- Causes of noise

- Popping sound when starting

- The column hummed and hummed

- Gas boiler whistles

- The burner burns as long as you hold the control knob

- Why does the oven go out?

- The smell of gas

- What to do if the pie constantly clicks by itself

- How to fix a problem without resorting to the help of a specialist

- Zero is electric and the indicator is on: reasons

- How to solve the problem with a "bad" zero

- Breakdowns and what indicates them

- We make a replenishment

- Repairing a frustrated electric ignition on a gas stove - on

- Reasons for auto-ignition

- Reason #1 - moisture inside the control button

- Reason #2 - Junction Formation

- Reason # 3 - mechanical connection of the contact group

- Other factors

Causes of noise

Due to the very principle of operation of the technique, you can hear a small noise, it crackles. Sounds may be amplified if the room is not well ventilated. There is nothing terrible here.

Does the appliance make sounds when turning on hot water or heating? When drawing water, you may feel vibration because the flow passes through pipes, turns, passes through obstacles. To reduce the noise level, you can adjust the water supply knob. Scrolling it, listen: as soon as the sound vibrations decrease, leave it in this position.

Popping sound when starting

You start the technique and hear the pop? Does the device twitch and vibrate? So, there were problems with the gas supply. When starting, fuel accumulates in the working part: when the amount of air or gas is correct, pops should not be heard.

An excess amount of gas leads to a volumetric explosion when the fuel hits the wall hard at the bend. This can happen when there is too much pressure in the system.

Such problems can even lead to the failure of the chimney. Therefore, contact the service center or try to fix them yourself.

- Turn off the gas and water supply.

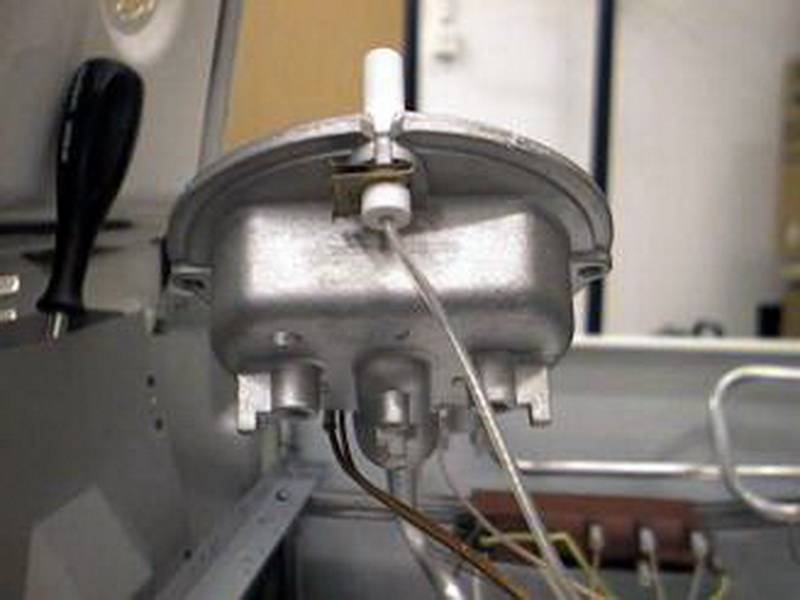

- Remove the equipment cover: pull the handle towards you, unscrew the two screws.

- Inspect the fuel supply system and burner. Clean the parts from dirt. How to clean the gas column, read the previous article.

- Loosen the two screws on the burner tongue.

- Check the condition of the injector. If it is clogged, clean it.

The column hummed and hummed

The main reason is poor traction. To test it, light a match and hold it close to the hole. If the flame deviates to the side, as from a stream of air, the draft is in order. If not, the chimney channel is clogged with soot and soot, which are produced during the combustion process. Need to clean it up.

Poor ventilation also contributes to increased noise. This often happens after installing plastic windows. The bags are so tight that natural ventilation becomes impossible.

What to do if the device cracks? This is possible when the nozzles (jets) of the burner are clogged. It is necessary to disassemble, as described above, and clean them.

