- Installation of heating with forced circulation in a one-story house

- How to connect a gas boiler in a private house in order?

- Materials and tools

- Phased connection of the heating circuit

- Connection to the heating system

- Equipment Installation Rules

- General requirements at the design stage

- Document preparation process

- Wall mounting

- Room preparation

- Room requirement

- Installation of double-circuit boilers

- How best to connect a gas boiler - choosing a scheme

- Stage one: installation of the boiler

- Installation of solid fuel units

- Tools and materials

- strapping

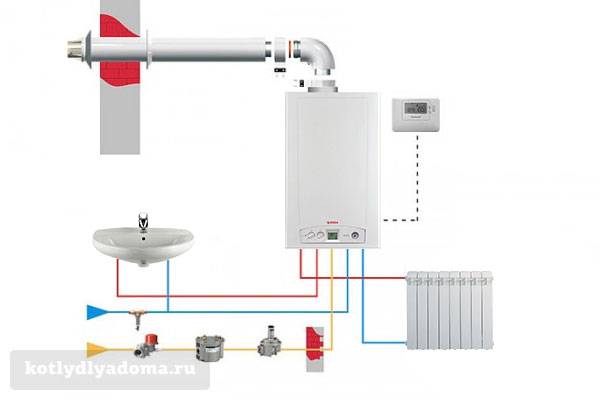

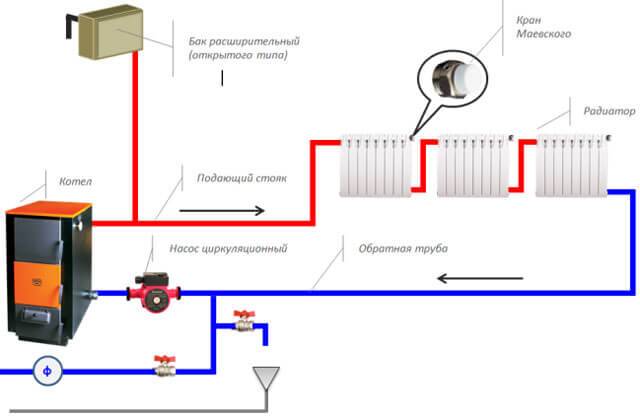

Installation of heating with forced circulation in a one-story house

Do-it-yourself heating of a one-story house is equipped according to a technology that includes the following operations:

- First of all, a heating boiler is installed;

- A chimney is connected to the boiler, brought outside the building;

- When using a gas boiler, it is necessary to connect to the mains (this operation must be performed by specialists from the gas service);

- Heating batteries are installed along the walls at pre-selected places;

- All structural elements are connected by pipelines;

- A circulation pump and an expansion tank crash into the return pipe;

- Pipelines are connected to the corresponding boiler nozzles;

- The assembled system must be run in test mode, after which it can be put into operation.

This technology is common for all types of heating systems - there are minor differences only in the laying of pipes and the installation of radiators.

How to connect a gas boiler in a private house in order?

It is possible to install and properly connect the device on your own, but this requires approval from the gas services. In the course of the work, thoughtful activity and the need for paperwork will be required: agreeing on a number of issues and obtaining documents.

First, an agreement is drawn up with a supplier of natural gas for its supply to private households. They are also involved in the project of gasification of the building and installation of the necessary equipment.

Before installation, all papers (certificate, serial number of the product) are verified. If everything is in order, proceed to the installation.

The installation location is selected according to the type of device.

The floor gas boiler is installed on a flat surface made of non-combustible materials. Used, for example, tiles or concrete screed. And also sometimes they put a sheet of galvanized steel with a ledge on the front side up to 30 cm. Access to the structure should be unlimited from any side.

Important! It is necessary that the boiler is located away from electrical appliances and sources of fire, and also not close to the wall. The structure must have a uniform load on all supports

The structure must have a uniform load on all supports.

The wall-mounted gas boiler is fixed with brackets (included). Installation height - about 1 meter above the floor.First, the slats are fastened, then the unit is mounted on them.

Then there is a connection to the chimney. Before this, the presence of traction is checked. To prevent the leakage of toxic gases, the connections are carefully sealed.

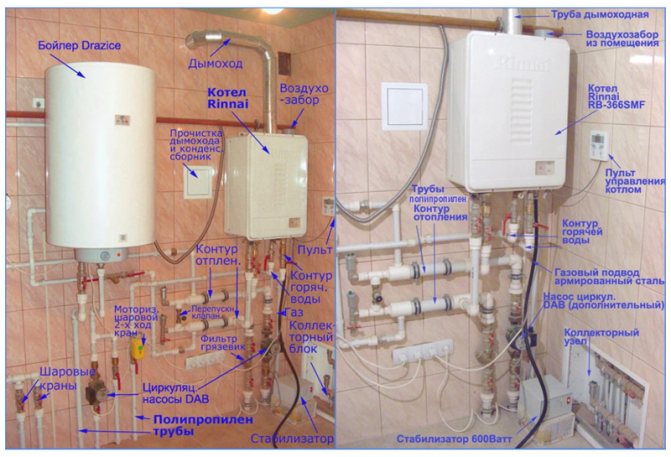

Photo 3. Wall-mounted gas boiler, installed more than a meter above the floor, connected to the chimney.

25 cm - the maximum length of the pipe segment that connects the boiler to the chimney.

