- If the equipment is still noisy?

- Cotton when turned on

- Why can the electric ignition of a gas stove click?

- Activation of protective mechanisms

- Reasons for auto-ignition

- Reason #1 - moisture inside the control button

- Reason #2 - Junction Formation

- Reason # 3 - mechanical connection of the contact group

- What to do if the gas stove clicks?

- Gas control malfunctions

- The oven burner burns with a red flame, with a gap

- Why does the water heater make noise when heating water?

- bottom type

- Electric ignition does not work on only one burner

- Why can the electric ignition of a gas stove click?

- How to check the performance of the lighter?

- Troubleshooting a Gas Stove

- Problem #1 - Burner Malfunctions

- Problem #2 - Broken Connecting Hose

- Problem #3 - Leak in the stopcock area

- How the function works

- Reason # 4 - problems in the water fittings

- What to do if the pie constantly clicks by itself

- How to troubleshoot at home

- If water is spilled on the stove

- Breakdown prevention

- Causes of the malfunction

- Speaker whistles

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

If the equipment is still noisy?

If, after the manipulations done, the gas water heater still ignites with cotton when the water is turned on, then it is better to stop further independent research. In such situations, you will need to seek help from qualified professionals.

They will make a competent diagnosis of the equipment, they will be able to clearly establish what is the cause of the cotton and, based on the data obtained, they will be able to provide you with options for solving the problem.

In certain cases, self-repair is impossible, then cooperation with qualified specialists will be a rational solution

Cotton when turned on

If, turning on the column, you hear a pop, this is a sign of problems with the gas supply. Each apparatus has a working area in which the accumulation of gas occurs during the activation of the equipment, as well as its gradual connection with air. In the case when the volume of accumulated gas and air meets the manufacturer's calculations, there will be no pops. If gas and air accumulate in excess, this causes a small volumetric explosion.

The author of the following video offers his solution to this problem. After watching his video, you can independently get rid of cotton when you turn on the geyser.

Why can the electric ignition of a gas stove click?

The basis may be different, however, none of them is terrible.

- If you notice a sound after washing dishes or cleaning the stove, then it may be due to moisture.

- The contacts are oxidized, which closes the circuit.

- Sticking of the contact and its oxidation by getting soot into the button of the electrical ignition system.

- Due to overheating or combustion, a breakdown of one button appears, and then a short circuit of the whole circuit may occur.

- The button simply jammed because grease or dirt got into it too often.

- Water intrusion on the ignition function switch.

- Incorrect use of the hob.

- Knocks out the circuit breaker in the apartment panel at startup.

- If clicks are heard and there is no spark, this means that there is no gas.

Contacting special services is a guarantee of the safety of the whole family, since a gas stove is a dangerous device, with one wrong set of circumstances, a real problem can turn into a large one.

Activation of protective mechanisms

-

If a electric hob turns off, the most likely cause of the hob malfunction is the inclusion of the function of maintaining the health of the main components. When the thermal protection is triggered, the stove will not work, because the system will understand the current state as overheating. Otherwise, the hob will require appropriate repairs or replacement of expensive parts.

-

An interruption in the power supply circuit, which accompanies the process of activation of the protective function, can be caused by breakdowns in the temperature controller for heating the burners, the control touch panel or the fan of the standard cooling system. Modern stoves are equipped with overload protection systems in the network. In this way, the leading components of the stove, such as the hob and other parts, are protected from destruction or deformation. This can be caused by short circuits or multiple overcurrents causing the panel to shut down.

-

The operation of the protection from which the induction hob is turned off may be the action of the RCD on the site or the fuse. Until the reasons for which the protection was activated are eliminated, the equipment will not turn on.

Reasons for auto-ignition

As it turns out, taking into account practical experience, the spontaneous clicks of a gas stove lighter in most cases are not connected in any way with the electronic circuit of the ignition unit.

The reasons for the appearance of an uncontrolled spark lie elsewhere. Often the place of formation of such a defect is the inner area of the ignition control button.

Reason #1 - moisture inside the control button

Surely the owners gas stoves had to deal with uncontrolled ignition clicks on the gas stove after washing and cleaning household appliances.

Most likely, during the washing process, some water got on the ignition control button, as a result, part of the moisture penetrated inside.

Given that a high discharge voltage is applied through the ignition button circuit, a small amount of moisture is enough to cause an uncontrolled spark to appear on the gas stove spark gap.

