- Button that starts processes

- Low prices

- A special case

- Technical breakdowns

- Washer connection rules

- Main reasons

- Let's start repairing

- Electronic "brain"

- Filter or wire?

- Motor problems

- Troubleshooting

- Electronic board

- When turned on, the washing machine does not show signs of life, does not turn on at all

- Check if the electricity in the apartment is turned off

- Network cable failure

- Power button broken

- FPS noise filter failure

- Control module failure

- All indicators are responsive when turned on.

- "Guilty" network button

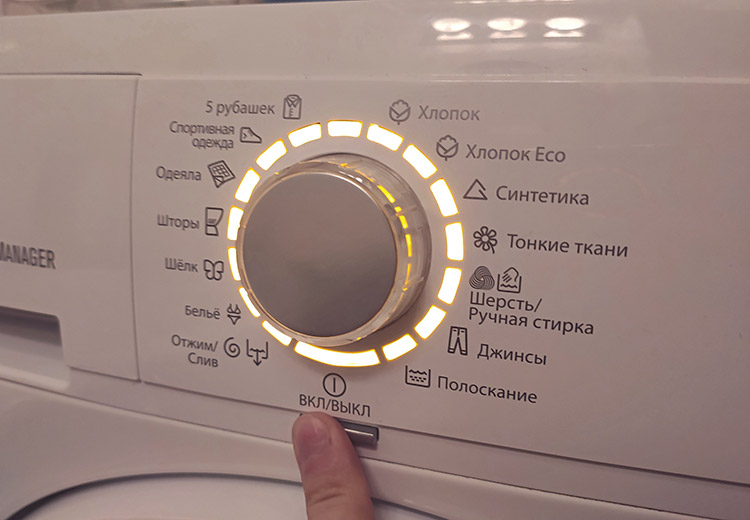

Button that starts processes

After successfully diagnosing the power cord and FPS, we go to the dashboard. The fact is that on the washers from Atlant, when one or more keys stick, a failure occurs, after which the entire system is de-energized. If modern washing machines are able to withstand such a blow and display the corresponding error on the display, then the old-style models cannot cope with the load and simply “fall silent”.

To understand if the problem is caused by a stuck key, you need to perform several steps:

- open the detergent drawer and, pulling it towards you, remove it from the case;

- unscrew all the screws holding the dashboard;

- carefully disconnect the panel from the machine (it is not necessary to completely unhook the board - you just need to gain access to the "insides");

- switch the multimeter to resistance mode;

- attach the probes to the button contacts and measure the resistance.

Practice shows that sticking of the "Start" button more often leads to an emergency shutdown of the machine. If it works, then there is a problem with other keys being used. We check everything in order. If sticky keys have nothing to do with it, then it is likely that the problem is in the electronic module. Here it is better to turn to specialists.

Share your opinion - leave a comment

Low prices

| Service | Price |

| Diagnostics | |

| When ordering a repair | Is free |

| Refusal to repair | 1 standard hour |

| Full diagnostics of the product (operability check) | 2 standard hours |

| Overhaul | |

| Electric motor replacement | 1.5 standard hours |

| Replacing the drum pulley | 2 standard hours |

| Replacing shock absorbers without removing the tank | 1.4 standard hours |

| Replacing the electrical harness | 2.2 standard hours |

| Replacement of supports, crosses | 2.2 standard hours |

| Replacing the drum, tank | 2.5 standard hours |

| Bearing replacement | 2.5 standard hours |

| Installation of counterweights | 1.3 standard hours |

| Replacement of body elements | 2 standard hours |

| Repair of medium complexity | |

| Sealing or replacing pipes | 1 standard hour |

| Drain pump replacement | 1.2 standard hours |

| Elimination of blockage of the drain pump, hard-to-reach pipes | 1.2 standard hours |

| Solenoid valve replacement | 1.5 standard hours |

| Replacing the heating element | 1.5 standard hours |

| Pressure switch replacement | 1.2 standard hour |

| Replacing the level sensor | 1.1 standard hours |

| Replacing the display unit, electronic module | 1.7 standard hour |

| Replacement (assembly-dismantling) of KSMA | 1 standard hour |

| Electrical circuit repair | 2 standard hours |

| Configuration (firmware) of the electronic unit | 2 standard hours |

| Replacing signal lamps of the dispenser, front panel | 1 standard hour |

| Belt replacement | 1.1 standard hours |

| Shoe drying | 1.5 standard hours |

| Drying heating element replacement | 1.5 standard hours |

| Replacement of the thermostat, drying timer, suspension springs, sunroof lock | 1.5 standard hours |

