- 2 How to calculate the culprit of the loss of pressure?

- The pressure in the boiler drops or rises, what are the reasons

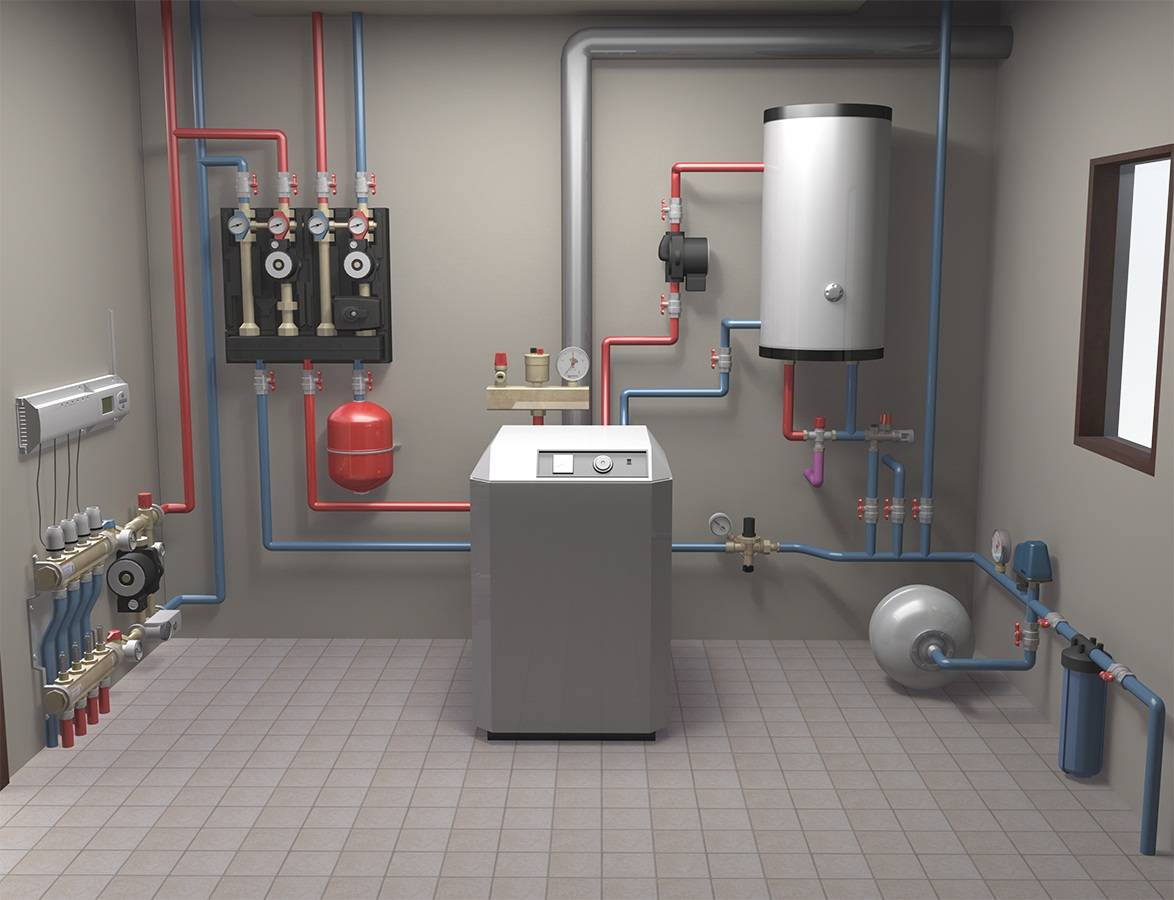

- Leak in the heating system

- Normalized indicators

- The main reasons for the decrease in pressure

- What pressure value is considered normal

- Leak test

- Training

- Stage 1 - cold test

- Stage 2 - hot check

- Plastic pipeline

- Air test

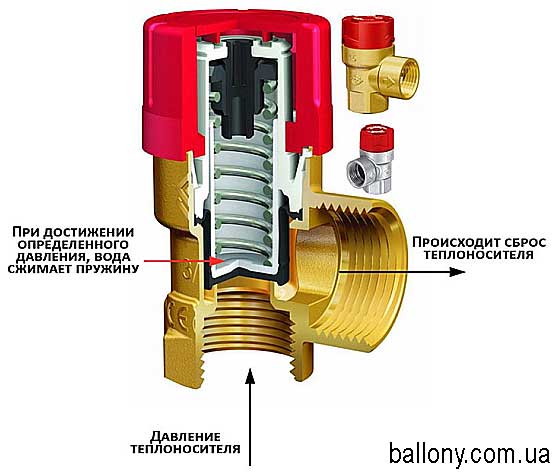

- Relief valve problems

- How to check the pressure in the boiler and circuit

- Pressure increase due to expansion vessel

- Reasons for reducing pressure in the heat supply network

- Leak in the heating system

- Excess air in the system

- Expansion tank problem

- Other reasons

2 How to calculate the culprit of the loss of pressure?

So, the most important thing is to understand what exactly led to the loss of pressure. To do this, follow the algorithm. First, we take an ordinary paper towel and wipe all the fittings. In this case, after each joint, you need to carefully examine the napkin - whether there is a wet spot on it. If so, the cause has been found. If not, you need to move on.

Secondly, we spread dry newspapers under the batteries and wipe all the pipes with the same blotting paper. If a wet spot is found, the leak is localized. If not, go to the next point.Thirdly, we measure the pressure in the expansion tank and pump it up. This can be done with a regular bicycle pump and a factory pressure gauge. The pressure no longer drops - congratulations, you have solved the problem with the air pocket. But if, after pumping, the pressure drops sharply or does not deviate from the original, the membrane is torn at your hydraulic tank. If the pressure drops smoothly, we move on.

