naturally, before checking with a pressure gauge and installing the station, check the nipple. If the air does not try to escape from it, then both the nipple and the membrane itself may malfunction. Be sure to keep in mind that it makes sense to measure air pressure only if there is no water pressure in the membrane, for which it is necessary to bleed it with the pump turned off.

The pre-set air pressure should be slightly higher than the start pressure of the pump. Then, by the time of launch, there will still be a small amount of water in the tank.

The non-return valve ensures the movement of water in the system only in one direction. The automation of the pumping station controls the pressure or the presence of flow in the pressure part of the water supply. This means that the check valve must always be installed in such a way that the pressure at the installation site of the automation cannot spontaneously decrease. Depending on the specific conditions, the check valve can be installed directly at the inlet of the pumping station or at the end of the water intake pipe lowered into the well. Sometimes installed at both points.

When starting up, the pump must be filled with water. This should also be taken into account when choosing a place to install a check valve. To protect the pumping station from sand, filters are sometimes installed on the intake line. At the end of the intake pipe, a check valve is often mounted, combined with a strainer into one unit. Surface pump stations are sometimes supplied with a rope filter at the inlet.Of course, you need to monitor its condition, as it becomes clogged, the suction depth will gradually fall.

Video clip about connecting the station

The plot provides the information necessary for clarity. How to assemble the station, as well as how to properly connect it to the well.

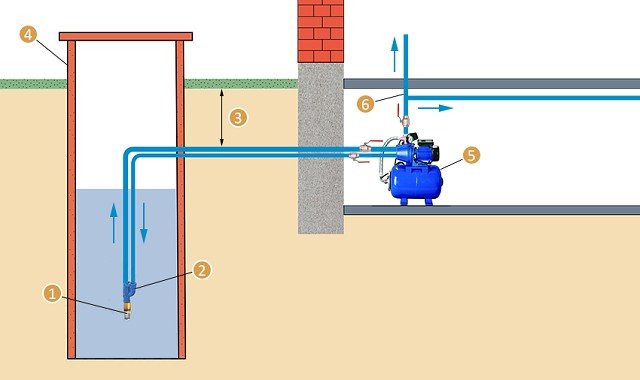

Selecting an installation site

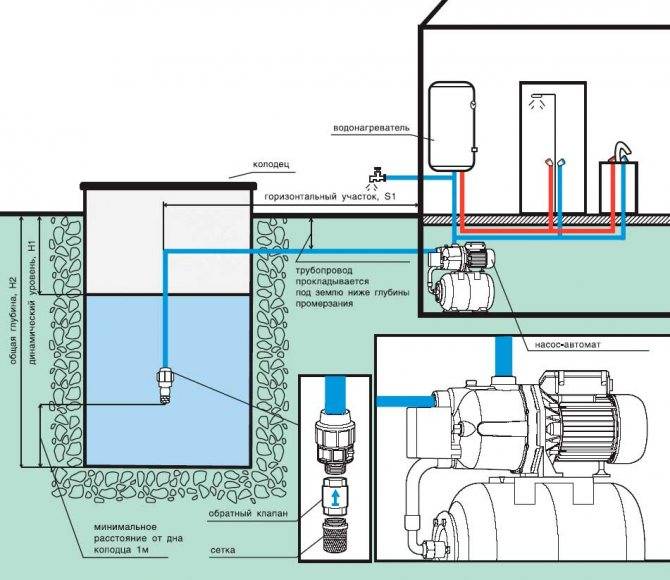

Pumping stations are installed near a water source - a well or a well - in a specially equipped pit - a caisson. The second option is in the utility room in the house. The third is on a shelf in the well (such a number will not work with a well), and the fourth is in the underground.

