- The use of HDPE pipes in the process of installing electrical wiring

- Methods and technologies for bending HDPE pipes

- Using a molding machine

- With the help of a building electric hair dryer

- Using a gas burner

- Hot liquid processing method

- other methods

- Which way is better

- Methods for laying an electrical cable

- Installation in enclosing structures

- Laying in the ground with digging a trench

- Trenchless laying

- Mounting technology

- Straightening methods

- Straightening under the sun

- Heating with hot water or sand

- The most affordable option is a building hair dryer

- molding machine

- Gas-burner

- Distinctive features of HDPE pipes

- DIY bending process

- Necessary tools and materials

- Work progress

- Main characteristics of HDPE pipes

- The composition of the pumping station and the purpose of the parts

- The principle of operation of the pumping station

The use of HDPE pipes in the process of installing electrical wiring

To protect electrical cables, either corrugated or smooth HDPE pipes are used. Such pipes are chosen because, firstly, they are elastic and flexible, and secondly, they do not conduct electricity.

When installing wiring using pipes, you can choose either a hidden location in the walls, or place them on the surface. In addition, pipes are also used in cases where electrical wiring needs to be laid in the ground.The tightness of the connections will be important in the last version of the arrangement of electrical wiring, as well as if the electrical cable is laid in rooms with high humidity or outdoors.

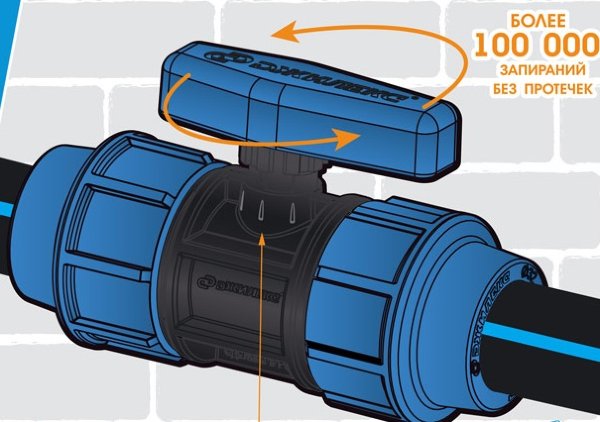

To make the connection tight, you can weld HDPE pipes end-to-end, or use couplings. It is also possible to apply hot casing of the pipe directly in the socket.

In the latter case, the pipe must be heated and then inserted into the socket with little effort. Partial deformation of the material inside the socket will fill all the irregularities, which ultimately will ensure tightness.

Methods and technologies for bending HDPE pipes

Low-pressure polyethylene at normal temperature is a fairly plastic material. For transportation, pipes are wound into coils of various diameters, so they must first be straightened before use. Polyethylene becomes plastic when the temperature rises to 80-135°C, so it needs to be warmed up.

There are many ways in which you can align or bend a polyethylene pipe:

- using a molding machine;

- using a building hair dryer;

- using a gas burner;

- with hot water.

Each of these methods has its own advantages and disadvantages, and we will describe them all below.

Using a molding machine

This is purely industrial equipment. Usually it is used for bending a large number of workpieces of not very large sizes - for example, bends. The pipe is cut into blanks, placed in a frame made of fiberboard, chipboard and other improvised materials with a smooth surface, inserted into a silicone shell, heated to a temperature of 80-90 ° C, then bent and allowed to cool.

It is impossible to actually use such a machine for unbending a bent pipe; it also makes no sense to purchase it for the home.

With the help of a building electric hair dryer

In order to straighten a wavy pipe, you should lay it out on a flat surface, heat it up with a hair dryer and stretch it. Then let cool in a stretched even state. This work is best done together.

To bend the pipe, it is better to make a mandrel from bars and chipboard, fiberboard. The pipe is heated with a hair dryer as evenly as possible, rotating, from all sides, throughout the entire bending section. Then gently bend, making sure not to tear; put in a bowl, let cool.

Underheating of the workpiece will lead to its damage during deformation.