| Closing the drum shutters | 2.5 standard hours |

| Removing foreign objects from the tank | 1.6 standard hour |

| Minor repairs | |

| Removing the transport locks | 1 standard hour |

| Replacing the hook, hatch handle, hatch fastening, glass | 0.8 standard hours |

| Replacing the door seal, hatch cuff | 1.6 standard hours |

| Opening the loading door | 1 standard hour |

| Replacement of the power button, capacitor, surge protector, power cord, repair of the KSMA indicator | 0.7 standard hours |

| Drain hose replacement | 1.2 standard hours |

| Aquastop (hydrostop) replacement | 1.2 standard hours |

| Minor repairs (without dismantling the machine) | 0.5 normal hours |

| Maintenance | 1 standard hour |

| Related | |

| Repair of nodes, modules | 50% off new price |

| Installation-dismantling of the built-in device | 1 standard hour |

| Cleaning the system | 1 standard hour |

| markup ratio | |

| Embedding | 1,8 |

| Premium Model | 1,8 |

| Urgent check out (within 15 minutes) | 1,5 |

| Cramped working conditions | 1,5 |

| Any repair associated with the complete disassembly of the product | 2,5 |

| Basic values | |

| Standard hour (rounded up to the nearest half hour) | 1000 |

| Final provisions | |

| ● When repairing the control board, the master collects the fee, returns it and installs it after repair ● Spare parts and consumables are paid separately ● Departure outside the city - 40 rubles / km ● The final price of the repair is determined by the master, based on the complexity of the breakdown and the amount of work performed |

We suggest you familiarize yourself with the Elimination of leakages of washing machines

A special case

In some situations, the automatic machine turns on normally, and the washing process starts as usual. Only directly during operation can the device turn off completely, and then it can no longer be turned on. If this is the case, then you need to do the following:

- unplug the machine from the outlet;

- check the level of its installation and the distribution of things in the drum;

- open the hatch door with the help of an emergency cable, spread things evenly over the drum and remove some of them from the machine;

- close the hatch tightly and turn on the device again.

If they did not bring the desired result, and other methods of solving the problem do not help, you should contact the service center for specialist help. Trying to start the machine yourself in such cases is not recommended.

LG washing machine repair in the video below.

Technical breakdowns

This group includes technical and electrical malfunctions, leading to the fact that the washing machine either does not work at all or does not start a number of functions. We list the main ones, many of which can be eliminated even without calling the wizard:

- violation of the integrity of the supply cable to the outlet of the external electrical network;

- damage to the cable of the unit;

- socket failure;

- fork breakage;

- lack of voltage in the home network;

- deformation of the sealing gum of the hatch of the loading chamber (because of this, the hatch does not close tightly);

- breakage of the hatch lock;

- deformation or breakage of the hatch guide parts;

- skewed hatch hinges;

- foreign object in the hatch opening;

- hatch handle malfunction;

- network filter failure;

- poor contact in the wires (or their loss from the sockets of the connecting elements);

- the drain pipe from the loading and washing chamber is clogged;

- clogging of the filter on the drain of dirty water;

- pump failure.

Washer connection rules

What to do if the machine does not turn on at the first start. First of all, after buying washing equipment, you need to:

- Study in detail the instructions with all the footnotes, which describe all the points of the sequential installation and the first start of the equipment.

- Unscrew the transport bolts on the rear side, intended for fixing the tank, during transportation and insert plastic plugs.

- Make sure it is properly connected to the water supply and sewerage.

- Open the inlet hose valve to allow water to enter the machine.

- When washing for the first time, it is recommended to use a small amount of detergent to remove industrial oil and dirt.

- Select a program with a long cycle and press start.

The launch will be successful if you have completed all the steps correctly

If you miss an important part, the machine will not work. You have completed all the steps, but the machine refuses to work, be sure to contact the wizard for help to determine the cause

Main reasons

Sounds trite, but the first thing you need to do is check if the washing machine is plugged in. If everything is in order, but the machine does not respond to attempts to start it, make sure that there is voltage in the network. The easiest option is to try plugging in some other device into the outlet.

