- Troubleshooting

- If smoke comes into the room from a gas boiler

- Pellets and wood briquettes

- Other reasons

- An open heating system with natural circulation has a number of features

- Causes of attenuation of atmospheric gas boilers with an open combustion chamber

- Clogged nozzle or burner filter

- Faulty thermocouple, circuit contacts, or electromagnet

- It's warm, it's cold

- Other sources of noise in the heating system

- Troubleshooting Solid Fuel Models

- Boilers with semi-automatic ignition.

- Malfunction of coolant temperature sensors.

- How to fire up a cauldron

- Warming up the boiler furnace and chimney

- Rated output

- Protection of a solid fuel boiler against overheating

- Scheme of connecting a solid fuel boiler to a closed heating system

- Causes of boiling in different types of boilers

- Causes of boiler smoke

- Knocking in boilers and pumps

- clogged radiator

Troubleshooting

All possible answers to the question "Why?" described above. And now the second question is “What to do?” If a solid fuel heating boiler smokes?

For kindling, you need to choose only dried logs, which should be stored under special covered sheds so that moisture gets on the fuel as little as possible. No need to use artificial materials as fuel.

Heating devices of such brands as Buderus Logano SW, Stropuva S and Zhytomyr D are heated only with dried firewood. If you want to use different types of fuel, you should think about purchasing universal units, for example, KST or Smoke.

You can test the degree of opening of the gate in air-heating options, such a brand as Siberia. If smoke appears, the chimney opening should be made larger.

It is required to ensure the flow of air masses to the boiler. According to safety rules, the window must be open all the time while the boiler is operating during the heating season. A solid fuel boiler needs to be cleaned from time to time.

Canopy for firewood from a profile pipe and polycarbonate

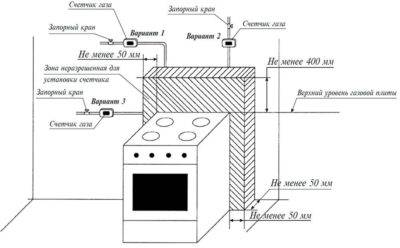

If smoke comes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: chimney malfunctions or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

Check for traction. This can be done either with a special measuring device, or by bringing a lit match. The flame should noticeably deviate towards the boiler. If this does not happen, then for some reason the chimney does not pull smoke out.

View the pipe with a mirror and a flashlight. If necessary, remove snow and foreign objects. If you can't do it yourself, call a chimney sweep.

If you are heating with raw wood, you need to clean the accumulated tar from time to time.

Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe; in your house, its end should end above the roof ridge.Outside, insulate it with glass wool.

Check the chimney for cracks

Pay special attention to the connecting seams. Remove right angles when turning and make transitions smooth .. In the room where the gas boiler is located, a window should be open for air to enter

This is especially true in the cold season in high-rise buildings, where a layer of cold air can prevent combustion products from escaping.

In the room where the gas boiler is located, a window must be open for air to enter. This is especially true in the cold season in high-rise buildings, where a layer of cold air can prevent combustion products from escaping.

If you are heating with a gas boiler and using cylinders rather than a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. This allows you to make the Ross Lux model

Pellets and wood briquettes

The Scandinavians were the first to come up with the idea of turning sawdust into fuel. Other European countries followed suit later. In our country, pellets have long been produced only for the European market, so until now only a few homeowners know what it is.

Pellets are divided into classes, their price depends on this. For example, for wood pellets of the first class (with a minimum content of bark and moisture) you will have to pay 110 euros per ton, for the second class - 100, for the third, the lowest - 85-90. The lower the class, the more ash is formed after combustion, the more fuel is required per season. For heating a medium-sized house, about 3-4 tons of pellets are bought per year. The main problem is to find a dry and ventilated room for their storage.

Burning such expensive fuel in an ordinary solid fuel boiler is not profitable. Pellets (granules) are intended for combustion in special heat generators with a pellet burner - fuel combustion occurs with forced air. Such boilers are an order of magnitude more expensive than any solid fuel, but the difference in price is justified. These boilers are automated: they can control several pumping groups, be equipped with weather-dependent sensors, room programmers, some models even have auto-ignition and automatic fuel supply from a special bunker. With a pellet boiler, you need to go into the "stoker" once or twice a week - replenish the bunker, clean the ash pan.

wood briquettes

can be burned in an ordinary solid fuel boiler. The main component for their production is the same sawdust. They burn well and leave little ash behind. Manufacturers claim that one cube of wood briquette can replace up to 3-5 cubes of firewood! After such statements, it is logical to assume that prices will be higher. For example, a ton of Pini Kay briquettes costs an average of 250 rubles per ton, RUF - 200 rubles per ton.