Using a gas burner

This is the most risky method of heating. The workpiece is very easy to melt, burn through, even ignite. In addition, with strong one-sided heating, the surface of the tube may foam and smoke. When heated in this way, it is easiest to get burned.

Without some experience, you should not use a gas burner. In any case, you should practice on scraps.

The technology of bending and unbending is similar to the technology when heated with a hair dryer.

Hot liquid processing method

This method is sometimes used in production. The bays are immersed in hot water baths, heated, taken out, rolled out on a flat surface and stretched. Let cool.

At home, this method is used for bending pipelines with a diameter of less than 50 mm and not too long. Several liters of hot water - 80-90 ° C are poured into the pipe using a watering can (preferably steel).

It is problematic to straighten a long pipeline at home in this way - there is simply nowhere to take a large amount of slightly cooled boiling water at once.

other methods

To straighten a long section of the pipe, in the summer it is worth using the folk method: unwind it from the bay, spread it out and slightly stretch it (without fanaticism) in the sun, warm it up for 5-10 or more hours - the polyethylene will become more plastic. Then stretch (either with the help of an assistant, or secure the ends with clamps or in some other way, let it lie for a few more hours. In non-hot polyethylene, the process of relieving internal stresses is slow, and this work can take all day.

To heat the bay, you can use the steam room in the bath.

There is another way to bend small workpieces using hot salt or sand. Bulk materials are heated on a baking sheet in the oven, poured into a pipe through a steel watering can (bell), wait until the workpiece softens, and bend with a mandrel similarly to the previous methods.

Which way is better

The easiest way is to heat the bay in the sun and stretch it. But this is not always applicable. For small workpieces, a method with heating with water is not bad - you can accurately determine the temperature (a pot of boiling water with an open lid will have a temperature of about 85 ° C in five minutes. You can also measure it with a thermometer). The method of heating with sand or salt is quite acceptable - if you measure the temperature and practice in advance.

If the farm has a building hair dryer, then you will have to use it to straighten long sections of polyethylene pipes.

The use of hot tubs and a molding machine at home is not possible.Using a gas burner is unsafe and difficult - there is a high probability of damaging the pipe.

The optimal and universal way to bend or straighten pipes made of low-density polyethylene is with a building hair dryer. That is what we will consider.

Methods for laying an electrical cable

The technical features of laying HDPE pipes depend on the location of the cable and its operating conditions. This also affects the list of equipment used and the necessary components.

Installation in enclosing structures

Indoors, electrical wiring using HDPE pipes is laid as follows:

- outline the location of the cable;

- fix the pipe, and it can be attached to the floor with metal brackets, and to the ceiling or walls - with special holders with a latch;

- pull the cable so that it is located freely, without tension;

- the structure on the floor is poured with a concrete screed, and in the wall or ceiling it is covered with plaster or other materials, depending on the diameter of the protective case.

Cable laying using HDPE pipes on the floor

HDPE pipe allows:

- reduce the length of the wiring;

- carry out repair work and cable hauling without damaging the surface of ceilings and walls.

When installing communications indoors, it is possible to use various connecting parts to fix individual sections of the protective casing: bends, couplings and other components. However, corrugated elements are most often in demand for turns at the points where the pipe enters the floor slab or the transition from the floor to the wall. In this case HDPE pipe for electrical wiring must be bent at an angle of 90⁰, and this is impossible without wrinkling and deformation of the material.

According to current regulations, for the installation of hidden electrical wiring, which is located inside floors or walls made of non-combustible materials, it is allowed to use smooth or corrugated HDPE pipes.

Laying in the ground with digging a trench

This technology is in demand when laying communications in summer cottages. Before starting work, you should inspect the cable and check the integrity of the sheath. If it is damaged, the protective function of HDPE pipes will be useless.

Then, during the laying process, the following operations are performed:

- make markings and dig a trench of the required depth;

- a HDPE pipe is placed in it with or without a broach of the desired diameter;

- stretch the cable and lay it in such a way that it is located without tension;

- the pipe is first covered with a layer of sand 10 cm thick, and then with soil by about 15 cm.

