- Reasons for clocking

- Gas burner goes out

- How malfunctions of heating equipment manifest themselves

- Heat loss does not match the boiler output

- Incorrect location of the gas boiler in the room

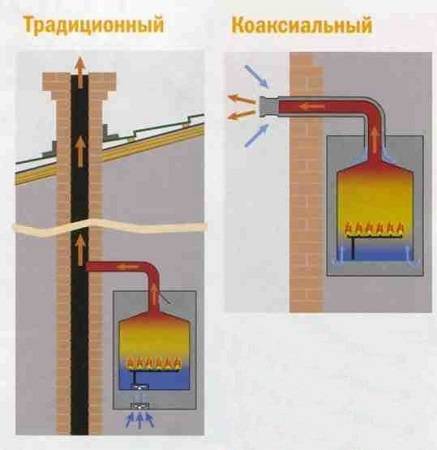

- Problems of open-type atmospheric boilers

- Traction problems

- Head freezing

- Low gas pressure

- Air supply problems

- Weakly burning wick

- Tips for proper proper operation of a gas boiler

- Reconstruction of the chimney is one of the solutions to the problem

- Typical problems with turbo boilers

- Icing of the hood or chimney

- Fan or turbine failure

- Causes 4 and 5 power outages and boiler problems

- Non-volatile boiler goes out

- Electrical circuit problems

- The maximum power is programmatically limited in the boiler

- How to eliminate the hum of the boiler when hot water is turned on

- Incorrect location of the gas boiler in the room

Reasons for clocking

Clocking indicates the frequency of switching on the device that provides heating of the heat carrier. In the absence of external control devices connected to the equipment, most often the time interval between switching on the boiler does not exceed 10 minutes, and by default such indicators are only three minutes. Frequent switching on and off is not a mode recommended for the operation of a gas boiler.

In order to maximize the economical consumption of blue fuel, it is advisable to choose the option of continuous operation of the equipment with compensation for heat losses. Among the main problems provoking the clocking of the unit, one can note:

- overheating of the device in conditions of high power;

- insufficient gas supply pressure;

- erroneous installation of the thermostat;

- various pump failures;

- filter clogging.

In small rooms, excessive gas consumption is often encountered, therefore, when choosing equipment, it is very important to correctly calculate its technical indicators and main operational characteristics. Among other things, the configuration parameters for different models often differ significantly, which implies a mandatory and very careful study of the instructions before setting up the equipment.

Let's look at the main reasons for the constant switching on and off of the boiler.