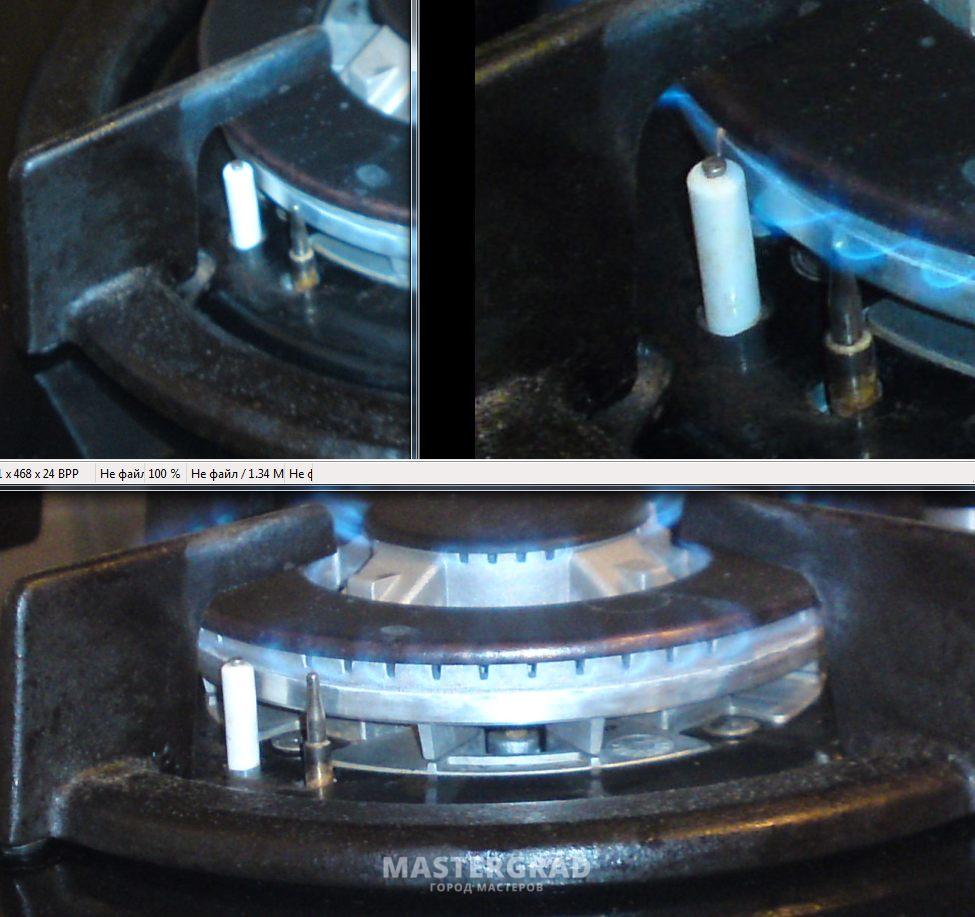

If your column is switched on by electric ignition, the reasons may be as follows:

- These devices run on batteries.When they are discharged, the fuel is poorly ignited or does not ignite at all. Clicks may be heard. In this case, replace the batteries.

- The flow control sensor is defective. Most often, its contacts are oxidized under the influence of moisture. You can try to clean the contacts, but it is better to replace the sensor.

- The spark does not ignite. The candle, which is responsible for ignition, has shifted, so the process is not completed. Put the candle back in place, resume the process.

- The ignition retarder does not work. Remove the item and shake. In this case, the sound of rolling the ball in the body should be heard. If nothing is heard, the ball is stuck or misaligned. Put it back in place with wire.

Rattles new equipment? Perhaps the reason is not in the boiler, but in an installation error. To find out, inspect all connections, correct connection. It may also be:

- Depressurization of the air duct. Air enters not only through the main opening, but also through the hole. So the noise gets louder.

- Incorrect burner placement. Perhaps it has shifted and cannot cope with the combustion of the entire volume of gas. You need to put it in place.

Gas boiler whistles

If the product whistles and squeaks, you need to find out where the sound comes from. What to do:

- Shut off the gas supply.

- Open the mixer in the "hot" position.

- Did the whistle get louder? So, the problems lie in the water path. The main reason is the deposition of scale on the parts of the heat exchanger or on pipes, blockage. It is necessary to clean all the elements in order to resume the performance of the equipment and eliminate the cause of the whistle. Reverse flow of water can clean the pipes from clogging.

If the whistling sound disappears when the tap is opened, the problem is in the gas path.There is probably a defect in the valve that controls the strength of the flame. Whistling may appear when the power is increased. Try turning the knob until the sound disappears. Does not help? Then it's a blockage in the tract. You need to disassemble and clean the device.

If you notice similar problems in your equipment, you can try to deal with the problems yourself. But it is better to contact the service center, especially with a valid warranty card. Employees will repair or remove faulty equipment.

The burner burns as long as you hold the control knob

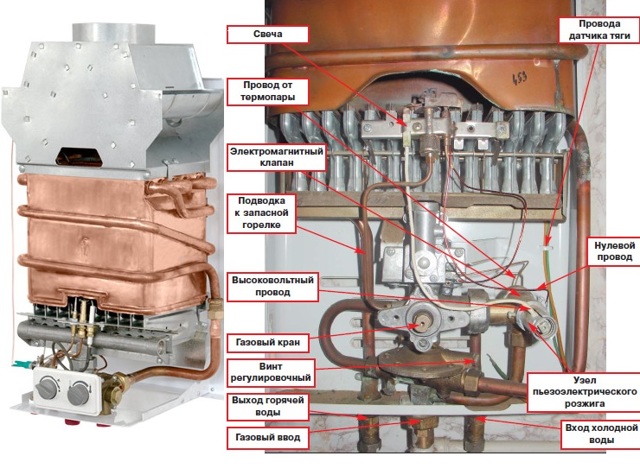

If the fire stops burning immediately as soon as you release the regulator knob, then the surest cause of the malfunction is a breakdown in the gas control system.

