- Fourth stage: connecting the unit to the gas pipeline

- Unit connection diagram

- The principle of operation of gas boilers

- Boilers with open and closed combustion chamber

- Documents for the boiler

- The main scheme for connecting gas double-circuit boilers and its main stages

- The gas boiler must be connected to:

- How to connect a gas boiler in a private house in order?

- Materials and tools

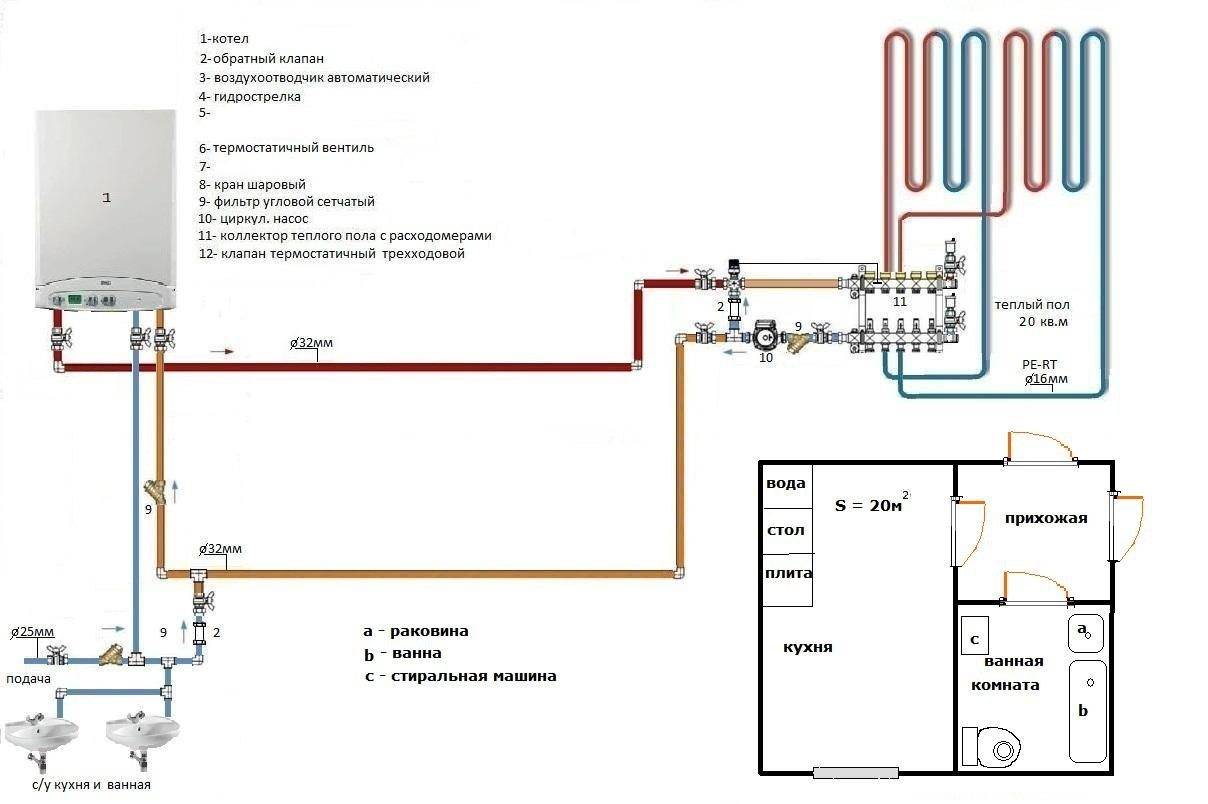

- Phased connection of the heating circuit

- Connection to the heating system

- Where it is possible and where it is impossible to put a gas boiler

- Benefits of gas heating

- Peculiarities

- Mini-boiler rooms

- With bithermic heat exchanger

- Gas heating installation process

- Conclusions and useful video on the topic

Fourth stage: connecting the unit to the gas pipeline

Connecting to a gas pipeline is an extremely responsible business. The slightest mistake can be very costly. If the installation work is not properly performed, then serious emergencies can occur that will lead to gas poisoning or an explosion. There should be no trifles when connecting the boiler to the gas pipeline.

The first step is to connect the pipe from the boiler to the branch pipe of the gas pipe. At the same time, there must be a shut-off valve on the gas pipe. A special filter for heating is also installed on it.

When connecting the gas pipeline to the boiler, you need to carefully ensure that all joints are sealed. Here, FUM tape or sealing thread, which do not provide high-quality insulation, cannot be used for sealing. The use of tow and paint is recommended.

Rubber hoses for connecting gas boilers to the gas pipeline are prohibited. Rubber can lose its performance properties (crack), which will inevitably lead to a dangerous gas leak. The hoses are attached to the branch pipe of the unit using union nuts and sealing paronite gaskets. Seals are required here, because they will achieve sufficient sealing of the connection.

As for connecting the Baksi boiler to the heating system, then you can’t do without the help of specialists. In this case, you can independently perform only the initial stages of its installation. The boiler will work for a long time and efficiently when it is connected professionally.

