- Accumulator problems

- Answer

- What happens if the "pear" (membrane) of the pumped storage tank of the pumping station is broken?

- 2 Model range of equipment

- 2.1 Marina CAM

- 2.2 Marina APM

- 2.3 Typical malfunctions and repairs

- If the pump sucks air from the well. Why is air in the water from the well and what to do

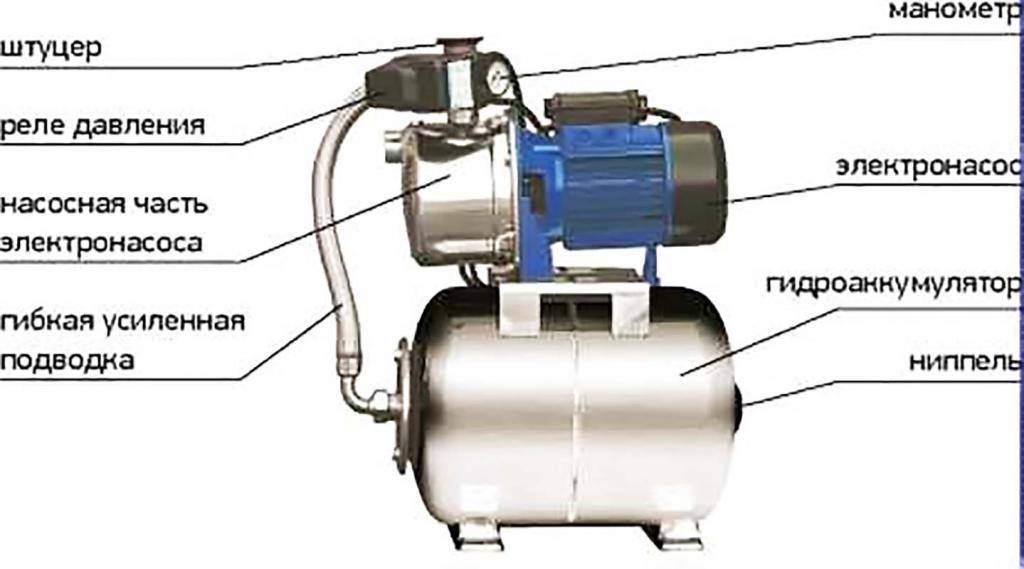

- Key components of the pumping unit

- The order of operation of the unit

- Breakdowns most commonly encountered

- The pump spins but does not pump water

- Turretless does not turn off - does not turn off automatically

- Pump repair

- Impeller replacement

- Oil seal repair

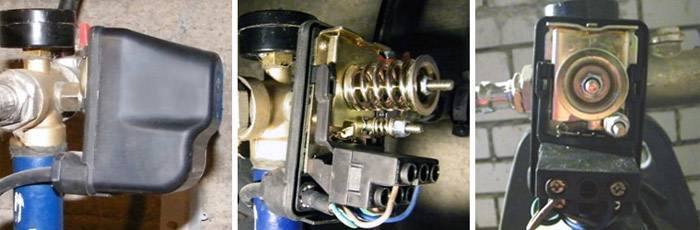

- What is a relay

- The pump does not draw water

- The pump does not draw water

- Low pump power

- The main malfunctions of the pumping station and their elimination

- The station works for a long time without shutting down, and the pressure gauge shows a low level of pressure

- The pump often turns on, and after a little work, it turns off again

Accumulator problems

Problems with the accumulator of a water station can occur when:

the pressure in the relay is set incorrectly - you need to slightly loosen the nut of the small spring, and then the unit will be able to gain the pressure it needs and turn off without delay;

- the rubber membrane is deformed - if water starts to drip when you press the air fitting, then the membrane has ruptured and should be replaced;

- there is no pressure in the tank - use a special air pump to pump air into the accumulator chamber;

- non-return valve leaks - if the pump starts to flow when the station is not in operation, then the non-return valve is clogged and needs to be cleaned.

So, before you are the most common reasons why the water station stops gaining pressure and turns off in a timely manner. Disentangled in nature malfunctions and how to eliminate them, you can not only protect yourself from discomfort due to breakdowns of the unit, but also free you from the need to call the masters to solve the problems indicated above.

Answer

What happens if the "pear" (membrane) of the pumped storage tank of the pumping station is broken?