It doesn’t matter what brand your appliance is: Gorenje, Indesit, Bosch or another, the problem that the hob or oven does not hold gas when you release the handle happens to all stoves

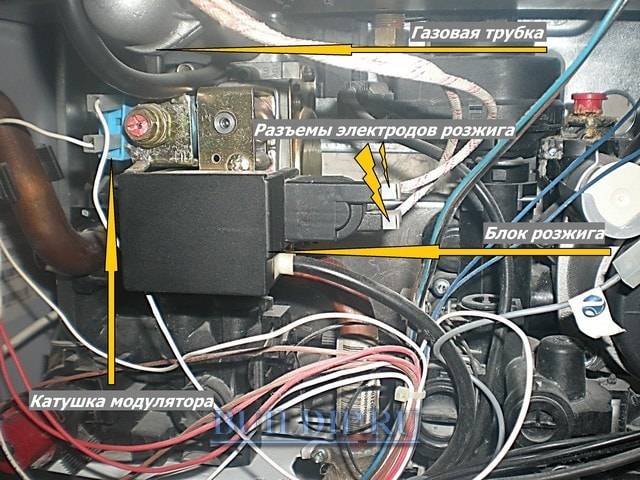

Gas control is an automatic system required to ensure safety and reduce the risk of propane leakage. Its design, from the point of view of the principle of operation, is simple: it has a small copper part, shaped like a coin, a thermocouple. It is fixed on an electronic igniter, which is triggered by pressing and turning the knob. This sensor (thermocouple) heats up due to the flow of fuel and begins to release a charge that is transferred to the valve. If there is no signal between the parts, the system turns off the supply and, accordingly, the flame goes out.

Most often, such a malfunction consists in the lack of contact between the thermocouple and the solenoid valve. Less often, there are cases when the torch of fire simply does not reach the temperature sensor.

In some cases, the craftsmen do not exclude contamination of the thermocouple, which, due to the presence of a layer of dirt, does not heat up well. To avoid such situations, you should always monitor cleanliness, carry out timely cleaning and, if possible, avoid "leakage" of cooked food.

Why does the oven go out?

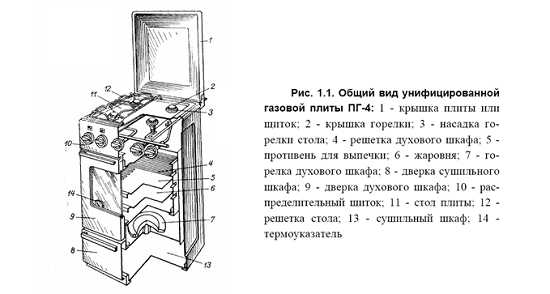

When operating gas ovens, there are often problems with gas control. To ignite the oven, it is enough to bring the flame to the cabinet opening through which fuel enters or use auto ignition, most modern models have this option.

A thermocouple is located next to the burner. If the flame goes out or does not light up at all, this means that the gas supply is blocked. The valve or thermocouple may need to be replaced. How to check their serviceability, we considered in the previous section.

Problems with the operation of a gas oven can occur due to too tight fitting of the doors, resulting in a lack of oxygen

First of all, you need to make sure that there is no blockage in the nozzle hole through which gas is supplied. Food particles often get into the plate part during cooking.

For cleaning you will need a soft thin wire. Insert it into the nozzle opening with a twisting motion. It is undesirable to use rigid steel wire, as a result, you can get a "roaring" burner. Not suitable for this purpose and a thin needle that breaks easily.

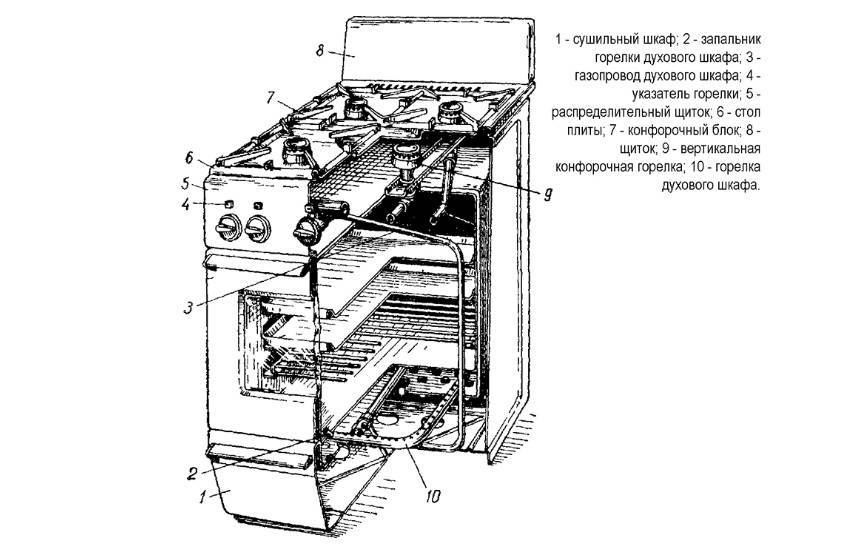

The design of the gas stove oven. The location of the grate, baking tray and other baking or grilling accessories can be adjusted

The flame in the oven can also go out due to low gas pressure.This can be determined by the insufficient height of the crown of the flame, the fire may go out after a while. Weak combustion and poor gas supply may be due to the hose supply to the stove, which is pinched or kinked. The hollow pipe is behind the stove.