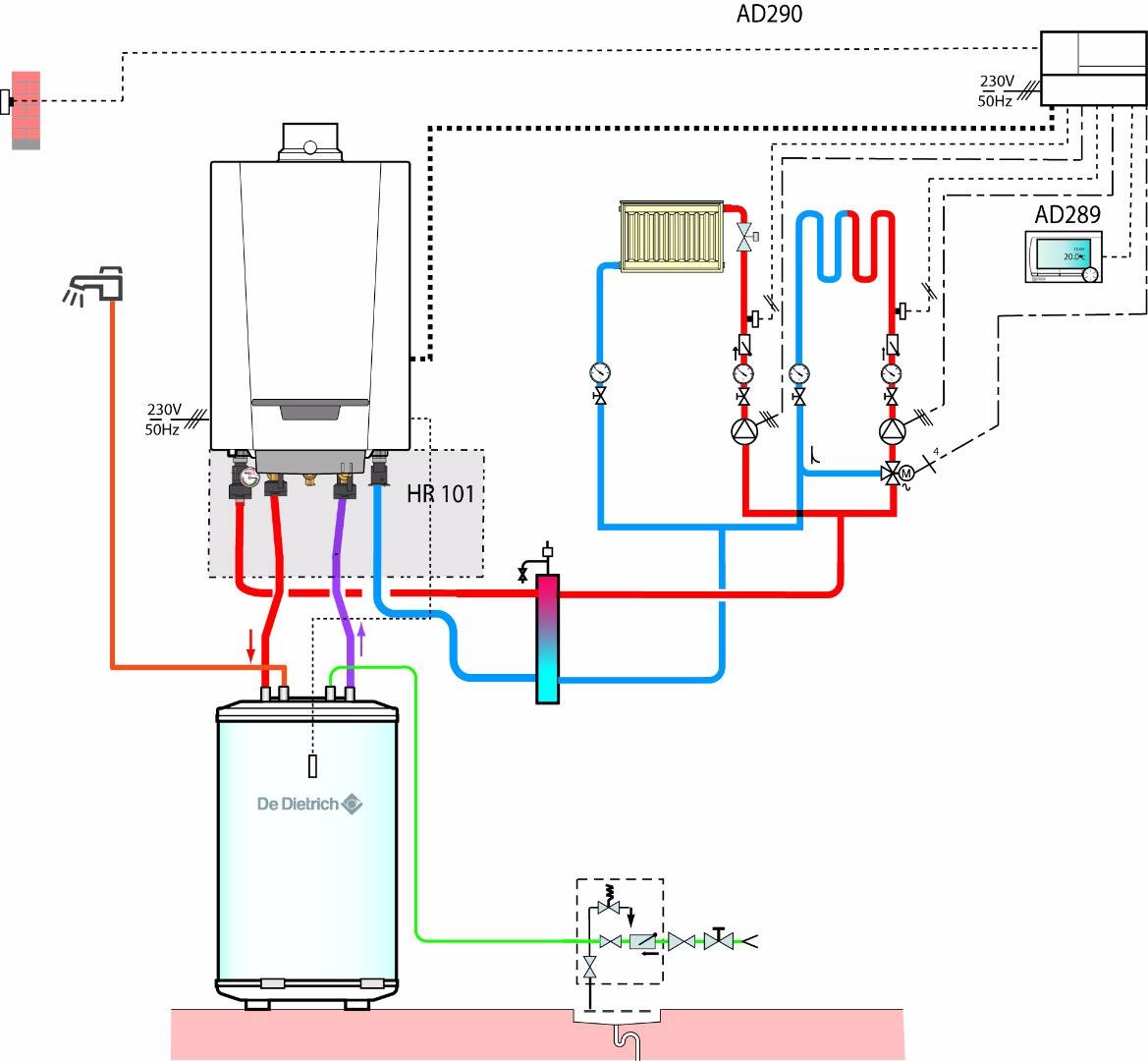

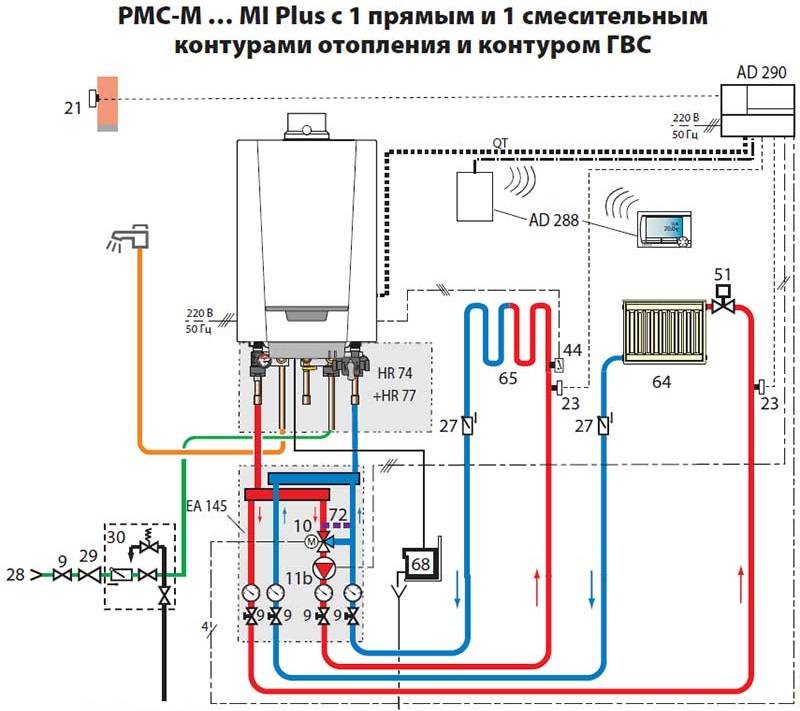

Unit connection diagram

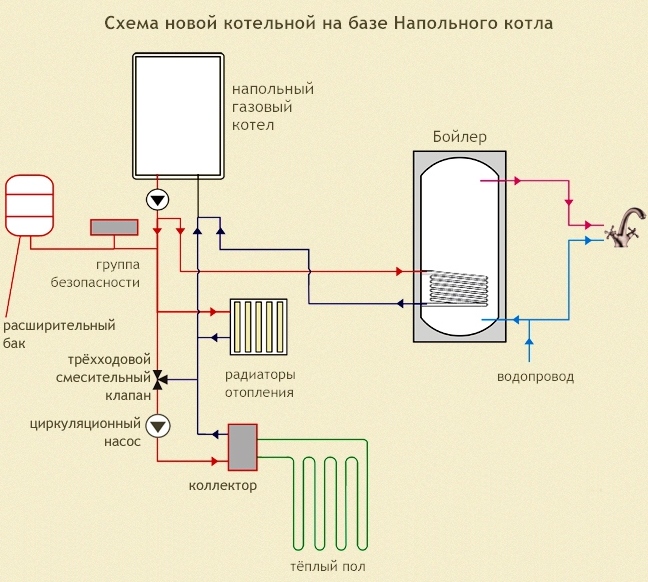

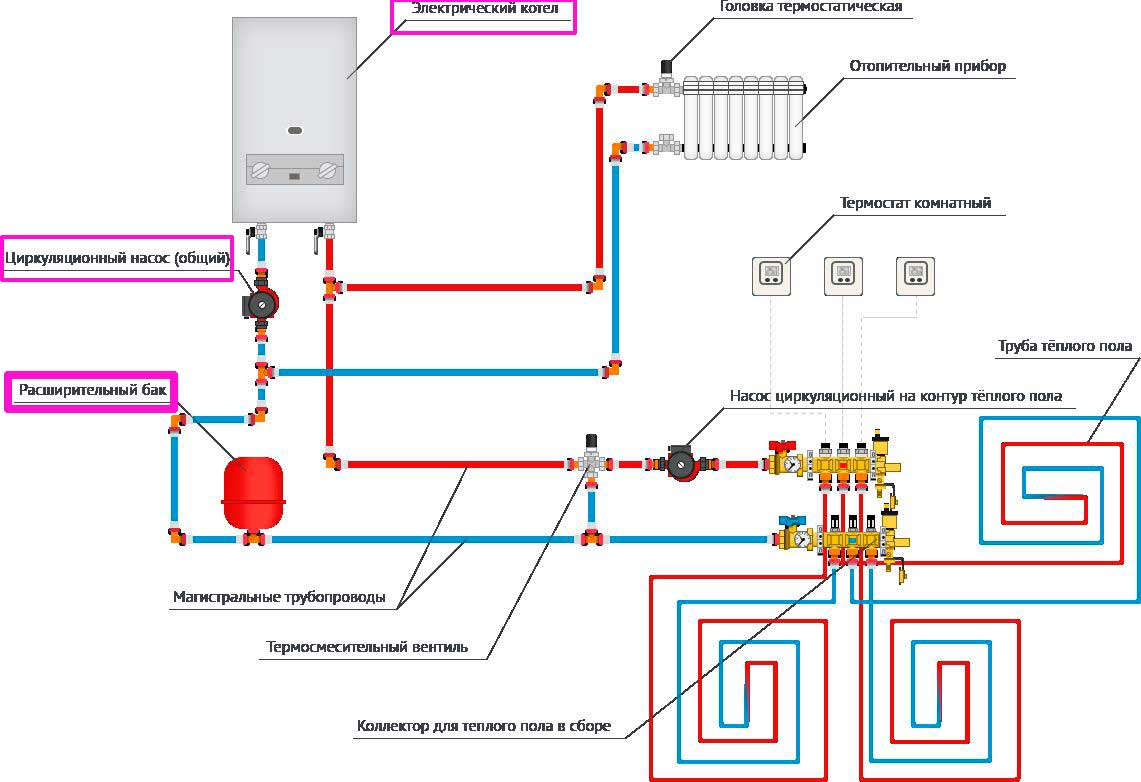

The connection scheme of the unit will depend on several factors, the first and most important, of course, is the type of heating system. There are three varieties in total:

- Those in which natural circulation is used. The movement of heat provides a difference in water pressure that occurs in the line due to the expansion of coolants due to an increase in temperature. Installation of such a line is cheaper, but you will not be able to regulate the temperature using a radiator, respectively, the second type is used on better automation.

- Forced circulation is carried out by special pumps, so you can freely adjust the amount of heat.Accordingly, the method is the most effective on the market, but the connection scheme is much more complicated, and installation is more expensive. In addition, the system is completely dependent on electricity, when it is turned off, the unit simply ceases to perform its functions.

- hybrid circulation. Now on the market there are practically no devices with this type of heating, however, such a device combines the advantages of both of the above. In the event of a power outage, the boiler freely switches to the mode of natural water distillation through pipes.

Accordingly, the connection diagram is available depending on the type of heating selected by the user.

The principle of operation of gas boilers

All existing models can be divided into two main groups:

Convection boilers have a simpler design and low cost. You can find these models everywhere. Heating of the coolant occurs solely due to the effect of an open flame of the burner. In this case, most of the thermal energy is transferred to the heat exchanger, but some (sometimes quite significant) part of it is lost along with the discharged products of gas combustion. The main drawback is that the latent energy of water vapor, which is part of the removed smoke, is not used.

Convection boiler Gaz 6000 W

The advantages of such models include a fairly simple design, the possibility of diverting combustion products due to natural draft (if there are chimneys that meet the requirements).

The second group is convection gas boilers. Their peculiarity lies in the following - convection equipment cannot use the energy of water vapor removed with smoke.It is this drawback that the condensing circuit of a gas boiler allows to eliminate.