Fourthly, we turn off the boiler and close the valves on the pressure and return pipes, cutting off the heater from the system. We measure the pressure for an hour - if it does not fall, then the water heater itself is to blame, or rather its heat exchanger. In addition, in the Navien boiler or any other two-circuit installation, a malfunction in the air vent or pressure relief valve may occur. Fifthly, we check the shut-off valve on the outlet for discharging the coolant into the sewer. If it is weakened, it must be blocked or replaced (it is better to cut another one downstream). After localizing the leak or determining the cause, you can begin to eliminate it. How to do it? We will talk about this below.

The pressure in the boiler drops or rises, what are the reasons

One of the frequent malfunctions is that the pressure in the heating system slowly drops and when it drops below normal, the boiler turns off.

There are two reasons

Leak in the heating system

First reason

—

in general, it is not connected with the boiler; it is rather a problem of the heating system itself. Namely, an elementary coolant leak from pipes or a radiator, but what is most often used as a coolant? That's right water!

Believe! Sometimes it’s not easy to detect such a leak, but the fact is that you won’t see a puddle on the floor, well, of course, unless it’s a serious leak, but most often it’s just droplets flowing out, for example, from under a radiator cap, or poor-quality connection or soldering, and you will not see these droplets, because during the heating season they immediately evaporate from the heated pipes. As a result, slowly but surely, the pressure drops, you add water over and over again and this continues to kill radiators and pipes.

Not infrequently, modern radiators, aluminum or bimetallic, also become unusable, sometimes in inconspicuous places, between the ribs or from below, they begin to dig due to metal corrosion. Not rust, of course, but various chemical processes also make them unusable. They need to be carefully inspected while searching for a leak.

It will be easier to detect all sorts of leaks if you turn off the heating for a while, let the radiators cool down and add pressure to about 2.5 bar. Carefully inspect the radiators themselves, pipe connections, soldering points.

