- Solution Methods

- Troubleshooting due to which the geyser does not ignite

- Problems with ignition

- Recommendations for the implementation of repair work

- Other malfunctions

- Sources of the accident

- Why does the column turn off during operation?

- Traction is poor or completely absent

- Soot accumulation on the heat exchanger

- Clogged shower head and hose

- Why does the column of the above models not light up, as well as for Neva transit?

- The geyser burns, but does not heat the water

- Features of maintenance and repair of speakers

- The nuances of cleaning the radiator from scale

- Features of elimination of leaks in the column

- Conclusions and useful video on the topic

Solution Methods

The following are the identified dilemmas and ways to solve them.

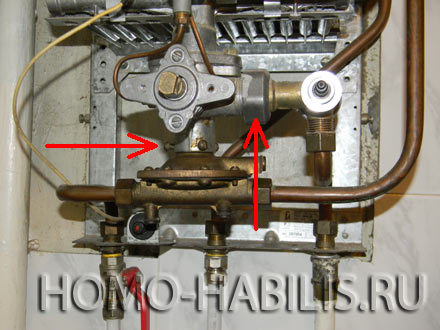

- The strainer is clogged. This is the most common reason why hot water does not flow well in a gas column.

If a filter breakage is detected in this process, it is replaced.

- Scale in TO. It may be insignificant, or it may be multi-layered deposits. In such cases, the water in the gas column has a weak pressure, or the apparatus does not light up at all.

The best option is to use a composition based on citric acid. It needs 50-70 g per liter of warm water.

- Clogged hot water pipes. You can do it yourself to fix the problem.If the actions do not bring the desired effect, then call the wizard.

After that, the spout is clamped with a finger. In this process, the reverse flow of water should push the blockage forward.

- Mixer problems. They appear when small contaminants pass through the column pipes and end up inside it. The most vulnerable are

- filter,

- crane box,

- hose with thin rubber walls.

- The device has low power. Here a logical decision arises: to replace it with a more powerful analogue.

With the latter option, a 500-liter tank is placed, and inside the pump.

Troubleshooting due to which the geyser does not ignite

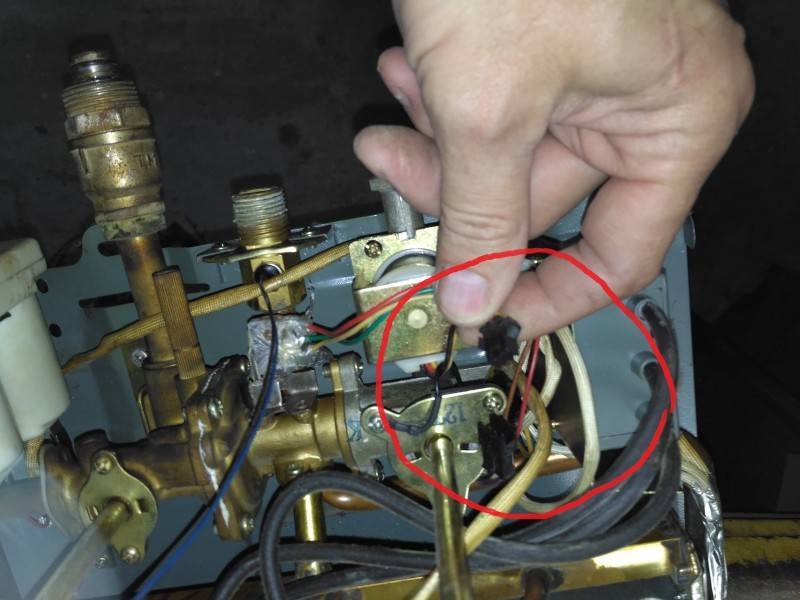

Available turbocharged geyser with electric ignition. When hot water is turned on, the column clicks, but does not light up. An electric discharge is heard, the fan turns on.

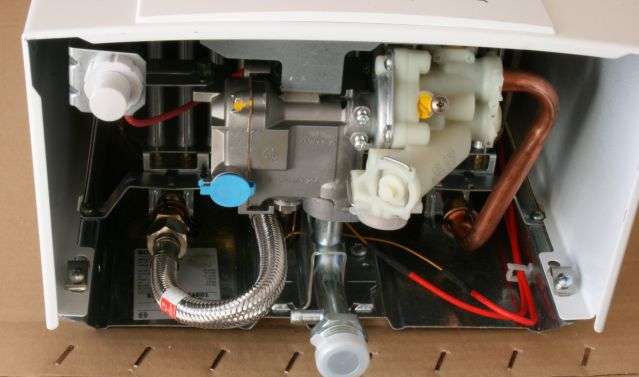

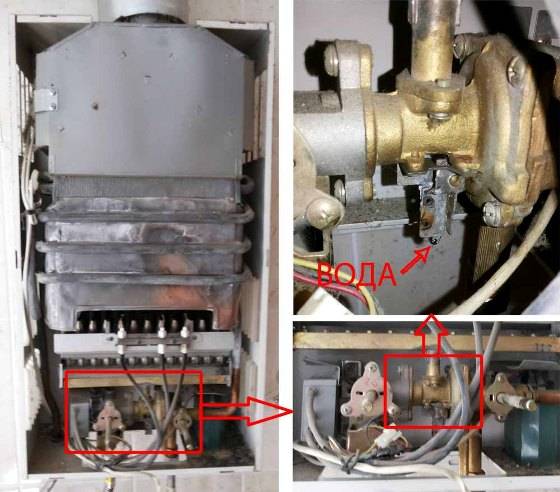

The first step is to inspect, for this we remove the column cover. It is mounted on four bolts: two from the bottom, two from the top. We also remove the knobs for the flame regulator, temperature, winter-summer mode. On examination, everything seems to be intact, the wires have not burned out anywhere, water does not leak anywhere.