Gas boiler Bosch Gaz 3000 W ZW 24-2KE

The essence of the operation of such devices is that combustion products that have a sufficiently high temperature pass through a special heat exchanger, into which water enters from the return of the heating system. Provided that the temperature of such a coolant is below the dew point for water (about 40 degrees), steam begins to condense on the outer walls of the heat exchanger. In this case, a sufficiently large amount of thermal energy (condensation energy) is released, which provides preheating of the coolant.

But there are some negative points that characterize the condensation technique:

To operate in condensing mode, it is necessary to provide a return temperature of no more than 30-35 degrees. Therefore, such units are mainly used for low-temperature (not more than 50 degrees) heating systems. Also, boilers of this type can be used in systems with high heat transfer, for example, in systems with a warm water floor. Boilers in which a condensing heat exchanger is used to provide hot water have proven themselves quite well.

Maintenance and adjustment of the optimal operating mode of the boiler can only be performed by a competent specialist. In the regions, there are not too many craftsmen who can understand condensing boilers. Therefore, maintenance of the device can be quite expensive.

In addition, the very cost of equipment of this class is high, it will not be possible to attribute such equipment to the budget option even with a strong desire.

But is it really worth giving up the opportunity to save more than 30% of the energy carrier because of such shortcomings.It is this savings and the short payback period of condensing boilers that make their purchase expedient from an economic point of view.

Boilers with open and closed combustion chamber

Such boilers differ significantly in their technical capabilities, while the conditions for their use also differ.

Atmospheric boilers are equipped with an open combustion chamber. The air necessary for gas combustion enters the chamber directly from the room. Therefore, when choosing such boilers, it is necessary to strictly control compliance with the regulatory requirements for air exchange in the room. An effective ventilation system must operate in the room, in addition, the removal of combustion products in the natural draft mode is possible only with the installation of high chimneys (smoke removal above the level of the roof of the building).

Wall-mounted gas boiler Logamax U054-24K atmospheric double-circuit

The advantages of such boilers include a fairly reasonable cost, simplicity of design. But it should be borne in mind that the efficiency of such units is most often not too high (compared to more advanced models).

The turbocharged wall-mounted double-circuit boiler is equipped with a closed-type combustion chamber. Such units are connected mainly to coaxial chimneys, which provide not only the removal of combustion products, but also the supply of fresh air to the combustion chamber from the street. To do this, a low-power electric fan is built into the design of the boiler.

Gas boiler FERROLI DOMIproject F24 wall-mounted double-circuit turbocharged

The main advantage of a turbocharged boiler is increased productivity, while the efficiency of the device reaches 90-95%. This makes it possible to reduce fuel consumption. But it is worth considering that the cost of such boilers is quite high.

Documents for the boiler

Let's say you equipped a furnace in compliance with all requirements. Buying a boiler Still early. First of all, check if the old papers have been lost for gas, and take them out into the light of day:

- Contract for the supply of gas, if the boiler is heating. Subconsumers may only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing to be done, you need to set it up and draw it up, but that’s another topic.

Now you can buy a boiler. But, having bought, it is too early to install:

- In BTI, you need to make changes to the registration certificate at home. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be applied, and clearly marked: “Furnace” or “Boiler Room”.

- Submit an application to the gas service for the project and specifications. As part of the required documents and the technical passport for the boiler, so it must have already been purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas piping.

- Submit an application to gas workers for commissioning.

- Wait for the arrival of the gas service engineer, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

