- Winter is coming. We drain the water

- Note

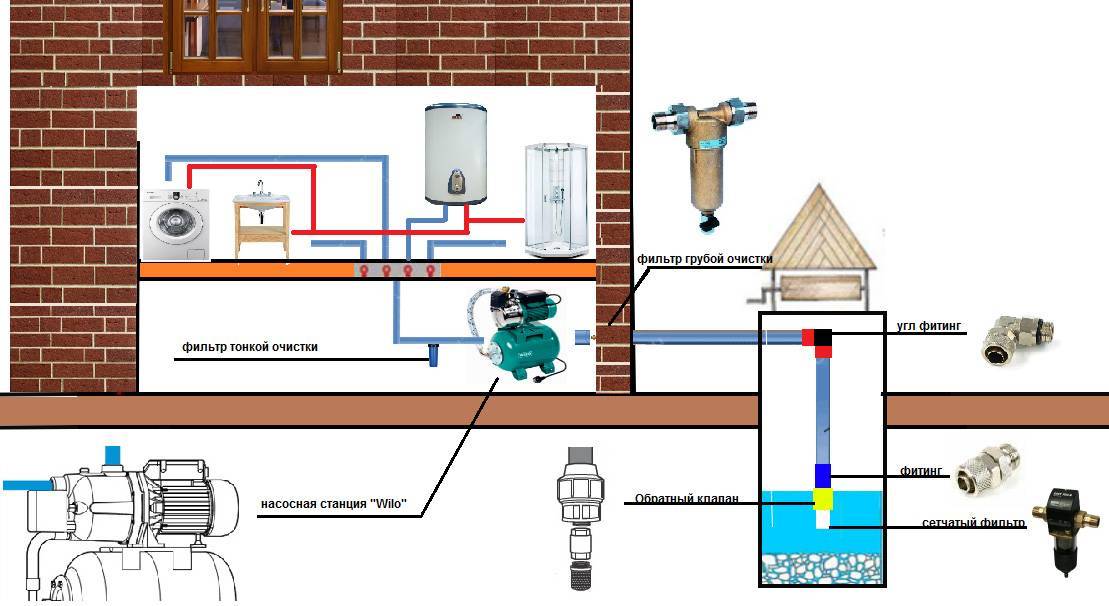

- How to connect the station to the well

- Operating principles

- Pumping station next to the well

- Methods of thermal insulation of the pumping station

- Equipment selection

- Caisson or adapter

- Pump units

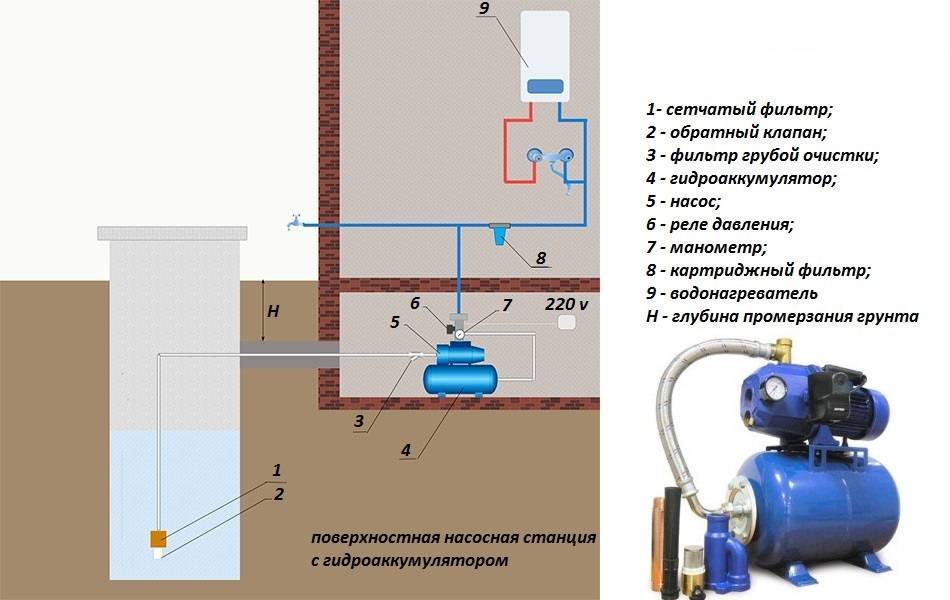

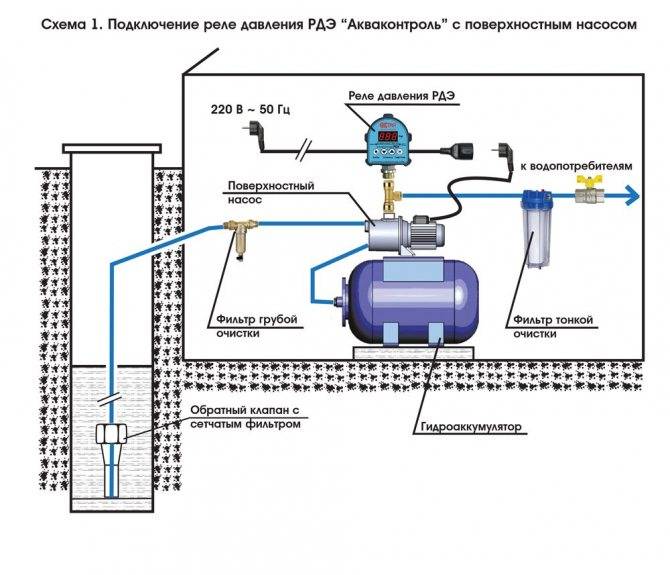

- Accumulator and relay

- Well cap

- Basic parameters for pump selection

- Selecting an installation site

- How to determine the depth of suction

- Security Considerations

- Convenience and operating conditions

- Making the first run

- HDPE pipes - an alternative to steel mains

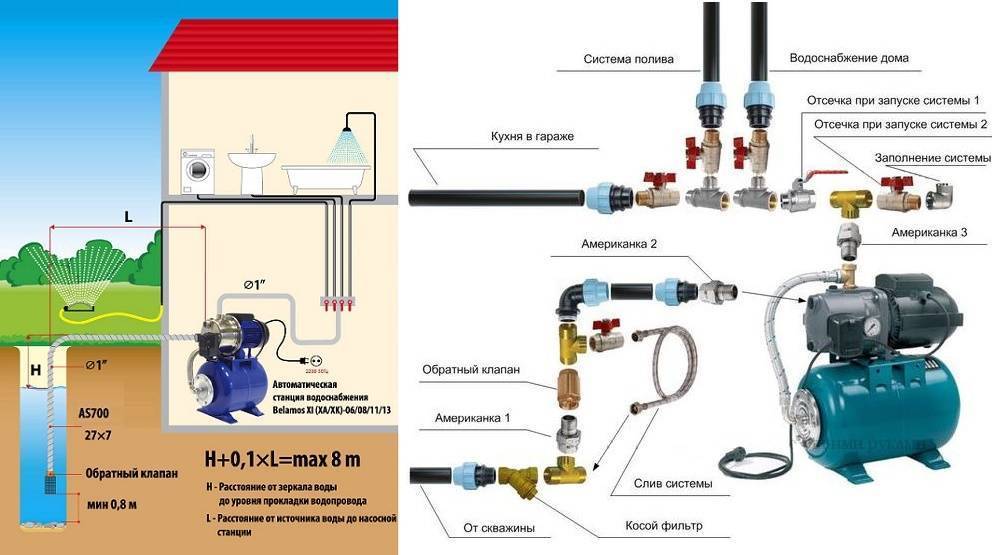

- Connection of a pumping station

- Water supply from a well for permanent residence

- Connecting the pumping station to the water supply

- Well connection

- Wiring diagram

- Materials and accessories for installation

- How to properly mount to a well or well

Winter is coming. We drain the water

There are many cases when, after the winter, people came to the dacha and found that the system was out of order and it was necessary to ditch the walls in order to change pipes, dismantle and send the pump for repair, there are many. The reason for everything is elementary forgetfulness or ill-conceived decisions when designing a house and a personal plot.

As with other engineering systems, water supply should be taken care of at the design stage.It was then that a fundamental decision had to be made: whether the country house would be operated in the winter or whether it would be conserved before the onset of cold weather. The arrangement of the water supply system and its seasonal maintenance depend on this.

If the owners plan to live in a country house only in the warm season, there should be no problems installing the system. The pump is connected to the electrical network, the hose is lowered into the well, and the pressure pipe is connected to the water supply network.

Before the onset of cold weather, the pump is removed (it is better to take it to the city), the water from all tanks - tanks, water pipes, batteries - is drained, drain taps and plugs should be left open. The drinking well must be cleaned and treated.

This can be done using special formulations, such as chlorinol, which is sold in pharmacies. After treatment, the water from the well is completely pumped out, the well is closed for the winter lid.

And by spring it will be filled with fresh drinking water, and all that remains is to use the pump to take life-giving moisture from it. A well that is not operated in winter is not insulated.

If the house is intended for year-round use, quite serious and costly preparatory work will be required. The pumping station must be installed in an insulated room, as it can operate at a temperature not lower than plus five degrees.

Note

The cost of an autonomous water supply system at home, including a well, wiring, a submersible pump or a pumping station and filters, is up to 15% of the cost of the entire house.

