- Troubleshooting new hardware

- Column microswitch failure

- Flow sensor malfunction

- Displacement of the working candle

- Incorrect operation of the ignition retarder

- Leakage in the system

- How to avoid subsequent breakdowns after repair

- Attenuation of the boiler due to causes within the system and their elimination

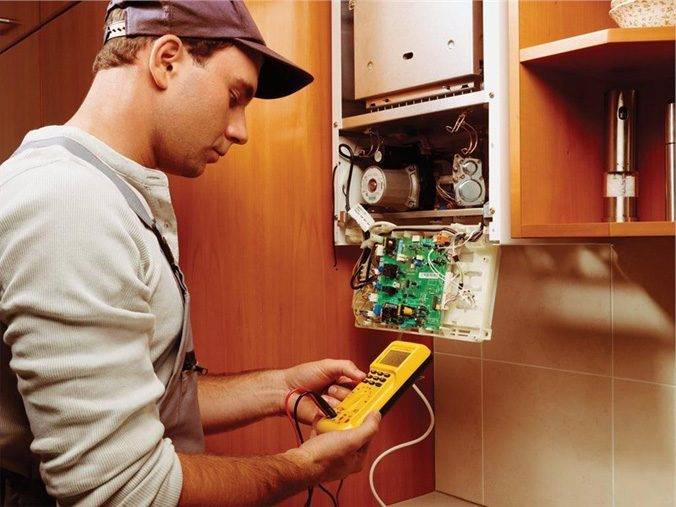

- Problems with the control unit

- Incorrectly installed thermostat

- Electric boiler goes out

- Why the gas boiler does not turn on: the main reasons

- Cases by models of certain brands

- Why does the burner go out at all?

- Additional factors

- Reasons for private switching on and off of a gas boiler

- Boiler malfunctions

Troubleshooting new hardware

New equipment can also cause various problems. Most often, they manifest themselves in the operation of the flow sensor, in the operation of a candle, or in the power system. Let's take a closer look at these issues.

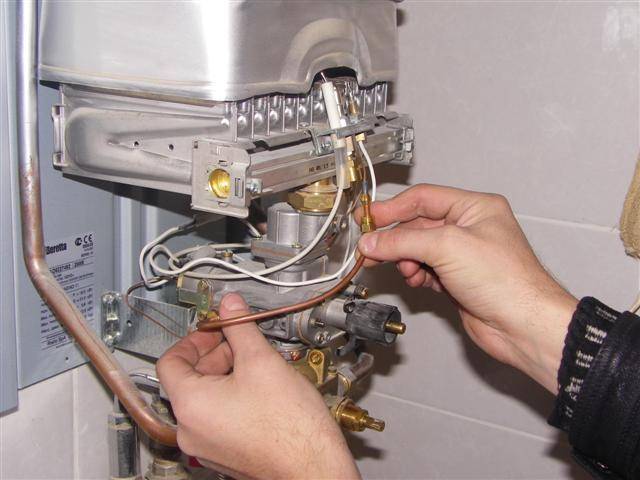

Column microswitch failure

Often, the problem of the occurrence of a loud pop during ignition becomes an insufficient discharge of the batteries, which provokes the inability to instantly ignite the gas-air mixture.

The power supply is connected to the control unit through special microswitches, which are responsible for the occurrence of a signal to activate the ignition when the DHW tap is opened. If the signal arrives out of time, this causes the problem. Such a malfunction occurs most often due to oxidized contacts. The microswitch cannot be repaired and will need to be replaced.

If the microswitch breaks down, repairs will not be possible, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem of cotton is in the duct sensor. It is located in the input circuit. A signal is sent to the controller of the control unit about the presence of liquid in the pipe. The data instantly activates the ignition system. Intensive use of this element forms an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often made in a non-separable design, therefore, in the event of a problem, they cannot be repaired, they must be replaced.

