- Why compress gases and how does it affect cylinders?

- Working with power tools

- Gas filling technology

- Protection and working conditions

- Winter and summer blends

- What is the difference between the seasonal versions?

- Calculation of proportions taking into account climate

- Versatile option for any temperature

- Safe operation of household gas cylinders

- Connecting the gas cylinder to consumption devices

- Safety requirements for the operation of gas cylinders

- Cylinder certification. How to find out the service life

- Deciphering the marking of cylinders

- Maintenance and repair of gas equipment

- Safety of heating and hot water on bottled gas

- Conclusions and useful video on the topic

Why compress gases and how does it affect cylinders?

In the gaseous state, substances do not have a definite shape, unlike solids. They can only be stored and transported in sealed containers.

But due to the low density, even a small amount of gas occupies a large volume. For example, to transport only 26.9 kg of propane in its usual gaseous state, a huge tank with a volume of about 14,000 liters would be required.

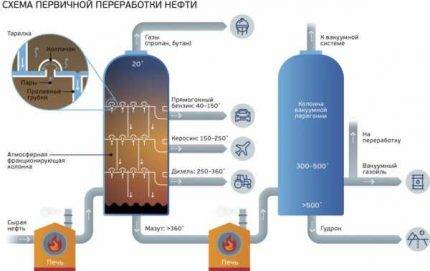

Propane and butane are the most commonly used gases in the domestic utility industry. They are obtained during oil refining or isolated from oil during its production, for example, using fracking technology

The problem is solved by compressing the gas by applying external pressure. As a result, its density increases and volume decreases. After compression, all the same 26.9 kg of propane fit in a 50-liter vessel.

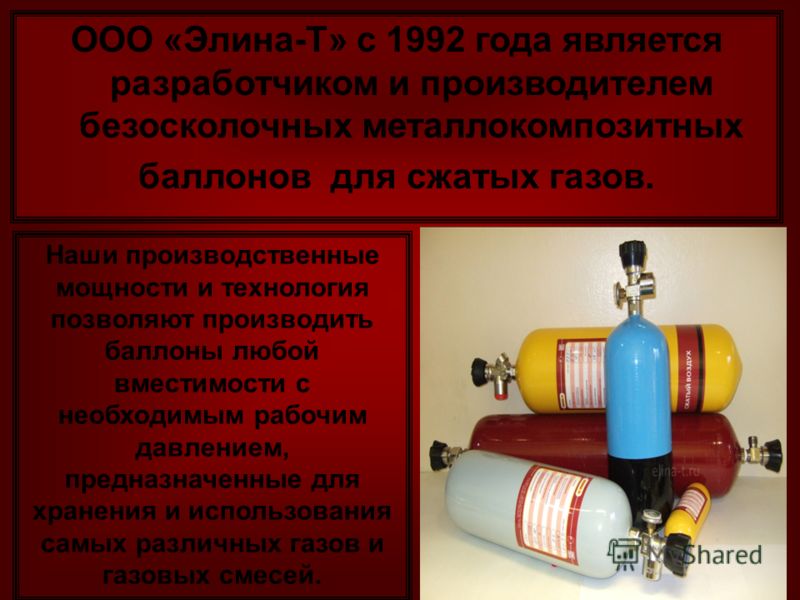

When compressed, gases such as propane, butane, ammonia, chlorine, carbon dioxide turn into a liquid state of aggregation, therefore they are called liquefied. Oxygen, argon, methane remain in a gaseous state and are called compressed gases.

Here it is necessary to make a clarification that any gases can be turned into a liquid by compression, but the pressure force must be higher, and the temperature must be much lower than the normal air temperature.

For compressed and liquefied gases, ordinary containers are not suitable. In an effort to expand, the gas will quickly destroy it and break free, and this is already fraught with explosions, fires, poisoning and financial losses. Therefore, special pressure vessels, better known as gas cylinders, are used.

Working with power tools

Each company tries to provide the maximum possible safety for its employees. There are also special rules for the operation of gas cylinders and power tools. Since production work is often associated with hot work (welding, cutting, etc.). For these tasks, containers with acetylene, oxygen or argon are used.