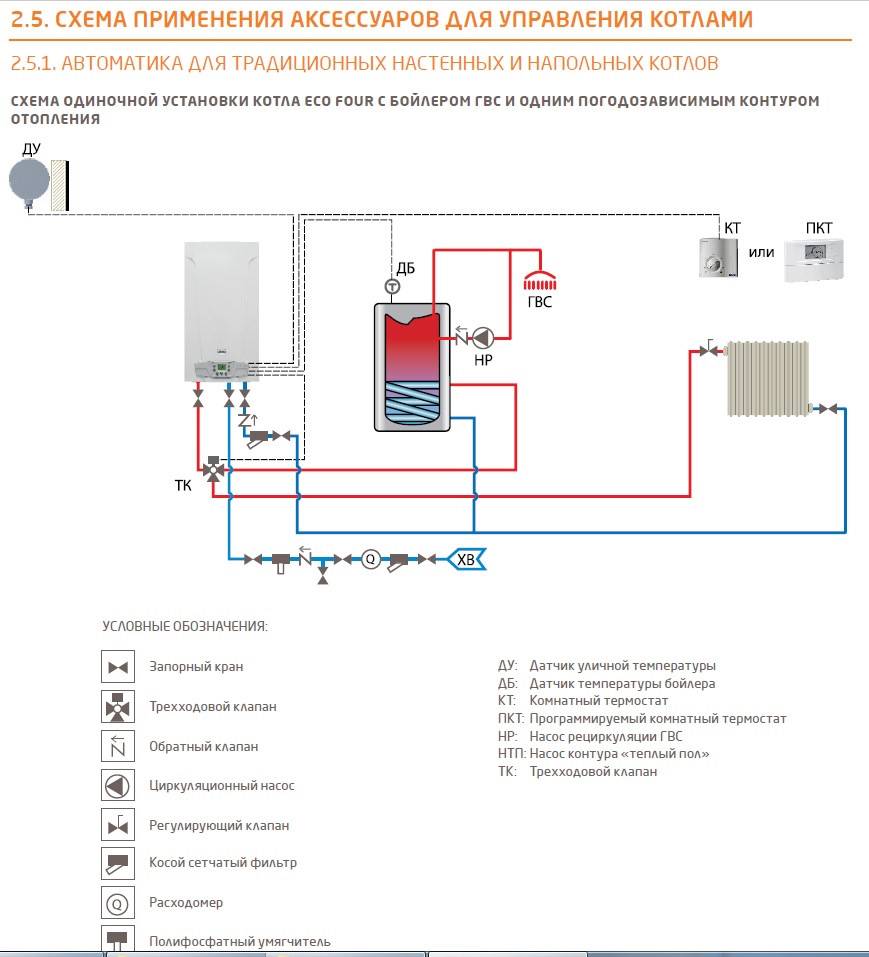

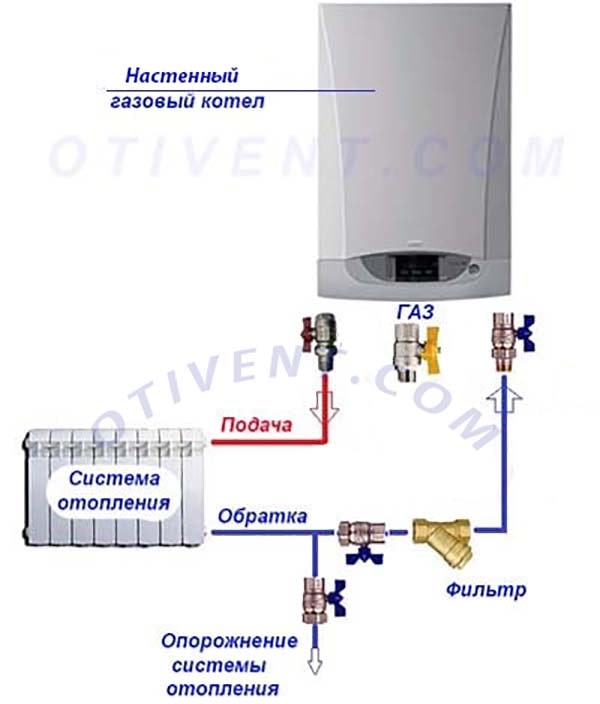

The main scheme for connecting gas double-circuit boilers and its main stages

The gas boiler must be connected to:

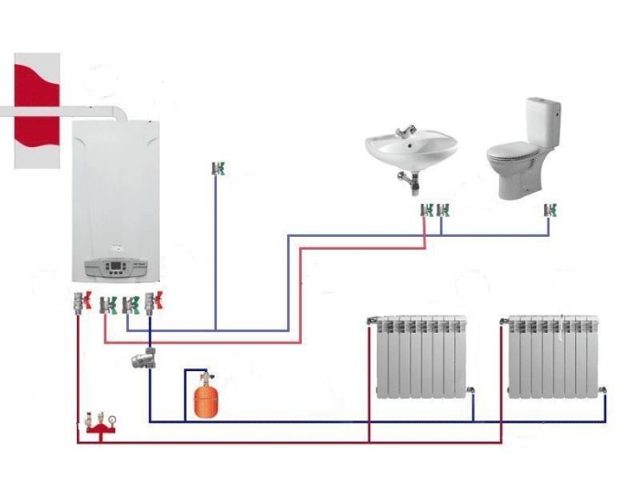

Connecting double-circuit gas boilers must begin with its installation and mounting the equipment on the wall. After that, the heating circuit is connected and the water supply is connected. Only then can the equipment itself be connected to the gas pipeline.

connection of double-circuit gas boilers

connection of double-circuit gas boilers

Such boilers are usually hung on special brackets that come with the device. The place for its location is chosen based on the convenience for the user. In the room where he will stand, there must be an opening window. also, do not install it near other equipment or near the gas meter.

You can not hang it from the ceiling, it must be mounted on the wall at least one meter from the floor level.

The connection scheme for gas double-circuit boilers is the same for all its types. All of them have a similar arrangement of all pipes for connecting them to gas, water supply and heating.

How to connect a gas boiler in a private house in order?

It is possible to install and properly connect the device on your own, but this requires approval from the gas services. In the course of the work, thoughtful activity and the need for paperwork will be required: agreeing on a number of issues and obtaining documents.

First, an agreement is drawn up with a supplier of natural gas for its supply to private households. They are also involved in the project of gasification of the building and installation of the necessary equipment.

Before installation, all papers (certificate, serial number of the product) are verified. If everything is in order, proceed to the installation.

The installation location is selected according to the type of device.

The floor gas boiler is installed on a flat surface made of non-combustible materials.Used, for example, tiles or concrete screed. And also sometimes they put a sheet of galvanized steel with a ledge on the front side up to 30 cm. Access to the structure should be unlimited from any side.

Important! It is necessary that the boiler is located away from electrical appliances and sources of fire, and also not close to the wall. The structure must have a uniform load on all supports

The structure must have a uniform load on all supports.

The wall-mounted gas boiler is fixed with brackets (included). Installation height - about 1 meter above the floor. First, the slats are fastened, then the unit is mounted on them.

Then there is a connection to the chimney. Before this, the presence of traction is checked. To prevent the leakage of toxic gases, the connections are carefully sealed.

Photo 3. Wall-mounted gas boiler, installed more than a meter above the floor, connected to the chimney.

25 cm - the maximum length of the pipe segment that connects the boiler to the chimney.

The next step is connecting to the water supply. The first step is to install a filter for hard water purification, which prevents clogging of the heat exchanger. On both sides of it, taps and / or valves are installed.

To ensure optimal pressure in the system, the tie-in to the water supply is carried out either to the place where the pipe branches, or as close as possible to its entrance to the building. Usually, the water supply pipe is connected from the top of the unit, for return - from the bottom.

All communications must be equipped with a locking mechanism to be able to urgently shut off the gas supply in case of danger.