The principle of operation is that when a water flow appears, the gas valve is activated, an electric discharge is created, the gas is ignited, and at the same time the fan is turned on to pull the spent combustion products out into the street. If the water pressure is insufficient or the hood does not work, the gas goes out, the column turns off.

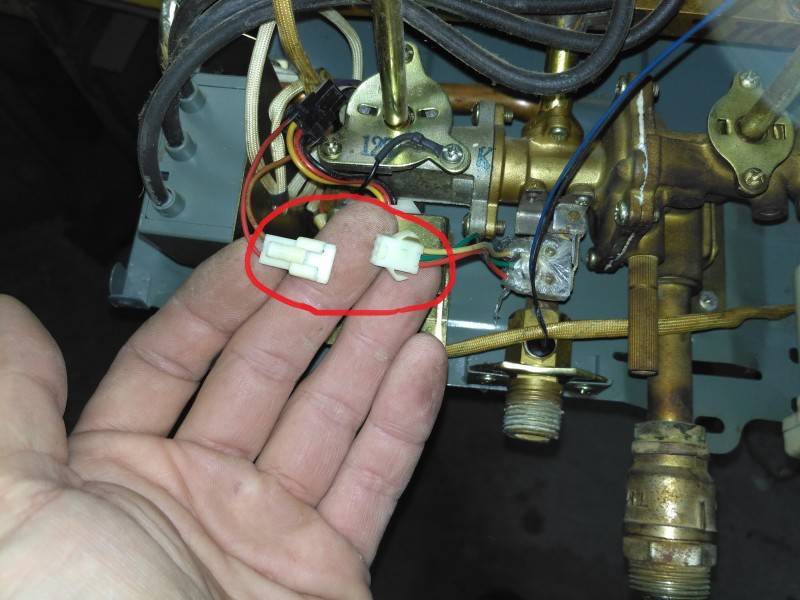

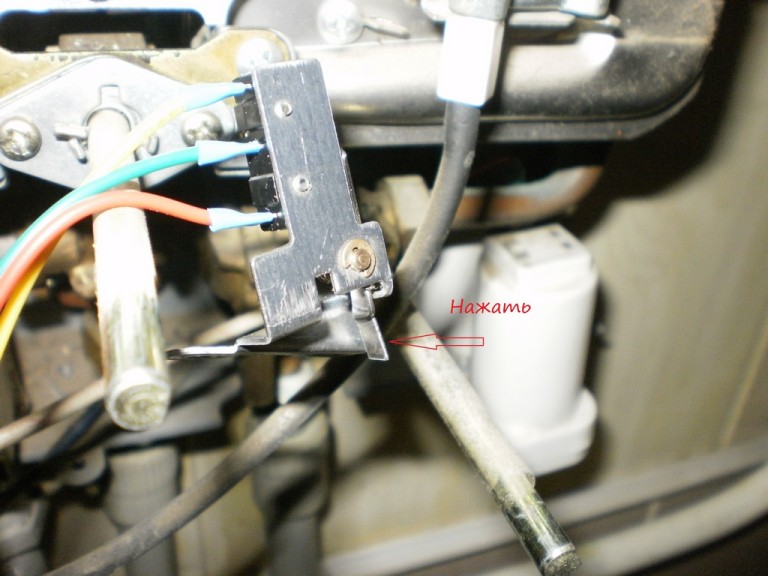

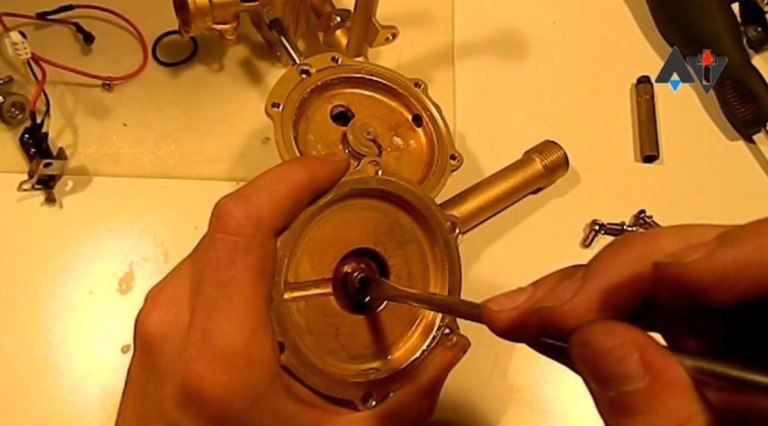

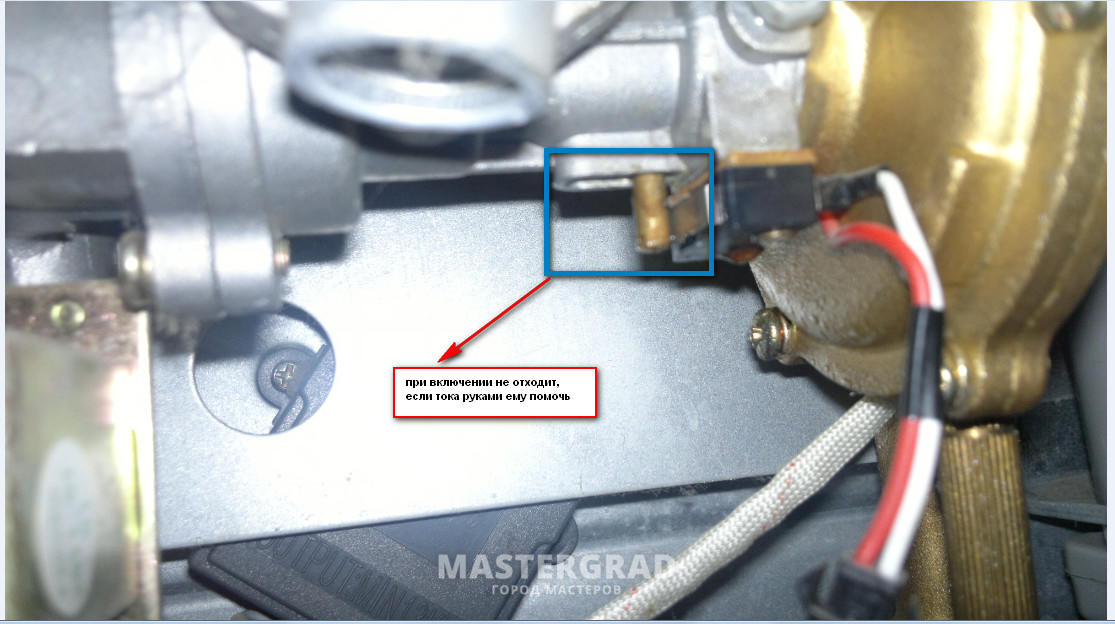

So, open the faucet and see what happens. Water rustled through the tubes of the heat exchanger, the electrodes gave a discharge, the fan turned on, but the gas did not ignite. Let's check if the relay (microswitch) is working, which works with sufficient water pressure and opens the gas supply valve.To do this, turn the tap again, the relay tongue should move away.

It works, which means that the pressure is sufficient for the operation of the gas column. Now let's check the operation of the gas valve. To do this, use a screwdriver to move the same tongue without opening the water. If there is a spark on the electrodes and the fan starts, then the gas valve is working.

The fault was found quite quickly, the ignition electrode did not spark. There are two of them: extreme. The one in the center is the control one, in the absence of a flame, it turns off the gas supply.

Problems with ignition

Usually, batteries in gas water heaters are located in the lower right corner, and replacing them does not require much effort.

Often there are situations when gas is supplied, there is traction, the pressure is normal, and the gas column does not ignite. If you have installed geyser Neva or Oasis with electric ignition, listen to see if there is a spark generation. The presence of a spark is indicated by a characteristic crack coming from when opening a faucet. If a crackling sound is heard, but the geyser does not ignite, try replacing the batteries - this is a very common reason for the lack of ignition (a weak spark makes normal ignition impossible). Owners of speakers with piezoelectric ignition need to make sure that the igniter is working. If it burns, then the column should light up immediately, without hesitation. If there is no flame, try to ignite it with the ignition button. If the gas in the igniter does not ignite, then the problem is in the fuse itself (in the jet) - it needs to be cleaned. To do this, we disassemble the geyser, get to the fuse and clean it with steel wire. Next, we try to light the column again.

When repairing your geyser, be careful and always turn off the gas supply before carrying out any operations.

