- Other malfunctions

- Membrane for accumulator how to replace it in case of malfunction

- How to test and troubleshoot

- Membrane selection

- Replacement cost

- Membrane replacement

- Repair or how to glue

- Hydraulic accumulator without membrane

- The Importance of Pressure Rating in a Workstation

- Prevention of the recurrence of a malfunction

- Pump station pressure regulation

- What pressure should be in the pumping station in the pear?

- What pressure should be in the expansion tank of the pumping station?

- Why does the pressure drop in the pumping station?

- Why does the pumping station not build up pressure and turn off?

- Why does the pressure in the pumping station not rise?

- The pumping station does not hold pressure and constantly turns on

- Turretless often turns on

- Malfunctions of the pumping station video

- How to change the membrane?

- Why the pumping station turns on when water is drawn in: troubleshooting

- pressure regulator

- Weak pump power

- Other causes of failure

- Problems and malfunctions of pumping stations and their correction

- The pumping station does not turn off (does not gain pressure)

- Repair of the pumping station: often included

- Air in water

- The pump station does not turn on

- The motor hums but does not pump water (the impeller does not rotate)

- If the pressure "jumps"

- Clogged inlet filter

Other malfunctions

During the operation of the pumping station, you may encounter other problems that can also be eliminated on your own.

During the operation of the pumping station, you may encounter other problems that can also be eliminated on your own.