The cost of its restoration in case of defrosting can be very high: only the dismantling and re-installation of the pump (excluding repairs) will cost from 500 to 800 dollars, and the replacement of broken pipes hidden in the walls will inevitably entail a major overhaul of the premises.

The pipe from the well or well to the house is laid below the freezing level of the soil and insulated for safety - for this purpose, an electric self-regulating two-core cable is usually used, which heats up to 65 degrees. To those who have well under the house, it will be easier, since the pumping station is located in the basement, and not in the open air.

To avoid the formation of frost on the walls of the well and ice on the surface of the water, the head and cover of the well are insulated with any environmentally friendly material. Then there will be a constant temperature in the well - from plus five to plus ten degrees.

The caisson is a metal bunker with a hatch, which is waterproofed from the outside, and coated from the inside with a primer and insulated with foam.

How to connect the station to the well

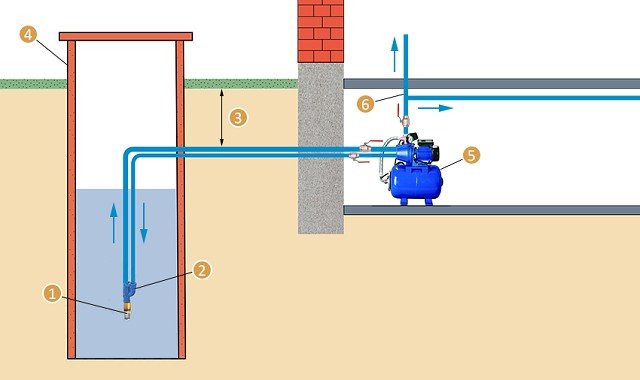

For installation, a utility room or a specially equipped caisson is suitable. It is necessary that there is a slight elevation above the floor, which will prevent breakage when groundwater appears.

The water supply is laid in soil that is not subject to freezing, so that when the water freezes, it does not lead to rupture of the pipes. If this fails, the pipeline can be insulated with heat-insulating materials. Connection must be carried out in stages:

- Prepare a polyethylene pipe of the desired diameter and length. Its size should allow it to be carried to the well and laid below.

- One end is equipped with a filter, an ordinary metal mesh and a check valve that controls the filling of the pump with water.

- The part is immersed in a well. The end of the pipe is connected to the pump.

- The exit of the station is equipped with a tap, which makes it possible to shut off the water, if necessary. A pipe must be attached to the faucet.

For a summer residence, you should not choose a pumping station that is too powerful

The second outlet is located at the top of the housing. It is connected to the water supply system. The crane is attached to the thread and equipped with a polypropylene coupling. A water pipe is soldered to it.

Operating principles

One of the main elements that a well station has is a hydraulic accumulator. The principle of its work is as follows:

- water enters the accumulator from the pump;

- automatic shutdown occurs when the pressure in the battery reaches 2.8 atm;

- water is delivered from the accumulator;

- the pump turns on when the pressure drops below 1.5 atm.

In some designs, the connected pump can be installed without a hydraulic accumulator. In such cases, the pump turns on automatically when the tap is opened and turns off after 5 minutes after closing.

