- Assembling the device and connecting it

- Step 1: Preparing the Tank

- Step 2: Thermal insulation of the device

- Step 3: Installing the coil

- Step 4: Assembly and Mounting

- Step 5: Connection

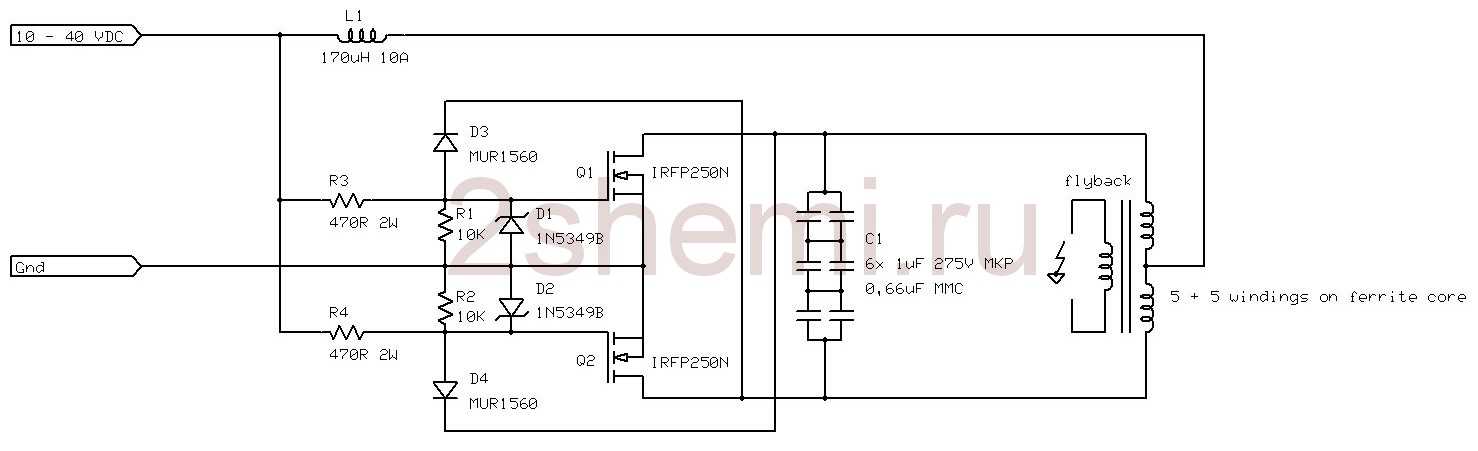

- Step 6: Possible Wiring Diagrams

- Calculation of an indirect heating boiler

- Subtleties of work

- Indirect heating boiler device

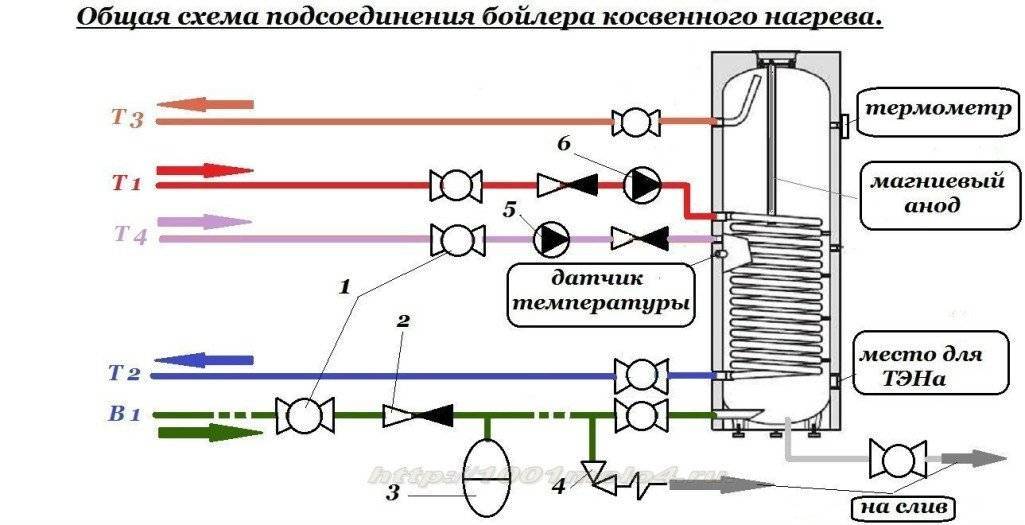

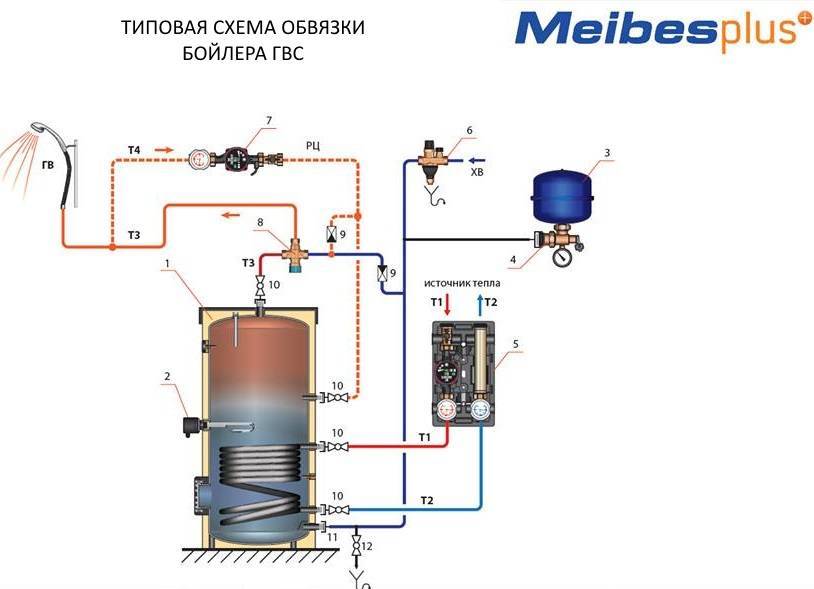

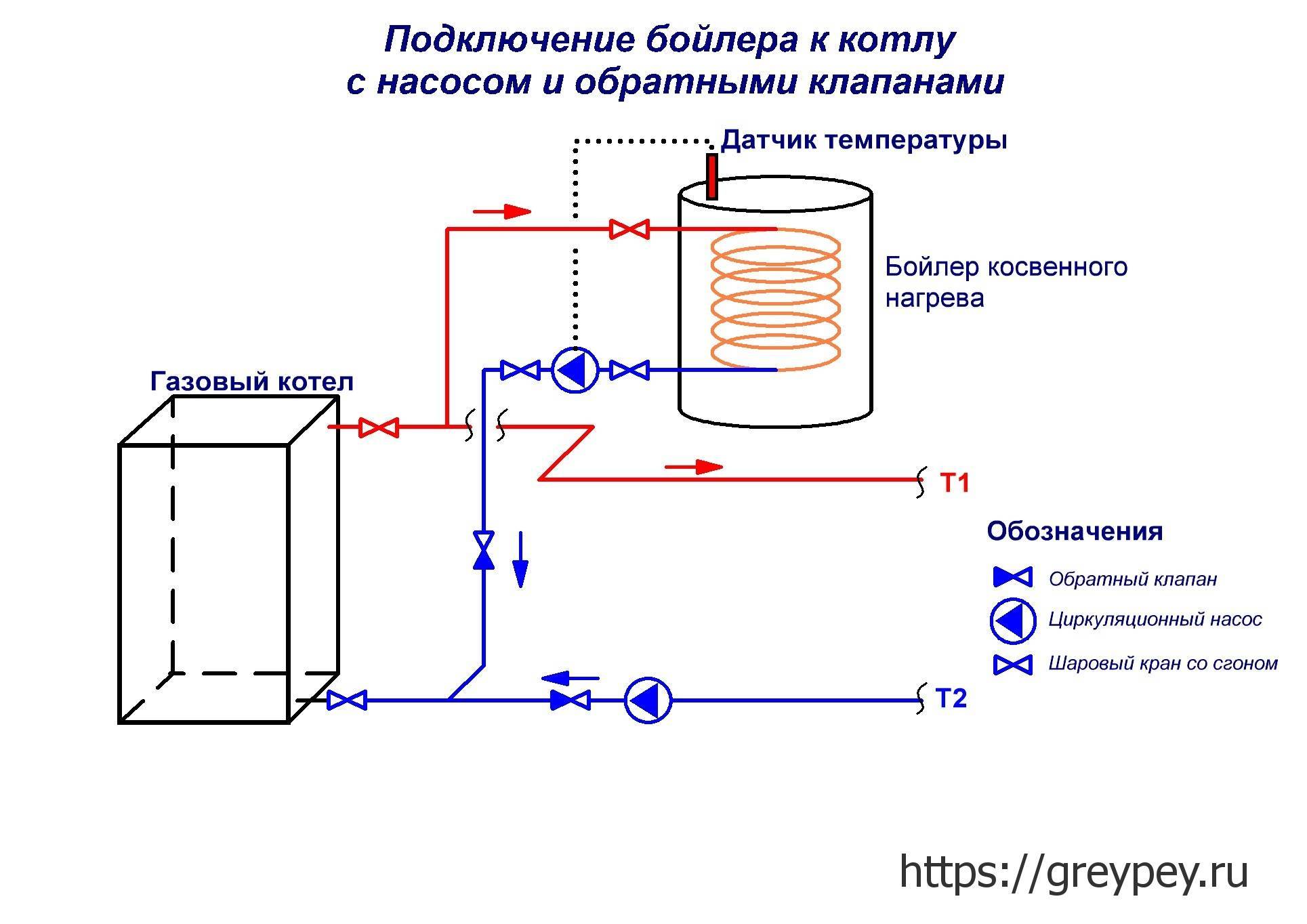

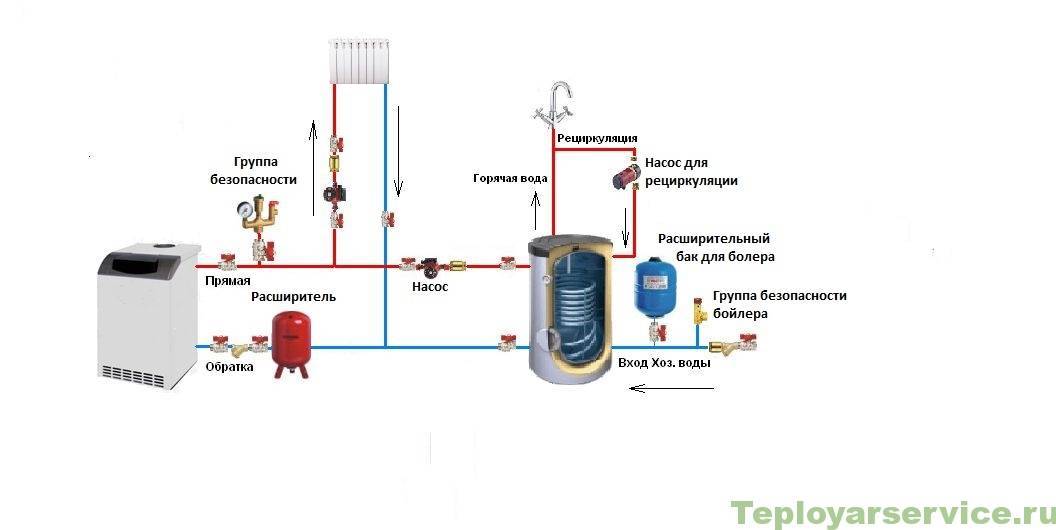

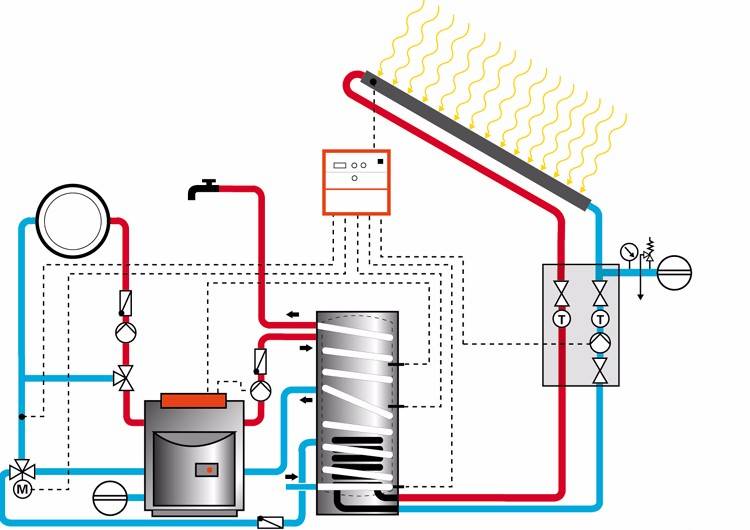

