- When should an injector be replaced?

- The principle of operation of the gas column gearbox

- General rules for choosing a balloon reducer

- Change to another pressure

- The main causes of noise and buzz

- Oxygen saturation of water in the heating system

- Sediment on parts from water circulation

- Fan failure

- Gas pressure reduction

- Why is a gas reducer used?

- Why the gearbox on the gas cylinder is buzzing: what to do if the gas pressure regulator is noisy

- Kinds

- Faults. Repair.

- Gas pressure reducing devices

- Types of gas reducers

- Design features and principle of operation

- Where applicable

- Knocking in boilers and pumps

- Why the gearbox on the gas cylinder is buzzing: what to do if the gas pressure regulator is noisy

- Replacing HBO filters 4th generation. — Chevrolet Lacetti, 1.8 liter, 2008 year on DRIVE2

- How does a geyser work?

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

When should an injector be replaced?

Modern gas stoves, for the most part, are designed for a centralized gas supply. Methane is used in central networks, the pressure in the system is different from the pressure in the cylinder, so a slightly larger nozzle hole is needed.When using bottled gas, propane is used for domestic needs, so a jet with a smaller opening is needed.

The basic configuration always uses nozzles designed to supply fuel through centralized lines. The package of modern models may include a spare jet designed for bottled gas. Also, for the use of cylinders, the gas reducer will additionally have to be replaced.

Trying to get rid of the cause of the appearance of soot on the burner of a household gas stove, it is important to purchase a jet that matches the brand of household appliance. Otherwise, the replacement of the part will not bring the expected result.

The correct selection of the jet, competent installation ensures the smooth operation of the gas stove. If there are installation errors, fuel will be supplied unevenly

In older models of gas stoves, the nozzle is missing. However, they are equipped with a mechanism that allows you to regulate the intensity of fuel flow. It needs to be configured correctly. Adjustment is carried out by turning the tap, which is equipped with a gas cylinder. Without unscrewing the valve to the end, it is easy to reduce the gas pressure in the system, minimizing the likelihood of soot.

In some situations, soot appears when the oven is turned on. It is likely that the injector needs to be replaced here. In most gas stoves, the jet is located behind the left wall of the oven chamber, into which the burner is inserted, curved in an arc. To replace the nozzle, unscrew the screws, remove the burner, find and replace the part.

With prolonged use of a gas appliance, the jet could stick to the burner nozzle. In such a case, it is necessary to lubricate it with a special compound, wait a few minutes.

When the jet is deformed, the fuel flows to the burner unevenly, soot may appear, gas may accumulate in the device, which is dangerous. To replace the nozzle, you need to look at the brand of the gas stove, select the appropriate components.

It is important to remember that gas equipment is potentially dangerous, therefore, in case of any breakdowns, it is advisable to invite specialists from the gas company with which you have a service contract

The principle of operation of the gas column gearbox

By opening a tap with water, water enters the reducer, resting against the narrowed Venturi nozzle, pressure is created that presses on the membrane. Water passes at the bottom of the membrane, at the top the pressure is less. The pressure difference bends the membrane upward, which acts on the plate, the plate presses on the stem. The steel rod signals the gas supply and ignites the burner.

Blocking the water, the membrane bends down, the stem goes down, water pressure in the reducer equalizes, the burner switches off.

The retarder ball is responsible for the gas supply rate. The pressure created by the membrane pushes the ball aside. Moving along the channel, the ball creates a smooth start of the burner. Turning off the water, the ball moves aside, without preventing the passage of water. The rapid outflow of water quickly turns off the gas.

The smoothness of the inclusion of gas is additionally regulated by a screw installed inside the plug. By turning the adjusting screw, you can adjust the speed of switching on the gas. Removing the retarder or incorrect manual adjustment will result in a sudden pop of throttle.

General rules for choosing a balloon reducer

Summarizing the rules for choosing a gearbox for a gas cylinder, it should be noted that:

Classification of gearboxes for gas cylinders

- it is necessary to sketch a diagram of the planned system from the gas cylinder to the end user;

- clearly state the following requirements for the device:

- Appointment.

- Operating pressure.

- The need for adjustment.