The pump constantly pumps water without interruptions

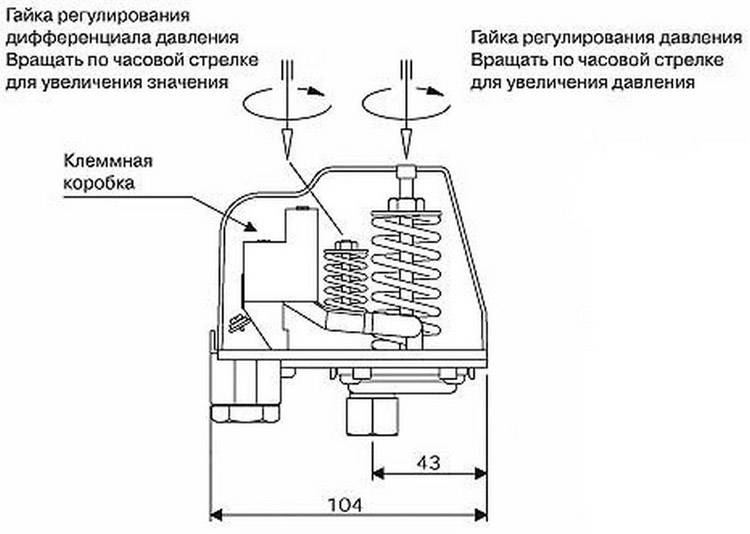

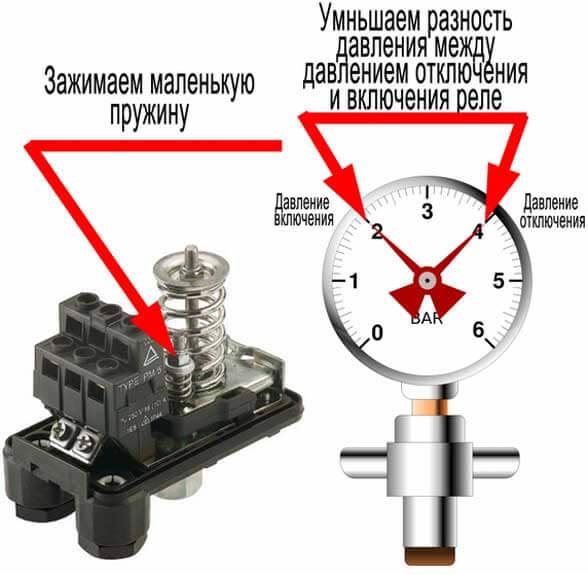

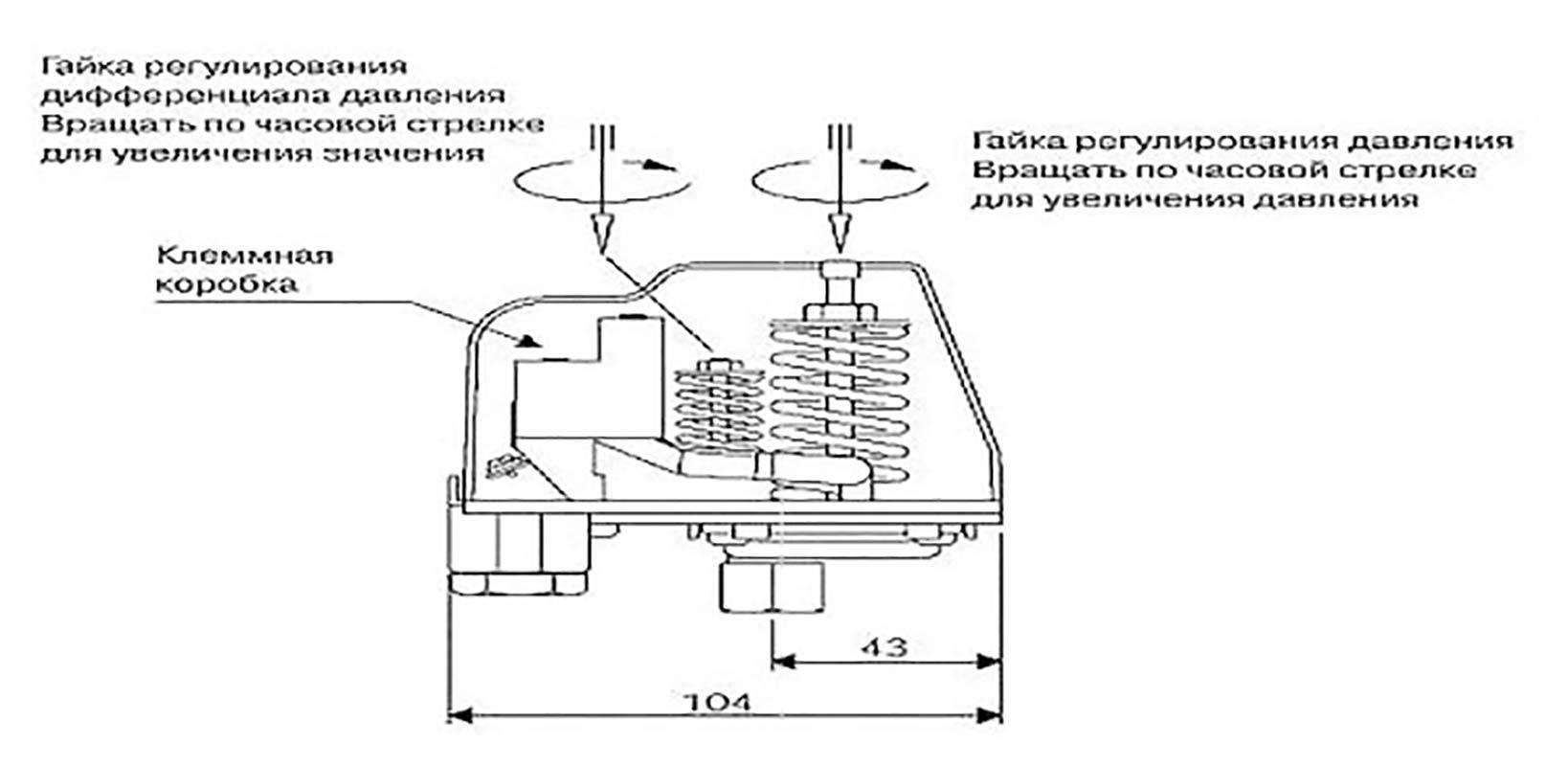

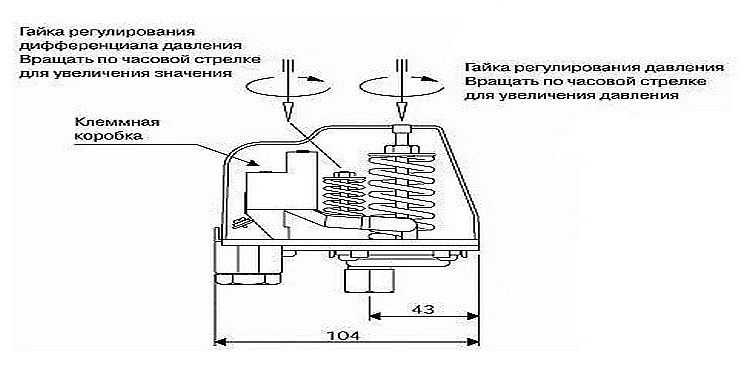

Most often, such a malfunction occurs due to poor adjustment of the relay, through which the pressure level in the piping system is fixed. Two different springs are used to adjust the relay:

- a small spring is used to adjust the pressure difference between the minimum value and the maximum;

- a large size spring sets the maximum and minimum limits for turning the pump on and off.

If the automation unit of the pumping station is used for a long time, then the springs may stretch, resulting in a knockdown of the indicators set during the initial adjustment. In addition, the installation may not be turned off during long-term operation of the station, the moving parts of the pump wear out, and the maximum indicators of the generated pressure decrease. In addition, after a long operation, the maximum pressure should be reduced, for which you should perform large spring adjustment. This should allow the device to turn off intermittently.

Also, malfunctions in the operation of the control relay may occur due to the narrowing of its outlet, which, during prolonged operation of the station, can become clogged with deposits contained in the pumped liquid. In this case, in order for the device to turn off, it is necessary to remove the relay and clean it.

Station won't turn on

If you encounter such a problem, then its cause may be either a lack of electricity in the network, or a voltage drop in the system.Therefore, it is necessary to check the electricity in the circuit and the voltage, for which you should use the test.

If the pumping station is connected correctly, and there is electricity in the network, then the breakdown may be due to a breakdown in the winding of the electric motor. If this is the case, then the motor stops and a characteristic smell of burnt insulation appears. If it was this fault that caused the inability to turn on the station, then to eliminate it, it is necessary to replace the electric motor with a new one.

The pumping device makes a hum, but it does not rotate

With a long downtime of the pumping station, owners most often encounter such a problem.