Usually, the defect of an uncontrolled spark of a lighter in such cases disappears after some time. The moisture inside the button dries up, the short circuit factor disappears, respectively, spontaneous clicks stop.

Often, the correction of a short circuit defect due to “water trapped after washing” is helped by lighting all the burners of the gas stove for about 15-30 minutes.

Reason #2 - Junction Formation

The junctions formed inside the ignition button can have different shapes.The formation of a junction can be facilitated by the same moisture that got inside the button after washing. Usually such a "water" junction is formed due to the periodic penetration of water.

Time after time, deposits build up, and eventually an oxide junction forms. In addition, grease, soot, dust can accumulate inside the button case. All these are also harbingers of a short circuit between the contacts.

With this development of events, you will have to disassemble the gas stove:

- remove the top panel

- open the front subpanel;

- remove the ignition button(s).

Or, in the case of more modern designs of gas stoves, it is necessary to get to the designs of disk control devices that simultaneously perform the functions of a button and a regulator of gas supply to the burners.

After removing the part from the body of the gas stove, deposits are cleaned, after which everything is assembled in the reverse order. However, this work is the prerogative of the specialists of the gas company. It is not recommended for an inexperienced user of a gas stove to disassemble the device on their own.

Reason # 3 - mechanical connection of the contact group

The mechanical connection of the contact group of the gas stove ignition button should also be attributed to the category of causes associated with a short circuit. Such a defect, as a rule, can occur on plates that have been in operation for a sufficiently long time. True, the same malfunction is not ruled out on new devices, where the quality of components leaves much to be desired.

A mechanical connection is formed by any of the contacts of the button, which simply breaks off, for example, due to physical wear. The broken part is displaced from the attachment point and forms an electrical connection with another contact.In fact, the effect of the switched on ignition button is created - that is, spontaneous operation electric ignition on gas stove burners.

With such a malfunction, the only way out is to completely replace the component.

What to do if the gas stove clicks?

If cleaning does not help, contact us

Please note that attempting self-repair with disassembly of the case may result in complete failure of the equipment or other malfunctions. This is due to the lack of a professional tool in the standard household, which is necessary for working with stoves.

At the same time, lack of experience will lead to an increase in the cost of future repairs due to incorrect diagnostics and replacement of working parts with working ones.

With constantly clicking piezo ignition, call us by phone8 or fill out an application online. We are a company with extensive experience and offer our customers the best conditions for cooperation. We never hide the progress of work from our customers. You always see diagnostics, broken spare parts and new components, which allows you to verify their originality. Also, "PlitHome" is chosen for such reasons as:

- We restore equipment at home;

- We have our own warehouse of spare parts;

- Extended work schedule;

- Affordable prices for services and parts;

- Official guarantee for the entire range of services.

If you have additional questions, you can also ask them to the operators. Professionals work with clients, which guarantees the competence of consultations. We will be glad to see you among our satisfied customers.

Gas control malfunctions

This is a common problem. After some time of operation, the owners of the stove notice that one burner or several of them ignite for a very long time, and when the handle is released, the burner goes out completely.

The reason lies in a contaminated thermocouple - a small mechanism located near each burner. A contaminated thermocouple does not do its job of heating, does not lift the valve, and obstructs the flow of gas. Regular cleaning with a knife or other handy item will help you cope with an unpleasant situation.

If such a home repair does not help, then the thermocouple itself or the magnetic valve may have broken, they will have to be completely changed. This is the work of a master.