Installation of a pumping station in the subfield - the noise from its operation may be too loud

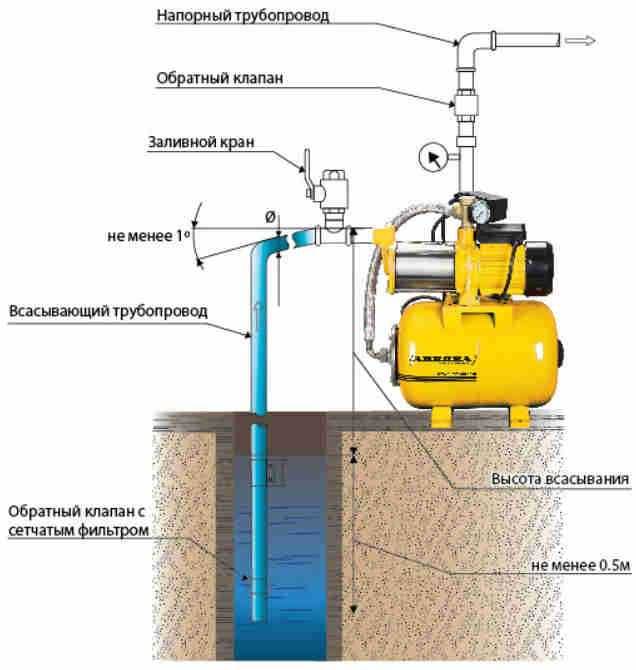

How to determine the depth of suction

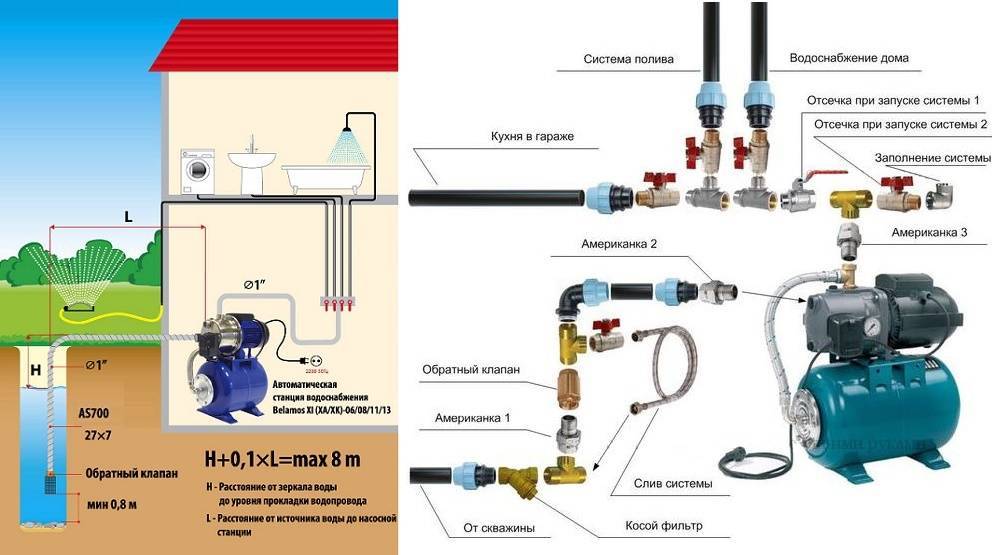

When choosing a place, they are primarily guided by technical characteristics - the maximum suction depth of the pump (from where the pump can lift water). The thing is that the maximum lifting depth of pumping stations is 8-9 meters.

Suction depth - the distance from the water surface to the pump. The supply pipeline can be lowered to any depth, it will pump water from the level of the water mirror.

Wells often have a greater depth than 8-9 meters. In this case, you will have to use other equipment - a submersible pump or a pumping station with an ejector. In this case, water can be supplied from 20-30 meters, which is usually enough. The disadvantage of this solution is expensive equipment.

Suction depth - a characteristic that determines the installation method

If you are only a meter away from being able to install conventional equipment, you can put the station in a well or above a well.A shelf is attached to the wall in the well, in the case of a well, a pit is deepened.

When calculating, do not forget that the level of the water mirror "floats" - in the summer it usually goes down. If your suction depth is on the verge, there may simply be no water during this period. Later, when the level rises, the water supply will resume.

Security Considerations

Another point to consider is the safety of the equipment. If the installation of a pumping station is supposed to be near a house with permanent residence, there are fewer problems - you can choose any option, even in a small shed. Only one condition - it should not freeze through in winter.

The installation of a pumping station in a barn is suitable for permanent residence and the condition of insulation / heating for the winter

If this is a dacha where they do not live permanently, the matter is more complicated - it is necessary to arrange such a room that is not striking. The safest way to install a pumping station is in the house. Although they can carry it away in this case.