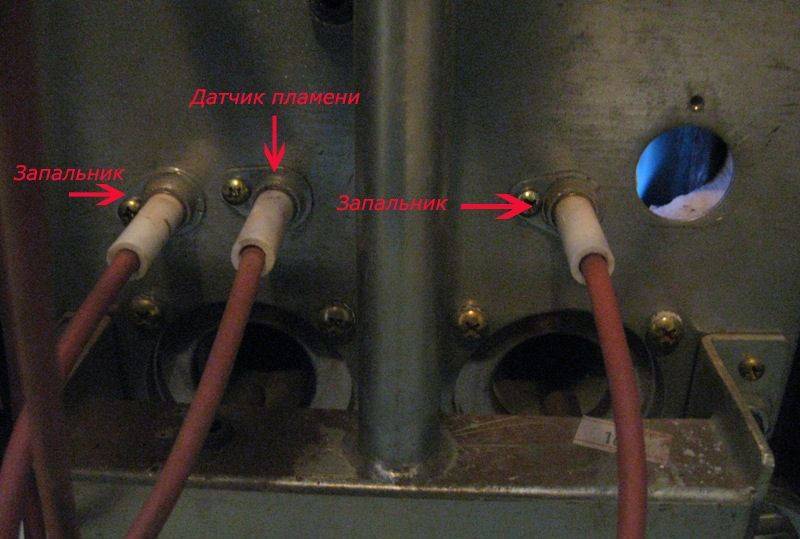

Gas burner goes out

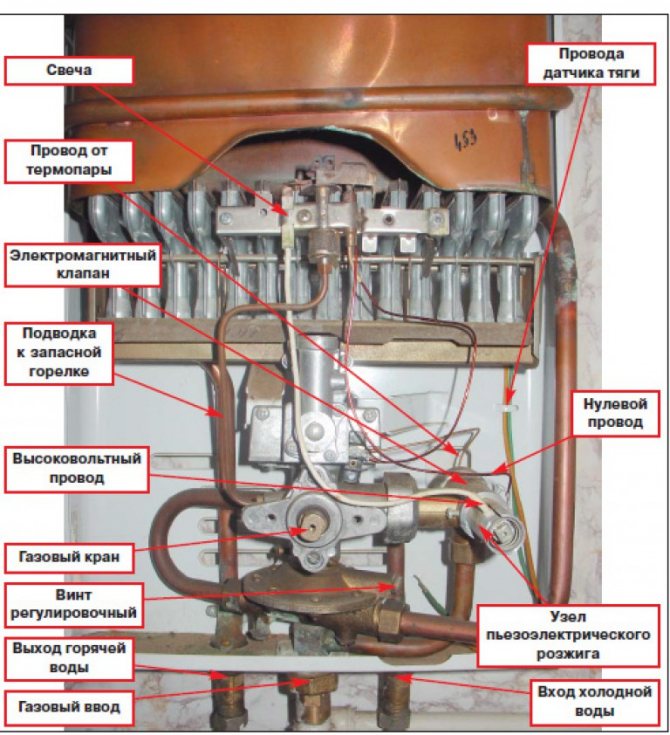

It is also possible that gas and electricity in the AOGV (Heating Gas Water Heating Unit) are available in the proper amount, but the burner is constantly dying out. The equipment turns on, works, and then the flame in the furnace goes out. Here the problem may lie in the draft or the thermocouple that controls the presence of fire. It is possible both a lack of air for combustion, and a breakdown of the internal elements of the boiler.

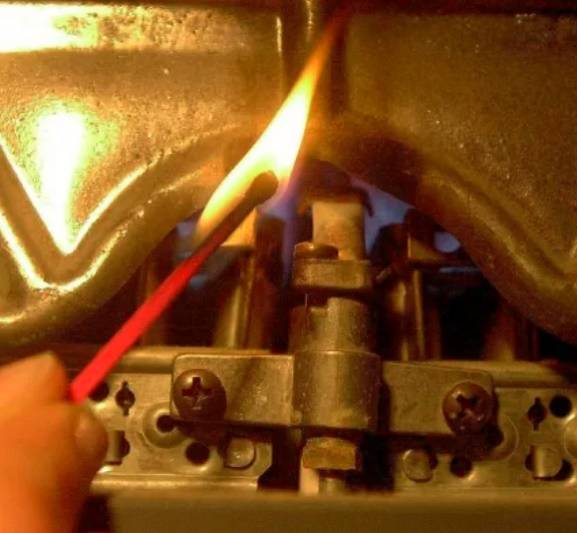

The first option is a malfunction of the thrust sensor or its absence in principle. To check whether there is an influx of air into the furnace, it is enough to bring a burning match to the viewing window of the gas boiler. The flame should deviate towards the firebox. If it is motionless, then there is no traction.

In this case, first you need to slightly open the windows and the door so that the air enters the furnace exactly.If this does not help, then you will have to clean the boiler and chimney. The cause of the problems lies in them, or rather in the accumulation of soot on the walls of the pipe and furnace.

The second option is a thermocouple. This sensor may simply have loose contacts. As a result, the relay blocking the nozzles constantly receives signals that the fire is extinguished. Fuel should not enter the combustion chamber, the solenoid valve shuts off its supply. It is necessary to check the connection of this device with the damper. The connector must be free of oxides and contamination. If they are, then you will have to clean them with a fine sandpaper.

Checking the thermocouple

How malfunctions of heating equipment manifest themselves

Even if a modern model of a gas boiler is used to heat a home, the probability of its breakdown cannot be ruled out. Every piece of equipment has occasional failures. In such cases, the competent actions of the master and high-quality spare parts for the gas boiler allow you to restore its performance. You need to be aware of the reasons that can lead to adverse situations.

There are several signs that something is wrong with the boiler. The most common reasons for the failure of such devices are the following:

- The heating appliance does not start. If nothing happens when you try to turn on the equipment, then the first thing the owner needs to do is to check for the supply of "blue" fuel. If the fuel pressure is weak or absent at all, the device will not work.