Other reasons

We can say that all cases when the radiator does not heat up are unique in their own way. For example, the radiator, which is the last in the system, does not heat. This means that the coolant simply does not reach it or the heat is “lost” on the way to it. If the latter, then the system is incorrectly calculated or the diameter of the pipes is incorrectly selected and, accordingly, the ratio of the amount of water / circulation intensity is incorrectly selected.

An expansion tank can help solve many problems. For example, airing can be removed if the coolant is pumped through the entire system.For this, some people insert a valve into the lower part of the heating, to which a tap and a fitting are connected. By putting on a hose, water can be supplied until air escapes through the expansion tank.

Only this approach is rather risky - excess water, and there will be a lot of it, will fill the tank and pour from it. In this case, they act with an assistant who will control the water level in the expansion tank.

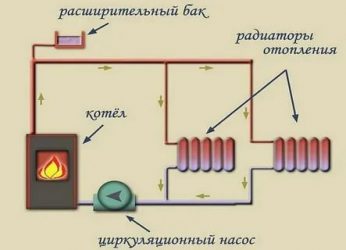

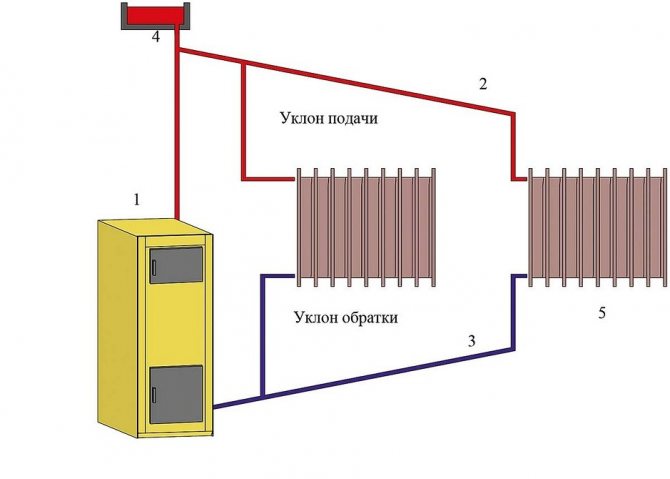

An open heating system with natural circulation has a number of features

- There is a lot of dissolved air in the system, which can lead to corrosion of internal metal elements in the system.

- Large inertia of the system. After turning on the heating, the house heats up slowly. It is necessary to warm up the system gradually, otherwise the water will simply boil in the boiler, while it will still be cold in the radiators.

- House warms up evenly

- Large temperature difference between supply and return

- More fuel consumption (low efficiency) than in a closed system with a circulation pump

- Independence from electricity

- The system is simple, there is practically nothing to break in it. Fairly simple installation.

- Aesthetically not too good, because. pipes of large diameter are used, and sometimes pipes of increased diameter are used as radiators

- The system is quite cumbersome

- Do not use antifreeze in the system

- Water from the system gradually evaporates, so it must be topped up periodically. It is advisable to install automatic topping up.

- The boiler must be installed at the lowest point in the system. Best of all - in the basement, or in some recess.

- The expansion tank is installed at the highest point in the system. If you install it in the attic - it must be insulated.

- Silent operation, due to the lack of a circulation pump

But nevertheless, this system has been successfully used and is being used when installing heating in small private houses with a height of 1 or 2 floors.

Let's describe the whole system in order:

Causes of attenuation of atmospheric gas boilers with an open combustion chamber

Atmospheric gas boilers usually fade due to external factors, but malfunctions in the operation of internal components can also be the cause:

- blockage of the holes of the gas burner device;

- violation of the connection of the emergency electrical circuit;

- lack of draft or wind blowing into the chimney;

- poor ventilation or clogged duct;

- insufficient fuel supply pressure in the line.

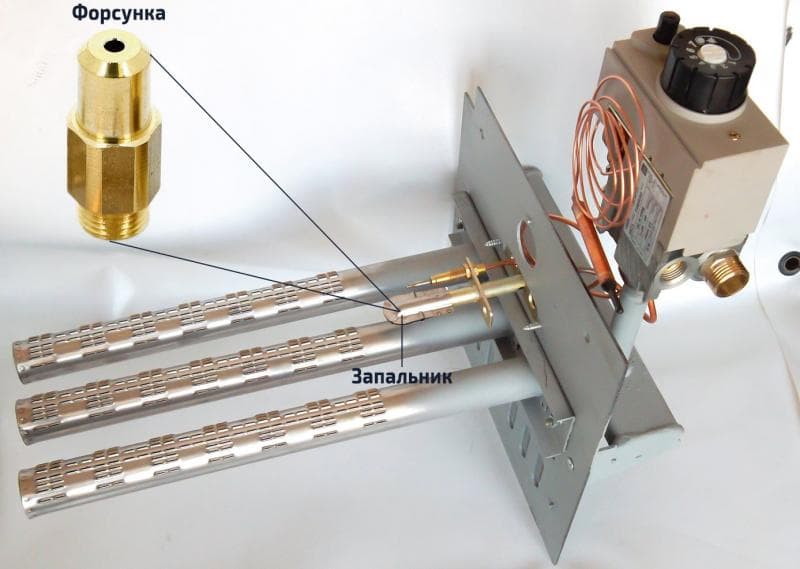

Clogged nozzle or burner filter

If, when the control knob is switched to the “START” position, the igniter (wick) does not ignite, this is a sure sign that the starting elements of the unit are clogged: nozzles (jets) of the igniter nozzle, a fine mesh filter at the inlet or a pilot burner filter. They can be easily cleaned with the help of improvised means.