Before work, in its process and at its completion, there are interpretations. This is a mandatory instruction for the operation of gas cylinders, which is carefully studied and passed by all gas welders. Its structure is:

Before starting work:

Checking the minimum distances: working areas - 10 m from ramp structures, single vessels - 1 m from the heating system and 1 m - from an open flame.

The position of the cylinders is strictly vertical. They are placed in special racks and securely fixed with clamps.

Equipment for canopies over tanks.

Checking the serviceability of all components, their tightness and the presence of water in the valve. In case of malfunction, the cylinder is sent to the filling point

On it is written in chalk "Caution! Full!"

The valve is opened with a special socket key, which is located on its spindle.

The faucet valve should open 0.7 or 1 turn.

In the process:

- Protection against heating or freezing (in work with oxygen model).

- Permanent control over tightness and protection from the sun.

After work:

- Based on the data of the manometer, the remaining gas is determined.

- The selection of acetylene is completed at a parameter of 50 kPa.

- Containers are placed in special places for storage.

Gas filling technology

First of all, when accepting a cylinder for refilling, the organization that will perform the work must check the technical condition of the cylinder. What is meant and what lies behind this technological definition?

If the cylinder is in an unsatisfactory technical condition, then it may be refused to be accepted for refilling. What specific defects can cause failure should be considered in comprehensive detail.

Replenishment of liquefied gas in a cylinder is allowed only at gas filling stations that have equipment for filling and weighing vessels

The main defects, upon detection of which they can refuse to refill the cylinder with gas:

- if a malfunction of the shut-off valves was detected (the cylinder valve is faulty);

- in the presence of obvious damage to the integrity of the hull - these can be obvious cracks in the weld, or traces of deep corrosion, dents or bulges on the hull;

- the absence of a plate with passport data or an unreadable plate is also a reason why they may refuse to accept a cylinder.

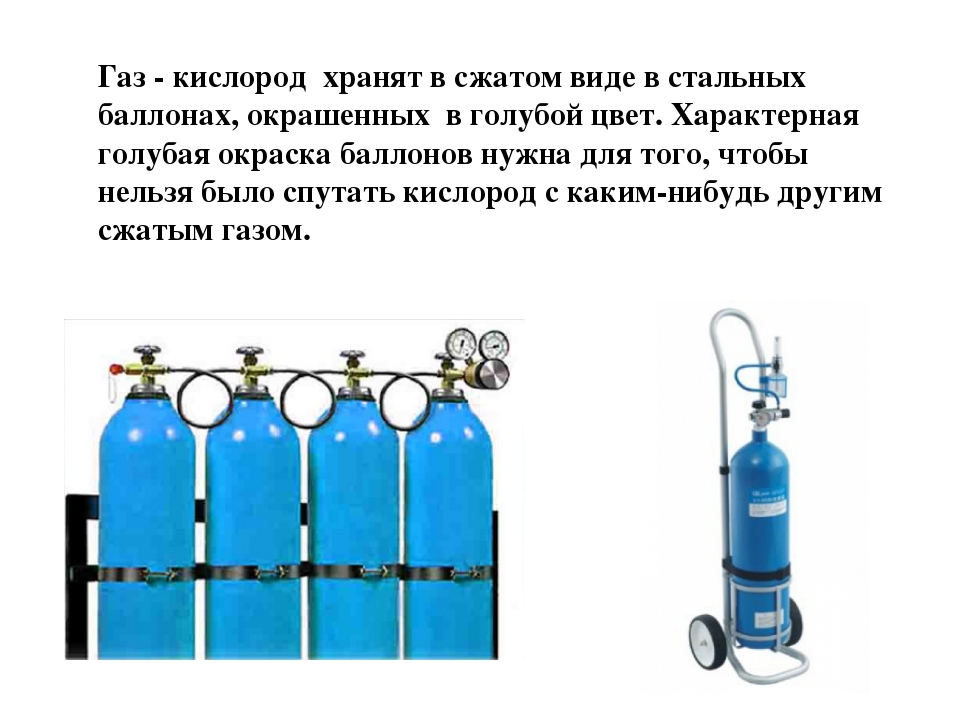

A cylinder of color that does not comply with state norms and requirements, as well as a tank without a standard inscription, is definitely not subject to refueling with blue fuel.

