- The geyser goes out as a result of the gradual extinction of the flame

- Reason 1 - Weak traction

- Water doesn't heat up well

- Reason 1. Insufficient speaker power

- Reason 2. The column is clogged

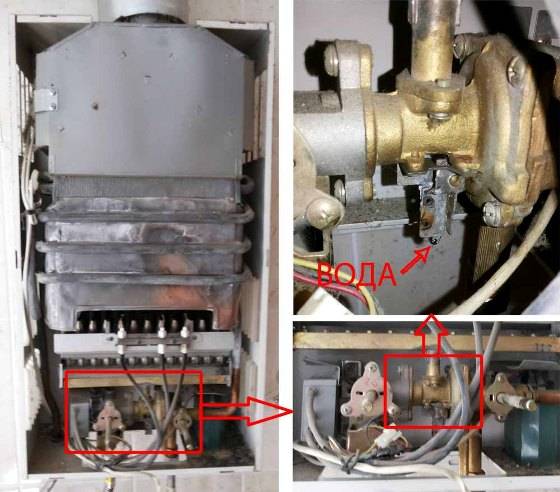

- Cause 3. Damaged column water assembly membrane

- Cause 4. Incorrectly installed water inlet-outlet hoses

- Other Sources of the Problem

- Elimination of violation of traction

- Basic steps

- Typical problems with turbo boilers

- Icing of the hood or chimney

- Fan or turbine failure

- Removing a clogged burner

- 3 Possible solutions - how to fix a column without specialists?

