- Pressure switch.

- Hydraulic accumulator.

- Collector.

- How to prevent problems?

- The pumping station does not turn off. The reason is the pressure switch.

- Diagnostics and prevention of breakdowns

- Preparing the pumping station for winter.

- Rules for the operation of the circulation pump

- 2 Wilo pump repair tips

- 2.2 The shaft does not rotate when the pump is on and characteristic sounds

- 2.3 When the temperature in the system rises above 40 ° C, a creak appears

- 2.4 The unit stalls after a short period of operation

- 2.5 The pump vibrates, accompanied by noise

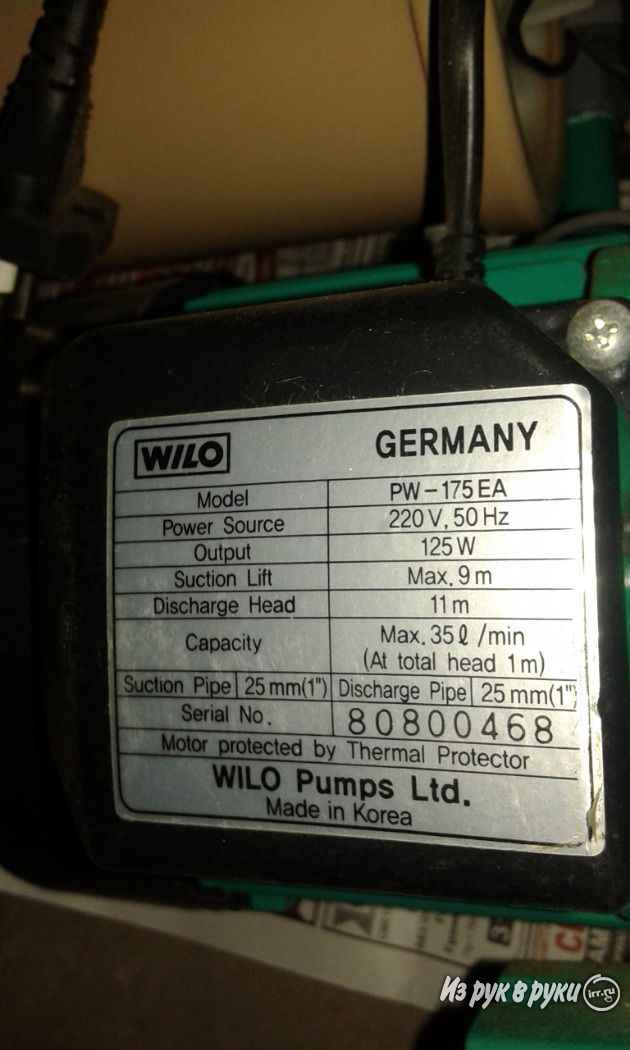

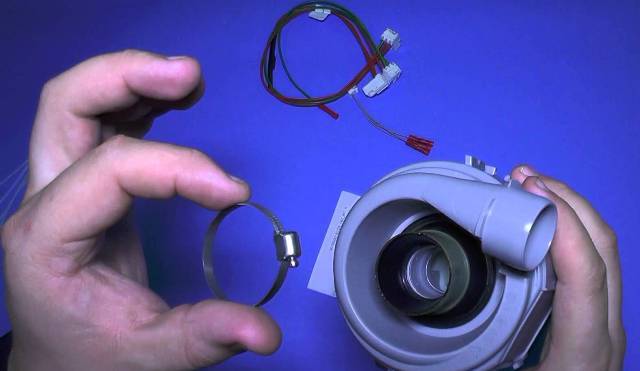

Pressure switch.

Pressure switch: 1. Contact group. 2.Small spring. 3. Large spring. 4..Wire attachments. 5. Pressure sensor.

Usually, a black box with two wires, usually screwed at one end to the pressure manifold. On the outside there is a plastic screw, unscrewing which, you can remove the cover and look inside. There are two springs inside: larger and smaller, as well as a contact group for connecting wires. The large spring is responsible for the shut-off pressure, the small spring is responsible for the difference between turning on and off. Accordingly, by tightening the large spring with a nut, we raise the cut-off pressure, i.e. the pressure in the system, releasing the spring - we reduce it.