Pumping station next to the well

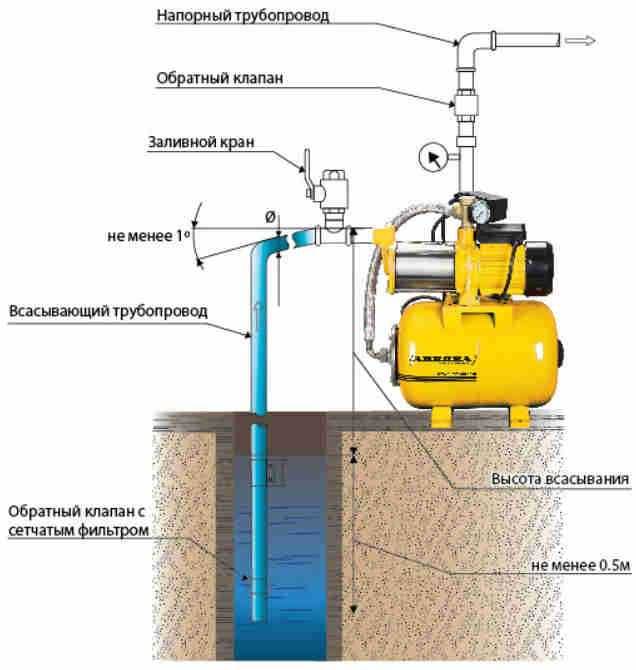

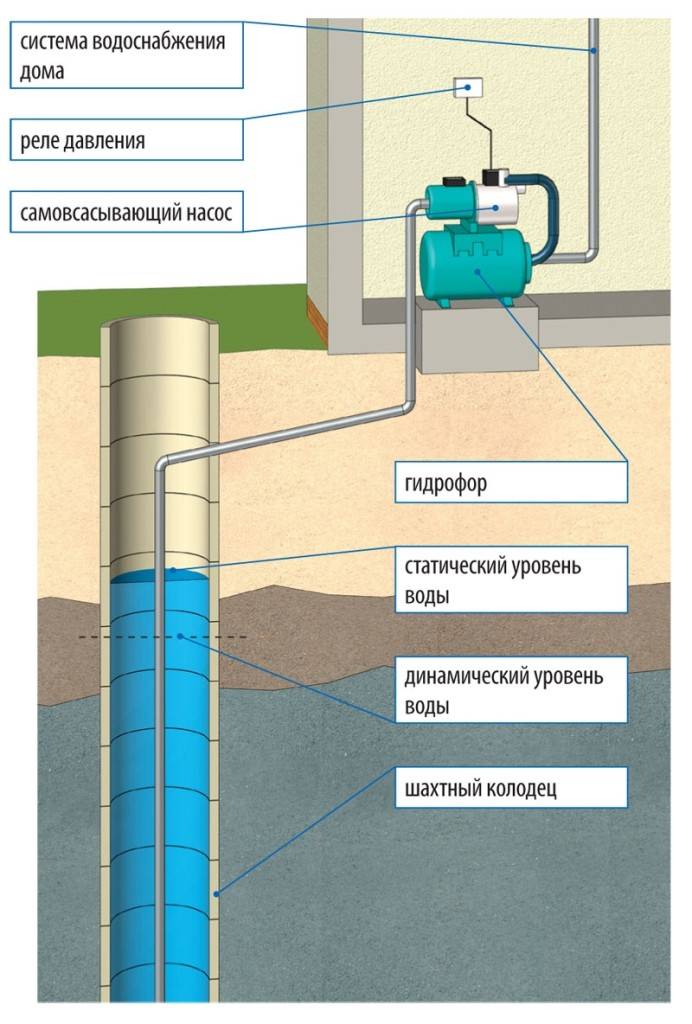

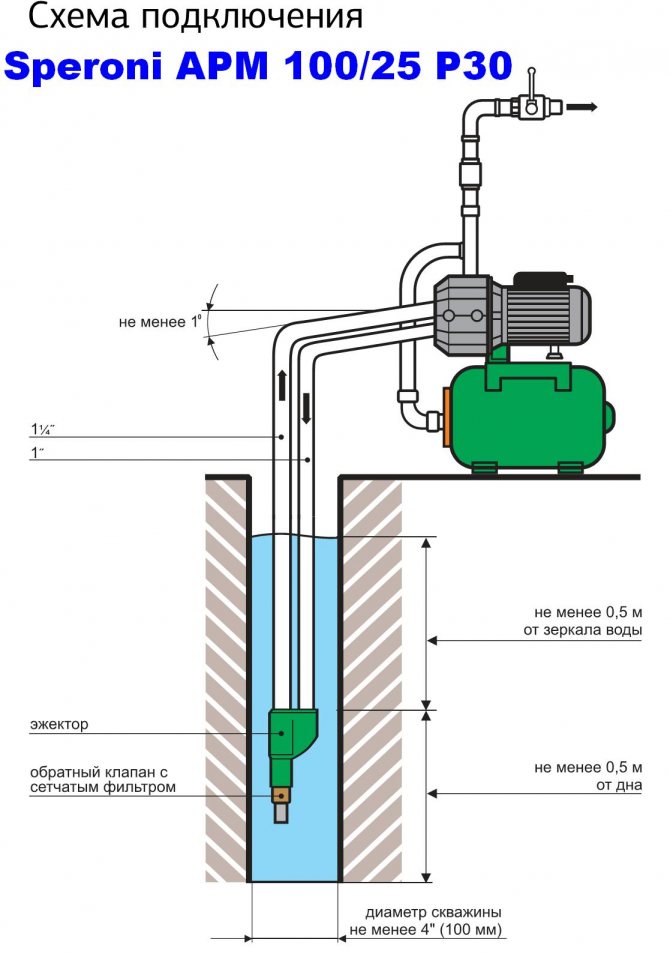

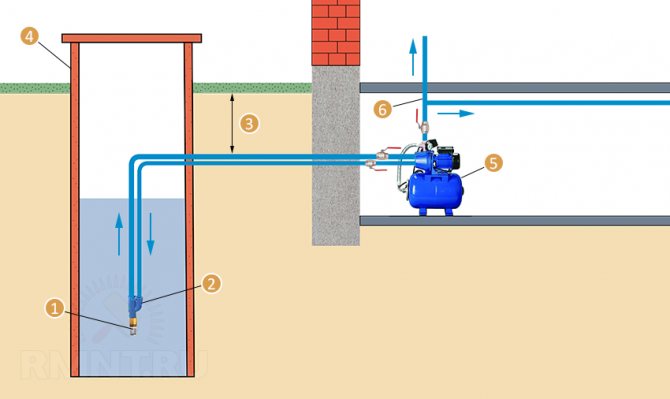

Is it possible to install a pumping station in a structure on the surface, without lowering it into a mine? In the case when the water in the well is high, then this can be done. The figure shows a diagram of switching on the station using a complete suction hose with a check valve installed on it and a threaded fitting for connecting to the pump. The procedure for starting the station is similar to that described in the previous paragraph.

How to install a pumping station in a well may not always be clear.Moreover, when buying it, a consultant is unlikely to be able to reveal all the subtleties. Using the detailed information from the article, you can do do-it-yourself connection.

Methods of thermal insulation of the pumping station

First of all, it is necessary to save the heat that comes from the well. To do this, it will be necessary to insulate the outer walls of the station. As a material, you can use foam or polystyrene foam. The upper revision cover is also made from them.

Additionally, you can equip a wooden frame. It will perform not only a decorative function. Insulation can be installed between its inner wall and the well. But even with a high degree of thermal insulation at sufficiently low temperatures in winter, the probability of water freezing in the pipes is high. Therefore, it is necessary to make a small heating system. It can be implemented in the following ways:

- Installation of resistive heating cable. It is installed on a concrete or brick floor. If the temperature in the well drops below +5°C, the cable is activated;

- Low power electric heater and thermostat. The latter must be adjusted to a certain temperature range. In case of a critical decrease in the level of air heating in the well, the thermostat will turn on the heater. As soon as the temperature stabilizes, it will give a command to turn off.