- When the station is not used for some time, the rotor wheels may stick to the inside of the pump. In this situation, you must try to manually turn the pump shaft. If on your own you cannot move the rotor from the current position, then in this case you will have to disassemble the device case and eliminate the defect of the impeller - its jamming.

- The cause of such a malfunction may also be the failure of the capacitor, which is located in the terminal box of the pump. This problem is not typical for all motors, but only for those that are connected according to a three-phase circuit. An electrical test is used to identify a malfunction and eliminate it.

Membrane for accumulator how to replace it in case of malfunction

The normal functionality of the home water supply system depends on the health of the accumulator. If there are malfunctions in the water supply network, it is necessary to immediately determine the cause of the malfunction and repair the equipment.Otherwise, more serious damage and irreversible failure of all equipment may occur. The most common cause of failure is the accumulator membrane. We will learn how to check, replace and diagnose the system.

How to test and troubleshoot

Most hydraulic accumulator malfunctions can be corrected independently. All reasons can be divided into several groups.

Table 1. Faults in hydraulic accumulators

Start draining water.

If at the same time air escape is observed, then the membrane has mechanical damage.

lack of compressed air in the tank.

Pumping air to the required pressure

Service recommendations accumulators:

How to check the initial pressure in the tank:

- Disconnect the tank from the system.

- Drop the water.

- Connect a pressure gauge to the nipple.

- If the readings are lower than the default ones, it is necessary to pump up the pressure to the working one (with a car compressor, for example).

Membrane selection

Hydraulic accumulators distinguish between vertical and horizontal versions. Accordingly, membranes are also distinguished in various shapes and designs: cone-shaped, cylindrical, spherical, ribbed.

When replacing a unit, you should purchase a product with similar characteristics - size, volume, neck diameter, maximum temperature of the working medium, material, working pressure, etc.

Replacement cost

The membrane is an element of equipment that most often fails, because. subjected to constant compression and expansion. The cost of replacement depends on the type of tank, capacity, type of membrane, manufacturer.

If the water supply system is operated continuously, it is advisable to purchase a more expensive membrane that can withstand more cycles of operation.

The cost of models of imported manufacturers reaches half the cost of the accumulator itself. At the same time, the nominal service life of products is several times higher than cheaper ones.

Membrane replacement

With minimal skills in working with plumbing equipment, replacing the membrane on the hydraulic tank is not difficult. By following the correct procedure, replacing a node takes a minimum amount of time:

- Disconnecting the tank from the water supply.

- Remove excess air pressure with a nipple.

- Drain the water from the container.

- Remove the pressure gauge, while freeing up space for the diaphragm to exit.

- Remove non-working part.

- Install a new membrane, fix the pressure gauge.

- Pump up pressure 0.2 less than the lower pressure of the pump switch.

- Install back.

After that, it is necessary to check the operability of the water supply. To do this, it is necessary to fill the system with water and control the operation of the tank.

Repair or how to glue

The membrane can be repaired by vulcanization. This method can extend its life by several weeks - until a serviceable product is purchased and installed. But any repairs are a temporary measure and in any case you will have to buy a new one.

Hydraulic accumulator without membrane

In addition to typical factory-made hydraulic tanks, you can make such a device yourself. A hydraulic accumulator without a membrane is an ordinary water tank. It is the membrane that helps maintain the pressure in the system. It is much easier to buy an inexpensive ready-made accumulator.

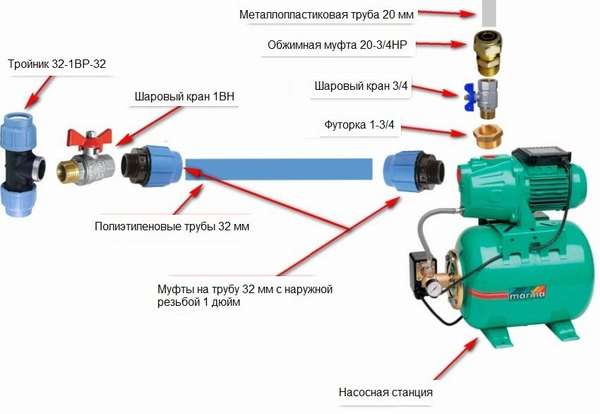

In order to build a hydraulic accumulator yourself, the following materials are needed:

- tank (capacity) with a volume of at least 30 l,

- stop valve,

- ball valve,

- half inch faucet,

- fasteners (washers and nuts),

- sealant (sealant),

- rubber pads,

- nipple,

- fittings (tee, chervernik).

- Make holes in the container (on the lid and bottom, on the side).

- Install a half-inch valve in the upper hole (on the cover), seal the connection with gaskets and sealant, fix with washers.

- Attach a tee to the faucet.

- Fix a ¾ shut-off valve in the lower hole, on which put a tee.

- Install a ball valve on the side hole.

A malfunctioning accumulator can affect the operation of the entire water supply system. By applying the tips and methods described in the article, it is easy to troubleshoot your home plumbing system. Timely prevention can prevent serious breakdowns and premature failure of hydraulic tanks and the entire system as a whole.

