- The boiler (titanium, water heater) makes a sound. Howls, squeaks, crackles, whistles, hums

- The freezer is noisy: a malfunction or a norm?

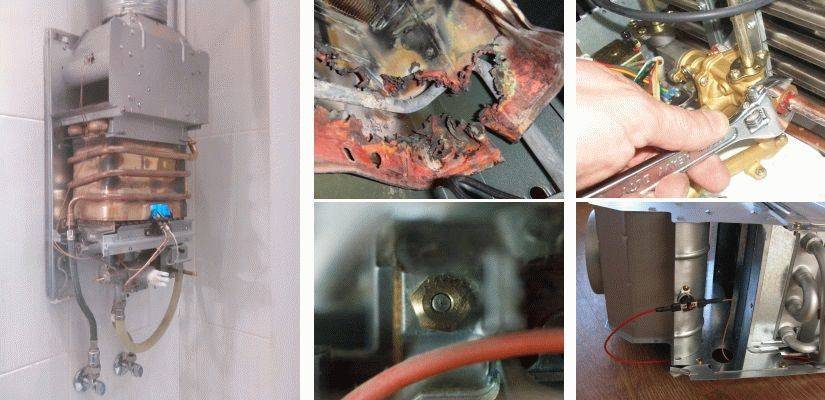

- Column with automatic ignition system

- Causes of noise in a device with electric ignition

- Prevention measures

- What to do?

- Columns of a new type with automatic ignition

- Columns of the old type with an ignition wick

- Speaker buzzes and buzzes

- Why does the circulation pump make noise in the heating system? Troubleshooting

- Unstable voltage

- Noise due to mounting error

- Pump whistles due to air locks

- Mismatch of parameters and power

- The device buzzes and cracks due to equipment failure

- Appliances are noisy when hot water

- Faults and what to do

- Start relay broken

- Faulty thermostat

- Broken compressor motor

- Loose compressor mounts

- Low voltage in the network

- How to get rid of sound?

- Computer settings

- Driver problem

- Recommendations

The boiler (titanium, water heater) makes a sound. Howls, squeaks, crackles, whistles, hums

Over time, any boiler (water heater) will sooner or later begin to make extraneous unpleasant sounds. In the space of the Internet, people talk about many reasons that are guilty of generating different sounds, but I could not see the right steps to eliminate these problems anywhere.

I can offer you my own version of troubleshooting these problems associated with the sound of the boiler.

The main reasons for the appearance of a squeak, buzz or whistle in the boiler can be identified in three ways:

A large layer of scale or limestone deposits appeared on the heating elements

Bypass valve and plumbing associated with it

Very poor water quality in your home

Now about everything in more detail ...

Scale on the boiler heating element (heater) may be the least likely problem in whistling. But, if the scale does not exceed a thickness of 1 cm on the element, otherwise, this will also be a source of whistles, crackles and other sounds in the boiler.

In some settlements and cities, local water treatment services do not carry out proper degassing of water, probably on purpose, as this increases the consumption of water by meters, with less water consumption. As a human being: as a rule, a certain percentage of air is always present in water, in some certain areas of our country this percentage is more or less than the average value. According to municipal standards, services must remove excess air in the water for a certain normalized value. This same air can later create the effect of a characteristic sound at the beginning of water heating. At my friend in the city, that is why the boiler squeaks. I myself live in Vladivostok, it seems that we do not have such an effect from water.

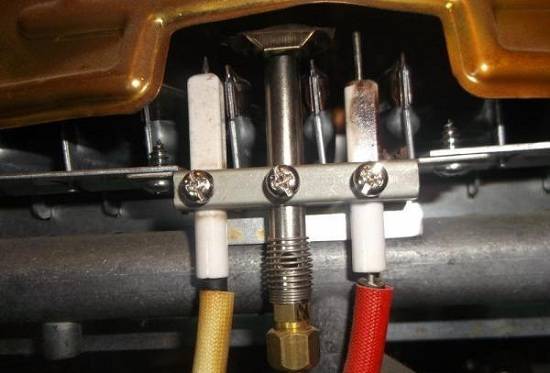

An even more common cause of boiler sounds is a problematic bypass valve. When buying a boiler with the tank itself, an accompanying combined device is equipped, which is designed to relieve excess (excessive) pressure in the tank and a check valve designed to prevent the outflow of water in the opposite direction. Over time, if the pressure in the boiler tank is constantly high, with frequent discharge of excess water, this valve begins to undermine. And it is recommended to replace it. Fortunately, this is not difficult, any man can handle it with his hands.

An even more common cause of boiler sounds is a problematic bypass valve. When buying a boiler with the tank itself, an accompanying combined device is equipped, which is designed to relieve excess (excessive) pressure in the tank and a check valve designed to prevent the outflow of water in the opposite direction. Over time, if the pressure in the boiler tank is constantly high, with frequent discharge of excess water, this valve begins to undermine. And it is recommended to replace it. Fortunately, this is not difficult, any man can handle it with his hands.

Also, this valve is responsible for equalizing the pressure not only in the water heater, but also in the pipes located below and above itself. For example, neighbors or you open a cold water tap, then the pressure in the water supply drops and some water passes through this valve with a sound from the water heater to the water supply.

In rare cases, the bypass valve may make noise when there is increased pressure in the cold water riser. The way to fix the problem is to install a pressure reducer on the water supply system of the apartment.

The freezer is noisy: a malfunction or a norm?

It should be noted that at present there is a tendency to reduce the noise level in household devices. Manufacturers come up with new technological solutions. Meanwhile, to date, completely silent models do not exist. The noise level is indicated in decibels in the operating instructions.

If the equipment is noisy, but no additional signs are observed: water does not flow out, there is no burning smell, the display shows the operating temperature, there are no alarms and error codes, most likely you should not worry!

All sounds are natural. So, crackling is emitted by elements of the cooling circuit.