- Preventive measures

- Variety of used geysers

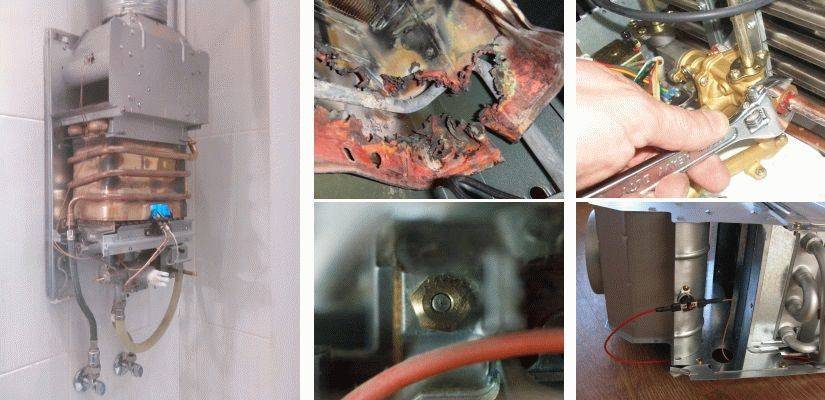

- Common Problems

- Water does not heat up

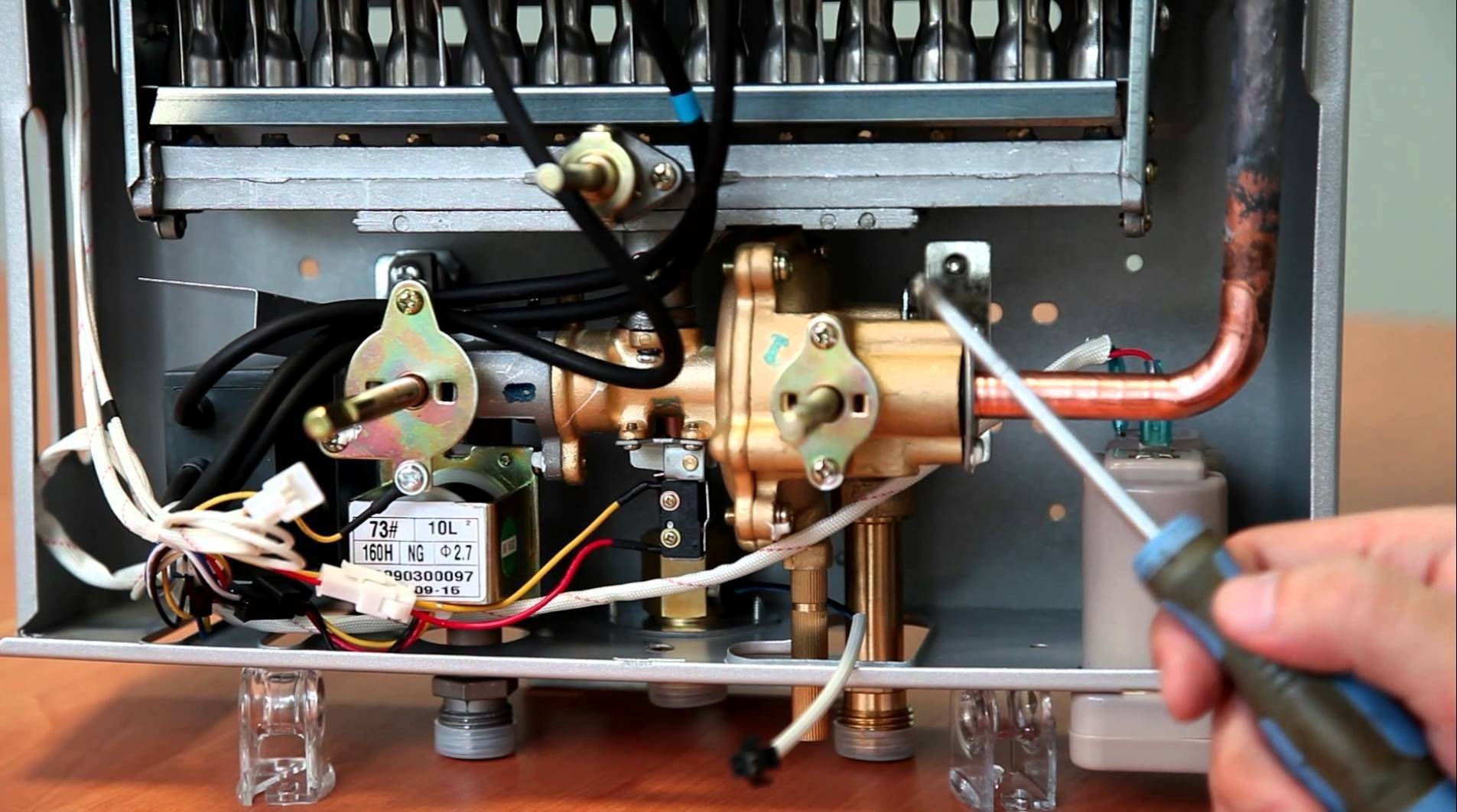

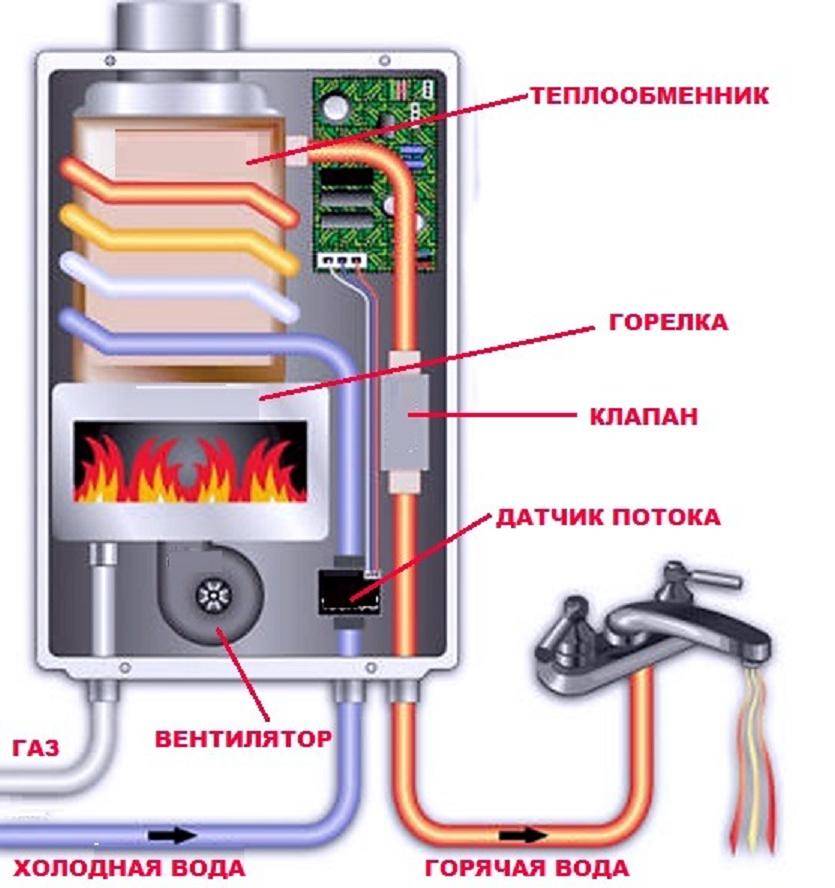

- Principle of operation

- Clap Questions

- Does the pressure of water affect the performance of the column?