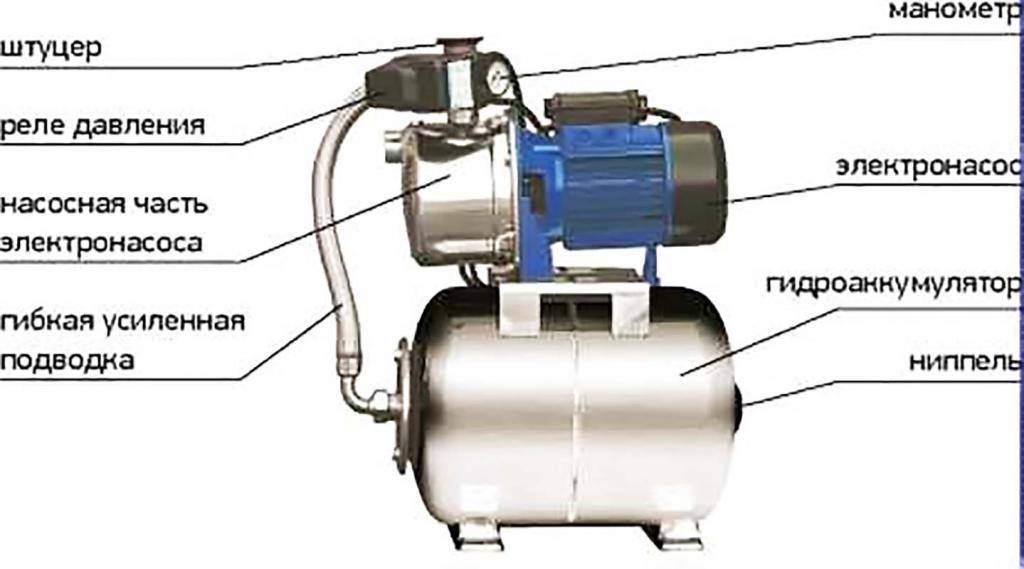

The Importance of Pressure Rating in a Workstation

So, the main character in the operation of the water supply station is the pump itself.

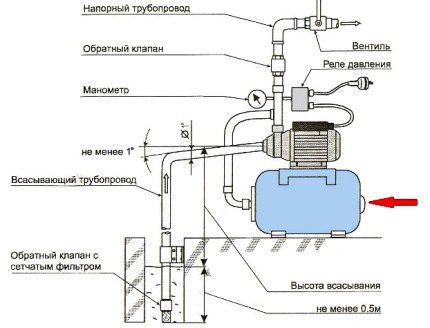

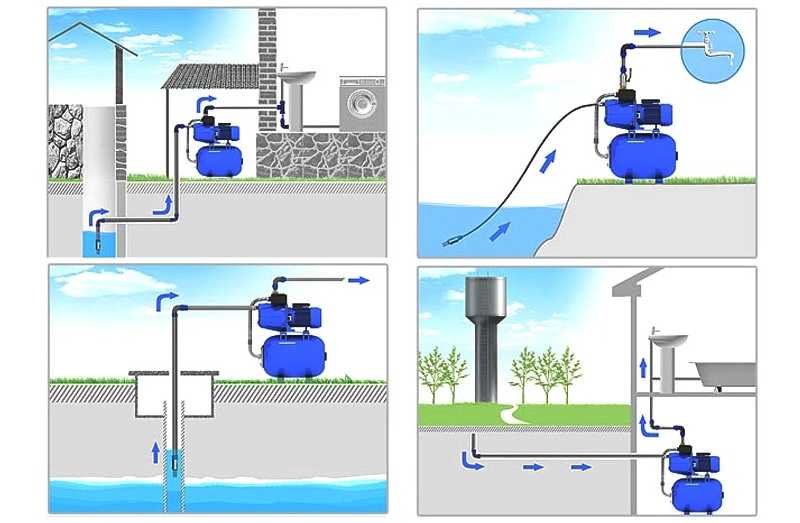

For those who do not quite understand why it is so important that pump-type water equipment gain a certain pressure, we suggest that you familiarize yourself with the principle of operation of the station and its device. Thanks to such knowledge, it will be much easier to carry out repair work and eliminate the causes of a possible breakdown on your own.

So, the main character in the operation of the water supply station is the pump itself. It is he who is designed to lift water and supply it to the system. But the pump is a powerful unit, but sensitive enough.Its work is based on the constant on / off of the engine, which can adversely affect the life of the mechanism. That is, the pump will fail faster due to engine burnout. To prevent this from happening, many complete the pump with a hydraulic tank, and this is already a water station.

The hydraulic tank (also called a hydraulic accumulator) is already responsible for the pressure in the system, creates its specified limits and controls the operation of the pump. In addition, it plays the role of a water storage tank. That is, first the pump pumps water into the tank. After that, water is supplied to the pipes when the taps are opened from the tank. The pump is at rest during this time. As soon as the pressure in the tank drops (namely, the water runs out), the pressure switch is activated, which drives the pump. Water is taken from the well until the accumulator is full. The cycle repeats over and over again. And if the pump does not turn off, then there is no necessary pressure in the system. It is necessary to find out why.