Some sources advise installing a simple incandescent lamp. However, its thermal energy will not be enough to heat the entire volume of the well. The above technique is costly, since electricity is consumed to maintain the temperature. But passive insulation does not guarantee the integrity of pumping equipment.

Preface. In order not to encounter once in a private house with a lack of water due to freezing of the water supply in the basement or in the ground, not only the pipes, but also the pumping station in the suburban area should be well insulated for the winter. Consider how to insulate the pump and all communications in the well responsible for the water supply, which is an urgent issue for Russian winters.

Thermal insulation of pipes from the well to the house and itself well pumping station - a topical issue for residents of country houses and those who like to come to their country house in winter to relax. Frozen water in communications is a serious problem that can cause a lot of trouble, much more than it might seem at first glance. Why is frozen water dangerous and is it worth insulating the pumping station?

Equipment selection

The choice of equipment for arranging your future well is one of the most important stages, since the quality and duration of its work will depend on the right choice.

The most important equipment, the choice of which should be paid attention to, is: a pump, a caisson, well cap and hydraulic accumulator

Caisson or adapter

The principle of arrangement with a caisson or adapter

The caisson can be called the main design element of the future well. Outwardly, it resembles a container similar to a barrel and is used to protect equipment from groundwater and freezing.

Inside the caisson, you can place all the necessary components for automatic water supply (pressure switch, membrane tank, pressure gauge, various water purification filters, etc.), thus freeing the house from unnecessary equipment.

The caisson is made of metal or plastic. The main condition is that it is not subject to corrosion. The dimensions of the caisson are usually: 1 meter in diameter and 2 meters in height.

In addition to the caisson, you can also use an adapter. It is cheaper and has its own characteristics. Let's consider below what to choose a caisson or adapter and what are the advantages of each.

Caisson:

- All additional equipment can be placed inside the caisson.

- Best suited for cold climates.

- Durable and reliable.

- Quick access to the pump and other equipment.

Adapter:

- To install it, you do not need to dig an additional hole.

- Fast installation.

- Economical.

The choice of caisson or adapter also follows from the type of well

For example, if you have a well in the sand, many experts advise paying attention to the adapter, since the use of a caisson is not always beneficial due to the short life of such a well

Pump units

One of the key elements of the entire system is the pump. Basically, three types can be distinguished:

- Surface pump. Suitable only if the dynamic water level in the well does not fall below 7 meters from the ground.

- Submersible vibration pump. A budget solution, it is rarely used specifically for the water supply system, as it has low productivity, and it can also destroy the walls of the well.

- Centrifugal borehole pumps. Profile equipment for water supply systems from a well.

Borehole pumps are widely represented on the market by a large variety of manufacturers, for every taste and budget. The selection of the characteristics of the pump takes place according to the parameters of the well and directly to your water and heat supply system.

Accumulator and relay

The key function of this equipment is to maintain a constant pressure in the system and to store water. The accumulator and pressure switch control the operation of the pump, when the water in the tank runs out, the pressure drops in it, which catches the relay and starts the pump, respectively, after filling the tank, the relay turns off the pump. In addition, the accumulator protects plumbing equipment from water hammer.

In appearance, the accumulator is similar to a tank made in an oval shape. Its volume, depending on the goals, can range from 10 to 1000 liters. If you have a small country house or cottage, a volume of 100 liters will be enough.

Hydraulic accumulator - accumulates, relay - controls, pressure gauge - displays

Well cap

To equip the well, a head is also installed. Its main purpose is to protect the well from the ingress of various debris and melt water into it. In other words, the cap performs the function of sealing.

headroom

Basic parameters for pump selection

So, about the height to which you need to raise water, we already wrote

What else should you pay attention to when choosing? We need to know exactly the distance of the well from the house, and the volume of pumped liquid, which will depend on the total volume of the water supply network and the maximum possible water consumption at any given moment. A banal example: we open the tap closest to the entry point to the building - we get good pressure, we open the second one - the pressure drops, and at the remote point the water flow will be the smallest. The calculations here, in principle, are not complicated, you can do them yourself using an online calculator, or simply by studying the instructions from the manufacturer

The calculations here, in principle, are not complicated, you can do them yourself using an online calculator, or simply by studying the instructions from the manufacturer.

What determines the pressure in the system? From the power of the pump and the volume of the accumulator - the larger it is, the more stable the average pressure in the water supply system. The fact is that when turned on, the pump does not work constantly, since it needs cooling, and when the operating pressure is reached, it should not continue to increase it. The system is designed in such a way that it pumps water into the accumulator, in which a check valve is installed that prevents water from flowing back when the pump is turned off. When the pressure in the tank reaches the set threshold, the pump stops. If at the same time the water intake continues, it will gradually fall, reaching the minimum mark, which is a signal to turn on the pump again.

That is, the smaller the accumulator, the more often the pump is forced to turn on and off, the more often the pressure will either rise or fall. This leads to accelerated wear of the engine starting equipment - in this mode, the pumps do not last long. Therefore, if you plan to use water from the well all the time, buy a tank with a larger capacity for the pumping station.

When arranging a well, a casing pipe is installed in it, through which water rises up. This pipe can be of different diameters, that is, it may have a different throughput. According to the cross section of the casing, you can also choose the right equipment for your home.

All the necessary information will be in the instructions for the purchased pump. You can also get recommendations from specialists who drill your well.They will know exactly the optimal operating parameters. It will not be superfluous to also make some reserve in terms of the power of the unit, so that the pressure in the system rises faster to a comfortable threshold, otherwise the water will constantly flow sluggishly from the tap.

Selecting an installation site

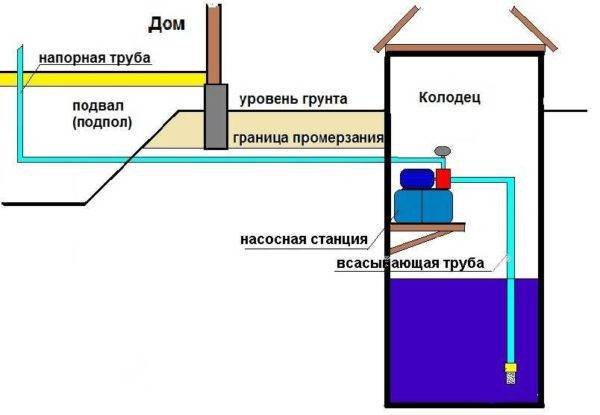

Pumping stations are installed near a water source - a well or a well - in a specially equipped pit - a caisson. The second option is in the utility room in the house. The third is on a shelf in the well (such a number will not work with a well), and the fourth is in the underground.

Installation of a pumping station in the subfield - the noise from its operation may be too loud

How to determine the depth of suction

When choosing a place, they are primarily guided by technical characteristics - the maximum suction depth of the pump (from where the pump can lift water). The thing is that the maximum lifting depth of pumping stations is 8-9 meters.

