- How is it different from an expansion tank

- Functions, purpose, types

- Purpose

- Principle of operation

- Large volume tanks

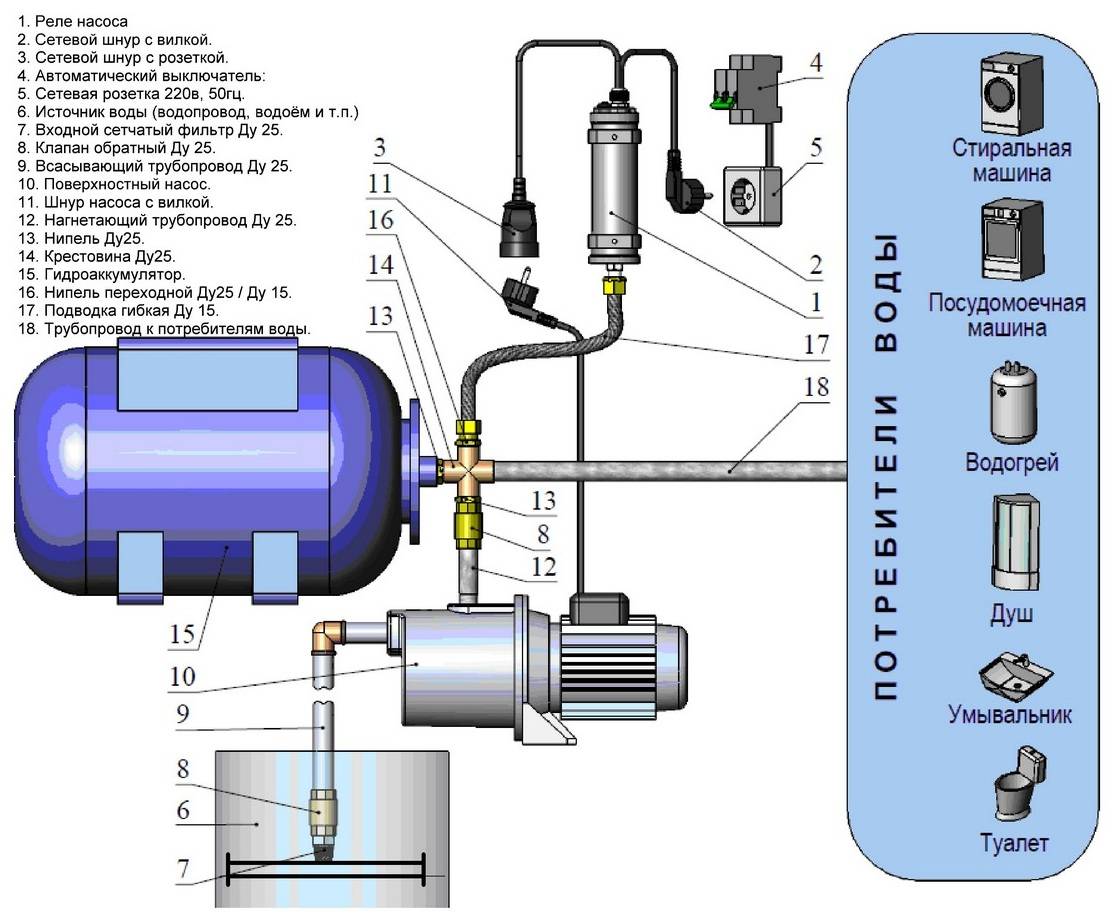

- Features of connecting to a surface pump

- Relay connection diagram for hydraulic accumulator

- 2

- Do you need a hydraulic accumulator

- The device and purpose of the hydraulic tank

- The cost of relays and accumulators of some manufacturers

- Criterias of choice

- Do you need a reserve capacity

- Optimal pressure

- How to choose tank volume

- The principle of operation of the pressure switch

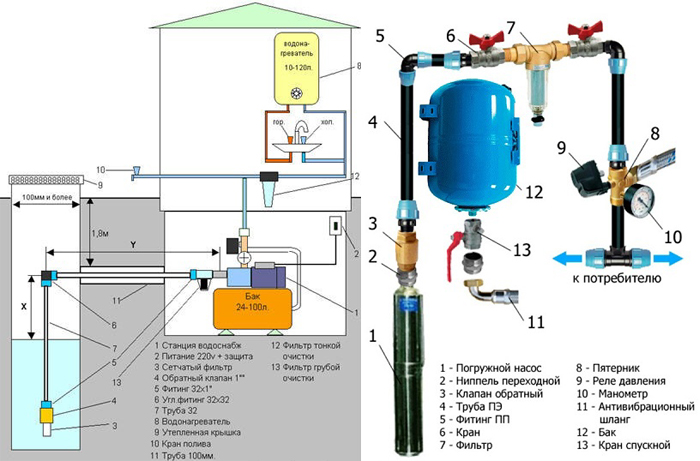

- Place of the device in the water supply system

How is it different from an expansion tank

Hydraulic accumulators are often confused with expansion tanks, despite the fundamentally different problems that these devices solve. An expansion tank is needed in heating and hot water supply systems, since the coolant, moving through the system, inevitably cools and its volume changes. The expansion tank is configured with a “cold” system, and when the coolant warms up, its excess, which is formed due to expansion, has somewhere to go.

As a result, the accumulator is installed in order to get rid of water hammer and extend the life of the system as a whole. In addition, the accumulator has other functions:

Creates a certain supply of water (useful if the power is turned off).

If there are frequent interruptions in water, then the accumulator can be combined with a storage tank

- Reduces pump start frequency. The tank is filled with a small amount of water. If the flow rate is small, for example, you need to wash your hands or wash your face, water starts to flow from the tank, while the pump remains off. It is activated after there is very little water left;

- Maintains stable pressure in the system. In order for this function to be performed properly, an element called a water pressure switch is provided, which is capable of maintaining a given pressure within strict limits.

All the advantages of hydraulic accumulators make this device an indispensable element of any autonomous water supply system in country houses.