The next step is connecting to the water supply. The first step is to install a filter for hard water purification, which prevents clogging of the heat exchanger. On both sides of it, taps and / or valves are installed.

To ensure optimal pressure in the system, the tie-in to the water supply is carried out either to the place where the pipe branches, or as close as possible to its entrance to the building. Usually, the water supply pipe is connected from the top of the unit, for return - from the bottom.

All communications must be equipped with a locking mechanism to be able to urgently shut off the gas supply in case of danger.

Materials and tools

- Adjustable wrenches and dowels;

- building level for choosing the place of attachment of the brackets, its length should not be less than 1 meter;

- a puncher with a set of drills of different diameters for making holes in the wall, designed to fix them;

- brackets - are included, but it is better to have a certain amount in reserve;

- scissors, so that when cutting pipes, they do not damage their protective layer, which is responsible for tightness;

- pipe flaring calibrator;

- valves, taps - for fastening locking mechanisms;

- galvanized steel sheets and tools for cutting them.

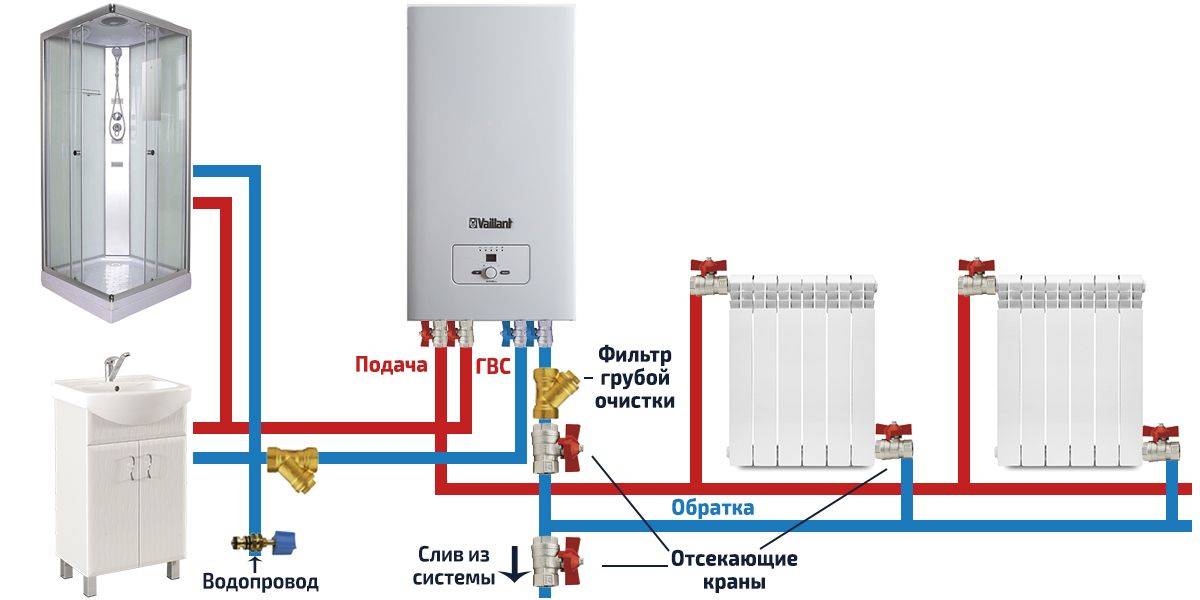

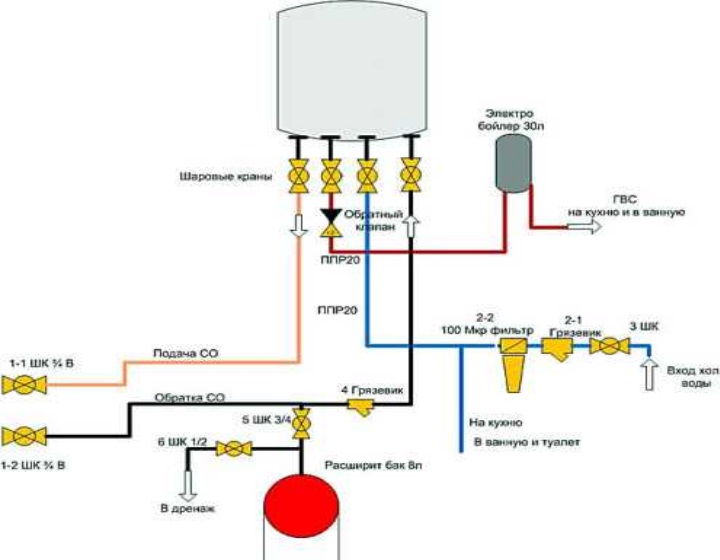

Phased connection of the heating circuit

There are several ways to connect the circuit to the boiler, depending on the model and accessories.

When connecting a single-circuit gas appliance to a heating system, the easiest way is to use shut-off valves and connect the circuit with their help directly to the boiler.

The circulation of the coolant occurs in natural mode, and a conventional expansion tank is installed in the system.