- Other Sources of the Problem

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

The geyser goes out as a result of the gradual extinction of the flame

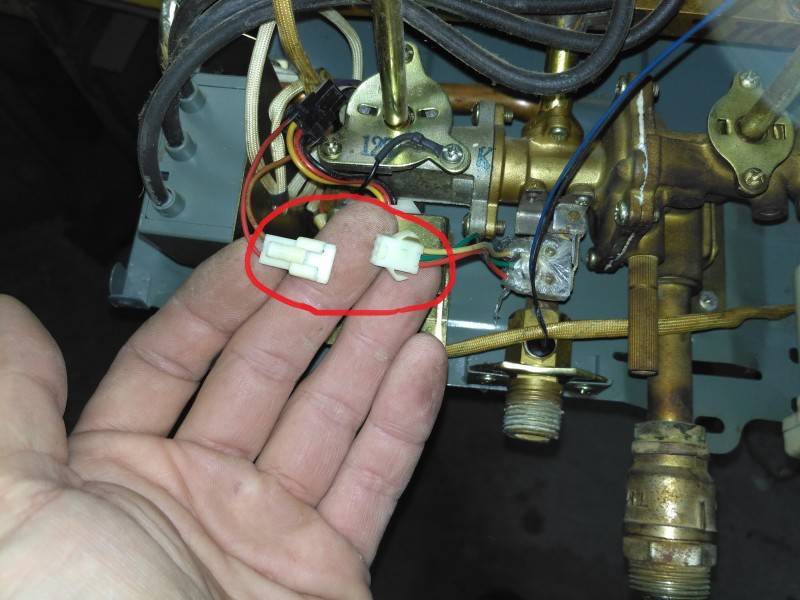

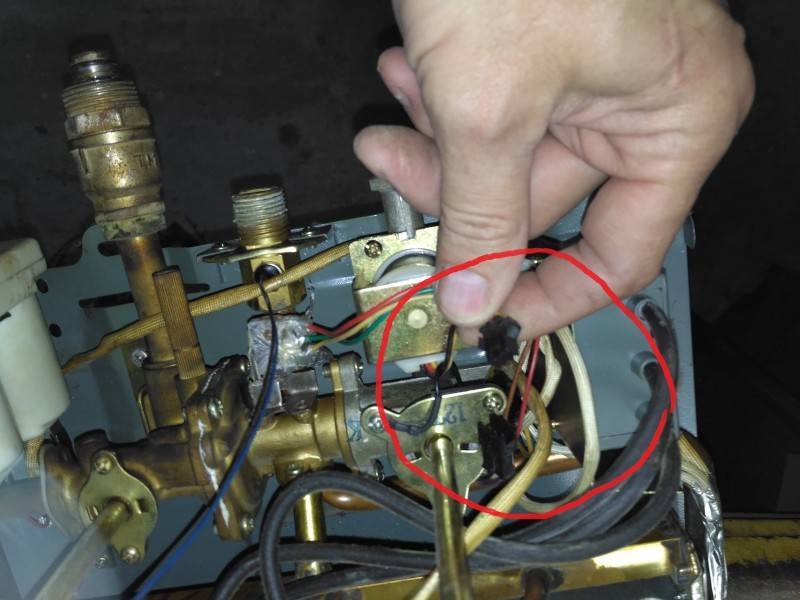

Another problem is the gradual extinction (reduction) of the burner flame after a short operation of the column. This is clearly due to the destruction of the water block membrane.