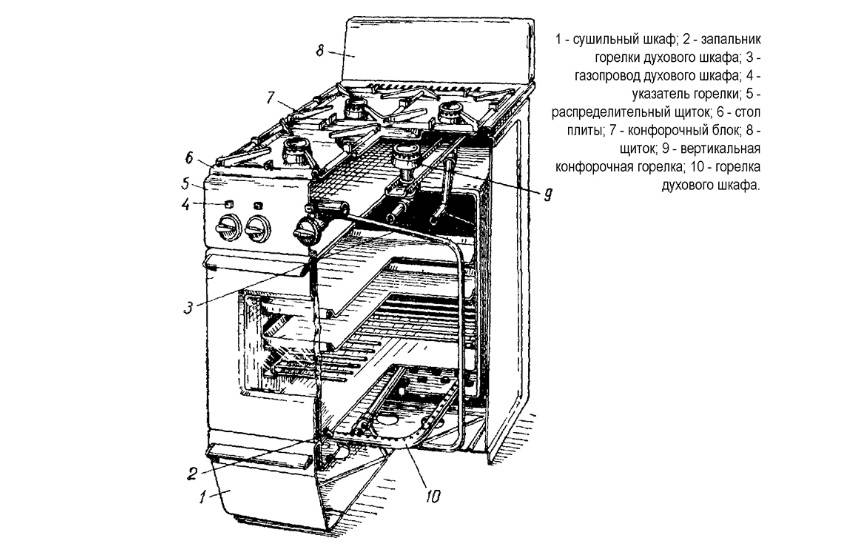

The oven burner burns with a red flame, with a gap

Sometimes the oven burner burns with a red flame. Or vice versa, there is a separation of the flame, that is, in front of some holes of the burner, the flame does not burn or periodically goes out. If the gas pressure is normal and the nozzle is clean, then this is due to the installation of the gate (Fig. 2. B). The gate is an ordinary elastic plate, bent into a ring and inserted into the hole. By moving it, you can adjust the proportions of mixing gas and air. If you move the gate closer to the nozzle, then there will be little air, the flame will burn with red tongues. If you move the gate away from the nozzle, then there will be more air, the flame will burn intensely, with a separation. We need a middle ground.

Why does the water heater make noise when heating water?

There are a number of reasons why the water heater makes noise when heated:

- In any, even a new and serviceable storage water heater, the water is buzzing due to the convention process. The heating element installed at the bottom of the tank heats the water.Bubbles form in it, which rise up and collapse with noise when they enter the upper, colder layers. The same thing happens when the kettle boils. This process is natural, it is impossible to fight it.

- A thick layer of scale has formed on the heating element. At the same time, salt layers are first heated, and water is already heated from them. In this case, part of the liquid gets under the layer of scale, and whistles when it boils and comes out.

New heating element and heater with scale The pieces of scale falling off may crack. To eliminate it, we disassemble the boiler, take out the tubular electric heater and clean it first mechanically, and then placing it in a solution with citric acid.

For prevention, cleaning should be done at least once a year. It helps to install an additional filter that will soften the liquid, cleaning it from excess salts. The magnesium anode does not allow the salts to harden, and if it is present, cleaning is much easier.

- Too much pressure in the water supply. At the same time, pipes can also make noise. This increases the load on the water heater and reduces its life. It is necessary to install a pressure reducer, which will reduce it if necessary.

- Microcracks appeared on the tube covering the heating element. This happens if a dry heating element is installed in the boiler. In this case, small drops of water fall directly on the heating element and boil. That is why the resulting steam squeaks and comes out.

Dry heater

- Noisy non-return valve. It is necessary so that the water from the boiler does not go back into the water supply. But over time, the valve wears out, becomes covered with scale and begins to let water through a little, which is accompanied by a buzz. You need to replace it with a new one or clean it.

- Bypass valve whine.When heated, water expands. To prevent the tank from bursting, each water heater has a bypass valve that, when overpressured, releases water into the sewer, which is sometimes accompanied by a whistle. It must be replaced.

- Increased noise can be if the boiler is airy, that is, air enters it along with water. This is usually short-term and goes away when the water supply is restored. The same effect occurs if a large amount of oxygen is initially dissolved in water.

bottom type

Now a few words about the type of product bottom. It can be in the form of a simple "pancake" made of steel or cast iron, or multi-layered.

Typically, a multi-layer bottom consists of a steel first layer, an aluminum second layer, and a non-stick third layer. This bottom is the most practical. Steel ensures the operation of the tile, aluminum easily accumulates heat and gives it to products, and a special coating will get rid of spoiled dishes.

Old utensils (even enameled ones) can also be suitable for cooking on this type of kitchen tile.

Check the bottom of each pot and pan with a magnet: if it is magnetized, the dishes are usable. But remember, not all old cookware has the right thickness of the bottom, in most cases it does not have a non-stick coating.

Electric ignition does not work on only one burner

If you cannot turn on only one burner using auto ignition, the first thing to check is if the spark plug is dirty. You may have spilled something on it, or the spark plug shows signs of oxidation. To clean, use WD-40 spray or just wipe it with a sponge. Did it not help or does the candle look perfect? Then it's a malfunction.

| signs | Breaking | Repair or replacement |

| There is no spark on one burner, the electric ignition works on the rest. | Faulty burner ignition plug. The power cord that goes from the ignition unit to the candle fails: the wire itself is damaged, the contacts are oxidized. |

In some stoves, when food gets on the power cord, it sticks to the case, and it is punched through this dirt onto the case.