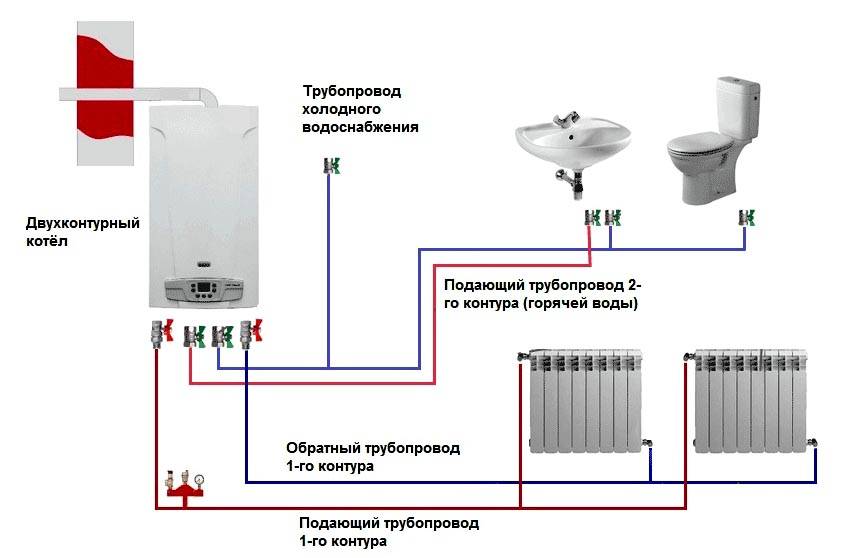

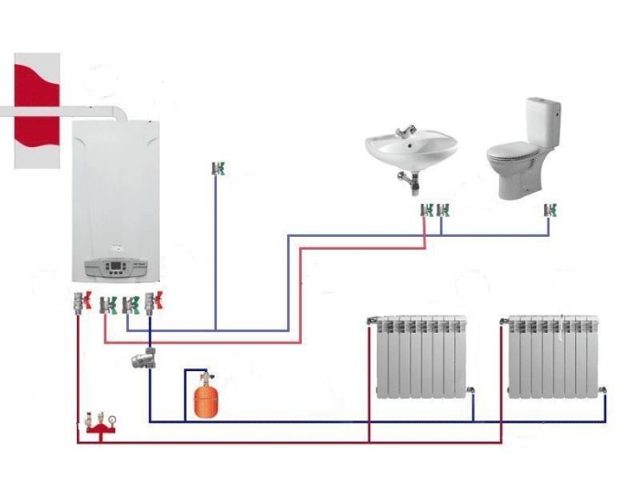

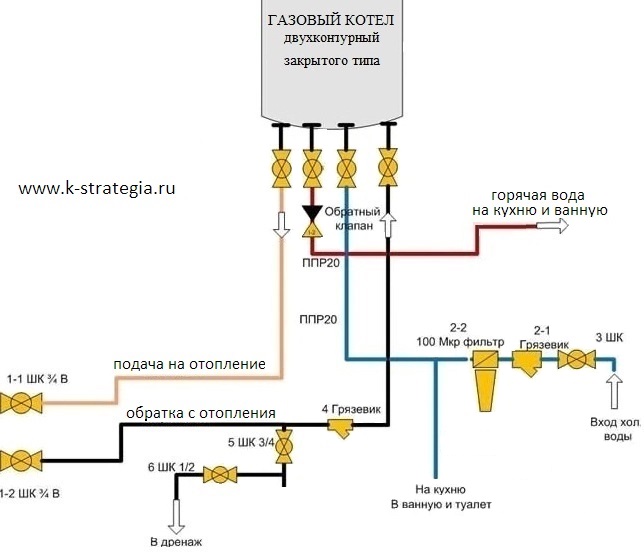

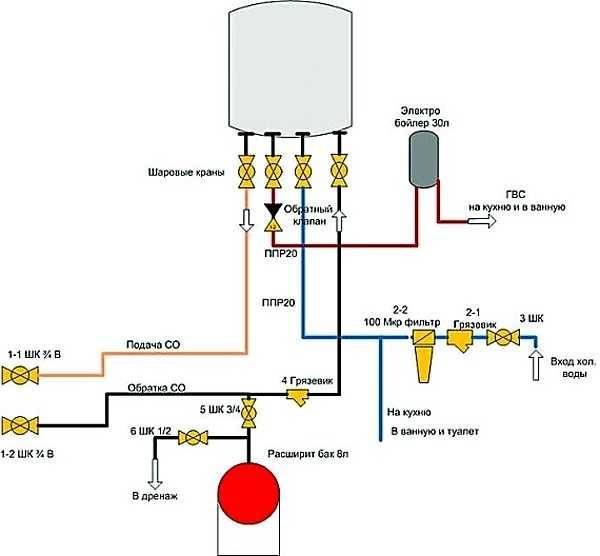

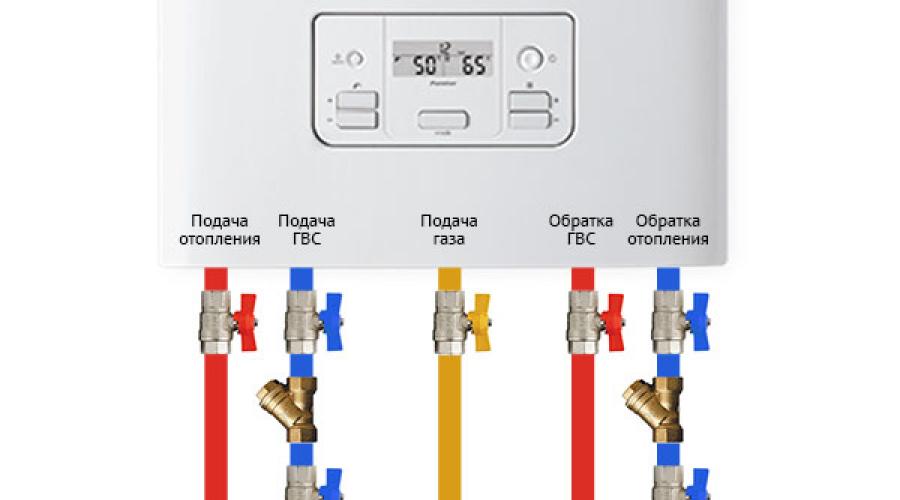

When connecting double-circuit devices, the work becomes more complicated, since a double set of pipes is brought to the boiler. The coolant flows directly through one, and hot water circulates through the second. The connection is also established using shut-off valves.

If the system is closed, then additional devices must be installed: a circulation pump, a diaphragm expansion tank and a safety group.

Connection to the heating system

Location of connection points to the heating system (on the front side):

- on the left - hot coolant supply to the circuit;

- on the right is the return line.

When connecting the boiler, it is worth carefully checking the sealing and tightening of the knots, but one should not be too zealous because of the risk of damaging the threads and encountering the problem of replacing all connecting elements.

It is also necessary to install a coarse filter on the return line, which will extend the life of the device by stopping solid particles.

Equipment Installation Rules

Installation and connection of the boiler to the system should begin after the design stage, when a place in the house has been prepared for the unit. If you install it in violation of the requirements, the specialists of the gas distribution company will not connect the equipment to the gas main.

General requirements at the design stage

The basic standards for the installation of gas equipment are prescribed in SNiP 42-01-2002. Auxiliary information is also contained in the already invalid, but useful SNiP 2.04.08-87.

Usually all the rules are taken into account by the design engineer, but it is also useful for yourself to know them. The room for the location of the boiler can be a kitchen, if the power of the device varies in the range up to 60 kW. A separate or attached furnace is relevant for units with a power rating of up to 150 kW.