To quickly locate the cable, you can lay a special signal tape over it.

Cable laying using HDPE pipes in the ground

When using HDPE pipes for laying power networks in the ground, it is desirable to exclude the use of couplings and other connecting elements, since this makes it difficult to ensure sealing. However, when the cable is brought into the building, fittings are simply necessary.

For laying the cable in a straight section, use solid pieces with a cross section of at least 4 mm. If the section is too long, then an elastic metal wire or a special nylon broach should be used to tighten the electrical wiring. They are first launched into the pipe, and then the tied cable is tightened.

Trenchless laying

Trenchless technology is used for laying electric cable, which is located in hard-to-reach places. Most often, it is in demand by public utilities, as it is carried out with the involvement of complex equipment and special equipment.

Horizontal drilling method

The essence of the method lies in horizontal directional drilling, which allows you to lay underground communications without disturbing the surface layer of the soil. First, they study the composition of the soil and obtain permission to carry out earthworks. Then the cable is laid in the HDPE pipe, which includes the following steps:

- Drilling a pilot well. The puncture of the soil is carried out using a drill head, which has a bevel in the front and built-in radiation. When it enters the ground through special holes, a solution is supplied that fills the well. It reduces the risk of collapse and cools the heated tool.

- Well expansion. It is performed by a rimmer that replaces the drill head.

- Laying HDPE pipes with cable inside. They are pulled into the well using a drilling rig.

Cable laying by horizontal drilling

The main disadvantage of horizontal directional drilling of soil is the complexity of its implementation, therefore, for such work, they conclude an agreement with an organization that specializes in such activities and has the necessary equipment.

Horizontal drilling rig

Laying a cable using HDPE pipes allows you to ensure its reliable protection for a long period of time, you just need to follow the technology for installing power lines and other communications.