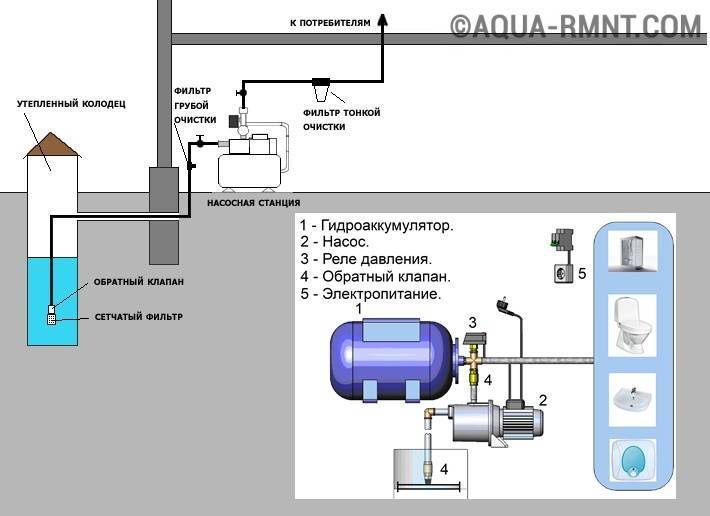

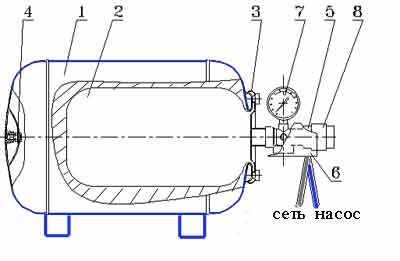

As you know, one of the main elements of almost any pumping station used for automatic water supply to a house or cottage is a hydroaccumulating membrane tank (Fig. 1). Usually, such a tank is a sealed metal container inside which is placed a rubber membrane or, in a popular way, a “pear”. Air is pumped into the tank space outside the “pear”, through the existing fitting with a spool, the pressure of which should be slightly less (by about 10%) of the value pump start pressure (lower).

It is necessary to measure and pump up air pressure with the station turned off and the liquid pressure in the water supply system bled to 0.

When the pumping station is turned on, water fills the “pear”, stretching it until the pressure in it is balanced with the air pressure behind it and reaches the specified maximum (upper) level.At the same time, the water pressure in the "pear" and the air in the space behind it will be the same, and the tank itself will be practically filled with water, providing a certain supply of it.

When the pumping station is turned on and running, its hydroaccumulation tank will be almost completely filled with water, with the exception of the air "cushion" behind the membrane, which will ensure smoother operation of the station. When the pumping station is turned off or, for example, the electricity is turned off, and water is drawn from the system, the liquid pressure will begin to drop and the air will gradually push it out of the tank, providing a supply of water in the amount of its volume.

Rice. 1 Variant of the hydroaccumulating tank of the pumping station in the section: 1 - air inside the tank; 2 - rubber "pear" (membrane); 3 - flange; 4 - fitting with a spool for pumping air into the tank; 5 - adapter-five; 6 - pressure switch; 7 - pressure gauge; 8 - "American" (water supply).

If there is no excess air pressure outside the membrane (pear), then it, stretching, will fill the entire space. In this case, the water supply will be maximum, but there will be little use for this, because when water is taken, in this case, the pressure in the system will drop, almost immediately. This is due to the fact that the liquid, unlike air, is practically not compressed. And when the station is turned off, water will not be supplied from the tank, because there will be nothing to push it out.

Sometimes, during operation, the membrane (pear) of the pumping station is damaged and water fills the entire hydroaccumulation tank completely. What will happen if the "pear" of the pumping station is broken and how to find out? You can determine this by the following signs:

- the pumping station starts to turn on and off very often - almost every time a tap is opened or another type of water intake (although this can also happen with a whole pear, when there is no air pressure in the tank or it is too low) - in this case, it is necessary to check the air pressure in the tank (this can be done using a pressure gauge that measures the pressure in the tires of a bicycle or car), but this must be done with the station turned off and the water pressure in the system bled;

- from the fitting designed to pump air into the tank, when you press the spool core, water comes out, not air - this indicates that water has entered the space behind the membrane (“pear”), which means it is broken.

In order to replace the pear with your own hands, you must:

- turn off the pumping station;

- relieve pressure in the system;

- disconnect the hydroaccumulation tank;

- unscrew the flange bolts and remove the "pear".

The new membrane is installed in the reverse order. Before installing the flange, it is advisable to apply silicone sealant to the place of its contact with the tank.