Materials and tools

- Adjustable wrenches and dowels;

- building level for choosing the place of attachment of the brackets, its length should not be less than 1 meter;

- a puncher with a set of drills of different diameters for making holes in the wall, designed to fix them;

- brackets - are included, but it is better to have a certain amount in reserve;

- scissors, so that when cutting pipes, they do not damage their protective layer, which is responsible for tightness;

- pipe flaring calibrator;

- valves, taps - for fastening locking mechanisms;

- galvanized steel sheets and tools for cutting them.

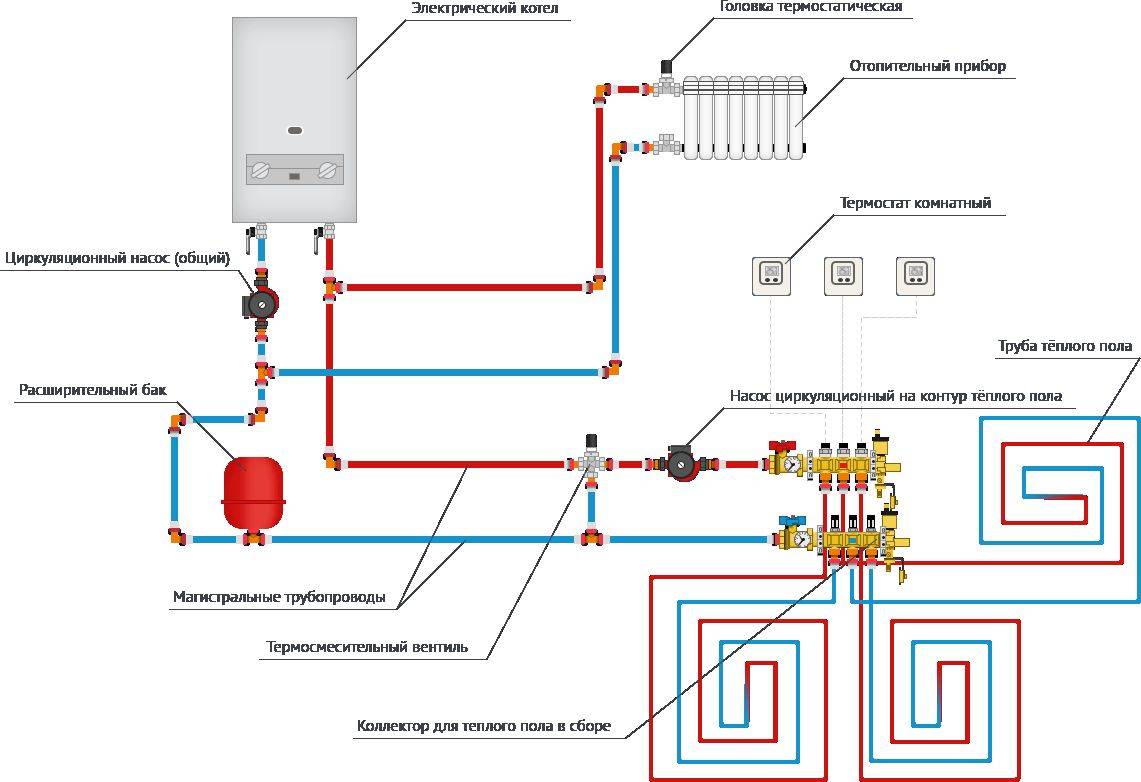

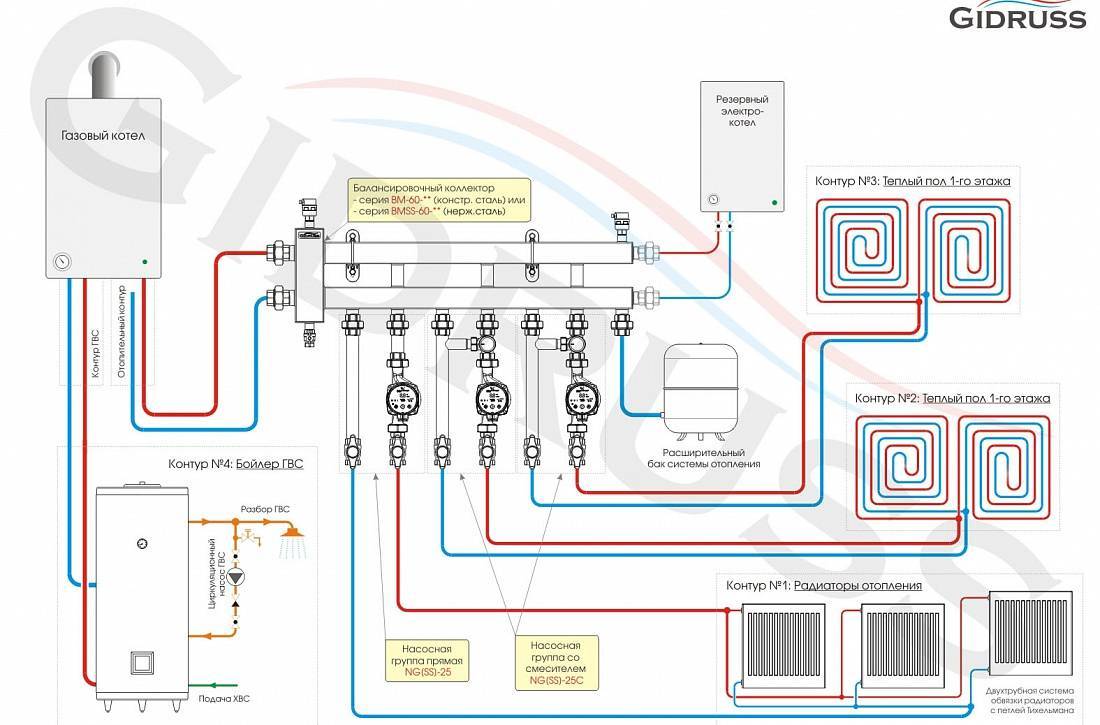

Phased connection of the heating circuit

There are several ways to connect the circuit to the boiler, depending on the model and accessories.