If there are defects in the body and fittings, filling the cylinder with gas is prohibited. It will need to be replaced or repaired.

The demands made by the tanker for the coloring of the cylinder and the inscription have already been discussed above, the technical malfunctions of the fittings and the body are quite understandable claims.

Consider the requirements for the plate. This is actually a cylinder passport, which reflects all its data, starting from the moment of production and ending with the date of the last verification (survey).

What exactly should be indicated on the plate:

- first of all, it is the brand of the cylinder and the stamp of the quality control department of the manufacturer;

- then the specific type of cylinder and the batch number in which it was produced are indicated;

- the weight of the cylinder must be indicated with an error of not more than 200 grams;

- respectively, the date of manufacture (release) of the cylinder;

- the date when the cylinder passed the examination for the last time and the date of the next verification;

- the working pressure of the cylinder and its test pressure are indicated;

- the volume of the cylinder must be indicated, i.e. its capacity is accurate to 0.2 liters.

In the absence of a plate, it will be problematic to identify the cylinder. Therefore, its condition must be regularly monitored. If operational information is stamped directly on the cylinder body, then the inscription must be covered with a colorless varnish and outlined in white.

Plates that are not stamped on the body, but attached separately, should also be kept intact, and the data on the “balloon passport” should be clearly visible and easy to read.

The plate of a liquefied gas cylinder contains all information about the technical characteristics, verifications and other data of containers for gas

The plate of a liquefied gas cylinder contains all information about the technical characteristics, verifications and other data of containers for gas

What is this data for? It is these characteristics that will be checked by the organization that fills the cylinder for compliance. Information about the weight of the cylinder and its volume indicate how much gas can be filled into this cylinder.

To make this clear, we will consider the main nuances of the technology of the rules for filling household gas cylinders, which are prescribed in the standard instructions for filling cylinders with propane or propane-butane mixture.

Filling of cylinders must be carried out in accordance with the recommendations of the manufacturer, the norms for filling the cylinder are:

- for technical propane, this is a volume of about 0.425 kg per liter of cylinder;

- for technical butane - this is a volume of about 0.4338 kg per liter of cylinder,

In this case, the liquid phase of the gas should not exceed 85% of the geometric volume of the cylinder being filled.

Filling the vessel with gas is carried out so that 15% of the total volume remains free. This is necessary in case of thermal expansion of the gas when heated.

The balloon must be weighed before filling. It must necessarily have a residual pressure if it has already been in operation.After filling, the cylinder must be weighed, and the gas storage and use tank valve plug checked for leaks by soaping all places where leaks are possible.

Protection and working conditions

The rules for labor protection in the operation of gas cylinders have some differences. The main criterion is the type of content. The general requirements are:

- The minimum age of an employee is 18 years. It has no health contraindications. He passed and passed the necessary instruction and training.

- Smoking and eating are allowed only in designated areas.

- For work, the employee puts on overalls and has suitable personal protective equipment.

- All cylinders are carefully checked for suitability before use. The criteria for working with them and their location after the shift are observed.

Winter and summer blends

Since only one 5-liter cylinder is allowed in residential premises, large volume containers are installed outside the home. Accordingly, the climatic conditions during use can be any. Taking this factor into account, gas compositions are created for the warm and cold seasons, which are described in more detail here.

What is the difference between the seasonal versions?

Inside the cylinder, liquefied gas is in two states of aggregation: liquid and gaseous. The intensity of filling the gas pipeline with the gaseous fraction directly depends on the temperature: in heat, the indicator is higher than at low temperatures.

The graph shows that mixing propane and butane allows you to balance the ability of these compounds to evaporate. This is the basis of the principle of creating "climatic" compositions.