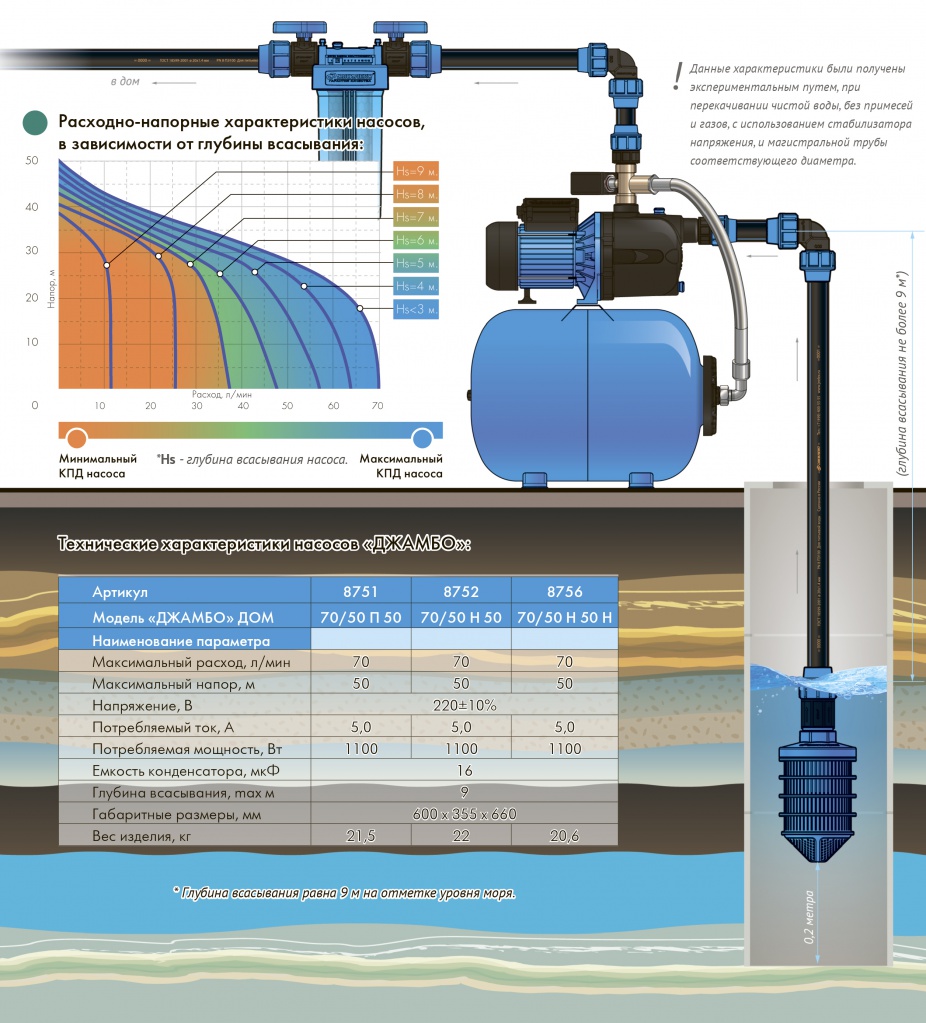

2 Model range of equipment

The product line of Speroni (Italy) includes 4 series of Marina pumping stations:

- Marina CAM is a budget option for water intake from wells up to 9 m deep;

- Marina APM - pumps for wells up to 50 m deep;

- Marina Idromat - units equipped with a regulator that turns off the pump when running dry.

Let's take a closer look at each of these lines.

2.1

marina cam

The CAM series consists of equipment made in a cast-iron or stainless steel case, with internal fittings made of food-grade polymers. Several models are presented, the power of which varies between 0.8-1.7 kW, and the head is 43-60 m.

The volume of the accumulator can be 22, 25 or 60 liters. These are the most affordable stations for private use, the cost of which starts at 7 thousand rubles.

Among the stations with the best price / quality ratio, we highlight:

- Marina Cam 80/22;

- Marina Cam 60/25;

- Marina Cam 100/25.

The Marina Cam 40/22 pumping station is equipped with a 25 liter hydraulic accumulator, the capacity of which will be enough for a family of 3 people. The capacity of the unit is 3.5 m 3 / hour, the maximum lifting depth is 8 m. The price is 9 thousand rubles.

Marina Cam 100/25 has similar technical characteristics - a tank of 25 liters, a throughput of 4.2 m 3 / hour, however, this model is equipped with a pressure boosting system that significantly increases the delivery head - up to 45 m, compared to 30 m for CAM 40 / 22.

2.2

Marina APM

Well pumps of the APM series have a maximum water intake depth of 25 m (model 100/25) and 50 m (200/25). This is more power and overall equipment, the weight of which can reach up to 35 kilograms. As an example, consider the popular station Marina ARM 100/25.

Specifications:

- head - up to 20 m;

- throughput - 2.4 cubic meters / hour;

- centrifugal motor power - 1100 W;

- the diameter of the supply pipe is 1″.

AWP 100/25 is made in a stainless steel case, the model is equipped with overheating protection and a water level control system in the hydraulic tank. ARM100/25 is designed for pumping clean water, without mechanical impurities, the temperature of which does not exceed 35 degrees.