Functions, purpose, types

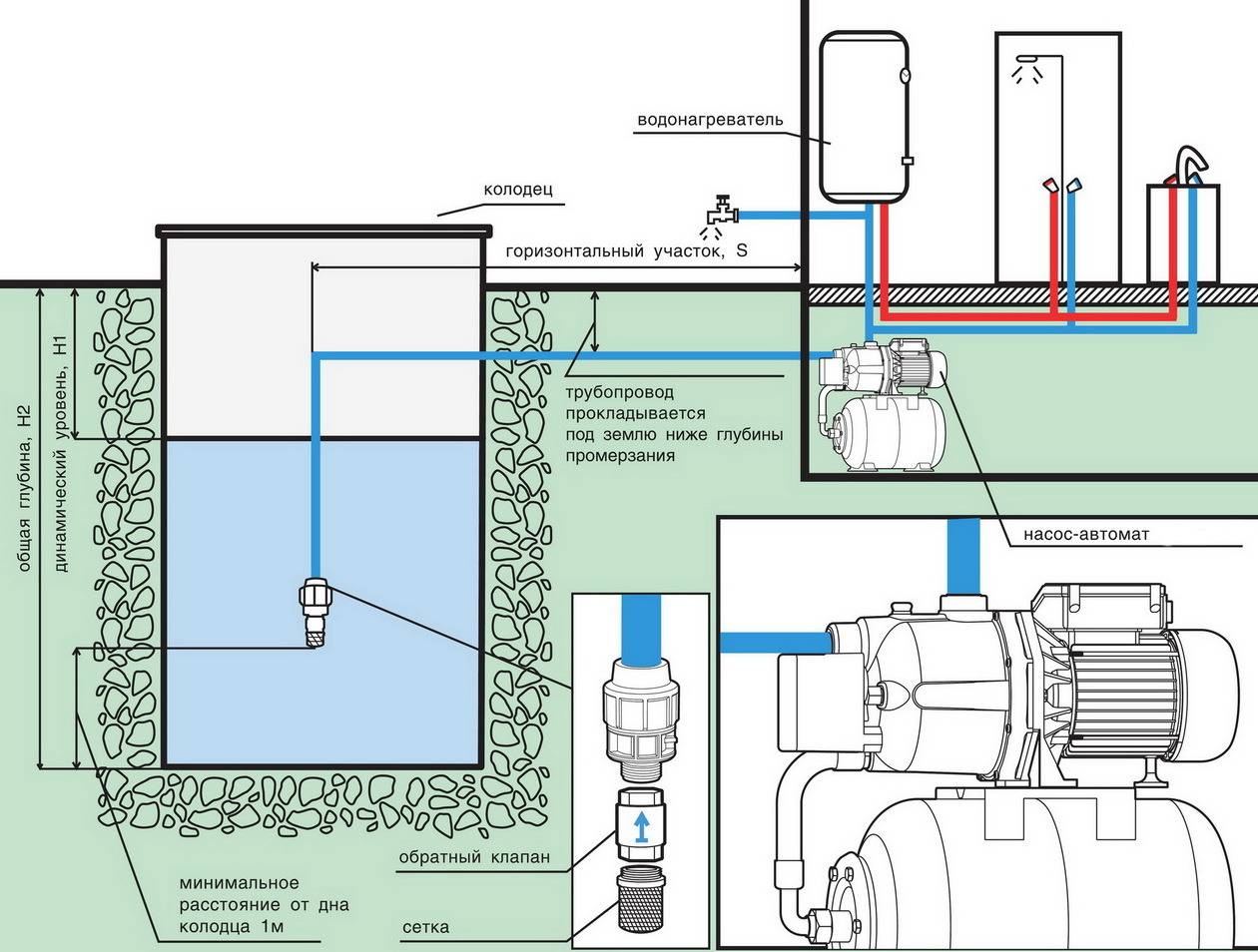

Place of installation - in the pit or in the house

In the water supply system of a private house without a hydraulic accumulator, the pump turns on whenever water flows somewhere. These frequent inclusions lead to wear of the equipment. And not only the pump, but the entire system as a whole. After all, every time there is an abrupt increase in pressure, and this is a water hammer. To reduce the amount of pump activation and smooth out water hammer, a hydraulic accumulator is used. The same device is called an expansion or membrane tank, hydraulic tank.

Purpose

We found out one of the functions of hydraulic accumulators - to smooth out hydraulic shocks. But there are others:

- Reducing the number of pump starts. There is some water in the tank. With a small flow - wash your hands, wash yourself - water flows from the tank, the pump does not turn on. It will turn on only when there is very little of it left.

- Maintain stable pressure.This function requires another element - a water pressure switch, but they maintain pressure within the required limits.

- Create a small supply of water in case of a power outage.

Installing a hydraulic accumulator in a pit

It is not surprising that this device is present in most private water supply systems - there are many advantages from its use.

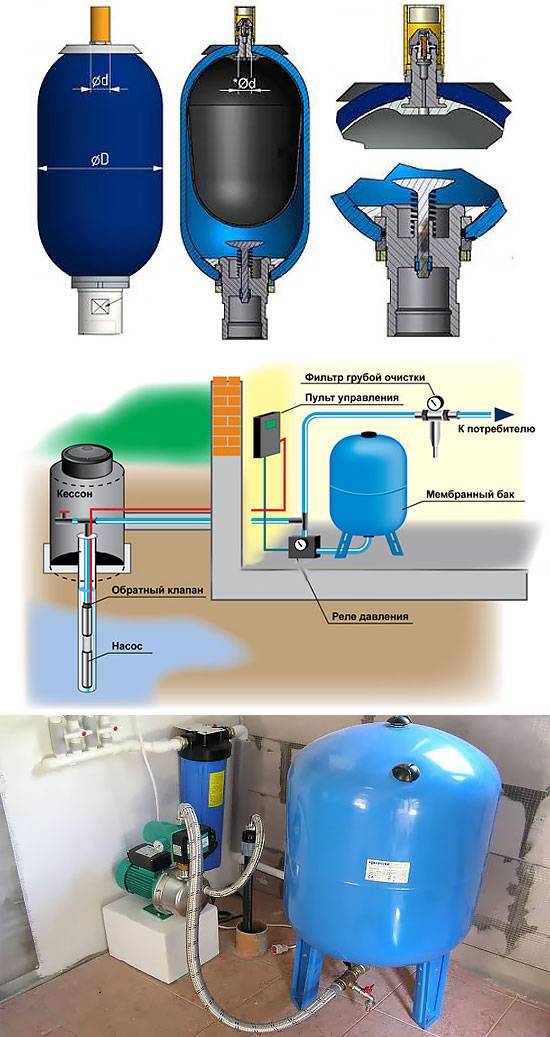

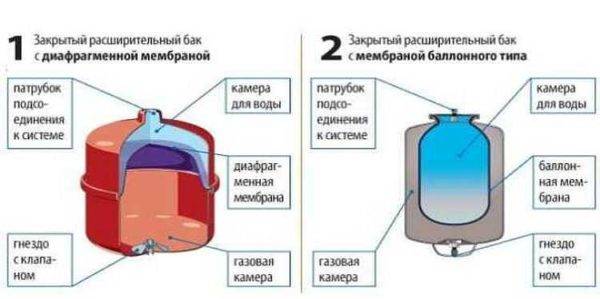

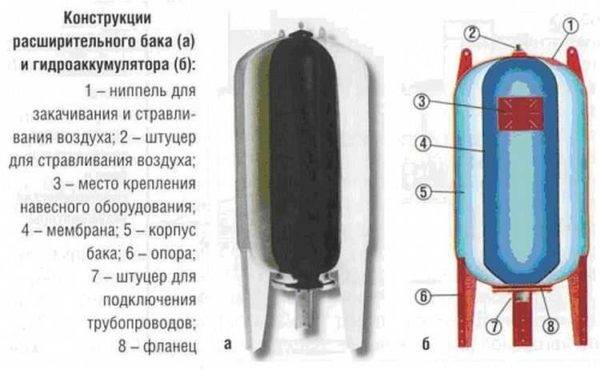

A hydraulic accumulator is a sheet metal tank divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (pear). The diaphragm is attached across the tank, the balloon in the form of a pear is fixed at the inlet around the inlet pipe.