Suction depth - the distance from the water surface to the pump. The supply pipeline can be lowered to any depth, it will pump water from the level of the water mirror.

Wells often have a greater depth than 8-9 meters. In this case, you will have to use other equipment - a submersible pump or a pumping station with an ejector. In this case, water can be supplied from 20-30 meters, which is usually enough. The disadvantage of this solution is expensive equipment.

Suction depth - a characteristic that determines the installation method

If you are only a meter away from being able to install conventional equipment, you can put the station in a well or above a well. A shelf is attached to the wall in the well, in the case of a well, a pit is deepened.

When calculating, do not forget that the level of the water mirror "floats" - in the summer it usually goes down. If your suction depth is on the verge, there may simply be no water during this period. Later, when the level rises, the water supply will resume.

Security Considerations

Another point to consider is the safety of the equipment. If the installation of a pumping station is supposed to be near a house with permanent residence, there are fewer problems - you can choose any option, even in a small shed. Only one condition - it should not freeze through in winter.

The installation of a pumping station in a barn is suitable for permanent residence and the condition of insulation / heating for the winter

If this is a dacha where they do not live permanently, the matter is more complicated - it is necessary to arrange such a room that is not striking. The safest way to install a pumping station is in the house. Although they can carry it away in this case.

The second place where you can install a pumping station is a buried camouflaged caisson.

Scheme of installing a pumping station in a well

The third is on a shelf in the well. Only in this case the traditional well house not worth doing. You need a steel lid, which is locked with a reliable lock (weld loops to the ring, make slots in the lid, on which to hang constipation). Although, a good cover can also be hidden under the house. Only the design must be thought out so that it does not interfere.

Convenience and operating conditions

Installing a pumping station in the house is good for everyone, except that the equipment makes noise during operation. If there is a separate room with good sound insulation and it is possible according to the technical characteristics, no problem. Often they make a similar room in the basement or in the basement.If there is no basement, you can make a box in the underground. Access to it is through a hatch. This box, in addition to sound insulation, must also have good thermal insulation - the operating temperature range starts from + 5 ° C.

To reduce the noise level, the station can be placed on thick rubber to dampen vibration (created by a cooling fan). In this case, even installation in the house is possible, but the sound will certainly still be.

Caisson from concrete rings

If you stopped at the installation of a pumping station in a caisson, it must also be insulated and also waterproof. Usually, ready-made reinforced concrete containers are used for these purposes, but a caisson can be made from concrete rings (like a well). Install the ring with the bottom down, the ring with the lid on top. Another option is to lay it out of brick, pour concrete on the floor. But this method is suitable for dry areas - the groundwater level should be lower by a meter below the depth of the caisson.

The depth of the caisson is such that the equipment is installed below the freezing level. Expanded polystyrene insulation. Better extruded. Then you also get waterproofing at the same time.

For a caisson of concrete rings, it is convenient to use a shell (if you find a suitable diameter). But you can also slab polystyrene foam, cut into strips and glue it. For rectangular pits and structures, slabs are suitable that can be glued to walls using bituminous mastic. Lubricate the wall, apply insulation, you can additionally fix it with a pair of nails / dowels.

Making the first run

The system needs to be filled. To do this, there is a special plug that hides the hole for the funnel. The hydraulic accumulator and the route between the check valve and the pump are filled with water. After that, the hydraulic tank is tested.Air pressure is measured, for which a car tire pressure gauge is suitable. Only after making sure that the pump pumps and the hydraulic tank is working, you can use the pumping station as an autonomous one that does not require constant monitoring.

This is interesting: Manual drilling of water wells - how to do it yourself carry out work manually

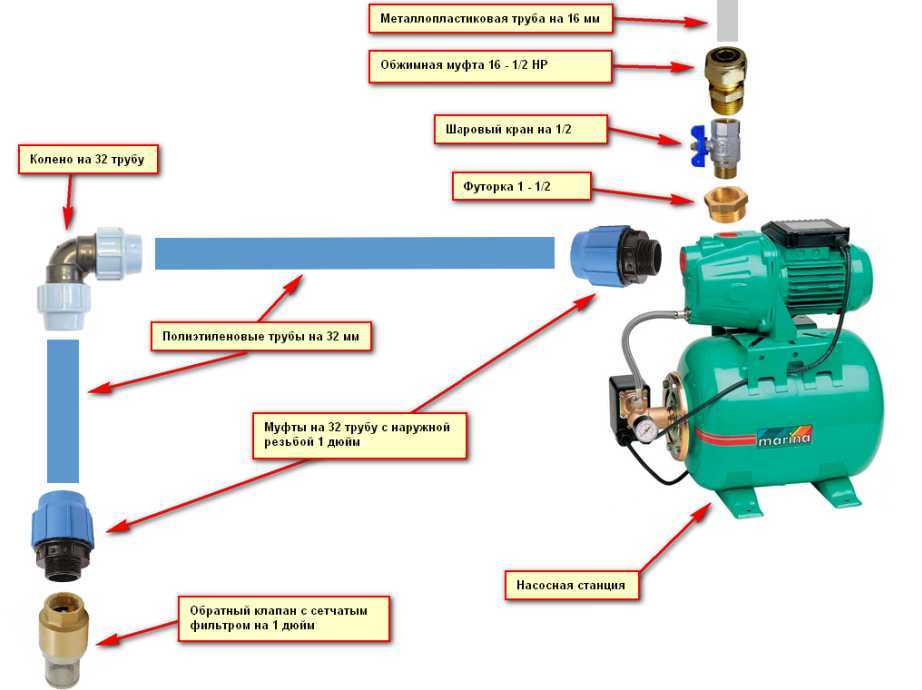

HDPE pipes - an alternative to steel mains

Let us dwell in more detail on the pipes connecting the submersible equipment and the surface centrifugal pump.

When choosing pipes for outdoor plumbing, it is necessary to focus on factors such as:

- convenient transportation;

- easy installation that does not require highly qualified knowledge;

- strength, resistance to abrasion;

- elasticity and deformation of the form without loss of functional qualities;

- non-toxic, safety for drinking water movement.

All of these requirements are met by low-pressure polyethylene pipes. Unlike metal counterparts, they do not corrode over time. The average service life of HDPE pipes is 50 years.

One of the advantages of HDPE pipes is the availability of a set of various fittings of a suitable standard (couplings, plugs, adapters) for quick and easy installation

We recommend purchasing only high-quality marked goods, indicating the following data on the outer part:

- grade;

- external diameter;

- wall thickness;

- nominal and maximum pressure.

On the pipe, which is necessary for laying the pressure line from the well, it is possible to indicate the destination - "drinking". For use in the country, products with a diameter of 32 are suitable mm and wall thickness 2.4 mm.The blue stripe indicates that the pipes are designed for pumping water (yellow - for transporting gas).