- The burner goes out intermittently. Such a problem can occur even in devices that have a natural removal of exhaust gases through a chimney.If the draft in the pipe is insufficient, then the automation will simply block the operation of the installation and turn off the burner.

- The required temperature is not reached. This case should be considered as a whole, since quite often several factors at once can lead to the appearance of such a situation. This usually happens if the air flow in the boiler room is weak. If the chimney is dirty or if low-quality gas is used, you also have to face a similar problem.

Heat loss does not match the boiler output

The constant operation of the boiler may be due to insufficient power of the device. The coolant, having passed through the pipes, returns, and by this time, the water did not have time to heat up due to insufficient power. Therefore, the gas boiler does not turn off. The power of the boiler is selected based on a number of key parameters:

- the area of heated premises and the number of storeys of the building;

- features of the climate of the region;

- the materials from which the house is built, the quality of thermal insulation materials, the quality of seams, window insulation, the number of chambers of window profiles, etc.

- the quantity and volume of all heating devices and pipe circuits installed in the system, additional buffer tanks, separators;

- temperature level to be maintained.

It is best to entrust the calculation of the boiler power to a professional or use special formulas or online calculators that allow you to determine the main characteristic of the boiler as accurately as possible, taking into account all the parameters.

Often, a simple formula is used to calculate power, which is defined as 1 kilowatt of power per 10 square meters. m. heated room.In this case, several correction factors are used that take into account climatic conditions, the degree of thermal insulation of the house and other parameters.

In addition to choosing the boiler itself, it is important to correctly select the remaining components of the system, pipes with the appropriate section to ensure the required throughput

Incorrect location of the gas boiler in the room

The location of the gas boiler in the room also plays an important role. In some cases, such situations were observed when, for example, the boiler is located in the kitchen, which, in turn, is located somewhere on the second or third floor of the building and this kitchen has a balcony.

So what's going on? People open the balcony door, the draft in the chimney is excellent and ... What happens? At first we had some kind of air flow from the corridor or from neighboring rooms when opening the door in the kitchen and the draft was more or less stable. And then, with a sharp opening of the balcony, what happens? A huge amount of fresh cold air enters the kitchen and a very sharp strong draft is formed in the chimney.

The amount of air increases and hot air begins to go into the chimney at an even greater speed. Thus, the wick literally begins to oscillate, to walk. That is, it can simply either be blown away, or if there are bad contacts in the safety circuit, or worn sensors. This can also lead to the fact that your boiler will go out.

It is worth noting that the above reasons are the most common problems. There are special cases where the cause of the damping and blowing out of the gas boiler can only be determined by a specialist as a result of a thorough examination.

Only one thing is important - follow the safety rules for gas supply and follow the standards prescribed there.

Problems of open-type atmospheric boilers

If your machine has been working properly for several years, and now the burner lights up and goes out, look for a problem among the indicated causes.

Traction problems

To check its presence or absence, light a match and bring it to the control window. In the presence of traction, the fire will deviate to the side; in the absence of it, it will burn evenly.

What leads to a violation of traction:

Weather. Wind, rain, atmospheric pressure affect the operation of the chimney. Foreign objects entering the shaft can lead to backdraft and carbon monoxide poisoning. It is necessary to clean the passage, install a check valve that will protect the system from such situations.

There is no proper ventilation. Natural ventilation is required to maintain the flame in an open chamber. Air intake comes from the room

Therefore, it is important to have a window with a window. Slightly open the window to resume the operation of the equipment.

frost

Condensate accumulates on the walls of the mine, after which it freezes. As a result, a layer of ice interferes with normal draft and smoke removal. The accumulated layer is knocked off, and the walls of the shaft are insulated to avoid such cases.

- Soot accumulation. This often happens when a solid fuel and gas boiler is connected at the same time. If you live in an apartment building, it is better to contact the utilities.

- The pipe burned out. Only a complete replacement will help.

As a result of the development of neighboring sites, a tall building can overlap your house, and the chimney falls into the leeward zone. Therefore, the recommended height of the shaft is from 2 meters above the roof.