As for hydrodynamic ignition, it is a combination of a small generator and an electrical circuit that generates a spark and feeds some other electronic components. If the generator or circuit is out of order, the geyser will not ignite. Self-repair here is only possible if you have the appropriate knowledge and experience in electronics repair.

Recommendations for the implementation of repair work

Membrane replacement for a column of each model is made only with compatible parts. The product should be purchased strictly from official suppliers or certified dealers. In terms of material, the silicone diaphragm is highly durable.

Removing the regulators from the body is carried out by moving them towards you. If the speaker is equipped with a display, you need to disconnect the cables associated with it. The casing is removed by unscrewing the bolts or pulling forward and upward to loosen the latches. After that, you can disassemble the assembly itself, which is responsible for feeding the system with water. No special methods are needed to change the batteries, but you should still know how to do it.

The flag holding the cover must be turned 90 degrees counterclockwise. When placing the batteries vertically and fixing them on flexible latches in the form of the letter G, you need to separate the parts to the side and remove the batteries. Immediately after that, you can put new energy sources and secure them in place with the same latches.In some versions, a retractable container is used, which comes out when you press the middle part of the bottom until it clicks.

It is not difficult to disassemble the geyser, most often you have to do this in order to clean it. Purification must be carried out on both the water and gas circuits. The presence of dirt on the ignition elements threatens with a catastrophe, and clogging of the pipeline with scale drastically reduces energy efficiency. The water-receiving unit, after being removed, is washed under the maximum possible pressure. The column radiator is also cleaned only when removed.

It is worth taking into account that if the scale has blocked the movement of the nuts, you should not demonstrate heroic perseverance or call for help from stronger people. It is more correct and safer to remove the blockage due to WD-40 liquid, which allows you not to break anything. At home, a hot solution of citric acid or vinegar can become a replacement for a special liquid when flushing a heat exchanger. When returning the cleaned part to its place, it is necessary to replace each seal. In the gas burner itself, without the help of professionals, it is permissible to clean only the fuse (using a steel brush).