By appointment, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for plumbing are painted blue. Expansion tanks for heating are usually smaller and cheaper. This is due to the material of the membrane - for water supply it must be neutral, because the water in the pipeline is drinking.

Two types of accumulators

According to the type of location, accumulators are horizontal and vertical. Vertical ones are equipped with legs, some models have plates for hanging on the wall. It is the models that are elongated upwards that are more often used when creating the plumbing systems of a private house on their own - they take up less space. The connection of this type of accumulator is standard - through a 1-inch outlet.

Horizontal models are usually completed with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

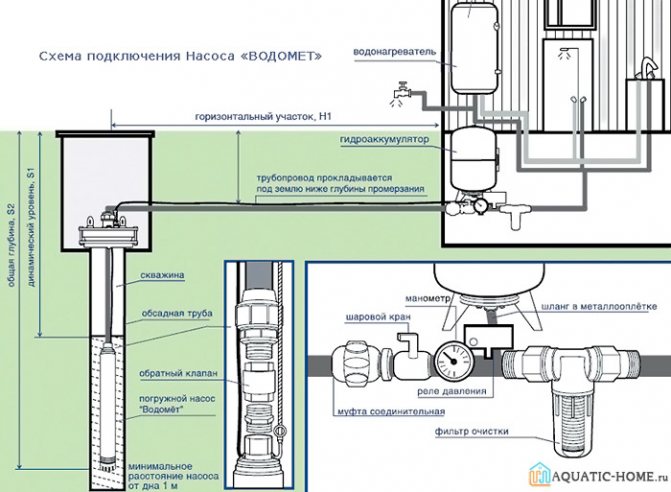

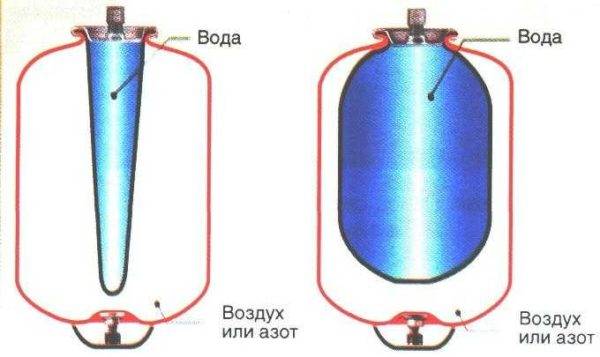

Principle of operation

Radial membranes (in the form of a plate) are used mainly in gyroaccumulators for heating systems.For water supply, a rubber bulb is mainly installed inside. How does such a system work? As long as there is only air inside, the pressure inside is standard - the one set at the factory (1.5 atm) or which you set yourself. The pump turns on, starts pumping water into the tank, the pear begins to grow in size. Water gradually fills an increasing volume, more and more compressing the air that is between the tank wall and the membrane. When a certain pressure is reached (usually for one-story houses it is 2.8 - 3 atm), the pump turns off, the pressure in the system stabilizes. When you open a tap or other flow of water, it comes from the accumulator. It flows until the pressure in the tank drops below a certain level (usually about 1.6-1.8 atm). Then the pump turns on, the cycle repeats again.

The principle of operation of a gyroaccumulator with a pear-shaped membrane

If the flow rate is large and constant - you are taking a bath, for example - the pump pumps water in transit, without pumping it into the tank. The tank begins to fill after all the taps are closed.

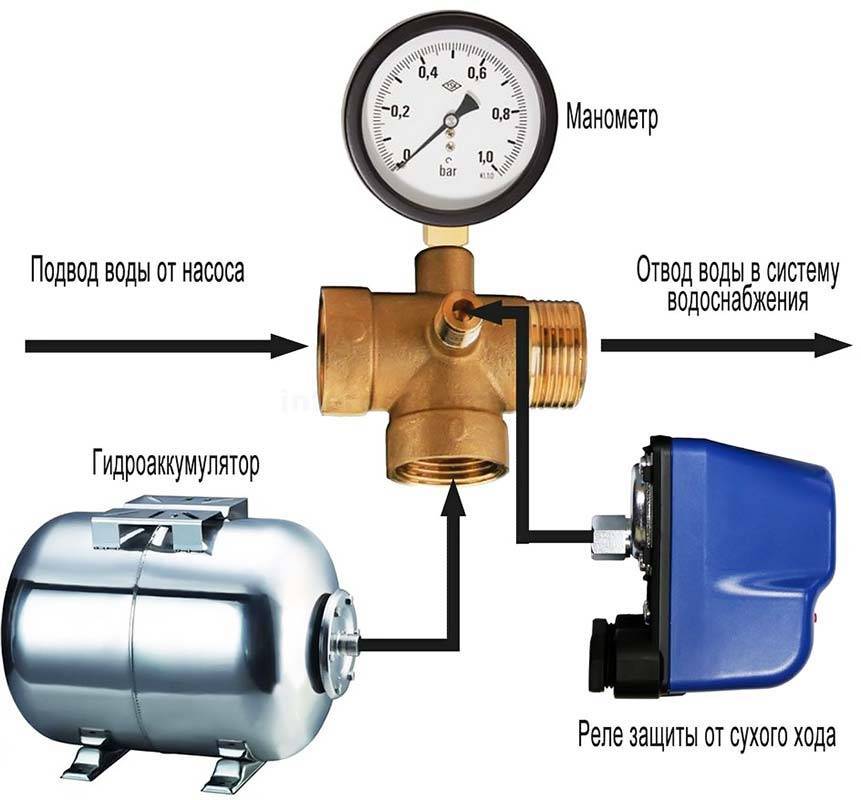

The water pressure switch is responsible for turning the pump on and off at a certain pressure. In most accumulator piping schemes, this device is present - such a system works in the optimal mode. We will consider connecting the accumulator a little lower, but for now let's talk about the tank itself and its parameters.

Large volume tanks

The internal structure of accumulators with a volume of 100 liters and above is slightly different. The pear is different - it is attached to the body both above and below. With this structure, it becomes possible to deal with the air that is present in the water.To do this, there is an outlet in the upper part, into which a valve for automatic air release can be connected.

