Advantages of circulation devices

Until 1990, heating systems in private buildings were designed and built mainly without pumps. The coolant moved through the pipes by gravity, and its circulation was provided by convection flows of liquid when it was heated in the boiler. Currently, natural circulation systems are still used, although not as often.

Inexpensive solid fuel boilers are produced without built-in pumps, because the manufacturer does not know the parameters of the heating circuit. For such systems, the purchase of a water pump is mandatory.

Now the movement of the coolant is carried out forcibly with the help of water pumps, which have a number of advantages:

- Reduced load on the boiler by reducing the temperature difference in the inlet and outlet pipe.

- Uniform distribution of heat throughout the rooms due to the same temperature of the coolant along the entire length of the heating rings.

- Possibility of operative control of temperature of the heat carrier.

- Rapid heating of the heating system when starting a cold boiler.

- No need to install pipelines with a slope to the boiler, providing spontaneous movement of the coolant.

- The possibility of using thin pipes that take up little of the interior space of the apartment.

- The power of the pump allows you to build up enough pressure in the heating circuit to supply the coolant several floors up.

- Use of shut-off valves on separate loops of heating networks.

- The possibility of integrating the pump into the automatic control system of the boiler.

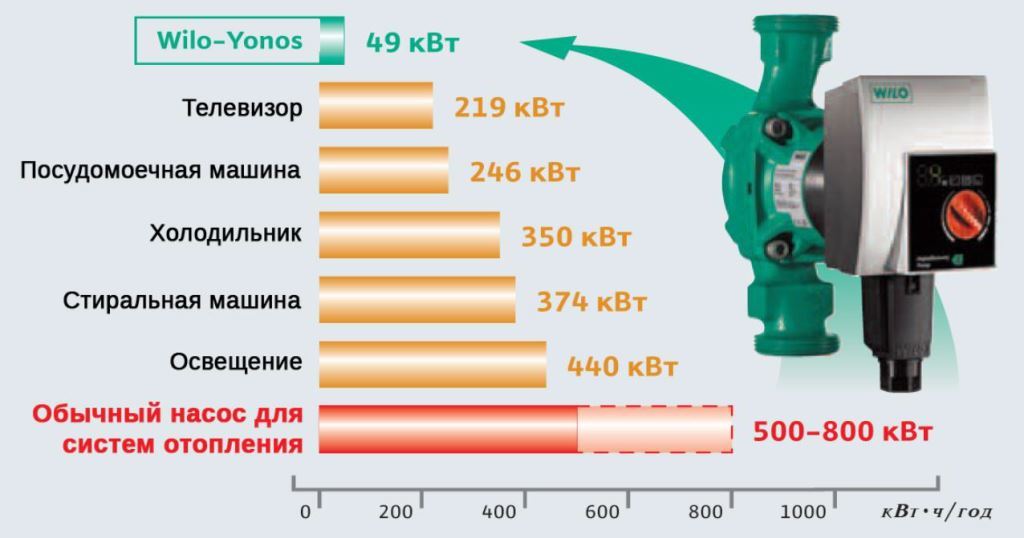

With a lot of advantages, circulating devices also have two drawbacks - this is dependence on power supply and additional costs for electricity.

But the disadvantages are easily compensated - installing a water pump saves 10-20% of fuel, and the share of the cost of electricity in total heating costs is only 3-5%. In addition, in case of frequent power outages, you can install a UPS that will ensure autonomous operation of the boiler and pump for a certain period.

Where to put

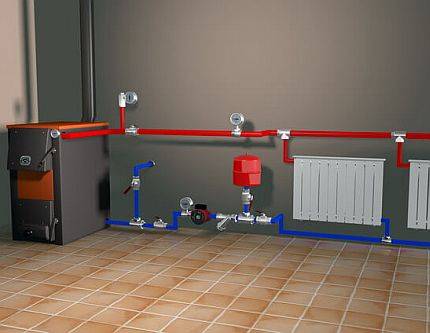

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If in heating system two separate branches - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