Second cause

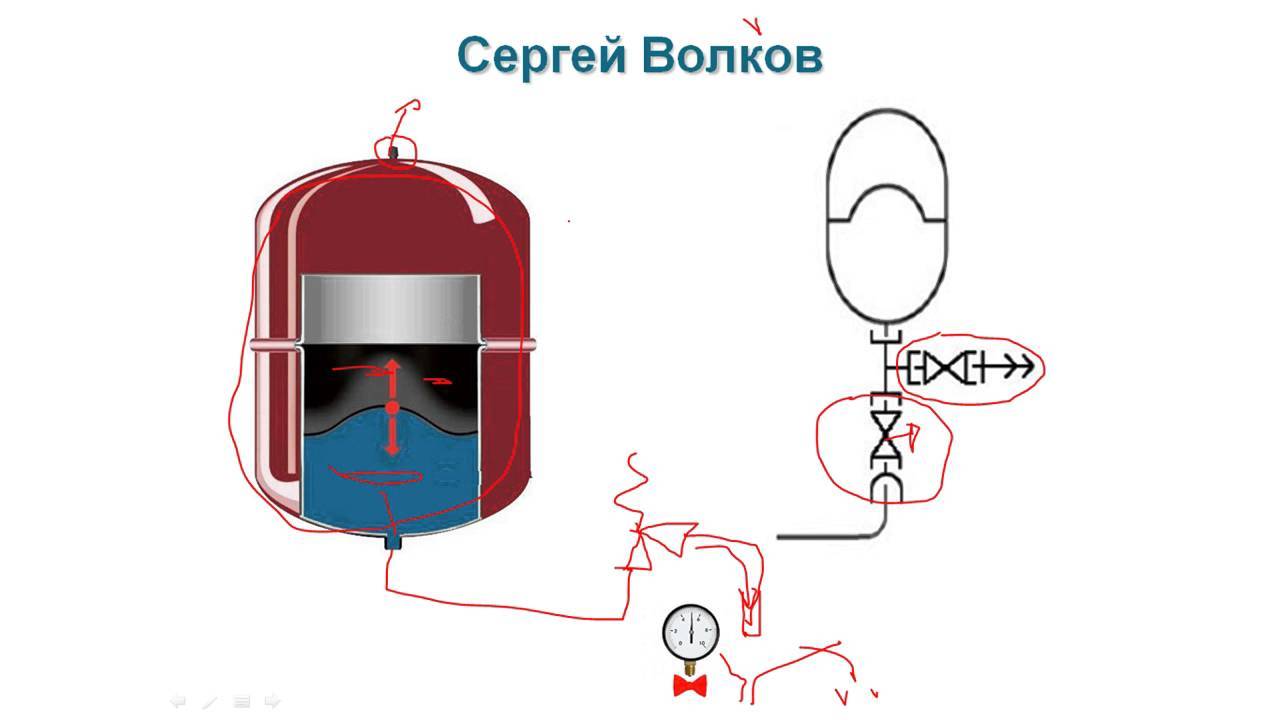

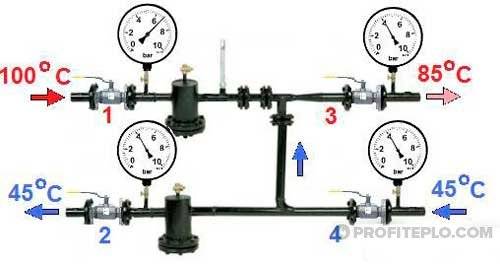

pressure drop in the heating system and, accordingly, in the boiler, is connected with the expansion tank. The expansion tank is designed to compensate for the pressure created during the expansion of the heated coolant, this is a container separated by a membrane, one half of the tank is filled with an inert gas or just air, the other is filled with a coolant (read water). When heated, the water expands and fills the tank, when cooled, it is again pushed into the heating system.

A) In an extremely rare case, there may be a malfunction of the tank itself. For example, the tank body has lost its tightness.Or there may be a rupture of the membrane inside the tank, but it is not so delicate, so it takes some effort to tear it. But if this happens, then the coolant enters from the heating system into that part of the tank that should be filled with air. It is not difficult to determine, in the upper part of the tank there is a spool through which air is pumped (as in a car, bicycle) if pressing the spool from the tank throws water out, the tank is for replacement.