A water supply network of complex design has branches (for example, to provide watering a garden or water supply to a bathhouse). To control the connection points of pipes, manholes made of bricks are arranged, concrete or plastic

Connection of a pumping station

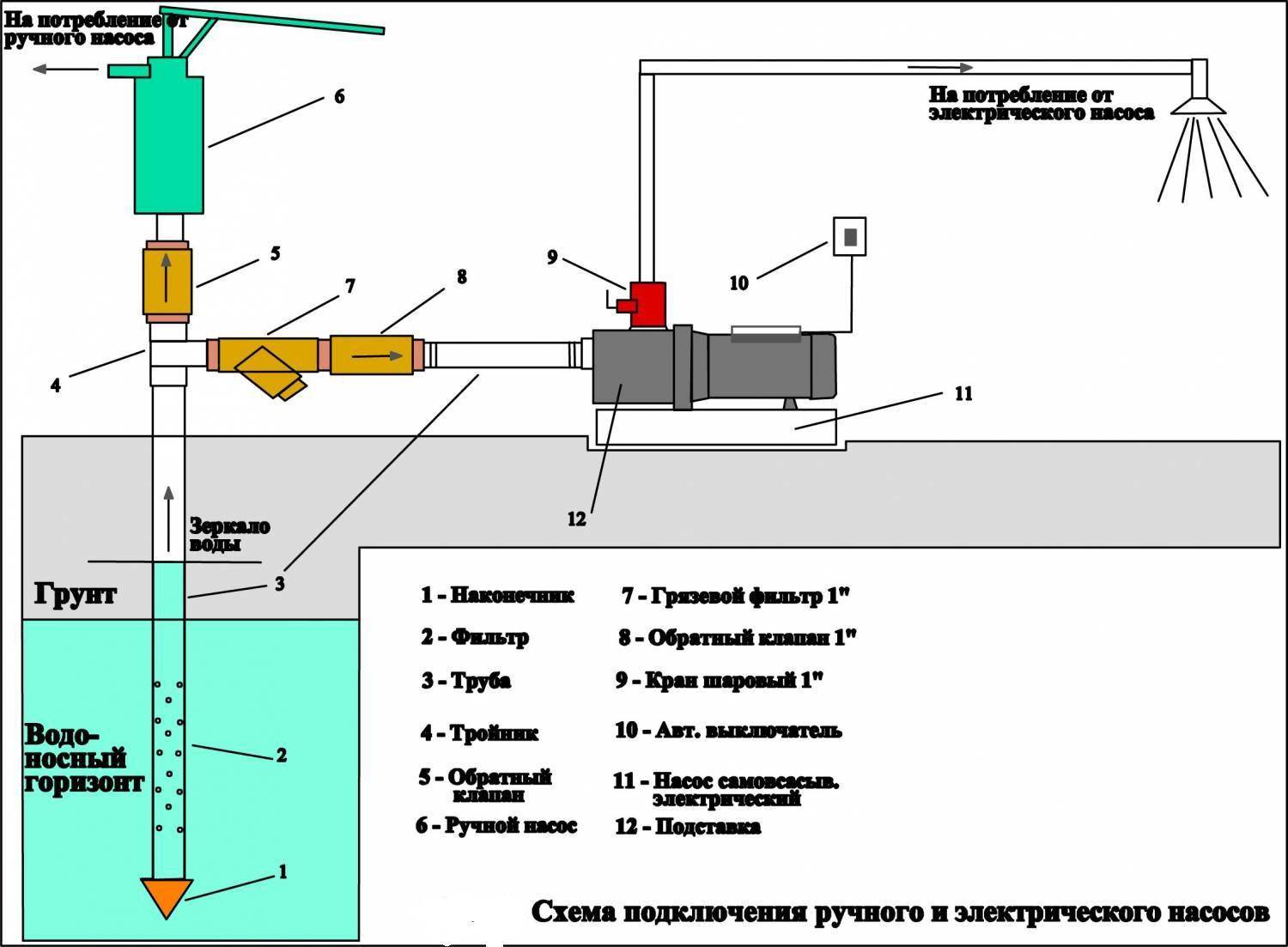

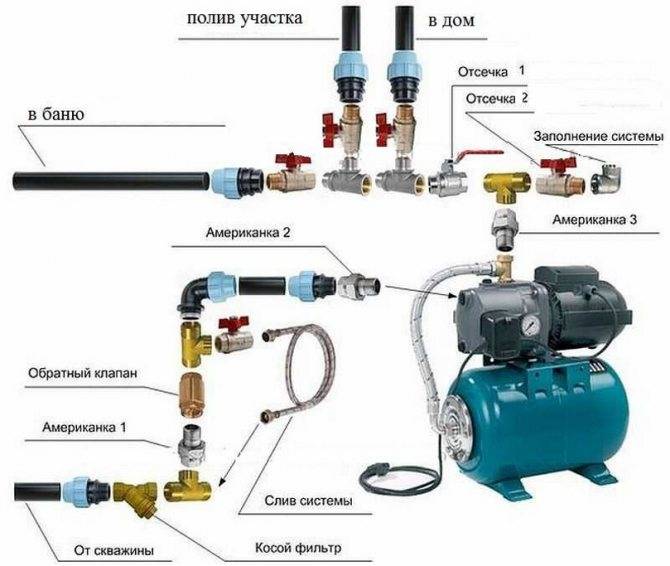

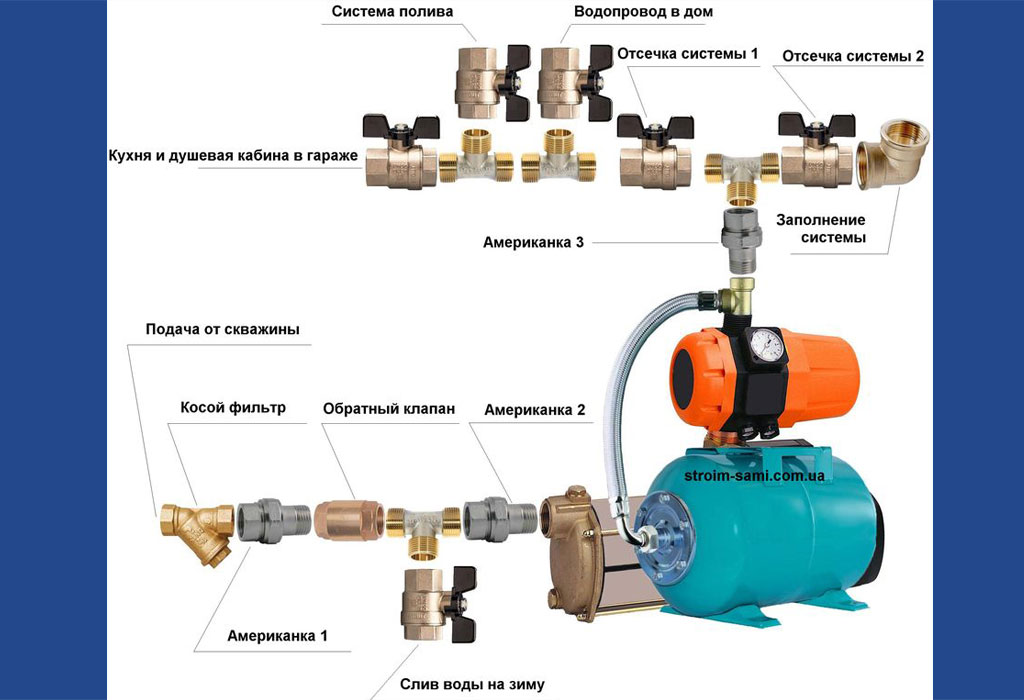

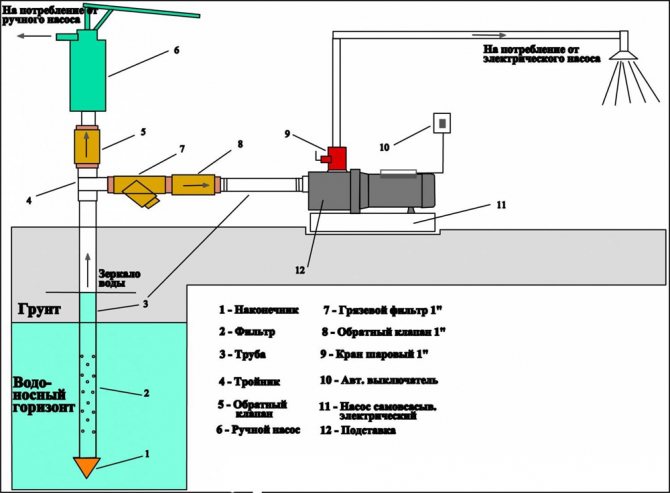

Choosing equipment and a place for installation is half the battle. You also need to correctly connect everything into a system - a water source, a station and consumers. The exact connection diagram of the pumping station depends on the chosen location. But anyway there is:

- Suction pipeline that descends into a well or well. He goes to the pumping station.

- The station itself.

- The pipeline going to consumers.