The structure of a large hydraulic accumulator

Features of connecting to a surface pump

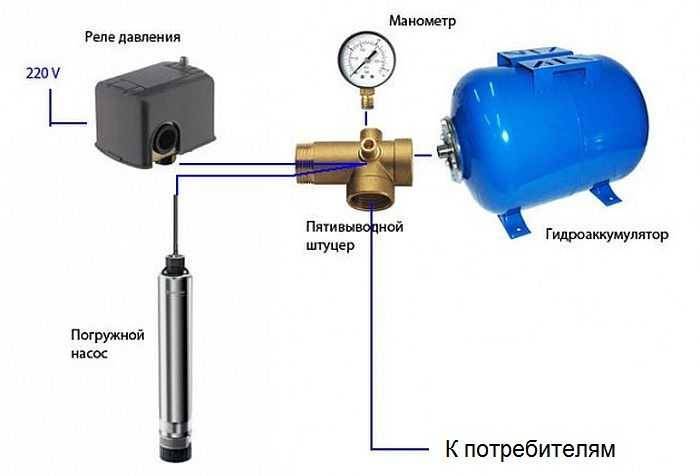

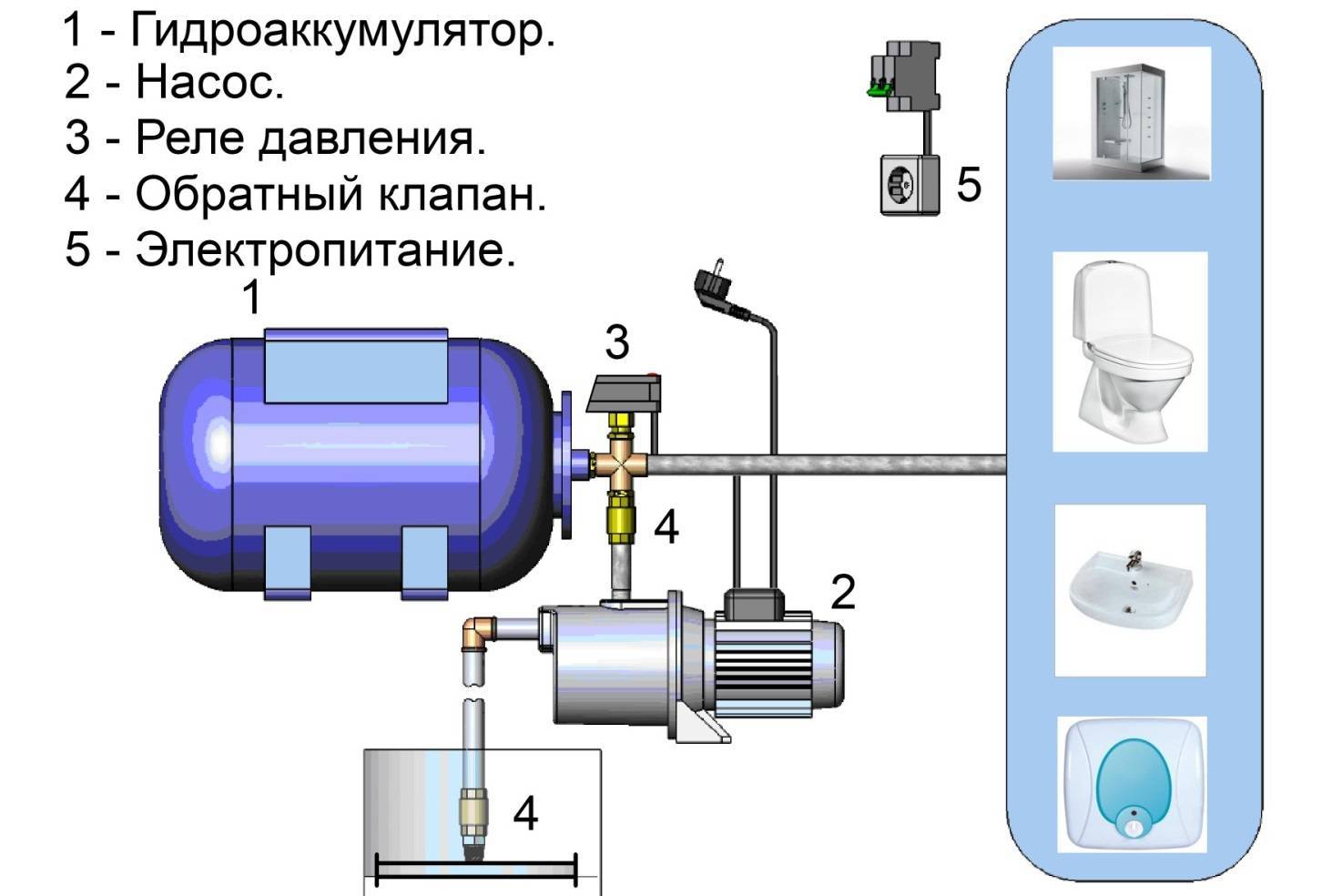

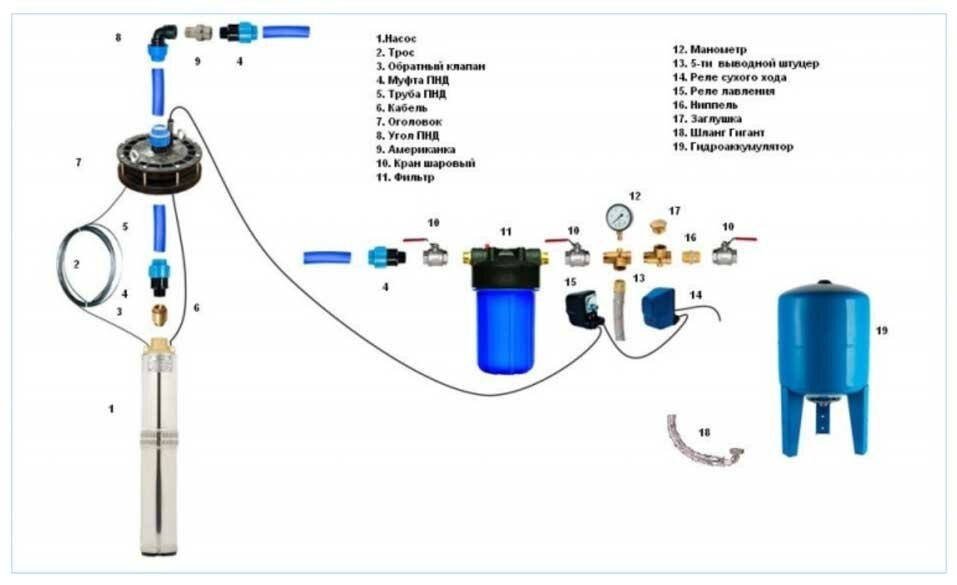

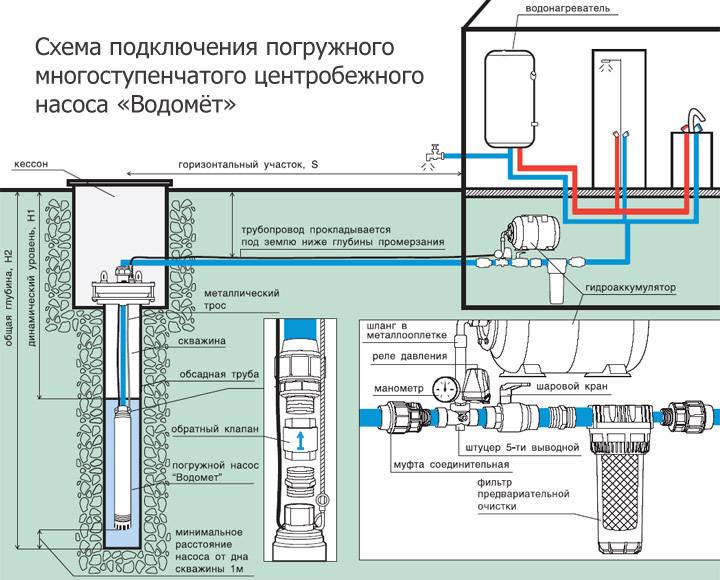

The hydraulic accumulator can be connected to a surface or submersible pump. The technology of work in different cases will be slightly different.

When connecting to a surface pump, you should first pay attention to checking the air pressure in the tank. To carry out the procedure, you may need a fitting with five outlets, a pressure gauge, a pressure switch, a tow and a sealant

The sequence of actions will look like this:

- Tank pressure check.

- Connecting the fitting to the tank.

- Relay connection.

- Manometer connection.

- Connecting the pipe leading to the pump.

- Testing and launching the system.

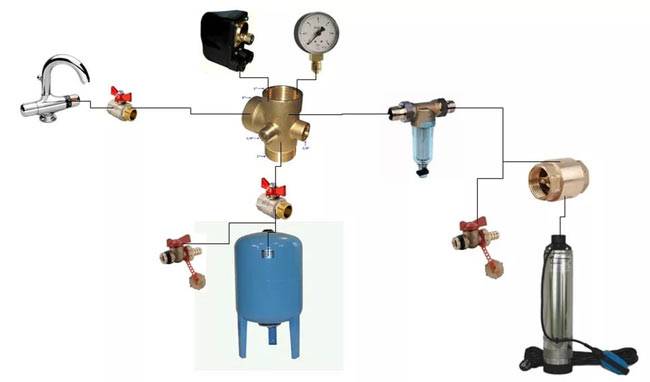

The fitting here is necessary for a high-quality connection of the pump, accumulator, pressure gauge and relay. The fifth exit may be needed to connect the water pipe leading to the house.

At the initial stage, the fitting should be connected to the tank using a rigid hose or flange. After that, a pressure gauge, a regulator and a pipe coming from the pump are screwed to it.

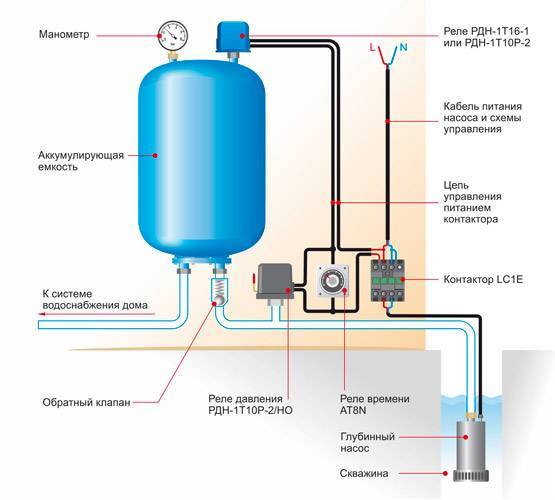

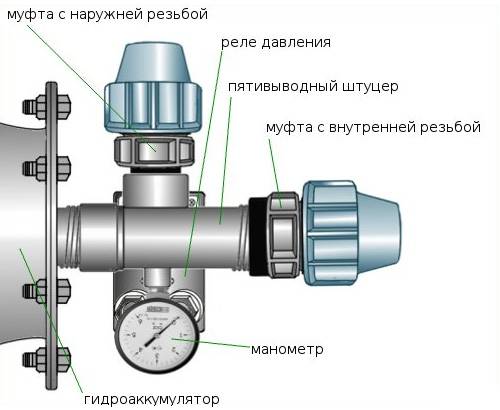