The location of the igniter nozzle on the burner block of a floor-standing gas boiler.

The filters are simply blown through in any convenient way (pneumatic sprayer, handheld vacuum cleaner or mouth) until air passes freely through them. But the nozzles will have to be more carefully scraped off soot (with a thin copper wire) - until the design diameter of the jets returns. In no case is it allowed to damage the nozzle or change the diameter of its hole provided by the manufacturer.

Faulty thermocouple, circuit contacts, or electromagnet

If communication with the thermocouple is interrupted, incorrect signals are sent to the solenoid valve that there is no flame, respectively, the gas supply is stopped.

It doesn’t matter if the gas boiler goes out immediately when you release the start button, or after turning on another mode - this behavior indicates problems in the circuit:

- the contacts of the thermostat, thermocouple or vacuum sensor are broken;

- the thermocouple does not give the required voltage or does not enter the flame zone;

- unsuitability of the thermostat, electromagnet coil or thermocouple.

It's warm, it's cold

It happens that periodically the air conditioner does not heat or even turns on in the cold. This is normal if the appliance has a defrost mode. The fact is that when working for heating, the temperature of the freon in the condenser of the outdoor unit drops sharply. Frost and ice may form on it.

Icing on the condenser radiator is fraught with problems. Therefore, the air conditioner periodically warms it up so that the frozen moisture evaporates. You only need to sound the alarm if your air conditioner does not have a defrost mode. In this case, problems with the temperature sensor, or electronics.

Snow-frozen condenser of the outdoor unit of the air conditioner that worked for heat.

Other sources of noise in the heating system

In addition to the reasons mentioned above, the following factors can be sources of various noises in heating communications:

- sudden pressure surges for one reason or another;

- non-compliance of the coolant with technological standards;

- noise coming from the pumps in the boiler room.

To prevent sudden pressure drops in the heating systems of private or apartment buildings, it is recommended to install special regulatory devices. Sometimes the pumps located in the boiler room can also be the cause of noise, the operation of which can lead to the occurrence of resonance in the water jet elevator of the heating system. In some cases, the resulting buzz or crackling can be eliminated by installing a valve between the elevator and the pipe.

Troubleshooting Solid Fuel Models

Solid fuel boilers can have the same chimney-related smoke causes as gas appliances described above. When firing, it is necessary to use well-dried raw materials. It should be stored in well-adapted places with a low level of humidity. Do not use synthetic materials as fuel.

Wood boilers such as Buderus Logano SW, Stropuva S and Zhytomyr D must be fired with dry wood only. To be able to use different types of fuel, you need to purchase combined devices such as KST or Smoke. You can experiment with the degree of gate opening in air-heating models from manufacturers such as Siberia. If smoke appears, make the chimney opening larger.

Provide air supply to the boiler room. For safety reasons, the window must be open constantly during the operation of the boiler during the heating season. A solid fuel appliance must be cleaned regularly. This is especially true if it is coal or diesel, working on mining, since these types of fuel clog the burner especially quickly.

Boilers with semi-automatic ignition.

Heating equipment equipped with Eurosit 630 or similar automation is classified as semi-automatic, because the main burners are ignited by a wick flame that burns throughout the entire operation of the boiler.

Causes and methods for eliminating boiling water in boilers with semi-automatic ignition.