It is important to remember that the small spring does not regulate the turn-on limit of the pump, but is responsible precisely for the difference between the pressures.For example, default settings: on - 1.5 bar, off - 2.8 bar

If you raised the cut-out pressure to 3.5 bar, the pump will now turn on at 2.2 bar without any further adjustment. To reduce this difference, the small spring must be tightened; to increase - let go.

Be careful! The thread on the RD may be different.

The device is quite simple and reliable. But (again, this is a “but”) after a certain period of operation, the on and off limits begin to “float”. Most often, they notice that the pump either does not turn off at all, or turns off after a long operation (several minutes). It is the pressure switch that is to blame for this, unless, of course, you overestimated the cut-off pressure when adjusting so that the pump simply cannot cope. Usually, they simply lower the shutdown threshold a little (by 0.1-0.2 bar) and that's it. Sometimes you have to change the entire pressure switch (fortunately it is not so expensive) due to burnt contacts of the contact group or due to the inability to normally adjust the shutdown threshold (either a lot or a little, and you can’t catch the average). I cannot but say about the ill-fated pressure switch cover (I myself came across more than once). It has the property, when it is closed and compressed, to change the shutdown threshold (usually upwards) due to the displacement of the pin on which the large spring is located, and for which this cover is attached. At the same time, pressure has to be caught, almost at random. But it's better than changing all the relays.

Hydraulic accumulator.

According to the device, an ordinary iron barrel with a rubber membrane inside, with a platform for mounting the pump and paws for mounting it.On the one hand there is a threaded outlet for water supply, on the other - a standard threaded fitting with a spool for pumping air, usually covered with a rubber or plastic cover. So what can happen to him?

Air fitting.

Most often, over time, air is bled from the air half of the HA. As a result, GA becomes just an iron barrel, accumulating nothing. The pump turns on faster (it also turns off quickly) and more often. I once watched the pump turn on and off 8 times in one minute with the faucet on the faucet fully open. Manufacturers allow no more than 2 times per minute. This disease is treated easily and quickly. With any pump (car) we raise the pressure in the air half to half the maximum water pressure. Initially, it was 1.5 bar, but 2.8-3.0 bar was initially set for water. Therefore, half is better or, if you did not touch anything on the pressure switch, 1.5 bar.

Unfortunately, any other incidents with GA are fatal for him. For example, a membrane rupture (almost impossible, but I saw it once) or freezing (this is more common, usually in summer residents). I think it is unnecessary to remind that the air pressure in the GA should be checked and, if necessary, raised with the pump turned off and zero pressure on the head.

Collector.

Broke despite all precautions. “Well, what is special about it?” - you ask, and you will be absolutely right

Nothing, collector and collector. But only after many years of operation of the station in adverse conditions, all threaded connections turn sour tightly.Where is your pumping station? At best, in the kitchen, but usually in the bathroom, in the corridor (in the hallway), in the basement, at the top of the well, in the well itself, in the bathhouse, in the boiler room, etc. And even after processing with a “liquid key”, it is not always possible to quickly and painlessly remove the pressure gauge or pressure switch, given the small thread size. Therefore, I only urge you to be careful, if possible, do not remove or replace them. Well, if anything ... you have to look in the store for a "collector for a pumping station"

“Well, what is special about it?” - you ask, and you will be absolutely right. Nothing, collector and collector. But only after many years of operation of the station in adverse conditions, all threaded connections turn sour tightly. Where is your pumping station? At best, in the kitchen, but usually in the bathroom, in the corridor (in the hallway), in the basement, at the top of the well, in the well itself, in the bathhouse, in the boiler room, etc. And even after processing with a “liquid key”, it is not always possible to quickly and painlessly remove the pressure gauge or pressure switch, given the small thread size. Therefore, I only urge you to be careful, if possible, do not remove or replace them. Well, if anything ... you have to look in the store for a "collector for a pumping station."

I will not write anything about the bypass pipe. Trumpet and pipe. Usually, this is a flexible eyeliner of a larger or smaller diameter. If the station is dispersed (for example, based on a deep-well pump), then it is just a pipe between the pump and the accumulator. Again, it's usually the connections that break, not the pipes. But if you have questions, ask, I will answer with pleasure.