- Maximum volume.

- Way of accession to a gas cylinder and to the working device.

- Availability of service and repair.

- Allotted budget.

- From the variety of products on the market, you should choose those that meet the formulated requirements.

- Next, you need to enter the models and their characteristics in a comparative table and conduct a price analysis.

If devices that are suitable according to the formulated requirements do not fit the allotted budget, then it is necessary to either revise the budget or simplify the requirements for the device.

Change to another pressure

Sometimes it becomes necessary to obtain non-standard pressure at the outlet. For example, having bought a stove for natural gas, I wanted to convert it to a balloon one. The usual way is to replace nozzles and low gas flow screws, but there is another way - to use a reducer for mbar 12. Such reducers are on sale, but they are rare and difficult to buy. You can change the normal one.

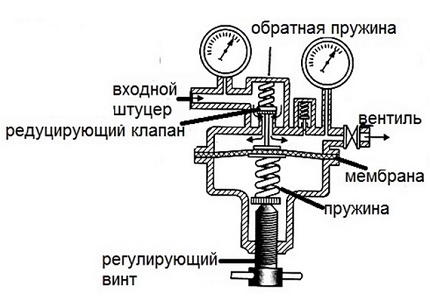

I will say right away that not any gearbox can be converted to any pressure. There are the following restrictions. The ratio of the areas of the diaphragm and the inlet, multiplied by the rocker arm, should be one and a half times greater than the ratio of the maximum inlet pressure to the outlet. Otherwise, the force developed by the membrane under gas pressure will not be enough to reliably close the inlet valve. In practice, it is usually easier not to carry out these calculations, but to adjust the gearbox experimentally.All the same, to carry out calculations, it must be disassembled in order to measure the area and the rocker arm.

For rework, it makes sense to buy a gearbox in which the mounting screws are accessible and not filled with paint. Alteration is reduced to a change in the elasticity of the spring. We disassemble the gearbox. If the pressure needs to be made less than it was, then we shorten the spring a little (by half a turn), if more pressure is needed, then we put a gasket between the gearbox housing and the spring. When laying the gasket, make sure not to block the hole in the housing. We collect, check the gas pressure at the outlet. Repeat until the desired pressure is obtained. If, after the next shortening, the pressure turned out to be less than necessary, then the spring can be stretched a little or a gasket can be placed.

If it turns out that the outlet pressure is too high, even in the absence of a spring, then the ratio described above is not observed. The selected reducer cannot be changed to the desired pressure.

When the elasticity is selected, you need to finally assemble the gearbox by applying silicone sealant between the bottom of the housing and the membrane.

The main causes of noise and buzz

Let's name the most common causes of noise and buzz of the boiler:

- oxygen saturation of water in the heating system;

- sediment on parts from water circulation (including in the heat exchanger);

- fan failure;

- decrease in gas pressure.

Oxygen saturation of water in the heating system

The noise or buzz of the device can be monotonous or spontaneous with crackling. With the first option, this happens even with new boilers. In this case, usually such sounds are produced by installations that are connected to a heating system with natural circulation. The reason may be the oversaturation of oxygen in the water in the pipes.Then, when the water is heated, small bubbles form, making noise. Noise does not pose a danger to the operation of the boiler. But a small nuisance is still present, as it creates discomfort with noise in the pipes of the rooms. In this case, the system can be reworked to a closed one. The process of changing the type of system consists in installing valves on the boiler and changing the expansion tank to a membrane one. You can choose a weather-sensitive automatic system. These measures will help extend the life of the boiler.

Sediment on parts from water circulation

But there are other reasons why the boiler is buzzing. Wines can be in the sediment, which is formed as a result of the circulation of water. It is not pre-filtered; when heated, after some time it forms scale on the parts. Their functions are weakening, extraneous noise from the work process appears. The heat exchanger loses its ability first. It heats up as a result of gas combustion, transferring heat. Scale is formed not only on the walls of pipes and radiators, but also on the entire system. The passage for water narrows, which provokes the appearance of steam. Such processes reduce the wear resistance of the equipment and the efficiency. There is a knocking sound. This means that the system needs to be descaled. Cleaning with special chemicals. After that, the boiler stops buzzing.