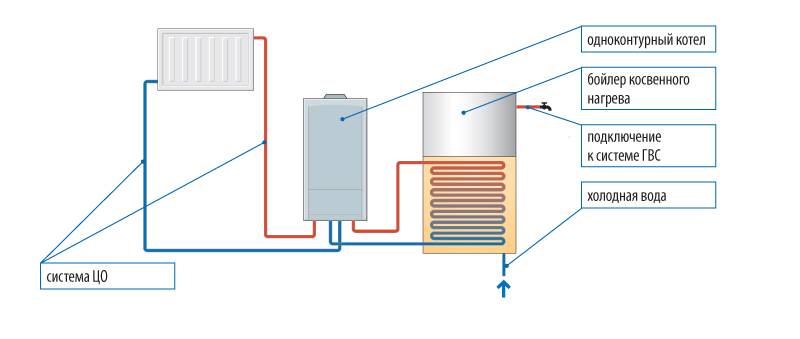

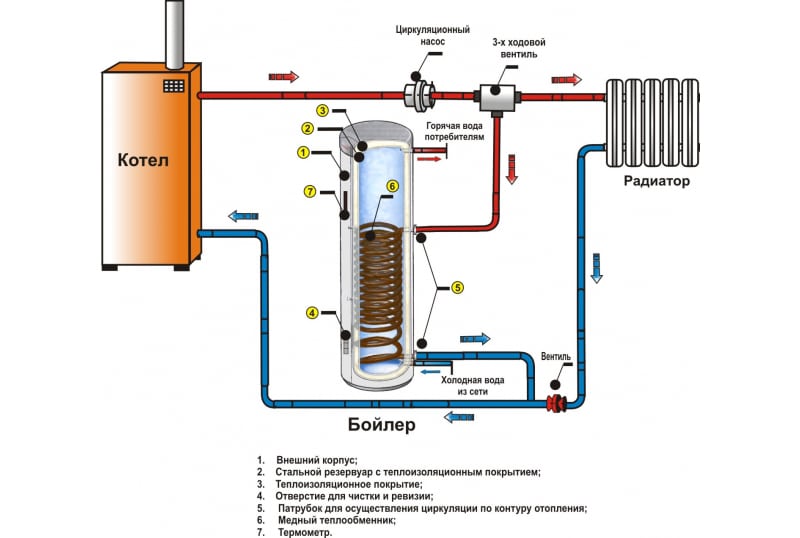

- Diagrams for connecting the boiler to the boiler

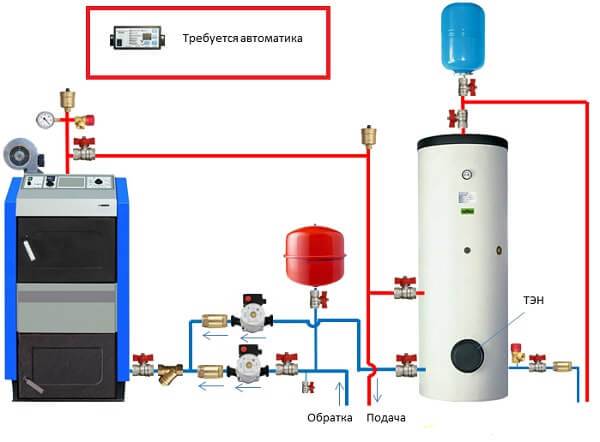

- Piping with boiler water circulation pumps

- Piping with a non-volatile boiler unit

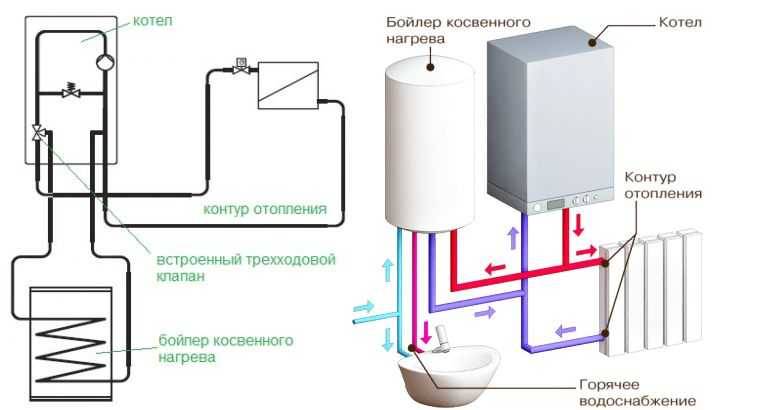

- Piping with 3-way valve

- Scheme with a recirculation line

- Is it possible to connect a boiler to a double-circuit boiler

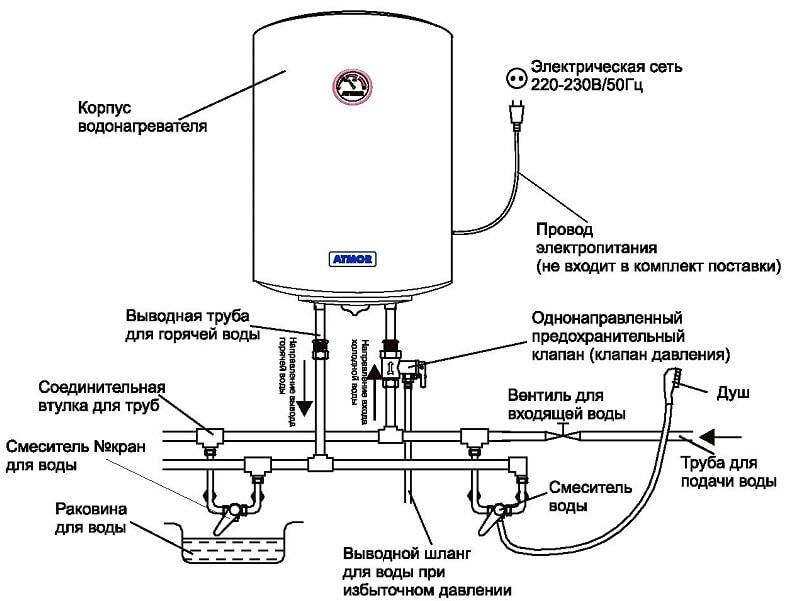

- How to connect a instantaneous water heater to the water supply and electrical network with your own hands

