- How to connect an indirect heating boiler to a single-circuit boiler

- Pipe material for piping BKN

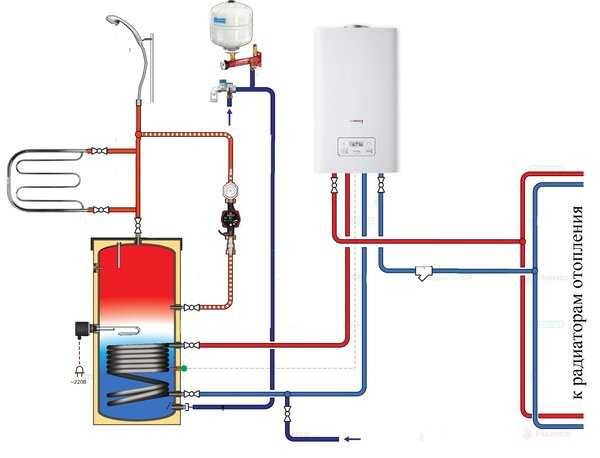

- Options for piping an indirect heating boiler

- Tying in a gravity system

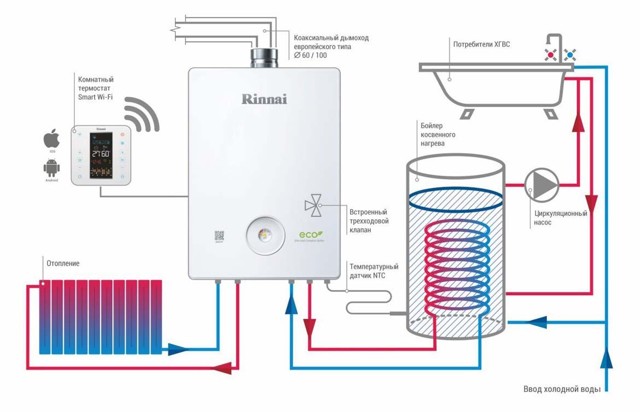

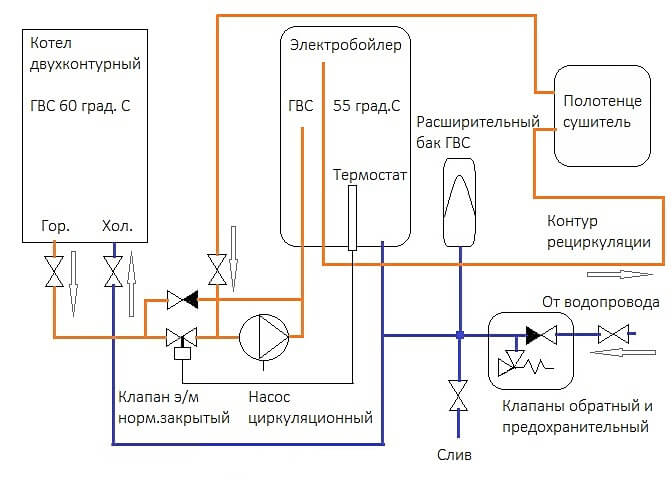

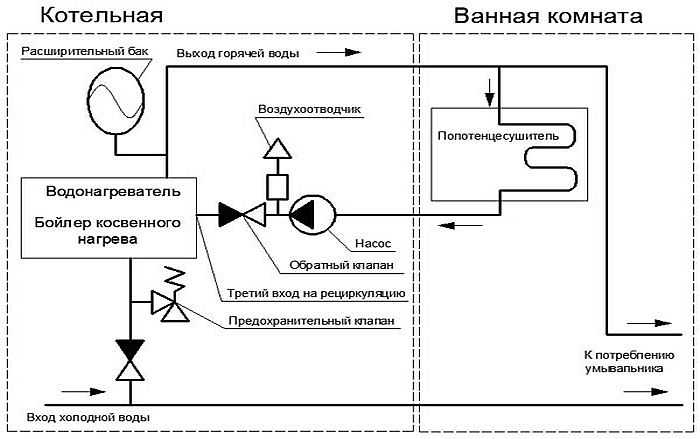

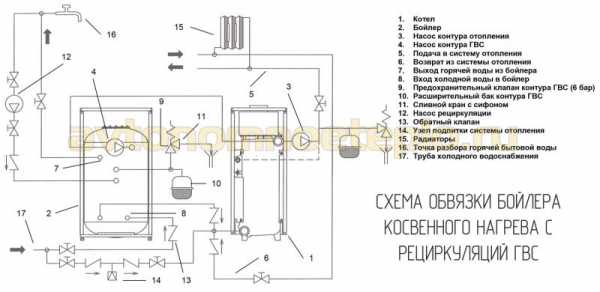

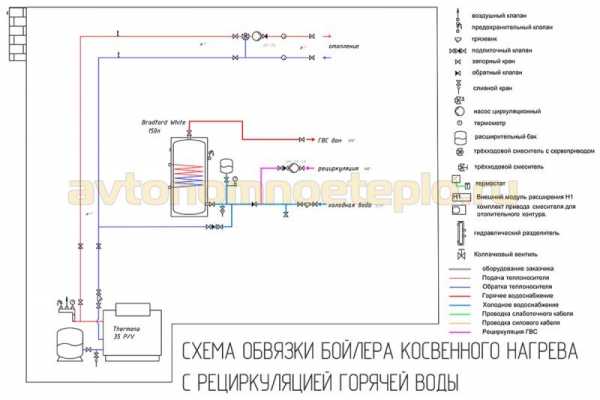

- Installation of DHW recirculation with BKN

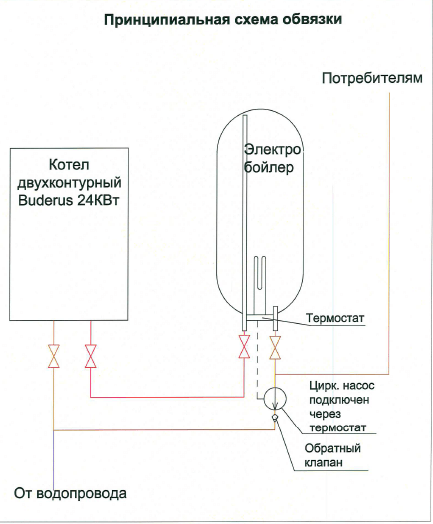

- BKN piping with a double-circuit boiler

- Materials and tools

- Installation process: how to connect

- Startup and verification

- Common installation errors

- How does a boiler work in tandem with a non-volatile boiler

- Norms and rules for installing a boiler in an apartment

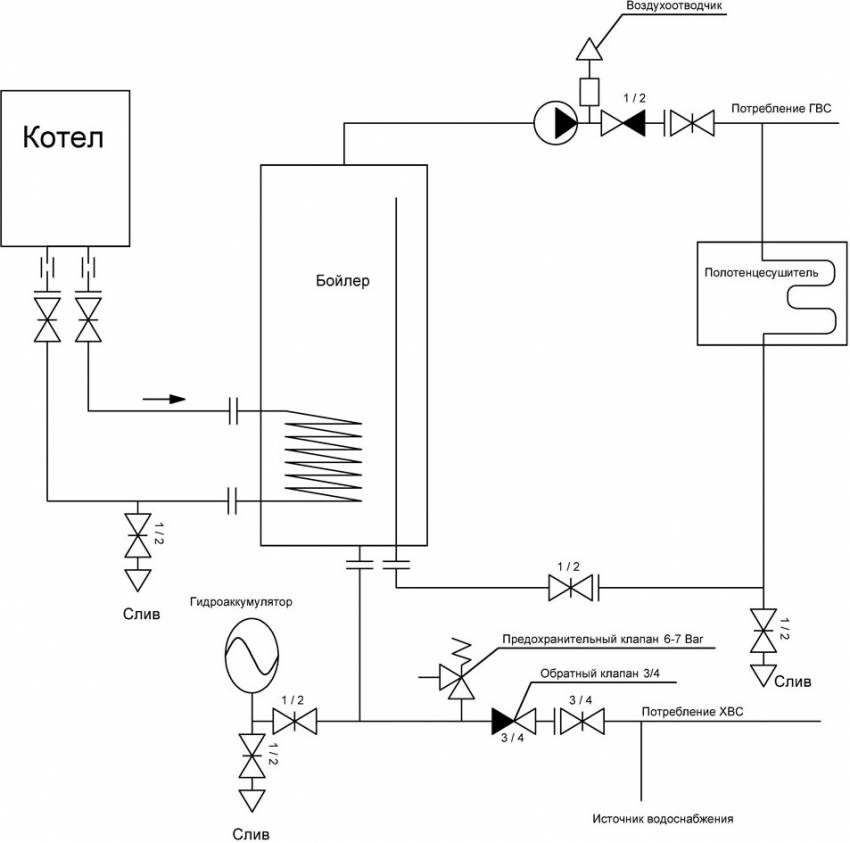

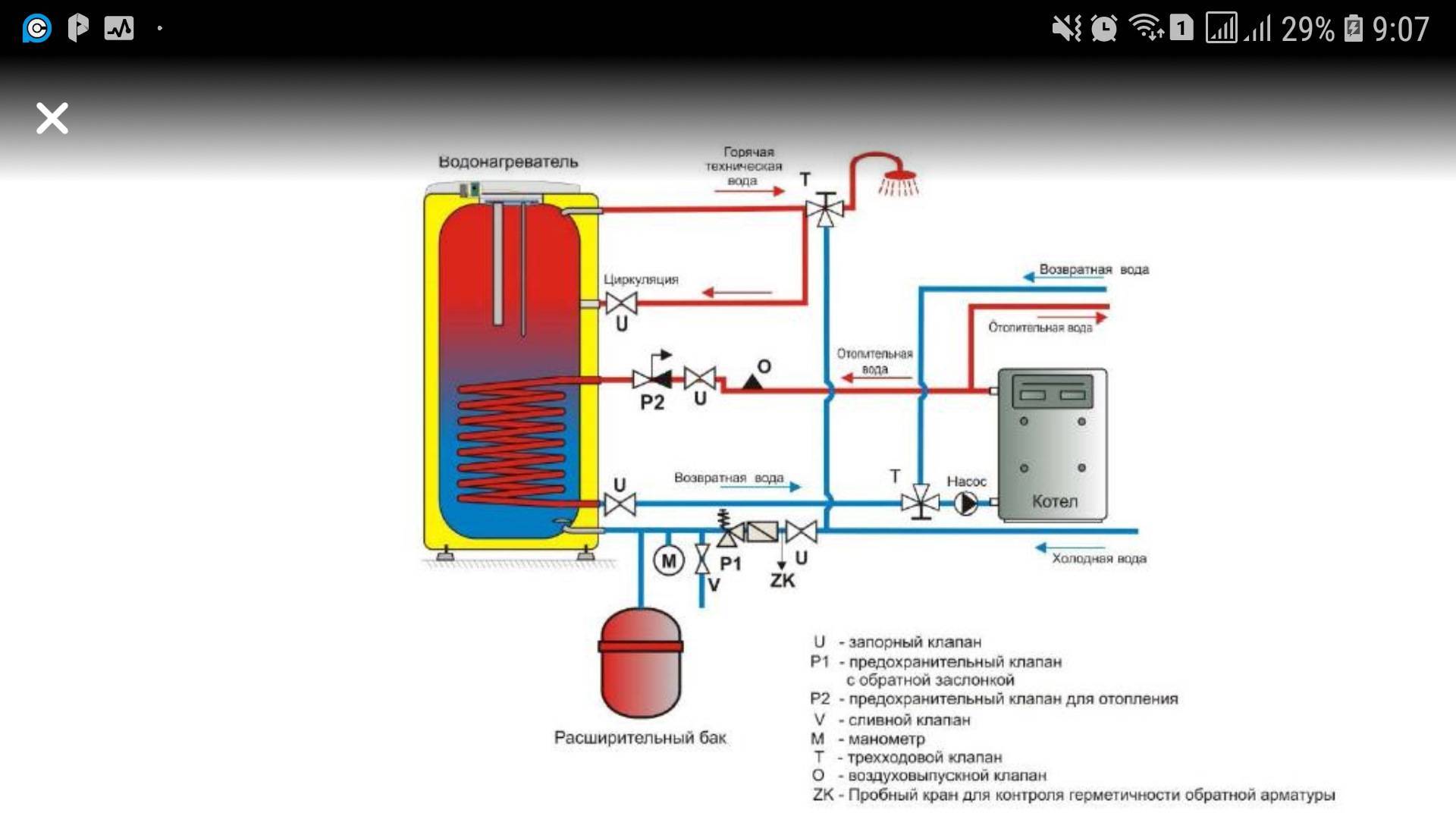

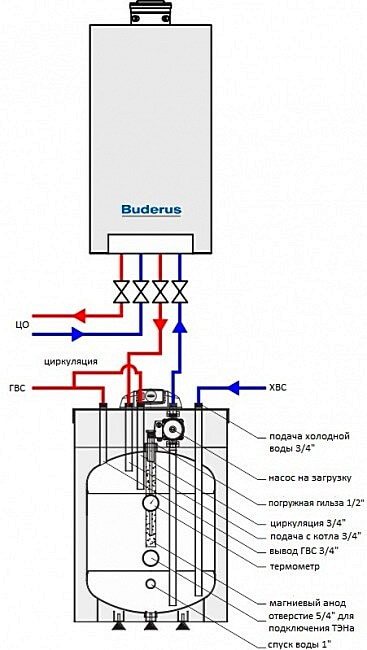

- BKN piping schemes with a single-circuit boiler

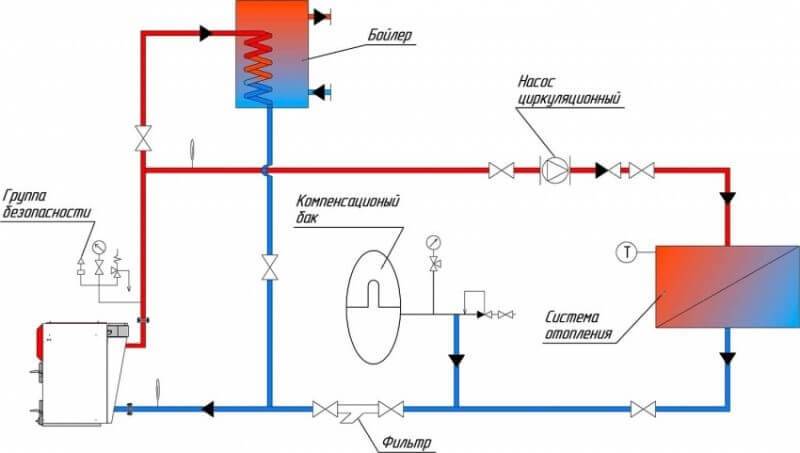

- Direct connection of BKN with a heating circuit

- Scheme with thermostat and automation

- Tying at increased coolant temperature

- Getting ready to connect

How to connect an indirect heating boiler to a single-circuit boiler