The gas oven also goes out when the button is released due to the tight fit of the oven door. You can get rid of the problem by simply increasing the access of oxygen to the oven.

Flame problems also arise for other reasons that are not breakdowns.

Why the oven in the gas stove often goes out:

- Modern stoves have a gas control system. The sensor stops the gas supply if there is no temperature increase. The regulator does not work immediately, so try holding the gas on knob for about 15 seconds, to speed up the heating of the sensor and ignite the oven, unscrew the knob to the maximum.

- Problems with ignition of the oven may occur after washing the oven. Burner misalignment can be identified by an uneven orange flame. If the part is installed incorrectly, the oven starts to smoke.

- The gas control system responds to a decrease in the intensity of the flame with a drop in gas pressure in the pipeline, which shuts off the fuel supply. This situation is common when using bottled gas. It is necessary to fill the container or replace it with a new one.

A weak burner flame in an oven can also be due to difficulty turning the knob. This can happen as a result of a stuck gas valve.

When checking the gas valve, you should pay attention to the remnants of the factory grease, sometimes this is the cause of the stove malfunction.If necessary, the part can be treated with grease: LG-GAZ-41, Germeton, Klad-M, LS-II are suitable for old-style plates; in modern models it is better to use Molykote 1102 and Germetil. It must be disassembled, cleaned of clogs and lubricated

If the faucet is damaged, replace it with a new one.

It must be disassembled, cleaned of clogs and lubricated. If the valve is damaged, replace it with a new one.