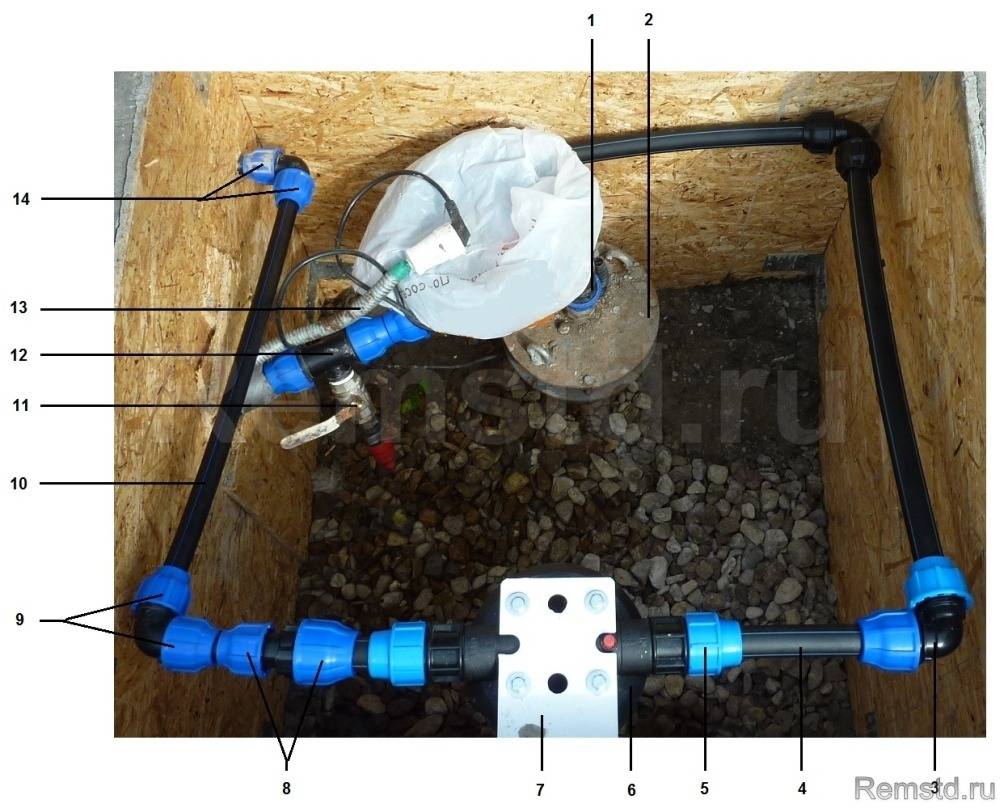

Mounting technology

The technology of laying HDPE pipes in the ground involves the creation of a project. It is possible to avoid it.But then there is a huge risk of redoing everything anew. Let's start with connections. For tightness, there are several ways:

- Welding. It is a guarantee of reliable coupling of elements under high temperature. Most suitable for laying pipes underground. It will be quite expensive if you buy the equipment yourself. The cost of the device can reach up to 2 million. In cooperation with construction companies, this option is quite acceptable.

- Insertion with fittings.

- Flange connection. Designed for situations where the fastened components are of different types of fittings, parts, and so on. It is not so reliable, because the junctions may be loose. This causes a leak.

- The use of an electrofusion option is used when repairing an already formed mechanism. For the option, you need specialized equipment that can read the code. It encodes the features of the corresponding temperature regime.

Also, determine the type of land in which the HDPE pipe trench will be laid. When laying, adhere to the following plan of action:

Digging and choosing the shape of the recess. The most common is trapezoidal. It is well suited for a depth of more than one and a half (1.5) meters. But the rectangular one is designed less than one and a half meters. It is worth considering the laying of ground veins here

It is important to make the width roomy. For example, for 120-140 cm, D plus 50 cm is suitable, and for 70 - 1.5D)

For difficult areas, you need to dig a trench with your own hands, but in other situations, it is better to turn to the services of an excavator. Assembly of pipes into one single. To check for water leakage, liquid is immediately supplied through the holes.If the pipeline is very long and large, then it is immediately placed in the ground. Before doing, it is necessary to sprinkle with sand, i.e. create a pillow. And after laying, fill it with sand, so that in case of an emergency, you can quickly get to it. Additional insulation stops freezing, because winters are harsh. For these purposes, use a casing made of mineral wool or rubber, enveloping the entire surface. At the final stage, draw a frame into the house. It is not recommended to fill the trench ahead of time. Start the water and check the performance. This will avoid all sorts of problems and prevent them immediately.

Straightening methods

There are several ways to straighten a HDPE pipe from a coil or after thermal deformation in order to return it to its original state on its own:

- heating in the sun;

- Use hot water, sand or other bulk materials as a heating element;

- A building hair dryer is the most affordable option;

- It is also possible to use a molding machine;

- With a gas burner.

These methods are discussed in more detail below.

Straightening under the sun

The properties of HDPE are such that under direct exposure to the rays of the sun, the material becomes more pliable and flexible, making it easy to change its shape.

Straightening the pipe in the sun

Straightening the pipe in the sun

The algorithm of actions is as follows:

- Unwind the required amount of HDPE pipes from the coil;

- Straighten the pipe and lay out, so that the material is constantly exposed to direct sunlight;

- Leave the pipe in this position for about 10 hours. During this time, the material will become pliable and flexible;

- After that, we straighten and securely fix the material in this position. Fixation can be carried out, for example, using bars;

- At the end, it is necessary to completely cool the structure. This process will take at least 24 hours.

The video of the straightening process:

Heating with hot water or sand

If the season or weather conditions do not allow using the first method, then you can align the HDPE pipe using the method used in production, namely by heating with hot water. In production workshops, the entire bay is immersed in large tanks with water of the desired temperature, and at home, it is necessary to first cut off the sections intended for straightening.

Pour water into the pipe, heated to a temperature of 90 degrees.

It is also possible to use salt or sand. To do this, in the oven it is necessary to heat the salt (sand) to 90 degrees. Then using a metal watering can and put salt (sand) into the pipe

It is important to remove bulk materials in time, they should be removed after 4 hours.