Fittings for binding BKN

- ensure continuous circulation of the coolant from the boiler to the water heater;

- prevent hydraulic and thermal shock;

- maintain the set temperature of water heating in automatic mode.

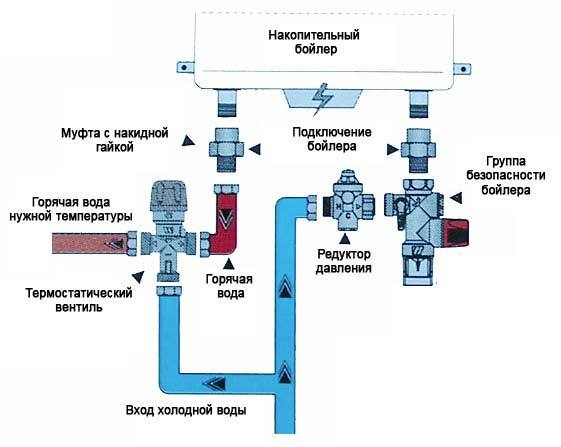

- Membrane expansion tank - designed to compensate for thermal expansion in the DHW system and prevent accidents. When connected, the BKN is installed together with the security group. The expansion tank must contain at least 10% of the total volume of the indirect heating boiler.

- Safety valve - needed for emergency draining of water from the BKN. With an excessive increase in pressure, it opens and discharges water from the boiler. The valve is used during maintenance to fill the tank with descalers.

- Indirect heating boiler safety group - includes a pressure gauge, a relief valve and an air vent. The unit is designed to normalize the pressure in the hot water supply and prevent water hammer. The installation of a safety group and an expansion tank is a requirement made by manufacturers for the BKN piping.

- Boiler temperature sensor - connects to the circulation pump that controls the pressure in the coil. The immersion thermostat works on the principle of a relay. When sufficient water heating is reached, the sensor gives a signal to turn off the pumping equipment. The water stops heating up. After cooling, the automation for the boiler starts circulation.

- Three-way valve - works as a mixing unit, opening and closing the flow of water to the boiler from the heating system. There are simple mechanical devices and precise servo operated three-way valves.

- Circulation pump - depending on the selected piping scheme, one or two modules are installed. The pump is used to create constant pressure and recirculation in the DHW system.

Pipe material for piping BKN

- Cold water - an ordinary polypropylene pipe can be installed. The material is suitable for soldering the entire cold water system.

- Hot water supply - the temperature of the DHW supplied to the user is maintained at 65-70 °.It is allowed to use polypropylene with fiberglass (reinforced) or aluminum reinforcement, intended for hot water supply. Another option: tie with a copper pipe. When laying a copper pipe, the use of thermal insulation is mandatory. Copper is a good heat conductor, which will inevitably lead to a decrease in the temperature of heated water during transportation to the end consumer. Thermal insulation of pipes will protect against heat loss.