Fan failure

Another common reason for a noisy boiler is a fan failure. He is responsible for the cooling of the system, the removal of combustion products outside the room, and smoke exhaust.The boiler specialist will determine the cause of the fan failure. This may be the location above the main heating pad or the lack of lubrication. Often just a spare part clogged with dust. They inspect, clean this part, lubricate the bearings. If necessary, it is worth changing the fan so as not to buy a new boiler.

Gas pressure reduction

It happens that the boiler makes noise and buzzes due to a decrease in pressure. As a result, less water begins to circulate in the system, air pockets appear, the boiler overheats and makes noise. The level of thermal output of the device and its sections decreases. It is enough to adjust the pressure. Most boilers have a lever for such cases. You should know the optimal performance and regularly check the condition of the boiler. Normal pressure is 1.5-2 atmospheres. Often a knock is heard from the pipeline and radiators, which means air has entered the system and must be removed. If the pump itself is noisy, then a factory defect is not excluded.

If you carry out preventive cleaning of the heat exchanger from scale in time, adjust the gas supply to the system, pressure, then you can extend the life of your boiler. But remember, the exact cause of the noise in the boiler and the elimination of this problem can only be eliminated by a qualified specialist in heating systems.

Why is a gas reducer used?

In any vessel, the gas is under high pressure. This simplifies its transportation and operation. However, to the consumer, whether it be a stove, boiler, welding or gas-flame equipment, it must be supplied under low pressure. For such a transformation, there is a special mechanical device - a gas reducer.