- Do-it-yourself instantaneous water heater installation

- Connecting the instantaneous water heater to the water supply

- Connecting the instantaneous water heater to the mains

- Scheme Summary

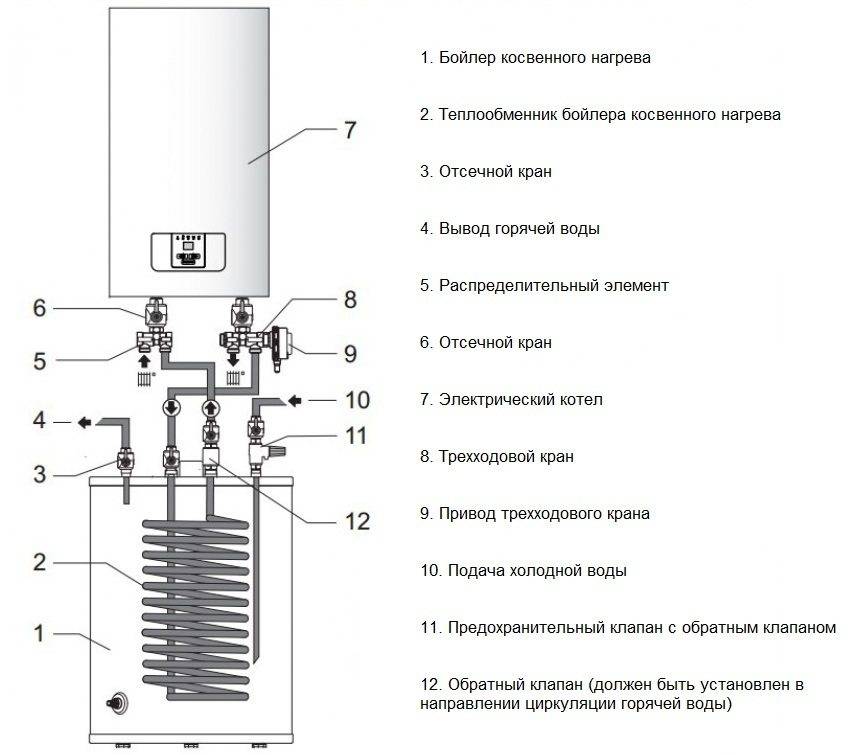

- How wall-mounted gas boilers work with a built-in indirect heating boiler

- How does a mounted gas boiler with a built-in boiler work

- Choosing a wall-mounted heating boiler with an internal boiler

- Rating of brands of boilers with an integrated boiler

- The cost of a boiler with a built-in boiler

- Connecting the tank to the boiler

- How to connect an indirect heating boiler (water heater) next to the boiler in a forced circulation system with a three-way valve

- Correct selection of a water heater with indirect heating

- Important Features

- Choice of tank volume

- Connecting an indirect heating boiler with two circulation pumps

Assembling the device and connecting it

Having dealt with all the features of such equipment, you should move on to the practical part and dwell on the installation in more detail. But first, we will consider how you can assemble such a boiler yourself.

Self-installation of equipment

Step 1: Preparing the Tank

The water tank can be made of any material, as long as it is corrosion resistant. Therefore, it is better to give preference to stainless steel containers, since simple metal coated with enamel or glass ceramics can deteriorate during the first year. It is also necessary that the tank holds the right amount of liquid. Sometimes gas cylinders are used. But in this case, the container must first be cut in half, thoroughly clean the inner surface and primed. But even after such preparation, the liquid will smell like hydrogen sulfide for the first few weeks. We make three holes in our tank, which will ensure the supply of cold and the removal of hot liquid, and are also responsible for fixing the coil.

Step 2: Thermal insulation of the device

To make our boiler correctly, you should take care of its thermal insulation. We cover the entire body on the outside with a material with the desired properties. For this purpose, you can use any insulation. We fix it with glue, wire ties, or prefer any other method.

Step 3: Installing the coil

Small diameter brass tubes are best suited for the manufacture of this element. They will heat the liquid faster than steel ones, and they are easier to clean from scale. We wind the tube on the mandrel.In this case, it is necessary to correctly select the dimensions of this element. The more water will be in contact with it, the sooner the heating will occur.

Step 4: Assembly and Mounting

Now it remains to assemble all the parts of the boiler, do not forget about the thermostat. If suddenly at this stage the heat-insulating layer is damaged, then it should be immediately restored. It remains to weld metal ears to the tank so that it can be mounted on the wall. The water heater is mounted on brackets.

Step 5: Connection

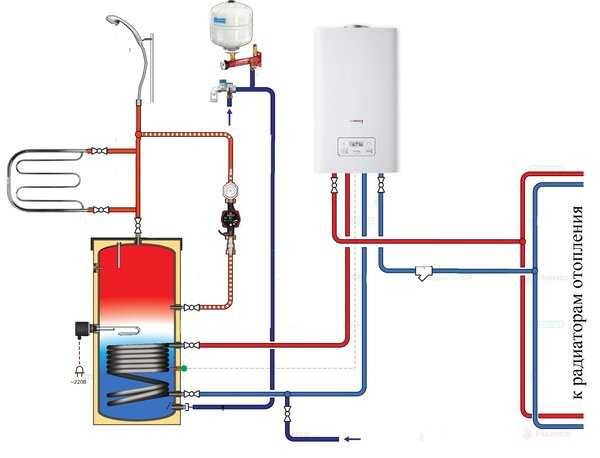

Now about the binding. This device is connected simultaneously to the heating and water supply system. In the first, the liquid is heated by a gas boiler or other heating equipment. In this case, the movement of the coolant should be directed downward, so it is fed into the upper pipe, and when it cools, it leaves the lower one and flows back to the gas boiler. The thermostat controls the water temperature. Cold liquid from the water supply enters the lower part of the water heater. It is best to install the boiler as close to the heating equipment as possible. We connect the water heater according to any scheme indicated in the next paragraph.

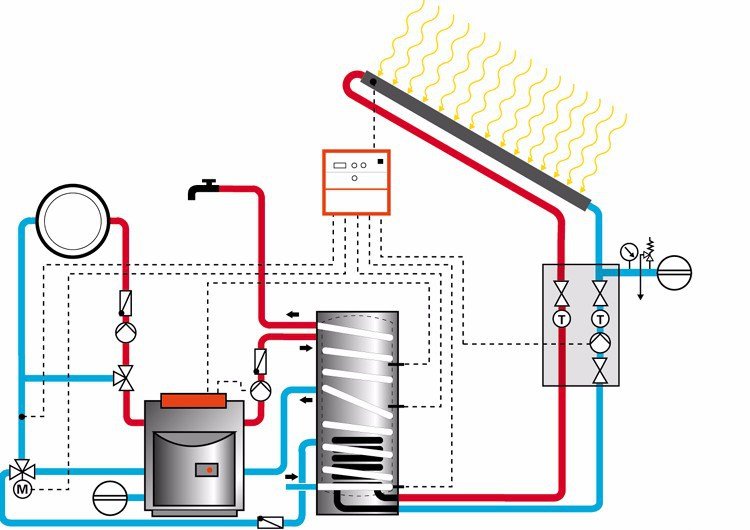

Step 6: Possible Wiring Diagrams

In this paragraph, we will consider all the options for tying such a water heater. In principle, it can even be used for heating with two circuits. In this case, the distribution of the coolant occurs through a three-way valve. It is controlled by special signals coming from the water heater thermostat. Thus, as soon as the liquid has cooled too much, the thermostat switches and the valve directs the entire flow of the coolant to the accumulator heating circuit.As soon as the thermal regime is restored, the valve, again, at the command of the thermostat, will return to its original position and the coolant will again enter the heating circuit. This scheme is a worthy alternative to a double-circuit boiler.