Additional norms for the installation of gas equipment are given in SNiP on boiler plants, as well as on heating, ventilation, air conditioning

The space requirements are as follows:

- The minimum room height is 2 m, the volume is 7.5 m3. If there are two or more gas appliances, the parameters change to 2.5 m and 13.5 m3, respectively.

- Not suitable for installation: basements, balconies, bathrooms, corridors, rooms without vents.

- The walls of the room must be covered with non-combustible materials or protected with special panels.

- Lighting: for 10 m3 of a room there is at least 0.3 m2 of a window. In the event of a gas explosion, the windows are an easily dropped structure, which increases the safety of equipment operation.

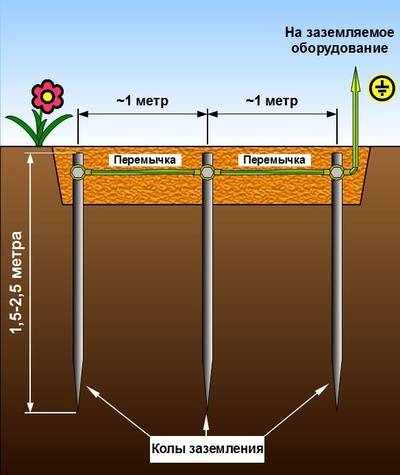

- Must have grounding, cold water pipeline.

- The cross section of the chimney corresponds to the power of the installed equipment.

- Space left around the device: in front - from 1.25 m, on the sides (if maintenance is necessary) - from 0.7 m.

- The distance from the vertical chimney to the unit is observed - no more than 3 m.

Ventilation should also be provided. Natural is calculated in the amount of 3 room volumes per hour.When organizing a supply air, combustion air is added to this value (the parameter is indicated in the boiler passport).

Requirements apply not only to premises. The distance from the attachment to the nearest structures is also regulated. This information is specified by the manufacturer in the instructions for the equipment.

If a double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a mineralite slab is attached to it. If the equipment is not located in the kitchen, asbestos is also possible.

Floor models of boilers are installed on non-combustible bases. If the surface is wooden, a metal substrate is required.

It is recommended to place the device as close as possible to the gas pipe. The use of special hoses is acceptable, but they should not be long. On sale there are bellows hoses up to 5 m, they are allowed for installation, but according to European standards, the length is limited to two meters.