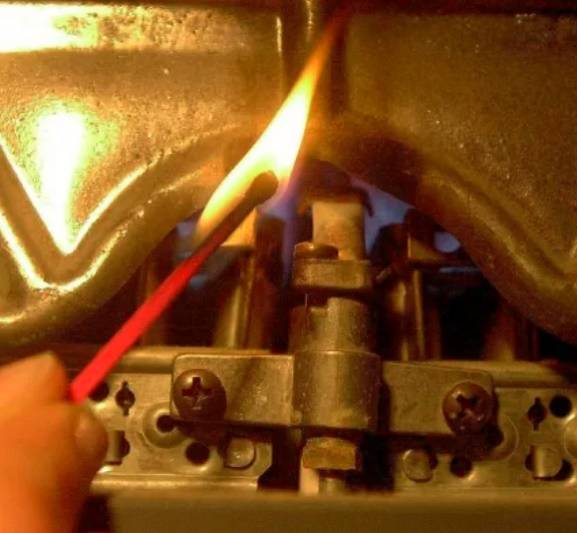

Displacement of the working candle

The problem may lie in the operation of the candle. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they are able to last for a long time. Element failures are rare, but do happen.

Most often there is a displacement of the ignition device relative to the nominal position. It can occur as a result of numerous heating and cooling. Such processes are associated with a change in the size of individual structural elements. As a result of adjusting the position of the candle, the spark parameters become normal, extraneous noises completely disappear.

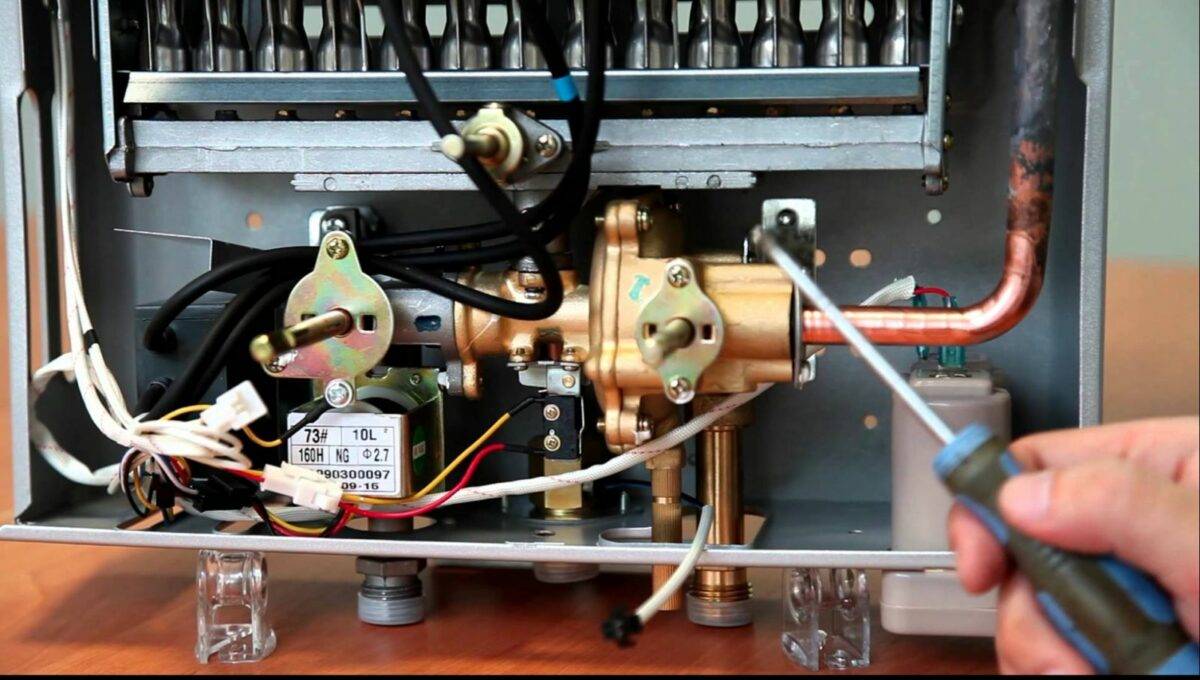

Incorrect operation of the ignition retarder

A rare breakdown is the incorrect operation of the ignition retarder. When disassembling the column, you need to remove the water regulator. On its cover there is a bypass hole, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when you shake the lid, you hear the sound of a moving ball, then you should not further manipulate this part. If there is no knock, then you can stir the ball with a thin copper or aluminum wire through the through hole, which is located in the regulator cover.

Most often, the retarder is a ball of metal or plastic that covers part of the bypass in the water regulator. In most dispenser designs, this retarder is located in the boss of the water regulator cap.