Head freezing

The head is the part of the boiler that is outside. In case of severe frost, the ice freezes inside and outside, then it cannot be knocked down. Therefore, the head is removed and defrosted. In this state, the device can be started, but first the unit must be warmed up. To do this, turn on the gas valve, then, gradually unscrewing, light the burner. Gradually increase the feed until the structure warms up.

Low gas pressure

If the burner constantly flashes and goes out, then the gas supply is unstable in the system. Wait for the pressure to recover.

Other reasons why the flame goes out:

- Gas leakage at joints. If you smell an odor, close the shut-off valve and contact the repair service.

- Clean the gas filter of the Mimax, Keber or any other boiler, try re-igniting the burner.

- Poor ventilation is the reason why the wick went out. How to adjust the air supply? Open a window or window, install a ventilation valve.

- Blockage or malfunction of the meter. After repair, the pipeline may become clogged inside the meter. In the event of a breakdown, you can hear crackling, noise, on the screen the numbers jump in jerks.

Air supply problems

Did the wick go out after switching on? If this happens frequently, check if there is enough air in the system. As we wrote above, an open chamber will not function without proper ventilation. Open the window and look at the flame in the burner. If it has stabilized, then there is not enough air under normal conditions.

Why does this happen:

- Newly installed plastic windows. The bags are sealed and do not allow air to pass through, so it is recommended to install a ventilation valve.

- You have replaced the door to the room.According to the norms, the gap between the lower part of the door and the floor must be at least 5 cm. When completely closed, the air flow stops.

- Simultaneously with the boiler, a powerful (forced) hood is turned on, which pulls the flow. Turn off the hood while the heating equipment is in operation.

In strong winds, parapet boilers suffer. Some of them are hung on the wall of the house from the outside, thus removing the products of combustion. If gusts of wind blow into one of the grilles of the device, then reverse thrust may occur. To solve the problem, identify the windward side and close the grating on that side.

Weakly burning wick

Gas boiler wick

The wick burns weakly for two reasons: either it is clogged and needs to be cleaned, or you have low inlet pressure. If you have a home controller, be sure to check its settings. You may need to increase the inlet pressure, as it constantly fluctuates due to the fact that the gas consumption is different in different periods.

Accordingly, during the heating season, when gas boilers are operating, gas consumption is greater and the inlet pressure also drops. And the regulator, as far as you know, keeps a certain differential between the inlet pressure and the outlet pressure. Accordingly, this differential also falls, because of this, your wick may burn weaker. Check the regulator setting and also clean the wick.

Tips for proper proper operation of a gas boiler

Any piece of equipment wears out over time. Therefore, when buying, it is necessary to carefully study the instructions and the main elements in order to know what can break. Knowing the design, you can determine which part is out of order.

The boiler will go out in strong winds, and therefore it is advisable to cover the chimney with protective caps.

If a gas boiler (Conord, Mimax or other popular types) is still under warranty, then the manufacturer should not repair it himself. In this case, you need to contact a specialist who will carry out the appropriate repair.

About once every six months, it is advisable to check the chimney for contamination in a gas boiler.

If you use the equipment correctly and follow the recommendations of experts, observe safety precautions, then problems with attenuation can be avoided or eliminated on your own.

If the damage is serious, then you will have to contact the service center, where they will replace the failed parts.

This information will be enough to understand what to do if the gas boiler goes out.

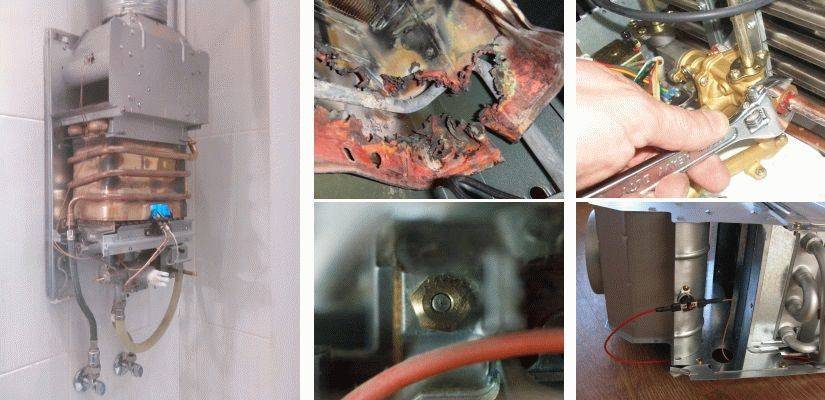

Reconstruction of the chimney is one of the solutions to the problem

The first sign of a permanently fading flame is an improperly designed chimney. It makes no sense to look for other reasons why the gas floor boiler blows out in the wind with such equipment. The gas supply is carried out under constant pressure, there are almost no significant drops. Any equipment malfunctions are unlikely, as modern boilers are reliable and simple in design. For example, the Conord boiler is known for its reliability and performance.