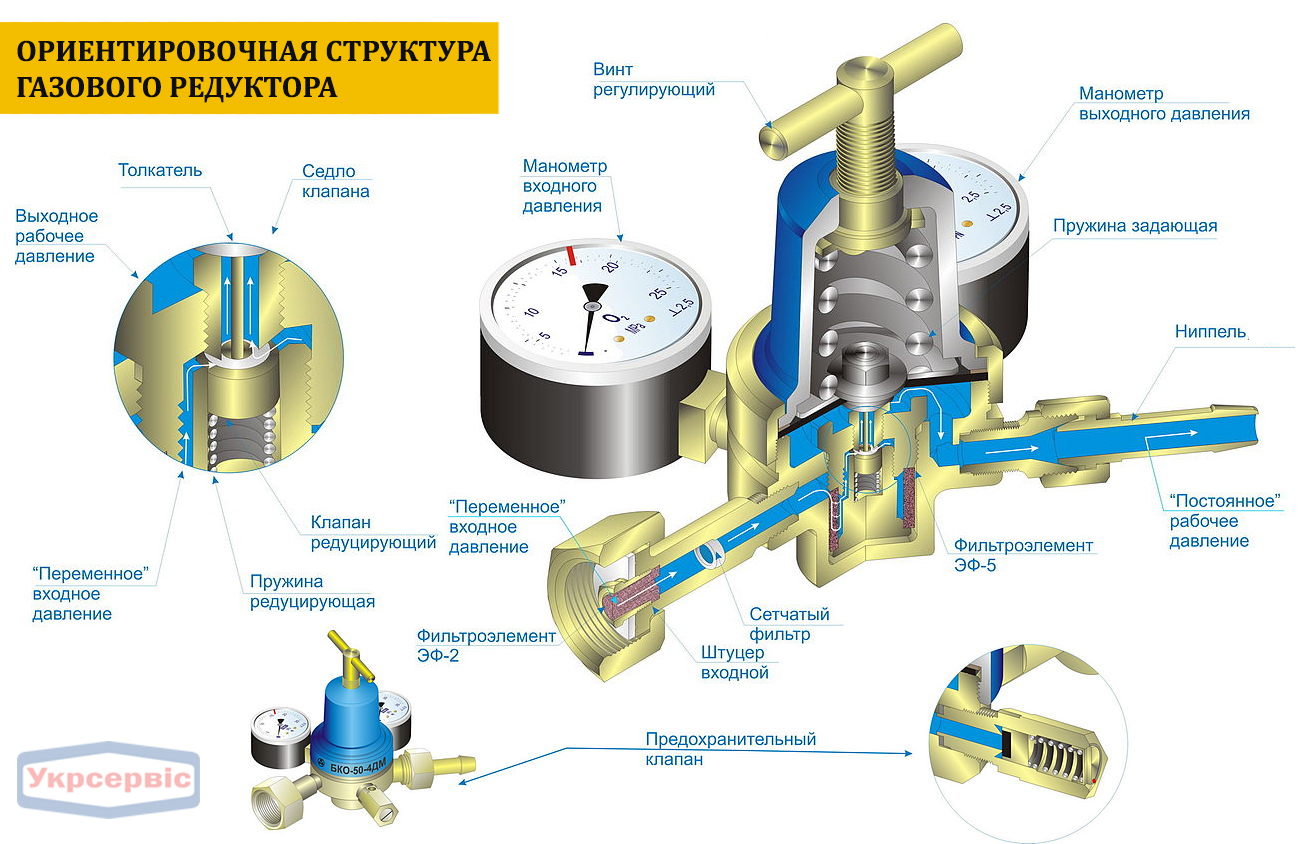

The figure shows a diagram of the internal device

Take, for example, a propane-butane mixture.In order to store it in a liquid state, a pressure of about 16 bar is created. At the same time, the consumer, in most cases, needs only a few tens of millibars. In addition, the outlet pressure must be maintained at a certain level during the emptying of the tank. It is for such purposes that a gearbox is needed. Any balloon installation is equipped with a similar device, without which its safe operation is impossible, regardless of whether it is used for industrial or domestic purposes. You can learn more about the operation of gas-cylinder equipment in the article: operation of cylinder installations in an autonomous gas supply system.

Why the gearbox on the gas cylinder is buzzing: what to do if the gas pressure regulator is noisy

The reducer is an obligatory component of the connection scheme for tanks with liquefied and compressed gas mixtures. They are installed on gas holders, single cylinders and cylinder installations to stabilize and bring to standard values the pressure of gas entering household equipment, welding torches and heaters.

It happens that during operation, the stable pressure device starts to make noise. We will tell you why the gearbox on the gas cylinder is buzzing, we will analyze for what reason the sound appears. We will show you how to eliminate violations in the operation of the device, which can be determined “by ear”.

The article presented by us describes in detail the types of gas pressure stabilizers and their design features. Methods for restoring full working capacity are given. Our recommendations will help home craftsmen cope with repairs on their own.

Kinds

Types of gearboxes differ in the following ways:

- View. Post model - for cylinders.Central - for pipelines.

- Working method.

- Connection type.

- Appearance.

- throughput potential.

- reduction level. 1 or 2 cameras.

There are household and industrial types. The second is equipped with manometers.

Since the value of the reducer for the gas tank is large (both safety and stable operation, etc.), the question of whether a reducer is needed for a gas cylinder disappears instantly.

And when choosing a device, one should take into account the correspondence of its dimensions to the needs of the equipment connected through it.

Cylinders with these devices are placed in the house or outside. In the first situation, the room should have the option of rapid ventilation in case of a dangerous situation.

Types of devices according to such a criterion as the passed gas:

- Acetylene. The gearbox is white.

- Hydrogen. Dark green color of the device.

- Oxygen. Blue gearbox.

- Propane-butane. Red gearbox.

- Methane. Also red.

Versions rated for other gases must not be used for liquefied hydrocarbon mixtures.

The characteristics of the device must have equal parameters with the cylinder and the apparatus on which it is mounted.

Of great importance is the competent setting of the power of the outgoing gas streams. When the parameters exceed the permissible values, automation in modern gas technology turns it off. If there is no such protection in the technique, an accident may occur.

There are such standards for connecting to a gas tank (threaded):

- W 21.8 x 1/14 - type cylinder DIN 477 / T1. In short - SP 21.8

- G - view pipe - cylinder. The number after the letter is the template diameter (measurement in inches).

- M - metric. The letter is followed by two numbers. The first is the diameter. The second is the thread distance (in mm).

A standard flexible hose can be used for connection.The fitting of the device is wetted with water. A screw clamp is used to fasten the connection.