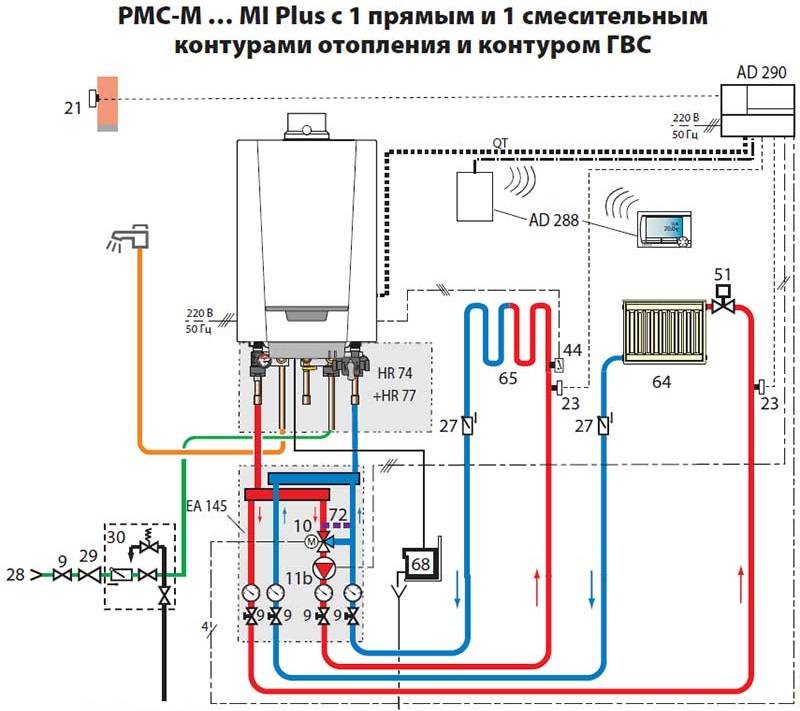

Document preparation process

After a general acquaintance with how to technically connect double-circuit gas boilers, you can begin to prepare documentation. The first stage is obtaining the TU. It is necessary to apply to the regional gas service with a statement indicating the expected volume of blue fuel consumption per hour.

Specifications are issued in 1-2 weeks. The document is a permit to connect housing to the gas main.

The second stage - according to the specifications, a project for the installation of equipment is being developed. The third is the approval of the prepared documentation by the engineers of the service gas distribution company.

The project includes both the installation scheme of the boiler itself and the laying of a gas pipeline from the connection point to the main.If we are talking about a private house, a drawing of communications on the site is added

The technical passport of the boiler, operating instructions, certificates, an expert opinion on the compliance of the device with all standards are submitted to the controlling organization. The necessary papers are provided by the manufacturer of the double-circuit boiler.

Coordination of documentation can take place in a week or last up to 3 months, it all depends on the complexity of the project. In case of refusal, the inspection is obliged to provide a list of edits to eliminate deficiencies. If all requirements are met, seals are affixed and you can proceed to connect the equipment.

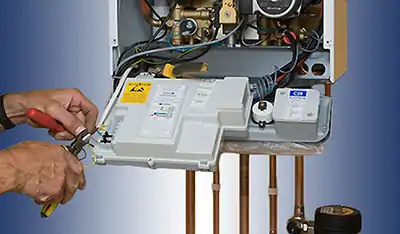

Wall mounting

The installation of gas boilers begins with determining the place where it will be located, taking into account the need for free space for maintenance and compliance with all rules. Then it is worth referring to the already mentioned template, according to which the places of attachment to the wall and the places of connection of wires are marked.

You need to transfer this drawing to the wall with a pencil or drill. A hole for the dowel is drilled with a drill of the required diameter, a corner is fixed. Dowels must match the material and thickness of the wall.

The next step is associated with a partial disassembly of the unit: you need to remove the front panel of the boiler. To do this, you need to flip the cover and release the crossbars on the right and left - this is how the trim panel is released. The final procedure is to hang the gas apparatus on the hanging bracket, which was previously fixed to the wall with fasteners.

Room preparation

In the case of installing and connecting a boiler with an open combustion chamber, a vent is strictly necessary.

We examined the process of connecting a dual-circuit turbocharged unit

But you need to pay attention to the premises in which the equipment is installed. If we look into the diagram of a gas boiler of this type, we will find a closed combustion system in it.

The technique takes air for its combustion from the outside and does not need additional vents (theoretically). In fact, gas services can make claims about its absence. If the boiler is installed in the kitchen, an extractor hood can act as an outlet.

If a floor-standing gas boiler is being installed and connected, then it is advisable to allocate a separate boiler room for this device. Here, without fail, an outlet is made, a gas analyzer is installed, a window is cut through. But it is not necessary to install a fire alarm here. Without fulfilling these requirements, it will not be possible to put the heating into operation.

Room requirement

Special requirements are also imposed on the room where the gas equipment will be installed (boiler room, or furnace). These requirements are quite strict

But their failure to comply will lead to penalties from the inspection authorities, and compliance will help prevent accidents, because gas is an explosive, flammable substance that must be handled very carefully.

The gas boiler can be installed in a closet, kitchen, basement or a special outbuilding equipped with ventilation and exhaust. At the same time, it is strictly forbidden to mount gas equipment in the toilet, bathroom and living rooms. Other requirements depend on the type of boiler.

So, a low-power single-circuit boiler (up to 60 kW) can be installed in any room of the house, except for the above.Double-circuit boilers cannot be installed in the kitchen.

If the total power of the equipment is within 150 kW, then the room where it will be installed can be located on any floor of the house. Installation in a private house of more powerful gas boilers and equipment (150-350 kW) is allowed only on the first and basement floors.

In addition, the rules for installing a gas boiler regulate the size of the boiler room: 0.2 m3 per 1 kW of equipment power with a ceiling height of 2.5 m, but not less than 15 m3 of total volume.

The walls must have a fire resistance of at least 0.75 hours. Installation of a raised floor and a false ceiling is not allowed. All instruments and auxiliary equipment must be easily accessible for adjustment, adjustment and maintenance.