Options for piping an indirect heating boiler

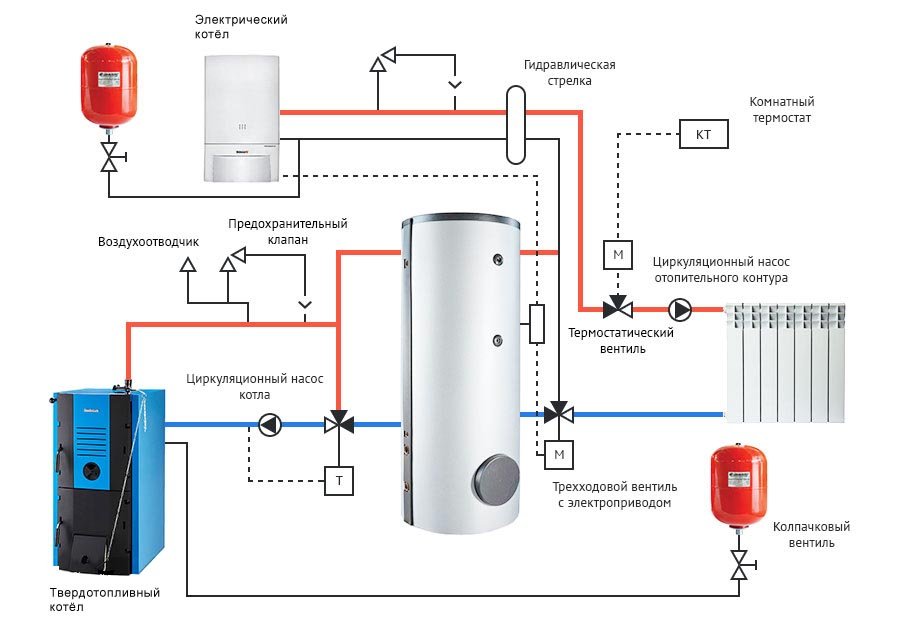

Another important factor to consider when choosing a connection type is volatility. There are gravity systems in which the circulation of water and coolant occurs independently, as well as schemes with the creation of forced pressure (pumping). The latter cannot work without electricity. BKN manufacturers in the operating instructions indicate the recommended piping scheme, which is also taken into account when connecting.

- rapid heating of hot water;

- savings with constant use of the boiler;

- the possibility of automating water heating.

Tying in a gravity system

Installation of DHW recirculation with BKN

- decrease in DHW heating temperature;

- increase in fuel costs;

- energy dependence.

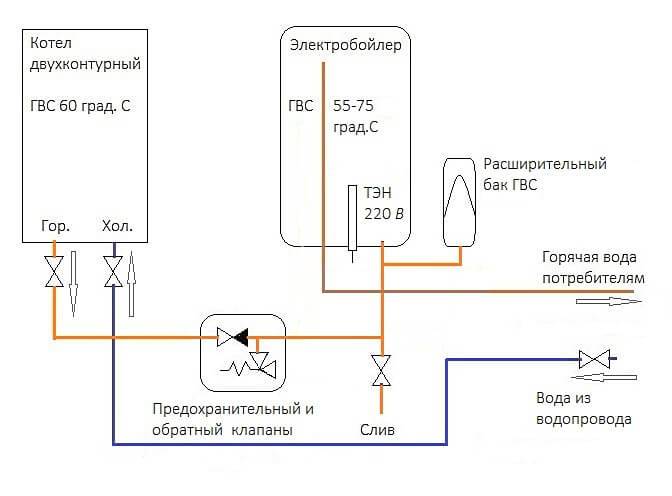

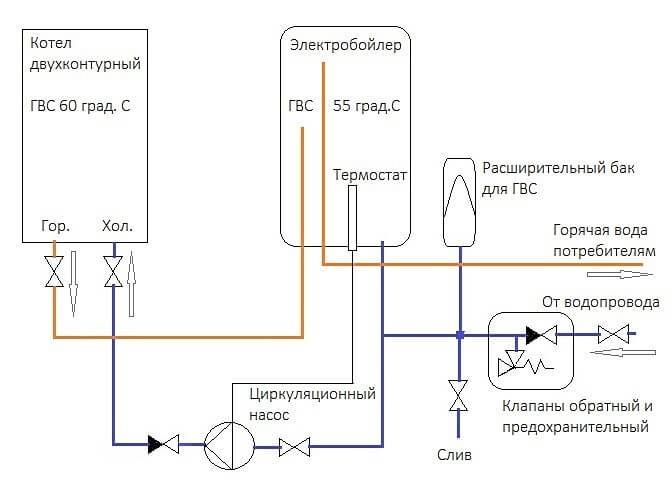

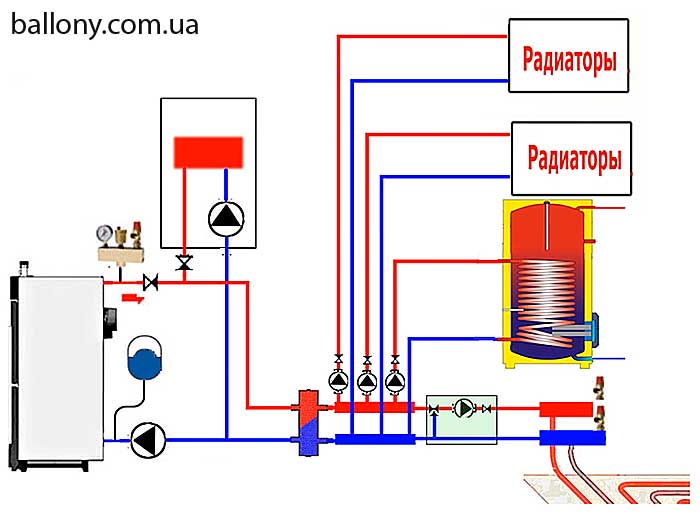

BKN piping with a double-circuit boiler

- When the tap is opened, the double-circuit boiler heats the DHW heat exchanger, spending the maximum amount of thermal energy on this. It takes time for the coil to warm up. For this reason, hot water is supplied to the user not immediately after the tap is opened, but after some time (the period depends on the distance of the draw-off point and the boiler power).

- Frequent starts and stops in the supply of hot water create a load on the heating elements, which can lead to a quick failure of the equipment.

Materials and tools

Materials:

- Pipes, valves, check valves - there are no special requirements for them: use the same materials as for working with hot water or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system, it serves to prevent sudden pressure drops when opening / closing taps.

Attention! The tank must be designed for use with hot water, usually such devices are marked with special markings. Circulation pump - a separate pump is usually installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate the water in the DHW circuit.

This eliminates the need to wait for hot water to flow through pipes of great length from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical piping - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall mounting, also for fixing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- perforator, screwdrivers, screwdriver;

- minimum electrician set: knife, wire cutters, electrical tape, phase tester.