As for the chimney, here the answer to the question of why the boiler blows out in a private house can be called such moments:

The ventilation channel of the heater is covered with an ice crust.As a result, the air circulation inside the chimney is disturbed and the gas boiler does not receive enough oxygen. In addition, water vapor enters the chimney channel, which is cooled from the ice layer and forms condensate. In turn, water drops freeze on the walls of the chimney and the ice crust grows. To solve the problem of what to do so that the gas boiler does not blow out, the insulation of the chimney channel helps. In this case, the resulting condensate will flow down the walls.

The occurrence of back draft due to insufficient height of the chimney. The increasing or changing direction of the wind creates a strong air flow that enters the chimney channel and reaches the combustion chamber. As a result, the flame in the burner is extinguished.

This situation is considered more dangerous, so it is important to know what to do when the boiler blows out in strong winds. The reverse movement of warm air captures the combustion products along the way, therefore, they enter the boiler and pollute the combustion chamber. It is not excluded the ingress of harmful gases into the living quarters.

It is not excluded the ingress of harmful gases into the living quarters.

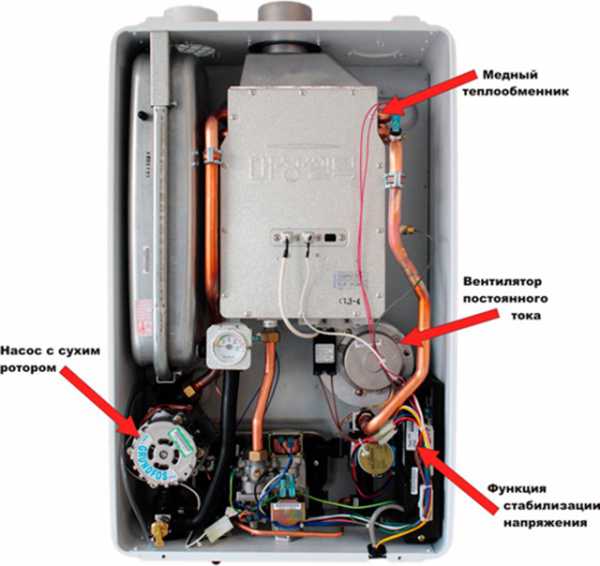

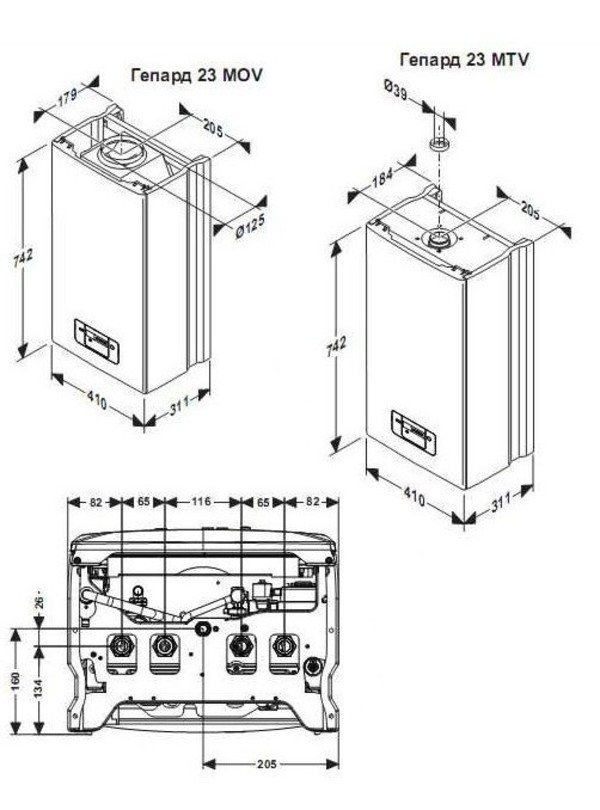

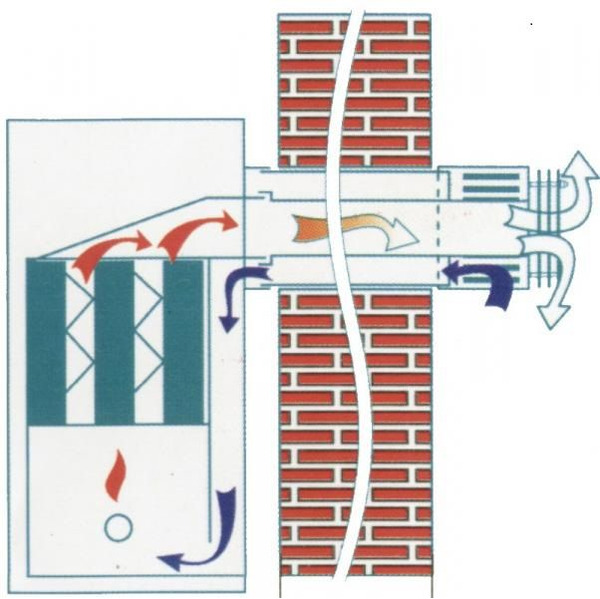

Typical problems with turbo boilers

The problems described above also apply to turbocharged boilers. But in addition, given the equipment with additional elements of boilers with a closed combustion chamber, additional “troubles” can also happen to them.

For example, in the process of their operation, you may encounter the following difficulties:

- icing of the coaxial chimney outside the house;

- failure of the built-in air blower.

Their design, of course, is more complicated than that of models with an open combustion chamber.But at the same time, all the same manipulations can be carried out with them as with atmospheric boilers.

The accumulation of condensate and icing is also a common cause of boiler damping. This happens if during installation the normative slope was not observed, which ensures the flow of condensation moisture.

But let us dwell in more detail on the breakdowns characteristic of this particular type of equipment.

Icing of the hood or chimney