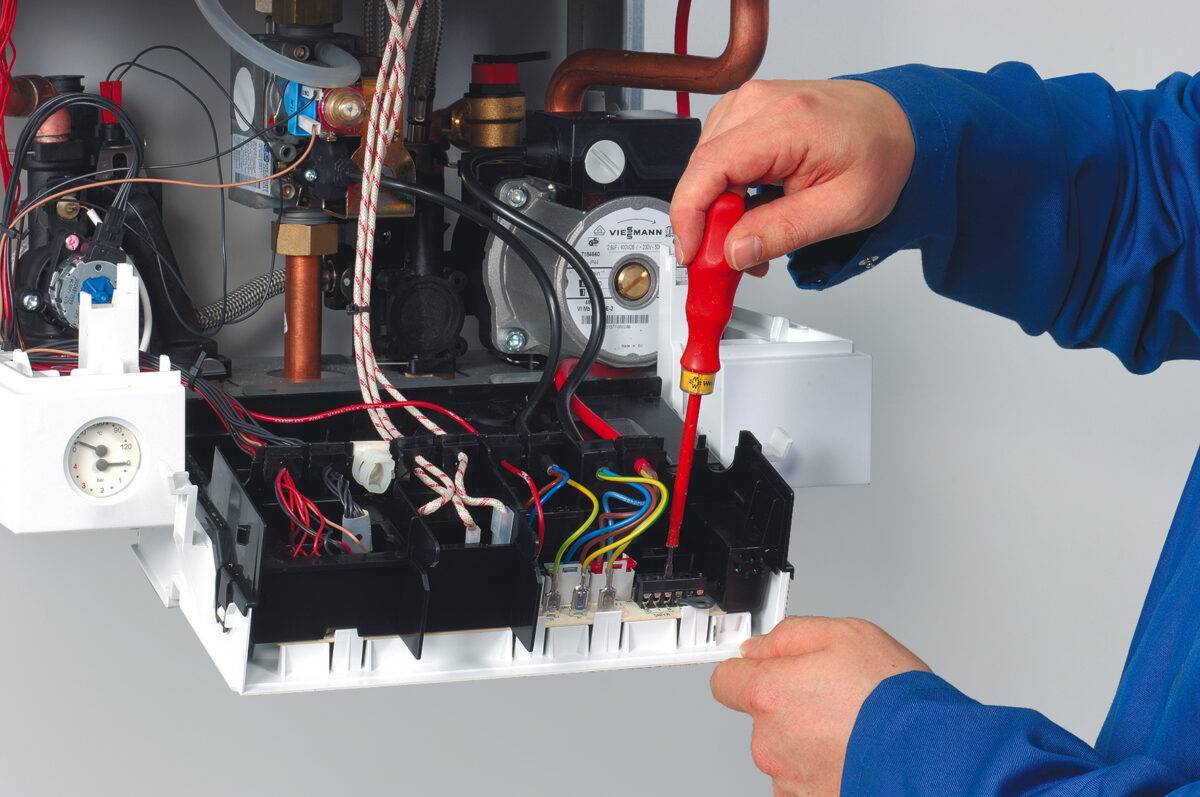

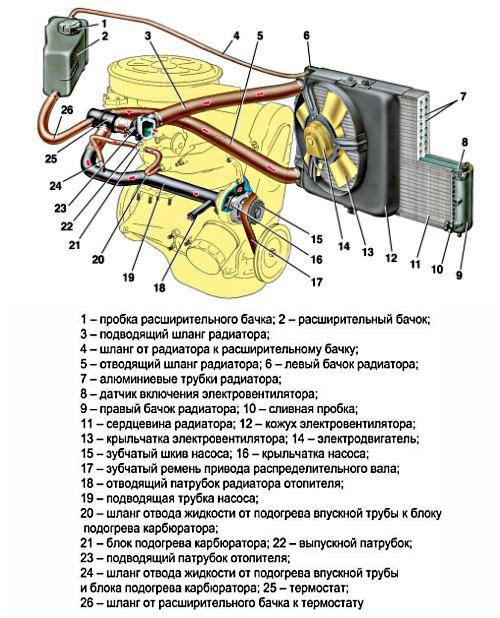

Malfunction of coolant temperature sensors.

The temperature of the water in the heating circuit is controlled by sensors (thermistors) that are placed in the supply and return lines of the boiler. A serviceable sensor changes its resistance when the temperature of the coolant changes. For example, at 25 0C it will be approximately equal to 10 kOhm, and at 45 0C - 4.913 kOhm. According to the type of design, the sensor can be overhead (takes parameters through the copper wall of the pipe) or submersible (contacts with the coolant without an intermediary). If the probes are not inspected in time, then non-metallic deposits form on the contact surface, which impairs heat transfer and causes damage to them.

To study the condition of the thermistor, a tester is connected to the sensor contacts in the position of an ohmmeter. If it fixes:

- resistance within 1 - 30 kOhm, then the sensor is working;

- 1 or 0, the probe must be replaced.

Temperature sensor replacement procedure:

- Depending on the type of probe, it can be unscrewed or removed from the pipe.

- Before installing a new sensor, for overhead thermistors, thermal paste, for example, MX 4, is applied to the prepared base, from which dirt, oxides, and fat are removed.

If the probe breaks down in automatic boilers, a fault code will be displayed on its dashboard.Also, the coolant may overheat due to a pump malfunction and filter contamination. Methods for identifying and resolving such problems are described above.