B) In the second case, the reason is that the air from the part of the expansion tank in which it should be has escaped or does not have sufficient pressure.

It may appear like this

: FIRST STAGE... The pressure in the boiler drops slowly, about once a week you have to make up the boiler, while there are no leaks in the heating system itself. SECOND STAGE…On the boiler pressure gauge, the pressure constantly “walks” in the heating mode rises until the relief valve is activated, in the hot water mode it drops to values less than 1 bar and then the boiler starts to turn off, the protection is triggered.THIRD STAGE… If there is no air left in the tank, then the pressure on the pressure gauge drops to zero in general in a very short time, sometimes in a minute.

Output: You need to create pressure in the expansion tank of your boiler.

Normalized indicators

To understand how the indicators deviate from the norm, you need to know the maximum allowable values for a certain type of network. In autonomous systems, the value should not exceed 1.5-2 atm. If the normalized indicators are exceeded, for example, up to three atmospheres, heating devices and pipelines may depressurize.All this can lead to the failure of various important components and equipment.

As a rule, in autonomous circuits, pressure is maintained within 1.5 atm. During the heating of the heat carrier, it expands. This will help increase the readings on the pressure gauge to operating values of 2 atmospheres.

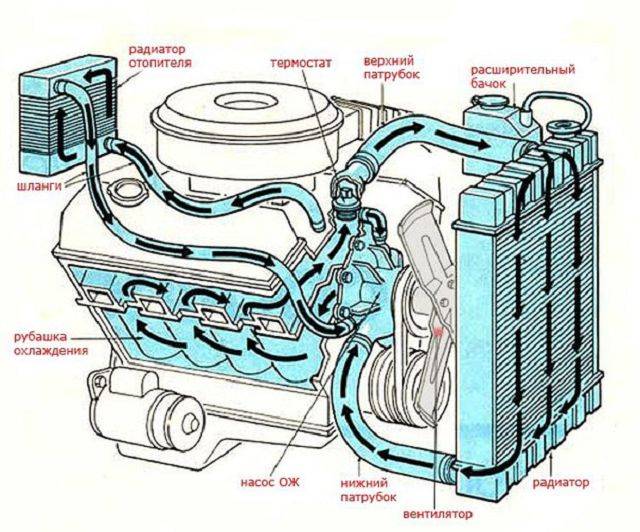

So that during the expansion of the coolant the pressure does not rise to critical levels, an expansion tank is installed in the circuit. When the operating parameters are reached, the excess of the expanded liquid enters this container. When the temperature of water decreases, it contracts. As a result, the shortage of the coolant is replenished by the liquid that came back from the tank to the pipelines and devices.

The main reasons for the decrease in pressure

Common reasons why the pressure in a gas heating boiler drops are:

- Coolant leakage. Damage to the heating main leads to leakage, loss of heating water and a decrease in pressure.

- Cracks in the heat exchanger. Leaks in the boiler itself will not only lead to a decrease in pressure, but can also provoke more serious equipment breakdowns and damage the electronics.

- Rupture of the membrane in the expansion tank. Through damage in the rubber partition, the liquid enters the air compartment and the pressure in the circuit decreases.

To determine the location of the leak in the system, it is fed to normal pressure and the circulation pump is stopped. Step by step, you need to examine the highway, identify the problem area and troubleshoot.

What pressure value is considered normal

A stable amount of atmospheres in the line helps to reduce the level of heat loss and the fact that the circulating coolant has almost the same temperature to which it was heated by the boiler.

It is necessary to talk about what the pressure should be, taking into account what kind of heating system we are talking about. Options:

Pressure in the heating system of a private house. With the open heating method, the expansion tank is the communication link between the system and the atmosphere. Even with the participation of the circulation pump, the number of atmospheres in the tank will be equal to atmospheric pressure, and the pressure gauge will show 0 bar.