In extreme cases, you will have to resort to the element parsing procedure. It must be said right away that the outer screw does not affect the position of the ball in any way.

The inner screw must be removed very carefully. You should first remember its original position, as well as clearly determine the number of revolutions by which this screw is screwed

This will allow you to save the required location of the element (ball) during subsequent assembly.

After repair work, be sure to check all connections to completely eliminate leakage of both water and gas. All connections must be treated with a sealant, ensuring tightness. After that, you can put the casing back in place and use the column in the usual way.

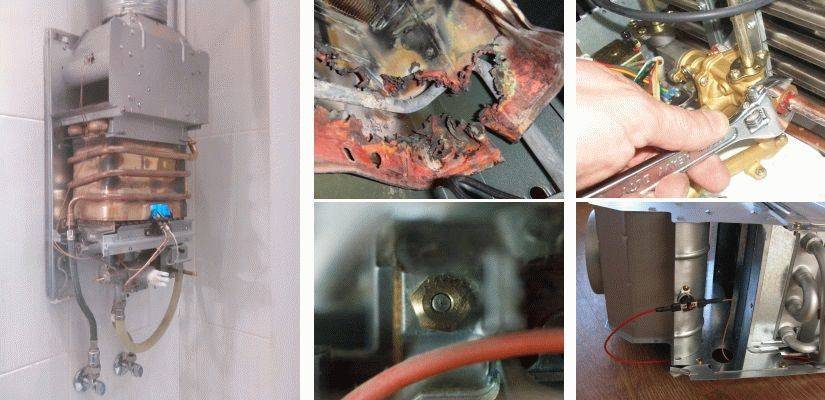

Leakage in the system

Logically, if the station does not turn off, it means that there is not enough water in the tank.There are two options: the pump does not have the ability to pump water, or the water leaves the system. In the second case, you need to check all pipes and taps, as well as the drain tank. If the pipes are metal, leakage may occur if the metal is rusted or corroded. Here you need to replace the segment that has become unusable. If it flows at the place of twisting of parts, it is necessary to use winding. Well, with a leaking tap, every man can deal with it.