Unfortunately, knowing almost nothing about the heating system in your home, we cannot help with specific advice. It's like in medicine: in order to make a diagnosis, the doctor must get the results of the tests and examine the patient. And we are not even aware of the “anatomy”, you did not attach a diagram to the question. You need to know not only the general location of the heating devices, but also the structure of the boiler room, the location of the air vents, etc. But, even knowing these parameters, trying to determine the nature of the problem in absentia is largely guesswork. There can be many local reasons for the system to malfunction, we will present the correct, in our opinion, algorithm for finding and eliminating them:

A manual air blower (Maevsky crane) must be installed on each radiator

The cause of poor circulation can also be the general contamination of the system, primarily the batteries are clogged. The heater can be removed and blown out with compressed air or washed out with a powerful jet of water.

The diagram shows that air vents, automatic on combs (5, 11) and Mayevsky taps (13) are placed on all heating devices without exception. This was done for a reason, but to eliminate situations like yours.

Cats on cold batteries do not sleep.

How to fire up a cauldron

In cycling, the most difficult thing is not to ride, but to start the movement and finish it. So it is in the operation of the boiler - it is most difficult to melt it.Do not expect that lighting the boiler will take you a little time: you will have to allocate about an hour for this procedure.

The firebox of a wood-burning boiler is a responsible occupation

The beginning of the furnace - cleaning the ash and preparing the boiler for work. After the ash pan and combustion chamber are cleaned, you can proceed to kindling.

Warming up the boiler furnace and chimney

For your own comfort and proper start-up of the boiler, you need to warm up its furnace and chimney. If the heater is not equipped with a forced smoke exhaust system, in order for the fuel to start burning, it is necessary to create draft. The formation of thrust is based on the law of Archimedes: heated gases become lighter and tend to "float". For their movement and removal, fuel-burning heating appliances are equipped with a chimney.