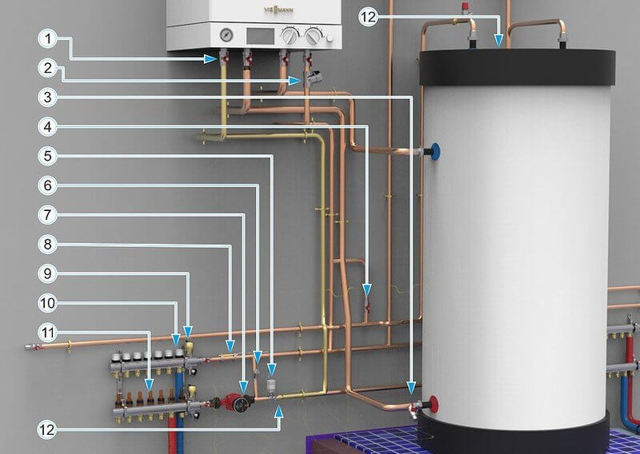

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the lower pipe of the boiler, and hot water is taken from the upper one.

- Choose the location of the water heater so that it does not interfere and is easy to maintain. Mount the brackets, stands, fix it on them.

- Connect to the cold water network: make a tap, put a stopcock and a coarse filter.

- Through a tee, divert the cold water line to consumers, connect the second outlet to the boiler through a safety valve.

- Connect the hot water line in the house to the boiler, not forgetting the expansion tank on it. In addition, install bypass valves so that you can disconnect it from the circuit for the duration of the service.

- Now connect the boiler to the gas boiler according to one of the above diagrams. Do not forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and verification

After installation, it is first necessary to connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system, and the boiler is completely filled so as not to cause it to overheat.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the supply of coolant from the heating system to the boiler.

When the system is operational, check that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no overpressure in the system. You should also check all connections, seals and taps for leaks.

Common installation errors

The manufacturer, referring to the norms of SNIP, requires during installation to perform insulation on cold water / hot water pipes with a layer of 20 mm and thermal conductivity of 0.030 W / m2.At the same time, both the pipe and all components are insulated.

They suffer without isolation and a cold water network, being a place where condensate is massively collected, creating unsanitary conditions. Another common mistake is installation without an expansion tank, especially for tanks with a volume of 200 liters or more.

List of other violations:

- The electrical cable is routed in a high temperature area or on sharp metal surfaces.

- The procedure for connecting to the water supply system specified in the diagram by the manufacturer is violated.

- The vertical/horizontal installation level is violated.

- No heater ground loop.

- The electrical network parameters do not meet the requirements of the manufacturer specified in the passport data.

Before starting the device, you must carefully examine the circuit, any, even the smallest mistake in the installation can become fatal during its operation, so every self-respecting owner should know how to connect the boiler correctly.

How does a boiler work in tandem with a non-volatile boiler

If a non-volatile boiler is used as a heating source, in order for the DHW to be a priority, the boiler must be located above the radiators. This is easy to do if the model is wall type. The best position is when the bottom of the hot water tank is higher than the boiler and radiators.

In the floor model, the water will heat up, but it will take much more time. In addition, the water at the bottom of the tank will remain unheated. Its temperature will not exceed the return heating level in the heating system. With such a scheme, the coolant flow occurs by gravity, the driving force is gravity.There is an installation method in which a circulation pump is connected to the boiler. But this is not an option, because in the absence of electricity, the water will not heat up. Specialists have developed several schemes adapted to gravitational heating systems.

The trick is that the diameter of the pipe intended for the water heater circuit is taken one step larger than the diameter of the heating pipe. The coolant, according to the laws of physics, will “choose” a pipe with a large diameter, that is, the boiler will be in priority.

In another way, a thermostatic head with a built-in sensor, powered by batteries, is installed in the heating system. Everything is very simple: with the help of the thermostatic head regulator, the desired level of water heating is set. While the water is cold, the thermostat opens the way for water to the boiler. As soon as the water warms up, the coolant is sent to the heating circuit.

Norms and rules for installing a boiler in an apartment

After the owner has made a decision and purchased an electric water heater, he must install it. Before installing a boiler in an apartment, you need to decide who will perform the installation work.

For this, many owners invite specialists who have the necessary tools and experience, and are ready to install a water heating device in a couple of hours with high quality and reliability. The cost of installing a boiler will depend on the capacity and location.

Home craftsmen can handle this on their own. Before you connect the boiler, so that the installed equipment lasts a long time and does not become a source of dangerous situations, you will need to follow a number of rules:

- The wall for placing the device must be solid, it is forbidden to install the water heater on plasterboard or wood partitions.

- The location area is as close as possible to the intra-house wiring of engineering communications: water, sewerage and electricity.

- The electrical socket for turning on the boiler must be located next to the appliance and used only for it, with a direct connection without an extension cord.

- There is a free space in front of the water heater for maintenance and repair, in addition, it is placed as high as possible so that it does not interfere with the passage of people.

- For emergency draining of water, the device must have access to sewerage.

- You will also need to first ground the boiler and install RCD protection on the power line.

- The boiler installation scheme must be carried out in accordance with the manufacturer's recommendations. To turn off the water heater for repair or maintenance, shut-off valves and a safety relief valve are installed, according to the standard sizes indicated in the documentation for the heater.

- In the event that the boiler design does not provide for a drainage line with a valve, it is installed on the cold water supply pipes at the lowest point in front of the storage tank.