Pressure in the system of a multi-storey building. A characteristic feature of the heating device in multi-storey buildings is a high static head. The higher the height of the house, the greater the number of atmospheres: in a 9-story building - 5-7 Atm, in 12-story buildings and higher - 7-10 Atm, while the pressure in the supply line is 12 Atm. Therefore, it is necessary to have powerful pumps with a dry rotor.

Pressure in a closed heating system. The situation with a closed highway is somewhat more complicated. In this case, the static component is artificially increased to increase the efficiency of the equipment, as well as to exclude air penetration. The required pressure in the heating system of a private house is calculated by multiplying by 0.1 the difference between the highest and lowest points in meters. This is an indicator of static pressure. Adding 1.5 bar to it, we get the required value.

Thus, the pressure in the heating system in a private house with a closed circuit should be in the range of 1.5-2 atmospheres.An indicator outside the range is considered critical, and when it reaches mark 3, there is a high probability of an accident (depressurization of the line, failure of units).

Yes, a large pressure improves the operation of the equipment, but the technical characteristics of the installed boiler should be taken into account. Some models withstand 3 bar, but most are designed for 2, and in some cases 1.6 bar

It is important, when setting up the equipment, to achieve an indicator in a cold system that is 0.5 bar lower than the value stated in the passport. This will prevent the pressure relief valve from constantly tripping. It is important to remember that it is pointless to measure the water pressure in the heating system or try to regulate it in a single apartment.

The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline

It is important to remember that it is pointless to measure the water pressure in the heating system or try to regulate it in a single apartment. The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline. For example, cast iron is not recommended, as they can only withstand 6 bar

And the use of pipes of a larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving to an apartment with old heating, it is better to immediately replace all possible elements

For example, cast iron is not recommended, as they can only withstand 6 bar. And the use of pipes of a larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving to an apartment with old heating, it is better to immediately replace all possible elements.

Another parameter that affects the amount of pressure in any heating main is the temperature of the coolant. A certain amount of cold water is pumped into the mounted and closed circuit, which ensures a minimum pressure. After heating, the substance will expand and the number of atmospheres will increase. Therefore, by adjusting the temperature of heating water, you can control the pressure in the circuit. Today, heating equipment companies offer the use of equipment with hydraulic accumulators (expansion tank). They do not allow pressure to increase, accumulating energy within themselves. As a rule, they are included in the work when they reach the mark of 2 atmospheres.

It is important to regularly check the accumulator in order to empty it in time. It would also be useful to install a safety valve, which can be activated at a pressure of 3 atm and a filled tank in order to avoid an accident.

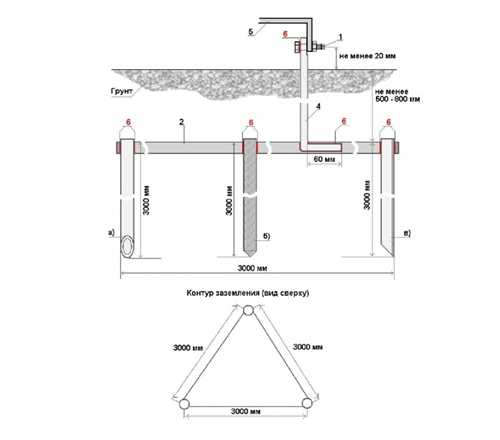

Leak test

In order for the heating to be reliable, after installation it is checked for leaks (pressure tested).

This can be done immediately on the entire structure or its individual elements. If a partial pressure test is carried out, then after it is completed, the entire system as a whole must be checked for leaks.

Regardless of which heating system is installed (open or closed), the sequence of work will be almost the same.

Training

The test pressure is 1.5 times the working pressure. But this is not enough to completely detect a coolant leak.Pipes and couplings can withstand up to 25 atmospheres, so it is better to check the heating system under such pressure.

Corresponding indicators are created by a hand pump. There should be no air in the pipes: even a small amount of it will distort the tightness of the pipeline.

The highest pressure will be at the lowest point in the system, a monometer is installed there (reading accuracy 0.01 MPa).