When connecting a single-circuit gas appliance to a heating system, the easiest way is to use shut-off valves and connect the circuit with their help directly to the boiler.

The circulation of the coolant occurs in natural mode, and a conventional expansion tank is installed in the system.

When connecting double-circuit devices, the work becomes more complicated, since a double set of pipes is brought to the boiler. The coolant flows directly through one, and hot water circulates through the second. The connection is also established using shut-off valves.

If the system is closed, then additional devices must be installed: a circulation pump, a diaphragm expansion tank and a safety group.

Connection to the heating system

Location of connection points to the heating system (on the front side):

- on the left - hot coolant supply to the circuit;

- on the right is the return line.

When connecting the boiler, it is worth carefully checking the sealing and tightening of the knots, but one should not be too zealous because of the risk of damaging the threads and encountering the problem of replacing all connecting elements.

It is also necessary to install a coarse filter on the return line, which will extend the life of the device by stopping solid particles.

Where it is possible and where it is impossible to put a gas boiler

The rules for installing a gas boiler provide for the following requirements for installing a HEATING boiler, regardless of whether it also provides domestic hot water or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications of the admissibility of a ceiling of 2 m. This is not true. 8 cubes is the minimum free volume.

- The furnace must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with combustible materials, the presence of a false ceiling or raised floor in it is unacceptable.

- Air must be supplied to the furnace through a through, non-closable vent with a cross section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly referred to as a chimney); the use of ventilation ducts for this is unacceptable - life-threatening combustion products can get to neighbors or other rooms.

- The length of the horizontal part of the flue must not exceed 3 m within the furnace and have no more than 3 angles of rotation.

- The outlet of the flue must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since the products of combustion form chemically aggressive substances during cooling, the chimney must be made of heat- and chemical-resistant solid materials. The use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest branch pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A strong fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- The room should not have cavities in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment / house:

- The slope of the horizontal pipe sections must be positive, but not more than 5 mm per linear meter in terms of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler in which everything is provided for: rules are rules.

- The condition of the heating system must allow it to be pressure tested at a pressure of 1.8 atm.

The requirements, as we see, are tough, but justified - gas is gas.Therefore, it is better not to think about a gas boiler, even a hot water boiler, if:

- You live in a block Khrushchev or other apartment building without a main flue.

- If you have a false ceiling in your kitchen, which you do not want to clean, or a capital mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which, in principle, can be removed, and then there will be no mezzanine, gas workers look through their fingers.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment that only the owner can do.

In all other cases, you can put a hot water boiler in the apartment; heating wall is possible, and floor - very problematic.

In a private house, any boiler can be installed: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside under the furnace, then the authorities will only have fewer reasons for nit-picking. In it, you can put a floor gas boiler of high power for heating not only the mansion, but also office space.

For private housing of the middle class, the optimal solution is a wall-mounted boiler; under it is not required, as for the floor, to arrange a brick or concrete pallet with sides of half a meter. Installing a wall-mounted gas boiler in a private house also does without technical and organizational difficulties: a fireproof closet for a furnace can always be shielded, at least in the attic.

Benefits of gas heating

Gas heating of a private house is ahead of other heating systems in terms of:

- Price. Complete combustion of fuel contributes to the high efficiency of the use of this energy carrier.In some boilers, the energy released by the condensation of exhaust gases is used, which increases the efficiency up to 109%.

- Compactness. Modern gas boilers resemble hanging furniture. They can be placed in the kitchen or in a small room. At the same time, the volume of the room is not lost, the interior is not overloaded with the type of equipment. There is no need to allocate space for storing firewood, coal or diesel fuel.

- Safety. Control over the operation of the system and the removal of burnt gases are carried out by automatic devices. At the slightest deviation from the norm, the blocking of the flow of fuel into the combustion chamber is triggered.

- Economic consumption. Due to rising energy prices, boiler manufacturers are developing and constantly improving models that consume little, but produce a large amount of heat energy.

- Possibility to regulate the temperature of the coolant. As a result, resources are saved, comfortable conditions are created in each room.

Double-circuit gas boilers simultaneously heat the house and supply residents with hot water. In the conditions of a country economy, this function is important.

Peculiarities

Gas heating is an object of increased explosion and fire hazard, therefore, special services deal with all issues of connection and maintenance.

Before connecting the house to the gas main, they draw up a project for laying the line inside the premises, and a power supply scheme for the devices. Documents are coordinated and approved by Gostekhnadzor.

The room where the gas boiler is installed is provided with good ventilation. For some models, a chimney is equipped, and a separate exit is arranged in the boiler room.

Boiler room in a private house

Boilers with forced emission of exhaust gases are connected to the power supply system. So that the equipment does not fail with a sharp jump in pressure in the line, automation is installed for adaptation.