It is necessary to replace the power cord along with the spark plug (as a rule, they are assembled).

A stuck power cord is enough to “unstick” from the case. To do this, it is necessary to disassemble the plate and remove contamination.

In a gas stove with auto-ignition buttons built into the handles of the burners, when you press the handle of one of the burners, there is no spark. The other hotplates light up as usual.

The handle of a burner with an inoperative ignition is pressed differently than others (softer, harder, etc.).

Auto ignition button failure. Modern models of medium and high price gas stoves, as a rule, have ignition buttons built into the burner handle. When the button on the burner handle fails, it stops lighting, while the rest of the burners light up normally.

Button failure is usually caused by mechanical damage or oxidation of the contacts.

In case of oxidation of the contacts, they are cleaned. If the button mechanism is damaged, replace it.

Why can the electric ignition of a gas stove click?

The causes of this malfunction can be very different, while all of them do not deserve much concern and, as a rule, are easily fixed:

- If a clicking sound is heard after washing dishes or stoves, then the reason for its appearance is moisture that has got into the electric ignition. From it, the contacts are oxidized and the circuit is closed.

- Carbon deposits on the ignition button, and subsequent sticking of the contact

- Overheating or breakage of the button, leading to the closure of the entire circuit.

- Failure of the button due to the accumulation of grease or dirt under it.

- Water ingress into the auto ignition switch.

- Violation of the rules for the operation of the stove.

- Problems associated with the functioning of the electrical panel responsible for supplying electricity to the premises.

- Lack of gas supply.

If all of the above reasons are not suitable for the situation that has arisen, you should not deal with repairs on your own, since only a specialist is able to solve the problem, in this case.

How to check the performance of the lighter?

In order not to dismantle a potentially serviceable component in vain, it is advisable to first check for a short circuit (short circuit).

It is easy to do this with the help of a measuring device - a tester that supports the possibility of measuring resistance in the "mOhm" range.

On almost all models of gas stoves, the ignition controls are connected by conductors through connectors. Therefore, each control is easy to disconnect from the circuit for testing. After removing the plugs with conductors from the connectors, the buttons connect the tester probes to the released contacts and control the readings on the scale.

If a short circuit is formed inside the button housing through the oxide junction, resistance measurements in the “mΩ” range will show some value anyway. When the instrument readings are equal to the absolute reference point (maximum resistance "mOhm"), there is no short circuit defect.

We also have other articles on the site about stove breakdowns and problems with burners:

Troubleshooting a Gas Stove

Before starting repairs, it is important to know that all gas fittings are made of their alloys, which do not spark when in contact. In the process of restoration work, it is worth using similar materials

Of the tools, pliers, an adjustable wrench for the stove and valve, and a gas wrench will be needed.

Problem #1 - Burner Malfunctions

When the smell of gas appeared as a result of an extinguished flame, it is necessary to immediately close the valve and ventilate the room. This situation is considered an emergency, so you need to immediately open the windows wide open

When the burner has cooled down, it is important to thoroughly blow it out, clean it of food residues, grease

During the operation of the stove, soot accumulates on the burners, which can give the flame a yellow tint. This can be misleading, creating the appearance of a malfunction where there is none.

A properly functioning burner produces an even, blue flame. If tongues of yellow, red color slip through, this indicates a malfunction of the burner, the likelihood of fuel leakage

After thoroughly cleaning the burner, it is necessary to install it in place, light it, check its operation.

If any defect became the cause of the malfunction, it is worth replacing the burner with a new one.

Problem #2 - Broken Connecting Hose

The hoses used to connect the gas are sold at specialized outlets. Visually, they differ from the rest in a bright yellow shell.

The gas supply hose, connecting elements, are distinguished by a bright yellow braid.This allows you to distinguish elements suitable for creating a gas pipeline from other similar products.

When the leak is caused by a crack in the hose, it is worth replacing it. After all, the repair will provide a short-term effect and the unpleasant smell will reappear very quickly.

Problem #3 - Leak in the stopcock area

To check the performance of the unit, it is necessary to apply a soapy solution to the nozzle. If a leak is detected, immediately turn off the gas supply, call professionals. If there is a new valve, linen tow, the master will promptly replace the gas valve.

At the end of the installation, the connection is tightened until the valve is in the desired position. The correct installation is determined by repeated application of the soap solution.