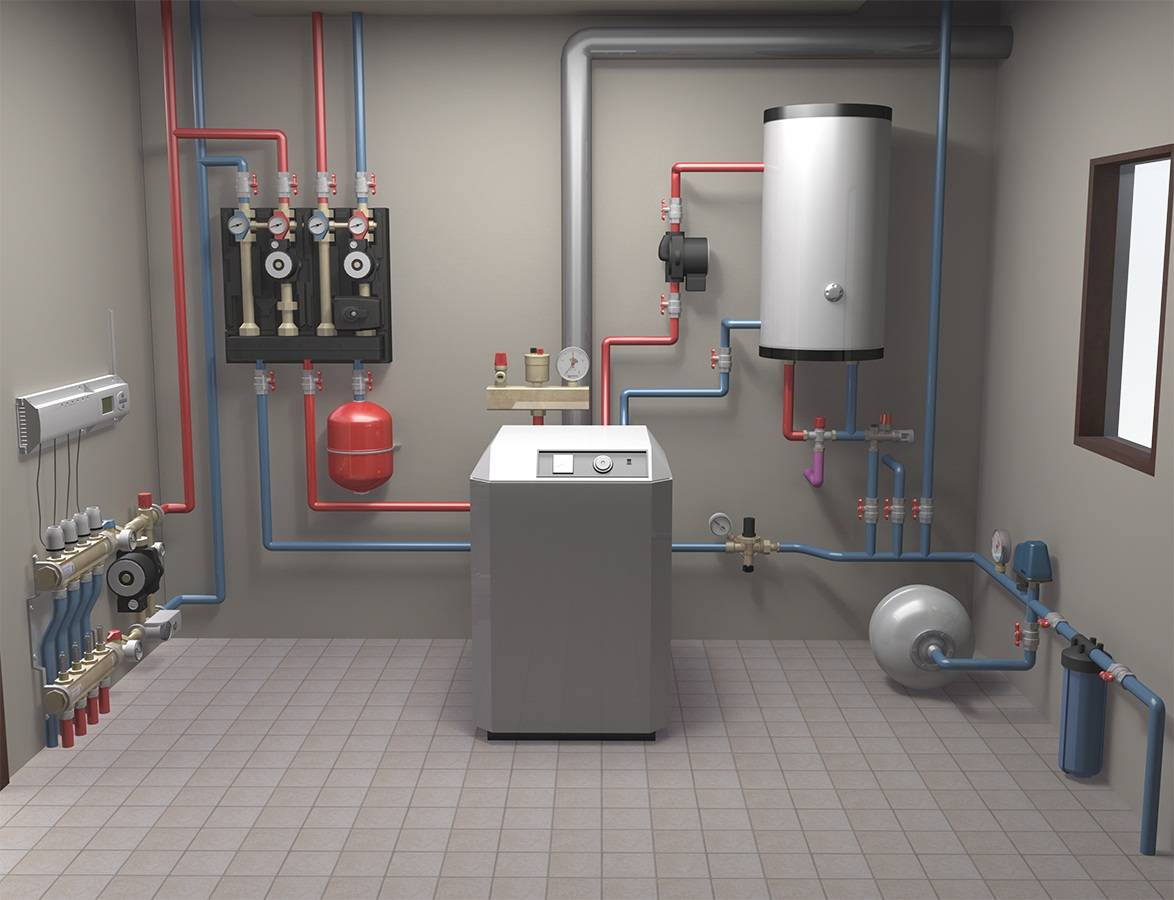

Plumbing scheme for the house. During installation, it should be taken into account that there is free access to all elements

It has become fashionable to hide pipes in the walls. But even plastic pipes can leak on twists. Detecting a water leak behind a wall is very difficult. In addition, in private homes it often happens that pipes are damaged by freezing, which can also cause leakage. To avoid this, insulate pipes that are on the street.

How to avoid subsequent breakdowns after repair

Sometimes it is more expedient to buy a new, modern refrigerator than to spend money on repairing a cheap, but old one. Here is what the masters advise on how to extend the life of the refrigerator:

instructions for technology - a useful document, not waste paper, as they treat it. Before turning on the refrigerator, study the features of the device. Unfortunately, most take up the instructions only after something is out of order;

when installing the unit, it is necessary to adhere to the level. It happens that the floor in the selected place has irregularities

Then a stand is placed under the refrigerator;

Where the technology is located is also important. There should be no sinks, stoves and heat sources (batteries, microwave ovens) nearby. Close to the wall is also better not to put

For normal air circulation and, accordingly, normal operation, at least 3 - 5 cm is required;

the refrigerator should be connected to a separate, not a common outlet. This is a large household appliance that consumes a lot of light, so it must have a separate power source;

do not leave the door open for a long time. Because of this, increased loads fall on the motor. It is easier with modern models of refrigerators - if the door is open for a long time, they beep;

if the refrigerator is without the “No Frost” function, then it will have to be defrosted every month;

The rubber seal in the door area must be clean. Pollution will lead to depressurization;

Do not put hot food in the refrigerator;

do not clog departments with products "to the eyeballs". Air should circulate freely in the chambers.

Close to the wall is also better not to put. For normal air circulation and, accordingly, normal operation, at least 3 - 5 cm is required;

the refrigerator should be connected to a separate, not a common outlet. This is a large household appliance that consumes a lot of light, so it must have a separate power source;

do not leave the door open for a long time. Because of this, increased loads fall on the motor. It is easier with modern models of refrigerators - if the door is open for a long time, they beep;

if the refrigerator is without the “No Frost” function, then it will have to be defrosted every month;

The rubber seal in the door area must be clean. Pollution will lead to depressurization;

Do not put hot food in the refrigerator;

do not clog departments with products "to the eyeballs".Air should circulate freely in the chambers.

These are simple guidelines, but you should always follow them. And then the refrigerator will please with a long service life and will not cause difficulties in the course of work.

There are several reasons why the refrigerator turns on and turns off after a while. Some are diagnosed on their own and eliminated without much difficulty. In other situations, you need to replace the part with a new one or even have to buy a new refrigerator. To avoid these troubles, before using the equipment, study the instructions.

Attenuation of the boiler due to causes within the system and their elimination

The most common cause of boiler decay is a lack of oxygen for the burner. Such a malfunction is inherent in economy class models, which are bought more often than others. Expensive boilers have a special exhaust device that multiplies the air flow, maintaining combustion in all weather and interior conditions.