You can also control the movement of the coolant by means of circulation pumps installed in various lines. The heating and boiler heating lines are connected in parallel and have their own pressure. As in the previous case, the modes are controlled by a thermostat, and as soon as the DHW circuit is connected, the heating is turned off. You can use a more complex scheme, including two boilers. One device provides continuous operation of heating elements, and the second - hot water supply.

A circuit using a hydraulic distributor is considered quite complicated in execution; only professionals can connect it correctly. In this case, there are several home heating lines, such as underfloor heating, radiators, etc. The hydraulic module controls the pressure in all branches. You can also connect a liquid recirculation line to the water heater, then you can achieve instant hot water from the tap.

Calculation of an indirect heating boiler

The main parameter for choosing a boiler will be the volume of its tank. The volume must be calculated from your needs for hot water consumption. To do this, the generally accepted sanitary standards necessary for one person are sufficient, multiplied by the number of your dependents.

Average hot water consumption rates:

- Washing: 5-17 l;

- For the kitchen: 15-30 l;

- Take water treatments: 65-90 l;

- Hot tub: 165-185 liters

The next point is the design of a hollow coolant tube.The best option is a removable coil made of high quality brass

This is important for maintenance. You can remove the removable coolant (coil) at any time for cleaning or replacement. The material of the tank has a significant effect on the durability of the boiler.

The best option is high quality stainless steel. It will be a little more expensive, but in the end you will only win.

The material of the tank has a significant effect on the durability of the boiler. The best option is high quality stainless steel. It will be somewhat more expensive, but in the end you will only win.

And of course, the effect of a thermos will be better from the quality of the insulation. The water will not cool quickly. Here recommendations - strictly do not save, Only high quality polyurethane.

Subtleties of work

If, when looking for heating equipment for your own house or apartment, the choice stops at a single-circuit boiler and it is planned to connect a boiler to it, then the following features of the boiler’s operation in tandem with this heat exchanger should be taken into account.

From the moment the boiler is turned on and until the water in it is completely heated, the heating system will not work on the DHW

Based on this trouble, it is necessary to choose a hot water heat exchanger according to the maximum water heating time, which would be enough to prevent freezing of heating pipes in the most extreme frost in the region of residence.

Choosing a boiler by power, linking it with the heated area of \u200b\u200bthe premises, not forgetting the climatic zone of residence, what the house is built from and whether its walls have thermal insulation - all this is important when choosing the power of the heating unit.

Having decided on the power, it is possible to say with accuracy whether such a boiler will pull the boiler water heating system or not.

Heating engineers believe that a boiler installation can only function normally with a boiler with a capacity of at least 24 kW. Another expert figure is that the boiler takes up to 50% of the power from the boiler. These are the numbers you need to focus on when choosing a gas boiler model for your home. And to prevent a situation where a 35 kW boiler is installed with an estimated power consumption for heating of 25 kW, and the boiler will take 17 kW. As a result, a boiler power deficit of 7 kW is formed.

It is also worth noting the fact that in some cases a boiler with a large capacity is required, with a capacity of 200 and even 500 liters.

Indirect heating boiler device

Let's take a closer look at what an indirect heating boiler is? The volume of the tank ranges from 50 liters up to 1000 liters of water. Inside the tank is the main heating element - a coil. It is through it that the coolant circulates and in this way the liquid is heated. Coils are usually steel or brass. This heating element has a complex shape, as you have already noticed. Thanks to this shape, the coil heats up faster. In most models of indirect heating boilers, the coils of the coil are located at the base of the tank, because. cold waters are heavier, as a result of which they are located below the layers of warm water. Of course, models are also being created with heat exchangers over the entire area of the tank, which contributes to the speedy heating of water.In the “indirect” device, of course, there is also a thermostat that controls the temperature of the water and ensures the safe operation of the device.

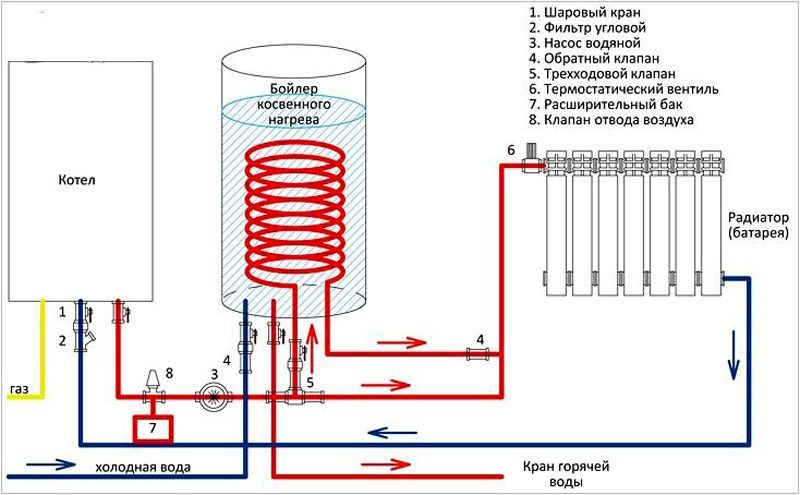

Diagrams for connecting the boiler to the boiler

Before connecting an indirect heating boiler, an executive connection diagram and installation parameters of the BKN are developed. They depend on the modification of the device, the scheme of the boiler unit and the heating system in the household.

The BKN boiler connection kit is most often used for double-circuit units and with three-way valves.

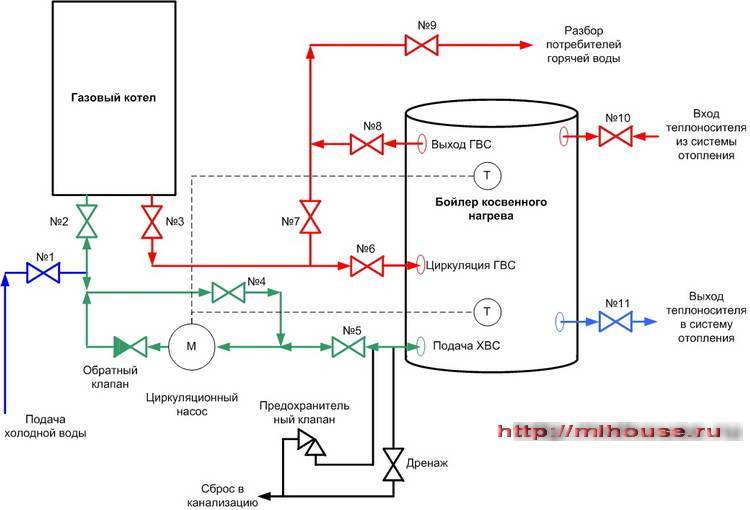

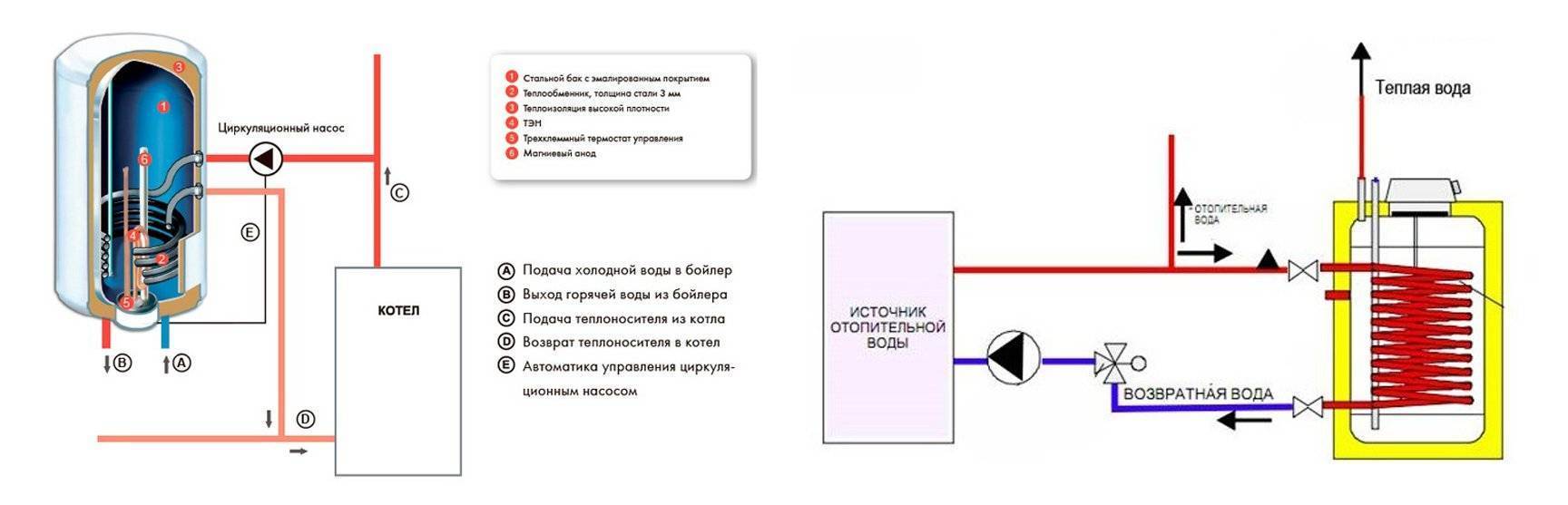

Piping with boiler water circulation pumps

The scheme with 2 circulation electric pumps is used for temporary heating of domestic hot water, for example, during seasonal operation of the BKN and when used on weekends. In addition, this option is applicable when the DHW temperature is set lower than the T of the heat carrier at the outlet of the boiler.