Refrigerator and freezer motor compressors

When you turn on the motor-compressor, the freezer starts, the thermostat clicks. A similar thing happens when you turn it off: a click - and the motor stops buzzing.

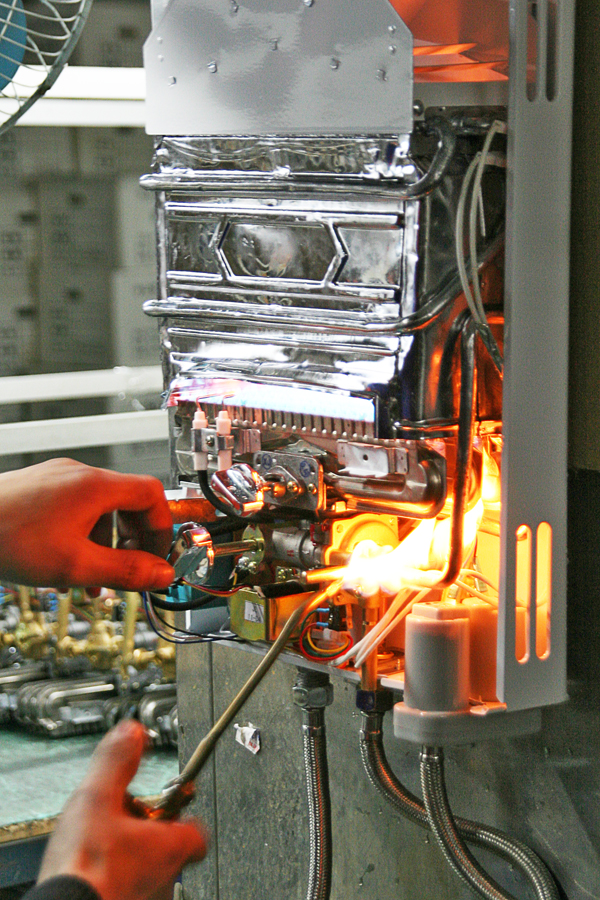

Column with automatic ignition system

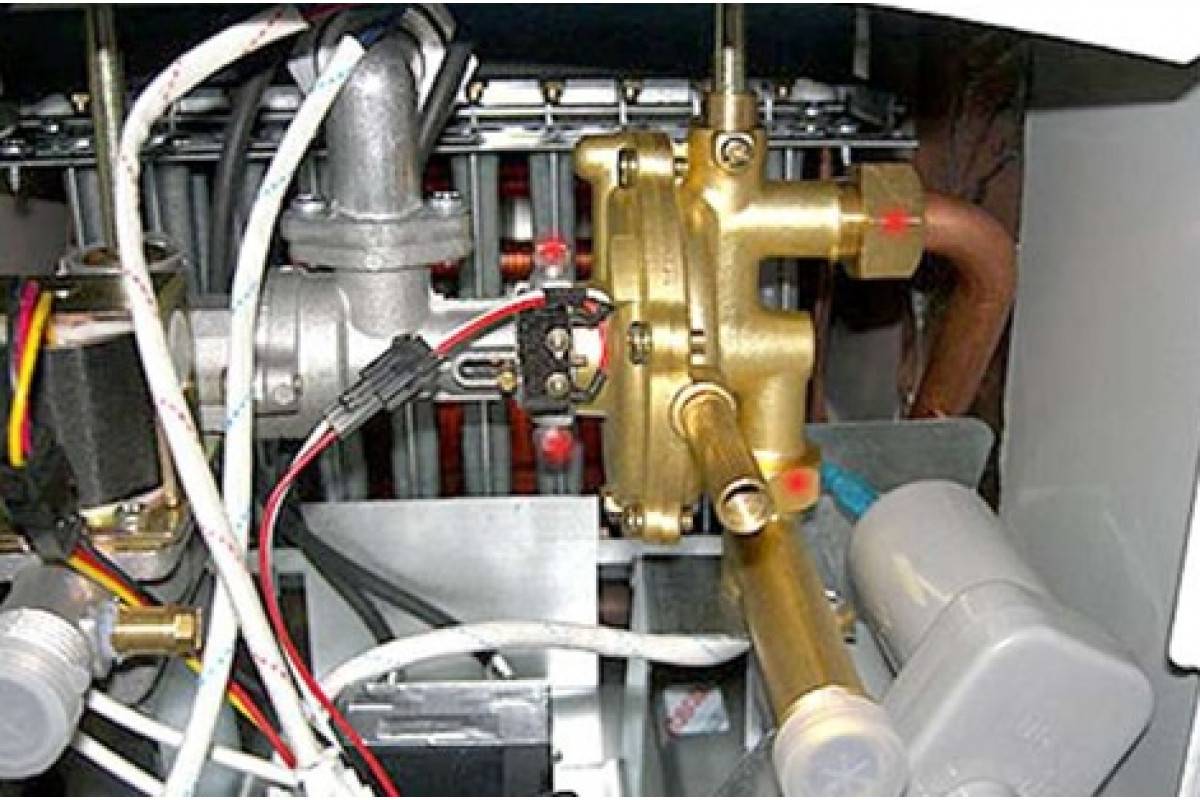

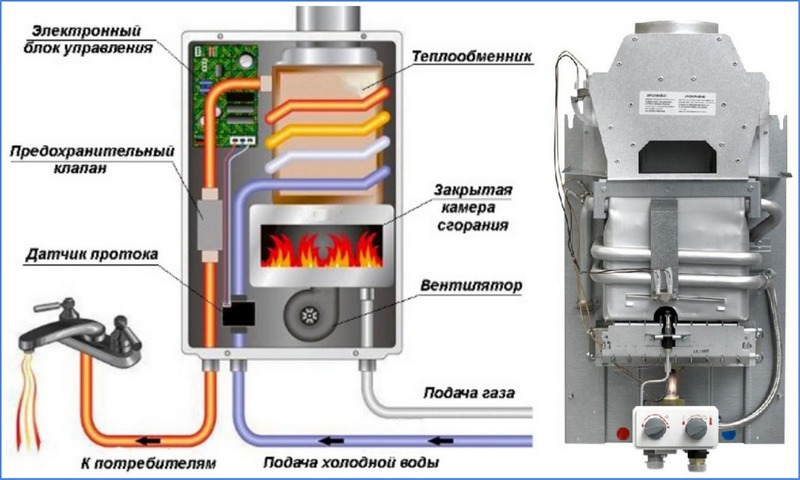

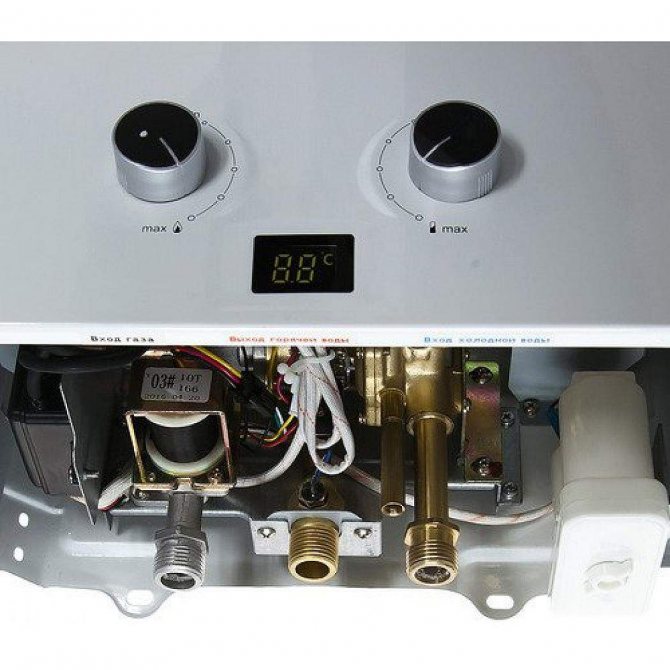

In modern models, ignition is carried out automatically. Thanks to this, the owner manages to save 10m3 of gas. But improved performance makes equipment more complex and less reliable. In it, ignition is controlled by an electronic control module connected to microswitches.

Failures rarely occur in the operation of such a system, but there is a certain risk. In this case, you will have to find out why cotton occurs when the gas column is turned on. Repairs can cost a lot. This is the main disadvantage of such devices.

If the Neva geyser clicks, then you must perform the following steps:

Check the charge of the batteries powering the module. There is an electronic ignition system in equipment such as the Neva gas water heater, Oasis and others. If the battery is discharged, then it will not work during ignition. Then you can hear something hissing or cracking. To cope with the problem, it is enough to change new batteries.