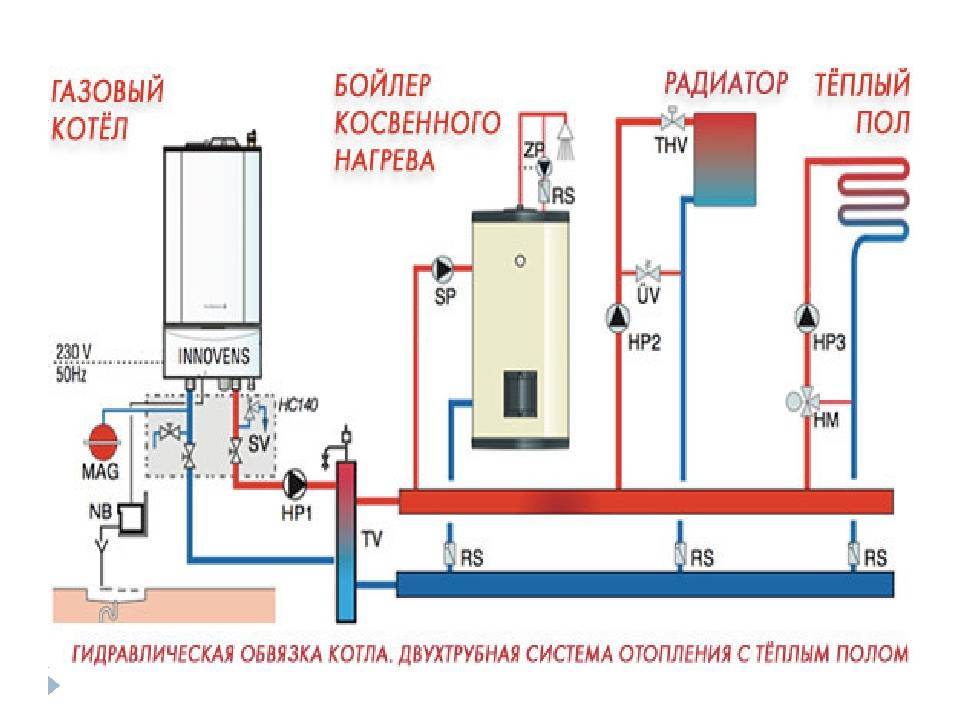

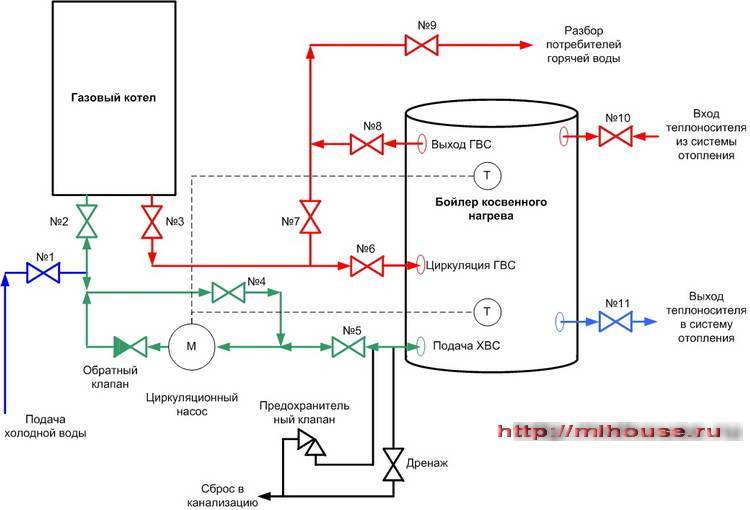

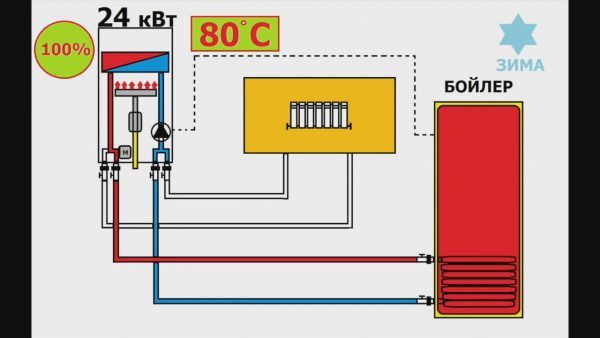

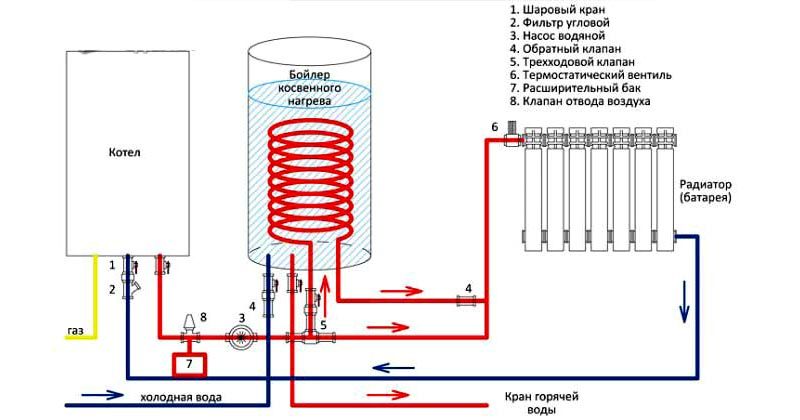

BKN piping schemes with a single-circuit boiler

There are various schemes for piping a single-circuit boiler with indirect heating boiler, the most common: connection of the housing directly and with automatic control.

In both cases, when installing boiler equipment, it is important to fulfill all the requirements for safe operation established not only by the manufacturer, but also by state standards.

Direct connection of BKN with a heating circuit

This is the simplest scheme for tying a single-circuit boiler with a boiler, experts consider it ineffective, especially if the boiler unit operates at the inlet with a coolant with a temperature of up to 60 C. In this embodiment, the BKN is included in the house heating system, in series or in parallel with respect to heating radiators.

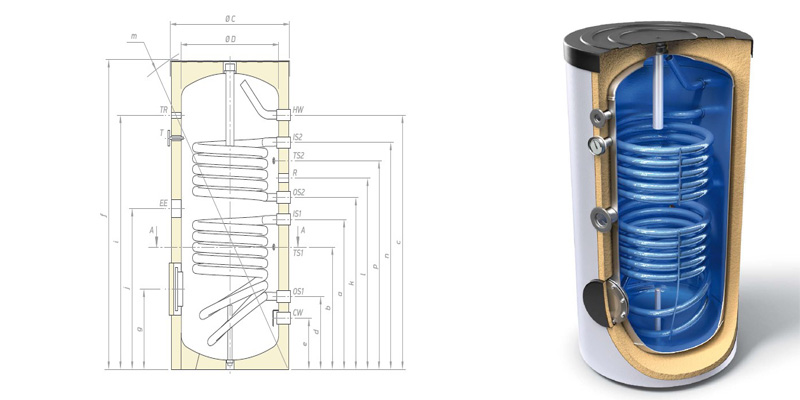

Source water is supplied to the BKN and hot water is supplied to the domestic hot water supply system to the mixers. Cold water enters the storage tank, in which a stainless or copper coil is located, through which heated boiler water circulates, thereby increasing the temperature of the water in the tank.

The level of control in such a scheme is manual, by opening / closing the coolant supply in the circuit using shut-off and control valves.