About how to fix malfunctions of geysers Neva, see the next video.

Other malfunctions

One of the simplest malfunctions due to which the flow heater with automatic ignition does not turn on is dead batteries. The estimated battery life is 1 year, but it happens that their charge ends earlier, it depends on the quality of the products.Ignition from a hydro generator implies the presence of a certain water pressure in the system, and if it is not there, then the unit will again not start.

Sometimes pops occur in the combustion chamber, which is caused by a clogged igniter jet. The flame on it becomes weak and a higher concentration of gas is needed to ignite the burner. When it is reached, there is already quite a lot of fuel in the chamber and cotton occurs. The presence of a weak yellow light on the igniter indicates that the jet needs to be cleaned.

In some situations related to water overheating, the gas valve is triggered by a temperature sensor command. The column ignites after the heat exchanger has cooled down. Here you need to consult a specialist, because you need to understand the causes of overheating. In addition, operation in extreme mode leads to the operation of the safety valve, water constantly drips from it.

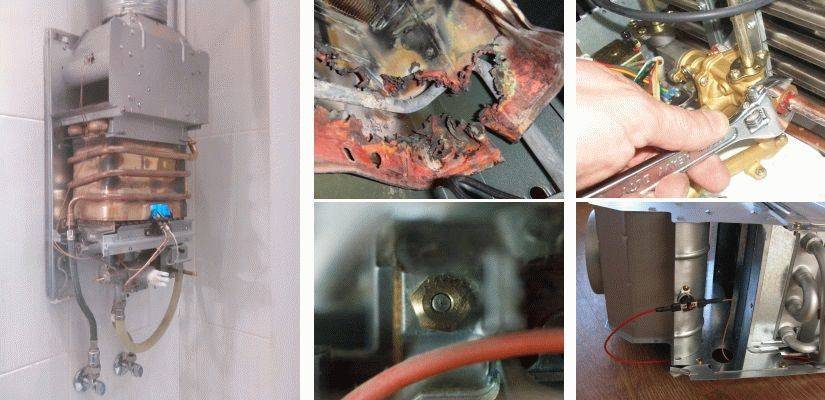

Sources of the accident

There are several reasons for the failure of the burner, the main ones are the following factors:

1. Lack of traction.

For any model, be it the Neva, Oasis or Vector, the flame goes out or does not light up due to the fact that the chimney is often clogged with dust, dirt and foreign objects. In modern equipment, in this case, a protective valve is activated, which automatically shuts off the fuel supply to the gas column. This is because the products of combustion are not discharged in full and in accordance with the technical requirements.

To verify the malfunction, you need to check the traction. To do this, open a window and bring a lighted match or a sheet of paper to the pipe. If the chimney is clogged, the wind will not be felt, so the geyser does not light up.The cleaning of the combustion waste disposal system is carried out by specialists

It is important not to miss this moment, as the exhaust gas enters the room, which can lead to serious consequences.

An ingenious way to almost NOT PAY for electricity! A clever meter that saves electricity Pays for itself in 2 months!

Sometimes the automation works when the hood is turned on, located nearby, the flame goes out or does not appear. If the device has a large power, it interferes with the removal of waste, so you should never install two units in one place, especially in small rooms.

2. Malfunction of sensors.

If the igniter flame goes out, it is necessary to inspect the device that controls the exhaust of gases. To do this, disconnect the wires and check the resistance using a special device. The indicator must be indicated in the passport, if it does not reach the optimal value, the sensor will have to be replaced. The burner goes out when the thermocouple breaks. In this case, the gas column does not ignite due to low voltage, the optimal parameter of which is 10 mV.

3. Discharged batteries.

The main function of the batteries is to keep the valve open during operation. The service life of the elements is no more than a year, therefore, manufacturers of such gas units as the Neva recommend changing batteries on time. In addition, the reason that the burner does not ignite may be a malfunction of the piezoelectric element or the power cable. It is necessary to disconnect the wires and check them for internal and external breaks. If there is still no spark, the column does not turn on, then the source of the problem is different.

4. Blockage of the inside.

When dirt and soot get into the supply tunnel gas from fittings to burners, the flame goes out or does not ignite. The injectors need to be cleaned. If the fuel pressure is not adjusted, a characteristic whistle will be heard, flame separation appears, then it disappears. Also, a burner of the wrong diameter can create such a malfunction. In this case, you need to correct the gas supply or replace the elements. When airing, the gas column ignites, but immediately goes out. To eliminate the defect, you need to unscrew the nut on the fitting and bleed the air, then return the mount to its place, fix it and check if the burner goes out.

5. Deformation of elements.

If the water is too hard, scale appears in the pipes, which gradually clogs the filters, so the gas unit goes out or does not turn on. The grate is taken out, thoroughly cleaned. If it has been damaged by deposits, it is better to replace it.

The membrane of the water supply unit often breaks, so the column does not turn on. To determine its condition, remove the top cover of the case. The plate should not be in cracks and gaps, has the correct shape, smooth and even. In case of the slightest deformation, it will have to be replaced. It is better to choose a part made of a durable and elastic material that is resistant to temperature fluctuations and the influence of scale. Install the membrane carefully, crimping the fasteners around the perimeter.