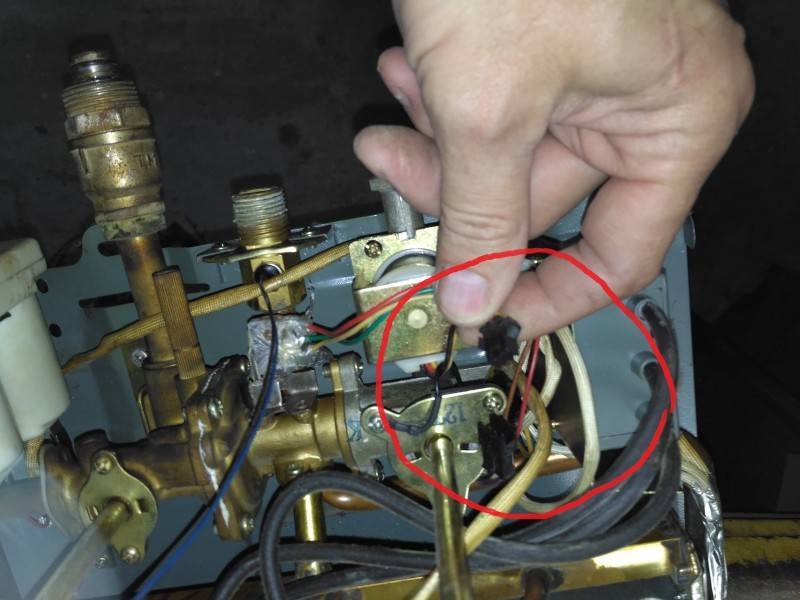

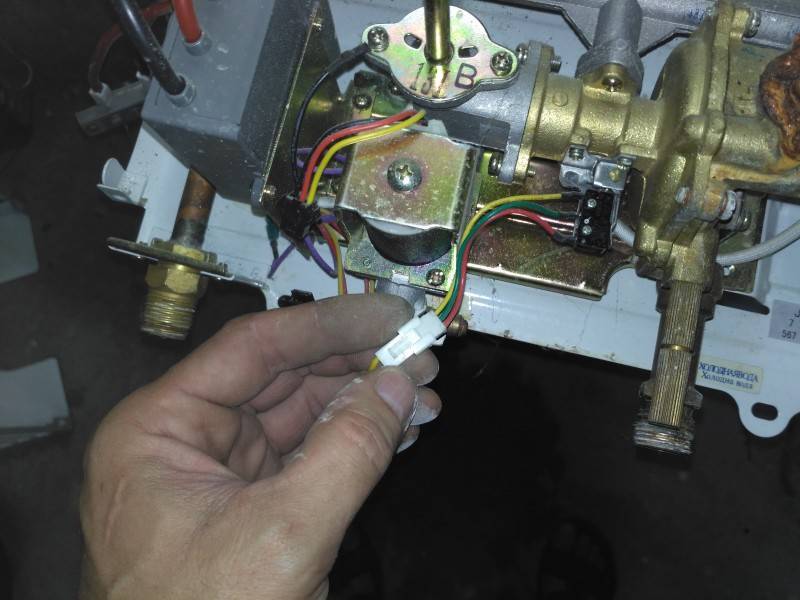

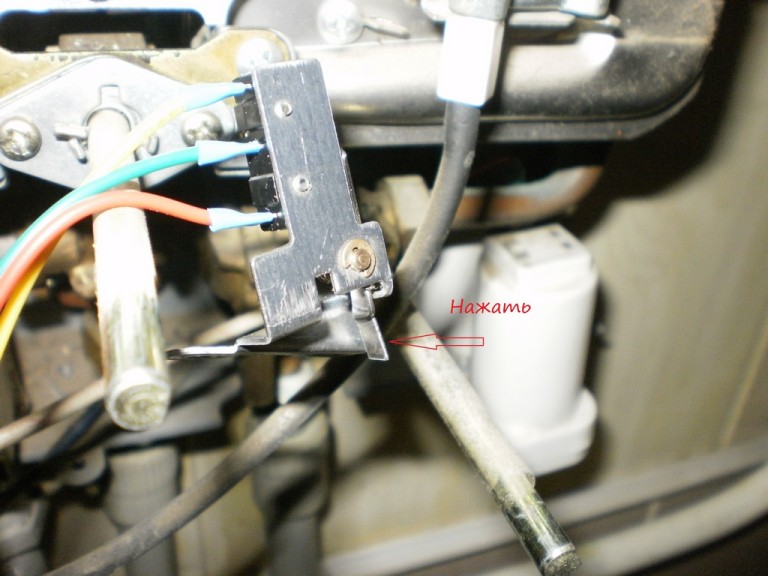

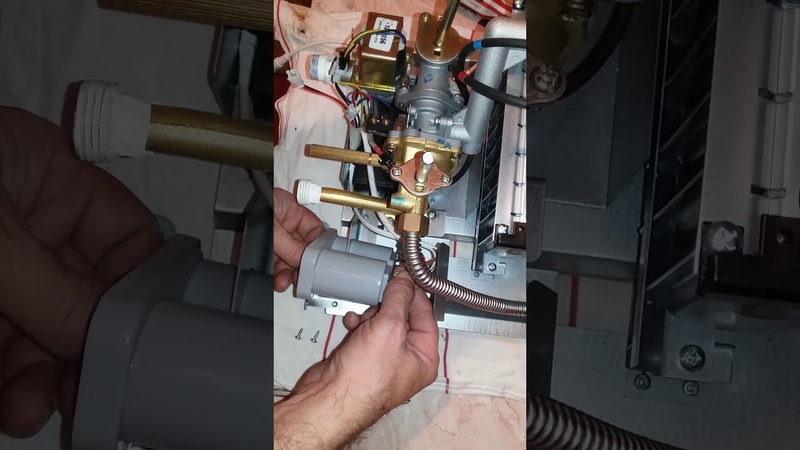

Evaluate how well the fluid pressure microregulator works. Manufacturer installed this element in the column for so that it sends signals to the control module. It is activated when the water supply starts and there is a need to ignite the gas. If there is a problem with the pressure micro-regulator, then when water enters, the commands will be incorrect. Because of this, geysers make noise. Use a multimeter or ohmmeter to check for problems.It should be used to measure performance. If they do not meet the requirements, the system is out of order, which is why the geyser pops. You can fix the situation by changing the old part to a new one.

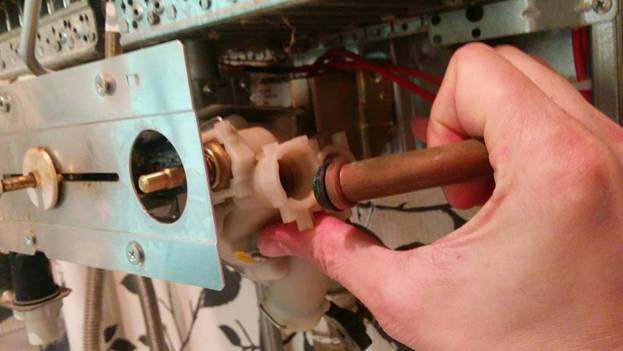

Find out whether the device for igniting the gas is correctly positioned or not. If popping occurs when the gas column is turned on, this element may be the reason. It can change its shape under the influence of sudden temperature changes, because of this, the dimensions of individual parts of the structure change. This part is held on by one screw, so it is not difficult to fix it. To do this, loosen the screw and align the candle. It is this element that provides the creation of an electric spark. Modern candles rarely break, as they are designed for long-term operation. If the ignition device has changed its nominal position, it is necessary to correct it so that the spark gap is 0.40-0.50 cm. After that, it must be checked that ignition does not occur with a delay.

Verify that the flame retardant is working. Quite often, during the operation of the water heater, gas begins to accumulate if the valve to slow down the flow of liquid is faulty. The reason is the usual breakdown or incorrect element settings. This part of the device is a small metal ball that closes the conductive valve in the pressure regulator. If the ignition retarder is normal, then it will move freely under the cover and not be fixed. To detect a problem, it is enough to dismantle the assembly and shake it. In this case, the ball should freely hit the walls of the housing. If the geyser pops violently when the water is turned on, the ball may have stalled.To move it, you need to use a thin wire made of soft metal, passed through the hole in the channel

You should also remove contaminants, but you need to proceed with caution. If there are no good reasons, experts advise not to clean once again.

If cotton still occurs when the gas column is turned on, it is necessary to check the water supply sensor. It is installed on the input circuit. This element provides a signal to the control unit that there is liquid in the pipe. This ensures timely ignition of the water heater.

Due to the intensive use of this device, the likelihood of breakdowns increases. For example, contact groups are oxidized. Modern sensors create non-separable. Therefore, if the device hisses when ignited, a replacement will be required. Indeed, from such malfunctions, columns often explode.

Causes of noise in a device with electric ignition

The causes of noise in a geyser equipped with electric ignition may be the following:

- The batteries are discharged - in this case, the ignition does not work well and the gas-air mixture ignites with difficulty. This problem is easily solved by replacing the batteries.