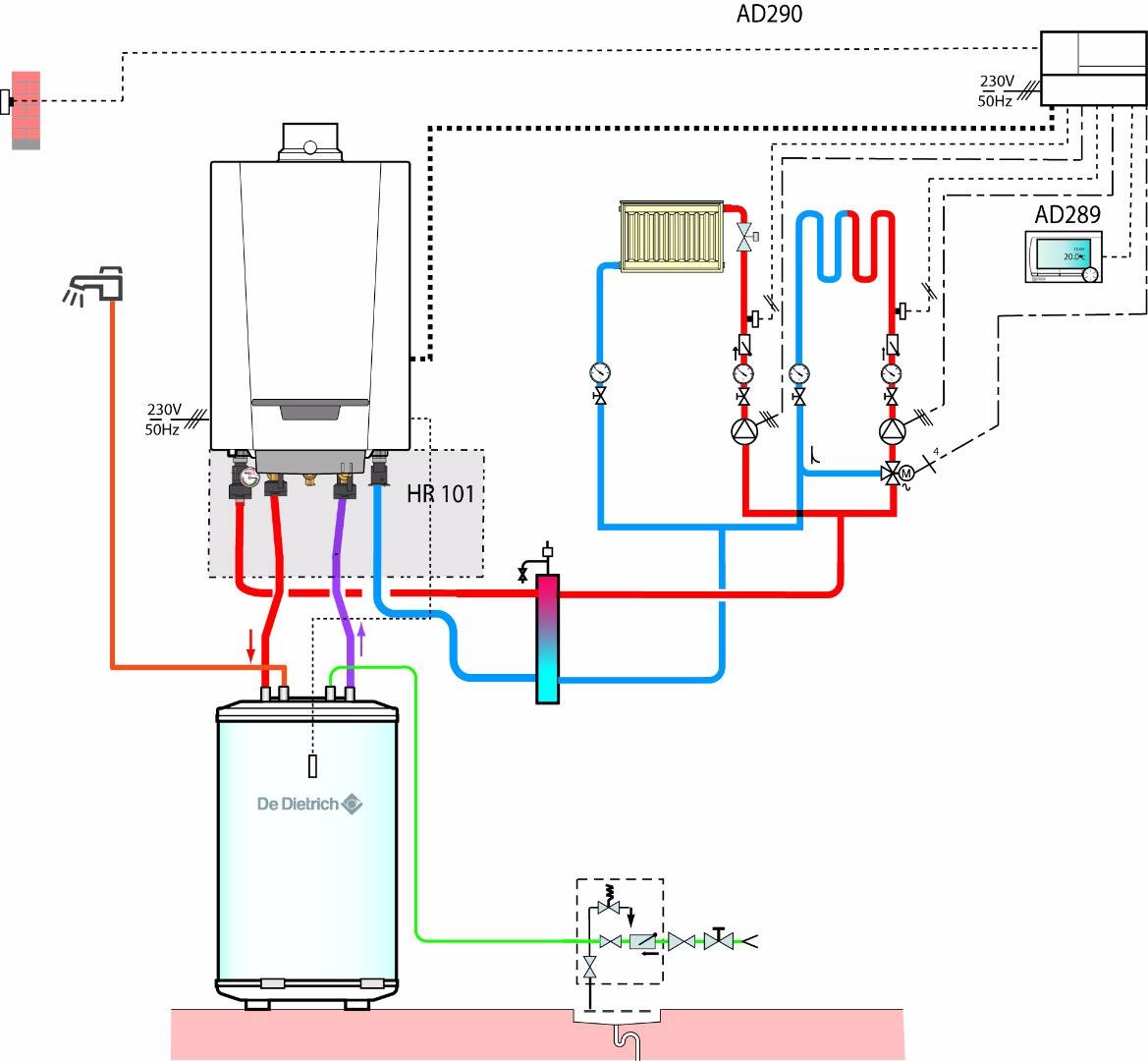

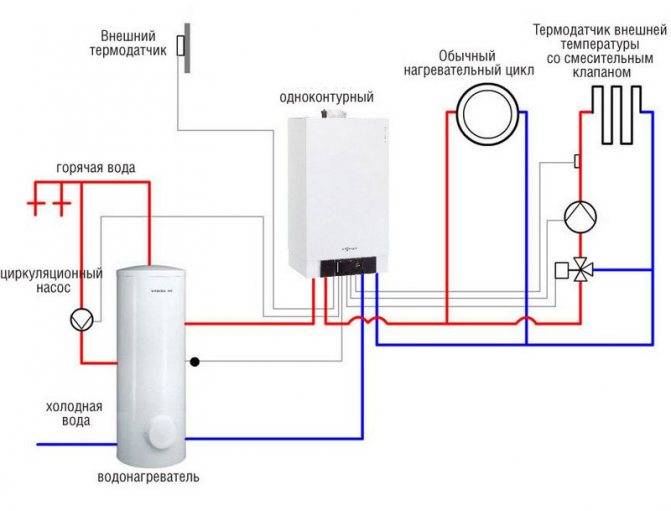

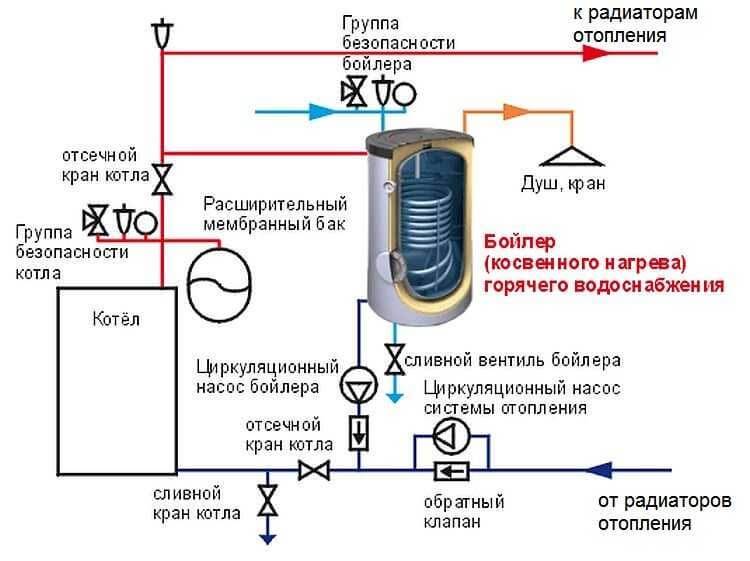

Scheme with thermostat and automation

It is clear that it is impossible to achieve either high-quality heating or the efficiency of the boiler with an indirect heating boiler using the manual method of controlling the thermal process. In reality, there will always be situations where the water is either overheated or cold.