Warm up until slightly softened.

Spread by hand, and let cool, after fixing in the correct position.

Free the cut from liquid or sand.

The most affordable option is a building hair dryer

Heating with a hair dryer

Heating with a hair dryer

First you need to make a frame out of fiberboard or thick plywood, on which the straightening pipe will be placed. At home, this operation is more convenient to carry out with a partner. It will be required to straighten the HDPE pipe while you are heating. You must follow the following sequence of actions:

Heat the workpiece with a construction hair dryer;

The workpiece must be constantly rotated for uniform heating;

Put the product brought to the desired temperature on a previously prepared frame made of fiberboard or plywood;

Next, carefully give the pipe the desired shape, fix it in this position and leave to cool;

Then take out the cooled workpiece.

Insufficient heating will occur if the hair dryer is held too far away. If you bring the hair dryer too close, then there is a possibility of melting the workpiece or igniting it. Therefore, when working with a building hair dryer, safety precautions should be observed.

molding machine

This method is mainly used in production, since it is not advisable to purchase a molding machine for domestic needs. Nevertheless, let's consider how a HDPE pipe is straightened under production conditions:

This method is mainly used in production, since it is not advisable to purchase a molding machine for domestic needs. Nevertheless, let's consider how a HDPE pipe is straightened under production conditions:

- The machine is set to straightening mode;

- The pipe is placed in the mold;

- Under pressure, the pipe is aligned into the required shape;

- Then you should wait for it to cool and take it out of the molding machine.

Gas-burner

This method is related to the blow dryer method above, but more dangerous and less reliable. Would need:

alignment over gas stove

alignment over gas stove

- On a sheet of fiberboard, lay out the pipes and hold the burner at a distance of 30 cm from the surface of the fiberboard sheet.

- Heating is carried out for 20-25 minutes by continuously rotating the heated pipe. Then you should firmly fix the segment and wait for it to cool.

Distinctive features of HDPE pipes

This immediately changed the performance of HDPE pipes. And their main difference from ordinary polyethylene pipes is that they begin to melt 20 ° C higher, and this greatly expanded the scope of this type, for example, they can be used in hot water systems at any water temperature.

Scheme of an extrusion line for the production of plastic pipes: 1 - loading device; 2 - extruder; 3 - forming head; 4 - calibrating sleeve; 5 - water vacuum baths (vacuum calibrators); b - thickness gauge; 7 - water cooling baths; 8 - counting and marking device; 9 - pulling device; 10 - cutting device; 11 - receiving device; 12 - winding device.

These pipes are elastic, and it is easy to give them a complex shape, that is, they “work” well both in tension and in compression, because when bent, one side of it, without collapsing, experiences a tensile load, and the opposite compressive load. They also have good impact strength and can withstand significant impact loads when in the ground, which is why they are called high-strength. In winter conditions with HDPE pipes it is possible to work outdoors even in northern regions.

HDPE pipes cannot be used to transport liquids and gases with which they can enter into a chemical reaction. Subject to this condition, the service life of HDPE pipes without loss of their inherent properties, even in the ground, is 50 years.

They are designed for internal pressure, which has the following range of values: 0.5 0.63 0.8 1.0 1.25 and 1.6 MPa; you can pick up pipes of almost any diameter in the range from 16 to 1200 mm and a length of 5 to 12 m with a multiplicity of 0.25 m.

HDPE pipes are much cheaper than steel and, especially, copper pipes. They can reasonably be considered the material of the future.

DIY bending process

There is not always a hot sun, hot water and sand, a home bath or sauna. In this case, a building hair dryer will come to the rescue of the home master.With it, you can bend a short workpiece, you can straighten a long piece for outdoor plumbing or bend it.

Necessary tools and materials

To perform bending you will need:

- building hair dryer;

- blank;

- mittens;

- mandrel. The mandrel is made of bars stuffed on chipboard, OSB, fiberboard (for small diameters).