Lack of oxygen - the appearance of soot and the attenuation of the gas burner. The fire goes out because the missing air flows are captured from all openings, the flame is displaced, the temperature of the thermocouple drops and the protection turns off the burner, as if the temperature had reached its maximum value. Other reasons for the attenuation of the boiler burner:

- In gas boilers with turbo draft, a built-in electric fan helps to pump air. If it does not work correctly, the burner may also go out. Diagnosing the fan is simple - when it is off, it continues to make noise.

- A non-working draft sensor is another reason for the attenuation of the boiler. It should turn on if the temperature in the smoke catcher rises from hot steam, which for some reason did not enter the chimney.

- The burner does not ignite or burns poorly - clogging of the nozzles. Clean them with a brush or wire of the appropriate diameter.

- If air enters the boiler's gas pipeline, the operation of the boiler is blocked and an error is displayed on the display. The reason why the gas boiler goes out is easily eliminated - you need to start the boiler again, first unlocking it according to the instructions.

- During the operation of the boiler, the gap in the igniter may be broken or contact with the wire may be broken, or the air filter on the air duct may become clogged. It is almost impossible to restore the gap with your own hands - you need the help of a gasman. But you can clean the filter and check the reliability of the connection of the current-carrying conductor yourself.

- The gas burner may not go out immediately, but after a few minutes. The reason most often lies in the contamination of the ionization electrode. Also, the correct gap could be broken in the electrode, or the connecting wire could fall off from constant heating.

- The flame breaks away from the burner and dies out. Usually at the same time the nozzle starts to make noise and whistle. The malfunction is eliminated by adjusting the gas pressure on the ignition electrode. The flame can come off if the draft is very strong - this phenomenon occurs with strong supply and exhaust ventilation.

- If the boiler is installed in a private house, then flame extinction may occur if the chimney is brought out very high.

- Spontaneous shutdown of the boiler, accompanied by loud noises, occurs due to a non-working pump or fan (explanation above). A non-working thermostat causes the water to boil, followed by the flame breaking off.

Diagnostics is a sure way to understand the cause of the attenuation of a gas boiler.

If the voltage in the network fluctuates and drops, then the boiler burner may go out - the automation is triggered, which recognizes the low voltage. After the power is restored to normal, the protection turns on the boiler again, so for the most part no one notices such cases.

And the very obvious reason for the attenuation of the burner is the low gas pressure in the line. This trouble can happen not only due to breakdowns in the external gas pipeline, but also due to internal malfunctions.

- Fault in the gas meter. Check visually whether the mechanism works, whether the numbers jump on the scoreboard. Even if this is the case, the malfunction may be delayed - and often the meter is noisy.

- Gas workers require the installation of monitoring equipment - gas leakage sensors and temperature sensors. They monitor compliance with the regimes around the boiler. The operation of the sensors leads to the shutdown of the boiler.

- Connections in the gas pipeline are leaking. A gas leak is a low pressure, so the automation immediately reacts and the boiler turns off. If there is no leak sensor, then this type of malfunction is determined by the smell of gas. To identify a malfunction and fix it, check the joints on the highway by applying soap suds - if there is a leak, the foam will bubble.