All this is true, only the strapping schemes will change depending on the circumstances. Let's consider the most common cases.

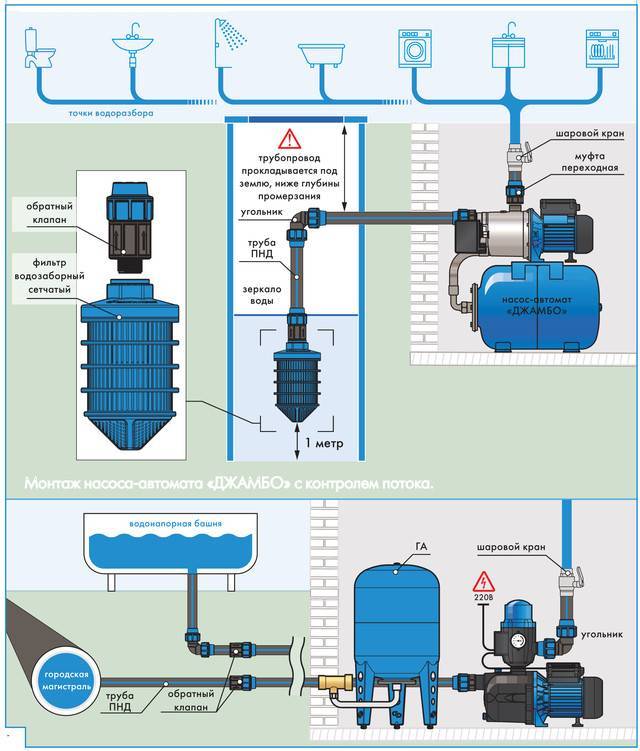

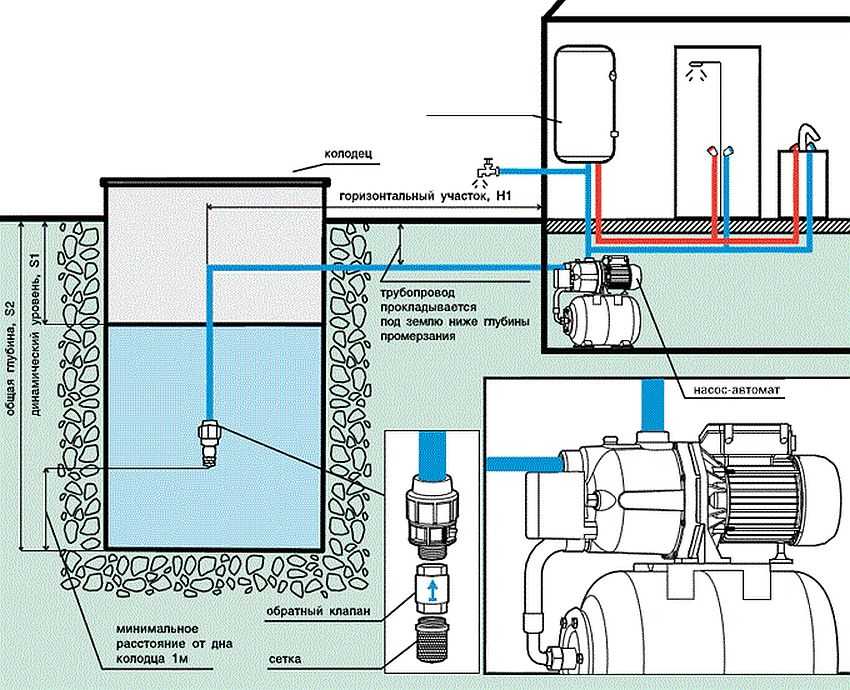

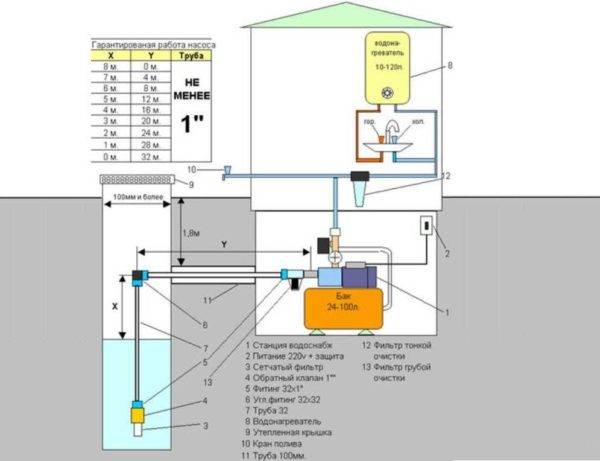

Water supply from a well for permanent residence

If the station is placed in a house or in a caisson somewhere on the way to the house, the connection scheme is the same. A filter (most often a regular mesh) is installed on the supply pipeline lowered into a well or well, a check valve is placed after it, then a pipe already goes. Why the filter - it is clear - to protect against mechanical impurities. A check valve is needed so that when the pump is turned off, water under its own weight does not flow back. Then the pump will turn on less often (it will last longer).