If you observe that the boiler goes out most often in cold weather, then most likely the chimney outlet is blocked by an ice mass.

This may be due to:

- formation and accumulation of condensate;

- snow sticking.

As you can see, the reason is bad weather conditions. Therefore, the solution to the problem is to protect the chimney from external factors.

In this case, again, it is worth considering the option of installing a "fungus", i.e. deflector. But this is a preventive measure. But what to do if the problem is already “overdue”, and the weather conditions exacerbate the situation even more? There is a way out in this situation.

You can “melt” the chimney, that is, rid it of ice plugs, by yourself using a building hair dryer or a gas burner on a can

The settling of condensate in the pipes is typical for convection boilers with a coaxial chimney. Plugs are formed in them due to the temperature difference between the air flows drawn into the burner from the street and going outside. These ice jams block the path both to and from the combustion chamber.

To remove the ice crust from the coaxial chimney, it may even be necessary to dismantle its outer part. Dismantling will not affect the daily operation of the system, but it is still better not to bring it to this.Sometimes, in order to prevent the accumulation of condensate in the gap between the pipes, a pair of holes are drilled in the outer contour.

Just breaking the ice is not an option. Moreover, the chimney can be damaged. It is better to buy a portable gas burner with a can and “melt” the chimney with it. After the cork melts, the boiler will work again. But so that such incidents do not arise in the future, the pipes should be insulated.

The second prerequisite arises in cases of installation of eaves caps: they protect the chimney from precipitation, but in winter they cause more trouble than good, making it difficult for the outflow of flue gases.

Fan or turbine failure

When the wick of a gas boiler with a built-in supercharger does not light up suddenly during operation or does not initially light up, listen to what sounds it makes.

During normal operation, the turbocharging system should hum steadily, so with the appearance of extraneous noise, you should be on your guard.

Turbocharging, applied to the design of boilers with a closed combustion chamber, in most cases cannot be repaired - it is easier to replace it immediately

If there are none during operation, the breakdown is obvious: that is, the automation does not allow you to open the protective valve, so the wick does not light up.