Natural light must also enter the boiler room. To do this, it is necessary to make a window in the room at the rate of 0.03 m2 of the opening area per 1 m3 of the boiler room volume. There must be a window in the window.

There are certain requirements for the width of the door leading to the boiler room - at least 80 cm

Please note that this refers to the width of the door leaf, and not the opening! In addition, it is necessary to leave a small gap in the lower part of the door or equip it with a ventilation grill.

Also, a ventilation grill can be made in the wall adjacent to the next room. The cross section of the ventilation duct is calculated based on the power of the boiler: 8 cm2 per 1 kW

In addition, it is necessary to leave a small gap in the lower part of the door or equip it with a ventilation grill. Also, a ventilation grill can be made in the wall adjacent to the next room. The cross section of the ventilation duct is calculated based on the power of the boiler: 8 cm2 per 1 kW.

If the gas boiler is installed in the basement or basement, the boiler room must be equipped with an additional exit to the street. If the gas boiler is located in an extension, it should be located near the blank wall of a residential building, at a distance of no more than 4 m to the nearest window, at a height of 8 m from the window to the ceiling (SNiP 41-01-2003 and MDS 41-2.2000).

Installation of double-circuit boilers

Modern appliances have automation that controls the degree of heating and maintains the temperature of the coolant. Double-circuit boilers can be called a real home boiler room, as they are able not only to maintain a comfortable air temperature in the house, but also to provide residents with hot water. However, such devices are complex, so they are not immune from breakdowns.

Natural gas is one of the best fuels, but there are some rules that must be followed when using it so that it does not become a source of danger.

When installing, it is important to adhere to the following recommendations:

- The boiler must be installed in a separate room (it is usually called a boiler room or furnace room). Its area must be at least 4 "squares". This room should have a fairly wide doorway. It is also mandatory to have at least one window (read: “Rules for installing a gas heating boiler - installation and connection instructions“).

- Flammable and flammable materials must not be used in the interior decoration of the boiler room.

- A sufficient amount of fresh air must enter the room, therefore, an unclosable through vent must be created.

- A separate gas duct is needed for the exhaust of the boiler.The ventilation system must not be used for this purpose, as the products of combustion will penetrate into the living quarters, which can lead to unwanted health problems.

- The flue outlet must protrude at least one meter above the roof ridge.

- A strong sheet of metal or other non-combustible material is laid on the floor under the boiler, its area must exceed the dimensions of the equipment, but be at least 1 "square".

- The double-circuit heating system of a private house must withstand pressure testing at a pressure of at least 1.8 bar.

All these requirements must be observed, since gas is a dangerous fuel. It is unacceptable to install the boiler in residential areas. Usually they build a separate extension for him so that he does not occupy one of the rooms of the house. If the boiler room is well ventilated, and combustible materials were not used in its decoration, then the heating system will be completely safe.