The second place where you can install a pumping station is a buried camouflaged caisson.

Scheme of installing a pumping station in a well

The third is on a shelf in the well. Only in this case, the traditional house for the well is not worth doing. You need a steel lid, which is locked with a reliable lock (weld loops to the ring, make slots in the lid, on which to hang constipation). Although, a good cover can also be hidden under the house. Only the design must be thought out so that it does not interfere.

Convenience and operating conditions

Installing a pumping station in the house is good for everyone, except that the equipment makes noise during operation. If there is a separate room with good sound insulation and it is possible according to the technical characteristics, no problem.Often they make a similar room in the basement or in the basement. If there is no basement, you can make a box in the underground. Access to it is through a hatch. This box, in addition to sound insulation, must also have good thermal insulation - the operating temperature range starts from + 5 ° C.

To reduce the noise level, the station can be placed on thick rubber to dampen vibration (created by a cooling fan). In this case, even installation in the house is possible, but the sound will certainly still be.

Caisson from concrete rings

If you stopped at the installation of a pumping station in a caisson, it must also be insulated and also waterproof. Usually, ready-made reinforced concrete containers are used for these purposes, but a caisson can be made from concrete rings (like a well). Install the ring with the bottom down, the ring with the lid on top. Another option is to lay it out of brick, pour concrete on the floor. But this method is suitable for dry areas - the groundwater level should be lower by a meter below the depth of the caisson.

The depth of the caisson is such that the equipment is installed below the freezing level. Expanded polystyrene insulation. Better extruded. Then you also get waterproofing at the same time.

For a caisson of concrete rings, it is convenient to use a shell (if you find a suitable diameter). But you can also slab polystyrene foam, cut into strips and glue it. For rectangular pits and structures, slabs are suitable that can be glued to walls using bituminous mastic. Lubricate the wall, apply insulation, you can additionally fix it with a pair of nails / dowels.

Pumping station next to the well

Is it possible to install a pumping station in a structure on the surface, without lowering it into a mine? In the case when the water in the well is high, then this can be done. The figure shows a diagram of switching on the station using a complete suction hose with a check valve installed on it and a threaded fitting for connecting to the pump. The procedure for starting the station is similar to that described in the previous paragraph.

How to install a pumping station in a well may not always be clear. Moreover, when buying it, a consultant is unlikely to be able to reveal all the subtleties. Using the detailed information from the article, you can make the connection yourself.

Caisson

Under this concept lies a structure located in the ground directly above the exit of the well. For its arrangement, they dig a pit, the depth of which exceeds the level of soil freezing. The location of the caisson at an insufficient depth will not allow the use of a pumping station. well station on water throughout the year, at low temperatures the pump will fail.

Equipping the caisson with your own hands, it is necessary to provide for additional waterproofing of the walls and insulation of the upper part. The volume of the room should allow you to freely carry out repair and maintenance activities. Installing a pumping station in this way allows you to position the structure at a certain distance from the living space, so the noise of the operating unit will not disturb the comfortable stay of people in the house.