Make sure the cord and plug of the washing machine are in good condition. If everything is fine with the outlet, but the device still refuses to turn on, it is likely that the problem is in the mentioned elements.

Carefully examine the cord and plug for external damage, breaks, fractures, burn marks, etc. If you find any of the above signs, refrain from plugging in the washing machine - using a faulty cord is extremely unsafe.

Carefully examine the cord and plug for external damage, breaks, fractures, burn marks, etc. If you find any of the above signs, refrain from plugging in the washing machine - using a faulty cord is extremely unsafe.

If everything is fine with the socket, cable and plug, the problem with a high degree of probability lies in the “innards” of the machine. In fact, there are a lot of reasons that can disable a car.

Some of them are elementary and can be eliminated even without special knowledge and the need to involve complex devices, others require qualified diagnostics and rather expensive repairs.

The following list presents the most common reasons for which the machine may refuse to turn on.

- The door of the loading hatch does not close, the machine does not turn on. If the door is not locked, the machine will not turn on. The problem occurs mainly due to the failure of the hatch blocking device. The main function of this mechanism is to block the door during washing, so that the water does not leave the tank and flood the installation site. In most cases, a UBL breakdown is a direct indication of the need to replace it with a new serviceable element.

- The machine does not turn on. The indicators are off. The power button is probably broken. To fix the problem, the button is replaced.

- The control element is broken. In machines with electromechanical control, the programmer is responsible for this. In electronic models - a special control module. The problem is solved by repairing a broken unit or replacing it with a new product.

- The noise filter is broken.The device is responsible for eliminating the occurrence of interference created during the operation of the machine, and their influence on nearby equipment. The problem is solved by replacing the noise filter.

- The lights come on but the machine does not turn on. With a high degree of probability, the problem is in the internal wires. Damaged items are being replaced.

Let's start repairing

Important! Before starting repairs, even if the washing machine does not turn on, unplug it!

-

Faulty socket. If, when diagnosing the outlet using the above method, you find that it is faulty (a hair dryer or other electrical appliance does not turn on as well as a washing machine), then you should repair the outlet. Because there are certain requirements for the sockets used to connect washing machines (for example, the presence of grounding), it is better to entrust its replacement or repair to a professional. If you still decide to repair the outlet yourself, do not forget to de-energize the apartment completely.

- Wire damaged. In the event that during a visual inspection of the wire you notice damage on it (breakage, wear, twisting), then the wire will need to be replaced with a new one.

- The power button is broken. On a machine that has already served for some time, sometimes there will be a violation of the contacts of the power button. Diagnostics of this breakdown is carried out using a special device, a multimeter. If a malfunction is detected, the button must be replaced.

- Faulty sunroof lock button. If, when the indicator button is on and the door is closed, the machine does not start to draw water and the wash does not start, then most likely the washing machine does not turn on due to the door being unlocked. The repairman will help you fix this problem.

- Breakage of wiring connections. During operation, the washing machine vibrates, which can cause mechanical damage to the wiring of the electrical circuit. It is possible to detect this malfunction only by disassembling the machine. Entrust this to a professional who, if a malfunction is detected, will be able to repair the device without any problems.

- Failure of the module or command device. If you have checked everything, and the washing machine does not turn on, this means that the electronic control module is most likely out of order. This part of the washing machine is difficult to repair, and even experienced repairmen will advise it better to replace the faulty module with a new one.

To understand the mechanism of the washing machine, watch this video:

Having found that the washing machine does not turn on, carry out a simple diagnosis of the breakdown yourself, and if necessary, contact the master.

Leave a request for the repair of a washing machine:

TOP stores of washing machines and household appliances:

- /- household appliances store, a large catalog of washing machines

- — profitable modern online store of home appliances

- — a modern online store of home appliances and electronics, cheaper than offline stores!