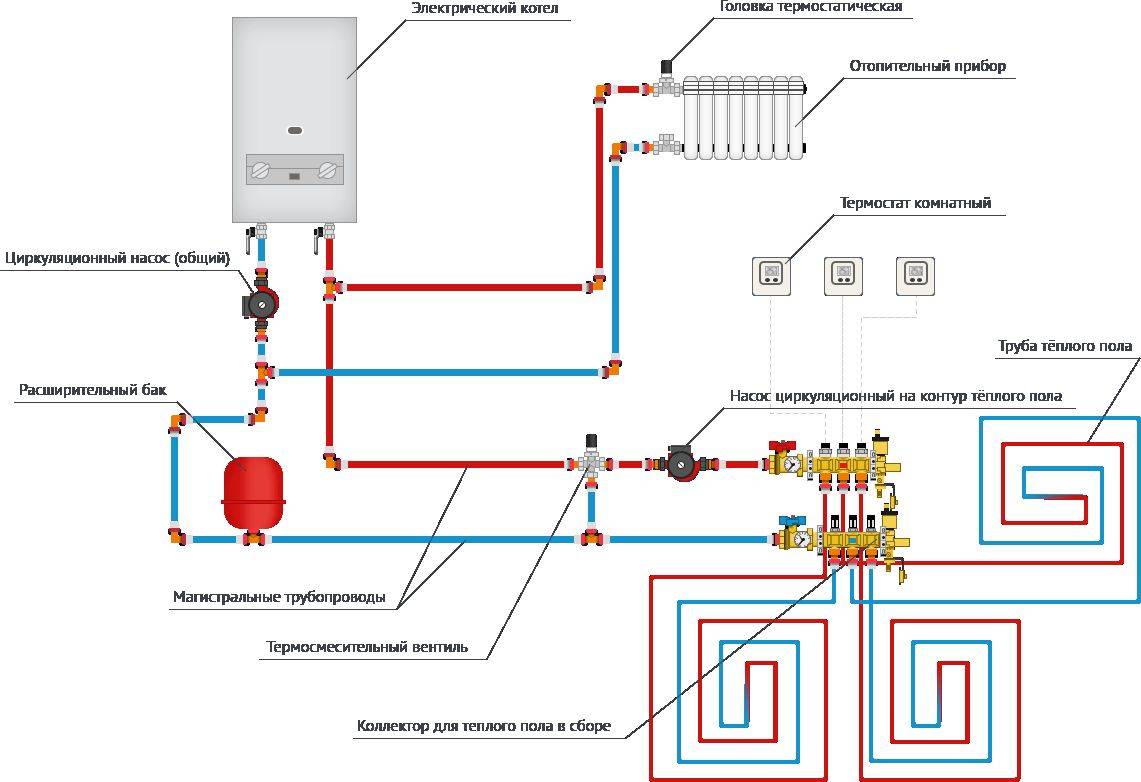

How best to connect a gas boiler - choosing a scheme

There are several boiler connection schemes: the connection may also include a DHW circuit for heating hot water. In the simplest version of the installation of a gas heating boiler, a dead-end scheme is used. Such a scheme for connecting a floor-standing gas boiler is also suitable for wall-mounted models, providing for the switching of heating devices between spills. The disadvantage of this option is the uneven temperature regime in different parts of the circuit: near radiators will always be hotter than distant ones due to the passage of the main volume of coolant through them. The problem can be solved by balancing (throttling) the connections of the batteries closest to the boiler.

In the circuit diagram for connecting a double-circuit gas boiler, DHW is prepared in a separate heat exchanger.In general, DHW is implemented very simply: cold water is supplied inside the heat exchanger.

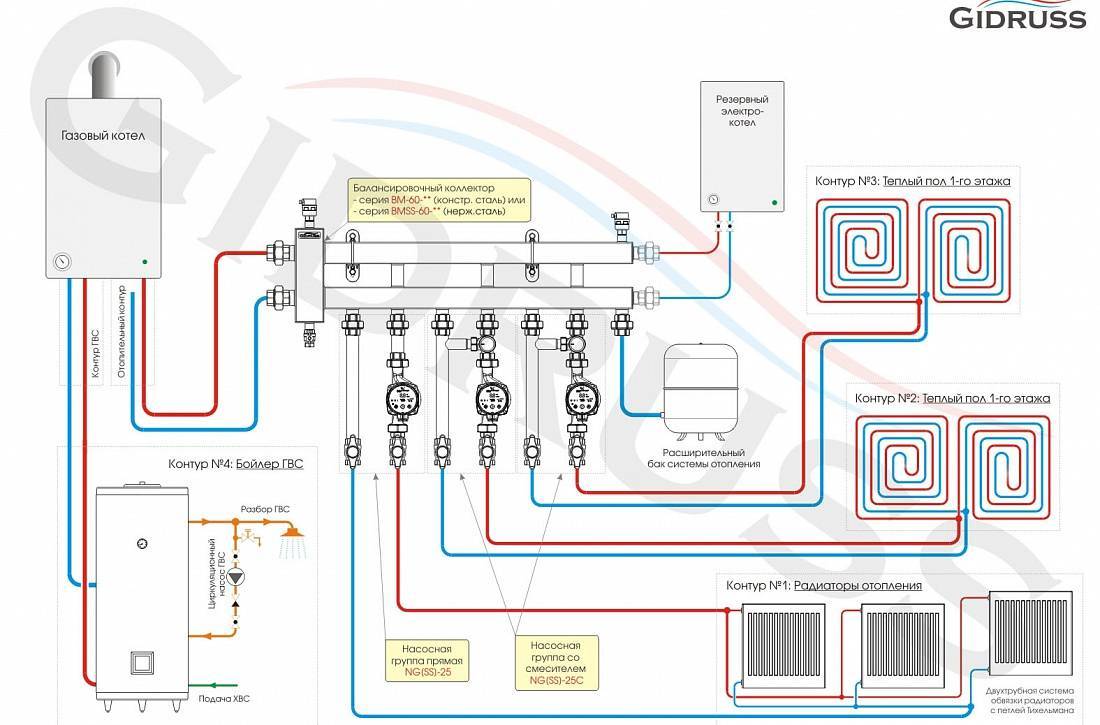

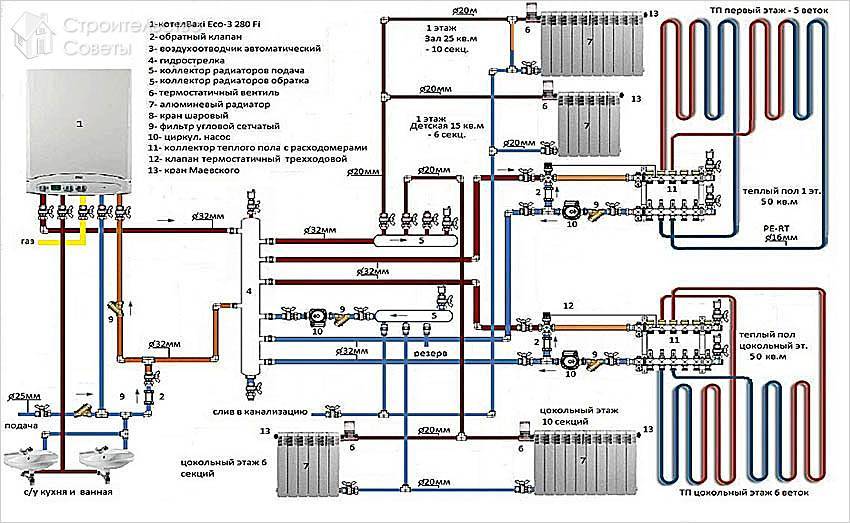

The scheme of how to properly connect a double-circuit type gas boiler is an order of magnitude more interesting:

- Circulation inside the small circuit is provided by a pump built into the boiler, which closes the heat exchanger and the hydraulic arrow.