- The sensor that controls the water supply has broken. Often, problems are associated with the process of contact oxidation. Basically, this sensor is not collapsible, so you have to change the element to a new one.

- Malfunctions in the mechanical ignition retarder. The presence of problems in this node is determined by removing it and shaking it. During this procedure, the noise of the movement of the ball inside the moderator will be heard.If there is no sound, this indicates the displacement of the ball. You can fix the problem and return the ball to its place using a thin wire.

- Spark plug failure due to which an electric spark does not appear. Basically, it moves after reusable heating and cooling processes. It is necessary to return the candle to its place, after which the possibility of a spark will be restored and extraneous noise will go away.

Prevention measures

Most often, the hum, buzz in household appliances is associated with its improper installation, operation and maintenance. The dishwasher is installed in the same way as a washing machine - by level, with adjustable legs. It should not be skewed, the door should open completely and close without problems. If it is not, adjust its position.

Most often, the hum, buzz in household appliances is associated with its improper installation, operation and maintenance. The dishwasher is installed in the same way as a washing machine - by level, with adjustable legs. It should not be skewed, the door should open completely and close without problems. If it is not, adjust its position.

Always load the basket with dishes as recommended by the manufacturer. Utensils should not touch the walls or touch the sprinklers. Don't overload your carts either.

After washing, it is advisable to clean the drain filter. This is easy to do: it is easy to get it without additional tools. It is worth using dishwasher cleaners - such household chemicals are available in all stores.

If, despite all the preventive measures, the dishwasher pump is buzzing during operation, you need to call a repairman for diagnostics. If you replace one part in time, you will not have to buy new equipment.

What to do?

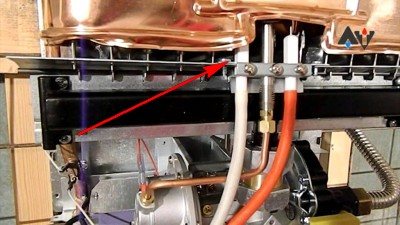

The first thing experts recommend doing is to check the presence and strength of draft in the chimney. Most instantaneous water heaters have a casing in which there are holes designed specifically for this purpose.If you are unable to find such holes, try to check the draft near the slot, which is located under the smoke hood. You can also feel the draft directly in the chimney at the cleaning hatch.

The draft is usually checked with a lit match. If the flame deviates well to the side, then the thrust is normal, if it only trembles, it is weak. A stationary flame means no traction - in this case, it is impossible to operate the gas column in any case.