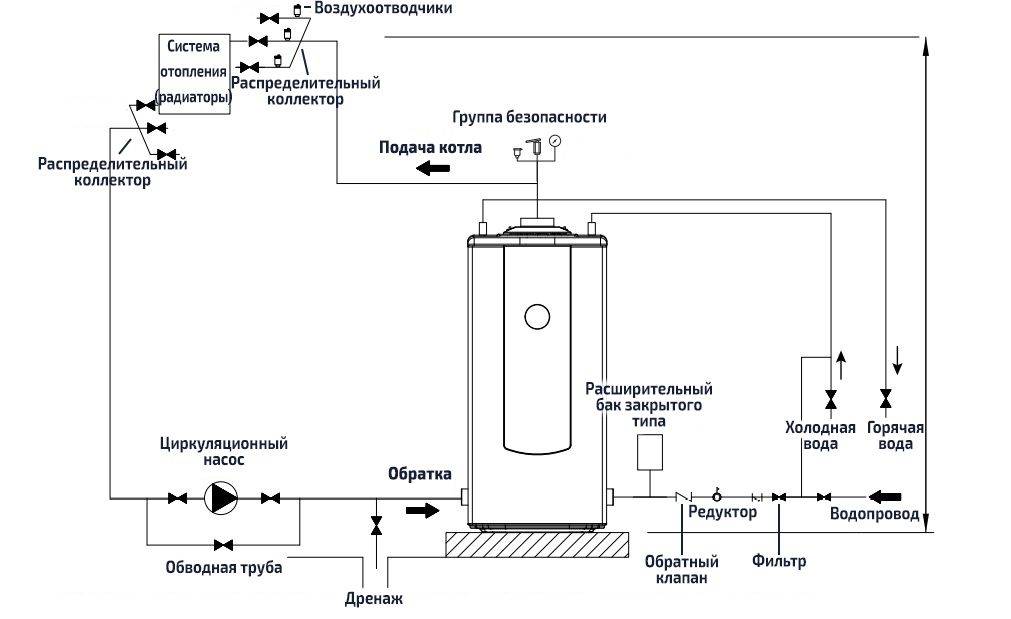

Mini-boiler rooms

Now models of boilers are produced, equipped with an expansion tank, a pump, a valve and a pressure gauge. These can be heating elements, electric, diesel, gas units with forced draft. These units can be called mini-boiler rooms. So, safety valves in the electric heating circuit of a private house with a pump are mounted immediately on the heat exchanger together with the heating element. This design allows you to quickly dump excess coolant if it boils when the pump stops.

The scheme for connecting the boiler to the heating system in this case is not complicated. It is necessary to mount only two ball valves, which can be used to cut off the boiler if necessary. Repair of the unit or any maintenance work will not cause difficulties.

With bithermic heat exchanger

The bithermic heat exchanger is arranged according to the "pipe in pipe" principle. The internal structure can be different - firms are trying to improve their products and try different options. One thing remains unchanged: one large pipe is divided into parts - along. They are separated by metal partitions, sealed and not connected.

One of the options for a bithermic heat exchanger for double-circuit gas heating boilers

How does a double-circuit boiler with a bithermic heat exchanger work? On one part of the pipe - the outer one - the coolant circulates, which is supplied to the heating system. In the second part - the inner one - water appears only after a hot water tap is opened somewhere.The heating circuit that was working before is closed (by a signal from the control board), all the heat goes to the preparation of hot water. All this time the circulation pump does not work.

The device of a double-circuit boiler with a bithermic heat exchanger

When the flow of hot water stops (the tap is closed), the circulation pump turns on, the coolant is heated again, which circulates through the heating pipes. As you can see, the arrangement of double-circuit boilers with bithermic heat exchangers is simpler - there are fewer parts, sensors, and, accordingly, easier control. This is reflected in the price - they are a little cheaper. At the same time, the efficiency of such boilers in the water heating mode is slightly higher (93.4% on average, versus 91.7%).

There are also disadvantages - bithermic heat exchangers are often clogged. In DHW heating mode, there is no circulation in the heating medium circuit. This is not a problem if the system is sealed (it should be) and does not require constant replenishment.

This is how a bithermic heat exchanger overgrows

But if there is a leak somewhere and in order to maintain the working pressure in the heating system, it is necessary to constantly add water, there is a gradual overgrowth of the lumen of that part of the pipe through which the coolant circulates. When this gap is clogged with salts, the part that conducts water for hot water is heated more actively. This leads to the fact that salts begin to clog and this part, the boiler, simply stops working.

Both circuits of the bithermic heat exchanger have been scaled up

Gas heating installation process

It’s nice to do everything in the house with your own hands, but when connecting and installing a gas boiler, it’s better to turn to specialists; on each instruction for the boilers "Aton", "Siberia", "Conord", "Ariston" this warning is indicated. Gas is a dangerous thing: special knowledge and experience are required to work with it.

Preparation for begins with checking its quality, the presence of components in the composition. Then

When installing the heating system, any negligence can cause the equipment to explode.

wash the pipes of the boiler. Examine the wall under the boiler; it must be solid. A gasket made of non-combustible material is attached to it. The boiler is located at a distance of 5 cm from the gasket; must have ventilation or a chimney.

Having permission to, you need to prepare the necessary tools:

- self-tapping screws large with a diameter of 6 mm - 4 pcs.;

- marker;

- victorious drill;

- drill;

- plastic dowels;

- level;

- parapet.

Acquire the necessary materials:

- three-core wire;

- chimney elbow;

- parallel bracket;

- corner strainer;

- Ball Valves;

- paronite gasket;

- gas alarm;

- gas certificate.

Conclusions and useful video on the topic

A few useful tips for installing a gas boiler will help you control the correct installation of equipment.

With all the perfection of gas equipment, in the presence of automation and serious technological protection, connecting the system requires compliance with established rules and regulations. Without this, it is impossible to guarantee the reliability of the operation of gas boilers.

Have something to add, or have questions about connecting a double-circuit gas boiler? You can leave comments on the publication and participate in discussions of the material presented.The feedback box is below.