2.3

Typical malfunctions and repairs

Marina pumping stations have established themselves as reliable and durable equipment, however, like any other equipment, they are not immune from breakdowns. We bring to your attention a list of the most common breakdowns and how to fix them:

- Lack of water supply when the pump is on, the cause of which may be a loss of tightness in the conductive pipelines and a worn check valve. First check if you forgot to fill the pump body with water. If it is, inspect the check valve and the tightness of its fit to the pump nozzle, and also check the condition of the intake pipe - all damaged components must be replaced. Similar problems are possible if the impeller is damaged, to replace which you will need to disassemble the unit.

- Water is supplied in jerks due to a damaged accumulator. The main malfunction of the hydraulic tank is a damaged membrane. To determine if it is intact, press the nipple (located on the tank body), if water flows from the nipple and not air, then the membrane is torn. It is quite easy to install the membrane, you just need to unscrew the fixing ring from the tank neck, pull out the old part and mount a new one in its place.

- Reduced water supply pressure. The reason for this can be either a faulty hydraulic tank or problems with the pump. In the first case, the depressurization of the tank is most likely to blame - inspect the body for cracks, repair the detected deformations and pump air up to the standard value. If the tank is intact, the problem must be sought in the deformed impeller of the centrifugal wheel inside the pump.

We will separately consider the situation when the pumping station does not want to work in automatic mode - the unit does not turn off when the tank is full and does not turn off when it is empty. The incorrect adjustment of the pressure switch is to blame here - it is usually calibrated at the factory, but there are exceptions.

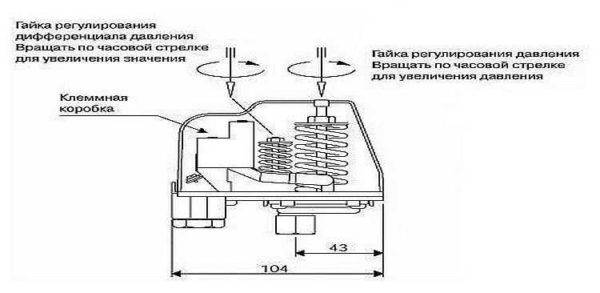

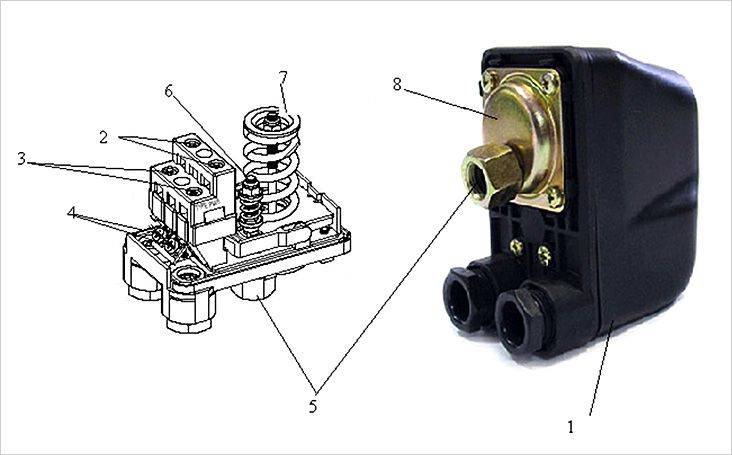

The above diagram shows a standard pressure switch for Marina pumps. On it, under the plastic cover of the case, there are two springs. Most of them rotate clockwise, it is responsible for the minimum pressure in the tank at which the station turns on. By rotating a small spring, we adjust the maximum pressure, upon reaching which the pump turns off.

Adjustment of the pressure switch must be carried out with the equipment disconnected from the mains. Before starting calibration water must be drained from the tank, the level of air pressure is also important - it must correspond to the value recommended by the manufacturer.

If the pump sucks air from the well. Why is air in the water from the well and what to do

Residents of private houses, dachas, country houses often urgently need to install a pumping structure for pumping water from a well or well. For some, this is the only way to have water indoors. Therefore, when, one day, the pump stops buzzing, it is urgently necessary to understand the origin of the breakdown.

If the pumping station stops pumping water, it is urgent to find the cause of the breakdown

Often the stumbling block is the air that enters the pump along with the liquid. Everything can be prevented, only initially you need to find out what elements the pumping structure is assembled from.