Scheme of installing a pumping station in a house

The pipe is brought out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into the trench at the same depth.When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay sheets of polystyrene foam on top, and then fill it with sand, and then with soil).

Passage option not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the place of passage should also be insulated), in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as bring the pipeline out / in through the walls, and also in the fact that it is difficult to localize damage when a leak occurs. To minimize the chances of a leak, take proven quality pipes, lay a whole piece without joints. If there is a connection, it is desirable to make a manhole.

Detailed scheme of piping a pumping station when connected to a well or well

There is also a way to reduce the volume of earthworks: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the site has a high level of groundwater.

There is another important point - the well cover must be insulated, as well as the rings on the outside to the freezing depth. It's just that the section of the pipeline from the water mirror to the outlet to the wall should not freeze. For this, insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system with centralized water supply.In this case, a water pipe is connected to the station inlet (also through a filter and a check valve), and the outlet goes to consumers.

Scheme of connecting the pumping station to the water supply

It is advisable to put a shut-off valve (ball) at the inlet so that if necessary you can turn off your system (for repairs, for example). Second shut-off valve - before pumping station - needed for repair piping or equipment. Then it also makes sense to install a ball valve at the outlet - in order to cut off consumers if necessary and not drain water from the pipes.

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Unless the pipeline exits at the point where the casing pipe ends. A caisson pit is usually arranged here, and a pumping station can be installed right there.

Pumping station installation: well connection diagram

As in all previous schemes, a filter and a check valve are installed at the end of the pipe. At the entrance, you can put a filler tap through a tee. You will need it for the first start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed in the country, it's okay, the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

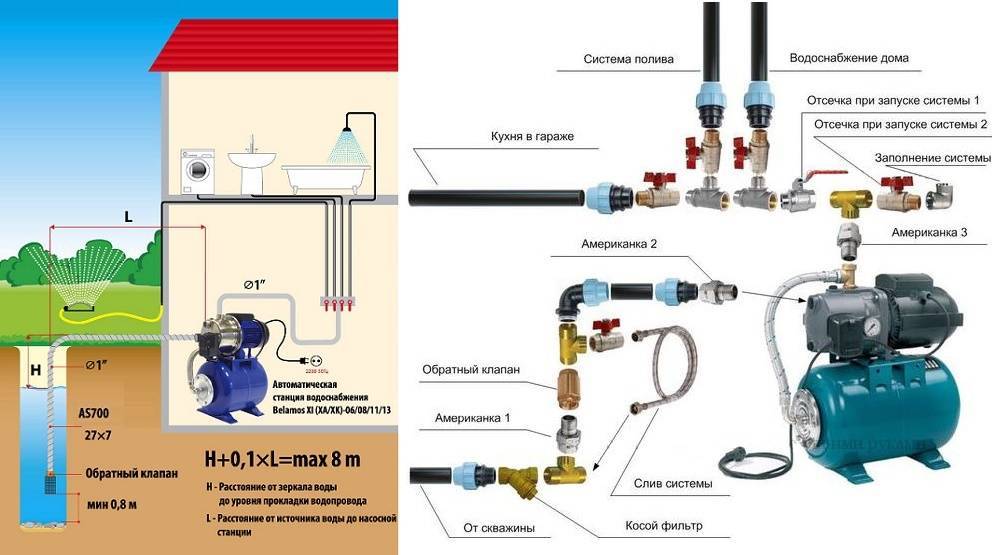

Wiring diagram

The procedure for creating a water supply system can be simplified by first drawing up a connection diagram.The pump must be selected so that it is characterized by good pressure-flow properties. The equipment should be insulated to prevent the water in the system from freezing when the temperature drops.

The first step is to choose the right place for installation.

Materials for connecting the pumping station can be bought at a hardware store

Connection Features:

- Mandatory preparation of the bearing base for the pumping unit.

- The surface must be covered with a rubber mat.

- The legs are fixed with bolts and anchors.

- In the process of connecting, an American tap is used.

When the pump is already in the well, you need to connect the power supply. The engine starts when the tap is opened. Then the water enters the pressure pipe and squeezes out all the air accumulated in it.

Installation to a well or well can be done independently. To do this, you need to select the type of station and familiarize yourself with the principles of its operation. When connecting, you need to take into account the depth of its location, as well as the diameter of the pipes used. The slightest mistake during installation can cause the entire system to malfunction.

Materials and accessories for installation

The steel mains of the central water supply, which supply dirty and rusty water to our homes, are forever a thing of the past. For the water supply of a private house from a well or a well, use modern HDPE polyethylene pipes of the PE-100 brand with a wall thickness of 3 mm, which are easy to lay and bring into the house with your own hands. In the vast majority of cases, a diameter of 32 mm is enough for external wiring.

To supply water according to the first scheme (with immersion of the pumping unit) from the well, you will need:

- head or downhole adapter;

- suspension cable with a diameter of 3 mm;

- the pump itself, equipped with a check valve;

- hydraulic accumulator with a capacity of 25-100 l;

- pressure switch type RDM-5 and "dry" running;

- coarse filter and mud collector;

- manometer;

- ball valves, fittings;

- electrical cable and circuit breakers rated 16 A.

If the scheme with a pumping station is more suitable for you, then you do not need to buy a relay and a hydraulic accumulator separately, since they are included in the installation kit. How to correctly calculate the minimum volume of the storage tank and the pump power, see the video:

How to properly mount to a well or well

Connection diagram of the pumping station. (Click to enlarge)

The first thing to do is determine where the pumping station will be located.

It can be a room inside the house (for example, a basement) or a caisson (this is a waterproof chamber that is located outside the house).

In order to connect the system to a well or to a well, you must:

- The legs of the station must be attached to the surface. This is done using a special fastener - an anchor.

- Lower the hose into the well (well). You need to be careful not to lower the hose to the very bottom, so that when pumping out water, various debris and dirt do not get into it. It is enough to raise it one meter from the bottom of the well.

- A polyethylene pipe is required at one end, which is placed in a well or well. But, before lowering it, it is necessary to attach a coupling (connecting element) to the pipe. In order for the pipe to be constantly filled with water, you need to put a check valve, and then a filter.

- The second end of the pipe, through trenches laid in advance, is led directly to the water supply of the house.

Please note: in order to avoid installation errors, before laying pipes in trenches, it is advisable to calculate the length of the pipe in advance. To do this, you need to take into account the number of bends and the thickness of the foundation.