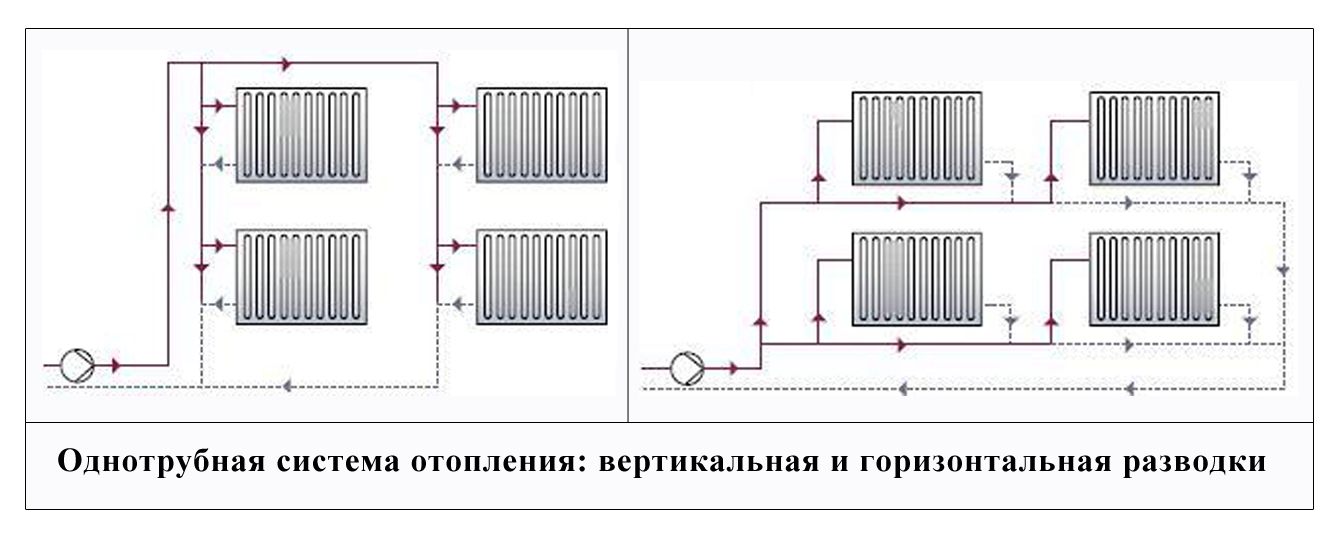

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

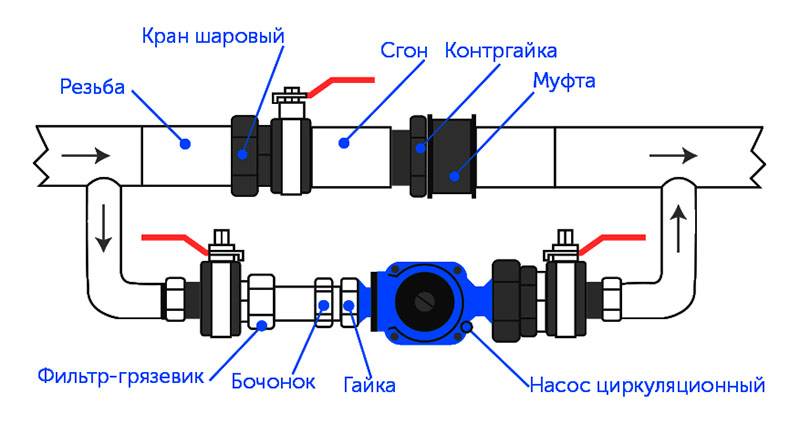

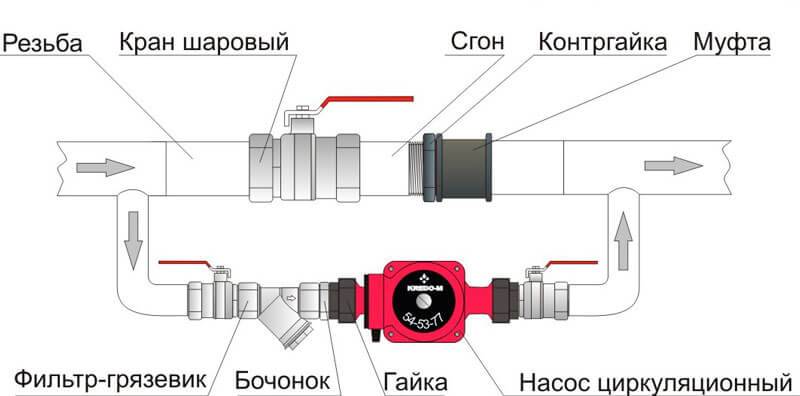

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

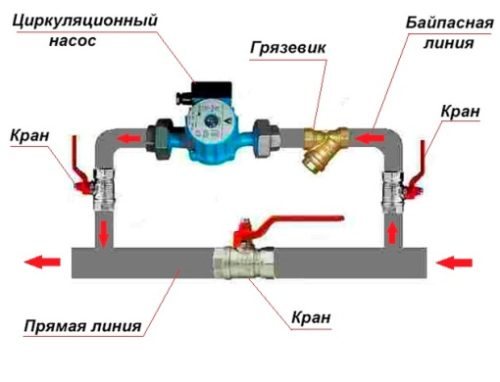

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

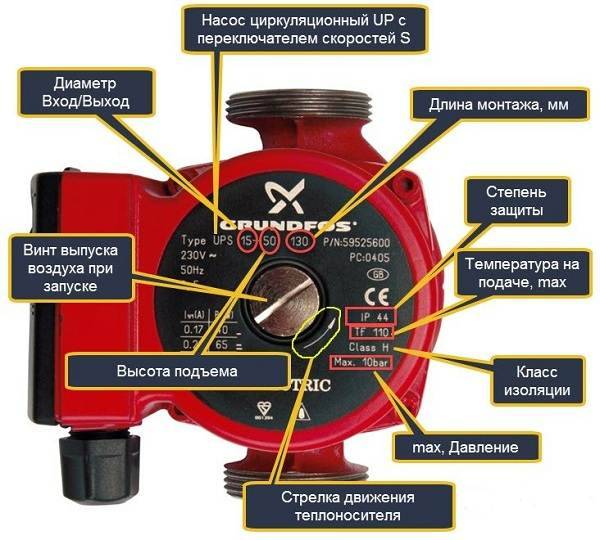

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Rules for choosing circulation equipment

The “wet” type of the circulation pump has a lower noise level. The opposite situation is with a "dry" rotor. In this case, noise is generated not only as a result of the operation of a purely pump, but also a fan, which is responsible for lowering the temperature of the electric motor.

"Dry" devices are mounted in industrial premises, and "wet" ones are relevant for residential premises. After all, the noise level exceeding 70 dB will have a negative impact on the psychological state of those living in the house.

In the arrangement of private houses, the “wet” version of the circulation pump is a priority. Its blades are constantly in the pumped medium, the parts will be lubricated with water and will last 5 years or more.

When you turn on the device in an open heating circuit, you should pay close attention to the quality of the coolant, you should not replenish it with water containing mineral and organic inclusions. The wet rotor option costs less than the dry rotor version.

You should stop at the first one if the heating system does not require a lot of power

The wet-rotor option costs less than the dry-rotor counterpart. You should stop at the first one if the heating system does not require a lot of power

Another criterion is the pressure indicator. So, if for optimal operation of a closed system it is within 10 m, then a “wet” rotor will do. Enough capacity of 25-30 m3 per hour.

When the heating system requires more pressure, then the best option is a pump with a “dry” rotor. In its design, the rotor is separated from the heating pipeline by an oil seal. This variety will consume less electricity than the “wet” counterpart with the same efficiency.

The following formula will help you find out the required pump power:

Q=0.86*P/dt

where:

Q is the pump power, m3/h;

P is the thermal power of the heating system, kilowatts;

dt is the difference between the water temperature before it enters the heating device and after it leaves it.

Let's take a concrete example. Let the area of a residential building be 200 m2. Let's assume that the heating system is two-pipe. To maintain the optimum temperature in winter, a thermal power of 20 kilowatts is enough.

By default, dt is 20 degrees Celsius. This indicator is sufficient for approximate calculations at home.