Important: the indicators of the working pressure of the lower and upper limits on the relay are marked with the symbols P1 and P2, respectively

Prevention of the recurrence of a malfunction

The main preventive measure is to bleed air that is released from the liquid and fills part of the hydraulic tank

The main preventive measure is to bleed air that is released from the liquid and fills part of the hydraulic tank

In order to prevent the pump from running dry and to prevent the above described malfunction, it is recommended to use a special circuit breaker. When the water level falls below normal, the pump will be turned off. The condition of the pumping station should be checked every couple of months. Particular emphasis during the test must be placed on the readings and settings of the pressure switch.In case of incorrect regulation of this unit, the structure will break.

Thus, if the pumping station refuses to build up pressure, you should “air out” the equipment by contacting specialists or by doing the process yourself. In order not to encounter this problem in the future, it is recommended to take preventive measures and bleed the air on a regular basis.

Pump station pressure regulation

The pressure switch in units with pumps is considered the main part of its normal functioning, then each owner of the unit should know how the setting is carried out:

- Ensure the pump is in working condition and pump water up to the mark of three atmospheres.

- Switch off the device.

- Remove the cover, and slowly turn the nut until the element turns on. If you make movements in the direction of the clock, you can increase the air pressure, against the course - reduce.

- Open the tap and reduce the liquid readings to 1.7 atmospheres.

- Shut off the faucet.

- Remove the relay cover and turn the nut until the contacts actuate.

What pressure should be in the pumping station in the pear?

The hydraulic accumulator of the unit with the pump contains such an element as a rubber container, which is also commonly called a pear. There must be air between the walls of the tank and the tank itself. The more water there is in the pear, the stronger the air will be compressed and, accordingly, its pressure will be greater. Conversely, if the pressure drops, then the volume of water in the rubber container has decreased. So what should be the value of the optimal pressure for such a unit? In most cases, manufacturers declare a pressure of 1.5 atmospheres.When purchasing a pumping station, it is necessary to check the pressure level with a pressure gauge.

Do not forget that different pressure gauges have different errors. Therefore, it is best to use a certified automobile pressure gauge with minimal scale graduations on it.

What pressure should be in the expansion tank of the pumping station?

The pressure in the receiver must not exceed the upper limit of the liquid pressure level. Otherwise, the receiver will cease to fulfill its direct duty, namely, to fill with water and soften water hammer. The recommended pressure level for the expansion tank is 1.7 atmospheres.

Why does the pressure drop in the pumping station?

- The pump is not powerful enough or its parts are worn out.

- Water is leaking from the connections or there is a pipe rupture.

- The mains voltage drops.

- The suction pipe draws in air.

Why does the pumping station not build up pressure and turn off?

The main purpose of such units is to supply liquid from various sources with great depth, to create and maintain constant pressure indicators. However, during the operation of the devices, various problems occur. It also happens that the unit cannot build up the required pressure and turns off. The reasons for this may be:

- Pump running dry. This happens due to the fall of the water column below the water intake level.

- An increase in the resistance of the pipeline, which occurs if the length of the line does not match the diameter.

- Leaky connections, resulting in air leakage. With this problem, it is worth checking all connections and, if necessary, providing each of them with a sealant.

- The coarse filter is clogged.After cleaning the filter, you can try to apply pressure to the pumping station.

- Malfunction of the pressure switch. Adjusting the relay will help solve the problem.

Having found the cause of the malfunction of the pumping station, you can begin to eliminate it.

Why does the pressure in the pumping station not rise?

When the pressure gauge of the pumping station shows low pressure, and it does not rise, this process is also called airing. The reasons for this problem may be:

- If this is not a submersible pump, then the cause may be hiding in the suction tube, through which unwanted air can be sucked. Installing a "dry run" sensor will help to cope with the problem.

- The supply line is not tight at all, there is no density at the joints. It is necessary to check all joints and ensure that they are completely sealed.

- When filled, air remains in the pumping unit. Here you can not do without distillation, filling the pump from above under pressure.

The pumping station does not hold pressure and constantly turns on

- The rupture of the rubber tank in the accumulator, as a result of which the tank is completely filled with water, even where there should be air. It is this element that regulates the constancy of the pressure of the station. You can find the problem by pressing down on the liquid injection fitting. If the liquid begins to seep, then the problem is in the rubber container. Here it is better to immediately resort to replacing the membrane.

- There is no air pressure in the accumulator. The solution to the problem is to pump air into the chamber using a conventional air pump.

- Broken relay. In the case when the fitting is without smudges, then the problem is with the relay. If the settings do not help, you will have to resort to replacing the device.

Turretless often turns on

Possible causes and ways to solve them:

- The pumping station often turns on if the air pressure in its pumped storage tank is very low or non-existent. In this case, the pumping station will turn on at each, even a small, flow of water from the water supply system. Since the liquid practically does not compress, the lack of air pressure in the tank will lead to the fact that immediately, with any opening of a tap or mixer, the pressure in the system will drop rapidly, which will immediately turn on the pumping station. When the tap is closed, on the contrary, the pressure will instantly rise and the pump will immediately turn off. Measure the air pressure in the hydroaccumulation tank and, if necessary, add to the required level: it must be 10% less than the lower pressure (turning on the pump).