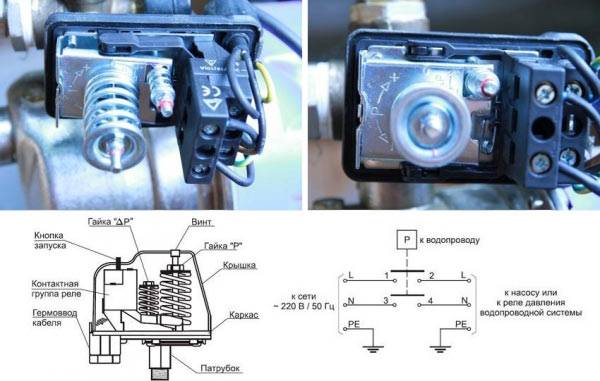

Relay connection diagram for hydraulic accumulator

If you purchased the pump assembled, then most likely the relay has already been installed and adjusted on it, so you don’t have to connect and configure it. If you are assembling the system on site, then you will have to install and configure the relays yourself.

The purchased device must be connected to the pipeline, power supply, pumping device.

The simplest way to connect includes integration into a circuit with a pump, hydro accumulator.

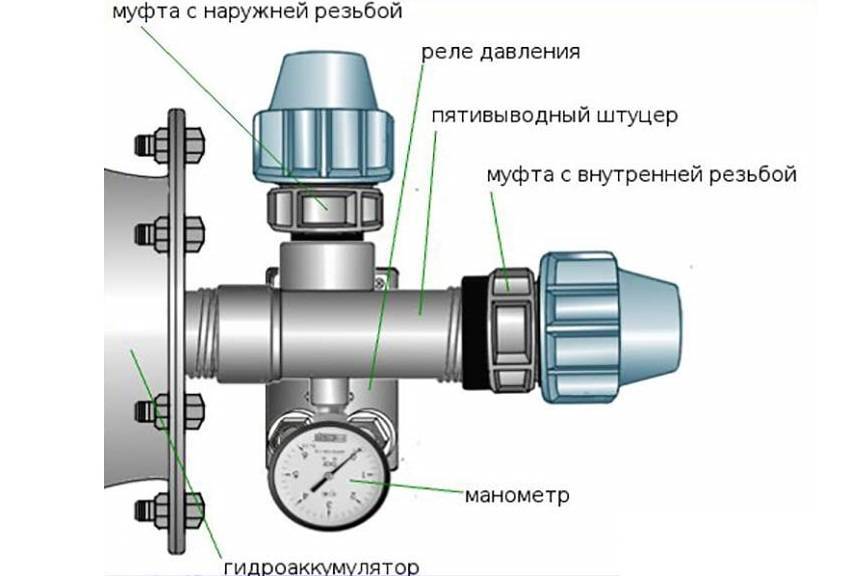

Connection is carried out in strict order: water supply, pump, power supply. Preliminary calculation of water supply is carried out: the average level of pressure of the water flow provided by the action of the accumulator is determined. To make measurements more accurate, the installation of a measuring device (pressure gauge), control devices (relays) is carried out as close as possible to the hydraulic accumulator. Most often they are attached to the branch pipe of the storage device using specially designed five outlet fittings. Connection to the fitting holes is carried out according to the following scheme:

- Water pipes are connected to two of the outputs: to the first - a pipe directed to the consumer; to the second - a pipe directed to the pumping equipment.