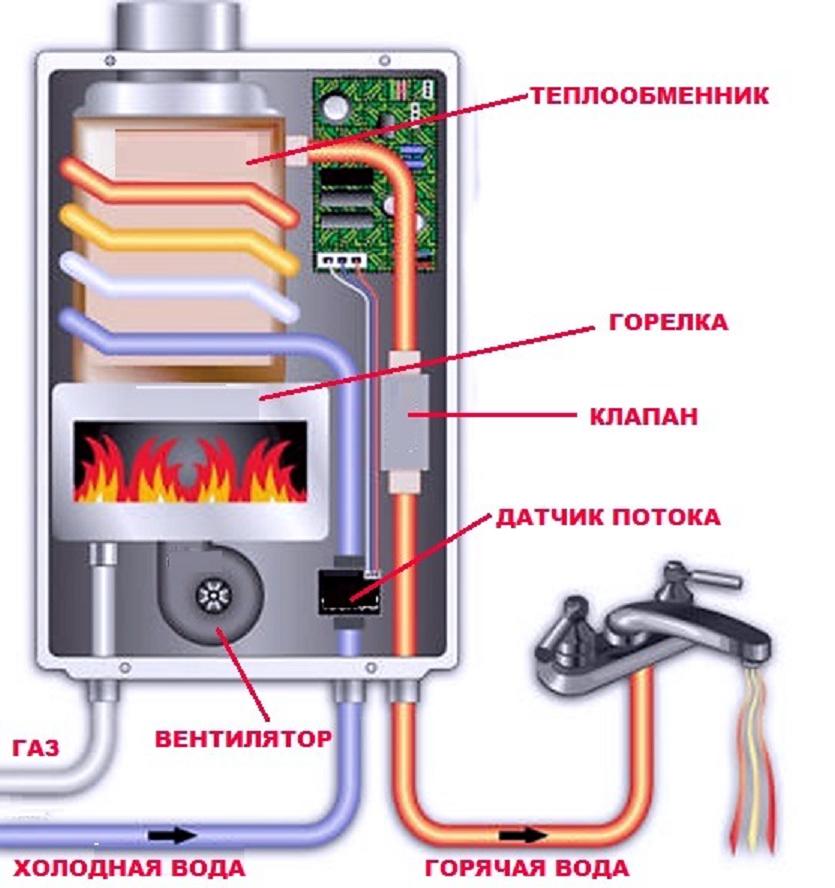

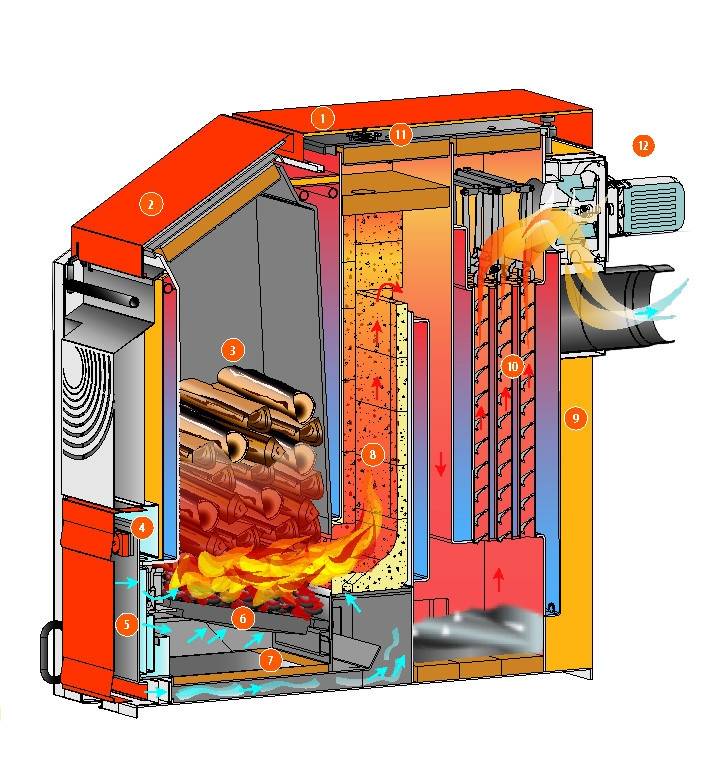

Boiler diagram.

The design of the boiler is such that the path for smoke is difficult: on its path there is a heat exchanger and a convective surface of a complex shape, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult to move smoke. Therefore, if the boiler is not warmed up, the combustion products look for the easiest way. And most often the smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a chimney (a small firebox used to warm the chimney) with a door that can be opened to burn a small amount of combustible fuel (for example, paper) directly in the chimney itself. When using the firebox, the inside of the chimney channel warms up.

If this possibility is not provided, then kindling is laid in the furnace - crumpled paper, birch bark - something flammable.On top of the kindling - chips and splinter, then logs of small thickness. The combustion chamber must be filled with firewood no more than half of the calculated volume.

At the moment of kindling, it is necessary to open the chimney damper and the blower valve, ensuring the flow of air for combustion.

There are tips before starting the firebox to open a window in the boiler room, if any: do not forget that oxygen is needed for the physical and chemical combustion process.

How to heat a boiler with wood

It takes about 5 cubic meters of air to burn a kilogram of firewood. If air is supplied to the boiler furnace from the boiler room, then it is imperative to arrange forced ventilation - especially if there are no windows in the boiler room or they are sealed (with double-glazed windows).

After laying the logs, kindling is ignited. When a steady burning appears, the firebox door must be covered and the bookmark should be allowed to burn out.

Rated output

Once the camera the combustion chamber and the chimney have warmed up sufficiently, you can proceed to the main stage of the boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main laying of firewood is already complete, in order, according to the instructions for the device, to fill the combustion chamber.

After the fuel has ignited, the boiler will reach its design power after a while. Now the combustion process will occur for some time on its own. How long depends on the volume of the combustion chamber and the principle of operation of the boiler. After the firewood bookmark burns out, you will need to make a new one.

A properly functioning boiler is a source of heat and comfort in a country house

Important! When kindling, do not use lighter fluids or flammable gasoline, diesel fuel, etc.

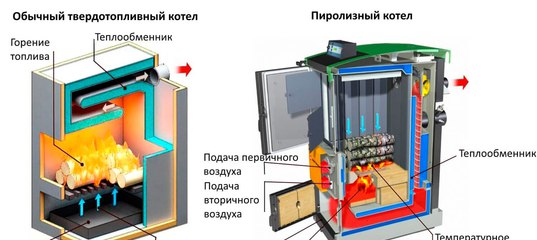

Protection of a solid fuel boiler against overheating

In a solid fuel boiler, burning fuel, and the boiler itself, have a rather large mass. Therefore, the process of heat release in the boiler has a large inertia. The combustion of fuel and the heating of water in a solid fuel boiler cannot be stopped instantly by cutting off the fuel supply, as is done in a gas boiler.

Solid fuel boilers, more than others, are prone to overheating of the coolant - boiling water if the heat is lost, for example, when the water circulation in the heating system suddenly stops, or more heat is released in the boiler than is consumed.

Boiling water in the boiler leads to an increase in temperature and pressure in the heating system with all serious consequences - the destruction of the heating system equipment, injury to people, damage to property.

Modern closed heating systems with a solid fuel boiler are especially prone to overheating, as they contain a relatively small volume of coolant.

Heating systems usually use polymer pipes, control and distribution manifolds, various taps, valves and other fittings. Most elements of the heating system are very sensitive to overheating of the coolant and pressure surges caused by boiling water in the system.

The solid fuel boiler in the heating system must be protected against overheating of the coolant.

To protect the solid fuel boiler from overheating In a closed heating system that is not connected to the atmosphere, two steps must be taken:

- Shut off the combustion air supply to the boiler furnace in order to reduce the combustion intensity of the fuel as soon as possible.

- Provide cooling of the heat carrier at the outlet of the boiler and prevent the water temperature from rising to boiling point.Cooling should take place until the release of heat is reduced to a level at which boiling water becomes impossible.

Consider how to protect the boiler from overheating, using the heating circuit as an example, which is shown below.