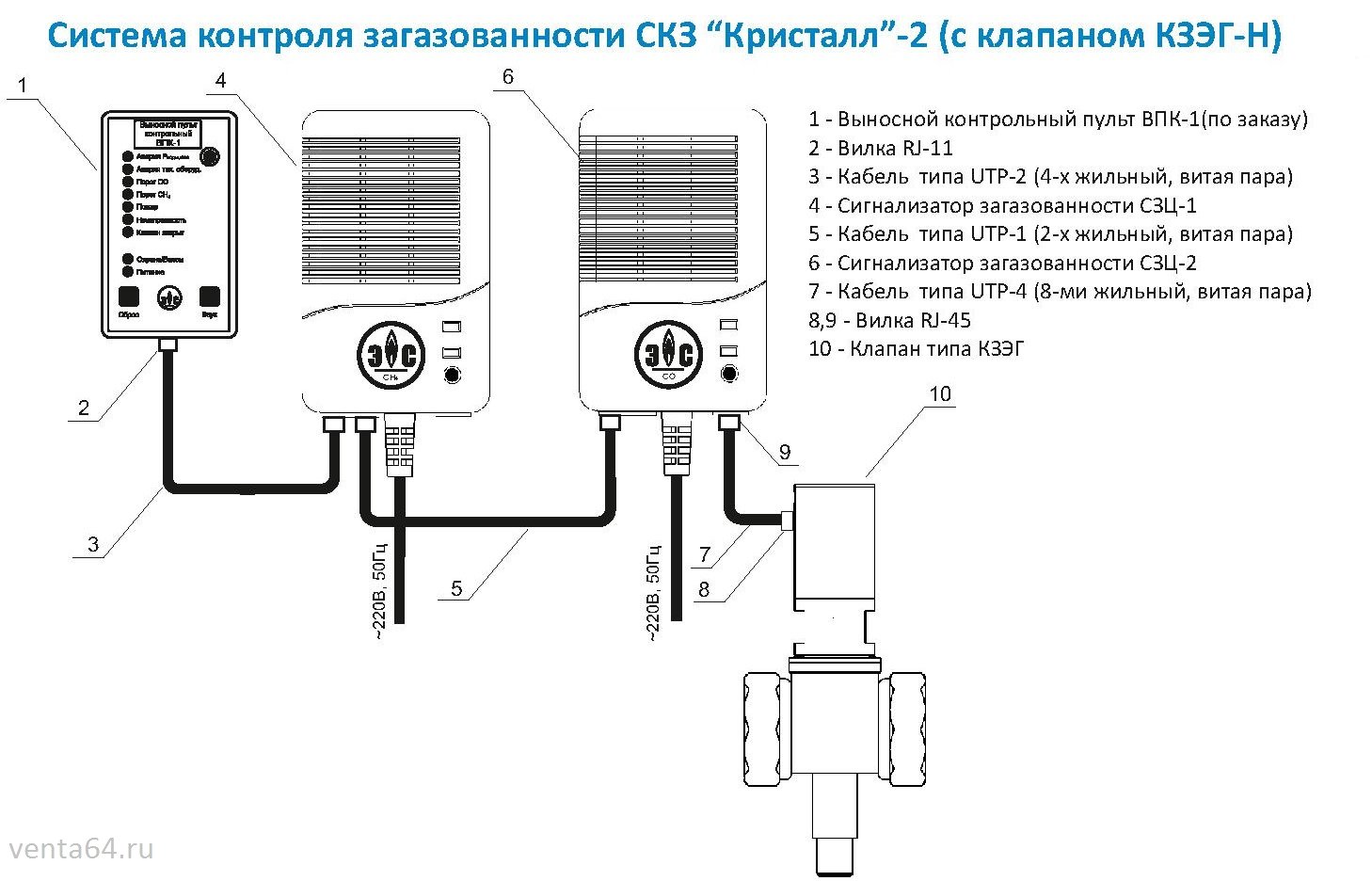

The smell of gas

The appearance of the smell of gas is one of the most dangerous troubles that can lead to an explosion, fire, and poisoning. It indicates a depressurization of the fuel supply system and can occur both when the equipment is turned off, and when it is turned on or during operation.

The first thing to do in such a situation is to turn off the gas supply and ventilate the room! Only then can you start examining your stove. You may not be able to fix the breakdown on your own, but you can identify the source of the leak.

Soapy water will help to determine the place of depressurization. Apply it to all joints of pipes and hoses, both outside the stove and inside it. Where there is leakage, bubbles will appear.

To understand how to fix this type of failure, you need to determine the type of connection. If the threaded connection is depressurized:

- disassemble the damaged assembly, check the integrity of all parts by cleaning them from winding or old sealant;

- apply fresh sealant or make a new winding;

- collect all parts and recheck.

If the connection with the gasket is depressurized:

- disassemble the leaking assembly;

- install a new gasket;

- collect the parts and retest.

The most common cause of this type of malfunction is incorrect flame adjustment. Less commonly, the problem is a breakdown of the connections that connect when the stove is turned on:

- nozzle installation points;

- places of connection of tubes from taps to nozzles;

- joints between tubes and nozzle bodies.

In order to determine the leak in this case, it is necessary to remove the burners, remove the cover, reinstall the burners in their places (without the cover), apply soapy water to the joints and carefully light the burners in turn. Be careful: bubbles will appear at the leak point, indicating a depressurization. The reason for such a malfunction may be the destruction of the sealing washers on the nozzles, too loose tightening of the connections, a defect in the sealing ring at the points of attachment of the tubes

The reason for such a malfunction may be the destruction of the sealing washers on the nozzles, too loose tightening of the connections, a defect in the sealing ring at the points of attachment of the tubes.

If you inspect the stove and do not find a leak, the cause of the smell may be improper connection of the equipment to the gas source. In this case, do not try to fix the situation yourself. You need to call a specialist!

What to do if the pie constantly clicks by itself

The most important thing in such a situation is to find the source of the malfunction, and then simply follow the instructions to fix it. Having found a breakdown, do not panic and strictly observing all safety rules, try to make repairs, guided by our advice. Remember - most of the causes of the problem, in this case, are absolutely safe and can be completely eliminated on your own without resorting to the services of specialists.

How to fix a problem without resorting to the help of a specialist

The following steps may help you troubleshoot the problem:

- If the cause of the breakdown is water, and its constant contact with the stove, then there is only one way out - dry it thoroughly, after turning off the auto-ignition from the outlet. Let the stove stand unplugged for several days - during this time it should dry thoroughly and the clicks will stop on their own. If such a “repair” did not help, it’s time to call the master and entrust the repair to him. When drying, one important point must be taken into account - it is impossible to dry the stove with a working oven - so moisture, on the contrary, will collect in huge quantities in the device and the situation will only worsen. Therefore, be patient and let the device dry naturally.

- If the ignition button does not work well, then the reason is the accumulation of dirt, dust or solidified fat under it. Clean it up. For the best cleaning effect, use a brush dipped in soapy water. Let the board dry after cleaning. It should be noted that this method is not always able to return the button to its previous performance. There is always a chance that due to the low landing, it will not fully press. If cleaning does not help, consider changing the auto-ignition button or its entire mechanism.

In the process of prolonged use, the auto-ignition unit may fail. If only one burner does not work, then the reason is very likely to be the damage to the wire located in the block channel. But do not forget that the burner itself may be faulty, and in this situation, self-repair is not only unacceptable, but dangerous to life.For an accurate diagnosis of the cause of a non-working burner, you should contact a specialist who can not only identify the real cause of the malfunction, but also replace the damaged element.

The main thing is that whatever happens to your favorite stove, do not panic and act deliberately. Remember, a well-thought-out repair can eliminate almost any damage.