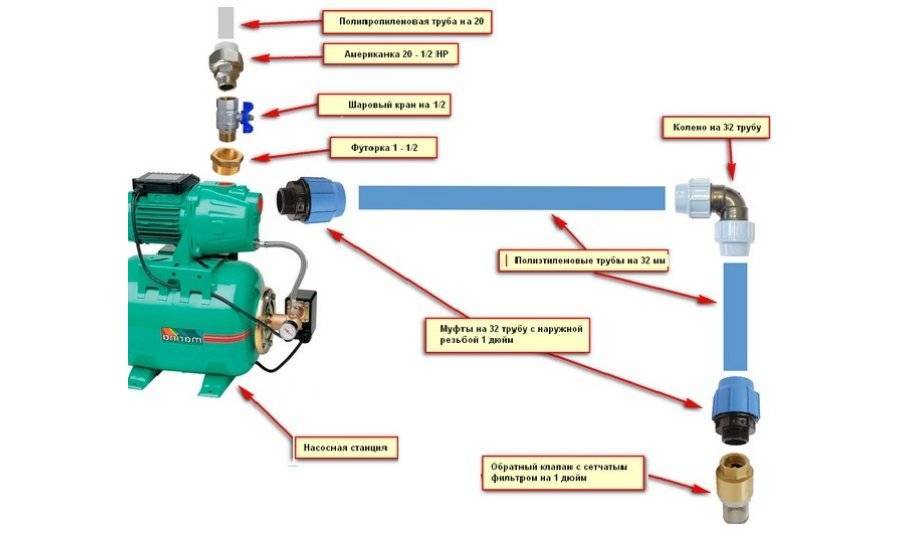

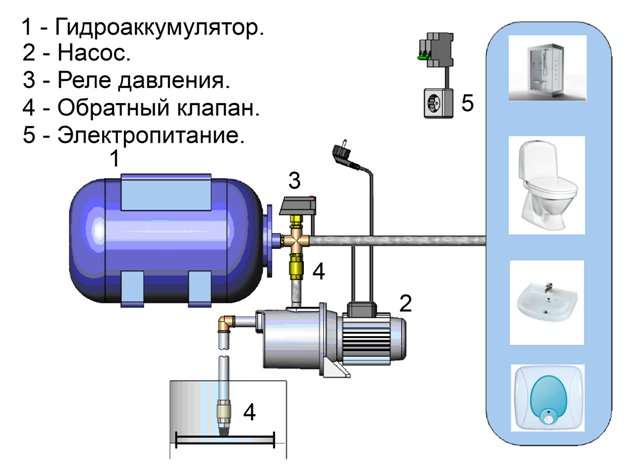

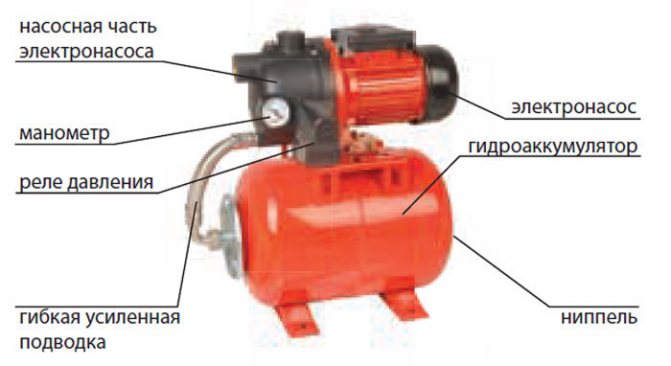

Key components of the pumping unit

There are many varieties of stations, but the main components are common to all.

- Self-priming pump. Principle of operation: the pump independently draws liquid from the recess with the help of a tube, one end of which is in the well, the other is connected to the equipment.

The pump is located a short distance from the water tank. The depth of the tube is also adjustable. - All units are equipped with a hydraulic accumulator. The vessel, using the energy of compressed gas or a spring, transfers liquid under pressure to the hydraulic system. It accumulates hydraulic fluid and releases it at the right time, thereby avoiding water surges in the system. Outside, it is metal, inside there is a rubber membrane, above it there is a gas cavity filled with nitrogen, and a hydraulic cavity. Water is filled until the pressure in both cavities is equal.

- Electrical engine. Through the coupling, it is connected to the pump, and with the relay - using the electrical circuit. Due to the fact that the pump does not turn on for short liquid intakes, the motor does not wear out.

- Air outlet.

- collector element.

- Pressure gauge. It allows you to monitor the level of pressure.

- Relay. By changing the pressure, by opening / closing the contacts, it supports the independent operation of the equipment.

The main purpose of pumping stations is to maintain continuous pressure in the water supply structure.

In order for all components to function like a clock, it is important to correctly select the required volume of the hydraulic accumulator and control the connection between the regulator and the pump itself

The order of operation of the unit

When turned on, the electric motor is the first to come into play, it starts the pump, and it pumps the gradually incoming liquid into the accumulator.When the accumulator is full to the limit, excess pressure will be created and the pump will turn off. When the faucet is turned off in the house, the pressure decreases and the pump starts working again.

The house has a battery connected to the water supply. The pipes fill with water when the pump starts. When the pressure in the station reaches the required peak, the pump is switched off.

The pump unit will solve the difficulty of supplying water to houses, baths, summer kitchens, outbuildings and other premises on the territory of your site. Having familiarized yourself with the details of the operation of the station, it is necessary to study the possible causes of the failure of the device and ways to eliminate them.

Breakdowns most commonly encountered

In the process of using any equipment, there comes a moment when it either wears out or breaks.