A threaded adapter is used to connect bellows hoses. It is screwed in instead of the fitting. After that, a check takes place - gas is passed when the devices are not turned on. The gas flow valve is unscrewed and the control screw is turned out. The spring is extremely weakened. When the pressure gauge reflects a gradual development of pressure, the device is not suitable.

Having assembled the system, you need to arrange the flow of gas from the tank to the reducer. It is necessary to rotate the adjusting screw, assign the optimal pressure at the outlet section. The contact points are wetted with a soapy composition. This is a gas leak test.

Faults. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you are qualified. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembling, check the tightness and correct operation of the device. Tightness is checked by applying a soapy solution to all joints. The absence of bubbling indicates that there is no leak. But you should not deceive yourself. The tightness will need to be checked several more times (after a day, three, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials for you:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, radiators, pipes, floor heating, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve passes, then the leak may not occur in the gearbox itself, but somewhere further, for example, in a gas stove, since in this case in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and in the gas pipes, the pressure can reach the inlet. The gas gradually seeps through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, then the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure returns to normal. There are no signs of overpressure (flame blow-off). A malfunction can only be detected by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than the nominal value.

For repair, the gearbox must be disassembled. Only a collapsible gearbox with a spring can be repaired. Sealed gearboxes are unsuitable for repair.

in the picture, the membrane lies with the bottom side up.

in the picture, the membrane lies with the bottom side up.

Inspection will show if there are membrane defects or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect a new membrane with washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time.As a result, the outlet pressure becomes lower than the nominal one. This malfunction is easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber, mounted on a rocker, is pressed against the end of the tube. The valve may not close for the following reasons: Firstly, the mobility of the rocker arm is impaired. Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly, a piece of rubber has worn out and torn. It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight fit. The butt can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak between the membrane and the lower part of the housing. Troubleshooting is easy. It is necessary to lubricate the edge of the lower part of the housing where the membrane is attached with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent assembly, it is quite easy to break the tightness of the membrane. If you disassembled the gearbox, then when assembling, in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

Gas pressure reducing devices

The need to use reducers is due to the difference in gas pressure in the tanks intended for storage and metered supply of gas to the devices, and the operating parameters of the pressure required by these devices to perform their duties. When taking fuel from a closed container, the pressure of the gas mixture must be reduced by a dozen or more times.

Reducing the pressure of liquefied or compressed gas mixture to performance - the main work of gearboxes. In addition, they automatically maintain the pressure of the gas flow within the limits required for normal operation. They also protect the gas reservoir from kickback, which is possible when the flame is activated.

With the help of reducers, the gas pressure is regulated. They can be configured to supply a gas environment with pressure parameters acceptable for literally any type of domestic and industrial equipment. Despite the extensive list of functions, structurally all types of devices are simple, and even work on a similar principle.

Types of gas reducers

In order to understand why the gas cylinder began to make noise, you need to study its structure. We will analyze what types of gearboxes for adjusting and stabilizing the pressure of gas mixtures are used in everyday life.

Classification is carried out according to the following grouping criteria:

- Principle of operation. Reducers are direct and reverse action. The former reduce the pressure in the tank itself and in front of the pipe connected to the gas equipment. The second - first lower the pressure in the cylinder, then at the outlet of it.

- Appointment. There are network (C), balloon (B) and ramp (R) devices.Network mounted on gas supply pipelines, ramp - on cylinder installations, providing the supply of gaseous fuel in large volumes. For domestic conditions and one-time welding work, balloon models are suitable.

- Reduced gas type. Pressure stabilizing devices are installed on all types of gas cylinders. To accurately select the required gearbox, they are painted in the colors of the balloon. Propane tanks are red, oxygen tanks are blue, and acetylene tanks are white.

- Regulation scheme. The pressure operating parameters can be set and adjusted mechanically; such devices are single-stage (O) and two-stage (D). Gearboxes with pneumatic pressure selection are only available in single stage.

- Connection. Reducers are produced for installation on cylinders with combustible and non-combustible gases. Devices are connected to containers with oxygen with union nuts with a right-hand thread, to cylinders with a propane-butane mixture - with nuts with a left-hand thread. The acetylene reducer is connected using a clamp and a stop screw.