Home Appliances Stove

Zero is electric and the indicator is on: reasons

Before climbing to repair the outlet, be sure to make sure that both conductors (phase and zero) are de-energized. However, in old houses, there is only one introductory machine on the electricity meters, which cuts off only the phase

Therefore, the first thing you need to pay attention to is whether the phase and zero are mixed up in places

Things are completely different when, when checking the phase and zero with an indicator screwdriver, both conductors are highlighted. There may be several reasons for this:

- Poor contact of the working zero at the substation or in the shield;

- The insulation in the electrical wiring is broken, which causes current leakage;

- Phase shift.

By itself, the neutral conductor (zero) cannot shock. However, dangerous voltage can pass through it, and when checked with an indicator screwdriver or when contact is made with the ground, zero can be shocked. Most often, such a problem is related to the fact that current leakage occurs through the phase wire, and touching the working zero, the circuit closes, due to which zero can be shocked.

Also, this often happens due to network overload or when the resistance of the neutral conductor becomes too large.

How to solve the problem with a "bad" zero

A radical solution to this problem is to replace the old electrical wiring. If the whole point is precisely in it, then finding a place where current leakage occurs is not so simple as it might seem at first glance.

Grounding in the house will also help, without which it is impossible to connect some electrical appliances at all. These, first of all, include a water heater, a washing machine and some others.

It will not be superfluous to check if the phase is mixed up with zero at the input, and also to make sure that there is no breakdown in electrical appliances. If such a breakdown is in phase, and it falls on the body of the electrical appliance, then a dangerous voltage may turn out to be at zero.

Often the reasons why zero is shocking turn out to be completely banal:

- In strong winds, wires are thrown onto tree branches;

- Someone steals electricity in the house by connecting a working zero to radiators, gas pipes and plumbing;

- There are many twists in the wiring, as well as wires made of different metals, different cross-sections of conductors, etc.

Some problems, in general, cannot be solved on their own. One of these is a bad zero on the CTP itself or its partial burnout. In this case, you must definitely contact the company supplying electricity to the house for help.

Breakdowns and what indicates them

When a gas stove starts to malfunction, or ceases to cope with its individual functions, every housewife will quickly recognize this. In this case, its main task is not to postpone the elimination of the malfunction, but to try to solve the problem as quickly as possible. Then the restoration will be cheap, and an experienced specialist will quickly return the stable operation of the device.

Damage is indicated by:

- Flame problems in burners and oven. Usually the nozzles are clogged, but sometimes things are more serious.

- Ignition or adjustment valve malfunctions (with mechanical control, as in the Gefest 1200-00 C 7 model). It is enough to add graphite grease, or repair the ignition.

- The hob is turned off completely, or only one of the burners. It is necessary to check the correct operation of the gas control system, repair or replace worn parts.

- The gas in the oven turns off abruptly, or goes out gradually. You need to check the hardware, disassemble the device. Usually the thermostat, thermocouple, or electromagnet is malfunctioning.

Annual maintenance will help extend the life of your home appliances. Prevention of the device contributes to the constant stable operation and the prevention of all complex problems, since they will be eliminated at an early stage of their occurrence.

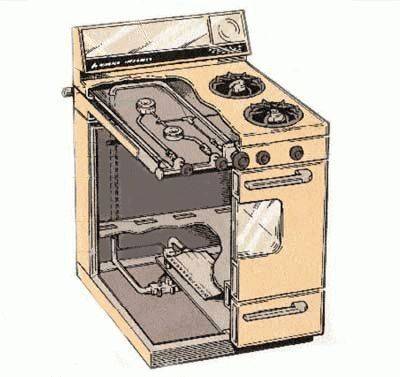

We make a replenishment

When you have inspected, found out the cause and diagnosed the problem, you are allowed to start self-repairing the gas stove. It is carried out similarly to please anyone) of all models. The famous Italian brand Ariston or the Belarusian orthostat Hephaestus, which is in great demand among Russians - there is no difference, the ignition systems were almost identical, except for purely individual nuances.

Before starting work, refresh your knowledge by reading the instructions for the number of times the product has been used. Knowledge of the principle of operation and the device of a gas stove will not go anywhere for its successful repair.