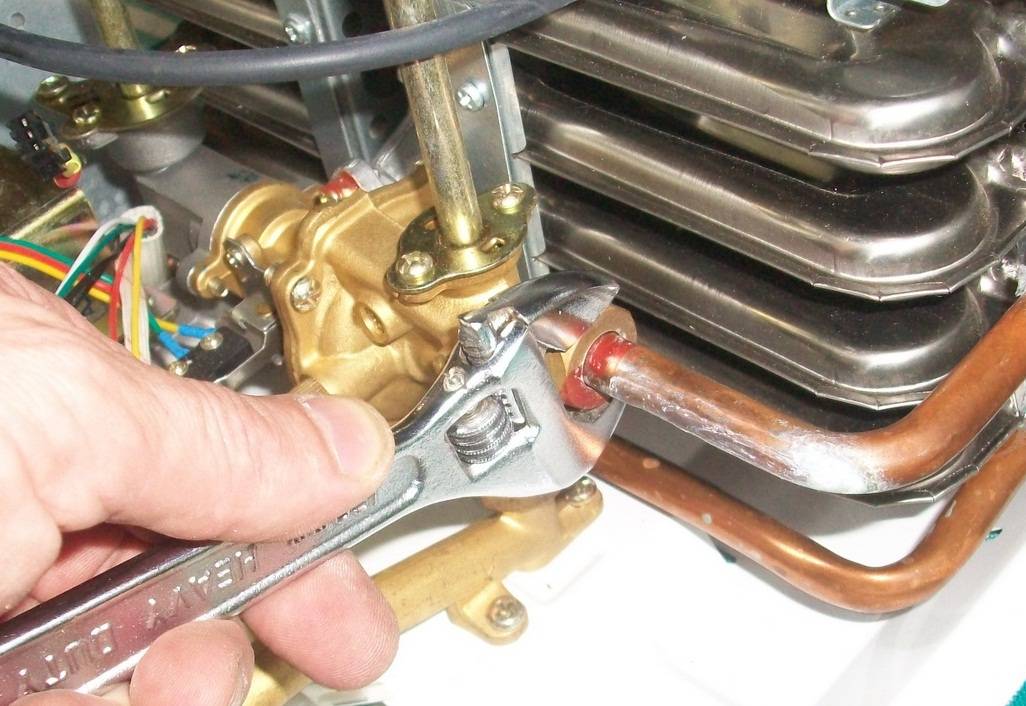

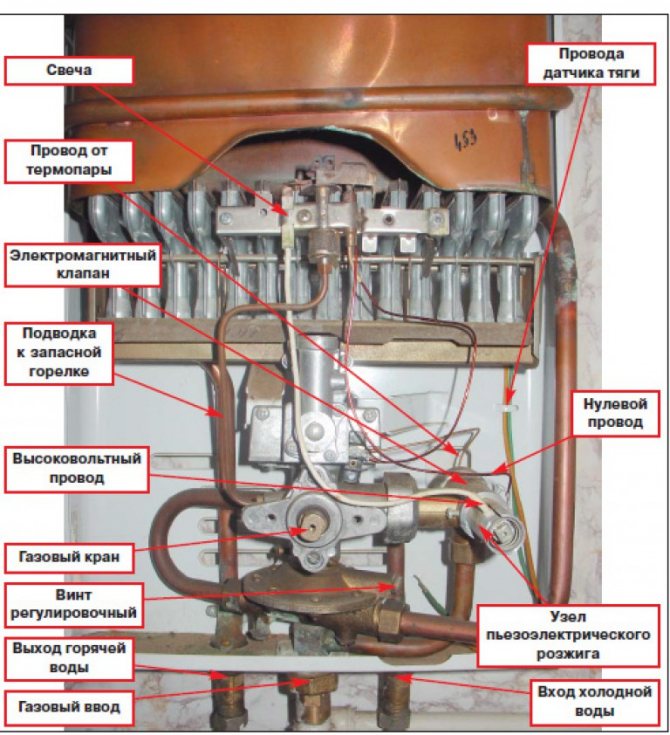

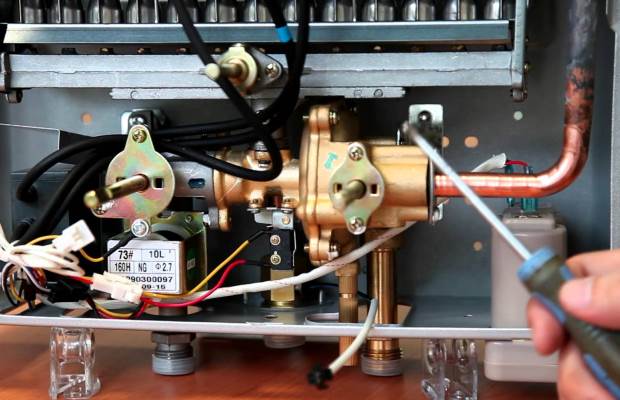

To repair, you will need to remove and disassemble the water-gas unit, which is designed to turn on the column, and also provides flame adjustment and flow of incoming gas.

The price of the membrane is from 200 to 300 rubles. To get to it and replace it, you have to work hard.

2016-11-12 Sergey Dyachenko

There are a number of reasons why a water heater flame may go out. To find out why the geyser goes out after turning on (read about the reasons for the failure of the Oasis column), you need to remember the time of its operation and your actions.

Reason 1 - Weak traction

The products of combustion must be removed through the chimney. When they are heated and there are no obstructions, this happens quickly. If the carbon dioxide and steam have time to cool, they can sink back into the column and contaminate the mixture of gas and air.

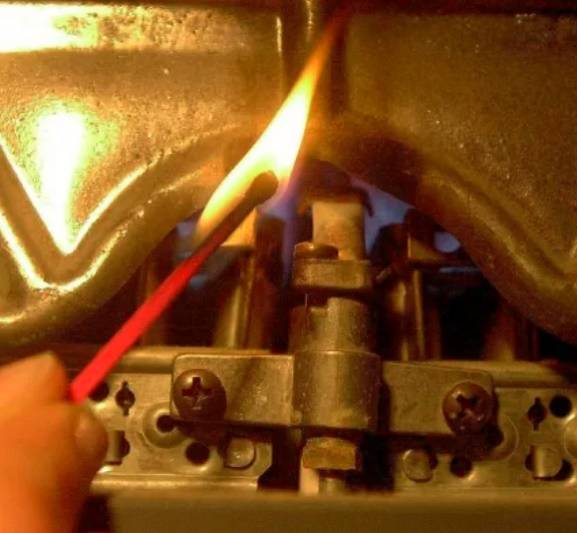

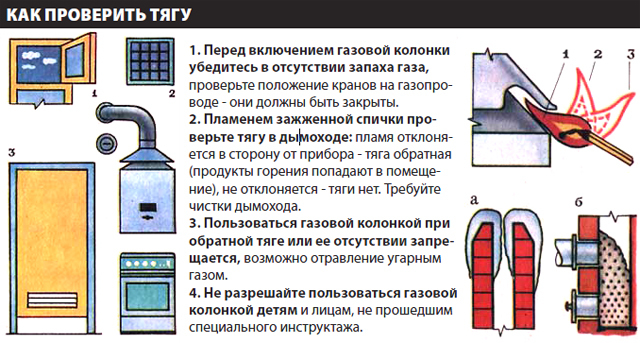

Traction test

To check the intensity of the draft, you need to bring a burning match or lighter to the chimney outlet (also in some models there are special control holes for this). The flame must actively deflect towards the water heater. If it stays in place, it indicates weak traction.

The main cause of weak draft is clogging of the chimney. Over time, soot accumulates in the chimney, which narrows the diameter of the pipes. Also, debris can get into the chimney from above. If the blockage is small, you can remove it manually. If the chimney is clogged much higher up the riser, you need to call the utilities for cleaning.

Also, if an active hood with a fan is installed in the kitchen, then the exhaust gas can be drawn into it, instead of going up. It is necessary to turn off the propeller during the operation of the water heater.

If metal-plastic windows are installed in the room and they are closed, then the lack of incoming air may interfere with the draft. For safety reasons, you should use a gas water heater only with an open window (or with a plastic window open for ventilation).

Water doesn't heat up well

Reason 1. Insufficient speaker power

Perhaps you often need to simultaneously supply water to the kitchen and bathroom, and the column does not have time to warm up such a volume.

Solution:

- Choose a unit with more power.

- Turn on hot water in different rooms alternately.

Reason 2. The column is clogged

Blockage can occur in the burner or heat exchanger due to excess soot. It will be signaled by a red-white color of the flame with normal water pressure.

The solution is to clean the column, preferably with the help of a specialist.

Cause 3. Damaged column water assembly membrane

If at first there is water of an acceptable temperature, but gradually it becomes colder, the flame of the column is blue, and the light is weak, then the problem is in the integrity of the membrane. Cold water is wedged into the hot stream, and the outlet temperature drops.

The solution is to replace the membrane.

Cause 4. Incorrectly installed water inlet-outlet hoses

If you just turned on a new column, and there was still no hot water, it is likely that errors were made during installation.

The solution is to switch the hoses.

Other Sources of the Problem

Let's look at other problems that cause the column decay problem after ignition.

For the same reason, you should not place a powerful hood next to the column. During its operation, sensors may be triggered, diagnosing a malfunction.

Sometimes the reason is hidden in the absence of natural ventilation.It is necessary to open the window or install a supply valve.