- 1 of the outputs is docked with a hydraulic pump.

- Devices are connected to a pair of small holes: a relay, a pressure gauge.

The pressure switch for the accumulator has a special hole 1/4 inch in diameter. It is threaded and designed to be connected to the pipeline, so it should be screwed onto the fitting. Consider in advance the need for waterproofing. To accommodate the waterproofing component, there must be a gap of sufficient size between the fitting and the threaded part. The tightness of the connection is ensured in various ways, for example, using the FUM tape.

You should also carefully connect the electrical cables by feeding them into the special cable openings provided in the relay.The first wire is designed to supply electricity to the outlet, the second - to the pump. After the cables are threaded through the openings, it will be necessary to remove the device cases and connect the contacts to the terminals, taking into account the polarity, grounding. The wires are connected according to the following scheme:

- The wire going to the power source is pulled through a special hole in the case.

- Further, it is divided into phase, neutral, on some wires there may be a ground wire.

- The ends of the cores are stripped of insulating material, connected to the terminals.

In a similar way, the wire leading to the pump is connected.

After the connection is successfully made, you can begin to configure the device.

2

According to the type of energy storage, the devices we are interested in come with mechanical and pneumatic storage. The first of these function due to the kinetics of a spring or load. Mechanical tanks are characterized by a large number of operational disadvantages (large geometric dimensions, high system inertia), so they are not used for domestic water supply systems. At the same time, it is worth noting that such devices do not need to be recharged and powered from external electrical sources.

Pneumatic storage units are more common. They function by compressing water under gas pressure (or vice versa) and are divided into the following types: piston; with a pear or with a balloon; membrane. Piston devices are recommended for cases when it is required to constantly have a sufficiently large supply of water (500–600 liters). Their cost is low, but in private dwellings such installations are operated extremely rarely.

Membrane tanks have small sizes.They are convenient to use. They are most often used for water supply systems of private housing construction. More simple balloon units are also actively used. Such devices are easy to install (you can install them yourself) and maintain (if necessary, any home master can easily replace a failed rubber bulb or a leaky tank). Although the need for repair of balloon accumulators is rare. They are truly durable and reliable.

Membrane tank for a private house

According to their purpose, storage tanks are divided into the following types:

- for heating systems;

- for hot water;

- for cold water.

And according to the method of installation, vertical and horizontal units are distinguished. Both the first and the second function in exactly the same way. Vertical hydraulic tanks with a volume of more than 100 liters usually have a special valve. It makes it possible to bleed air from the water supply network. Horizontal devices are supplied with a separate mount. An external pump is fixed to it.

Also, expansion tanks for differ in their volume. On sale there are also very small units, designed for 2-5 liters, and real giants for 500 liters or more. For private houses, it is recommended to purchase hydraulic accumulators for 100 or 80 liters.

Do you need a hydraulic accumulator

A reasonable question: is it possible to do without a hydraulic accumulator? In principle, this is possible, but with a conventional automation unit, the pump will turn on and off very often, reacting even to a slight flow of water. After all, the amount of water in the pressure pipeline is small, and the slightest flow of water will lead to a rapid drop in pressure and its same rapid increase when the pump is turned on.It is precisely because of the fact that the pump does not turn on for each of your "sneezes" that they put a hydraulic accumulator, at least a small one. Since water is an incompressible substance, air is pumped into the accumulator, which, unlike water, compresses well and acts as a kind of damper that regulates the accumulation and flow of water. If there is no or too little air in the accumulator, then there will be nothing to compress, that is, there will be no accumulation of water.

Ideally, the capacity of the accumulators should be only slightly less than the debit of your water source, and the pump, in this case, will turn on only when some fairly decent supply of water is used up, i.e. very rarely, but for a long time. But then it will be very expensive in cost.

Now pumping stations with improved automation units with built-in dry-running protection have appeared on sale, which smoothly start and stop the pump, regulate its power depending on the given pressure. It is believed that the accumulator, in principle, they do not need. But all this works well only in the absence of power surges, which our remote areas and summer cottages cannot boast of. And, unfortunately, stabilizers do not always save from this trouble. In addition, the price of such a station is very often much higher than usual, which, in my opinion, does not justify itself.