It is carried out with two pumping units, the first is placed on the supply pipe in front of the BKN, the second - on the heating circuit. The circulation line is controlled by an electric pump through a temperature sensor.

According to its electrical signal, the DHW pump will be switched on only when the temperature drops below the set value. There is no three-way valve in this version, the piping is carried out using conventional mounting tees.

Piping with a non-volatile boiler unit

This scheme is used for a non-volatile boiler unit operating with natural circulation of the coolant, therefore, in order to ensure the required hydraulic regime and the coolant could circulate through the boiler unit and radiators in the rooms. This scheme is for wall modifications that allow installation at a level of 1 m from the “O” mark in the furnace.

Floor models in such a scheme will have low circulation and heating rates. It may happen that the required level of heating cannot be achieved.

This scheme is used only for emergency modes, when there is no electricity. In normal energy-dependent modes, circulating electric pumps are installed in the circuit to ensure the required speed of the coolant.

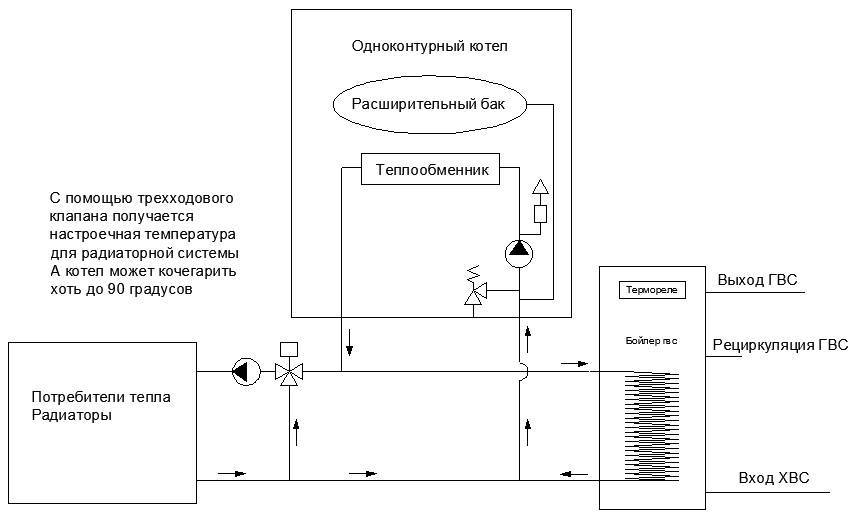

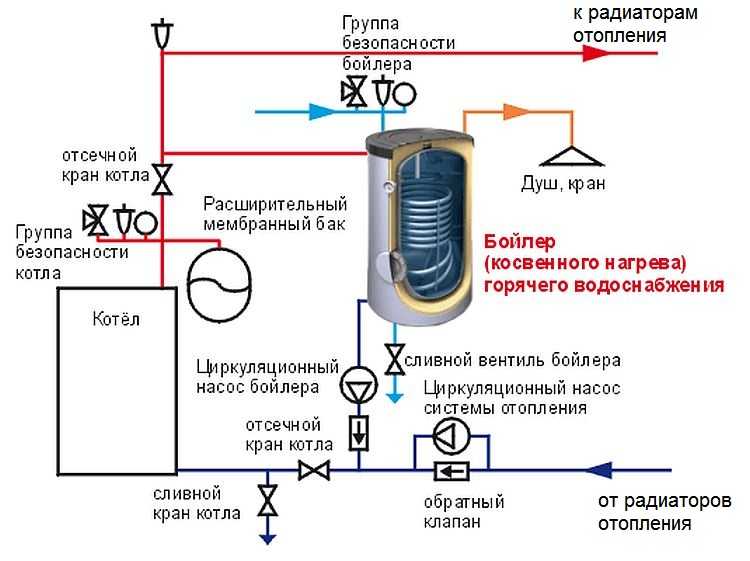

Piping with 3-way valve

This is the most common piping option, as it allows the parallel operation of both heating and hot water. The scheme has a fairly simple execution.

BKN is installed next to the boiler unit, a circulation electric pump and a three-way valve are mounted on the supply line. Instead of one source, a group of boilers of the same type can be used.

The three-way valve acts as a mode switch and is controlled by a thermal relay. When the temperature in the tank drops, the temperature sensor is activated, which sends an electrical signal to the three-way valve, after which it switches the direction of movement of the heating water from heating to DHW.

In fact, this is a BKN operation scheme with priority, which provides fast heating of the DHW with the radiators completely turned off during this period. After reaching the temperature, the three-way valve switches and the boiler water enters the heating system.