"Smart" geysers may not ignite due to a burned out control board. They are sensitive to the quality of the electricity supply, so they must be connected through a stabilizer and not turned off at night

Also, during the operation of the heater, it is not recommended to mix hot and cold flows. This leads to a drop in pressure in the line and attenuation of the wick.

The problem is solved by adjusting the indicators to a comfortable level and reducing the pressure with a special handle. If you still have to mix water, you need to leave the main hot stream.

Attenuation can cause a malfunction of the solenoid valve or servomotor. Only calling the wizard will help here.

Elimination of violation of traction

To test the thrust, try using an ordinary match. Bring it to the chimney and determine if there is a draft, then the flame will deviate towards the chimney.

If there is no draft, then the geyser will not ignite, and users will not receive hot water. In many columns, draft sensors are installed, and if they show insufficient draft, ignition will not be possible. There are situations when the flame ignites and immediately goes out - this is due to the fact that the combustion products simply have nowhere to go, they remain in the combustion chamber, and the flame goes out due to lack of oxygen. Lack of draft will require an inspection of the flue gas collector and the chimney itself. If there are blockages, they can interfere with the normal passage of combustion products. The column perceives this as a lack of traction and does not allow the gas to ignite (or the gas goes out immediately after switching on).Unfortunately, only a part of the chimney, which is visible before entering the wall, can be independently checked - further work should be carried out by specialists. If the house is private, you can try to deal with the chimney yourself.

Basic steps

What to do if the geyser whistles? The first step is to determine the source of the sound. Shut off the gas. Open the faucet to the hot water position. If the problem is not serious, the gas unit immediately stops whistling.

If the whistle only gets louder, pay special attention to the water path. Learn its components: pipes and maintenance, and its components

They could get dirty. A particularly common situation is the accumulation of scale on them.

And scale often accumulates if the set temperature parameters of the water constantly exceed the value of 60 degrees.

Backpressure should be done only after turning off the gas and water. It is also required to unscrew the eyeliner at the inlet.

The easiest way to carry out this operation is to use a faucet in the bathroom. The shower switch must be set to the neutral position. The taps should be slightly open.

To remove lime deposits, use a descaling agent. You can work with folk remedies: acetic or citric acid. They are bred in the correct proportions. The resulting composition is poured slowly into the water path. By the degree of attenuation of the sound, it is added. Then repeat this procedure three more times.

And when you open the tap, and there is no whistle, the problem could be hiding in the gas path. This means that there is a possible damage to the valve for adjusting the power of the flame.

This is the most common answer why the unit does not stop whistling.The problem manifests itself especially clearly when the optimal ratio of gas flow dynamics and valve clearance width is reached. This ratio in different columns can have different values.

If a geyser whistles when working in enhanced mode, it is necessary to adjust the regulator until the opposite sound disappears completely. Turn it smoothly, then in one direction, then in the other. The dynamics of the gas flow will decrease. It is not enough to produce sound. If it is increased, the valve clearance will expand, and the unit may start whistling again.

If these measures do not give the desired effect, then the gas path is clogged. The device will whistle even louder. It is urgently required to disassemble, calculate the problem area and thoroughly clean it.

If your geyser is still under warranty, contact the service immediately. You will have to go there if the warranty period has expired, and you cannot solve the problem on your own.

An independent solution to the dilemma is possible when you have the necessary knowledge and skills. The task is to clear this tract. Scale or winding elements could be stuck in it. If so, the speaker will start to whistle very powerfully.

Typical problems with turbo boilers

The problems described above also apply to turbocharged boilers. But in addition, given the equipment with additional elements of boilers with a closed combustion chamber, additional “troubles” can also happen to them.

For example, in the process of their operation, you may encounter the following difficulties:

- icing of the coaxial chimney outside the house;

- failure of the built-in air blower.

Their design, of course, is more complicated than that of models with an open combustion chamber.But at the same time, all the same manipulations can be carried out with them as with atmospheric boilers.

The accumulation of condensate and icing is also a common cause of boiler damping. This happens if during installation the normative slope was not observed, which ensures the flow of condensation moisture.

But let us dwell in more detail on the breakdowns characteristic of this particular type of equipment.

Icing of the hood or chimney

If you observe that the boiler goes out most often in cold weather, then most likely the chimney outlet is blocked by an ice mass.

This may be due to:

- formation and accumulation of condensate;

- snow sticking.

As you can see, the reason is bad weather conditions. Therefore, the solution to the problem is to protect the chimney from external factors.

In this case, again, it is worth considering the option of installing a "fungus", i.e. deflector. But this is a preventive measure. But what to do if the problem is already “overdue”, and the weather conditions exacerbate the situation even more? There is a way out in this situation.

You can “melt” the chimney, that is, rid it of ice plugs, by yourself using a building hair dryer or a gas burner on a can

The settling of condensate in the pipes is typical for convection boilers with a coaxial chimney. Plugs are formed in them due to the temperature difference between the air flows drawn into the burner from the street and going outside. These ice jams block the path both to and from the combustion chamber.

To remove the ice crust from the coaxial chimney, it may even be necessary to dismantle its outer part. Dismantling will not affect the daily operation of the system, but it is still better not to bring it to this.Sometimes, in order to prevent the accumulation of condensate in the gap between the pipes, a pair of holes are drilled in the outer contour.

Just breaking the ice is not an option. Moreover, the chimney can be damaged. It is better to buy a portable gas burner with a can and “melt” the chimney with it. After the cork melts, the boiler will work again. But so that such incidents do not arise in the future, the pipes should be insulated.