So in the second case, it would be important for the owner to understand the causes of damage. Here is a short list of grounds that violate operation of the pumping station:

- no electricity - trite, but also not excluded, since the operation of the unit directly depends on the electric current;

- the pipeline is not filled with liquid;

- pump malfunction;

- hydraulic accumulator broken;

- damaged automation;

- cracks in the hull.

The pump spins but does not pump water

What to do when the station does not pump water? A frequent cause of failure is the lack of fluid in the pipes or in the pump itself. It happens that the unit is functioning, but the water is not pumping. Then you should inspect the tightness of the entire water supply, if there are any places where the pipes are poorly connected.

Check that the pump is not empty. The check valve is not working properly. The throughput must be one-way.This is one of the most important parts of the station, because, after the pump is turned off, it prevents water from flowing back into the well.

Diagram of a pumping station valve that can become clogged with debris

It happens that the valve is clogged and does not physically close, debris, salt, grains of sand can get into it. Accordingly, the liquid does not reach the pump. We solve the problem.

Before spinning the unit, we advise you to check the voltage of the electric current. It happens that it is below normal, and the pump is simply unable to turn on. Etc

Turretless does not turn off - does not turn off automatically

The pumping station does not turn off if it cannot reach the set maximum pressure in the water supply network (shutdown pressure) or if the pressure switch is not correctly adjusted or is faulty, which does not turn off the pump when the set maximum pressure is reached.

In the first case, the pumping station may not be turned off for the following reasons:

- water leakage through connections, plumbing fixtures or a pipe rupture in a volume equal to or greater than the capacity of the station pump, so the pump pumps, but cannot raise the pressure in the system to a predetermined maximum level and the relay, of course, does not work;

- very low voltage in the network and the pump cannot develop the necessary power to reach the set upper pressure;

- malfunction of the mechanical part of the pump;

- air entering the suction pipe of a surface pump without an ejector;

- relay faulty.

If the pumping station does not turn off when the maximum pressure is reached, then the reason is the pressure switch.You can remove the cover of the pressure switch and inspect the contacts (if they are burnt and can open) or try loosening the nuts on the regulators a little, they may be very tight, which can also cause the relay not to work. The inlet and relay diaphragm may be clogged. In order to check this, it is necessary to relieve the pressure in the system and unscrew the nut, remove the relay. If this does not help, replace the relay with a new one.

If the station still turns off, but it takes much longer to reach the maximum pressure (shutdown) than before, then it is possible:

- the non-return valve does not pass water well (clogged or defective);

- clogged mechanical water filter installed in front of the turretless;

- small water leakage in the system (less than pump capacity);

- malfunctions in the mechanical part of the pump.

Pump repair

Unfortunately, repairing the pump with your own hands is not so simple. It's still an electrical appliance. After a long operation and if the pumping station did not work for a long time, for example, it was mothballed for the winter period, then sometimes when turned on, the pump starts to buzz, and its rotor does not rotate. The main reason for this malfunction is that the motor bearings are jammed because moisture has penetrated into them. During long-term storage, corrosion has formed on the surfaces of the bearings. She prevents them from spinning.

Pump station details

The easiest way to start the pump is to move its rotor. What can be done for this.

- It is necessary to remove the back cover of the unit, where the impeller is installed to cool the device.

- You can try to spin the impeller by hand.If she succumbed, then you also need to spin the motor shaft by hand, and then turn on the pump itself by pressing the "Start" button.

- If it didn’t work out by hand, then you will have to remove the impeller from the motor shaft and try to spin it with an adjustable, but better gas wrench.

Of course, it would be better to open the pump motor and lubricate the bearings. But with your own hands, if you have never done this, it is better not to open anything and not disassemble the design of the device. And even more so to engage in the replacement of the bearing of the water pump.

Impeller replacement

Exactly the same situation, that is, the motor hums and does not rotate, may occur due to jamming of the impeller, which is also called the impeller. It is located inside the working chamber, and there is a very small gap between it and the pump housing. It is after a long storage of the working unit that rust growths form in this gap, which cause the rotor to jam.

You can solve the problem by spinning the shaft, as is the case with bearings. But if this did not help, then it means that the impeller has firmly stuck to the body. And it is best to replace it with a new one. How to replace the impeller of a pumping station?

- The working chamber of the pump consists of two parts, which are interconnected by four bolts. Therefore, they must be unscrewed and disconnected from one part to another. How the impeller is removed

- The impeller is mounted on the motor shaft. To remove it, unscrew the clamping nut that holds it.

- Since the shaft rotates in bearings, the bolt cannot simply be unscrewed. It is necessary to fix the rotor itself.

- Therefore, it is necessary to remove the back cover and the fan impeller.