Stage 1 - cold test

In the course of half an hour in the system filled with water, the pressure is increased to the initial values. Do this twice, every 10-15 minutes. For another half an hour, the fall will continue, but without exceeding the mark of 0.06 MPa, and after two hours - 0.02 MPa.

At the end of the inspection, the pipeline is inspected for leaks.

Stage 2 - hot check

The first stage has been successfully completed, you can proceed to the hot leak test. To do this, connect a heating device, most often it is a boiler. Set the maximum performance, they should not be more than the calculated values.

Houses are preheated for at least 72 hours. Test passed if no water leak is detected.

Plastic pipeline

The plastic heating system is checked at the same temperature of the coolant in the pipeline and the environment. Changing these values will increase the pressure, but in fact there is a water leak in the system.

For half an hour, the pressure is maintained at a value one and a half times higher than the normative one. If necessary, it is slightly pumped up.

After 30 minutes, the pressure is sharply lowered to readings equal to half the working one, and they are held for an hour and a half. If the indicators began to grow, it means that the pipes are expanding, the structure is tight.

Often, craftsmen, when checking the system, make a pressure drop several times, then raising it, then lowering it, so that it resembles normal, everyday working conditions. This method will help to identify leaky connections.

Air test

Multi-storey buildings are tested for tightness in autumn. Instead of liquid in such cases, air can be used. The test results are slightly inaccurate due to the fact that the air is first heated during compression, then it is cooled, which contributes to a pressure drop. Compressors will help increase this parameter.

The sequence of checking the heating system is carried out as follows:

- The structure is filled with air (trial values - 1.5 atmospheres).

- If a hiss is heard, it means that there are defects, the pressure is reduced to atmospheric pressure and the defects are eliminated (for this, a foaming substance is used, it is applied to the joints).

- The pipeline is again filled with air (pressure - 1 atmosphere), hold for 5 minutes.

Relief valve problems

Such a valve is also called a safety valve. It is arranged in a security group or mounts separately. Its function is to relieve excess pressure in the heating network.

The principle of its operation is as follows: there is a spring pressure on the shutter, blocking the movement of the coolant. When the pressure exceeds the normalized values, it contracts and opens the shutter, excess air or coolant comes out.

In such valves, the spring wears out after 7-10 cycles. Stable pressure is not maintained and constant leaks form.

This valve needs to be repaired. This should only be done by a specialist. But, as a rule, the whole mechanism changes.

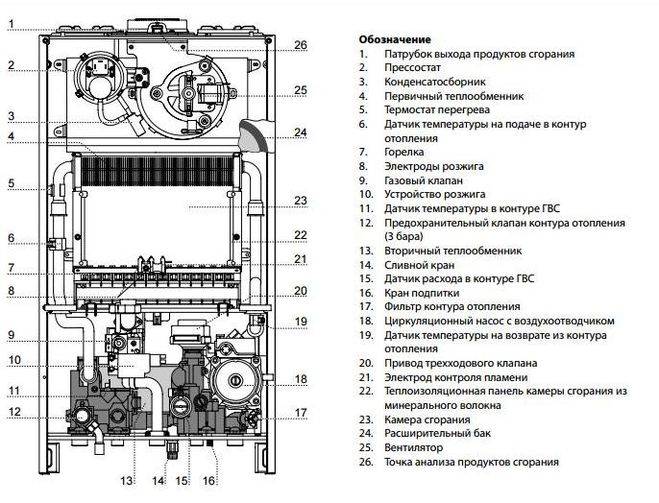

How to check the pressure in the boiler and circuit

Pressure control in the system is carried out using instruments that measure and reflect the pressure in the circuit using a digital or mechanical dial. Sensors are installed by the manufacturer on the outlet pipe of the boiler.

During the installation of the system, pressure gauges are also installed near the collectors, which distribute the coolant to various parts or floors of the building.