- Another reason that the turret often turns on may be the destruction of the membrane of the hydroaccumulation tank. In this case, water will come out of the air inlet when you press its core. Replacing the membrane chamber can be done by first disconnecting the front flange of the tank, which is bolted. When installing a new membrane, it is advisable to cover the places of its contact with the tank and flange with silicone sealant.

- The third possible reason for frequent switching on, if the membrane is intact and the air pressure in the tank is normal, may be that the pressure switch adjustment is violated - the difference between the pump on and off pressures (Δ P) is set too small. In order to increase the difference, tighten the nut on the smaller of the two regulators clockwise.

Malfunctions of the pumping station video

- How to choose a pumping station

- Bezbashenka: pumping station for water supply at home

- Installation of water supply at home: internal water supply

- Pumping station for giving

| < Previous | Next > |

|---|

How to change the membrane?

Of course, the first rule is to empty the containers (if any) next to the accumulator and block all inlets and outlets for water in the accumulator, after “bleeding” the pressure to zero.

Then you need to press the spool at the back and release air from the rear compartment of the tank.

Nipple for pumping air.

Then the fun begins: you need to unscrew the 6 bolts that secure the flange to the accumulator. As a rule, access to one or more nuts is blocked by a pressure gauge and pressure switch. You can slightly turn the splitter by hand, which is attached directly to the tank flange, without unscrewing it entirely (otherwise you will have to rewind the FUM tape on the thread.

Usually, in the factory configuration of hydraulic accumulators, the flange is made of galvanized iron and quickly begins to corrode. In this case, it is better to change the flange to a plastic one (these are often sold in hardware stores) in order to forget about it once and for all.

So, substituting the containers, we take out the old "pear" and empty it. If a gap is visible on it, then it is also worth draining the water that has got into the metal tank itself.

This is a new membrane.

And this is the membrane after 2 years of operation. From the personal photo archive of the author

We install a new membrane, put the flange and inflate about 2 atmospheres at the back (or a bar, these are very similar values). Happy using!

Typically, the membrane in a new accumulator lasts 3-4 years, each replacement one is 1.5-2 times less.

plumbinghouse water supplyhydraulic accumulatorbulb accumulatorpump stationpressure drop in the accumulator

Why the pumping station turns on when water is drawn in: troubleshooting

The essence of the operation of the water supply complex is to maintain water pressure in the system due to its periodic operation. Reaching the indicators set on the control unit, the pump should turn off. If it starts to work continuously, you will have to turn off the equipment and determine the cause of the malfunction.

pressure regulator

Trouble with the regulator is when the pressure switch of the pumping station often trips or does not turn off at all. To verify your assumptions, it is enough to perform a number of operations:

- Check that the built-in pressure gauge is reading correctly. To do this, you can use a car pump, at the same time, if necessary, restore the working pressure through the spool.

- Before checking the adjustment unit, disconnect the equipment from the mains, drain the water from the accumulator tank.

- Remove the control box cover.

- Use a screwdriver to turn the adjusting screw that fixes the large relay spring: clockwise the water pressure threshold increases, and counterclockwise it decreases.v

- If the pumping station turns on too often when taking in water, then apparently the limit is too high - turn the screw of the large spiral counterclockwise. Then bleed and pump air again. The relay should automatically operate in the process of bleeding air, when the minimum pressure level recorded in the instructions is reached.

- Frequent spontaneous switching on of the pump may also be due to an incorrectly set operating range.A smaller caliber spring is responsible for the interval between the start and end of the pump. After setting the lower level (large spiral), you need to set the upper threshold for shutting down the equipment, which is 95% of the allowable pressure in the system.

Weak pump power

Someone will say that there can be no problem with insufficient power, because before buying a station, the required power is calculated, depending on the depth of the well, the amount of water consumed and the design features of the pipeline. However, power problems arise when:

- wear parts of the pump;

- changes are made to the pipeline system;

- the water level in the well drops.

Wear of parts occurs more often in centrifugal pumps. If the water is not of high quality, and there are sand impurities or small specks in it, they fall between the pump shaft and cause parts to loosen. So the unit works, but cannot provide sufficient water pressure.

You can avoid this by setting special filters. And to cope with the problem, you will have to take the pump for repair, well, or replace it with a new one. In a vibration pump, a rubber valve may wear out, which must be changed, and thereby solve the problem.

Before you install a new washing machine or dishwasher, or install additional pipes, consider whether there is enough for this pumping station capacity. Some experts advise buying a pump more powerful than necessary in advance. After all, technology does not stand still, and you may want to connect an additional device that consumes water.

If the water level in the well has dropped, the water pressure will decrease significantly or completely disappear.When the water drops too low, it may be necessary to purchase a submersible pump. Buying a more powerful pump will solve most of the problems: having spent money once, you will no longer be nervous due to station malfunctions.

Other causes of failure

Most often, the pumping station does not turn off due to a reason that may be hidden in the following problems:

- power supply is lost;

- no water enters the pipeline;

- failure of the pump itself;

- breakdown of the hydraulic accumulator;

- malfunction in the automatic system;

- there were cracks in the hull.

There are times when the pumping station does not pump water, but the automation is working properly. The reason for this may be a banal crack in the pipeline. Or the valve that is responsible for the return in the pipeline does not work. In this case, the water will not knock, which leads to a lack of fluid.