All that remains after a frosty winter.

You'll get a good grind.

And now, especially for summer residents.

How to prevent problems?

To avoid possible problems, it is necessary to correctly approach the selection of a pressure switch. The characteristics of automation must be optimal for working with specific equipment. It is better to seek the help of a specialist in this matter.

Preventive measures to prevent problems are:

- The use of a magnetic starter to relieve the load from high currents from the relay contacts.

- Periodic external inspection of the relay and checking the most critical points - connecting pipe and contacts.

- At least once every 2 months, check and, if necessary, adjust adjustments.

Important! The pressure threshold for switching on the relay to start the pump should be 0.2 atm. lower than the pressure in the accumulator.

The pumping station does not turn off. The reason is the pressure switch.

For the pumping station to work properly, so that it turns on and off as expected, it is necessary to adjust the relay. At first glance, this may seem like a rather difficult task. But setting the switch is a simple and quick job that requires minimal skills that we can do on our own. As a rule, there are different types of switches, but the principle of operation is the same, so the adjustment is made in accordance with the same and simple instructions.

To adjust this mechanism, you need to tighten or loosen the adjusting nuts (1 and 2 in the picture below).

The first nut is called "differential" because it regulates the difference in pressure value at which the pumping station will start and stop. As a rule, it is located on a smaller side spring. The factory setting is a 20 psi or 1.4 bar differential, which is standard and recommended. You can adjust the differential to your needs, comfort.By turning the small adjusting nut on the relay clockwise to increase or counterclockwise to decrease the differential. This action is rarely required.

The small spring is also considered to regulate the launch rate of the station. And this is understandable, because it changes the differential. Twisting it, we will reduce the launch value, and unscrewing it, we will increase it.

The second nut, located on the central spring, determines the pressure at which we want the pump to turn off. By turning the nut clockwise, we increase the pressure value at which the pumping station will turn off. For example, it turned off at 3.5 bar, turning a quarter of a turn, it began to turn off at 3.9.

Diagnostics and prevention of breakdowns

It is possible to determine whether repair of the circulation pump is required by a number of signs. The easiest way is to turn on the equipment and check if it makes noise. Sometimes extraneous sounds are accompanied by a noticeable vibration. It is recommended to make sure that the pump motor does not overheat.

Check whether the force of water pressure in the pipe corresponds to the parameters in the technical data sheet of the device. Features of the circulation of the coolant do not depend on what characteristics the heating boiler has, and are completely determined by the operational properties of the pump.

Visually inspect the pump casing to make sure there are no leaks. The most vulnerable point is considered to be the articulation of the pipe with the unit. Check the condition of the gaskets and fastening of the bolts, as well as the presence of grease on the threaded flanges.

Pay special attention to the electrical circuit: check the fixation of the wires, get rid of moisture in the electrical wiring and, if necessary, attach the housing ground to the appropriate terminal

Preparing the pumping station for winter.

Disconnect the power supply from the station (pull the plug out of the socket, turn off the circuit breaker).

Relieve pressure in the system: open, if there is, drainage; if there is no drainage, open the valve closest to the station.

Disconnect suction hose

Attention! The remaining water from the system will flow out of the pump! Be attentive and careful.

Disconnect the pressure hose or pipe.

Check the air pressure in the accumulator. If there is nothing, we can safely skip this item.

If the air pressure in the HA is greater than or equal to 1.5 bar, then skip the next step.

If the air pressure in the HA is less than 1.5 bar or it was not possible to check (p. 5), we pump the pressure indicated above with any suitable pump or until the water stops flowing from the suction pipe of the pumping station.

If a suitable pump was not found, we urgently run to the store for a bottle for a neighbor who may have such a pump, and be sure to follow step 7

A hydraulic accumulator costs much more than a neighbor's bottle.

We drain the remaining water from the pump, turning it over in every possible way.

We drain the remaining water from all hoses and pipes.

We hide the pumping station and hose pipes in a secluded place until spring.

Preparation of the pumping station for start-up after winter.

- We get a pumping station and the hoses and pipes we need from a secluded place.

- We check the air pressure in the accumulator, I hope there is something now.

- We bring the air pressure to the required level. (Have you already bought a pump? Well, at least a bicycle pump?)