The result is 0.86 m3/h. We can round up to 0.9. Still, it's better to be safe from error. And over time, the circulation pump wears out, so the power will be less.

Another parameter of the equipment is pressure. Every hydraulic system has resistance to water flow.This characteristic also necessitates the use of the device to ensure the circulation of the coolant in the system.

The parameters of the pump must prevent the resistance of the heating system and ensure the required efficiency

To get the exact value of the hydraulic resistance index, calculations are carried out according to the following formula:

H=N*K

where:

N - the number of floors of the building (the basement is counted as a floor);

K - average hydraulic costs per floor of the house.

K ranges from 0.7-1.1 meters of water column for two-pipe heating systems. And for the collector-beam, its value is in the range of 1.16-1.85.

For example, a two-story house with a basement has three levels. If the calculations are performed by a non-professional, then you can take the maximum value from the above ranges. For a two-pipe system, this is 1.1 meters. That is, we calculate K as 3 * 1.1 and get 3.3 m of water column.

In a three-story house, the total height of the heating system is 8 meters. However, according to the formula, we received only 3.3 meters of water column. This value will be sufficient, since the pump is not responsible for raising the water, but only for reducing the negative effects of system resistance.

Power connection

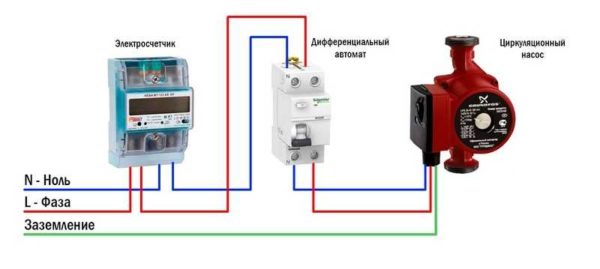

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be organized using a three-pin socket and plug.This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

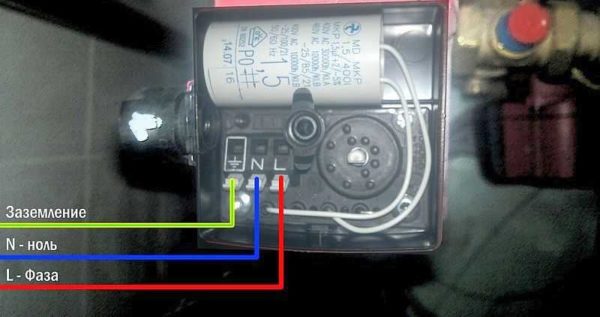

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Nuances of equipment installation

Household devices for forced circulation of water do not consume very much electricity - conventional pumps require up to 200 W, but powerful ones, with a maximum head of more than 10 m, can take more than 1 kW of energy.

Therefore, their contribution to the total current strength of the circuit must be taken into account. In this case, it must be remembered that for such devices the rated power exceeds the active (consumed).

Also, large pumps can operate from 380 V. But usually they heat large areas to which three-phase power lines are connected and there are no problems with their connection.

If the pump has a maximum head of 8 meters or more, then you must remember to look at the type of connection to the power supply

Since the coolant, passing through the system, gives off energy and cools down, its temperature at the end of the circuit is lower than at the beginning. Therefore, it is better to integrate the pump into pipes closer to the heat exchanger inlet, i.e. to "reverse". This will increase the life of the appliance, since very hot water is worse for metal parts than partially cooled water.

The tie-in location must be selected in accordance with the rules for installing pumping equipment, which are given in the installation manual. For each model, there are permitted engine orientations that must be followed.

The heating circuit, as a rule, is designed taking into account the physical laws that justify natural circulation, and the introduced pump must “help” the flow to gain the required speed. In order not to be mistaken with the orientation of the device, there is an arrow on its body showing the direction of pressure.

Sometimes there are unforeseen situations associated with a power outage. In this case, the pump will become an obstacle to the flow, and a sharp slowdown in speed or a complete stop will most likely lead to boiling and damage to the heating system. To prevent this from happening, a bypass pipe is organized at the pump insertion point.

In the event of a power outage, open the valve on the bypass to allow flow. Also, this design allows you to remove the pump without draining the water.