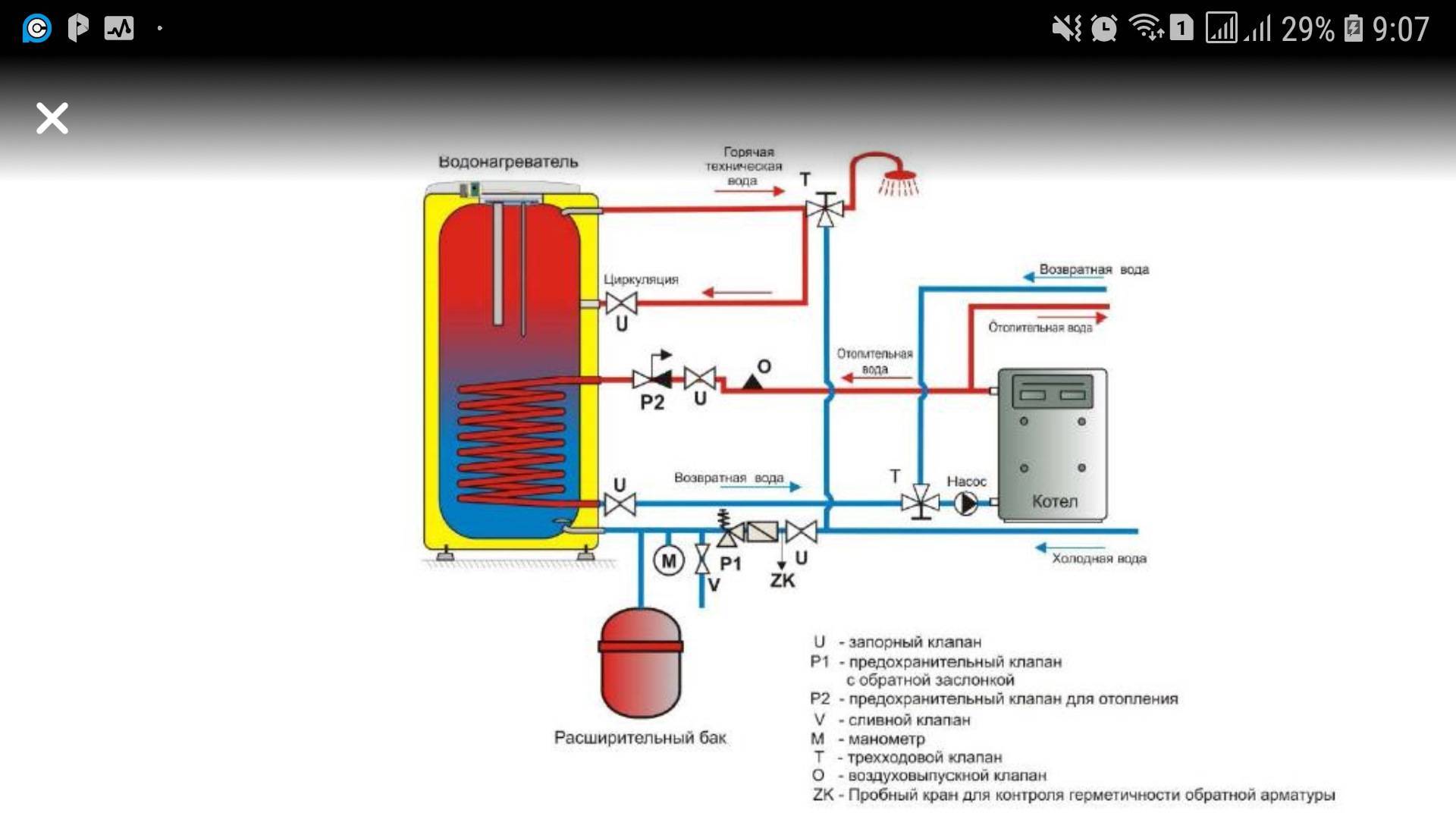

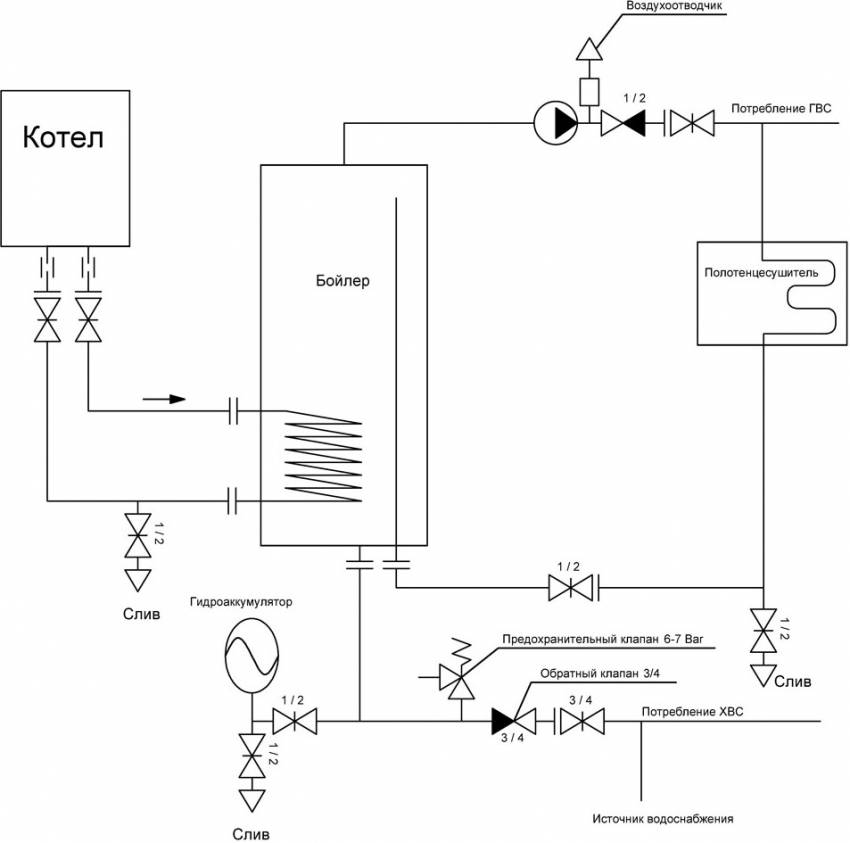

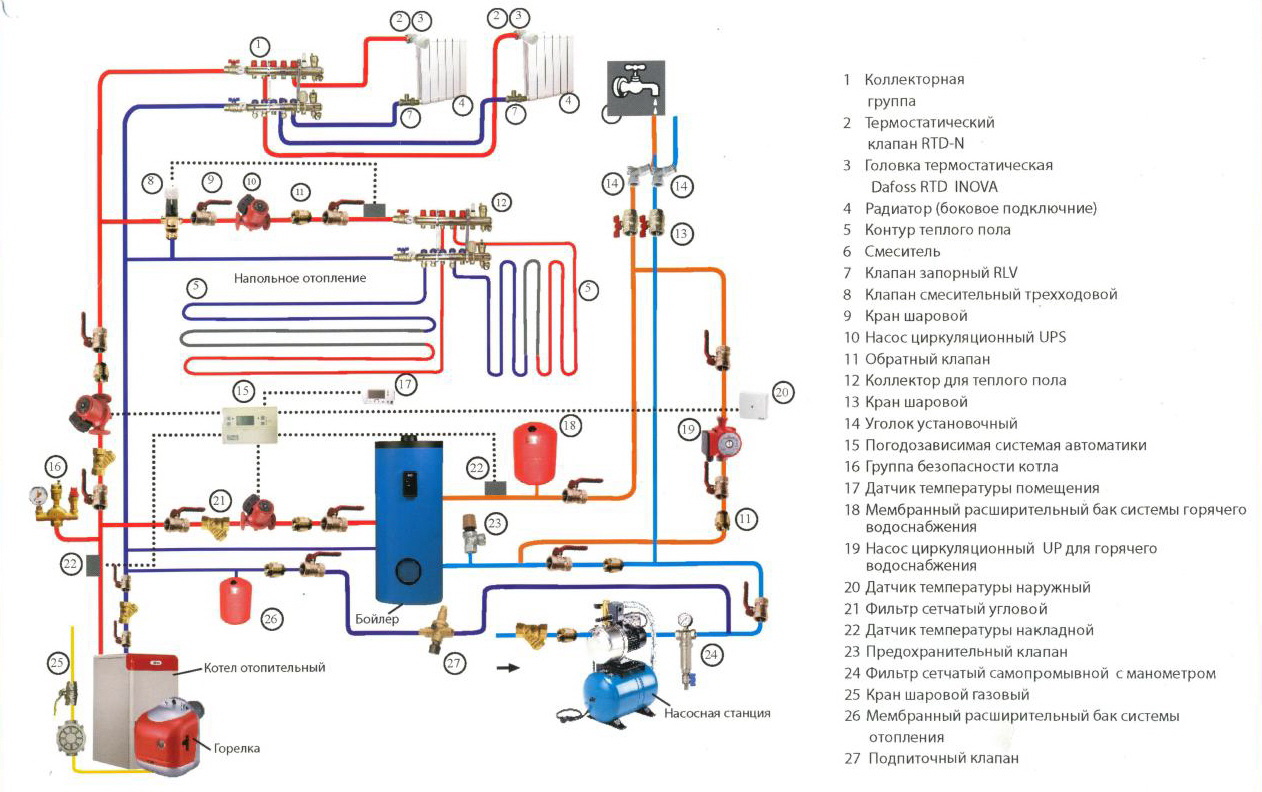

Scheme with a recirculation line

Coolant recirculation is used when there is a circuit in which hot water must circulate all the time, for example, in a heated towel rail. This scheme has great advantages, because it does not allow water to stagnate in the pipes.The user of DHW services will not need to drain significant volumes of water into the sewer in order for hot water to appear in the mixer. Consequently, recycling saves the cost of water supply and hot water services.

Modern large BKN units are supplied to the market with an already built-in recirculation system, in other words, they are equipped with ready-made pipes for connecting a heated towel rail. Many for these purposes acquire an additional small tank connected to the main BKN through tees.

Is it possible to connect a boiler to a double-circuit boiler

This option is performed using an indirect heating boiler connection scheme with a hydraulic arrow for structures with a working volume exceeding 220 liters and multi-circuit heating schemes, for example, in a multi-storey building with a "warm floor" system.

A hydraulic arrow is an innovative unit of a modern in-house heat supply system that simplifies the operation and repair of a water heater, since it is not necessary to install recirculation electric pumps on each heating line.

It increases the security system, as it prevents the occurrence of water hammer, since it maintains equal pressure of the medium in the circuits of the double-circuit boiler unit.

How to connect a instantaneous water heater to the water supply and electrical network with your own hands

Previously, we conducted a review in which the device of an instantaneous water heater is thoroughly covered, as well as recommendations for choosing.

So, the new "protochnik" got rid of the packaging, read the instructions and now is the time to think about where it is better to install the instantaneous water heater.

It is advisable to choose a place for installing an instantaneous water heater based on the following considerations:

- whether in this place spray from the shower will fall on the device;

- how convenient it will be to turn the device on and off;

- how convenient it will be to use the shower (or faucet) of the device.

Before proceeding with the installation, you need to decide:

- whether it will be convenient to use the device directly in the place of taking a shower (or, say, washing dishes);

- whether it will be convenient to use different modes of operation (if there are such adjustments);

- whether moisture or water will get on the device (after all, there are clean 220V!).

- It is also necessary to take into account the future water supply - how convenient it will be to connect the instantaneous water heater to the water supply. There will be no special conditions for the wall - the weight of the device is small. Naturally, it will be somewhat more difficult to mount the device on curved and very uneven walls.

Do-it-yourself instantaneous water heater installation

Usually, the kit contains the necessary fasteners, but it often happens that the dowels themselves are short (for example, there is a thick layer of plaster on the wall) and the screws themselves are short, so I would recommend purchasing the necessary fasteners of the required dimension in advance. On this installation can be considered complete.