Columns of a new type with automatic ignition

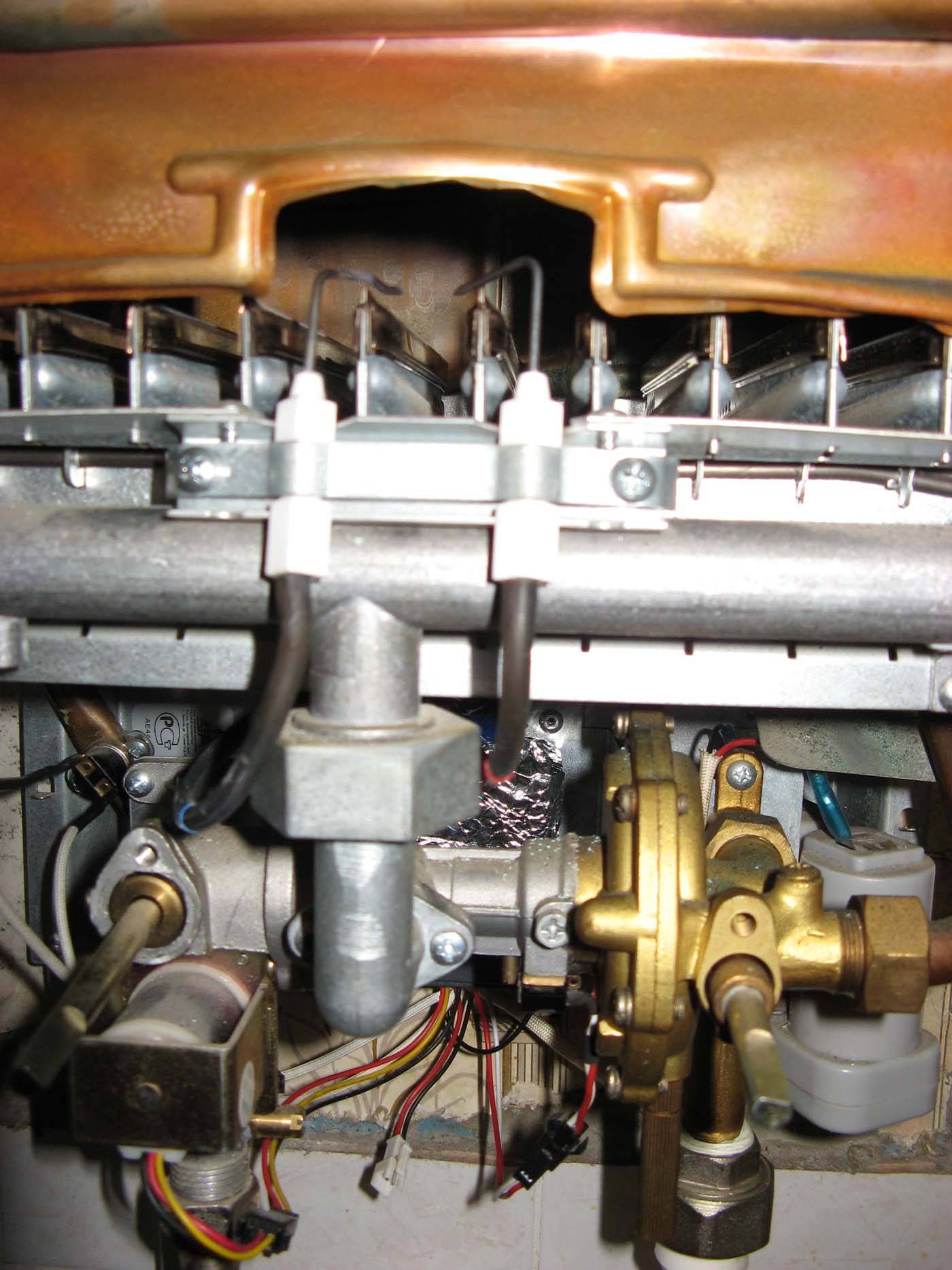

Instantaneous gas water heaters equipped with an automatic ignition system are much more economical in terms of gas consumption. They operate under the control of an electronic module, which receives commands through microswitches located on the water and flame regulators. Such devices are considered very reliable, but they also have disadvantages, for example, expensive and complex repairs.

So what should you do when you hear gas pop?

- Check the condition of the power supplies. A “bad” spark that does not immediately ignite the gas may be due to a low battery level. This problem is fixed very easily and does not require the intervention of a wizard.

- Check the water pressure micro-regulator. This device is designed to inform the control module that water is being supplied and the gas needs to be ignited. The micro-regulator may break and give incorrect signals if water gets on it. You can diagnose such a malfunction using a multimeter or ohmmeter. If the readings of the device do not meet the standards, then the microregulator is broken and should be replaced.

- Check the position of the spark plug.This part can be deformed under the influence of high temperatures or due to temperature changes. Correcting its position is quite simple since it is fixed on a single screw. This screw needs to be slightly loosened and the candle installed so that the spark gap is approximately 0.4-0.5 cm. In this case, ignition should occur on the first attempt.

- Check the condition of the ignition retarder. Gas can accumulate because the valve that slows down the flow of water is broken or poorly adjusted. The part in question is a small metal ball that partially covers the bypass in the water pressure regulator. In good condition, the ignition retarder should move freely (this can be checked by ear by shaking the cover). If this does not happen, you can try to set the ball in motion by picking it up with a flexible cable passed through the hole in the channel. If the retarder does not give in, you can try to remove it and clean the channel, but it is advised to do this only as a last resort.

- After any repair, all connections should be checked for tightness, and, if necessary, sealed with rubber rings or special sealing compounds.

The cost of a pressure microregulator varies on average from 50 to 200 rubles.