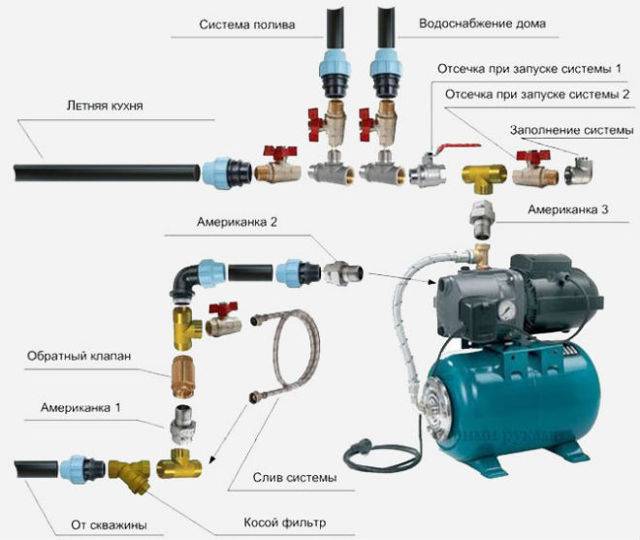

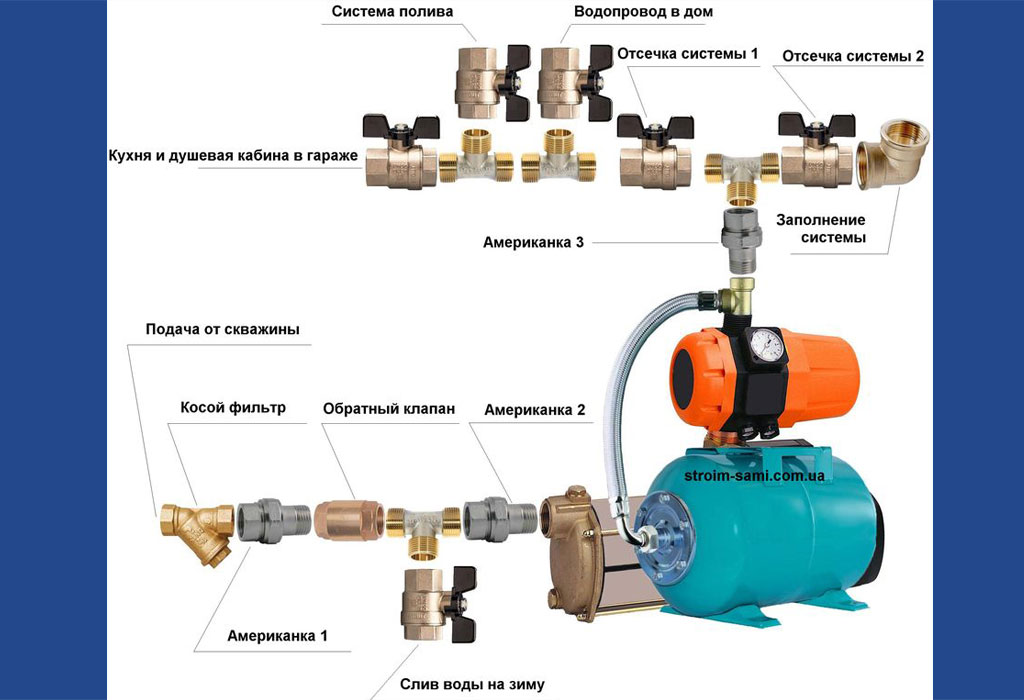

Connection order: step by step instructions

Not everyone knows how to properly connect a pumping station. When installing block equipment, the assembly implies the combination of pressure and suction pipelines.A filter with valves is connected to the pipe immersed in the well, it is brought out through an adapter or head.

The suction line is carefully sealed. Otherwise, air will enter the water supply system, which will disable the pump. The pressure part is supplied with a valve.

12 steps to connect a pumping station:

It is worth considering how the pumping station is connected to the well when choosing modular equipment. Connecting a well to a pumping station includes the following steps:

- Hydraulic accumulator harness. First of all, a fitting with 5 nozzles is mounted. It is connected directly. After that, they set up and install a protective relay, a pressure gauge and a water inlet. The remaining outlet is used to connect the pressure pipe. Submersible pumps are installed in wells with a depth of more than 10 m. This avoids the problems caused by the need to install an ejector and a suction part.

- Pipeline outlet. Produced through the head of the source. Pressure pipes are laid in a trench leading to the house. Elements should be located below the freezing depth of the soil.

- Connection to the electrical network. During the installation process, the starting block of the station is installed, the output is connected to it with copper wires. The pump must be powered by a separate automatic switch.

After the assembly process is completed, the tightness of the joints is evaluated. For the first time, the accumulator is filled slowly so as not to violate the integrity of the membrane.

Equipment and materials

Many are wondering how to make plumbing with their own hands. This is quite within the power of anyone who has a desire to understand its device.

Selection of equipment is carried out after determining the source.To connect to the central water supply, pipes and shut-off taps are sufficient. It is desirable to install a well at the connection point, but you can do without it. This is determined by the technical conditions issued by the water utility.

In the case of an autonomous variant, the water supply scheme is much more complicated. Various equipment will be required for lifting and cleaning.