6. Water pressure.

As in the draft situation, the automation blocks the gas supply; if the supply is poor, the burner immediately goes out. It is worth contacting the utilities to find out the reasons, turn off the unit until then. You can use the column only if the water pressure is normal. In private homes, the pressure is increased using a compact station and a regulator.If the column turns on and works normally, and the water is still cold, the device may not have enough power, the parameters are noted in the passport.

Here's the secret to saving water!Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

Why does the column turn off during operation?

If the geyser ignites normally, but for some reason goes out during operation, this may indicate the correct functionality of the device's security system.

The column design has a sensor that is triggered when the internal temperature rises. Inside the system, there are two plates that repel each other, stop the power supply, turn off the column. This happens when the internal temperature rises quickly and uncontrollably.

The gas column automation system includes three sensors: thrust, flame, overheating. Plus two valves: gas and discharge. They ensure the safe operation of the device.

The gas column automation system includes three sensors: thrust, flame, overheating. Plus two valves: gas and discharge. They ensure the safe operation of the device.

You can check the sensors by resistance. A serviceable part shows the sign of infinity. When another value is highlighted, we call the wizard.

If the device works long enough, and then turns off, check the settings. Sometimes users accidentally set automatic shutdown after a certain time.

What else leads to a shutdown:

- poor water or gas pressure;

- violation of contact between the thermocouple and the solenoid valve (you need to clean the contacts, tighten the connections);

- oxidation of the contacts of the power supply when the device clicks, but does not light up.

It is useful to check the batteries. Standard replacement of power supplies is carried out every six months.Batteries hold charge longer.

Traction is poor or completely absent

The accumulation of combustion products is most often associated with clogging of the chimney with soot, soot, and debris. When there is no traction or it is insufficient, working out is not displayed.

To check the draft, you need to bring a burning match, a lighter to the control window of the column. If the flame deviates to the side, there is thrust. It remains to burn evenly - it is not

It is important to remember that the flame can go out due to external factors - gusts of wind, for example. The draft in the mine increases or decreases under the influence of a draft

You can clean the chimney through a “pocket” located 25 cm below it. If such manipulations did not help, call the utilities.

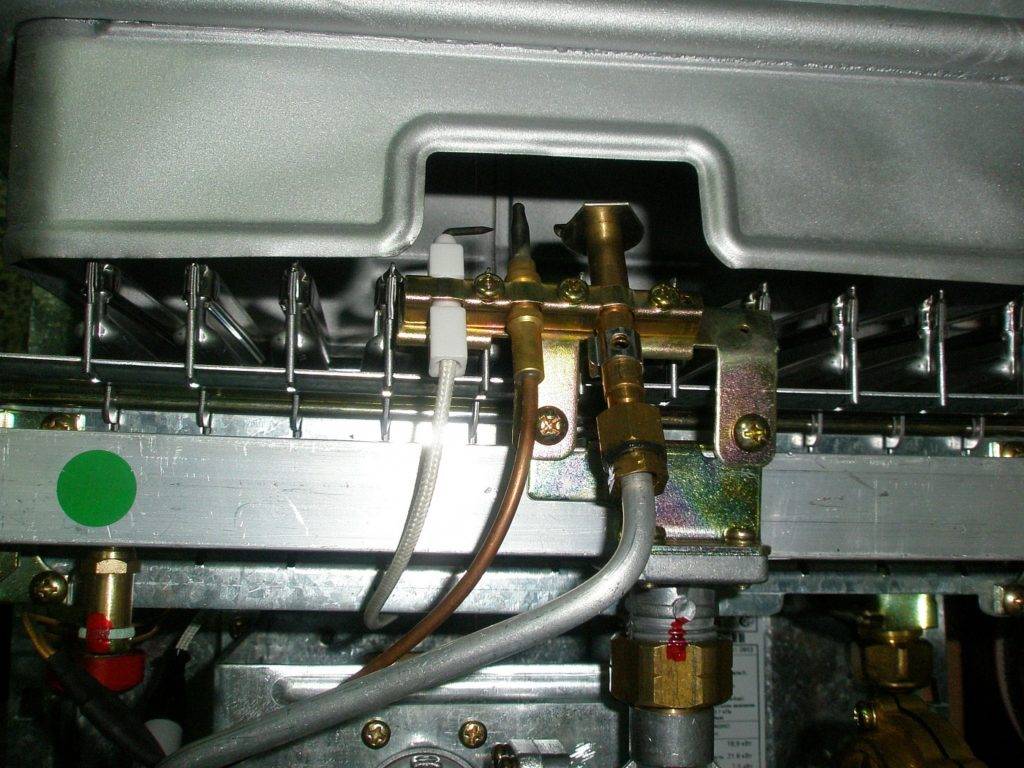

Soot accumulation on the heat exchanger

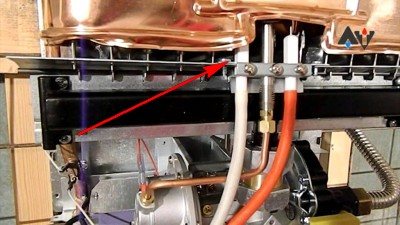

The heat exchanger accumulates soot, soot, and scale during operation. When it clogs, the color of the flame changes from yellow to blue.

How to clean the heat exchanger:

- We remove the cover.

- Unscrew the screws holding the cover.

- Shut off the water supply.

- Open the faucet to drain hot water.