Let's analyze and study the design with the principle of operation of gas reducers traditionally used in everyday life to regulate the supply of a gas mixture to appliances.

Design features and principle of operation

Summer residents and owners of small private houses to supply gas to stoves, heaters and heating boilers use one of the most common gas reducer models in everyday life: NZGA RDSG-1-1.2, popularly called "frog", or its analogues.

Where applicable

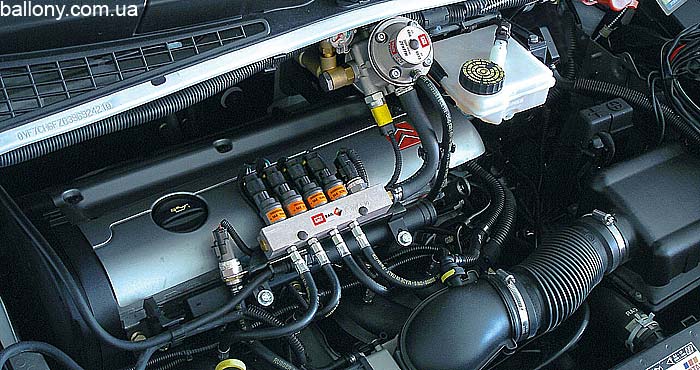

After purchasing and installing a gas reducer, it must be periodically serviced, and this is the inevitability that the owner of any gas-cylinder equipment will have to put up with, which, by the way, can be of the following purpose:

- HBO installations as part of autonomous gas supply to residential and non-residential premises;

- Automotive HBO;

- Free-standing gas cylinders for gas burners, stoves and other household equipment;

- Cylinders with various gaseous media for gas welding (oxygen, acetylene, propane);

- For medical purposes, gas-air mixtures for ventilators are stored in HBO. Such cylinders are also used by rescuers and firefighters.

These and other types of gas-balloon equipment, designed, for example, for storing inert gases needed in the chemical industry, are necessarily equipped with gas reducers, because without them the use of LPG would be impossible in principle.

Knocking in boilers and pumps

Boiler equipment used to equip heating systems can operate on various types of gaseous, liquid or solid fuels, or also on electricity. However, the operation of boilers of any type can be accompanied by certain side processes that often affect the heating system and can cause noise in it.

In particular, wood or coal solid fuels can lead to clogging of the chimney with a decrease in traction. The operation of boiler houses on liquid diesel fuel may be accompanied by its incomplete combustion and the accumulation of soot.All this often leads to noise and buzz in heating communications, and requires measures to eliminate these problems.

Noises may also occur due to malfunctions in the operation of pumps, valves or other devices and mechanisms located in the boiler room or in the basement. The solution to the problem in such situations is to repair the faulty elements or replace them.

In general, any specific situation with the occurrence of noise in the heating system requires an individual approach, and there cannot be universal methods here. In some cases, identifying and eliminating faults on your own can be very difficult, and in this situation, the only way out of the situation is to contact qualified specialists.

Why the gearbox on the gas cylinder is buzzing: what to do if the gas pressure regulator is noisy

The reducer is an obligatory component of the connection scheme for tanks with liquefied and compressed gas mixtures. They are installed on gas holders, single cylinders and cylinder installations to stabilize and bring to standard values the pressure of gas entering household equipment, welding torches and heaters.

It happens that during operation, the stable pressure device starts to make noise. We will tell you why the gearbox on the gas cylinder is buzzing, we will analyze for what reason the sound appears. We will show you how to eliminate violations in the operation of the device, which can be determined “by ear”.

The article presented by us describes in detail the types of gas pressure stabilizers and their design features. Methods for restoring full working capacity are given. Our recommendations will help home craftsmen cope with repairs on their own.

Replacing HBO filters 4th generation. — Chevrolet Lacetti, 1.8 liter, 2008 year on DRIVE2

The deadline has come, and the expense has increased ... I decided to change it on my own, since this service costs 180 UAH at the service station. For what such money is not clear. There is one truth but - if your HBO is under warranty, self-replacement of filters will deprive you of it. I will describe the procedure in detail, maybe it will be useful to someone. Reducer Tomasetto Alaska. On other gearboxes, the filter can be combined with a solenoid valve into one unit and stand separately. Also, a fine filter can be of a more complex design - for example, sedimentation filters.