Work progress

Bending technology:

- the workpiece is heated in the area that will be bent, for uniform heating it is necessary to rotate the workpiece;

- then you need to smoothly bend the pipe, then lay it in the frame;

- let cool, hold for a few minutes;

- then remove and let rest for at least 15 minutes.

Main characteristics of HDPE pipes

HDPE polyethylene pipes are selected based on their main technical characteristics.

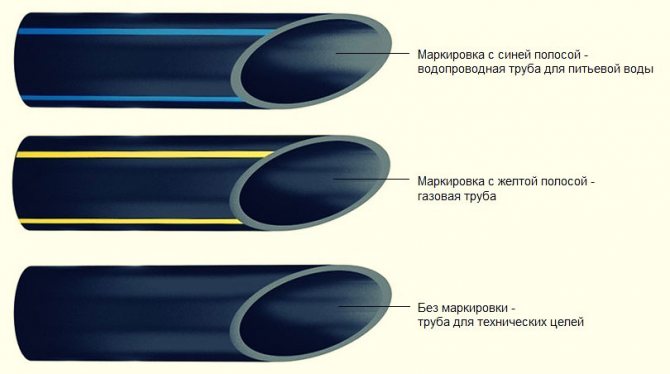

- operating temperature. The maximum indicator of the transported working medium does not exceed 40⁰C. Therefore, the marking of water pipes is a blue longitudinal line, gas pipes are yellow. Despite the declared range, PE pipes can withstand temperatures up to 80⁰C, and when frozen, they do not burst, but only stretch.

- diameter. Low pressure PE pipes are manufactured with different diameters - from 10 mm to 1200 mm. For plumbing in an apartment, for example, pipes D 20 mm can be used, products of large diameters are used to create highways.

- Pressure. It depends on the brand of polyethylene (the most durable pipes are PE 100), the dimensions of the wall thickness (the thicker the wall, the more pressure the product will withstand); pipe diameter (the wider the pipe, the less pressure per unit area). The working pressure of the pipe is indicated by the SDR indicator - the ratio of D to the wall thickness. More about this parameter in the article "What is SDR in the marking of polyethylene pipes".Depending on the maximum pressure indicator, pressure and non-pressure pipes are used (usually technical, without requirements for permissible loads).

- Bandwidth. Polyethylene pipes have a high index due to a small coefficient (0.1) of roughness.

- Safety margin. This indicator determines the load that the pipe can withstand. Polyethylene pipes for water supply have a coefficient of 1.250, for a gas pipeline - 3.150.

The service life of plastic pipes is usually predicted to be up to 50 years. However, it should be remembered that the manufacturer, indicating the service life of products, is based on their use in a stable temperature regime. Requirements for HDPE pipes are regulated by GOST standards.