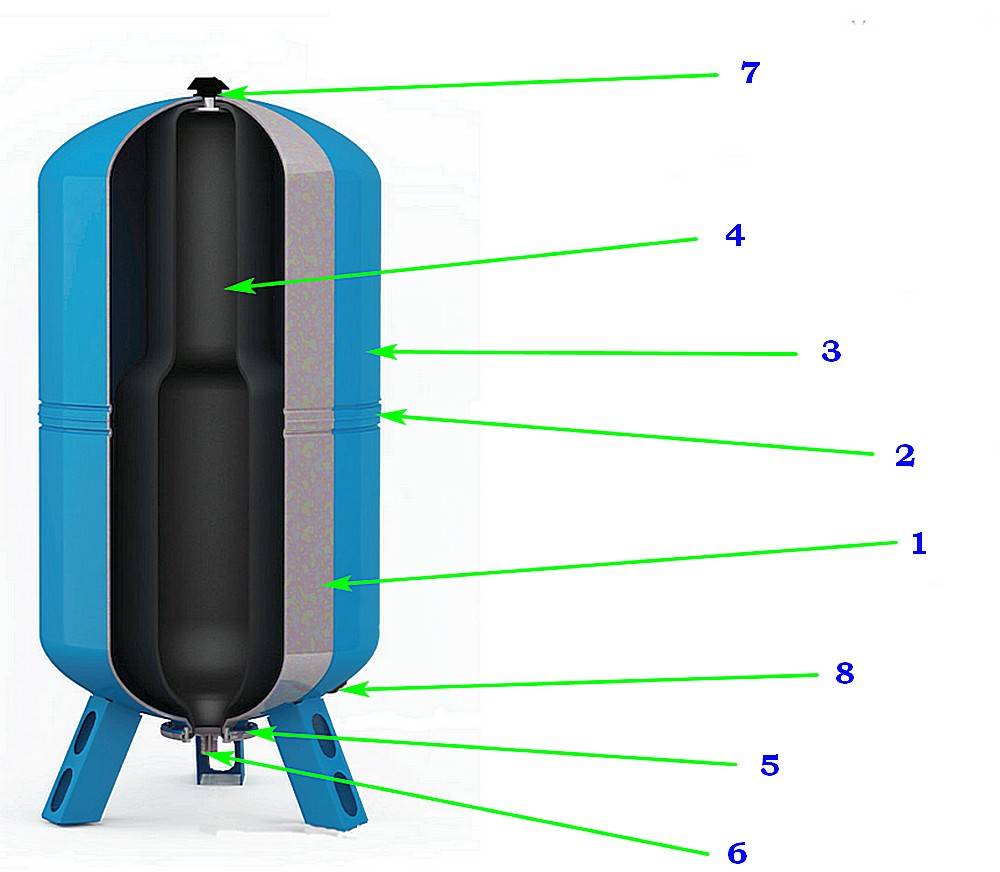

The device and purpose of the hydraulic tank

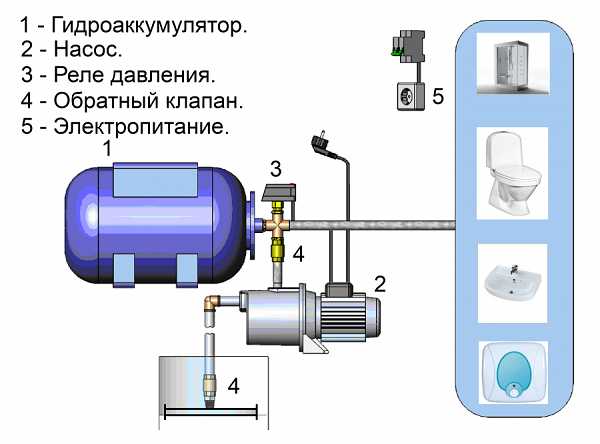

A hydraulic accumulator, which is otherwise called a hydraulic tank or a membrane tank, is a sealed metal container in which an elastic pear-shaped membrane partially filled with water is placed.In fact, the membrane, placed in the body of the hydraulic tank and attached to its body with a flange with a pipe, divides its capacity into two parts: water and air.

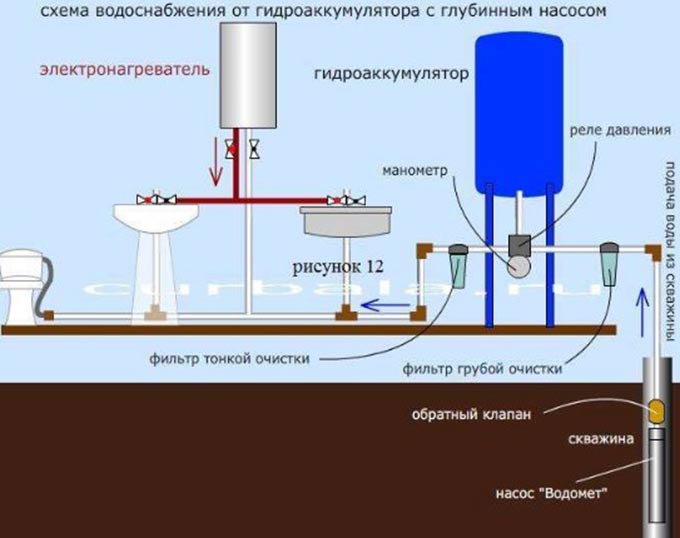

As the volume of water in the hydraulic tank increases, the volume of air naturally decreases. As a result, the pressure in the water supply system increases. When the pressure parameters set by the user are reached, it is fixed by a relay, which systematically gives a command to turn off the pump.

Image gallery

Photo from

A hydraulic accumulator is a metal tank, inside of which an elastic membrane in the form of a flask is placed, filled with water. The rest of the space between the flask and the body is occupied by gas or air

The change in the volume of water in the flask and air in the body is fixed by automation, which controls the on / off cycles of the pump

Hydraulic tanks are used both as part of systems with a submersible pump, and in tandem with a surface pump. In both cases, they are required to automate the operation of the system.

Hydraulic accumulators are installed either at the inlet of the water supply to the house, or near the water well directly in the caisson

A non-return valve is installed on the inlet pipe to the hydraulic tank, which prevents the outflow of water back into the mine after the pump stops

The optimal place for installing a pressure gauge is considered to be the outlet from the accumulator, which is required to control the pressure parameters in the system

In the arrangement of dachas and small country houses, hydraulic tanks with a capacity of 12 to 24 liters are used. To work in tandem with submersible pumps, the volume is taken more, calculated based on the technical characteristics of a particular unit

If for the normal operation of an autonomous system a water reserve of 300 - 500 liters is required, then the circuit with a hydraulic tank is supplemented with a large hydraulic accumulator, a ready-made or home-made storage

Components of a water supply system with a hydraulic tank

Hydoaccumulator as part of a pumping station

Installing a hydraulic accumulator in a caisson

Hydraulic accumulator at the inlet of the water supply to the house

Check valve location

Place of installation of the manometer

Accumulator Volume Standards

Water reserve system

The body of the tank is made of metal, but water does not come into contact with it: it is enclosed inside a membrane chamber, which is made from durable rubber butyl. This bacteria-resistant material helps water not to lose the qualities that sanitary and hygienic standards require. Drinking water, when interacting with rubber, retains all its wonderful properties.

Water enters the membrane tank through a connecting pipe equipped with a threaded connection. The pressure pipe and the outlet of the connecting water supply should ideally have the same diameter. This condition allows avoiding additional hydraulic losses inside the system pipeline.

In those accumulators that are part of domestic water supply systems, air is used. If this device is intended for industrial use, gas is pumped into it

To regulate the pressure inside the device, a special pneumatic valve is provided in the air chamber. Air is pumped into the compartment allotted for it through a conventional automobile nipple. By the way, through it you can not only pump air, but, if necessary, bleed its excess.

Air is pumped into the membrane tank using a compact automobile or simple bicycle pump for this purpose. When water enters the rubber bulb, compressed air resists its pressure, preventing the membrane from breaking through. The pressure inside the accumulator is also regulated using compressed air.

The hydraulic accumulator consists of the following elements: 1 - a metal case, 2 - a rubber membrane, 3 - a flange equipped with a valve, 4 - a nipple through which air can be pumped, 5 - air under pressure, 6 - legs, 7 - an installation platform for the pump

The cost of relays and accumulators of some manufacturers

Relay models can be purchased relatively inexpensively. Usually the cost of products does not exceed one thousand rubles. However, electronic counterparts may have a higher price, as they allow for more precise tuning. The table shows the models of some manufacturers and their cost.