- Behind the hydraulic arrow there is a collector wiring for 6 autonomous circuits: 2 for standard sectional radiators, and 4 for a floor heating system. Each pair of underfloor heating combs is able to provide 2 circuits.

- Be sure to synchronize the circuits with different temperature conditions. For this, the movement of the coolant through the pipes of the water-heated floor is used.

- Connection of a gas heating system is possible only after obtaining the appropriate permit.

To organize the hot water supply of a private house, a separate heater is often used, since it is much easier to connect a single-circuit gas boiler. The preparation of hot water here takes place in an indirect heating boiler, with further partial transfer of energy from the coolant to the heat exchanger. For the possibility of organizing a system of underfloor heating, a connection scheme for a single-circuit gas boiler with a three-way valve and recirculation is provided here. In summer, water is supplied only through the boiler and the boiler.

After the heater stops, the circulation of water between the heat accumulator and the heating radiators continues. The regulation of the temperature of the batteries here is also provided by a three-way valve and a thermostat.For these purposes, a certain volume of water or antifreeze from the return is recirculated.

Results

As a conclusion, we can say that the connection scheme for a gas boiler in a private house largely depends on the way the coolant circulates inside the heating system. The simplest in terms of organization are single-circuit gravity schemes, where the coolant moves by gravity due to the creation of the necessary pipe slope. However, forced systems are considered more efficient, which include a circulation pump: it provides a more intensive movement of the heated coolant through the pipes. The presence of excess internal pressure in closed circuits requires the mandatory use of additional control devices and safety valves.

Stage one: installation of the boiler

Installing a gas appliance, as a rule, does not cause difficulties. This is the easiest stage of installation work of the heating system. Manufacturers have developed a detailed installation manual for each type of boiler.

It is easier to put on the floor, despite the fact that it is heavier in weight and larger in size. For wall mounting, special brackets are required. They are included with the device. The scheme for connecting a wall-mounted boiler to the heating system is indicated in the instructions for the device

The most important thing is to choose the right place for installing the boiler, while foreseeing how the pipes will be connected to the boiler.

When choosing the location of the unit, take into account not only ease of maintenance. It is necessary to comply with the norms and requirements that apply to gas appliances. Their implementation is a guarantee of the efficiency and safety of using the heating unit.

Two basic rules to follow:

- The room where the boiler will be installed must be provided with a window or a window that can be easily opened if necessary.

- Do not place any appliances or objects near the gas unit.

The floor boiler connection diagram provides for careful preparation of the base. The wall-mounted boiler is located at a height of 80 cm from the floor, no closer than half a meter from the walls. These are standard operating safety requirements.

To know how to properly connect a double-circuit boiler, you need to get acquainted with the conditions that are required for chimney and ventilation systems.

Turbo boilers greatly simplify the task, which do not require the installation of bulky chimneys and exhaust systems. This type of boilers is gaining more and more popularity today. A feature of turbo boilers is the device for the forced removal of exhaust gases and the simultaneous inflow of street air, according to the "pipe in pipe" type. This is the safest system, as it allows you to install gas units in almost any room.

There is another type: floor parapet boilers. These are non-volatile non-volatile units. They are used where it is impossible to build a large chimney. Parapet boilers have a closed combustion chamber, it is completely isolated from the room. In such boilers, the coolant circulates by gravity, without an electric pump. This is their main difference from turbocharged boilers with a coaxial chimney.

Installation of solid fuel units

These units are installed in a private house in dry rooms, the dimensions of which are directly proportional to the dimensions and power of the unit. The walls of the boiler room must be plastered or upholstered with sheet iron.The scheme of their connection implies the presence of supply and exhaust ventilation, which will provide good traction.

The boiler is installed level on a horizontal foundation, covered with a layer of sheet iron. The foundation must be 10 cm larger than the base of the unit along its entire perimeter. Security zone from the furnace side - not less than 40 cm.

Tools and materials

To connect to the heating system, you must purchase:

- two ball valves with a "coupling-fitting" connection with a diameter of 50 mm;

- two rounds with the same diameter;

- manometer;

- safety valve;

- automatic air vent;

- two ball valves with a diameter of 15 mm;

- three steel couplings with a diameter of 50 mm;

- transitions 57 x 32 mm with a wall of 3 mm;

- bends 57 x 3.5 mm;

- chimney with slide gate valve;

- pipes 57 x 3.5 mm;

- heat-resistant sealant;

- sanitary winding;

- circulation pump.

strapping

The piping of the unit is equipped with a security system, which consists of a heat accumulator, a three-way valve for mixing cold water, and a thermostat. What need to do:

- place the boiler on the foundation;

- connect heating pipes with the obligatory use of ball valves, sealing the joints with sanitary winding;

- make grounding and connect the power cable;

- install a security system (pressure gauge, safety valve, automatic air vent);

- assemble the chimney, sealing the joints of the knees with a heat-resistant sealant;

- fill the heat exchanger with water;

- check the location of the grate, kindling damper, plugs for cleaning, etc.;

- relieve the pressure in the heat exchanger to the working one;

- set the dampers in the chimney and furnace to the required position;

- carry out the laying of firewood.

In general, any heating equipment can be connected to the heating system with your own hands with the right approach and the availability of basic knowledge and skills.