Another way to avoid problems during a power outage is to purchase a backup power supply for the pump. If the power of the device is small and does not exceed 0.5 kW, then the best solution would be a battery and UPS kit with a built-in stabilizer.

With a battery capacity of 200 Ah, a device with a 100 W motor can work autonomously for about 20 hours.

For more powerful pumps, if you need to maintain its operation for a long time in the absence of electricity, you will have to purchase a generator. If you want to automatically turn on the backup power system, then it must support the autostart function and work in conjunction with the automatic selection of the reserve.

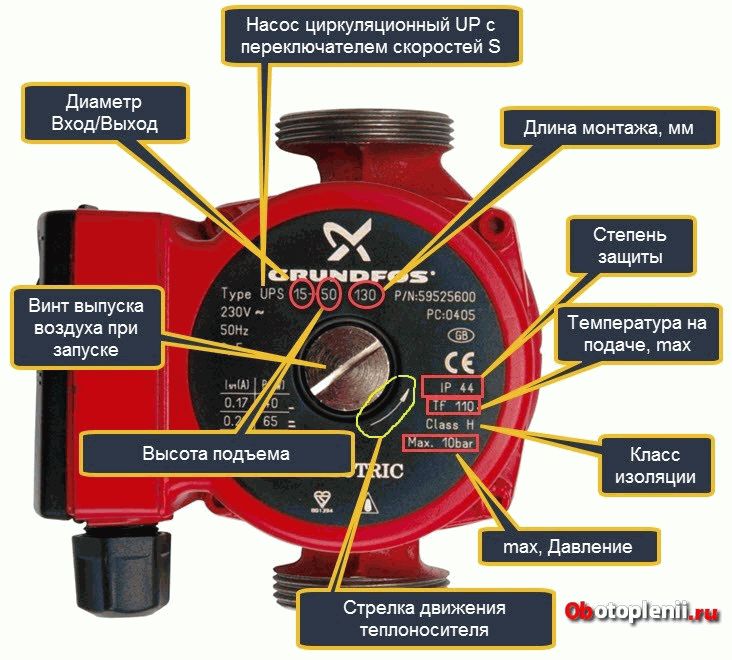

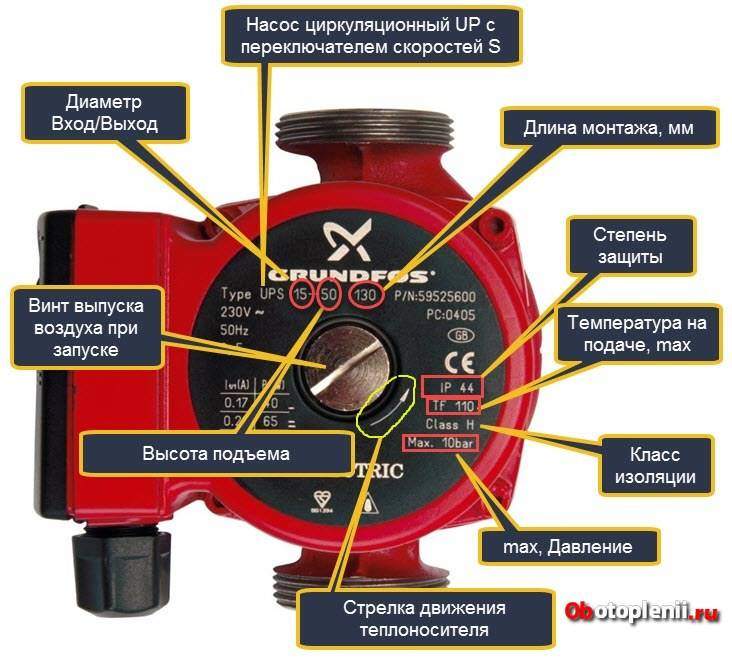

Grundfos pump models

UPS pumps are circulating pumps with a wet rotor. On these models, a motor with an asynchronous type of action is used. The pump is equipped with a special terminal box, which provides the connection of the unit to electricity. During the initial start-up, it is recommended to open the technological opening and bleed the air from the working chamber of the pump. The design also provides for the possibility of manually scrolling the rotor in case of souring.These pumps have three speed modes, which are set manually and ensure the stable operation of certain systems.