The second prerequisite arises in cases of installation of eaves caps: they protect the chimney from precipitation, but in winter they cause more trouble than good, making it difficult for the outflow of flue gases.

Fan or turbine failure

When it suddenly goes out during operation or does not initially light up gas boiler wick with a built-in supercharger, listen to what sounds it makes.

During normal operation, the turbocharging system should hum steadily, so with the appearance of extraneous noise, you should be on your guard.

Turbocharging, applied to the design of boilers with a closed combustion chamber, in most cases cannot be repaired - it is easier to replace it immediately

If there are none during operation, the breakdown is obvious: that is, the automation does not allow you to open the protective valve, so the wick does not light up.

In this case, we strongly recommend that you do not engage in amateur activities, but immediately call the gas workers. In most cases, a turbocharger cannot be repaired - most likely it will have to be changed, and such work is associated with the risk of carbon monoxide spreading throughout the room.

Therefore, it is better if the control over this process will be carried out by a gasman from a company with which a contract has been concluded for equipment maintenance and gas supply.

Removing a clogged burner

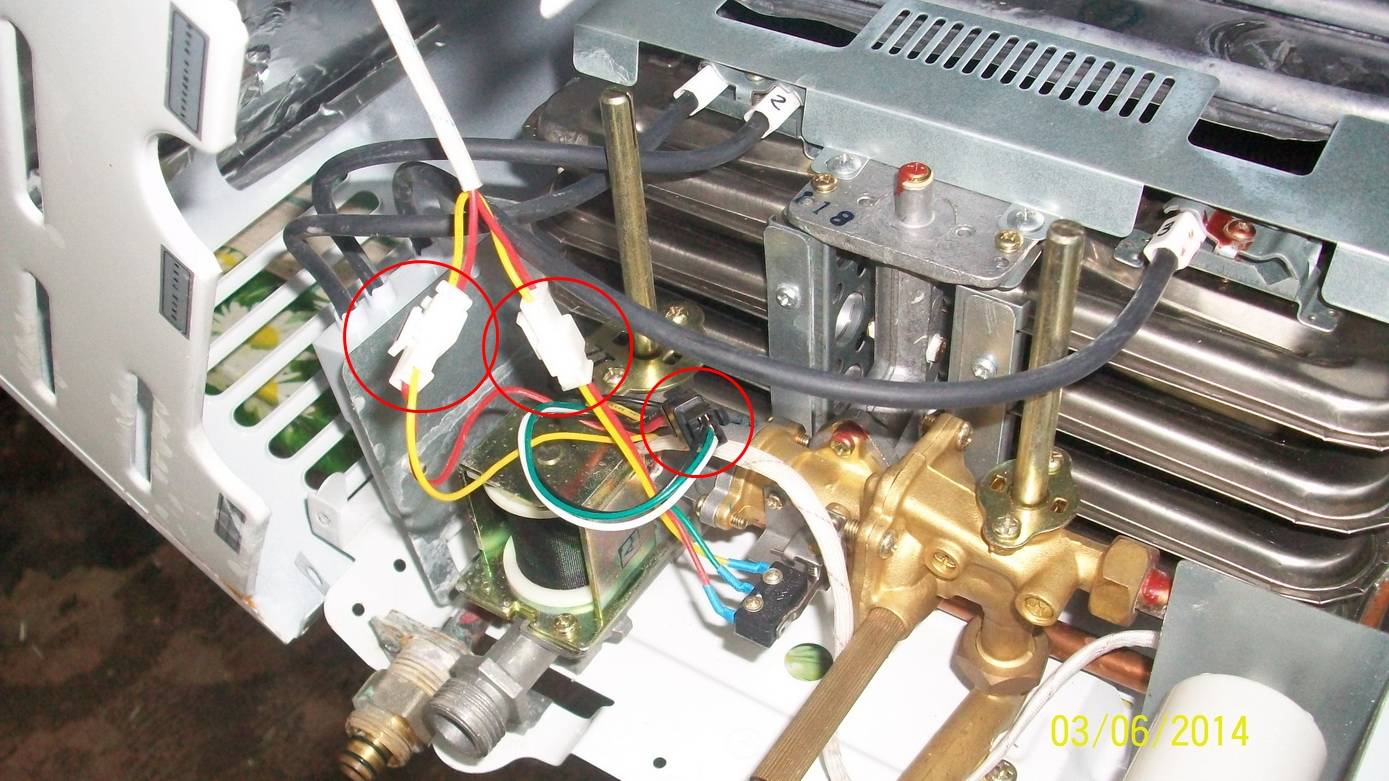

Unfortunately, the burners geysers Neva and Oasis (as in many others) are prone to blockages. Most often, this picture is observed in models with piezoelectric ignition. The cause of clogging is the accumulation of soot. It must be removed, for which the column is disassembled and the burner itself is removed from it. For cleaning, any improvised tools are used. After cleaning, the burner should be installed in place and checked. If necessary, you can immediately clean the heat exchanger - its clogging leads to a loss of traction and a deterioration in heating.

If your geyser does not light up, and you decide to clean it, do it on the balcony or in the open air. Otherwise, soot flying into the air will surely stain the entire room in which the column is installed.

3 Possible solutions - how to fix a column without specialists?

The easiest way to identify and resolve the issue is if the case is related to the gas leak sensor. The display has a special field where the resistance is indicated. In the case of a working sensor, this indicator under normal conditions is designated as an infinity sign, that is, an inverted figure eight. Otherwise, you can try to set up the sensor with your own hands using the instructions that came with your model.