This situation is corrected by changing the proportions of propane and butane.The first is able to evaporate at 42 degrees below zero. The second loses this ability immediately after crossing the zero mark.

Therefore, in winter, the volume of propane increases. In summer, on the contrary, it decreases. This approach makes it possible to reduce the cost of summer versions due to cheaper butane and ensure the effectiveness of winter ones.

Calculation of proportions taking into account climate

When determining the recommended proportions, the central strip of Russia was taken as a reference point. The minimum propane content for the winter version is limited to 70%. In the summer version, a 50% content is acceptable.

The abbreviation SPBT means a mixture of propane and technical butane - the proportions are selected in accordance with the needs. BT - technical butane contains 60% butane. PT - technical propane - at least 75% propane

The composition for other regions is carried out taking into account the distance from the middle lane, climatic features. This must be done by licensed professionals.

Versatile option for any temperature

The correct functioning of portable gas systems in a wide temperature range is typical for the combination of propane, isobutane and butane. Having different combustion temperatures, these substances made the complex composition as versatile as possible.

Safe operation of household gas cylinders

To figure out how to safely use a gas cylinder, you need to dwell in more detail on their connection, installation, operation and refueling.

Connecting the gas cylinder to consumption devices

It is not enough to have a gas cylinder and a device to which it will be connected.

Autonomous gasification implies the presence of a whole system of equipment:

- A device that will “feed” on gas (stove, column, grill, etc.);

- Gas cylinder;

- gas hose;

- Reducer;

- Hose clamps.

The pressure in the gas cylinder depends on the temperature and is not constant. Therefore, to equalize it, a gas reducer is used, which not only lowers, but also equalizes the pressure to the value necessary for the normal operation of the equipment.

A simple gas reducer (frog) reduces and equalizes the gas pressure to the rate required for the operation of gas equipment

The reducer is screwed onto the valve fitting and connected to the gas consumption device using a hose. 3-4 layers of gas fum tape are pre-wound on all threaded connections. The connecting hose at the fixing point must be additionally secured with steel clamps.

When connecting threaded connections, it is necessary to pre-wind 3-4 layers of gas fum-tape and tighten the nut with sufficient force

All connections should be checked for their degree of tightness. The reliability of the connection is checked by applying soap suds - the presence of bubbles indicates insufficient tightness. To eliminate leakage, tighten the nut connecting the fitting to the reducer with great force.

If a gas leak is found in the area of the connecting hose, tighten the clamp bolts. After completing the adjustment, it is necessary to re-check with soap suds. This check must always be carried out when connecting the gas bottle, both for the first time and after replacing it.

Soapy solution always helps in identifying insufficient tightness of joints.

Some gas masters check for gas leaks with a lit match. This type of leak test is prohibited by safety regulations. Firstly, in daylight, small flames can simply be overlooked. Secondly, a significant gas leak can lead to ignition and even an explosion.

Safety requirements for the operation of gas cylinders

One of the most important criteria for the safe operation of a gas cylinder is constant monitoring of overheating and possible leakage. The propane-butane mixture itself is odorless, but the presence of a mercaptan hydrocarbon in the composition allows you to determine the leak.

Basic safety requirements for the operation of bottled gas:

- Gas equipment must be in good working order. Cylinders should be inspected at least once every 5 years. When connecting a cylinder or replacing it, check the tightness of all connections with a soapy solution.

- Do not use cylinders with traces of rust, with a faulty valve, in the absence of gas labeling.

- It is necessary to store the cylinder in a special ventilated cabinet that protects the cylinder from direct sunlight and precipitation. The distance from the cabinet to the window or door must be at least 1 m.

- When placed indoors, the distance to an open flame source must be at least 5 m. Also, the distance to heat sources (heating radiators, electric heaters, etc.) must be at least 1 m. Large-capacity cylinders should be placed in a special cabinet with outside of the housing.

- It is forbidden to store cylinders in the basement or bury them in the ground.