The pumps of the new model AIpha 2 (L) are the first in the general line of the series. This pump has more features than UPS series pumps. Here there is an electric motor that has permanent magnets on the body. If one of the magnets is removed, which in many cases is done by Russian craftsmen, the power consumption of the unit can be significantly reduced. Also in the new design there is no technological nut for air release. In this model, air is automatically vented when the pump is briefly turned on at the third speed. Connecting to the power supply has become easier, this is done using a plug connector. This model already has seven modes of operation. To the existing three, two more modes of operation with a constant differential pressure and two modes of proportional control were added.

The operation of the pump in the constant differential mode - assumes stable operation of the pump even in cases where changes in fluid flow and pressure drop occur in the system. A certain level of pressure created by the pump will always be automatically maintained at the same level.

Proportional control mode - this mode of operation ensures reliable operation of the pump in the event that a variable flow occurs in the system. This mode is not replaceable if during operation there is a periodic overlapping of the radiators, which leads to an increase in pressure in the system.There is an automatic decrease in the speed of rotation of the pump, as a result, the flow and pressure in the system will decrease proportionally. There are three main operating modes. The systems in which they are applied;

- warm floor,

- single pipe systems

- dead end systems,

- collector systems,

- two pipe systems

- radiator systems.

The AIpha 3 model can be called the most innovative. This model can be considered as a very accurate tool capable of simultaneously ensuring the reliable operation of the entire system and at the same time allows you to control the flow of the coolant. This feature can be used in conjunction with the Grundfos GO Balance app. The presence of these applications allows you to configure the entire fuel system at a remote location. This equipment can also be used to measure and balance the entire heating system, installing it in place of another circulation pump, suitable in size and dimensions. The pump is especially good when balancing radiators, short loops in the underfloor heating system, as well as at low coolant flow rates. The possibility of a three-fold gradation of modes of both constant and proportional pressure makes this model very reliable and productive. After all, as you know, for any master who installs a heating system, the ability of the equipment to be installed to ensure normal coolant flow is very important, and for the customer, the reliability and efficiency of this system are important. The circulation pump gives a positive result to both. Economical and fairly easy to maintain, this pump is very well suited for arranging autonomous heating in country houses and individual apartments.

Criterias of choice

Before you go to the store, you should make yourself a list of system parameters - the volume of liquid, elevation changes, the number of radiators, length, etc. This data will allow you to check the characteristics of the installation and choose the most suitable instance. First of all, it is necessary to compile a list of the parameters of the boiler itself, since it provides the initial conditions for the operation of the heating circuit. It is necessary to be guided by the rule of maximum compliance - if the device is inferior to the requirements of the system, you cannot buy it - it will not cope. The redundancy of characteristics is also harmful - noise will appear. It is necessary to try to find the best option that allows you to meet the needs of the heating circuit without excessive power or pressure.

Pump performance is calculated by the formula:

Q = 0.86 x P/dt where

- Q - pump performance (calculated);

- P is the power of the system (thermal);

- dt is the temperature difference at the outlet and at the inlet of the boiler.

The resulting value cannot be considered final. It is necessary to make an allowance for the height of the system, otherwise the actual performance will be much less. It should not be assumed that the height of the system can be balanced by the return. In practice, there is always hydraulic resistance created by radiators, turning points, branches and other system components. As a rule, for a two-pipe system (a simple loop without branches), the performance is calculated by multiplying the height by a factor of 0.7-1.1 (depending on the length and number of radiators), and for a collector system, the factor is higher - 1.16-1.85.

There are graphs in the pump passport showing its performance at different speeds.It is necessary to find such an option, where the calculated value and the height of the lift will be approximately in the middle. This position is called the "midpoint". If the calculated parameters are in it, the device will work in the optimal mode.

Expert opinion

Kulikov Vladimir Sergeevich

You should not buy a pump "for growth". If you plan to expand the circuit, in any case, you will have to buy a new device. It is necessary to choose a sample that meets the existing conditions.