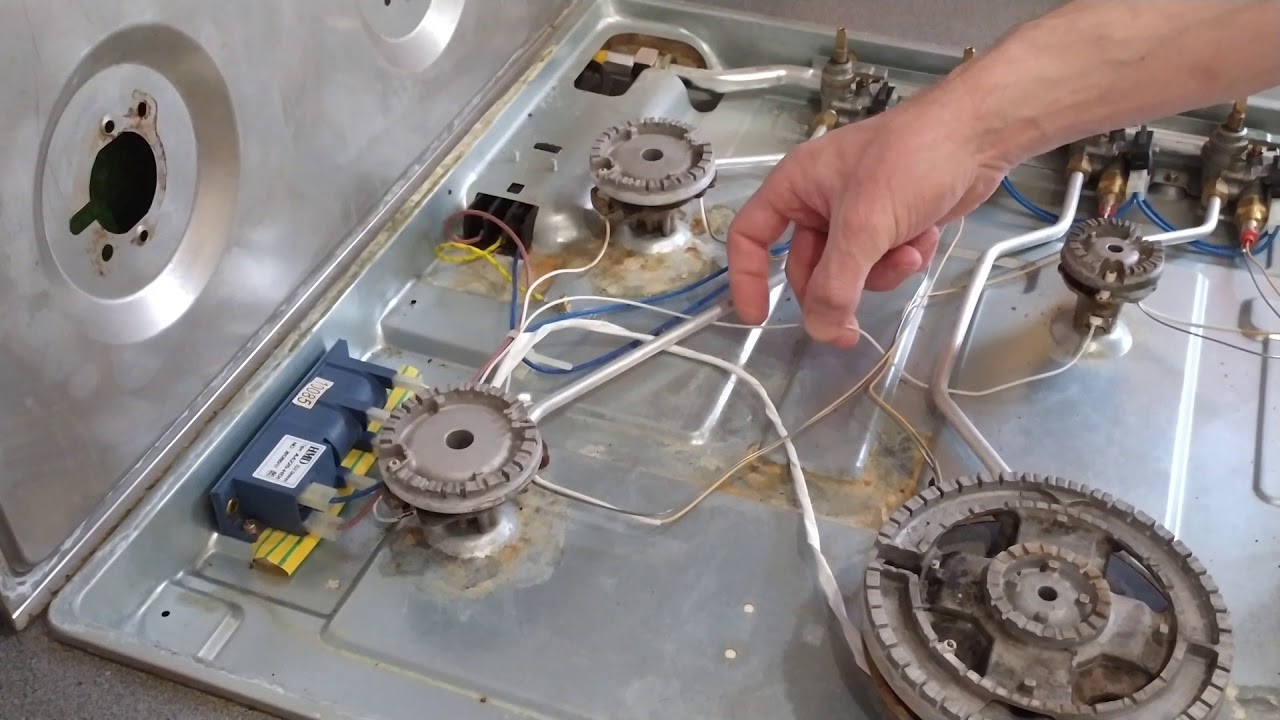

- We set fire to a faulty burner using a third-party source of open fire, matches or a special lighter - the flame should be even and distributed around the entire circumference of the divider.A thick yellow flame means that the concentration of gas and air is incorrect: the nozzle needs to be cleaned or replaced. It is possible that the divider holes are clogged or moisture has got there. It is necessary to do prophylaxis, blow through all the holes, remove the body of the burner and inspect it.

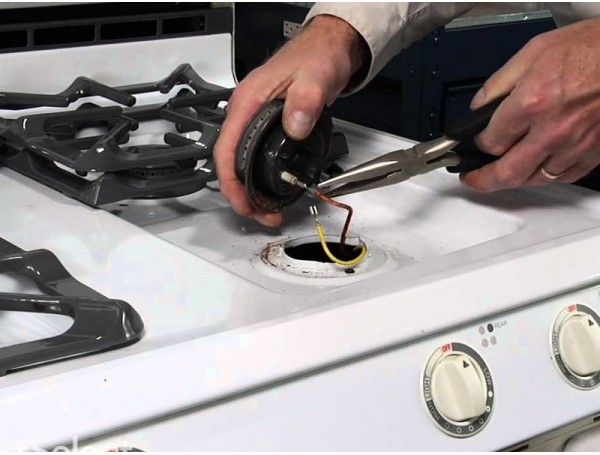

- All electrodes and switches are connected at once. Each electrode is powered by a single ignition unit, but their foreign particle comes from different buttons. To make sure that this button simply does not work, and the control unit is normal, you need to turn on the next burner. If no gas ignition occurs, repair the button, and everything else in the system works diligently.

- If the ignition device constantly cracks, then it is necessary to check the contacts - they could stick from grease or carbon deposits formed as a result of oxidation. Before repairing, do not forget to unplug the stove from the mains, then carefully dismantle it, clean the contacts or dry them with a hair dryer to dry your hair. Following the safety instructions will protect you from injury.

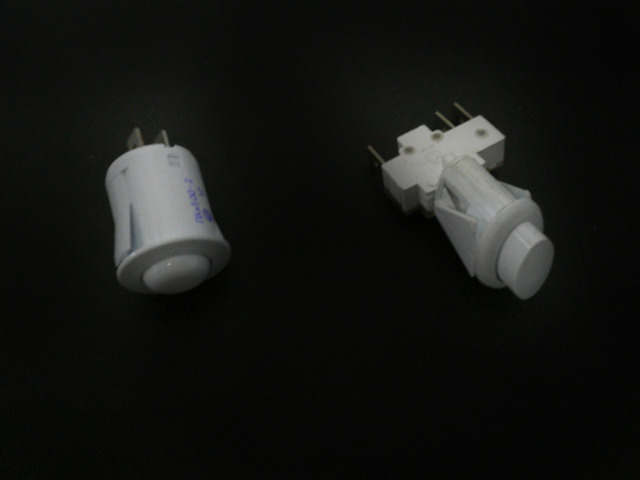

(absolute breakdowns that led to failure can be eliminated on their own - they are not dangerous for the benefit of any user, but it must be remembered that gas stoves are potentially dangerous products, (as a result, even preventive work must be done carefully. Sometimes a breakdown of the ignition button leads to, and repair will not help - a complete replacement is necessary

In this case, the crisis has passed, go to special stores and purchase a similar option.