- Then clamp the rear end of the shaft, for example, with the same gas wrench, and on the other side, unscrew the nut with an adjustable wrench.

- After tapping lightly on the impeller with a hammer, you need to pry it off with a screwdriver and pull it off the shaft.

- A new impeller is installed in its place, and all operations are performed from the reverse order.

This is how you can answer the question of how to remove the impeller from the pumping station. Let's face it, the complexity of this operation lies in the fact that during long-term operation, the impeller can stick to the shaft. Therefore, before dismantling it, it is necessary to lubricate the connection point, for example, with technical oil or plain water.

Oil seal repair

By the way, when replacing the impeller, it is necessary to repair the stuffing box of the pumping station. If the working chamber is already open, then it is worth checking everything in it thoroughly. The weak point in this part is the stuffing box, which separates the working chamber from the compartment where the electrical parts of the pump motor are located. It consists of two parts: one is located inside the working chamber, the second in the electrical compartment.

Seal in the pump

Therefore, the first part is first removed, for which it is necessary to remove the retaining ring, which the stuffing box supports. The rubber element itself is removed by hand.

The second part is more difficult. You will have to pull the rotor of the electric motor out of the stator. To do this, unscrew the four bolts from the back of the motor, remove the cover along with the rotor. Just pull it towards you, holding on to the cover.

Next, the second part of the gland is removed.

Assembly is done in reverse order.

It is very important here when pulling out and inserting the rotor into the stator not to damage the copper winding.

As you can see, do-it-yourself repair of a pumping station (replacing the stuffing box, impeller) is not the easiest process. But if you understand it, then you can do without a master. By the way, if you have already opened the electric motor, then immediately lubricate its bearings. But most often in these designs, the bearings have a closed design, so if they work poorly, it is better to change the parts.

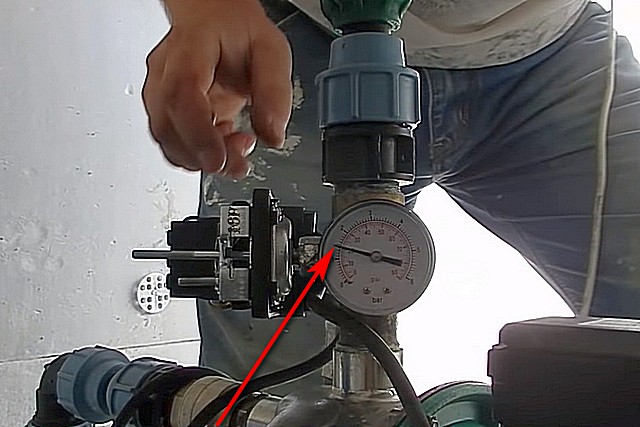

What is a relay

Before answering the question why the pumping station does not turn off after water is drawn, you need to understand some seemingly insignificant elements of the station. A relay is a small device that closes and opens a circuit as a result of reaching the maximum or minimum pressure in the pipeline.

Do not forget to set the pressure thresholds in the relay

If water is selected from the pipeline by the owner, then the pressure naturally drops, which gives a signal to the pump to turn on. After the required pressure is built up, the relay opens the circuit and the equipment stops working.

The pump does not draw water

When it turned out that the pump does not pump water, one of the reasons may be that the pressure in it is not adjusted correctly. Troubleshooting is carried out according to the scheme:

- the pumping station is turned off from the mains;

- water is drained from the water tank;

- the air pressure in the tank is measured through the nipple with a car pump with a pressure gauge or a compressor, its optimal value is 90-95%;

- air is pumped into the water supply system.

- water is poured into the station;

- joins the network with pressure control.

The air in the water supply system is pumped as follows.The cover from the pressure switch is removed by removing the plastic screw and changing the tightening force of the existing assembly springs. Turning one nut turns on the lower value of the pump. Clockwise rotation causes the pressure to increase and counterclockwise rotation causes the pressure to decrease.

Turning the other nut adjusts the pressure range between the lower and upper limits. The range limits are changed by rotating the element clockwise to expand it, counter-clockwise to decrease it. After the steps taken, the pumping station is connected to the mains, and its performance is checked.

The pump does not draw water

When it turned out that the pump does not pump water, one of the reasons may be that the pressure in it is not adjusted correctly. Troubleshooting is carried out according to the scheme:

- the pumping station is turned off from the mains;

- water is drained from the water tank;

- the air pressure in the tank is measured through the nipple with a car pump with a pressure gauge or a compressor, its optimal value is 90-95%;

- air is pumped into the water supply system.

- water is poured into the station;

- joins the network with pressure control.

The air in the water supply system is pumped as follows. The cover from the pressure switch is removed by removing the plastic screw and changing the tightening force of the existing assembly springs. Turning one nut turns on the lower value of the pump. Clockwise rotation causes the pressure to increase and counterclockwise rotation causes the pressure to decrease.