We buy in the store (I took at the intersection of Kuibyshev St. and Yugoslavskaya St.) two filters and seals - 90 UAH. We drive the car into the garage. Although you can and on the street. Even better outside. We climb into the trunk, open the lid on the cylinder, look for a valve. Maybe one, or maybe two (one for refueling, one for delivery). Shut off the gas supply to the reducer.

The arrow shows the shut-off valve

We climb under the hood. You can immediately replace the fine filter, it is usually easily accessible. We unscrew the clamps, remove the old one, put the new one. There is an arrow on the filter so as not to put it back to front.

Then we climb to the gearbox. I have it in my own ... opera, I had to build such a crutch to unscrew the filter cover.

The filter on the gearbox is right here, under the cover.

We loosen the bolts, release the pressure. There is quite a lot of gas in the line, at least for me. With a blocked cylinder, a car on gas can still drive a couple of kilometers. Therefore, it is better to adjust the replacement of the filter to an empty cylinder, or before disassembly, start up and let the engine run out of gas in the line.

I just bled by loosening the filter cover bolts (open

How does a geyser work?

To understand whether there is any threat from extraneous sounds emitted by the speaker, you need to consider all possible causes. If the column is old, then there will likely be more options. In addition, each model of water heating equipment may have its own characteristics. But still, the principle of their work is similar. Therefore, first you need to figure out how the gas column works and whether it is possible to fix the problem yourself.

Any modern water heater consists of a rectangular box and a supply of gas and water to it. Cold water enters the device and passes through the radiator compartment, where it is heated with a special burner.

As soon as you open a hot tap, a valve opens in the device, which is designed to supply gas to the system. It enters the combustion chamber through a special ignition burner and the process of direct heating of the heat exchange element through which the water passes begins.

Carbon monoxide, which is produced after the combustion of natural gas, is discharged to the street through the chimney. Withdrawal is carried out naturally or forcibly (turbocharged speakers).

To determine and eliminate the cause of a malfunction in a geyser, it is necessary to study its structure and the principle of operation of all elements of the device

In cases where there is no chimney, and its construction is not possible, a turbocharged type of water heater is used. The removal of combustion products is carried out using an additional fan installed in the device. All exhaust gases are forcibly removed to the street through a coaxial pipe.The design of this chimney also provides for the intake of fresh air necessary for combustion from the outside. Such water heater models are made with a closed combustion chamber.

In all geysers, emergency shutdown systems are provided. As soon as the system detects some kind of malfunction, the water heater will stop working.

Automatic protection works under the following conditions:

- weak draft in the ventilation passage or chimney;

- weak fire in the burner, which heats the heat exchanger;

- when the water pressure decreases, the system automatically shuts off;

- with excessive heating of the copper heat exchanger.

Let's take a closer look at the causes of malfunctions in the operation of a gas water heater.

Conclusions and useful video on the topic

Video #1 The design of a simple gearbox for five-liter cylinders:

Video #2 An example of the repair of common gearboxes of the BKO series:

The selection of a reducer for a liquefied gas system must be made taking into account the required pressure parameters and the throughput. Simple maintenance and timely elimination of minor faults will allow the device to perform its functions for a long time and with high quality.

Please write comments in the box below. Tell us about the choice of the reducer that you put on the gas cylinder, write about the rules for operating the device. Ask questions, share your opinion and photos on the topic of the article.

Conclusions and useful video on the topic

Below we offer you instructions on how to fix two common causes of noise.

The first video shows the step by step process of replacing the gasket, which allows you to get rid of the strong noise accompanied by vibration.

The second video instruction tells in detail how to bleed air from the heating battery. This process not only helps to improve the heat transfer of the radiator, but also eliminates humming sounds.

Before starting repairs, you need to find out why water, sewer or heating pipes are noisy. Having established the cause of the sounds that have appeared, you can easily deal with the problem with your own hands or with the help of a master plumber.

Have something to add, or have questions about the topic? Please leave comments on the publication and participate in discussions. The contact form is in the bottom block.