The shut-off valve is located on a pipe connected to the central line. Also, the problem may be in the valve at the place where the stove is connected to the cylinder. If the connection is leaking, a gas leak may occur.

To extend the life of the connection, it is painted over with oil paint. After drying, the composition creates a dense film that can reduce the likelihood of leakage.

How the function works

The electric ignition system is provided in stoves with a gas type. Its main purpose is to ignite the fuel that comes from the burner divider. The electric ignition device can be of two types:

Auto ignition has special piezoelectric elements, which, when the switch on the panel is turned, ignite the gas-air mixture. When using a mechanical device, you need to press a special button. When pressed, a spark is supplied, from which the gas ignites and ignites.

The principle of operation of electric ignition looks like this:

- when the user presses the button, voltage is applied to the capacitor area;

- after that, the charging of the capacitor begins;

- further, an increase in the level on the thyristor is observed;

- as soon as it reaches the permissible limit, the discharge of the capacitor begins;

- at the output of the device, a voltage appears, due to which the arrester is actuated;

- the spark released ignites the gas.

Despite the fact that the process looks complicated, it happens in a matter of seconds. The spark supply always falls on the area of the burner, which at that moment is in the on state. In obsolete products, a spark was supplied to all burners, but ignition took place only on the one on which the gas supply was open.

The electric ignition is powered from an electrical network with a voltage of 220 volts. Its work also depends on voltage drops, which can occur quite often. If a power surge occurs, a clicking sound may appear, this usually indicates a breakdown of the electric ignition device.

High voltage block device

Reason # 4 - problems in the water fittings

The simplest solution to the issue of rattling pipes in an apartment is sometimes in water fittings. If the cause of the hum lies in a faulty mixer (when the tap is opened, the pipe starts to vibrate), or in a shut-off valve, the problem can be solved independently by turning off the water through the riser and carrying out a simple repair.

All that needs to be done to eliminate the hum in the pipes in this case is to remove the bushing valve and deal with the gasket at the end of the rod.It either dangles freely on it, or its edges have a pointed conical shape. In the first case, the used gasket should be replaced, and in the second, just cut its edges with scissors. We collect the crane box in place and check it. If done correctly, the noise should be gone.

These problems can only happen with old-style mixers that are equipped with valve or half-turn crane boxes. In modern single-lever mixers and ball valves, there are no gaskets that block the flow of water, therefore, in principle, they cannot cause noise in the pipes.

We looked at the most common causes of humming pipes in an apartment and how to fix them. Perhaps now you can independently, without the help of a plumber, eliminate disturbing noise as quickly as possible so as not to negatively affect not only the water supply system, but also your own nervous system. After all, it is at home that we want to relax in silence from the bustle of the city. And in conclusion, we suggest that you familiarize yourself with an interesting video that shows how you can measure the water pressure in the plumbing system.

What to do if the pie constantly clicks by itself

You need to find the source of the problem. Then follow the instructions for eliminating defects in work, which are written in this article. Refresh all your knowledge about it

It is important not to panic in any situation, strictly follow the rules, only then the outcome of events will be favorable.

How to troubleshoot at home

For example, when the cause is water, that is, due to the constant ingress of liquid on the stove, it is necessary to dry the device well. You should unplug the plug from the outlet, turn off the device for several days (recommended from two to three). During this time, the device should have time to dry. If, after this procedure, the clicking remains, then you will have to call in special craftsmen who will surely cope with the task.

- If only one burner does not work, then the thing is that the wire is damaged, the malfunction lies in the channel of the whole unit itself.

- If the burner is out of order, then it should be replaced.

- However, with the incessant repetition of the click, it is worth using ignition with a lighter or matches.

- Or call a professional master who will be able to qualitatively diagnose the cause and repair your equipment.

The main thing is not to panic when a breakdown is detected, but to act consistently.

If water is spilled on the stove

Humid area around the burner or a wet burner can create an ignition problem.. Water conducts electricity well, and a spark from a spark plug can strike in the other direction without igniting the gas. In addition, a gas burner flooded with water makes it impossible to ignite.

In this case, it is necessary to turn off the stove from the network, wipe everything thoroughly with a dry cloth or napkins. You can dry everything with a hair dryer, only using cold air.

If your electric ignition always clicks on the hob, then the best way out is to turn off the stove from the network and leave it inoperative for 2-3 days

. It dries completely naturally, and there will be no such problems.