Columns of the old type with an ignition wick

Flowing gas heaters of the old model "clap" quite often. This is due to the peculiarity of their design. They are considered less safe and convenient than new gas burners, but they are much easier (and cheaper) to repair.

The most common cause of gas accumulation in the cavities of this type of water heater is the incorrect position of the wick for the fuse. In this case, the flame becomes too small to reach the rim of the main burner - most often this is due to insufficient gas being supplied to the wick. The gas supply may be difficult because the gas jet is clogged.

Speaker buzzes and buzzes

If the geyser is noisy, then most likely the reason is:

- poor traction;

- lack of ventilation;

- wick contamination.

The reason for the noise when heating water is often a lack of traction. Therefore, if the geyser makes noise during operation, first of all check the presence of draft in the chimney. This is easy to determine with a lit match or lighter, which is brought to the control hole of the chimney or its hatch:

- if the flame is drawn into the chimney, then there is a draft;

- if the fire is not moving, there is no thrust.

If there is no draft, clean the chimney. During operation, it becomes clogged with soot and debris.

Leaking geyser – causes and ways to eliminate them

Read here The geyser does not work - what to do

Noise can be caused by lack of air in the room. Most often this happens if the owners changed the old frames to plastic ones. Their seals interfere with natural ventilation in the room. In this case, to stop the noise, it is necessary to increase the air flow.

A clogged pilot burner wick is also a common cause of excessive noise. In this case, to eliminate sounds, it is enough to simply clean the jets in the main burner. Then the noise problem will be solved.

Why does the circulation pump make noise in the heating system? Troubleshooting

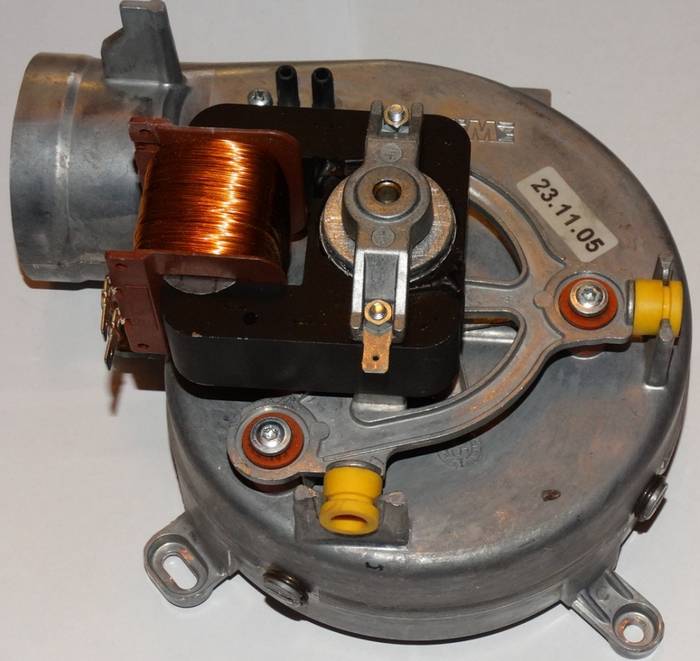

Choosing the right circulator will help prevent annoying noises. The store presents units with motors of two types:

Dry. Devices of this type cope with high loads. The rotor stays dry. Cooling occurs with the help of a fan that will make noise.

Photo 1. Circulation pump for heating systems from the manufacturer Wilo. There is a fan on the back to cool the device.

Wet. The pump is located directly in the water. The unit is protected from overheating by an almost silent coolant.