Turning the other nut adjusts the pressure range between the lower and upper limits.The range limits are changed by rotating the element clockwise to expand it, counter-clockwise to decrease it. After the steps taken, the pumping station is connected to the mains, and its performance is checked.

Low pump power

Before purchasing a water station, it is imperative to calculate the required pump power, taking into account the depth of the well, the volume of water used and the design features of the water supply. But even this cannot protect against the fact that one day the power of the unit will begin to decline.

Water station connection

Insufficient power of the pumping unit may be due to the following reasons:

- Wear of structural parts. Most often, the cause of the problem is the imbalance of parts: grains of sand and small contaminants accumulate between the pump shafts, which loosen the elements of the unit and prevent it from working at full capacity. The simplest solution to the problem is to install cleaning filters at the water inlet. The second possible reason is the deformation of the rubber valve. In this case, it is recommended to completely replace the part, since even after repair, the valve will not allow the pump to develop the necessary power.

- Reducing the water level in the well. The most rational, albeit costly, way to solve the problem is to purchase a deep pump.

The main malfunctions of the pumping station and their elimination

The device is made up of the following parts:

- A pump for taking water and supplying it to the house system.

- Membrane tank (hydraulic accumulator) to maintain the set pressure in the system.

- Pressure sensor that starts equipment when the pressure in the system decreases.

- Pressure gauge.

- Drain cock.

Each of the listed nodes performs its task, and if any of them fails, the device fails. The list of malfunctions, as well as options for their repair, is approximately the same for pumping equipment from various manufacturers. Let's analyze the most typical breakdowns of the pumping station.

The station works for a long time without shutting down, and the pressure gauge shows a low level of pressure

Possible causes of failure and ways to fix them:

- Lack of water in the supply well. Such a "dry" operation is fraught with the failure of the pump motor.

- Dynamic resistance inside the highway. It is possible with a large length of the intra-house network with a small diameter of water pipes. Elimination - dismantling of the main pipes and replacing them with thicker ones.

- Lack of tightness of joints or plumbing fixtures. As a result, air leakage occurs in the line, which causes a pressure drop. The solution is to find the leak and fix it.

- Filters or valves clogged with mechanical debris. They should be removed, washed and tested for performance. Defective components must be replaced.

- Incorrectly set indicators on the pressure switch. It is necessary to reduce the minimum pressure limit in the water supply network on the relay, at which the station should turn off.

- The pressure sensor does not work. To remedy the situation, you can try to clean the contacts, or replace the device.

- The pressure indicator is set to the minimum level, and the pump does not create the necessary pressure, and works continuously. Perhaps the impeller has simply worn out and the efficiency of the pump has fallen. The solution is to replace the impeller with a new one.

- Low power supply voltage.The pumping equipment is still working, but the pressure sensors do not work, or the pump speed is not enough to create the desired pressure.

The pump often turns on, and after a little work, it turns off again

Such frequent on/off cycles lead to premature wear of the equipment.

- Small volume of the accumulator tank with a large number of draw-off points. The way out is to replace the membrane tank with another, larger one, or install another, parallel hydraulic accumulator.

- The relay is set to a too small gap between the minimum and maximum head pressure. It is necessary to increase this "corridor" to the standard 1.5 atm.

- The check valve clogged, as a result of which it stopped blocking the return flow. When the pump is turned off, the water goes back into the well, and the pressure in the network drops. Clean the valve or replace it with a new one.

- Damage to the membrane of the battery tank. If its tightness is lost, water penetrates into the second, “air” half of the tank and it ceases to function in the specified mode. As a result, the entire "responsibility" for maintaining pressure in the plumbing system lies with the pump. The way out is to replace the hydraulic tank membrane.

- Also, another malfunction of the hydraulic tank can lead to frequent operation of the pump - failure of the spool. As a result, it begins to “poison” air from the air chamber of the tank, not allowing it to create the necessary pressure in it.

Unstable pressure in the water supply, as a result of which the taps of the mixers begin to “spit”. The reason is the airing of the pipeline, as a result of which plugs appear in it. The way to correct the situation is to find and seal the pipeline depressurization point.If the pump refuses to work at all, that is, it does not show signs of life when the power is turned on, the reason is a malfunction in the electrical part. To identify the exact problem, you should diagnose the electrical circuit.

When the station motor hums, but the impeller does not rotate, the reason for this may be either low voltage on the motor, or some kind of mechanical obstruction. In the first case, the terminal capacitor may burn out. In the second case, the rotor or impeller is “overgrown” with limestone deposits or oxides as a result of a long idle time of the station. Repair here consists in disassembling the station and cleaning its internal parts.

Oil seal replacement - repair of pumping stations, how to eliminate water leakage along the shaft:

Repair of the pumping station ALKO HW3500 (does not pump):