Pump equipment

A submersible or surface pump is used to supply water. Surface pumps are much cheaper than submersible ones and can be purchased immediately with a hydraulic accumulator, this installation is called a pumping station. They are easy to maintain, and the well casing can be small enough to fit a water pickup hose with a filter tip.

Pumping stations are suitable for drawing water from surface sources. They are also installed if the pressure in the central water supply is very low and does not suit the consumer.

If the depth to the surface of the water in the well (well) is more than 5 meters, then the choice definitely remains with the submersible (deep) pump.

When choosing a pump, consider:

- the height of the water rise (pressure) from the depth of the pump to the highest point of the water intake in the house;

- required hourly consumption (liter/min.), taking into account the number of users;

- pump diameter, taking into account the well casing diameter:

- pump type: vibration, vortex, borehole, centrifugal (the last 3 pumps are a kind of centrifugal).

Vibratory pumps are inexpensive, but they are not recommended for use in wells, due to the vibration created in the environment, they are suitable only in wells. The most reliable choice is the vortex pump. It has the lowest requirements for water purity.

Important: in each case, taking into account the type of well, water purity, lifting depth, the right choice can only be made by a specialist who has experience in operating pumps in a given area.

Hydraulic accumulator

For each electric motor, the most difficult moment is the start-up. Increased currents by 7 times, low torque, starting under load, all this significantly reduces its service life. To prevent the pump from starting often, due to a glass of water, a minute washing of hands, flushing in the toilet, leaks in the network and other trifles, a hydraulic accumulator must be installed.

And the larger the volume of the tank, the better for the pump. As, however, for users, in case of a power outage

Its installation is mandatory, and good condition is very important

The volume of the accumulator for water supply is determined by a special calculation. Simplified, you can choose by pump performance per minute, if the pump was selected taking into account the number of users. The result obtained is the minimum volume. If the space allows you to install a larger tank, it is worth taking a couple of sizes larger. The dimensions of the tanks are different for each manufacturer. This row serves as an example, the volume is indicated in liters: 8, 10, 12, 18, 25, 30, 35, 40, 50, 60, 80, 100 and more.

It must be borne in mind that the useful volume of the tank, that is, the volume of water that it will give out when the power is turned off, is only 1/3 of its volume. This is assuming that the air chamber has a free pressure 0.2 bar lower than the pump shutdown pressure. The owners pump air above this value, therefore, the tank will give even less.

Water storage tanks

In fact, this is the same accumulator, only much larger. If the accumulator serves to protect the pump from frequent switching on, then the storage tank-accumulator also serves to create a reserve supply of water. But do not flatter yourself, a tank of 500 liters will be able to give no more than 225 liters of useful water, with the right pressure in the air chamber.

Therefore, it is easier and cheaper to install a simple tank of the required volume, but you will have to take water from it with a bucket. It can be installed in the attic, but the pressure will not be enough, and in winter you will need to take care that the water does not freeze.

Tip: by installing an automatic storage tank replenishment system, you can ensure uninterrupted water supply at home.

Automatic systems and elements that ensure control and reliable operation of the pumping station system

It is necessary to say in more detail about modern systems as part of pumping stations that will ensure uninterrupted water supply to your home, as well as guarantee long-term operation of the pump.

So, when implementing a pumping station of any type, it is necessary to implement the following automation systems: - Dry protection pump stroke ("Protection against "dry run" for the well pump using a pressure switch and level sensors.

Electrical circuit for protecting the pump from "dry running");

- The use of a pressure switch or electrocontact pressure gauge (signaling) to maintain pressure in the water supply system (“Water pressure switch (installation, characteristics, design, configuration)” and the article “Electrocontact pressure gauge (signaling) (principle of operation, application, design, marking and types) for water supply systems”.

In addition, if you are assembling a pumping station, which is said from A to Z, then information on choosing a receiver “Hydraulic receiver (hydraulic accumulator) for a house water pumping station (selection, design)”, as well as information on pipe installation “ Installation of metal-plastic (metal-polymer) pipes with threaded fittings”, “Do-it-yourself soldering of plastic (polypropylene) pipes”.

Now, having already a certain amount of information, and, accordingly, knowledge, we hope that the selection of components, as well as the assembly and connection of your pumping station will take place more deliberately, faster, and also with minimal deviations and errors.