In this case, we strongly recommend that you do not engage in amateur activities, but immediately call the gas workers. In most cases, a turbocharger cannot be repaired - most likely it will have to be changed, and such work is associated with the risk of carbon monoxide spreading throughout the room.

Therefore, it is better if the control over this process will be carried out by a gasman from a company with which a contract has been concluded for equipment maintenance and gas supply.

Causes 4 and 5 power outages and boiler problems

Since a modern gas boiler is equipped with electronics that operate on current, it can turn off during power outages. At the same time, when the voltage returns to normal, the automation itself turns on the unit again. However, due to this mode of operation, some elements of the boiler may fail. To avoid this, you should purchase a voltage stabilizer.

If all systems are checked, and the boiler still goes out, then the matter is directly in it. It can be turned off for the following reasons:

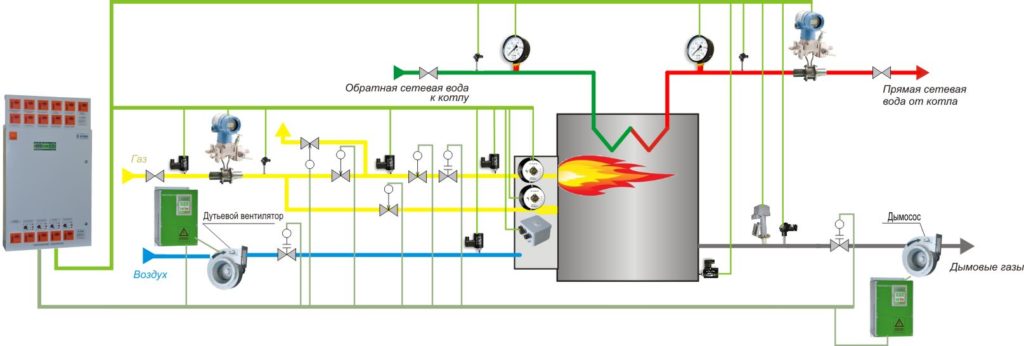

Scheme of the functionality of a gas boiler.

- burner problems. This element of the unit is very often clogged. Because of this, the boiler goes out. To solve this problem, it is necessary to clean the burner nozzles with a thin wire or brush. If it does not turn on at all, then the reason is a clogged filter. It can also be cleaned with your own hands;

- incorrect operation of the igniter. If flame separation is observed during operation of the boiler, then the pressure is not selected correctly. It is required to adjust this parameter on the igniter;

- sediment breakdown. When this element fails, you can observe how the boiler goes out and a lot of noise comes from it. The pump needs to be repaired if possible, otherwise it needs to be replaced.

Non-volatile boiler goes out

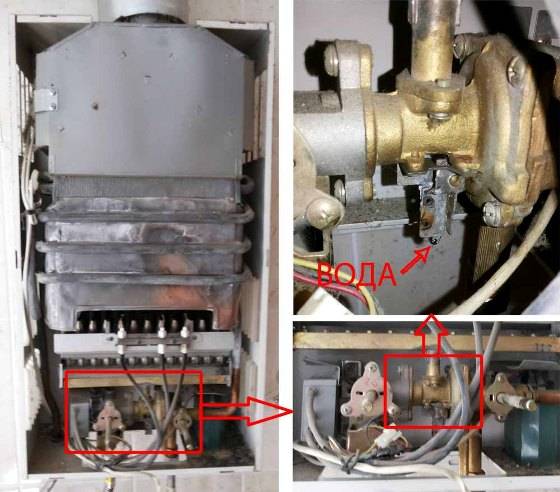

Conventional atmospheric gas boilers also have a number of features that lead to trouble in the form of burner damping.

- When trying to ignite the boiler, the igniter goes out immediately after the gas supply valve button is released.In this case, it is worth sinning for a malfunction of the thermocouple, which heats up from the wick and maintains the solenoid valve in the open state.

- Even the ignition of the burner and igniter does not occur. Most often, this is a weak contact in the electrical circuit between the automation unit and the draft sensor. It is worth cleaning the contacts with fine sandpaper and stretching their connections.