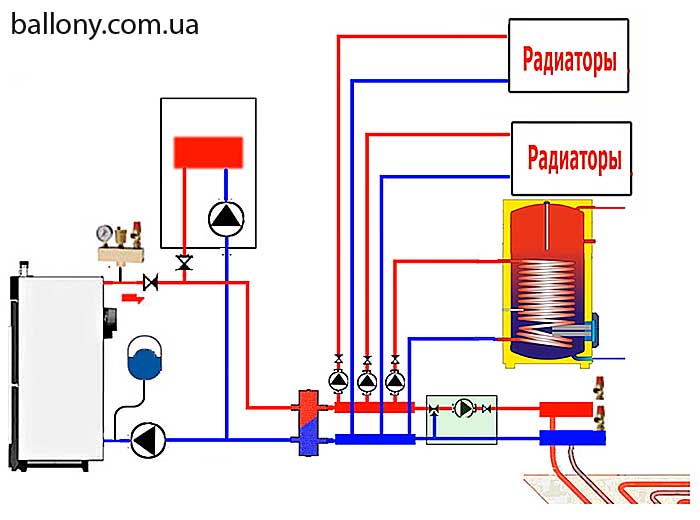

Additional pressure control is required when using boilers for hot water in underfloor heating systems. A drop or increase in pressure can be observed in different ways in different parts of the heating system.

When starting a gas boiler, check the pressure gauge readings while the heating water is still cold - the pressure should not be lower than the minimum value indicated by the red adjustable arrow on the pressure gauge. The adjustment is carried out by a representative of the company with which a contract for the maintenance and supply of gas has been concluded.

Initial setup is done on first start heating. In the future, the pressure is checked every week, if necessary, the system is fed with water. Make-up is carried out at a coolant temperature below 40 °C.

Pressure increase due to expansion vessel

Increased pressure in the circuit can be observed due to various problems with the expansion tank. Among the most common causes are the following:

- incorrectly calculated tank volume;

- membrane damage;

- incorrectly calculated pressure in the tank;

- improper installation of equipment.

To solve this problem, it is necessary to correctly calculate the volume of the tank, which should be at least 10% of the total water volume in the gas boiler circuit and at least 20% if a solid fuel boiler is used for heating. In this case, for every 15 liters of coolant, a power of 1 kW is used. When calculating the power, it is necessary to determine the volume of the heating surfaces, for each individual circuit, which allows you to get the most accurate values.

The cause of the pressure drop may be a damaged tank membrane. At the same time, water fills the tank, the pressure gauge shows that the pressure in the system has dropped. However, if the make-up valve is opened, the pressure level in the system will be much higher than the calculated working one. Replacing the membrane of the balloon tank or completely replacing the equipment if a diaphragm tank is installed will help to correct the situation.

A malfunction of the tank becomes one of the reasons why a sharp drop or increase in operating pressure is observed in the heating system. To check, it is necessary to completely drain the water from the system, bleed the air from the tank, then start filling the coolant with pressure measurements in the boiler. At a pressure level of 2 bar in the boiler, the pressure gauge installed on the pump should show 1.6 bar. At other values, for adjustment, you can open the shut-off valve, add water drained from the tank through the make-up edge. This method of solving the problem works for any type of water supply - upper or lower.

Improper installation of the tank also causes a sharp change in pressure in the network.Most often, of the violations, the tank is installed after the circulation pump, while the pressure rises sharply, and a discharge is immediately observed, accompanied by dangerous pressure surges. If the situation is not corrected, then a water hammer may occur in the system, all elements of the equipment will be subjected to increased loads, which adversely affects the performance of the circuit as a whole. Reinstalling the tank on the return pipe, where the laminar flow has a minimum temperature, will help to solve the problem. The tank itself is mounted directly in front of the heating boiler.

There are many reasons why there are sharp pressure surges in the heating system. Most often, these are incorrect installation and errors in calculations when choosing equipment, incorrectly made system settings. High or low pressure has a very negative effect on the general condition of the equipment, so measures should be taken to eliminate the cause of the problem.