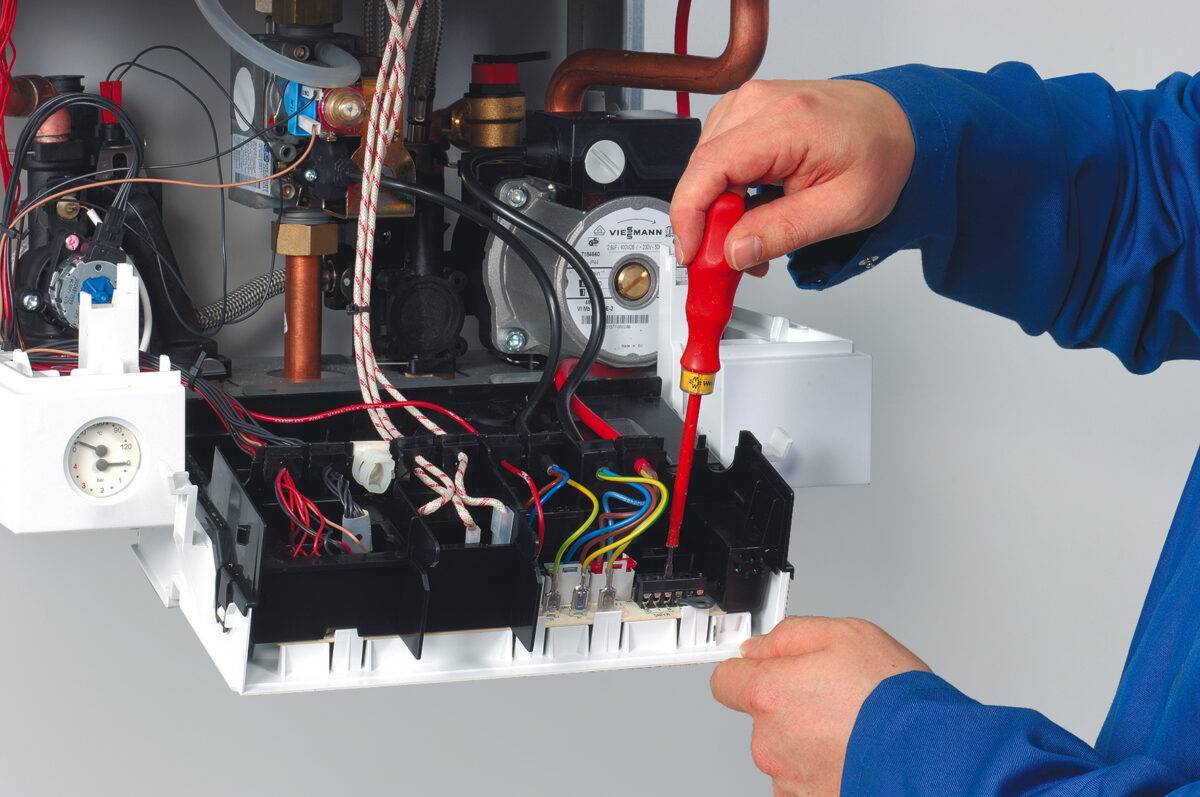

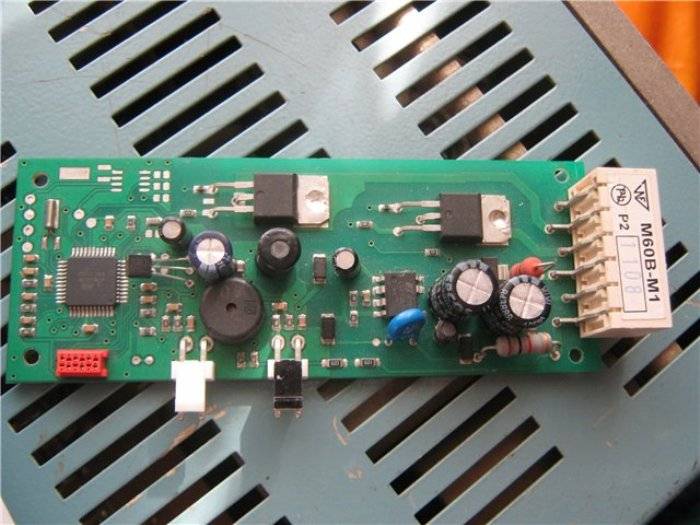

Problems with the control unit

If you have a modern refrigerator at home, then check its electronic board (control unit). She is responsible for turning the refrigerator on and off. When it fails, commands to stop and resume work come randomly.

The refrigerator control board is responsible for turning off and on the device.

Unfortunately, it is not possible to diagnose such a breakdown without specialized equipment. The unit can be repaired by reprogramming, or its complete replacement is required. Both that, and another, can be carried out only in repair shops.

Incorrectly installed thermostat

In practice, a couple of types of temperature controllers are used: built-in and remote type. The first option does not involve transfer. Remote models require proper installation. Installation should be carried out in the most rapidly cooled room, which allows you to organize the operation of the heating system in normal mode. Installation prohibited:

- in basements;

- near window and door openings;

- next to household appliances;

- very close to the surface of the ceiling, floor;

- under direct sunlight.