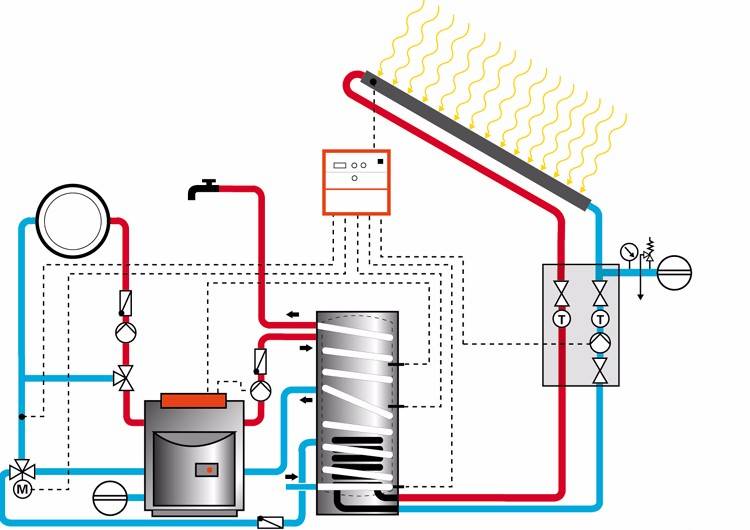

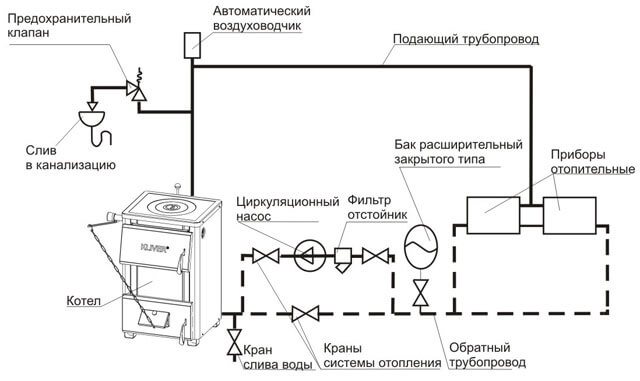

Scheme of connecting a solid fuel boiler to a closed heating system

Scheme of a closed heating system with a solid fuel boiler.

1 - boiler safety group (safety valve, automatic air vent, pressure gauge); 2 - a tank with a supply of water for cooling the coolant in case of boiler overheating; 3 - float shut-off valve; 4 - thermal valve; 5 - group for connecting an expansion membrane tank; 6 - coolant circulation unit and boiler protection against low-temperature corrosion (with a pump and a three-way valve); 7 - heat exchanger protection against overheating.

Boiler protection against overheating works as follows. When the temperature of the coolant rises above 95 degrees, the thermostat on the boiler closes the damper for supplying air to the combustion chamber of the boiler.

Thermal valve pos.4 opens the supply of cold water from the tank pos.2 to the heat exchanger pos.7. Cold water flowing through the heat exchanger cools the coolant at the outlet of the boiler, preventing boiling.

The supply of water in the tank pos.2 is necessary in case of lack of water in the water supply, for example, during a power outage. Often a common storage tank is installed in the water supply system of the house. Then the water for cooling the boiler is taken from this tank.

A heat exchanger to protect the boiler from overheating and coolant cooling, pos.7 and a thermal valve, pos.4, are usually built into the boiler body by boiler manufacturers.This has become standard equipment for boilers designed for closed heating systems.

In heating systems with a solid fuel boiler (with the exception of systems with a buffer tank), thermostatic valves and other automatic devices that reduce heat extraction must not be installed on heating devices (radiators). Automation can reduce heat consumption during the period of intensive fuel burning in the boiler, and this can cause the overheating protection to trip.

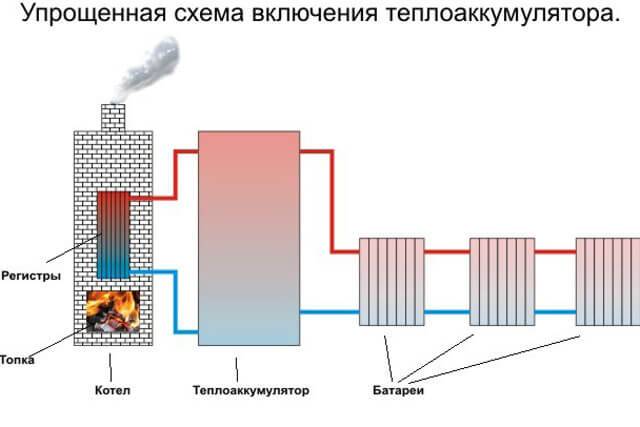

Another way to protect a solid fuel boiler from overheating is described in the article:

Read: Buffer tank - protection of a solid fuel boiler from overheating.