Official BAXI Forum in Russia

- Topics without replies

- Active Topics

- Search

- Users

- our team

- Thanks

- 07/19/2019 — BAXI Seminar Notebook 3rd Quarter has been released. 2019 (119 Mb). Download

- 06/20/2019 — BAXI Energy voltage stabilizers went on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4th quarter seminar notebook was published. 2018 (8 Mb). Download

Reasons for reducing pressure in the heat supply network

There are only two provoking factors - a malfunction of the heating equipment or a leak in the pipeline system. If there is a problem with the heating boiler in a private house, the defect is eliminated by oneself, in multi-apartment residential buildings this is the work of specialists. Network leakage can be repaired with your own hands.

Leak in the heating system

The pressure will drop if it happens water hammer in the heating system. Hydraulic failure leads to depressurization of the structure. As a result, the coolant leaks, the pressure drops. Most often, the leak zone is the junction of radiators with the pipeline, intersection joints. But if the pipes and batteries are old, the leak appears at the place of metal corrosion.

To check the integrity of the membrane in the expansion tank, press the nipple at the top of the device. The air comes out with water, the leak area is found, if the air comes out without water, the problem is elsewhere.

Excess air in the system

Test run and commissioning of the network are related to the release of excess air from the network

In this case, air is bled from the circuits and the boiler, so it is important to note the pressure gauge on the boiler. If the pressure gauge readings fall during network operation, there is only one reason - air comes out of the heat exchanger. Gas enters the system circuit or is released by an automatic air vent

Bleeding gases with an air vent is normal, but if the valve is clogged, the excess enters the heating network and the pressure drops

Gas enters the system circuit or is released by an automatic air vent. Bleeding gases with an air vent is normal, but when the valve is clogged, the excess enters the heating network and the pressure drops.

Causes of excess air entering the heating network:

- violation of filling standards - water is supplied to the network in a large jet;

- pouring low-quality coolant with a high content of gases;

- air leakage through depressurized joints;

- blockage of the automatic air vent.

To determine the accumulation of gases in radiators and pipelines, noise in radiators will help.Extraneous sounds are allowed only when the circuits are filled with coolant. If noise is heard when starting the network in constant mode, this is a sign of air.

Expansion tank problem

An expansion tank or compensator is installed on any heating system. The device is needed to compensate for pressure during heating and cooling of the coolant. An open tank works according to a simple principle - when water is heated, its volume in the tank increases, and when it is cooled, it decreases. The pressure in the sealed network is maintained optimally.

Another thing is a closed expansion tank. Inside the device is divided into two compartments - for water and air. Between the compartments is a flexible membrane. When the coolant is heated, the volume of water increases, the membrane moves towards the air chamber. Cooling down, the coolant decreases in volume, and to maintain pressure, the membrane shifts towards the compartment with water. This requires a constant volume of air. And if the tank is faulty, the air comes out, the pressure drops.

Other reasons

Sometimes the pressure on the pressure gauge constantly creeps up - this is also a malfunction. It is required to understand why the pressure in the gas boiler is increasing. As a rule, this is a breakdown of the coolant inlet valve - it will let water into the system. A defect in the secondary heat exchanger may also form, it occurs only in double-circuit boilers.

Now about why the pressure drops in the heating boiler:

- Flow. When laying a pipeline in a hidden way, the owners do not always see the depressurization of the system. The same with the contours of underfloor heating - here the leak is not visible until it manifests itself as a wet spot on the floor.

- Violation of network calculation technology.Poorly fixed joints, pipe breakage, a large number of bends or the selection of the wrong section cause a drop in pressure level.

- Microcracks on the boiler heat exchanger. Most often found with cast iron products if cold water is poured into them. Despite its strength, cast iron is brittle and may not withstand water hammer.

- The boiler control and management system has failed.

- The use of aluminum radiators. The problem lies in the formation of a thin film inside the tunnel - it is formed when the metal comes into contact with water. The physical process is associated with the release of hydrogen, the compression of which reduces the pressure in the network.