The problem of water supply is at the forefront of creating a comfortable living environment in the country. This most often helps to solve the problem of connecting the pumping station to the water. Communications to provide a home is not just a banal plumbing facility with liquid Gander, after all, a complete home water supply system.

The need for an independent water supply, the basic needs of rural dwellers, leads to the constant use of water for cooking, sanitary and domestic use, as well as refrigerants in the heating system.

Household pumps are not always faced with such a variety of work functions.

In addition, installing a pumping station in a private home allows evacuation and supply of water to increase system pressure if the existing pump is not strong enough to deliver liquids to the right place on the surface, in the garden, in the garden or at home.It offers various models on the market, but only a few components for a sufficient distribution of the base model, which is reflected in each pump installation system:

- storage tank;

- pump;

- control relay;

- non-return valve that does not allow leakage;

- filter.

A filter is needed, otherwise the grain of the grains will lead to rapid abrasive wear of machine parts.

Equipment location

The installation and operation of the pumping station ensures long-term reliable operation of the equipment, subject to the following conditions:

- when installing the station in a bunker, it is placed below the level of soil freezing in winter, which is at least two meters;

- The place where the station is installed (basement or casson) must be heated in winter;

- When assembling the connection plan by hand, it is necessary to prepare a stand, which is then installed on the station in order to prevent groundwater floods.

It is important!

Do not touch the equipment with walls so that the mechanical vibration of the operating mechanism does not affect the room.

How is the pumping station set up?

The level of comfort in a country house is largely determined by the presence of a professionally debugged water supply system, the main component of which is a pumping station.

The structure of the devices involved in the organization of water supply must be known in any case. It will come in handy if you lay the plumbing yourself or entrust the installation work to professionals.

Knowing the principle of operation of individual elements of the system, in the event of an accident or failure of one of the devices, you can independently, and most importantly, quickly repair the pumping station or replace it.