- We install the pumping station in its crown place.

- We connect the suction hose, after checking the operation of the check valve on its tail.

- Pour water into the pump through the pressure pipe to the top (until it flows).

- Connect the pressure hose or pipe.

- We connect the power supply to the station: turn on the safety machine.

- Once again, we check the reliability and correct connection of all connections.

- We turn on the plug in the socket, we make sure that the pumping station is working.

Now, it seems, everything is about pumping stations. But you ask, I could miss or forget something.

Rules for the operation of the circulation pump

When using a circulation pump for heating, you should follow some rules:

- The pump must not run at zero flow. Therefore, you should constantly monitor its work.

- The boiler should be used frequently. With rare inclusions, some elements may oxidize, and the device will fail. It is recommended to turn it on for a short time at least once a month.

- If there is no water in the heating system, the pump must not be turned on.

- Check engine temperature periodically. Do not allow the device to overheat.

- Hard salts often precipitate in pumps. To avoid this, it is necessary to control the temperature of the coolant. It must be less than 65°C. Then the circulation pump can work normally.

- It is necessary to check the connection of the electrical wires that are in the terminal block.

- Be sure to control the pressure of the water supply to the heating system. With slow or strong flow, the pump may degrade its performance or even cease to perform its function.

- It is necessary to check the pump housing and find out if grounding is present.

- Periodically check pump operation.This should be done based on the technical characteristics of the equipment.

- During operation, the pump should not make noise or vibrate. The circulation pump should work without any noise.

- It is necessary to frequently check the connections of the pipes to the pump. Sometimes there is a coolant leak. If you have such a problem, then you need to replace the gaskets or tighten the connecting components. Leaks must not be allowed when the circulation pump is running.

2 Wilo pump repair tips

Repair of the pump is carried out only after disconnecting the power cable and drainage of the site. It should be said that pumps with a wet rotor are equipped with modules depending on the required power and size. Restoring the health of these devices is facilitated - the faulty module is replaced with a new one.

If the warranty period has expired and the repair is minor, you can do it yourself; in case of a more serious malfunction, take your pump to a service center. Most often, repair work comes down to replacing entire assemblies or the entire pump. The following working parts are subject to replacement: connection block, capacitor, speed controller, bearings.

2.2 The shaft does not rotate when the pump is on and characteristic sounds

The reasons are: oxidation of the shaft after a long period of inactivity or the ingress of a foreign object into the impeller. In the first case, you need to repair the pump by following these steps: drain the water, unscrew the screws that tighten the motor and housing. Remove the motor with rotor and impeller. Turn the last knot by hand. Low power products require a screwdriver to unlock the shaft. For her, there is a special notch at the end of the shaft.

Testing the electrical box of the circulation pump

In the second case, it is enough to dismantle the electric motor and remove the foreign object. To eliminate this situation in the future, install a strainer in front of the pump. Also, the reason for the failure of the shaft may be problems with the power supply.

Check the voltage in the network for compliance with the passport data of the circulator, pay attention to the presence of phases and the correct connection in the terminal box

2.3 When the temperature in the system rises above 40 ° C, a creak appears

The reason is that the motor pulley hits the drain plug. Noise is eliminated by putting an additional plastic gasket on the cork; if necessary, the cork thread is turned. If the creak appears again, it is advisable to saw off part of the pulley (with markings for a screwdriver) using a grinder. It should be cut about 3 mm and exactly the area that does not go along the sleeve.

2.4 The unit stalls after a short period of operation

The "root of evil" lies in the scale formed in the immersed part of the rotor. To eliminate the problem, disassemble the drive, then clean the limestone deposits between the rotor and stator with a brush. To prevent the formation of scale on the impeller, pouring the stator cup, install a filter.

2.5 The pump vibrates, accompanied by noise

The reason lies in the wear of the bearings that ensure the rotation of the impeller. Worn parts must be replaced. Since the bearings are pressed into place with a puller, you will need a wooden mallet. Drive new bearings into the seat with precise, but gentle blows. The reason for vibration and loud noise may be low pressure in the system.Elimination implies its increase at the inlet, do not forget that the liquid level in the coolant also needs to be increased.

Double-rotor circulation pump Vilo