- Not recommended for kitchens

Particular attention is paid to proper connection in accordance with the schemes recommended by manufacturers, according to the technical characteristics of the device.

Electric boiler goes out

The easiest way to identify the cause of the attenuation of the flame in a gas boiler is if it is of a volatile type. Most often, the gas in such units stops burning due to power outages or power surges. The burner ignition electrodes and circulation pumps need a constant power supply. These are classic long-burning wood-fired boilers for the home that can do without connecting to a 220 V network. This will not work with volatile gas boilers.

We check the connection of all electrical circuits

Due to problems with electricity in a gas boiler:

-

The settings are reset or incorrectly set;

-

The remote control is turned off;

-

The fire goes out, since the electric igniter does not receive current;

-

The sensors are de-energized, due to which the automation forcibly extinguishes the torch.

To get rid of these problems, the boiler must be equipped with a stabilizer and an uninterruptible power supply. Eliminate power surges and accidents in the village electrical network in a state of energy only. At home, you can only install additional electrical equipment for safety net.

UPS for gas boiler

The stabilizer levels the fluctuations in the current parameters, and the uninterruptible power supply provides power to the heat generator in question when the light is completely turned off. But when choosing them, you need to look so that “pure sine” is written in the marking. Only such equipment is intended for gas boilers. Conventional rectifiers and UPS for computers will not work here.

Why the gas boiler does not turn on: the main reasons

Gas-fired heating equipment comes in different models:

- parapet;

- chimney, having an open type combustion chamber;

- turbocharged.

Equipment failure occurs for several reasons.

If the gas boiler dies out, there may be insufficient gas pressure in the pipes due to a malfunction in the distribution network. More often the pressure drops if the meter is faulty. There is no gas flow through it. A breakdown is signaled by sounds uncharacteristic for this part, as well as significantly low pressure inside the boiler.

Modern units are usually equipped with displays that display an error code determined by the self-diagnosis system, for example, in the Valliant, Baksi, Ferroli models. If there is no message on the display with an error code message, you will have to look for a breakdown yourself.

The main malfunctions of gas equipment:

- the boiler does not turn on or off;

- the flame in the burner is extinguished;

- no temperature rises.

Cases by models of certain brands

The following are common causes of various noises in well-known brands of boilers.

First. Navien. If the error is not reflected on the display of the device, but the equipment is very buzzing and noisy, then you immediately need to quickly figure out why the Navien gas boiler is making noise?

The reasons:

- Blockages in the form of scale.

- Problems with the thermal carrier.

Actions:

- The device is disassembled.

- The heat exchanger is cleaned or replaced.

- Valves are checked for maximum openness.

- The water temperature is dropping.

Second. Beret. Usually in their apparatus there is an atmospheric burner. Then the noise is very low. But if they rise, then in the Beret units, the reasons for this are most often:

- Poor heat transfer in the heat exchanger. This ends the use of DHW. Scale builds up in the heat exchanger.

- Incorrectly selected pipes.

Third. Conord. These models are most often noisy under increased loads, for example, in cold weather. According to the documents, they are one power limit, in practice - less. If the documentation indicates an indicator of 13 mbar, then in reality it is 10 mbar. Therefore, you do not need to tune the device to the maximum.

Fourth. Baksi. Most often they make a lot of noise during the heating function, with DHW - the noise is weak. Actions: bypass check, valve cleaning and adjustment. Usually this work is carried out by service employees.

Fifth. AOGV. Their users often complain about the whistle. Once ignited, it becomes stronger. Disappears after shutdown. For example, if the AOGV-17.4 model whistles, the reasons for this are:

- Scale accumulations.

- Clogged inlet filter.

Sixth. Vaillant.Often these boilers hum after lighting up and turning off the fire (the pump is on). Without the heating function, there is no noise. The reasons:

- Clogged strainer. The solution is cleaning.

- Problems with the valve on the bypass line. The solution is valve adjustment.

Seventh. Ariston. The reasons for the noise in the boilers of this company lie in the poor circulation of the heat carrier.

It is necessary to remove and thoroughly clean the heat exchanger, blow it with a compressor.

Eighth. Arderia. When the Arderia gas boiler makes noise, usually the reason lies in the erroneous setting of the pump. If it is not possible to set up the pump, it is replaced under warranty.

Why does the burner go out at all?