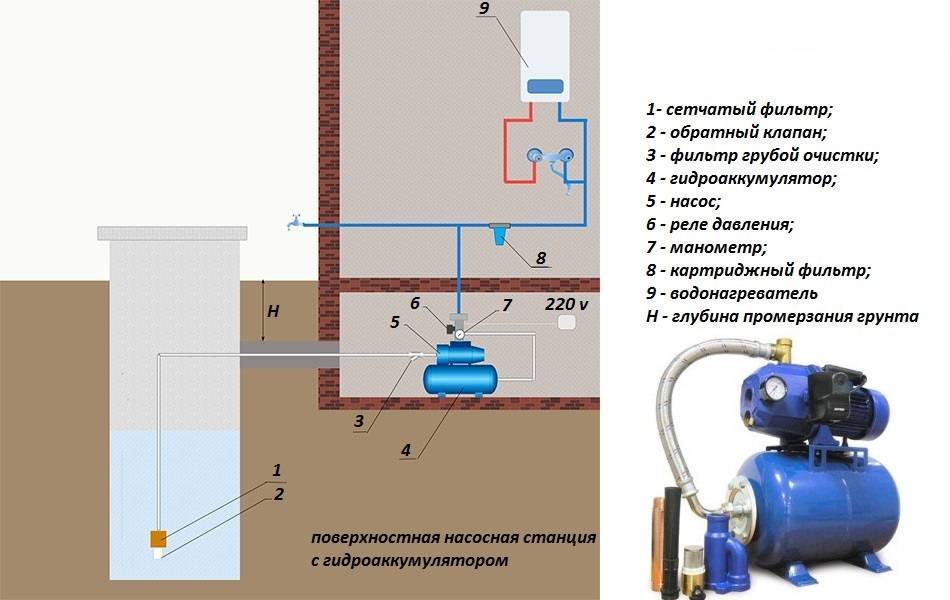

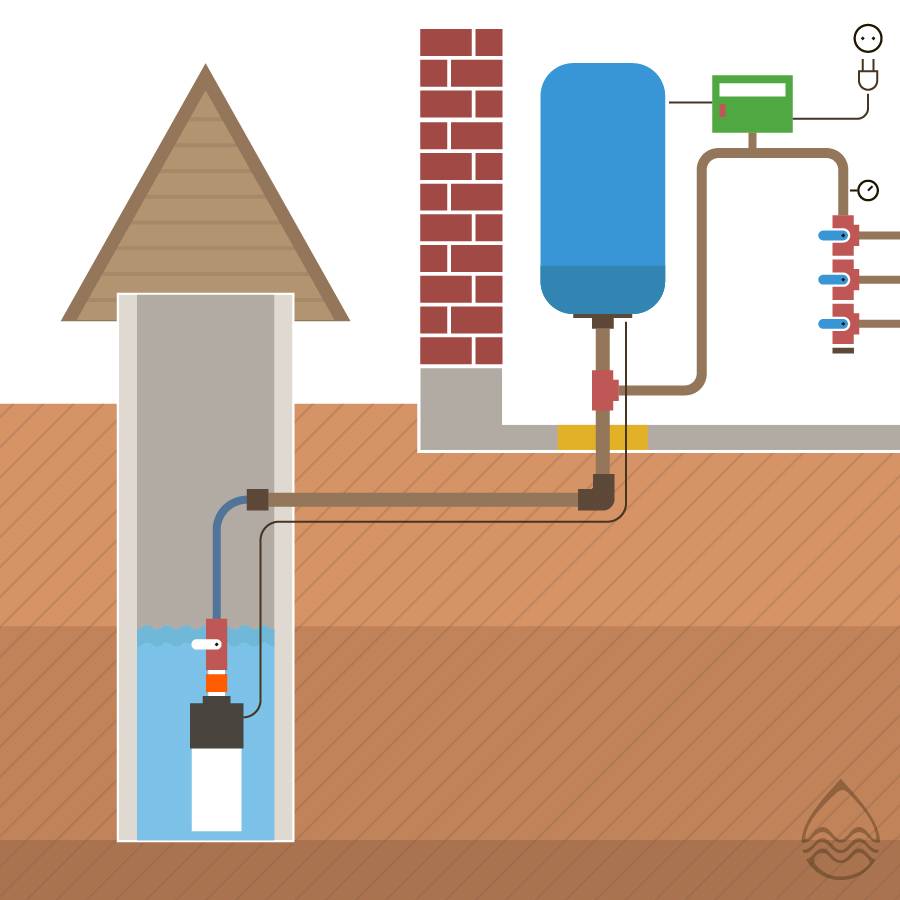

So, the most important components of the water supply scheme using a pumping station are the following:

- device for water intake with a filter;

- non-return valve that prevents the movement of water in the opposite direction;

- suction line - a pipe leading to the pump;

- pressure switch for adjusting the water supply;

- pressure gauge showing the exact parameters;

- hydraulic accumulator - automatic storage;

- electric motor.

Instead of a hydraulic accumulator, a more modern and practical device, a storage tank is sometimes used, which has several disadvantages (weak pressure, inconvenient installation, etc.).

The diagram shows one of the ways to install a non-pressure storage tank and a hydrophore that can regulate the pressure and water level in the system

However, now that many modern inexpensive models with a hydraulic accumulator have appeared in stores, there is no point in self-assembly of a system with a storage tank.

If you still decide to purchase a container for collecting water, try to consider the following nuances:

- The reserve tank is installed in the highest possible area (for example, in the attic) in order to create the necessary pressure.

- The volume of the tank should be such that there is a reserve for 2-3 days in case of failure of the pumping equipment (but not more than 250 liters, otherwise sediment may accumulate).

- The base for mounting the tank must be reinforced with beams, slabs, additional ceilings.

The reserve storage tank, as well as membrane equipment (hydraulic accumulator), should be equipped with a filter. In addition, it is mandatory to install a safety pipe to drain excess water.The hose connected to the branch pipe is led out into the drainage system or lowered into containers designed to store irrigation water.

Standard diagram of a pumping station with the designation of the main elements: check valve, pressure switch, pressure gauge, pressure pipeline; red arrow points to accumulator

The principle of operation of the pumping station is cyclical. As soon as the supply of water in the system decreases, the pump turns on and begins to pump water, filling the system.

When the pressure reaches the required level, the pressure switch is activated and turns off the pump. The relay settings must be set before starting the equipment operation - they depend on the volume of the tank and the characteristics of the pump.