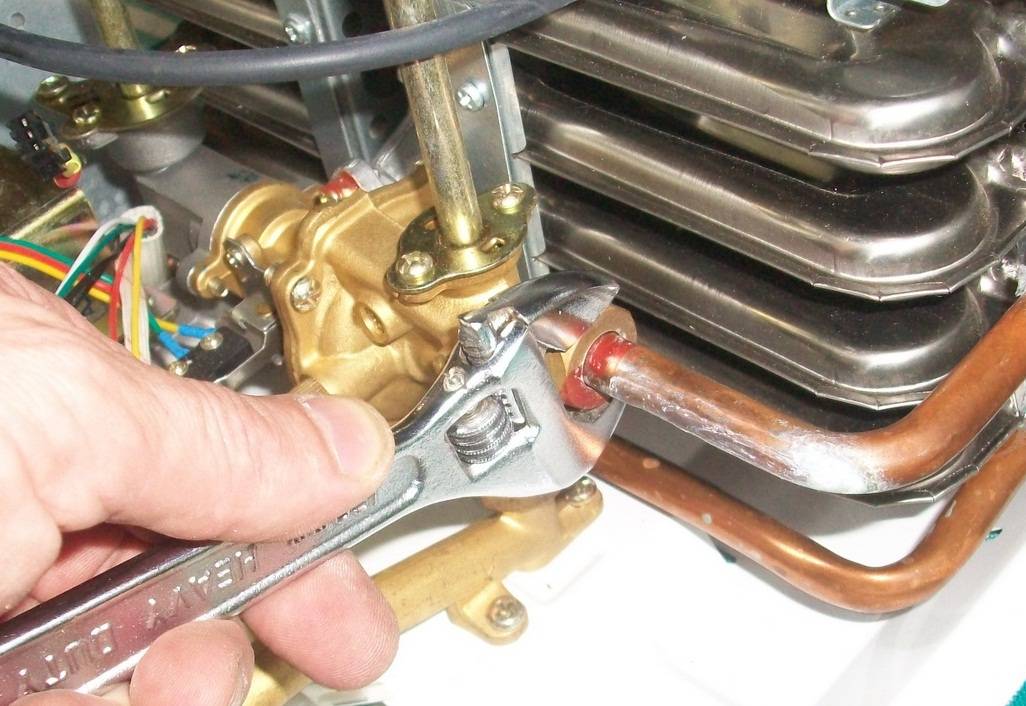

- We disconnect the thread of the heat exchanger and the tap. You will need a stand - water can flow.

- We prepare a solution of hydrochloric acid (3-5%).

- Take a pipe with a diameter of 1/2 "or use a hose.

- We connect one end to the input, the other to the output.

- Pour the solution into the funnel. If foam appears during washing, this is normal.

- As soon as a strong pressure appears at the exit, we stop the procedure.

Be sure to wear gloves while working. After descaling, rinse the heat exchanger thoroughly to remove acid residues.

If during the cleaning process defects were noticed on the tubes, then the heat exchanger will have to be repaired.

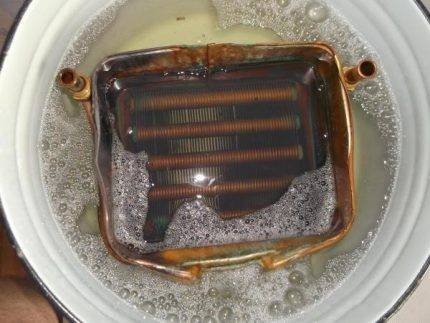

To clean the heat exchanger from scale, you can use citric acid (700 ml of water will need 80 g of powder). Boil the radiator in the solution for half an hour, leave to cool and rinse

To clean the heat exchanger from scale, you can use citric acid (700 ml of water will need 80 g of powder). Boil the radiator in the solution for half an hour, leave to cool and rinse

Cleaning work is recommended to be carried out once a year. Regular maintenance will help the machine function properly.

Clogged shower head and hose

It happens that the geyser turns on and for some reason immediately goes out when you switch to the shower. This may be due to clogging of the openings of the watering can.

It is necessary to unscrew the watering can, clean and rinse the holes. Soaking metal elements in a solution of citric acid is also effective.

Scale on the watering can is formed due to the increased hardness of tap water in some regions. To prevent this, install filters or buy a faucet with a shower equipped with a built-in anti-scale system.

Scale on the watering can is formed due to the increased hardness of tap water in some regions. To prevent this, install filters or buy a faucet with a shower equipped with a built-in anti-scale system.

The next detail that can cause the wick to go out is the shower hose. If it gets tangled or clogged, the pressure power decreases and the column goes out.

The mixer can also break or become clogged. You need to disassemble it, check it, clean it if necessary.

At the entrance to the water supply unit there is a filter that traps small debris. It is also useful to clean it periodically. To do this, unscrew the screws, remove the element, rinse, brush with citric acid.

Why does the column of the above models not light up, as well as for Neva transit?

You can find out complete information on the selection, operation and maintenance of gas water heaters (instantaneous water heaters) of all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems on other people on this topic who have already bought geyser or instantaneous water heater and thus avoid them. You will find a regularly updated list of such problems and their solutions.

One of the most common reasons for a device to malfunction is that it does not ignite. That is, the column does not start to heat the water when you open the tap. Consider the possible breakdown options:

The water pressure is less than the minimum allowable (for all Neva models).