Before each action, carefully check the instructions.

Another common and easily fixable problem is the chimney. Infrequent maintenance of this component is the cause of the formation of large blockages, which leads to poor burning of the column, as well as its regular shutdown. The lack of a constant and normal working draft is the reason for the unstable operation of the equipment.To avoid blockages, do the following regularly:

- timely clean the chimney from soot and plaque;

- look carefully so that the installation of other equipment, for example, satellite dishes, does not interfere with the normal operation of the chimney;

- using a soapy solution, periodically check the chimney for leaks of gas fuel (if there is a leak, soap suds will bubble).

If there is no normal draft in the chimney, then the geyser will also heat very weakly and regularly go out. You can determine weak traction using an ordinary burning match.

Bringing it to the viewing slot, we pay attention to the flame. During normal operation of the equipment, the flame begins to be drawn inward after a while.

If there is no result, you can disconnect the shaft opening from the chimney pipe. If now the flame is drawn towards the column, then the problem was precisely with the draft.

The most difficult case is the failure of automation. As a rule, it will be extremely difficult to adjust the equipment without calling specialists at home. In addition, incorrect adjustment of the automation can lead to further malfunctions in the operation of the gas burner. Thus, the temperature of the main burner can drop to a minimum if the values for the overheating or ignition protection systems are not set correctly.

Finally, we note that external factors, including gusts of wind, can rarely cause the burner to fade. Another thing is if there is a stable draft in the mine, which negatively affects the draft in the chimney. Low pressure when supplying fuel can also cause deterioration in the operation of heating equipment, since the gas shut-off valve is activated in automatic mode.Blockages in the filters in some cases lead to a decrease in the power of the fire, so it is necessary to constantly clean all the main elements of the burner, removing blockages and debris.

Preventive measures

To increase the life of the heating installation, some simple steps should be taken.

- Keep equipment away from hard and contaminated water. This can be done by installing coarse and fine filters in the water supply system.

- Once a year, carry out product maintenance: remove scale from the heat exchanger, clean the inlet filter, burner, wick and chimney.

- Check the condition of the rubber parts (especially the membranes) and change if necessary.

So, many malfunctions of a gas instantaneous water heater can be fixed with your own hands, but in some cases you cannot do without the invitation of a professional, especially with a gas leak. Prevention significantly extends the life of the product, since the main causes of breakdowns are often dust, dirt, soot, hard water, humidity and instability of gas and water supplies.

Variety of used geysers

The principle from different manufacturers does not have significant differences. Specifications differ.

How do the models differ?

- Performance;

- Type of burner;

- Degree of security;

- Ignition method;

- Flue gas removal method.

Classification by type of ignition:

- Manual. Found on older models. Most modern manufacturers prefer not to use this type of ignition. To turn it on, you need to light the burner yourself with a match.

- Piezo ignition. To turn on the heater, just press the button. After a few seconds, the water from the column will be hot.

- Electronic ignition.Allows you to save gas, as the automation turns off and turns on its supply.

According to the type of installed burners, there are two types of heaters. At constant power, manual temperature control is required. With a variable, automatic adjustment occurs. Modulating burners supply water at a uniform temperature.

Column power is one of the main selection criteria. The minimum value is -16-19 kW. Maximum - 28-32 kW. A heater with low power will heat up to 10 liters of water per minute. This is not enough for a large family. You can only wash the dishes. Average indicators increase the volume to 20.

In order not to encounter the fact that there is no water pressure in, you should choose trusted manufacturers. A German and Italian company has gained confidence in the market. But there are domestic popular brands. Geyser "Neva" combines proven quality and affordable price.

Common Problems

Let's look at why the geyser goes out. Attenuation can be caused by a number of reasons. A sensor may turn on that detects a gas leak. There may be problems with the operation of the chimney. A clogged pilot also often causes damping problems. Sometimes the automation fails.

Often the problem of attenuation is also related to the quality of the fuel. Some gas facilities do not supply pure gas, but diluted. Such low-quality fuel is easily identified by the orange color of the flame. If there are serious automatic protection systems installed in the column, they will turn off the system.

Water does not heat up

The weak pressure of hot water from the geyser is not the only problem that owners of water heaters face. The device may not heat at all, resulting in a cold liquid.

Why does not hot water come from the gas column:

- Dirty deposits have collected on the outside of the heat exchanger.

- The heating flame is not strong enough. The problem of insufficient gas pressure will have to be corrected. Maybe clean up the details.

- The heat exchanger is overheating. Such a violation leads to the appearance of a layer of scale. The normal operation of the device is disrupted. Cold fluid flows.

- The pressure level in the gas pipes is low. This is a reason to contact the gas service.

- Lack of ongoing care and prevention of pollution. It leads not only to a violation of heating, but also to poor water pressure from the column.

What to do if cold water flows:

- Turn the regulator all the way to the right. Close the faucet half way. This will slow down the movement of water and improve heating.

- Check gas pressure. This can only be done by a specialist.

- See how the mixer works. It can add cold water to heated water.

- Determine if the filter or mixer is clogged.

Principle of operation

In such a wall-mounted water heater, there is no storage tank for storing and heating water. The device is compact in size. The temperature of the water rises instantly as it passes through the heat exchanger. The main advantage is the provision of warm water to several water intake points at the same time. The energy source of such water heating systems is natural or bottled gas. This is what explains their popularity of installation in those houses where installation of gas equipment is possible.