The power of the pumping station directly depends on the parameters of the pipes and the goals set

In order for the pumping station to work without interruptions and breakdowns, it is necessary to take into account many nuances that can affect its functionality. Most problems are easy to fix on your own. If the characteristics of the pumping station do not meet your needs, then this can also greatly affect its operation.

Water will not flow to its destination if the power of the station does not match the diameter of the pipes, as well as the length of the entire pipeline

For this reason, you must always pay attention to the power of the equipment. Other reasons why the pumping station does not turn off may be as follows:

- Air in pipes. This is due to improper connection of the pipe and pump. The connection is not sealed.Or the pressure disappears due to a rupture of the pipeline.

- The water runs back. This happens if the tap breaks or the pipe breaks again.

Having discovered such problems, you must immediately stop the pumping station and carefully examine it. In addition, you should check the voltage in the mains.

Filters need to be cleaned regularly

In addition to a pipeline malfunction, the pump may not pump due to the fact that the filter is very clogged. In this case, you need to proceed as follows:

- clean the filter from dirt;

- add liquid to the tank using a separate hole, which is closed with a cork;

- before looking for the cause of the breakdown, the pump and the suction pipe are checked for fullness, only after that the station is started. If the liquid has disappeared after checking and starting, then it is first recommended to inspect the check valve.

- tightness is checked by drying and careful inspection.

- if the impeller of the device is stalled, then you must first turn it and start the entire system.

If the station is working properly, then the engine makes a uniform sound, but if unusual sounds are heard during startup, you need to look at the capacitor. Over time, it will be necessary to replace old parts, since they completely wear out during operation.

The correct setting of the accumulator is of great importance when starting the pumping station. If everything is configured correctly, the system will work for a long time and without interruption. The operation of the accumulator directly depends on the normally set pressure limits, the tightness of the tank and the ratio of pipes to the nozzle.In addition, air may enter the system due to the fact that the membrane will be broken.

Care must be taken to ensure that the tank is not covered with rust.

The main causes of a malfunction can be:

- preventive examination is ignored;

- wheel not working

- inappropriate power;

- membrane rupture;

- pressure drop;

- the pump often turns on and off;

- voltage fluctuations.

The battery reservoir rusts over time, dents appear. All these factors need to be eliminated immediately.

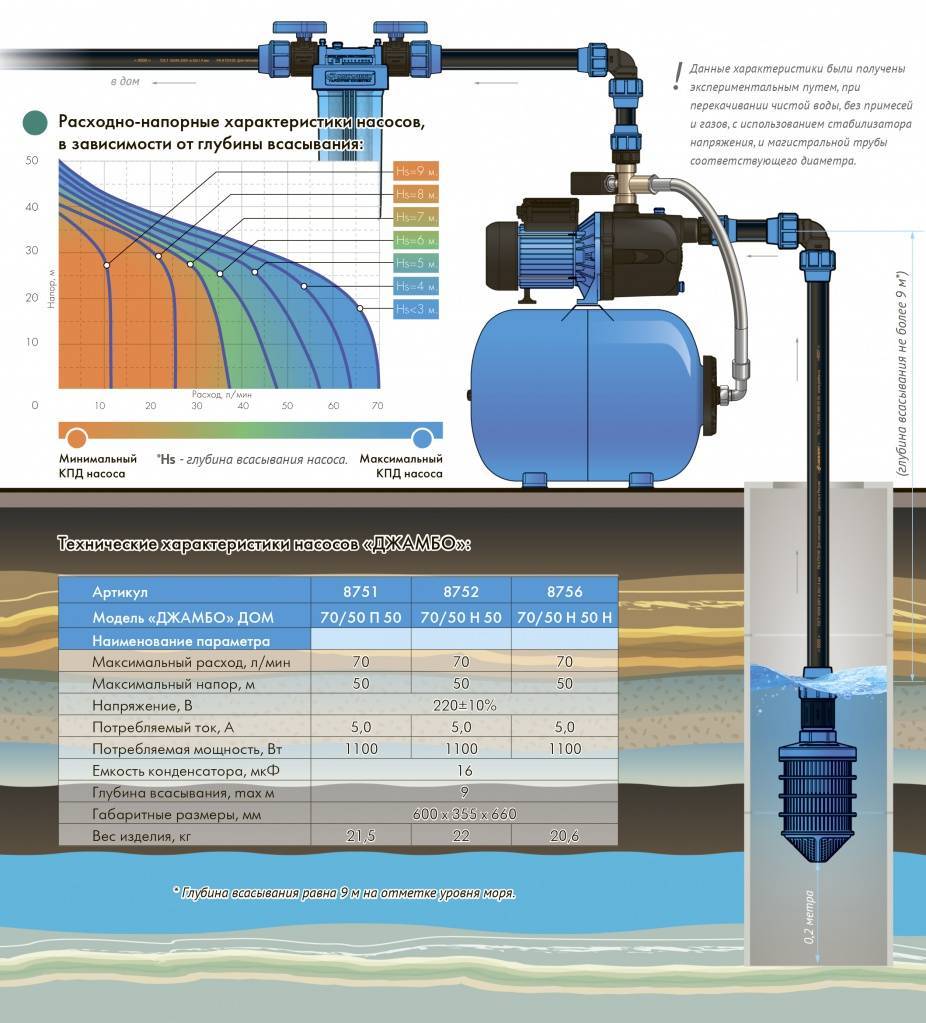

Problems and malfunctions of pumping stations and their correction

All pumping stations consist of the same parts and their breakdowns are mostly typical. It makes no difference whether the equipment is Grundfos, Jumbo, Alco or any other company. Diseases and their treatment are the same. The difference is how often these malfunctions occur, but their list and causes are usually identical.