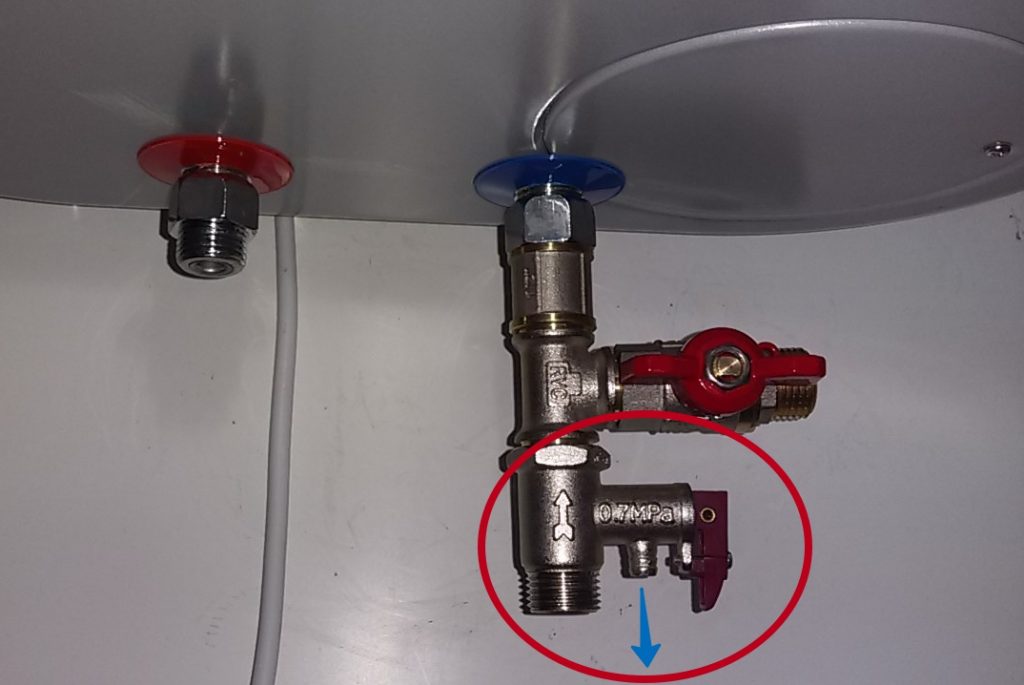

Connecting the instantaneous water heater to the water supply

An instantaneous electric water heater can be connected to water in several ways.

The first method is simple

We take a shower hose, unscrew the “watering can” and connect the hose to the cold water inlet to the water heater. Now, by setting the faucet handle to the “shower” position, we can use the water heater. If we put the handle in the "tap" position, then cold water comes out of the tap, bypassing the heater.As soon as the centralized supply of hot water is restored, we turn off the water heater from the “shower”, fasten the “watering can” of the shower back and continue to enjoy the benefits of civilization.

The second method is more complicated, but more correct

Connecting the water heater to the water supply of the apartment through the outlet for the washing machine. To do this, we use a tee and a skein of fumlents or threads. After the tee, a tap is needed to disconnect the water heater from the water and to adjust the pressure and temperature of the water from the water heater.

When installing a crane, you should also pay attention to the ease of use of the latter. After all, we will repeatedly open and close it in the future. The section of our water pipeline from the faucet to the water heater can be mounted using various pipes: from metal-plastic and PVC to ordinary flexible pipes

The fastest way, of course, is to make an eyeliner using flexible hoses. If necessary, our plumbing can be fixed to the wall (or other surfaces) using brackets or any other means of fastening

The section of our water pipeline from the faucet to the water heater can be mounted using various pipes: from metal-plastic and PVC to ordinary flexible pipes. The fastest way, of course, is to make an eyeliner using flexible hoses. If necessary, our plumbing can be fixed to the wall (or other surfaces) using brackets or any other means of fastening.

Connecting the instantaneous water heater to the mains

It is forbidden to use standard sockets for power supply, due to the fact that in most cases they do not have proper grounding.

When connecting wires to screw terminals, phasing must be observed:

– L, A or P1 – phase;

- N, B or P2 - zero.

It is not recommended to perform electrical work on your own, it is better to use the services of a specialist.

Scheme Summary

Such systems for connecting a water heater exclude the simultaneous operation of heating the liquid and heating the house. This will cause inconvenience only once at system startup. Since the coolant will be cold, the whole process will take about an hour in time, depending on the amount of coolant. With constant operation, much less time will be spent on maintaining the temperature, so temperature drops will not be felt.

These schemes can be applied in more complex heating systems. Heating boilers are divided for them: one will work only for heating water, the other for heating.

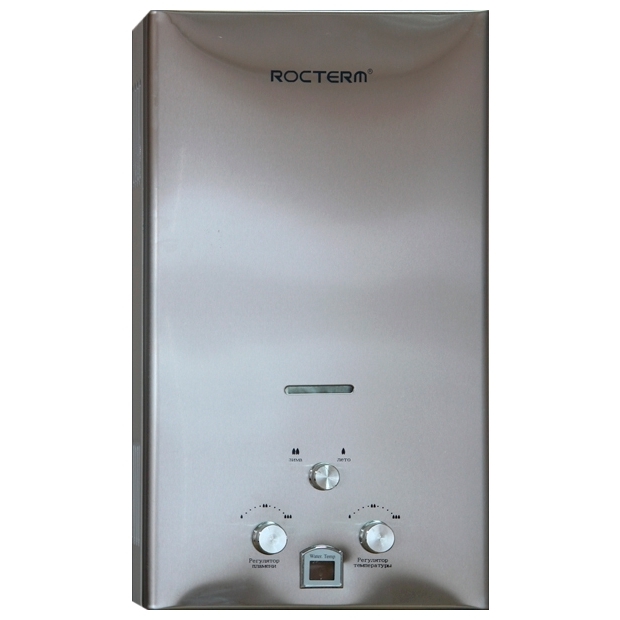

How wall-mounted gas boilers work with a built-in indirect heating boiler

How does a mounted gas boiler with a built-in boiler work

- The primary and secondary heat exchangers operate continuously.

- The boiler maintains a constant liquid heating temperature. A coil is installed inside the boiler, through which hot water circulates. Layer-by-layer heating of the liquid is carried out.

- After opening the water supply tap, hot water is immediately supplied to the consumer, displaced by cold liquid entering the boiler.

- The type of combustion chamber - the consumer is offered gas boilers with an open and closed combustion chamber:

- Atmospheric, connected to a standard classic chimney.

- In turbo boilers with a closed combustion chamber, smoke removal and air intake from the street is carried out through a coaxial chimney.

- The volume of the storage tank - the built-in indirect heating boiler, depending on the selected model and its power, has a capacity of 10 to 60 liters. There are boilers with a larger capacity, but, as a rule, they are made in a floor version.

An indirect heating boiler is equipped with gas heating equipment with a power of over 25 kW. In boilers with lower productivity, the storage tank is usually not installed.

Choosing a wall-mounted heating boiler with an internal boiler

- The volume of the storage boiler - the capacity of the tank depends on how much hot water will be available. For a large family, it is better to choose models with a storage capacity of at least 40 liters.

- Throughput - the technical documentation clearly stipulates how much hot water the boiler can heat within 30 minutes. The heating temperature is indicated as 30°C.

- Power - accurate heat engineering calculations will be made by a consultant of a company selling heating equipment. With self-selection of equipment, use the formula 1 kW = 10 m². To the result obtained, add a margin of 20-30% for hot water supply.

- Protection of the boiler and storage tank - boilers equipped with 2-3 degrees of protection against scale, which is the main reason for the failure of the storage tank, are considered the best.

Rating of brands of boilers with an integrated boiler

- Italy - Baxi, Immergas, Ariston, Sime

- Germany - Wolf, Buderus

- France - Chaffoteaux, De Dietrich

- Czech Republic – Protherm, Thermona

- US and Belgium co-production - ACV

The cost of a boiler with a built-in boiler

- Manufacturer - Czech, German and Austrian boilers, take the lead in terms of cost among analogues manufactured by factories located in other EU countries.

- Power - a 28 kW Baksi boiler, an Italian manufacturer, will cost approximately 1800 €, and for a 32 kW unit, you will have to pay 2200 €.

- Type of combustion chamber - models with a closed burner device using the condensing principle of heating the coolant are the most expensive. Atmospheric counterparts are 5-10% cheaper.

- Bandwidth and storage capacity. Wall-mounted gas boilers for heating and hot water heating with a built-in boiler, capable of heating 14 l / min, will cost approximately 1600 €. Analogues, with a capacity of 18 l / min, already cost 2200 €.

Advantages of boilers with built-in boiler

- Possibility of heating water even during peak periods. A double-circuit boiler, at low water pressure, does not go into operation. The gas supply opens when a certain intensity of liquid circulation in the pipeline is reached. Water heating in the boiler is carried out in advance when there is a normal pressure in the system.

- Compactness - all gas mounted heating boilers with a built-in storage boiler are small in size, which allows them to be placed in any utility and domestic premises used as a boiler room.

- Instant supply of hot water - the boiler is connected to the recirculation system. After heating the water in the tank, a constant temperature is maintained. Hot water starts flowing from the water supply faucet a few seconds after opening.

- Simple installation - the device of the boiler in the boiler is made in such a way that the consumer does not need to additionally configure the operation of the unit. It is enough to supply electricity to the automation, gas to the burner and a pipeline to the supply and return pipes of the water supply system located on the body.

Cons of built-in boilers in boilers

- High price.

- Boiler susceptibility to failure as calcium deposits build up.