Presented pressure switch Gileks RDM-5

Note! On average, for a family of 4-8 people, as a rule, a hydraulic accumulator with a capacity of 50 liters is enough. With a smaller number of people living, a capacity of 24 liters is purchased, and with a larger number - 100 liters

Hydraulic accumulator Gileks, containing 24 liters

Criterias of choice

For long-term operation, experts recommend purchasing models with a pear. Membrane accumulators are more susceptible to corrosion, since the membrane is not able to isolate the walls of the housing from water. However, for models with a pear, repair is more difficult than for membrane counterparts. When choosing a drive, you also need to take into account the future water consumption.

If there are more users, then an appropriate hydraulic accumulator is required.Please note the following before installation:

- number of users;

- number of water points;

- the number of household plumbing fixtures;

- the presence of heating elements.

Both procedures have approximately the same complexity and comparable equipment costs.

Do you need a reserve capacity

Many people believe that one of the functions of a battery is to store water. However, this is not the case and the functions of the device are completely different. Of course, a small margin of capacity is needed - there are times when water consumption may increase. In addition, a slightly increased volume will positively affect the operation of all equipment.

However, given the price, there is no need to overpay extra money for additional capacity. For these purposes, special plastic tanks are designed that are built into the water supply system.

Moreover, if in the future it is planned to increase consumption points, you can buy an additional hydraulic tank. Their total volume will be summed up. For example, if two devices of 40 and 80 liters are installed in the system, then the total working power will be 120 liters.

Optimal pressure

In order for the GA to do its job well, the pressure must be set correctly in it. In general, the calculation of the required value is done on the basis that for every 10 meters of elevation, 1 atmosphere is required. In addition, another atmosphere provides normal pressure in the plumbing system.

For example:

- the accumulator is installed in the basement, and a distance of 6 meters is obtained to the highest point;

- thus, 0.6 atmospheres will be required to lift water and one more to work;

- i.e., the working value will be 1.6 atmospheres.

When installing, you must immediately check this value, and if it is below normal, then pump air into the tank. Also, you need to correctly set the pressure switch. After all, the frequency of switching on the pump and the pressure of water in the system will depend on this.

How to choose tank volume

You can choose the volume of the tank arbitrarily. There are no requirements or restrictions. The larger the tank, the more water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that is in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent barrel - about 850 mm high and 450 mm in diameter. For her and the strapping, it will be necessary to find a place somewhere. Somewhere - this is in the room where the pipe comes from the pump. This is where most of the equipment is installed.

The volume is chosen based on the average consumption

If you need at least some guidelines to choose the volume of the accumulator, calculate the average flow rate from each draw-off point (there are special tables or you can see it in the passport for household appliances). Sum all these data. Get the possible flow rate if all consumers work at the same time. Then estimate how many and which devices can work at the same time, calculate how much water will go in this case per minute. Most likely by this time you will already come to some kind of decision.

The principle of operation of the pressure switch

An autonomous water supply system in a private house consists of water pipes, a pump, and controls and cleaning elements. The hydraulic accumulator in it plays the role of a water pressure control device. First, the latter is stored in the battery, and then, as necessary, it is consumed when the taps are opened.

This configuration of the water supply system allows you to reduce the operating time of the pumping station, as well as the number of its “on / off” cycles.

The pressure switch here performs the function of controlling the pump. It monitors the level of filling of the accumulator with water, so that when this tank is empty, it will turn on the pumping of liquid from the water intake in time.

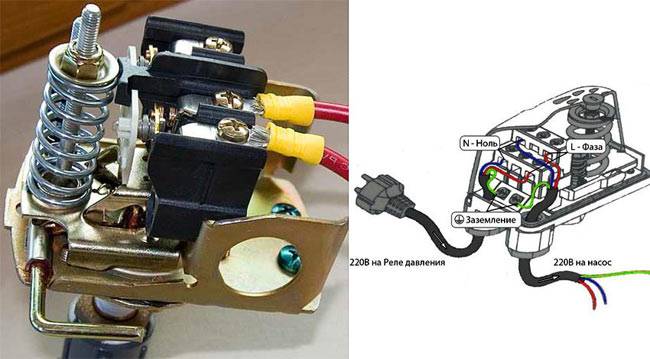

The main elements of the relay are two springs for setting pressure parameters, a membrane responsive to water pressure with a metal insert and a 220 V contact group

If the water pressure in the system is within the parameters set on the relay, then the pump does not work. If the pressure drops below the minimum setting Pstart (Pmin, Ron), then an electric current is supplied to the pumping station to make it work.

Further, when the accumulator is filled to Рstop (Pmax, Рoff), the pump is de-energized and switched off.

Step by step, the relay in question works as follows:

- There is no water in the accumulator. The pressure is below Pstart - set by a large spring, the membrane in the relay is displaced and closes the electrical contacts.

- Water begins to flow into the system. When Rstop is reached, the difference between the upper and lower pressures is set by a small spring, the membrane moves and opens the contacts. As a result, the pump stops working.

- Someone in the house opens a faucet or turns on a washing machine - there is a decrease in pressure in the water supply.Further, at some point, the water in the system becomes too small, the pressure again reaches Rpusk. And the pump turns on again.

Without a pressure switch, all these manipulations with turning the pumping station on / off would have to be done manually.

The data sheet for the pressure switch for accumulators indicates the factory settings to which the control springs are initially set - almost always these settings have to be changed to more suitable ones

When choosing the pressure switch in question, first of all, you should look at:

- the maximum temperature of the working environment - for hot water and heating, their own sensors, for cold water, their own;

- pressure adjustment range - the possible settings of Pstop and Rpusk must correspond to your particular system;

- maximum operating current - the pump power should not be higher than this parameter.

The setting of the pressure switch under consideration is made on the basis of calculations, taking into account the capacity of the accumulator, the average one-time water consumption by consumers in the house and the maximum possible pressure in the system.

The larger the battery and the greater the difference between Rstop and Rstart, the less often the pump will turn on.

Place of the device in the water supply system

(GA) consists of a tank, a bleed valve, a flange, a 5-pin fitting (tee) with couplings for connection, as well as a pressure switch (control unit), which sets the pace for all work.

Functions:

- main control element

- ensures work without overloads

- controls the optimal filling of the tank with water

- prolongs the life of the membrane and all equipment as a whole

A pressure gauge that shows the pressure in the tank is included in the kit or purchased separately.

The pump pumps water out of the well, sends it through the pipes. Further, it enters the GA, and from it - into the home pipeline. The task of the membrane tank is to maintain a stable pressure, as well as the pump cycle. For her, there is a certain maximum of activations - about 30 per hour. When exceeded, the mechanism experiences loads and after a short time may fail. It is necessary to adjust the water pressure switch so that the devices work as expected, without exceeding the critical load.