The pumping station does not turn off (does not gain pressure)

Sometimes you notice that the pump has been running for a long time and will not turn off in any way. If you look at the pressure gauge, you can see that the pumping station is not gaining pressure. In this case, the repair of the pumping station is a lengthy business - you will have to sort out a large number of reasons:

If the shutdown limit of the pressure switch is much lower than the maximum pressure that the pump can create, and for some time it worked normally, but then it stopped, the reason is different. Possibly the pump the impeller worked. Immediately after the purchase, he coped, but during the operation the impeller was worn out and "now there is not enough strength." Repair of the pumping station in this case is the replacement of the pump impeller or the purchase of a new unit.

Another possible reason is low voltage in the network. Maybe the pump is still working at this voltage, but the pressure switch is no longer working. The solution is a voltage stabilizer. These are the main reasons that the pumping station does not turn off and does not build up pressure. There are quite a few of them, so the repair of the pumping station may be delayed.

Repair of the pumping station: often included

Frequent switching on of the pump and short periods of its operation lead to rapid wear of the equipment, which is very undesirable. Therefore, the repair of the pumping station should be carried out immediately after the discovery of the "symptom". This situation occurs for the following reasons:

Now you know why the pumping station often turns on and what to do about it. By the way, there is another possible reason - pipeline leakage or some connection, so if all of the above does not apply to your case, check if the joint is leaking somewhere.

Air in water

There is always a small amount of air in the water, but when the faucet starts to “spit”, something is not working properly. There can also be several reasons:

The pump station does not turn on

The first thing to check is voltage. Pumps are very demanding on voltage, they simply do not work at low voltage. If everything is fine with the voltage, things are worse - most likely the motor is faulty. In this case, the station is carried to a service center or a new pump is installed.

If the system does not work, you need to check the electrical part

Other reasons include a plug / socket malfunction, a frayed cord, burnt / oxidized contacts at the point where the electrical cable is attached to the motor. This is something you can check and fix yourself. A more serious repair of the electrical part of the pumping station is carried out by specialists.

The motor hums but does not pump water (the impeller does not rotate)

This error may be caused low voltage in the network. Check it, if everything is normal, move on. You need to check if it's burned out. capacitor in terminal block. We take, check, change if necessary. If this is not the reason, go to the mechanical part.

First you should check if there is water in the well or well. Next, check the filter and check valve. Maybe they are clogged or defective. Clean, check the performance, lower the pipeline into place, start the pumping station again.

We check the impeller - this is already a serious repair of the pumping station

If that doesn't help, the impeller may be jammed. Then try manually turning the shaft. Sometimes, after a long period of inactivity, it “sticks” - it becomes overgrown with salts and cannot move itself. If you cannot move the blades by hand, the impeller may have jammed. Then we continue the repair of the pumping station by removing the protective cover and unlocking the impeller.

If the pressure "jumps"

How to adjust the pressure in the pumping station if it constantly changes for no apparent reason, and the equipment itself turns on and off too often or every time you use plumbing fixtures? First you need to understand why this is happening.

The reasons may be as follows:

A rupture of a rubber membrane or a pear chamber inside a hydraulic accumulator, which leads to the filling of the entire tank with water, including that part of it in which compressed air must be located to provide pressure. Violation of the integrity of the membrane is easy to detect by pressing the fitting for air injection. If at the same time water starts to drip from it - this is it.Since it is impossible to increase the water pressure in the pumping station with a faulty accumulator (see Hydraulic accumulator for a well: types of equipment and methods of its use), the rubber chamber must be replaced.

Membrane replacement

Lack of air pressure in the accumulator. If when you press the fitting, no water comes out of it, then most likely it is. This is the most harmless of all problems, since in this case it is simple to increase the water pressure in the pumping station: you need to pump air into the chamber using an air pump.

Measuring the air pressure in the accumulator

The pressure switch is defective. This is indicated by the absence of smudges from the fitting at normal air pressure in the tank. The device must be replaced (see Water pressure regulator for pumping station: settings for comfortable network operation).

You can replace the relay yourself

Clogged inlet filter

The water of an autonomous water supply system contains a huge amount of mechanical particles (sand, silt, clay), the presence of which will lead to wear of parts of the pumping station. A special filter installed on the supply pipe accumulates all this debris, which ultimately increases the life of the system.

Pump station with installed filter

The constant operation of the pumping station can be associated with a break in the supply pipeline or clogging of the filter with small particles of debris. In this case, the liquid will not flow in the required volume to the pump. All you need to do is clean the filter or eliminate other malfunctions, add water through a special plug, and start the pump back.