Breakdown prevention

Gas stoves are used everywhere and are popular because they are quite unpretentious in use and maintenance. There are many brands of slabs, the most popular and safe are the Hephaestus model slabs. But in order for the stove of any model to serve you faithfully for many years, you need to properly care for it, follow the safety precautions. This is the only way to reduce the likelihood of breakdowns and generally minimize them.

In order for the stove to serve you for a long time, you first need to properly care for it.

It is useful to carry out a complete cleaning of your stove from dirt at least once a week. Try to wash the surface immediately after cooking if you see stains of oil, any other liquid and or food leftovers there. First remove large residues, crumbs, and then wipe the surface with a damp cloth or sponge.

Causes of the malfunction

To accurately determine the problem, our masters conduct diagnostics. It is necessary in order to accurately find the source of the problem. This is due to the fact that several components and external factors influence the failure of the system. The main reasons are:

- Water penetration into taps or the power button, which caused the contacts to oxidize or close;

- A large accumulation of fat deposits on the mechanisms, because of which they do not return to their original position;

- The spark generation unit has closed;

- The power button burned out or melted;

- Increased dampness inside the device. Improper operation of the stove;

- other external causes.

It is worth focusing on the accumulation of grease and dirt on the ignition button or power controls, which is why they wedge when pressed and the candles continue to work.This problem is quite relevant, since the owners do not pay attention to the care of household appliances.

At the same time, many do not thoroughly clean the moving mechanisms. Before contacting our company, we recommend that you check the purity of these components and, if necessary, clean them. Use rags and other materials with minimal moisture to prevent water from getting inside. If after cleaning the mechanisms work properly, but the problem remains, the professionals of our company will repair or replace the defective parts.

Speaker whistles

If a monotonous loud whistle comes from the equipment, first of all, you should determine where it comes from. To do this, close the gas valve, and then open the hot water valve. Further actions depend on the resumption or absence of "trills":

- If a whistle appears, its occurrence is associated with the water path. The most common cause of such a sound is scale deposits in the heat exchanger or a foreign object getting inside the pipe. In this case, the performance of the column drops. In this case, to get rid of the whistle, you need to clean the heat exchanger from scale, and the reverse flow will help wash the foreign object from the column.

- In the absence of a whistling sound, the cause of its occurrence was problems in the gas path. Most often they are associated with a defect in the valve that modulates the power of the flame. Then the whistle appears only at a certain power, and in order to eliminate it, you need to adjust the power in any direction. Another common cause is blockage of the tract. Whistling sounds at the same time appear at any power.To identify the place of contamination, it will be necessary to carry out an extraordinary cleaning, which is best entrusted to a specialist working with gas equipment.

After watching the following video, it will be possible to independently clean the heat exchanger from scale without contacting the masters.

Attention, only TODAY!

Similar

Conclusions and useful video on the topic

Search for the reasons why the gas water heater turns on with cotton and how to eliminate them in the following video:

There are a lot of reasons for the appearance of extraneous sounds when the speaker is turned on. Most you can diagnose yourself and try to fix the problem on your own. If you still could not determine the cause of the breakdown, then the only solution in this situation will be to contact specialists in the repair of gas equipment.

Do you want to tell another user about your experience in finding the cause of the popping gas water heater? Or do you have questions that we have not paid attention to in this material? Ask them in the comments block - our experts will try to help you. Share your experience, take part in discussions - the contact form is located below

Conclusions and useful video on the topic

Concluding the review of the defect of the constantly clicking gas stove, as well as the possibilities of correction, we recommend that you familiarize yourself with the thematic video below:

In some cases, the elimination of the defect is quite possible on its own. However, theoretically and in accordance with the rules, any malfunction of gas stoves is the prerogative of special (gas) services. This approach is due, first of all, for reasons of general fire safety, and not just directly for the owner of household appliances.

Today, all manufactured household appliances are focused on being as convenient as possible and at the same time easy to use. Kitchen appliances, in this case, are no exception. One of the main appliances in the kitchen is the stove. You can’t do without it in any house, you can’t cook food, you can’t heat dishes, and you can’t boil water.

There are different stoves - electric, gas and combined. Today we will talk about one of the most modern models - a stove with auto-ignition. The appearance of this model made it possible to replace the usual matches and lighters with a simple push of a button, but at the same time, it gave rise to a number of problems associated with intermittent malfunctions of the electric ignition mechanism, including its constant clicking.