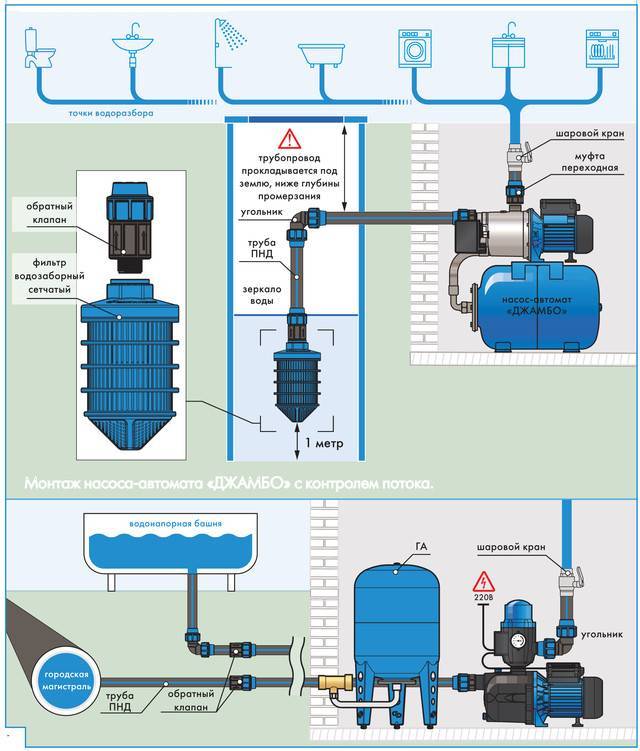

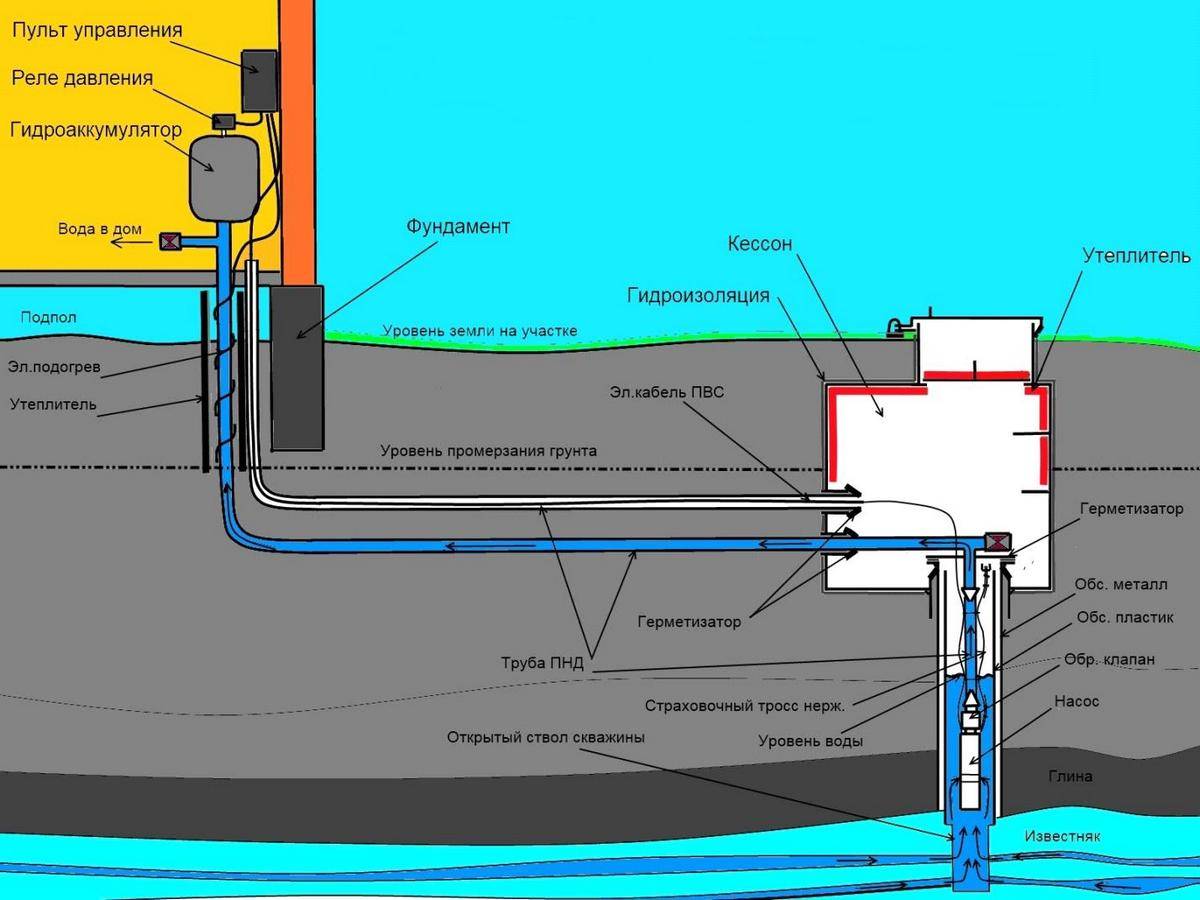

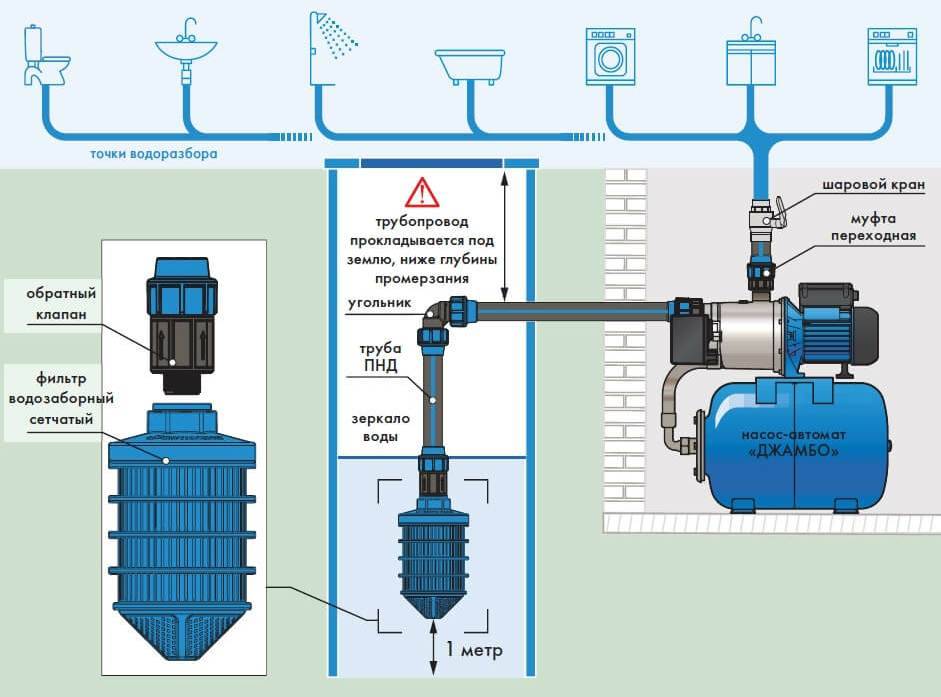

The composition of the pumping station and the purpose of the parts

A pumping station is a collection of separate devices interconnected. To understand how to repair a pumping station, you need to know what it consists of, how each of the parts works. Then troubleshooting is easier. The composition of the pumping station:

- Submersible or surface pump. Pumps water from a well or well, maintains a stable pressure in the system. It is connected to the house with pipes.

-

A check valve must be installed on the pipeline. It does not allow water to drain from the pipes back into the well or well when the pump is turned off. It is usually installed at the end of the pipe, lowered into the water.

- Hydraulic accumulator or membrane tank. Metal hermetic container, divided into two halves by an elastic membrane. In one, air (an inert gas) is under pressure, in the other, until a certain pressure is created, water is pumped.A hydraulic accumulator is necessary to reduce the number of pump starts and extend its service life. Creates and maintains the required pressure in the system and a small reserve supply of water in case of station inoperability.

- Block of control and management of the pumping station. Usually this is a pressure gauge and pressure switch, installed between the pump and the accumulator. A manometer is a control device that allows you to evaluate the pressure in the system. The pressure switch controls the operation of the pump - it gives commands to turn it on and off. The pump is turned on when the lower pressure threshold in the system is reached (usually 1-1.6 atm), and it is turned off when the upper threshold is reached (for one-story buildings 2.6-3 atm).

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of various devices.

The principle of operation of the pumping station

Now let's look at how all these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) equals the upper threshold set on the pressure switch. While there is no water flow, the pressure is stable, the pump is off.

Each part does its job

A faucet was opened somewhere, the water was drained, etc. For a while, water comes from the accumulator. When its quantity decreases so much that the pressure in the accumulator drops below the threshold, the pressure switch is activated and turns on the pump, which pumps water again. It turns off again, the pressure switch, when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bath is taken, watering the garden / vegetable garden is turned on), the pump works for a long time: until the required pressure is created in the accumulator. This happens periodically even when all the taps are open, since pump delivers water less than follows from all points of parsing. After the flow has stopped, the station works for some time, creating the required reserve in the gyroaccumulator, then turns off and turns on after the water flow appears again.