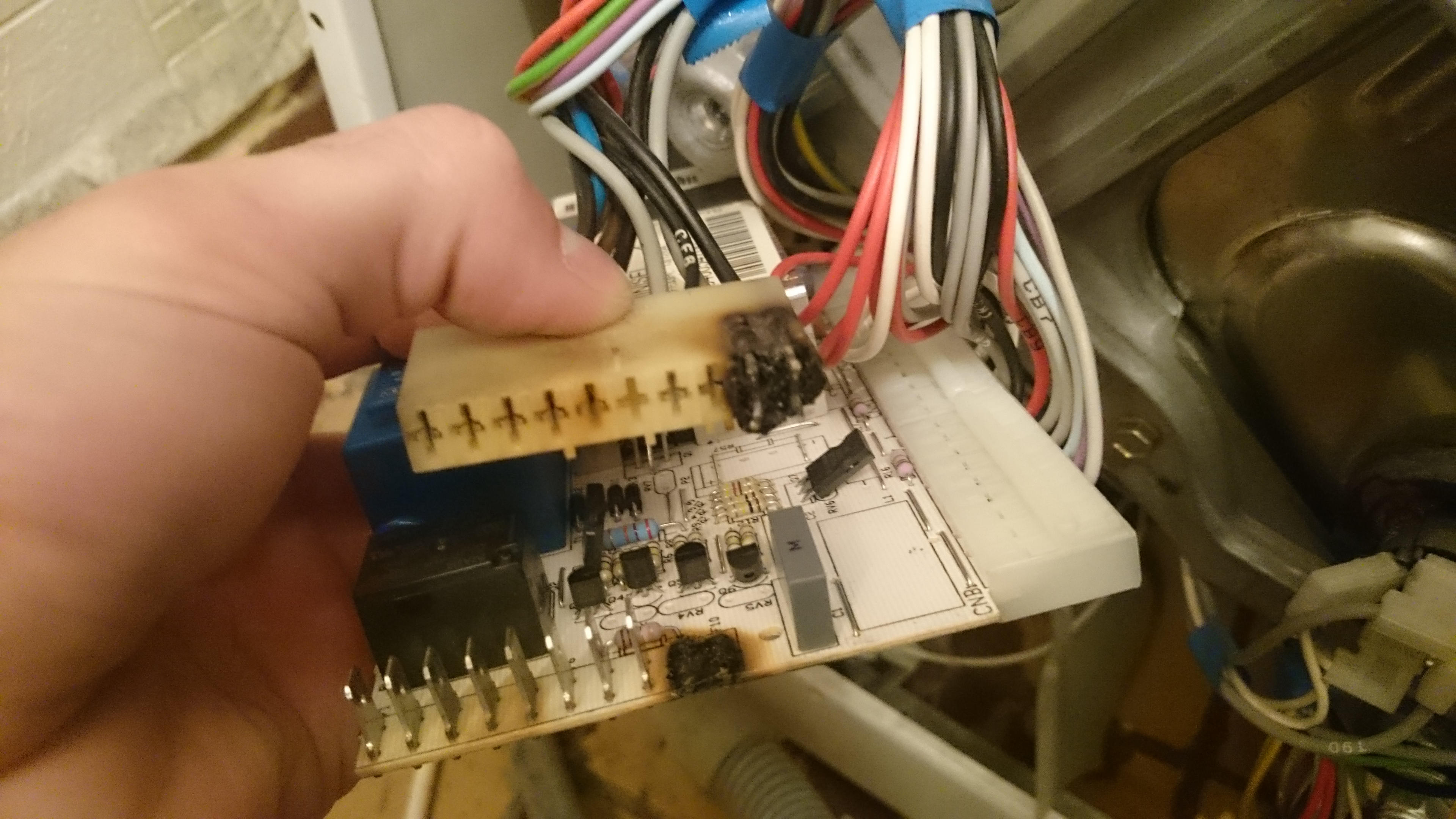

Electronic "brain"

Rarely, but it happens that the washer does not turn on due to a broken control board. The electronic unit on Siemens is a rather complex mechanism that has many microcircuits, tracks, "legs" and sensors. Only a professional master can determine exactly where the failure occurred. However, some problems are easy to notice at home, by carefully examining the module. To assess the condition of the board, you must disconnect it from the case. The instruction is as follows:

- disconnect the washer from communications;

- take out the dispenser;

- in the “nest” freed from the powder receiver, find and unscrew two screws;

- loosen four more screws holding the dashboard;

- take hold of the panel, lift it up by snapping off the plastic latches, and disconnect from the case;

- using a screwdriver, disassemble the panel;

- take out the board.

Wires better not unhook! Reverse connection of the terminals will be problematic. He lived a lot, the marking is clear only to professionals, and the price of a mistake is too high. It is only allowed to inspect the board on your own. If outwardly everything is in order, then we turn to the service. There are probably hidden breakdowns that only a professional can handle.