Sometimes a breakdown of the ignition button leads to the fact that the repair will not help - a complete replacement is necessary. In this case, the crisis has passed, go to special stores and purchase a similar option.

Repairing a frustrated electric ignition on a gas stove - on

Gone are the days when all housework was done by hand. Household art has become our reliable assistant in housekeeping. Tireless electrical "workers" help to cook food, wash clothes, wash dishes, clean up and clean, death as making life easier for us

However, in order for homework to be argued and progressed apart from interruptions, it is important to choose the right devices, paying attention to throughput, speed, functionality, number of modes and other performance characteristics.

How to avoid common mistakes when buying this or that equipment, how to use it correctly, which models are considered the best, what to find the cause of the breakdown and repair the device with your own hands. An exhaustive notification of all types of equipment is presented: both small and large, how much to make budgetary and expensive, both domestic and foreign. Read useful articles and replenish your extraordinary knowledge about household appliances with new valuable information!

Read useful articles and replenish your extraordinary knowledge about household appliances with new valuable information!

Share the link and your string bag and fucker will know that you know the answers to all questions. Gloriousツ

Reasons for auto-ignition

As it turns out, taking into account practical experience, the spontaneous clicks of a gas stove lighter in most cases are not connected in any way with the electronic circuit of the ignition unit.

The reasons for the appearance of an uncontrolled spark lie elsewhere. Often the place of formation of such a defect is the inner area of the ignition control button.

Reason #1 - moisture inside the control button

Surely the owners of gas stoves had to deal with uncontrolled ignition clicks on the gas stove after washing and cleaning household appliances.

Most likely, during the washing process, some water got on the ignition control button, as a result, part of the moisture penetrated inside.

Given that a high discharge voltage is applied through the ignition button circuit, a small amount of moisture is enough to cause an uncontrolled spark to appear on the gas stove spark gap.

Usually, the defect of an uncontrolled spark of a lighter in such cases disappears after some time. The moisture inside the button dries up, the short circuit factor disappears, respectively, spontaneous clicks stop.

Often, the correction of a short circuit defect due to “water trapped after washing” is helped by lighting all the burners of the gas stove for about 15-30 minutes.

Reason #2 - Junction Formation

The junctions formed inside the ignition button can have different shapes. The formation of a junction can be facilitated by the same moisture that got inside the button after washing. Usually such a "water" junction is formed due to the periodic penetration of water.

Time after time, deposits build up, and eventually an oxide junction forms. In addition, grease, soot, dust can accumulate inside the button case. All these are also harbingers of a short circuit between the contacts.

With this development of events, you will have to disassemble the gas stove:

- remove the top panel

- open the front subpanel;

- remove the ignition button(s).

Or, in the case of more modern designs of gas stoves, it is necessary to get to the designs of disk control devices that simultaneously perform the functions of a button and a regulator of gas supply to the burners.

After removing the part from the body of the gas stove, deposits are cleaned, after which everything is assembled in the reverse order. However, this work is the prerogative of the specialists of the gas company. It is not recommended for an inexperienced user of a gas stove to disassemble the device on their own.

Reason # 3 - mechanical connection of the contact group

The mechanical connection of the contact group of the gas stove ignition button should also be attributed to the category of causes associated with a short circuit. Such a defect, as a rule, can occur on plates that have been in operation for a sufficiently long time. True, the same malfunction is not ruled out on new devices, where the quality of components leaves much to be desired.

A mechanical connection is formed by any of the contacts of the button, which simply breaks off, for example, due to physical wear. The broken part is displaced from the attachment point and forms an electrical connection with another contact. In fact, the effect of the switched on ignition button is created - that is, the spontaneous operation of the electric ignition on the burners of the gas stove.

With such a malfunction, the only way out is to completely replace the component.

Other factors

In addition, I note that if the burner is still lit, but the combustion is very weak, the reasons should be sought in the low gas pressure. If you see a small flame in the oven, check only when the chamber is cold.Otherwise, the thermostat will reduce the gas supply when the set temperature is reached, which is its regular function, and the diagnostics will be incorrect. If the pressure is really low, this moment should be adjusted.

If the stove runs on a cylinder, and does not ignite at all, perhaps the gas has simply run out. It is also worth looking at the condition of the gearbox, suddenly it is blocked. When the appliance is connected to the gas supply, check the valve. If everything is in order, but there is no gas, immediately call the gas service. The suspension of the supply of blue fuel is a serious state of emergency. This situation can cause airing of the system and extremely unpleasant consequences.

And the last piece of advice: in case of problems with electronics, I first advise you to check the presence of current in the outlet. Plug in another device. Do not forget that repairs are carried out only when the power is off.