Continued on next page 2:

Causes of boiling in different types of boilers

In addition to insufficient circulation and airing, gas devices suffer from clogged filters: the latter need to be periodically cleaned or replaced. If exfoliated scale particles clog the duct, knocking, clicking sounds can be heard, here you need to clean the unit with special chemicals. Overheating can be caused by prolonged stagnation of the system and the subsequent abrupt start (it is necessary to ensure a preliminary run of the ventilation engineering).

Actions relevant when the gas boiler boils:

- checking the completeness of the circulation of the coolant and filters;

- control of serviceability of cranes on radiators and the circulation pump;

- chimney draft control;

- cleaning the heat exchanger.

Solid fuel boilers overheat due to incorrect correlation of their power with the parameters of the serviced premises. Also, the problem of pressure growth in the equipment caused by the shutdown of the circulation pump is often fixed.

Steam boilers are seriously dependent on the presence of liquid in them: due to the low level, the walls overheat, an emergency occurs. Here you should stop the fuel supply, wait for the device to cool down and top up the working medium.

Why does an electric unit boil:

- clogging with scale;

- thermostat malfunction, causing the heating element to function even after the temperature rises;

- membrane failure;

- insufficiency of the coolant;

- breakdown of the circulation pump;

- the regulators on the return flow are not open.

Prevention of overheating will be the introduction of a buffer tank that does not allow the boiler to boil, excess heat energy will be directed into it. An uninterruptible power supply will allow you not to be afraid of turning off the control units and the pump. An additional circuit for a solid fuel boiler will provide timely cooling. Also, experts recommend periodically inspecting and maintaining (cleaning) the ventilation system.

Causes of boiler smoke

Some signs help determine what to look for first of all when fumes and soot appear in the room. Conventionally, the causes of smoke can be divided into 4 groups:

- A clogged chimney is one of the most common problems. This may be either a foreign object that has fallen from the outside, or the result of using low-quality fuel.

- The mismatch of the chimney with the power of the boiler or the height of the building is less common and is detected almost immediately, at the very first heating. In a situation where at first everything was fine, and then it began to smoke, this reason should not be considered.

- Damage to the chimney is the least likely case.But if the boiler smokes at the beginning of a new heating season, then inspection of the pipe should be one of the first tasks.

- Weather conditions affect natural draft in only two cases: a low chimney height and an incorrect location of the fresh air inlet point.

The smoker must be raised above the roof ridge. The diameter of the pipe is selected in strict accordance with the power of the boiler: a small section simply cannot cope with the removal of smoke from a serious firebox. You should also avoid right angles in places where the pipe changes direction - this makes it difficult for air to circulate, which is not the best effect on traction. Visual inspection allows you to identify these shortcomings and eliminate them.

Knocking in boilers and pumps

Boiler equipment used to equip heating systems can operate on various types of gaseous, liquid or solid fuels, or also on electricity. However, work boilers of any type may be accompanied by certain side processes that often affect the heating system and can cause noise in it.

In particular, wood or coal solid fuels can lead to clogging of the chimney with a decrease in traction. The operation of boiler houses on liquid diesel fuel may be accompanied by its incomplete combustion and the accumulation of soot. All this often leads to noise and buzz in heating communications, and requires measures to eliminate these problems.

Noises may also occur due to malfunctions in the operation of pumps, valves or other devices and mechanisms located in the boiler room or in the basement. The solution to the problem in such situations is to repair the faulty elements or replace them.

In general, any specific situation with the occurrence of noise in the heating system requires an individual approach, and there cannot be universal methods here. In some cases, identifying and eliminating faults on your own can be very difficult, and in this situation, the only way out of the situation is to contact qualified specialists.

clogged radiator

Sometimes the reason that the radiator does not heat up can be its banal clogging. Determining the causes of blockage, we highlight the symptoms:

- Heats only around the perimeter.

- Only the top.

- The bottom is hot, the top is not.

- Only a few sections of all possible provide heat (if the bypass location is correct)

- from prolonged use.

- Due to installation errors.

- Precipitation of high water hardness.

- Erosion of system elements (oxide, rust).

How to get rid?

Modern heating appliances with well-installed shut-off valves incorporate an American tap, by blocking which the non-working part can be easily dismantled and cleaned, purged, and pressure washed.

It is heavier where the equipment is “without counting years”. For disassembly, you may have to turn to specialists, emptying (previously or already with their help) the entire volume (as a rule, it's just water).

Cast iron radiators are cleanable. Steel flat flow-through welded radiators are recommended to be replaced with new ones of other models. But it is they, ironically, that are most often subject to rusting, clogging of channels - due to the design features and materials used. Therefore, they often do not heat properly.An additional reason not to clean this type of heater is the risk of leakage of the eroded wall due to its thinning in the process of exfoliation of oxidized metal flakes. A leak can be expensive (even if you forget about the cost paid for the repair of "junk"). The very case when the stingy has every chance to pay twice, or even thrice.