Share your opinion - leave a comment

Filter or wire?

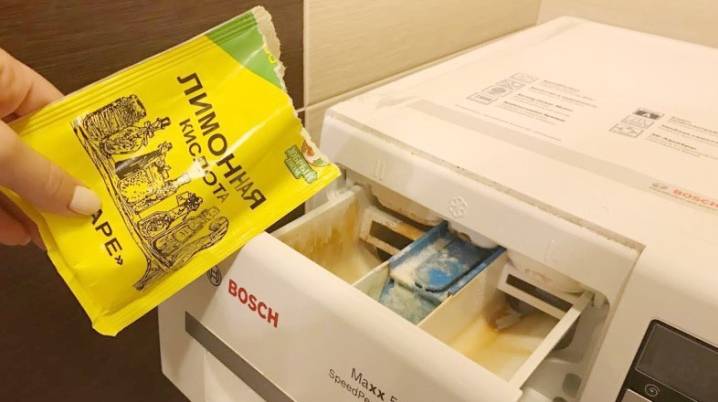

If there are no problems with the outlet and the general power supply, then we proceed to the second stage - checking the power cord and noise filter. On Daewoo washing machines, these elements are connected, so their diagnostics are carried out together. But first, the wire and FPS must be dismantled. We act like this:

- disconnect the machine from communications;

- turn Daewoo backwards;

- remove the top cover by unscrewing the bolts holding it;

- we find the FPS - the capacitor is located at the bottom left, where the power cord connects to the machine;

- loosen the fastener that secures the power wire;

- pull out the noise filter along with the cord and plug.

After dismantling, we begin the diagnosis. The first in line is the power cord. We disconnect the FPS from it and carefully inspect the surface of the wire for signs of fire, damage or squeezing.If outwardly everything is in order, then turn on the multimeter in the buzzer mode and apply the probes to the insulation. Having fixed the breakdown, we completely change the cable. Do-it-yourself local repairs using twisting or electrical tape are prohibited - this is not safe!

Do not forget that before using the multimeter, you need to make sure it is working. Checking the tester is easy - turn on the ohmmeter mode and bring the probes together. The working device will display zeros or a value close to them. Next, check the noise filter. We take the multimeter set to the buzzer, touch its probes to the contacts and evaluate the result. If the device “rang out”, then we set up the tester for an ohmmeter and measure the resistance. The fault will be confirmed by the values \u200b\u200bof "0" or "1" - the FPS has burned out and needs to be replaced.

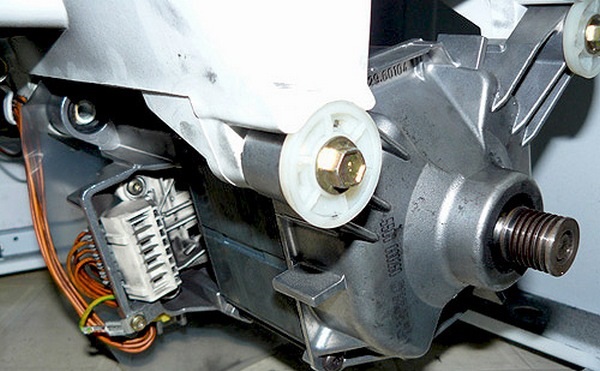

Motor problems

If the machine activates the UBL, draws water, but does not start washing, then the problem is in the electric motor. The motor rotates the drum, thanks to which the washing, spinning and rinsing of the laundry takes place. Some modern models of the vertical type have a reversible engine that spins in both directions.

It is not difficult to suspect problems with the engine: the UBL works, the machine makes noise, but there is no cycle start, and the rotation of the drum does not start. In this case, you need to make sure that the motor is working.

First of all, remove the drive belt and try to start the engine without it. For washers equipped with direct drive, you need to temporarily disconnect the soft coupling. If the engine starts to work without parts removed, then the cause of the problem lies in the drum shaft or in the pump.

To verify the nature of the breakdown, it is necessary to conduct additional diagnostics. We reconnect each mechanism separately and evaluate the “behavior” of the motor.If the engine does not start to rotate, but at the same time it hums at idle, then it is better to dismantle and replace the engine.

When diagnosing a motor, it is important to follow the safety rules. The motor is under high voltage and if the current leaks, it can lead to serious consequences

The driving components of the washing machine are also dangerous.