This means that the device does not perceive the stream, since it is weak. From a technical point of view, it looks like the membrane changes shape due to the force of water pressure. Deflection may occur as a result of the inappropriate structure of the node. Geysers make it possible to solve the problem with water pressure using a regulator located on the device.

The geyser burns, but does not heat the water

One of the most frequent breakdowns. There are several reasons why the geyser is on fire and cold water is flowing:

- Soot contamination of the outer part of the heat exchanger - the metal cavity is in contact with combustion products. Over time, a thick layer of soot forms on the walls. The geyser does not heat water for the reason that soot is a good heat insulator that prevents heat transfer.

- Problems in the operation of the cold water regulator - the gas pressure is regulated using a membrane and a stem connected to the supply valve. In the "frog" there are two cavities separated by a rubber gasket. When the DHW valve is opened, the membrane bends and presses on the stem that opens the fuel supply to the burner. If the geyser does not heat water well with good water pressure, the reason is in the stem or membrane:

- Rubber Diaphragm - Gasket may break.In this case, the column turns on only with a strong pressure of water, the temperature of which is much lower than that set in the settings. Symptom: leak in the water unit.

Another reason why the water heater does not heat water, but the fire burns is that under the influence of hard water the membrane has become rigid and cannot press enough on the metal rod to completely open the gas supply. - The stem is a rod connected to the valve. When the membrane is exposed, the rod presses on the sensor, opening the supply of blue fuel to the burner. The stronger the mechanical effect on the rod, the greater the pressure of the gas. Over time, rust can form on the metal, making it difficult for the stem to move, resulting in a weak flame on the burner.

- Rubber Diaphragm - Gasket may break.In this case, the column turns on only with a strong pressure of water, the temperature of which is much lower than that set in the settings. Symptom: leak in the water unit.

- Low gas pressure - in this case, the water does not heat up in the geyser, not due to failures and malfunctions in the water heater. You can fix the problem by contacting the local branch of Gorgaz.

The causes of poor water heating by a gas column are eliminated after replacing the membrane or rod, as well as cleaning the heat exchanger. To prevent frequent breakdowns, regular maintenance of the heat generator should be carried out.

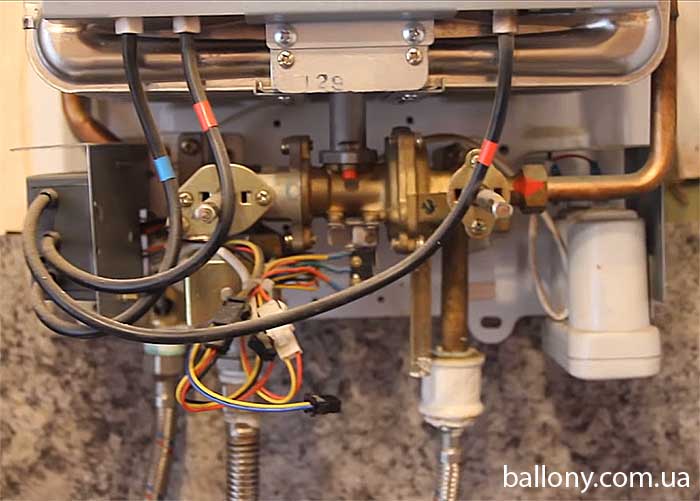

Features of maintenance and repair of speakers

Malfunctions in the operation of water heating equipment are often associated with blockages, difficulties in supplying water and gas. To easily diagnose problems, it is advisable to familiarize yourself with the device of the water heater, the principle of its operation.

Outwardly, the speakers may look different, but the principle of their work remains the same.

All equipment that provides flow-through water heating has similar components and parts:

- The housing that protects the device can be made of steel, cast iron, various alloys. It houses the control panel, and in advanced models there is also a display for displaying information. If the column does not heat the water well, an error code will appear on the screen.

- Main burner, igniter.

- Heat exchanger made in the form of tubes. Water moves through it, here it is heated. Often this node is the cause of a malfunction of the gas heater.

- The combustion chamber. It can be open or closed. Here, the energy of the fuel is converted into heat.

- Water node. After opening the tap, the flow of water, passing through this node, activates the membrane. It acts on the stem, which, in turn, opens the valve and passes gas into the burner.

- Gas valve. He is responsible for supplying gas to the system. If there is a malfunction in its operation, the column may not work correctly.

- Chimney - an opening for the exit of products of combustion of fuel.

The principle of operation of the gas column is quite simple. When the user opens a hot water faucet, cold water, gas is supplied to the device, and the burner is ignited at the same time.

Cold water passes through the tubes of the heat exchanger, gradually heating up. Combustion products through a chimney or a special opening are redirected to the street.