- Weak wick burning or unstable twitching yellow flame. The reason for this is a clogged gas supply nozzle, namely jets or a strainer, or both at the same time. Solving the problem by cleaning and blowing the listed elements.

Let's sum up a little. There are a lot of reasons why a gas boiler goes out. If this still happened, I recommend that you first try to establish the cause yourself, and not call the gas service. After all, everyone wants to make money. It is easy for an experienced gasman to breed an amateur (owner) for money. And the reason may not be in the boiler at all.

Electrical circuit problems

When the solenoid valve (EMV) makes poor contact with the thermocouple, false indications of no flame are given. Because of this, the fuel supply is blocked.

For this reason, the gas boiler lights up and goes out after a short time or when options are selected.

This is a symptom of a problem in the electrical circuit:

- The thermostat and thermocouple or the vacuum indicator do not contact.

- The thermocouple is outside the flame or does not provide the required voltage.

- The indicated parts and the EMC coil are broken.

These difficulties can be eliminated with your own hands, strictly following this algorithm:

- Consistent check of resistance on indicators and contact devices. The norm is considered to be indicators of 0.3 - 0.5 ohms.

- Cleaning of all oxidized areas with fine sandpaper. Tightening loose contacts.

- Disconnecting the thermocouple from the main unit. Tester connection. Turning on the pilot burner by pressing the release button.

- Voltage measurement. Normalized values: 10 - 50 mV.

If the readings are normal, adjust the position of the thermocouple. In the absence of voltage, the following measures are needed:

- remove the top cover of the main unit,

- thermocouple warms up with the help of a torch,

- pressure is applied to the safety valve, after which it is released.

If the thermocouple does not work correctly, the wire contacts are checked.

If, after pressure and release, the valve is static, it is necessary to remove the complex with contacts and direct a voltage of 220 V to the coil, bypassing the thermostat.

Then the boiler starts up. If problems persist, the EMC coil and thermocouple must be replaced.

The maximum power is programmatically limited in the boiler

There are cases when the power of the boiler, declared by the manufacturer, corresponds to the volume of the coolant and the area of \u200b\u200bheated premises, while the gas pressure is normal, but the power of the device is not enough to maintain the desired temperature. The reason may be the maximum power limit in the software settings. To fix this problem, you need to go to the menu and change the settings. If you can’t cope with the task yourself, or if the electronics are faulty, you need to contact a specialist. The boiler will stop working constantly, switch to high power and start turning off.

Read also:

How to eliminate the hum of the boiler when hot water is turned on

In the event of noise from the boiler, you can resort to the following measures:

- call a master specializing in the repair and maintenance of gas boilers;

- try to find the cause of the problem yourself. To do this, it is necessary to diagnose all the nodes of the system - from the gas pipe to radiators and hot water taps;

- clean the system with suitable products. You can use special factory chemicals or folk remedies such as vinegar and citric acid;

- check the pressure in the system, and if possible adjust it to the optimum level.

Do not interfere with the operation of the equipment in the absence of professional skills. This entails a serious danger to others. Work with gas equipment should be trusted only by specialized craftsmen. It is best to contact a service center recommended by the boiler manufacturer.

Climate technology Boiler

Incorrect location of the gas boiler in the room

The location of the gas boiler in the room also plays an important role. In some cases, such situations were observed when, for example, the boiler is located in the kitchen, which, in turn, is located somewhere on the second or third floor of the building and this kitchen has a balcony.

So what's going on? People open the balcony door, the draft in the chimney is excellent and ... What happens? At first we had some kind of air flow from the corridor or from neighboring rooms when opening the door in the kitchen and the draft was more or less stable. And then, with a sharp opening of the balcony, what happens? A huge amount of fresh cold air enters the kitchen and a very sharp strong draft is formed in the chimney.

The amount of air increases and hot air begins to go into the chimney at an even greater speed.Thus, the wick literally begins to oscillate, to walk. That is, it can simply either be blown away, or if there are bad contacts in the safety circuit, or worn sensors. This can also lead to the fact that your boiler will go out.

It is worth noting that the above reasons are the most common problems. There are special cases when the cause of attenuation and blowing out of the gas boiler can only be determined by a specialist as a result of a thorough examination.

Only one thing is important - follow the safety rules for gas supply and follow the standards prescribed there.