- In working condition, the cylinder must be in a vertical position.

- When replacing the cylinder, you need to make sure that there are no sources of ignition.

Never neglect the above rules for the safe operation of bottled gas, as even the slightest violation can become a threat to life.

Cylinder certification. How to find out the service life

Household propane cylinders are metal sealed containers of a certain volume for storing gas. The material of manufacture is a steel alloy with the addition of chromium and molybdenum. From the manufacturer, they fall into free circulation. They are used in specialized companies as equipment, at enterprises, in everyday life of the population.

Each cylinder is accompanied by the issuance of a paper passport from the manufacturer. The data is duplicated in the form of metal inscriptions on the reverse side of the case, next to the brand of the enterprise.

The technical condition of the cylinders must be strictly controlled in accordance with GOST 15860. To determine the possibility of further operation, an examination procedure is carried out.

Subject to inspection once every five years:

- products manufactured before February 2014 can last up to 40 years;

- products manufactured after February 1, 2014 - up to 20 years.

The "metal passport" indicates the date of issue of the product, volume, weight, date of the last examination. According to the rules of use, cylinders without metal passports or with indistinct inscriptions are not refueled and cannot be exchanged.

On the body of the rating plate, data on the mass, production date, date of the last certification are applied

It is important to treat the product with care so that the inscriptions are well read, otherwise the cylinder will be taken out of service. And it is right

The “life” of each cylinder proceeds differently: some products are in constant use, others can gather dust in the garage for years in order to be used for certain purposes at the right time

And it is right. The "life" of each cylinder proceeds differently: some products are in constant use, others can gather dust in the garage for years in order to be used for certain purposes at the right time.

Do not forget that faulty equipment for storing hazardous substances (gas) can bring trouble.

Deciphering the marking of cylinders

By reading the label correctly, you can get complete information about the gas cylinder. If it is a propane cylinder, then its passport is in the valve area, on a metal mug.

The passport of the propane cylinder indicates: working pressure in MPa, test pressure in the same units, volume of the tank in fact in l, serial number, date of manufacture in the form "MM.YY.AA", where the first characters indicate the month, the second - the year , the third - the year of the upcoming certification.

Followed by empty weight in kg, the mass of the filled balloon. The last line is the letters "R-AA". "R" - the stamp of the recertification site or the plant. The combination of the characters "AA" reveals information about the year until which this certification will be valid.

The decision on the suitability of the cylinder should be taken only after a complete decoding of all data about it. If defects are found on it, then it is emptied and sent for repair.

The marking of the oxygen cylinder has its own order and consists of four lines.The first contains information about the manufacturer, as well as the container number. The second contains the release date and the recommended review date. In the third - hydraulic and working pressure. In the fourth - the volume of gas and the mass of the cylinder without a valve and a cap.

When buying a balloon, you should pay attention to how information is applied to it. On the body, it is not applied with paint, but is beaten out, and then covered with a special colorless varnish in order to protect against corrosion

Often the last line contains the brand of the manufacturer.

Maintenance and repair of gas equipment

An important issue that is often overlooked by the owners of a non-gasified private house or cottage is the maintenance of gas cylinders and individual cylinder installations. At large enterprises, maintenance is carried out by personnel who have been trained and tested on technology, but in individual farms no one undergoes such training.

When supplying and replacing cylinders by an organization that offers filled cylinders, a briefing is carried out with an entry in the journal of the gas supply structure about its implementation. Such briefing concerns the correct operation of the already installed balloon equipment and safety measures during use.

Maintenance of balloon equipment and individual balloon installations should be carried out by representatives of organizations that have specialized permits for these types of work. During the work, not only the condition of the cylinders themselves, but also the cabinet of an individual cylinder installation, should be checked.

The gas pipeline from the installation to the gas equipment is inspected, the gas equipment itself is examined.Be sure to check the connections for leaks. All connections are "soaped" to detect leaks

If any violations were identified during the maintenance process, they must be eliminated without fail.