On frontal machines, such malfunctions are common. Both mechanical damage and factory defects, as well as linen stuck between the drum and the cuff, lead to engine jamming. In the latter case, there is no need to disassemble the washer: it is enough to carefully inspect the hatch.

Troubleshooting

Depending on the identified cause of the malfunction, the device may require:

- simple repair - such malfunctions can be installed on their own without contacting the master;

- complex repair - it includes complex diagnostics, replacement of individual components and, as a rule, is quite expensive.

If the Start button breaks, you need to purchase a new button and put it in the place of the failed one. If the electronic unit fails, repairs can only be performed by a specialist with experience in working with an electrician.

If you notice that some wires and mounting sockets have fallen out, then you need to replace the burnt ones with new ones, and insert the fallen ones into their places.

The device may not turn on if there is no voltage. Troubles of a similar plan are detected with the help of a tester and immediately changed to working ones. A broken outlet needs to be repaired - most automatic machines do not start washing when plugged into an outlet with loose contacts, in unstable sockets.

Constant heating of the device and rapid cooling lead to the fact that the door lock breaks - in this case, a complete replacement of the lock is required. To dismantle, you need to unscrew the screws that secure the lock to the body of the machine

After the part is released, it must be removed by carefully supporting the hand on the other side.

Replacing a faulty lock with UBL is not difficult at all:

- you need to unfasten all the connectors with wires from the old part, and then connect them to the new unit;

- put a new part and fix it with bolts;

- return the cuff to its original position and secure it with clamps.

After that, it remains only to run a short test wash.

If a new machine does not start up or if the equipment is under warranty, there is most likely a factory defect. In this case, you should immediately contact a specialized service center, since any attempts to fix the breakdown on your own will lead to the fact that the warranty will cease to operate and you will have to carry out repairs at your own expense.

In order for CMA to work properly, and problems with launching do not bother users, the following recommendations must be followed.

Give your equipment a chance to rest - do not operate it in intensive mode. If you plan to carry out a couple of washes a day, then between them you must definitely take a break of 2-4 hours. Otherwise, the unit will work at the limit of functionality, quickly wear out and fail.

Obviously, there are a lot of reasons for not launching the SMA. We have reviewed the most common ones.

The following video shows one of the possible breakdowns of the washing machine, in which it does not turn on.

Electronic board

Worse, if the Daewoo washing machine does not start due to problems with the control board. As a rule, the problem is in the varistor - a semiconductor resistor that protects the microcircuit from voltage drops in the mains. With a sharp jump, he takes the "blow" on himself and burns out. As a result, the machine remains cut off from the power supply.

Fortunately, you can check and repair the varistor on the control board yourself. The main thing is to follow the following instructions:

- disconnect Daewoo from the mains and water supply;

- take out the powder receiver;

- find and unscrew two bolts "hiding" behind the cuvette;

- remove the top cover from the case;

- loosen the three screws on the top bar;

- carefully detach the dashboard from the case;

- disassemble the panel, taking out the control board;

- find a burned-out varistor (they turn black when burned);

- if it is not possible to visually determine the burnt varistor, then it is necessary to measure the resistance with a multimeter on each of them;

- unsolder the "legs" of the burned-out varistor with a soldering iron and dismantle it;

- purchase a similar varistor and solder it in place of the old one;

- assemble the machine and connect to communications.

If you act carefully and correctly, then the washing machine will start again when connected to the network. But sometimes, in addition to the varistor, other elements burn out on the electronic unit: “tracks” and triacs. In this case, replacing one part will not bring success - you will have to carry out a complete diagnosis of the board. It is not recommended to repair the module yourself, it is too risky. It is better to entrust the verification and repair of the "brain" to specialists. It should be understood that the vast majority of official services will insist on replacing the entire control board.For them, it is more profitable than local repair. It is better to call private craftsmen, who often undertake the restoration of the block.

When turned on, the washing machine does not show signs of life, does not turn on at all

Why won't the washing machine turn on? There can be no single answer to this question. After all, there are many reasons:

- Socket failure.

- Overvoltage in the power system and, as a result, knocks out the machine.

- The machine's network cable is not working.

- The power button has failed.

- The FPS noise filter needs to be repaired.

- The control module is not functioning.