Therefore, users use a simple control principle in the operation of a boiler with a heating boiler by integrating a three-way valve and a temperature sensor into the system.

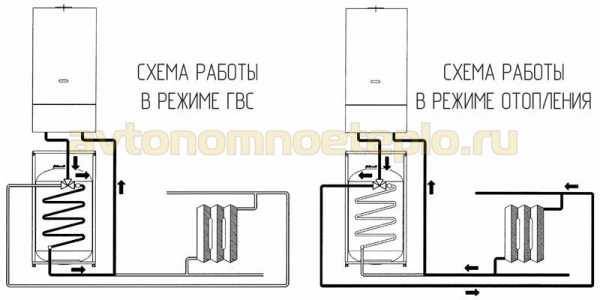

Upon reaching the set temperature regime of 55 - 65 C, the thermostat gives a command to the three-way valve, which accordingly switches the heating boiler coolant from heating the water in the tank to the heating circuit.

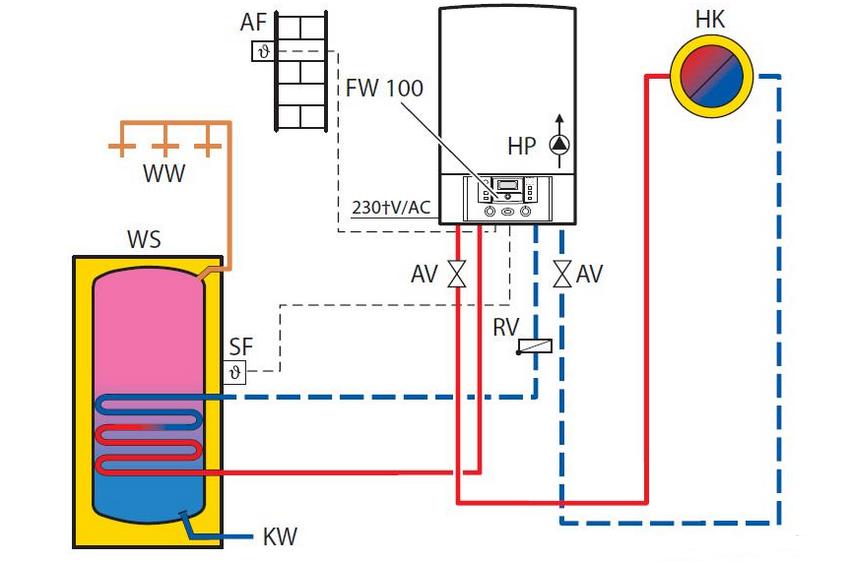

Tying at increased coolant temperature

A water heater of this modification refers to a capacitive type water heater, that is, water is heated for a certain time from 2 to 8 hours, depending on the temperature of the coolant, the circulation rate and the heating area of the internal coil.

It is clear that the higher the hot water is heated at the outlet of the heating boiler, for example, 90-95 C, the faster the liquid in the tank will heat up to 65 C, which means that the coolant will return to the heating circuit, the temperature in which will not have time to cool below 65 C and mean in the premises will be maintained the necessary living conditions.

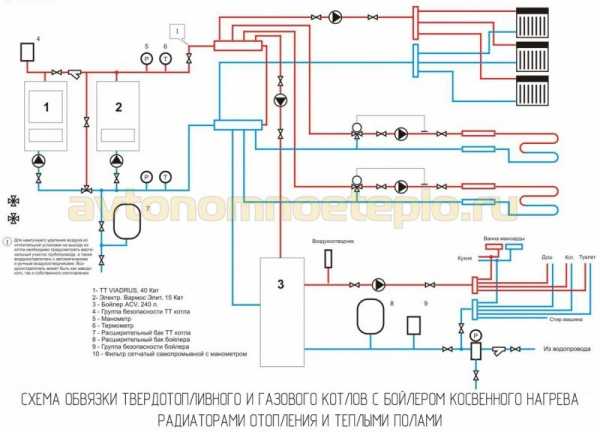

This scheme, in principle, is no different from the previous one, except for the temperature settings. In order to set it up simultaneously in two heating circuits / BKN, install 2 sets of thermostats and three-way valves, for each circuit separately. The temperature regime in the boiler is set to a temperature of 95-90 C, and in the BKN - 55-65 C.

Getting ready to connect

The best option for installing a boiler is a bathroom. If, due to limited free space, it is not possible to install a boiler in this place, then you should choose a place in the kitchen or in the utility room. When choosing an installation site, care should be taken to ensure the possibility of supplying a 220 V electrical network and cold water supply.

The boiler is installed at a considerable distance from the floor. In most models, communications are connected from below, so the device should be placed at a height of at least 50 cm. If the boiler is connected in the bathroom, then it should be placed at least 1 meter from the bathtub and sink.

This eliminates the possibility of water on the surface of the device and reduces the possibility of electric shock in the event of a malfunction of the device.

It should be borne in mind that a boiler filled with water has a significant mass and must be securely fixed. Water heaters are usually installed on the wall. For the correct location of the mounting holes, you can use a very simple marking method. It is necessary to prepare a sheet of cardboard and a marker.

The measurements are carried out in the following order:

-

A sheet of cardboard is laid on the floor.

- The boiler is placed flat on top of the cardboard, while the mounting brackets must fit snugly against the cardboard.

- The holes for the mounting bolts are marked on the cardboard with a marker.

- Marked cardboard is applied to the place where the boiler will be installed, and the points for drilling holes for anchor bolts are marked with a marker. When marking is done, holes are made in the wall with a diameter of 12 mm with a puncher. The depth of the holes depends on the bolts used.

For proper installation of the boiler, you will need to install a separate outlet and supply cold water to the device.

To do this, you will need to prepare the following materials and tools:

- Hammer drill or impact drill.

- Pliers.

- A hammer.

- Socket.

- Socket box.

- Anchor bolts.

- Electric cable with a core diameter of at least 3 mm.

- Spanners.

- Screwdriver.

- Building gypsum.

- Automatic switch 20 A.

- Chisel.