A number of rules that are mandatory for those who use gas cylinders:

- cylinders at the installation sites should not be subjected to direct heating;

- installation of gas equipment in the basement or basement floors is unacceptable, since gases can accumulate there in the event of a leak;

- install cylinders near heating appliances (radiators, etc.) and a gas stove should be no closer than 1m;

- the room in which the cylinders (and gas equipment) are installed should not have basements in which gas can accumulate.

Questions about whether and how it is possible to fill a gas cylinder directly at home are quite often asked by the owners of individual cylinder installations. This is understandable, because for refueling they need to carry several cylinders, and sometimes over considerable distances.

The answer to this question is unequivocal - you can not fill the gas cylinder at home. There are several reasons for this and they relate to the technology of filling cylinders.

Safety of heating and hot water on bottled gas

In the absence of access to a centralized gas supply, liquefied gas can be used as fuel for autonomous heating systems and water heaters. It is cheaper than electricity. Unlike firewood, coal or diesel, it does not pollute the air with solid combustion products, that is, it is more environmentally friendly.

Instead of cylinders in private households, gas tanks up to 20,000 liters can be used if there are no problems with their refueling

When organizing a heating and hot water supply system for LPG, it is necessary to take into account the requirements of SNiP 42-01-2002.

In addition to cylinders (50 l), the following equipment is used:

- gas boiler;

- reducers;

- stop valves;

- gas pipeline components;

- radiators.

The boiler can be single or double circuit, but always with a burner for liquefied gas. If bottled gas is a temporary solution and the house is planned to be connected to a centralized gas supply, it is rational to buy a boiler for main gas and additional equipment for LPG. A double-circuit boiler will provide both hot water and space heating at the same time.

It is possible to install a highly efficient condensing boiler equipped with two heat exchangers for heating the heating medium and hot water supply. In such a boiler, water vapor formed during the combustion of gas is converted into a liquid, which makes it possible to obtain additional thermal energy.

The power of the boiler is chosen based on the area of \u200b\u200bthe heated room and preference is given to models with higher efficiency.

Several gas cylinders are connected to gas boilers, which increases the total volume of gas and extends the interval between refueling

At the same time, several of the most capacious 50-liter cylinders are used, combined into a single battery. The cylinders are placed in metal, ventilated cabinets on the street on the north side of the house, in order to avoid heating by solar radiation. Another option is a detached non-residential premises.

So that during severe frosts the pressure in the system does not fall, cabinets must be insulated with non-combustible materials, and minimal heating must be ensured in the room.

It is important to ensure that the distance from the boiler is at least 2 meters and that there is free access to the equipment for inspection. There should be no drain pits, cellars, basements, ditches near gas equipment

Gasification of basements and basements is prohibited.

Cylinders are connected to the gas pipeline through a gas reducer, which allows you to adjust the gas pressure during its selection. It can be separate for each cylinder or common to all.

The color of the reducer must match the color of the cylinder, that is, be red (for propane-butane). It must not be allowed to become clogged, otherwise the pressure may increase and the equipment may fail. Once a week, the gearbox is checked for the presence of gravity and the operation of the safety valve.

When combining cylinders into a single battery, it is rational to use a pressure stabilization rail consisting of a connection module, a reducer, a filter, a valve, a stabilizer

To create a gas pipeline, steel pipes with walls no less than 2 mm thick are used. The section of pipe that passes through the wall is placed in a protective case. A flexible pipe can be used to connect to the gas pipeline of the heating boiler. The reducer is connected to the gas pipeline using a durite hose (rubber-fabric sleeve).

What gas mixture is best used for storage in a gas tank is described in detail in the following article, which we recommend reading.

Conclusions and useful video on the topic

In order not to make a mistake when choosing, you can focus on the color of the container. To connect to the gas stove, use red cylinders with a white inscription:

The most popular composition used to fill household cylinders is a mixture of propane and butane.Properly selected proportions allow you to effectively use the physical properties of both substances.

Please note that a cylinder with an inscription that does not meet the requirements must be removed from service. Any attempts to paint over, change the name is a violation of the rules