In DHW mode, the boiler consumes approximately 30% less gas. Therefore, the cost of purchasing the unit pays off in the first few heating seasons.

Connecting the tank to the boiler

Owners of expensive and powerful boilers quite often connect the boiler to the general heating system. Is it correct? Technically yes. In such a heat supply scheme, the hot liquid simultaneously passes through the boiler and heat exchangers. Sophisticated automation becomes unnecessary. There is enough excess power for the entire system to work properly, so there is no incentive to separate hot water and heating.

Unfortunately, such a scheme, when used, exhibits a number of significant drawbacks:

- Excess heat is wasted: 80°C for hot water is the required minimum, which is 1.5-2 times higher than the requirements of the heating system.

- The wall-mounted gas boiler does not have high power ratings, but the scheme assumes an even distribution of heat between the elements. The boiler, when connected to the boiler, will heat up not for 10 minutes, but for 40. In addition, the delivery of hot water in the duct will decrease by three to four times from the required rate.

Automation is a necessary element that significantly simplifies the interaction between boiler and wall gas boiler.It allows you to timely redistribute the power of the heater between all elements of the system.

As a rule, users of budget boilers prefer to separate the heating system and hot water. This is a smart solution that can be implemented in three different ways:

- The boiler has pipes for connecting an indirect heating boiler. The heater itself is single-circuit, but at the outlet there is a division into two pipes: for the heating system and hot water supply. In fact, most of the time the heater works for heating. If necessary, the automation gives a signal and all the power of the gas boiler is used to heat the boiler. The operation takes 5-10 minutes, after which the heater switches back to the heating system.

- The boiler does not have pipes for connecting an indirect heating boiler. In this case, you will have to purchase a three-way valve separately. A distinctive feature of such a connection is the need to synchronize the automation of the boiler and the valve.

- Hydraulic arrow. The heater is connected to a complex system of pumps and pipes, which allows the simultaneous operation of several separate circuits. The heating system and hot water are separated, as in the first two methods. The automation of the hydraulic arrow can be fine-tuned, which also allows you to rationally distribute the power of the boiler. Most likely, you will have to install a controller - an element that synchronizes the operation of the pumps of the arrow and the boiler.

Each of the three schemes involves one thing - the separation of hot water and heating.Modern automation monitors the parameters set by the user for each circuit and distributes heat according to the established algorithms. Only in this way a low-power wall-mounted gas boiler is able not only to ensure the uninterrupted operation of two systems, but also to reduce fuel consumption to a minimum.

Read also:

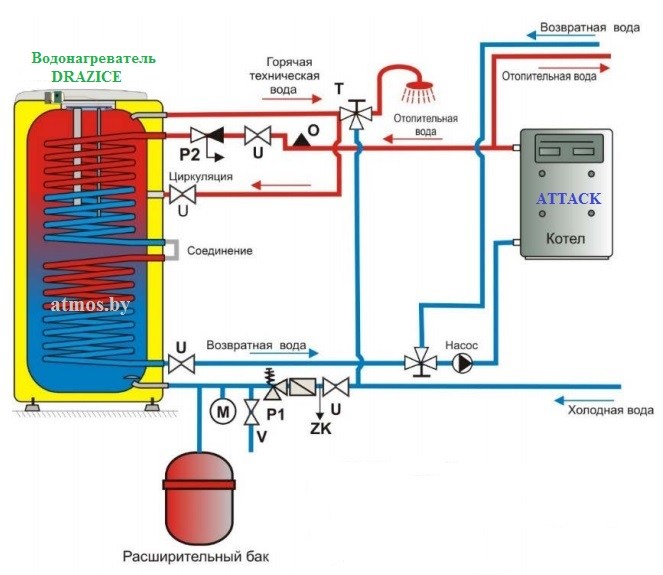

How to connect an indirect heating boiler (water heater) next to the boiler in a forced circulation system with a three-way valve

In order to connect an indirect heating boiler according to the indicated scheme, organize a separate circuit that will come from the heating device. A prerequisite for this installation is the location of the circulation pump in the supply. Such a connection is most relevant for owners of a gas or other boiler, in which the pump is located on the supply pipe. This scheme works by connecting the heating system and the water heater in parallel.

This method of tying an indirect heating device involves the location of a three-way valve after the circulation pump. The valve is controlled by a thermostat located on the water heater. The free outlet of the three-way valve is connected to the water heater to connect the heating. We cut a tee into the pipe opposite the supply pipe to connect the boiler pipe, pursuing the function of draining water from the water heater. Thus, we are successfully tapping into a forced circulation system.

Now let's see how it works? The circuit works in the following order:

- When a signal is received from the thermostat that the water has cooled down, the three-way valve switches the coolant to the indirect water heating device.In this case, the entire heating system is turned off;

- Due to the passage of the flow of hot water through the heat exchanger, the liquid in the boiler is heated;

- When the water reaches the required temperature, the thermostat gives a signal, after which the three-way valve again redirects the coolant to the heating system.

Correct selection of a water heater with indirect heating

Indirect heating boiler (BKN) is a highly efficient device with modern automation systems for thermal processes, it is used to produce hot water T up to 65 C.

Externally, the BKN is similar to a traditional electric water heater, although its modern modifications have a more ergonomic rectangular shape.

The source of thermal energy is a heating boiler that runs on any energy source from waste to electricity.

The basic element is a steel or brass coil-type heat exchanger with a large heating area in a relatively small volume of a storage tank covered with a protective enamel layer.

Before installing the BKN, it is necessary to correctly select it for the actual operating conditions: the source of heat supply and the volume of water use for DHW services.

The main parameters for choosing a connection scheme for an indirect heating boiler:

- Working volume in liters. At the same time, the terms "total volume" and "working volume" are different, since the coil heat exchanger takes a certain part of the tank, so you need to choose according to the working indicator.

- External heating source, type of fuel and coolant outlet temperature.

- Thermal power of an external source. The boiler must provide not only the heating load, but hot water.So, to heat a volume of water of 200 liters, a reserve power of at least 40 kW is required.

- Working container material: coated with enamel, glass-ceramic and glass-porcelain, stainless metal or heat-resistant plastic.

- Thermal insulation - to protect the BKN from heat losses, it is best if polyurethane is used as thermal insulation.

- Protection and regulation system.

Important Features

In addition to choosing the geometric and thermal characteristics of the BKN, it is necessary to take into account many parameters so that the thermal scheme for connecting an indirect heating boiler to a gas boiler is as efficient as possible.

To do this, the user must fulfill certain conditions:

- To choose the optimal location, experts say that the location of the BKN should be as close as possible to the boiler.

- Provide protection against thermal elongation of the structure, for this, integrate a membrane hydraulic accumulator with a volume of 10% of the working volume of the boiler into the BKN circuit at the DHW outlet from the device.

- Before connecting the boiler, each inlet / outlet line for the heating and heated medium is equipped with ball valves.

- To perform backflow protection, a check valve is installed on tap water.

- Perform water purification with the installation of a filter before supplying tap water to the BKN.

- The installation of the BKN wall structure is carried out on the main walls with preliminary treatment with fireproof materials.

- Installation of BKN is carried out above the level of the boiler unit or at the same level with it.

Choice of tank volume

In the trading network today there are many offers for BKN devices, both domestic and foreign manufacturers with round and rectangular tanks, floor and wall mounting.And if for electric heaters the most popular models are from 80 to 100 liters.

For BKN, more powerful options are used, ranging from 200 to 1500 hp. This is due to the fact that many owners use this design to create a storage tank in order to create a uniform load on the heat supply source at night. In such a scheme, hot water is heated at night, and consumed during the day.

The size of the working tank is chosen, taking into account the need to provide all family members with hot water. There is a formula for estimated water consumption.

In practice, the following information is often used:

- 2 users - 80 l;

- 3 users - 100 l;

- 4 users - 120 l;

- 5 users - 150 l.

The dimensions of the BKN are also important to consider during installation. For wall placement, installations with a working volume of the tank - up to 150 l can be used, and with larger sizes it is allowed to install only with floor placement

The installation site must have free access so that the piping can be correctly performed and auxiliary equipment in the form of shut-off and control equipment, safety valves, air vents, pumps and a hydraulic accumulator can be placed.

Connecting an indirect heating boiler with two circulation pumps

If you decide to install an indirect system in the circulation pump system, but at some distance from it, a scheme with two circulation pumps will be relevant for you, in accordance with it, the best location of the pump is in the circuit to the water heater.

In this scheme, the pump can be installed both on the supply pipe and on the return pipe.The presence of a three-way valve is not required here, the circuit is connected here using conventional tees. It is possible to switch the coolant flow by turning on or off the circulation pumps, which are controlled by a thermostat that has two pairs of contacts.

If the water cools down, the pump located in the boiler circuit starts working, and the pump responsible for transferring the coolant to the heating system is turned off. When the water reaches the desired temperature, the reverse reaction occurs: the 1st pump turns off, and the 2nd turns on and transfers the coolant back to the heating system.