Attention! Dry type devices will create discomfort due to the sound of the fan running. For domestic needs, a wet type of pumps is used. They are installed directly in the room.

They are installed directly in the room.

Extraneous hum, noise or rattle of the device can be associated with some system malfunctions. The most common problems:

- Unstable voltage.

- Poor quality installation.

- Air lock in the system.

- Power and parameters mismatch.

- Hardware failure.

Unstable voltage

With voltage drops, the operation of the pump is uneven. Lack of synchronization leads to intermittent circulation of water in the system, extraneous sounds occur inside radiators or pipes.

To find out the cause of noise, diagnostics are carried out, which makes it possible to identify malfunctions in the functioning of the device. Such a procedure requires the involvement of a specialist with additional equipment.

Noise due to mounting error

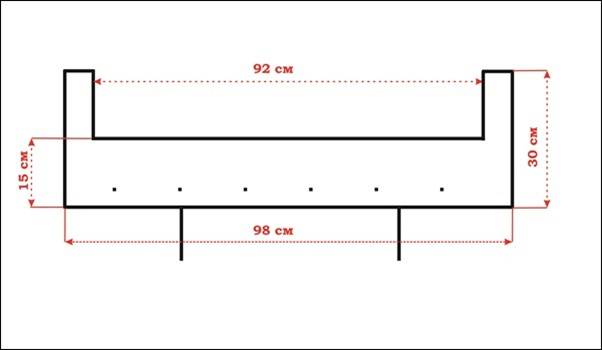

Rustle occurs due to increased cavitation loads.The installation of a hydraulic compensator will help to avoid the problem: a membrane tank that helps regulate static pressure when heated. This device draws excess moisture from the system and prevents water hammer. A properly installed hydraulic compensator will significantly extend the life of the pump.

Pump whistles due to air locks

Whistling sounds that occur when heating is started are often caused by air locks. Air enters the system when pipes and radiators are filled with water.

What to do if the pump suddenly starts to whistle? To fix the problem, Mayevsky cranes are provided in the design - special holes closed with a screw plug located in the upper parts of the radiator.

Photo 2. Mayevsky crane on a heating radiator. Allows you to release excess air from the heating system.

Open the device with the pump off using a screwdriver or wrench.

Reference. Installing automatic air vents will help to eliminate air congestion in time.

Mismatch of parameters and power

Noise when turning on the heating is sometimes due to the installation of an unreasonably powerful pump. The technical characteristics of the unit specified in the instructions necessarily correspond to the design parameters of the entire system. The pump becomes one of the final purchases when the exact length of the pipes and the number of radiators are known. The overall performance of the device at maximum load is calculated relative to low outdoor temperatures in the winter season.

The device buzzes and cracks due to equipment failure

Common problems with a circular pump include a defect in the rotor or impeller.In addition to constant noise, this problem leads to poor system performance.

The hum is a consequence of technological gaps that have increased over time and shaft trembling. Repair and replacement of adjusting washers will solve the breakdown.

Burning motor windings can crack. Correction of this defect is best entrusted to a specialist.

Appliances are noisy when hot water

Modern boilers are quiet, so vibration, noise, extraneous sounds should alert you. What can be the indirect cause:

- Incorrect installation, connection.

- Incorrect setting.

- Node wear.

There are very specific reasons why the boiler is buzzing.

High oxygen content

The water in the pipes is supersaturated with oxygen, which is why bubbles are released when heated. This effect leads to increased noise and vibration not only of the device, but also of the batteries.

Air accumulation in the system

If the boiler knocks and puffs, it is necessary to bleed the air in the pipes. Taps are installed on modern radiators. By unscrewing them, you can remove the accumulated air.

Scale formation

A high salt content in water leads to their deposition on the walls of the heat exchanger. Therefore, when heated, the unit will hiss. In addition, the heating rate and heat transfer are reduced. It is recommended to clean the radiator once a year. To do this, a pump with a reagent is prepared, a cleaning liquid is pumped through the hoses.

Fan operation problems

The fan works in models with a closed chamber and forced removal of combustion products. Why does it make strange sounds when it rotates, whistles:

The grease in the bearings has dried up due to placement above the burner. When exposed to high temperatures, the grease dries quickly, which leads to bearing wear.Parts are disassembled and lubricated.

Imbalance of the blades, accumulation of dirt and dust. The blades are cleaned, adjusted from rotation.

Overpressure in the heating pump

The pump pumps high pressure, you need to adjust its settings. Too high pressure in the system can lead to an emergency. The values can be adjusted by toggling the white lever on the terminal box.

A lack of water in the system leads to serious overheating. First of all, check the thermostat values, set lower values. Measure the pressure, add coolant if necessary.

As well as:

- If the boiler howls, the problem is in the wrong setting of the gas valve or bypass (pipe jumper).

- When operating at high power, the gas meter may rattle.

- A worn valve makes rattling noises.

Faults and what to do

Extraneous noise emanating from equipment, in some cases, indicates the failure of parts or malfunctions. To understand why the refrigerator clicks, you will need to take into account additional factors. They will help identify problems and find a way to fix them. At the same time, repairs are not always expensive, the replacement of some parts does not exceed 3,000 rubles.

Start relay broken

When clicks are heard intermittently, and the engine does not start, it is dark in the refrigerator compartment, this indicates a failure of the relay. The mechanism cannot be repaired, it needs to be replaced.

It is difficult to repair on your own. Better to entrust it to a professional. When the master puts in a new part, extraneous noise will disappear.A similar problem most often occurs in Hotpoint and Samsung appliances equipped with the No Frost system. However, the cost of repairs is low: it reaches 1,500 - 3,000 rubles. depending on the model.

When the refrigerator clicks during operation, but the engine starts, the start-up relay has nothing to do with it. Technique often reacts this way to temperature changes. It is necessary to close the door more tightly and not keep it open unnecessarily.