We talked about the principle of operation of the column in more detail in the article: The principle of operation of the gas column: features of the device and gas water heater operation

For operational heating of water, it is important to maintain the operability of all units of the column, to carry out periodic maintenance of gas equipment

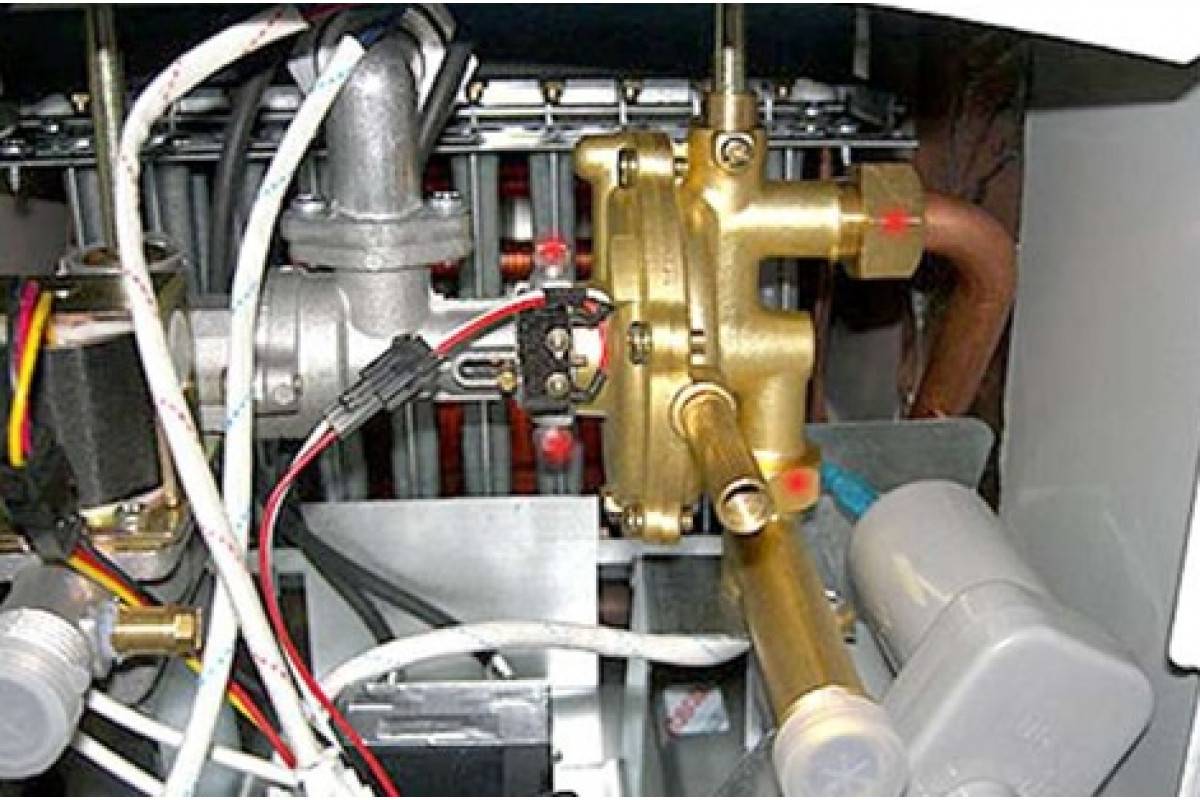

The nuances of cleaning the radiator from scale

During the operation of the gas column, scale can form inside the radiator tubes - when hard water is heated, salts and metals are deposited on the inner walls of the heat exchanger. As a result, the gap narrows, and deposits attached to the walls do not allow the heat exchanger to warm up well.

As a result, cold water is supplied perfectly, the gas burner is working normally. However, at the exit, the user receives slightly heated water. This defect can be corrected independently.

To clean the water heater, it is necessary to thoroughly rinse the pipes. Professionals use a special radiator cleaner. For the work of a home master, a solution of vinegar (citric acid) is suitable.

To disassemble and clean the gas column, you must have the following tools and materials:

- a set of keys;

- silicone gaskets;

- a tube with a funnel for filling the cleaning mixture.

Close before starting work cold water taps, gas. Open a hot water tap to drain fluid from the system. Then you need to remove the fittings, unscrew the case.

After that, you need to remove the tube adjacent to the heat exchanger, drain the remaining water, which may still be about half a liter.

For cleaning, it is necessary to pour a heated solution of citric acid (vinegar) into the heat exchanger, leave for a couple of hours. At the end of the term, connect the coil to the water supply, rinse thoroughly. If desired, repeat the procedure.

Features of elimination of leaks in the column

When water leaks are noticed during use of the gas heater, the cause of the malfunction may be as follows:

- incorrect connection of the device to the water supply;

- failure of seals located at the joints;

- the appearance of a fistula in the heat exchanger tube.

In the first two options, repairs will not be difficult since it is enough to correctly connect the device or replace the gaskets.

Professionals recommend choosing silicone seals that provide tight connections and last a long time. When planning work, it is worth stocking up on gaskets for all connections in order to replace them simultaneously in the entire column and not face a similar problem elsewhere in a short time.

You can try to solder the flowing section of the heat exchanger tube. This will provide a temporary effect, prolong the operation of the gas heater. However, after a fairly short period of time, the fistula may appear elsewhere, so it is advisable that instead of soldering, professionals recommend a complete replacement of the heat exchanger.

Conclusions and useful video on the topic

How the gas column works: the principle of operation of the device:

How to correct the position of the flame adjustment sensor:

Analysis of two non-obvious reasons why the geyser can turn on and immediately go out:

How to diagnose a malfunction by removing the heater cover:

p> The main problems with the attenuation of the heater are listed. In most cases, they do not depend on the instrument model or manufacturer. Some you can handle on your own. But if you are not sure about this, it is advisable to contact a service center or gas service.

Do you want to talk about your personal experience in diagnosing the cause of column attenuation and how to repair it yourself? Or do you have questions that we have not covered in this material? Write your comments, participate in the discussion - the feedback form is located below.