These and other reasons affect the health of the washing machine. What to do in each specific case should be decided by a highly qualified specialist after a comprehensive diagnostics of the device: visual inspection and, if necessary, hardware testing. Independent unprofessional actions to restore the device's performance can harm, lead to a complete failure of the washing machine.

Check if the electricity in the apartment is turned off

When the washing machine does not start, the first thing that comes to mind is the lack of electricity in the apartment or part of it. Of course, it's easy to check if other devices turn on. However, if only the machine does not respond, then the machine may have been knocked out due to overvoltage in the system. That is why household appliances with high power consumption must be separated from different outlets. You should also carefully monitor the wiring of the entire apartment to avoid short circuits.

Power surges are not terrible for modern models of automatic machines, as they are equipped with RCDs, residual current devices. In the absence of such an element, interruptions in the supply of electricity disable large household appliances. With frequent power surges, we recommend installing stabilizers that control the amount of voltage supplied to the shield. If the value exceeds 260 W, then blocking occurs and the consumer is disconnected from the network. Such control is important not only for a washing machine, but also for other large household appliances, such as a refrigerator or stove, and especially electronic devices.

If the washing machine does not show signs of life, it is worth checking the performance of the outlet. You can do this with a multimeter or by connecting another device.

Network cable failure

So, electricity is supplied to the device, we continue the test. The power cord comes into view: if a part malfunctions, the machine does not turn on at all. You need to check the household appliance with a multimeter. No voltage? Cable break detected? It's time to change the cord. Home craftsmen often solve the problem using ordinary electrical tape. This method is extremely unreliable, we recommend calling a specialist at home. The master will quickly cope with the replacement of the cable, the equipment will continue to work reliably.

Power button broken

Is the power button broken? Don't worry, the problem is small. It's not time to choose a new machine. Invite our master at a convenient time for you, who first diagnoses the breakdown using a multimeter. If the device emits a squeak, then there is current. Otherwise, the problem is really in the power button, a replacement is required.Our employees always have the necessary spare parts at hand for urgent repairs. The problem often occurs with Beko and Candy brands of washing machines.

FPS noise filter failure

If during the diagnostics the FPS interference filter turned out to be faulty, then its replacement is required. The part is responsible for ensuring that the control module, engine and other electronic equipment do not interfere with the operation of the washing machine. The filter is located immediately under the top cover, in the corner. In the event of a malfunction, the part does not pass electronic current, so the machine does not work.

On the Internet, you can read that the machine will perform its functions without this filter. However, remember that the machine will not work for a very long time, as it will not be protected from power surges.

Control module failure

If the machine does not function, the display does not light up, then a malfunction of the electronic module may have occurred. Only a highly qualified technician can diagnose the problem. The breakdown is typical for machines of the Ardo, LG and other brands. It is impossible to solve the problem on your own without special knowledge and skills. It is better to contact our service center and get professional help at attractive prices.

All indicators are responsive when turned on.

You connected the washing machine to the network, it started up, but suddenly all the lights lit up or started flashing randomly. These symptoms may indicate a wiring problem.

In such a case, you will either have to completely replace the wiring in the house, or repair the part that is causing the problem. The breakdown can be associated with loose contacts that are easy to fix on your own. Also, blinking indicators sometimes indicate damage to the program module.

If all indicators light up at the same time when you turn on the washing machine, this indicates problems with contacts or wiring.

If all indicators light up at the same time when you turn on the washing machine, this indicates problems with contacts or wiring.

If the washing machine does not turn on the first time, this is not a reason to panic. Perhaps the problem is not serious and you can solve it in a few minutes. If none of the proposed methods gave results or you could not figure out the intricacies of repair, it is best to entrust the work to the service department.

"Guilty" network button

Owners of Daewoo, released 15-20 years ago, should also check the power button. On older models, the On / Off key often sticks and closes, which de-energizes the entire washing machine. As a result, the machine does not respond to the connection to the mains. To check the health of the power button, you must:

- remove the dashboard and remove the control board from it;

- find the network button and its contacts on the board;

- Measure the resistance of the key with a multimeter.

The resistance is measured on the switched on button, and then the result is evaluated. If the value is not within the normal range, then the key is burned out and must be replaced. Replaced with a similar item. You can figure out why the washing machine does not turn on yourself - more often the matter is quickly solved by replacing the outlet or noise filter. If experience is not enough, the breakdown is too serious, or the cause could not be established, it is better to contact the service.

Share your opinion - leave a comment