Users also experience crackling when loading recently purchased products. Due to the different temperatures, the unit makes noise. After 1-2 hours they disappear.

Faulty thermostat

If the refrigerator clicks and does not freeze during operation, the problem is a malfunction of the thermostat. You will need to make a replacement by calling the master. The equipment should be turned off before his arrival, otherwise there is a risk of engine failure.

It is important to remember that the thermostat is always working, making clicking sounds. If they are observed when turned on, and the unit freezes, there is no water under it, you should not worry

The system is working properly, there is no need for repairs.

Broken compressor motor

If the Indesit, Bosch or Samsung refrigerator creaks and cracks at the back when it is turned on, and the engine hums at the beginning of work, there is a smell of burning in the air, then, most likely, the motor-compressor has failed. At the same time, the start-up relay may make unpleasant sounds.

You need to turn off the unit and call the wizard. He will conduct an examination and replace the motor-compressor. The cost of repairs is up to 6,000 rubles. It is difficult to replace it yourself, because. knowledge is needed.

The following may indicate an engine failure:

- loud sounds before turning off;

- a clicking relay that prevents the engine from starting;

- lack of cold in the chamber when the compressor is turned on.

If the compressor does not start, you need to urgently turn off the unit and call the wizard. The motor will most likely need to be replaced, especially when it turns on but won't turn on.

Loose compressor mounts

If the refrigerator clicks loudly before the engine stops, but there is light in the chamber, the equipment produces cold, this indicates loose engine mounts. The motor at the moment of stopping is in contact with the body, hence the cause of the rattle.

You do not need to call the wizard to fix the problem. It is necessary to slightly tilt the equipment or adjust the springs that are responsible for supporting the compressor. After that, the clicking will stop.

A similar problem is most often encountered by owners of new refrigerators from Samsung, Hotpoint, Deu. Ariston and Bosch rarely have such a crack, because they have better assembly and parts.

Low voltage in the network

If the refrigerator crackles, the motor turns on, but after turning off it does not start for a long time, the problem may be low voltage in the network or drops. It is recommended to check it several times during the day.

In order to avoid breakdowns, the masters are advised to purchase a stabilizer. The device will protect the engine from burnout and save money. The cost of stabilizers is low, but thanks to them, the equipment will function without failures. The purchase of the device is recommended for owners of Bosch models. German units may not turn on if there is no stable voltage in the network.

An ordinary person does not understand the reason why the refrigerator cracks during operation. In most cases, you don't need to worry. This sound is typical for many models.If the equipment produces cold, does not give errors on the control panel, you should observe it for 2-3 days. With an increase in noise, the appearance of water under the unit, you should call the wizard for diagnosis and repair.

How to get rid of sound?

You can get rid of extraneous hum in the columns yourself. Consider what to do for this.

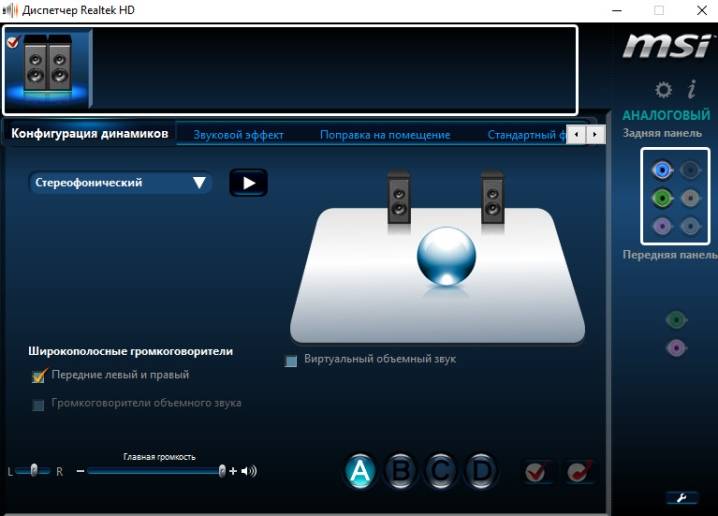

Computer settings

Incorrect settings used when setting up Windows (the common operating system installed on most computers) often cause hum in the speakers.

To fix problems, you need to perform a number of steps.

- Open the Control Panel. You can find the required item in the Start menu.

- Click on the Hardware and Sound section. There will be a subsection called "Sounds".

- Select the audio playback device marked with a green check mark.

- Right-click on it and then click on the "Properties" line.

- The "Levels" tab will appear in the window that opens.

- In the Realtek settings, under the first line, additional sources will be displayed that need to be reduced to the minimum mark.

- Next, you need to open a tab called "Improvements". Opposite the "Loudness" parameter there should be a checkmark confirming that it is enabled. In different versions of the operating system, this parameter may be called differently, for example, “Volume Equalization”.

- After making new settings, you should check the sound.

Driver problem

Software is an important part of the operation of the equipment. In some cases, the problem can be completely fixed with a regular software update.Some operating systems independently notify the user that the driver needs to be updated and perform this procedure automatically.

Otherwise, you can find the desired program on the Internet. They are in the public domain.

After you need to make the necessary settings.

- The procedure begins by opening the "Control Panel".

- The next item is "Hardware and Sound".

- Find the subsection that is responsible for the sound driver settings. In most cases, it is called "Realtek HD Manager".

- Open this item and carefully evaluate the menu. By changing the parameters, evaluate the result. You can turn some sound filters on or off, and change the volume.

Recommendations

In order for the equipment to work for a long time and properly, listen to the following operating recommendations.

- Surround, clear and loud sound is only possible when using high quality equipment. You should not demand much from cheap acoustics.

- Move your speakers carefully by packing your appliances using boxes, foam, bubble wrap, and other options.

- Update the driver regularly.

- Acoustic equipment quickly becomes unusable due to high humidity.

- Make sure that the cables are not under strong tension.

For information on the reasons for the buzzing of the speakers, see the following video.