- the draft in the chimney has decreased or disappeared;

- the gas pressure in the supply line has dropped;

- the flame in the burner went out.

Moreover, these processes can occur both as a result of internal breakdown, and due to the influence of external factors.

If we consider floor models (manufacturers: Danko, Aton, ROSS, Zhitomir), then they have a primitive internal design. Therefore, if you look into them, there is nothing special to break into them. Attenuation in this case occurs most often due to strong winds on the street or other external factors.

Floor-standing gas boilers are simple in design, so it will not be so difficult to eliminate the cause of their attenuation

But wall-mounted gas boilers in their design already resemble autonomous mini-boiler room, and therefore there may be more options for stopping the operation of a gas boiler:

- the circulation of the coolant was interrupted or did not start after the repair of the circuit (the flow sensor reacts);

- the air supply has decreased / stopped (the pressure switch is activated);

- voltage fluctuations occur;

- power outage.

If the mounted heat generator goes out, it is not easy to restore its operation. However, some malfunctions are still quite possible to fix on their own. Find out how to do this below.

Additional factors

Hidden leaks in the water supply pipe system can also cause unstable operation of the complex. The situation is complicated, since damage to the pipe is also possible underground. It is quite difficult to detect such a breakdown.

If the question arises of how often the pumping station should be turned on, then you should pay attention to the calculations of water consumption. It is possible that your water demand has increased and you need to consider installing another tank in parallel or replacing it with a larger receiver.

It does not hurt to take into account a few more factors:

- The check valve is clogged - the water flow does not stop, it leaves the system, the pressure decreases, and the pump constantly turns on. There are two ways out: remove and clean the valve or replace it with a new one.

- The capacitor in the terminal box has failed - in this case, the pump will not start at all. The part is checked by a tester and changed if necessary.

- The spool is faulty - the air from the tank escapes into the atmosphere and its pressure drops, which leads to the rapid operation of the pump. To eliminate the malfunction, the accumulator must be dismantled, the membrane removed, and the nipple replaced.

Reasons for private switching on and off of a gas boiler

It may happen that you just installed a new gas heating boiler at home, just set it up and put it into operation, and then it starts turning on and off every five minutes.In fact, he should regulate his work on his own, but turning off and on on his own too often indicates that something is wrong here. In addition, this behavior of the heating equipment adversely affects the length of the operating period, as the working parts wear out and the boiler fails.

There are several reasons why the heating boiler often turns on. If you do not have enough experience, you should call a specialist for help, since blue fuel does not tolerate a careless attitude. So, the main factors provoking frequent switching off and on of gas heating equipment:

- Boiler selected incorrectly. Its power is designed for large rooms, and it was installed to heat a small room.

- Errors when installing the circulation pump.

- Temperature range set incorrectly.

- The absence of a thermostat in the room, the boiler operation is regulated only by the temperature of the coolant.

The problem is not complex, but in some cases the solution is to replace the heater.

Problems with ignition piezo in a gas boiler

Boiler malfunctions

Typical problems with the operation of heating equipment:

- malfunction of the built-in pump;

- the heat exchanger is clogged;

- three-way valve does not work.

If the boiler is working, the radiators are cold, experts recommend, first of all, to assess the technical condition of the main heating element. More specifically, to establish whether the built-in device works. This detail is an invariable attribute of modern equipment and is designed to increase the efficiency of its work.Very often, after a long period of inactivity in the summer, the pump may become clogged or covered with a layer of limescale. As a result, it is untimely to remove the heated coolant from the heat exchanger. The boiler is boiling, and the batteries are cold.

Experts do not recommend using ordinary tap water as a coolant, as it is hard. Dissolved salts, when the temperature of the coolant rises, settle on the heat exchanger. As a result, the following problem arises: the boiler is working, and the batteries are slightly warm. Scale reduces the thermal conductivity of the heat exchanger, so the water in the circuit does not heat up, although the heating element is constantly operating with excessive consumption of energy. You can fix the problem by changing the coolant and cleaning the heat exchanger. How to clean the heat exchanger correctly, the video will help you figure it out:

Double-circuit boiler heats water, but does not heat batteries

Here you need to pay attention to the serviceability of the three-way electric valve. It is responsible for switching the bypass from heating circuit service mode to DHW and CO mode