Gas is cheaper than electricity, and although the cost of such units is many times more expensive, they pay off during operation.In turn, the quality of this raw material must be at the proper level, otherwise, the service life of the equipment will not be long. In addition, the constant clogging of the filtration system due to poor-quality composition of the gas mixture will lead to the fact that the device is constantly turned off.

Read more about the device and the principle of operation of the geyser.

Clap Questions

If the geyser does not immediately ignite and slams hard, the reasons for this lie in weak traction or its absence, lack of fresh air in the room and a faulty ignition retarder.

If this dilemma exists in wick machines, then the pilot wick fire is not correctly positioned here.

If the unit has automatic ignition, then the causes of such problems are:

- Dead power supplies in the control unit.

- Microswitch malfunction in the water mechanism.

- Incorrect positions of the spark plug.

The biggest problem is the microswitch. It is checked with an ohmmeter. In an open format, the minimum resistance should be several megaohms. In a closed one - less than ten thousandths of OM or not calculated at all. If these values are not determined, this part should be replaced.

If the spark plug has shifted, then it is necessary to loosen its screw and arrange it so that a gap of 4-5 mm is obtained. The spark should ignite the fuel on the first try.

Does the pressure of water affect the performance of the column?

The reason why the equipment does not ignite may be a weak water pressure in the supply pipe. Checking this is easy, you just need to turn on the cold water tap at the sink.If you see that the pressure is weak, then this is the reason. But if the pressure is excellent, then the problem of the malfunction lies in the water unit of the gas device itself. Most likely, the filters are clogged or the special membrane is deformed. In some cases, the hot water supply valve is clogged, which is covered with scale from the inside.

In very rare cases, the cause of low pressure is a deep filter, which is placed additionally. How to troubleshoot? If the pressure of the cold water supply is very weak in the public water supply, it is necessary to call the utility services to find out why this is happening. If the column does not ignite due to the fact that the filters are clogged, then they should be removed, washed with special products.

If the filters are very dirty, they need to be replaced, since it is already useless to clean them. In case of clogging of hot water pipes, it is necessary to call a master who can clean them; you do not need to do this work yourself. If the membrane is deformed, it is not necessary to try to straighten it, it is necessary to purchase a new one and install it. In case of clogging with combustion products and soot, the column should be turned off, then remove the casing and clean its components from traces of soot.

The column refuses to light up when turned on or goes out immediately, due to the fact that the supply of cold or hot water is not adjusted. In this case, one should not strive to dilute hot water by increasing the flow of cold water, as this will lead to a gradual attenuation of the flame and turning off the column. Such incorrect actions will shorten the life of the device.It is also necessary to correctly adjust all the taps during installation, if you cannot do it yourself, then it is better to call the master.

Other Sources of the Problem

Let's look at other problems that cause the column decay problem after ignition.

The fading of the wick may be due to the presence of powerful ventilation near the column. Exhaust air is drawn into the ventilation, which leads to attenuation. It is necessary to turn off the ventilation or turn its power to the minimum for the duration of the gas heater.

For the same reason, you should not place a powerful hood next to the column. During its operation, sensors may be triggered, diagnosing a malfunction.

Sometimes the reason is hidden in the absence of natural ventilation. It is necessary to open the window or install a supply valve.

The extinguishing of the wick can also occur in models with piezo ignition. The button must be held for at least 10 seconds.

Also, during the operation of the heater, it is not recommended to mix hot and cold flows. This leads to a drop in pressure in the line and attenuation of the wick.

The problem is solved by adjusting the indicators to a comfortable level and reducing the pressure with a special handle. If you still have to mix water, you need to leave the main hot stream.

Attenuation can cause a malfunction of the solenoid valve or servomotor. Only calling the wizard will help here.

Conclusions and useful video on the topic

How the gas column works: the principle of operation of the device:

How to correct the position of the flame adjustment sensor:

Analysis of two non-obvious reasons why the geyser can turn on and immediately go out:

How to diagnose a malfunction by removing the heater cover:

p> The main problems with the attenuation of the heater are listed. In most cases, they do not depend on the instrument model or manufacturer. Some you can handle on your own. But if you are not sure about this, it is advisable to contact a service center or gas service.

Do you want to talk about your personal experience in diagnosing the cause of column attenuation and how to repair it yourself? Or do you have questions that we have not covered in this material? Write your comments, participate in the discussion - the feedback form is located below.

Conclusions and useful video on the topic

The following video clip will clearly acquaint you with the reasons for the attenuation of the gas boiler burner:

p> Do not forget that the problems listed above may not arise if you monitor the condition of gas equipment and carry out its routine inspection.

At the same time, if you cannot determine the breakdown on your own or there is already a pronounced smell of carbon monoxide in the room, call the master immediately.

Have you had to deal with the extinction of the flame in the burner of a gas boiler? Share your own experience and troubleshooting options. Please leave comments in the block below, post photos and ask questions on the topic of the article.

Conclusions and useful video on the topic

Below we offer you instructions on how to fix two common causes of noise.

The first video shows the step by step process of replacing the gasket, which allows you to get rid of the strong noise accompanied by vibration.

The second video instruction tells in detail how to bleed air from the heating battery.This process not only helps to improve the heat transfer of the radiator, but also eliminates humming sounds.

Before starting repairs, you need to find out why water, sewer or heating pipes are noisy. Having established the cause of the sounds that have appeared, you can easily deal with the problem with your own hands or with the help of a master plumber.

Have something to add, or have questions about the topic? Please leave comments on the publication and participate in discussions. The contact form is in the bottom block.