- Cylinder safety rules

- How to thaw gas when it freezes?

- Car and HBO

- Why is there a "splash" of water in the container?

- Safety Compliance

- Safety Compliance

- Actions in case of freezing of the container

- Where does the ice on a propane tank come from?

- Types of insulation

- Achieving security

- What condenses in a gas cylinder?

- Errors when installing ceilings

- Why does the gearbox freeze on carbon dioxide?

- Safety measures to become a habit when using city gas

- The frequency of draining condensate from the cylinder

- Option # 1 - refueling at a specialized substation

- Option # 2 - refueling at the gas filling station

- A little about tent insulation

- Where does frost come from

Cylinder safety rules

Gas cylinders are extremely dangerous. Every year, dozens and hundreds of household gas cylinders explode, destroying housing and killing people, and in most cases the reason for this is a violation of the rules for their operation.

Filling gas legally at a specialized substation, along with a full cylinder, you will receive a reminder on its safe transportation, storage and use.Among other things, it is forbidden to install cylinders closer than half a meter from a gas stove or a meter from a stove, heater or battery.

Do not allow the cylinders to heat up - from any devices or in the sun - this is fraught with their rupture. Also, you can not store them in a tightly closed cabinet without ventilation at the bottom of the doors: in the event of a leak, the gas will fill the cabinet, and in combination with oxygen from the air, the mixture becomes extremely explosive. The slightest spark or electric discharge is enough, and there will be an explosion.

You should not use a winter gas mixture with a high propane content in the summer: it will evaporate too actively, and the cylinder may swell or even burst from excessive pressure - and this is with 3 mm thick steel walls.

It is also forbidden to use swollen, dented or damaged cylinders: there is no guarantee that they are airtight and can withstand gas pressures up to 8 bar.

How to thaw gas when it freezes?

Consider the last questions: what to do if the gas is already frozen and how is it allowed to heat the gas cylinder in winter?

If you notice that the body of the vessels is covered with frost, the supply of fuel to the burners is difficult or completely stopped, you can try to warm the cylinder.

In no case should open flame sources be used - bring lighters, burners, blowtorches, a burning torch, etc. to the body. As a result, an explosion may occur with unpleasant consequences.

The result of the "meeting" of a gas cylinder with an open fire. Rapid heating causes an increase in pressure, expansion and a powerful explosion that breaks the metal shell

The result of the "meeting" of a gas cylinder with an open fire. Rapid heating causes an increase in pressure, expansion and a powerful explosion that breaks the metal shell

Methods that can be used for disposable, emergency heating:

- Pour the vessel with hot water or act with hot steam.The procedure must be performed slowly, with the valve closed. At the end, the gearbox should be blown out to remove moisture.

- Use a chemical or salt heating pad, as happens in field conditions. Chemical heating pads are disposable and last 6-7 hours. Salt - reusable, but the heating temperature is up to +50 ° C, while the recommended one is +40 ° C.

- Temporary transfer of the vessel to a warm room. Heating will be more effective if the cylinder is briefly placed near the radiator.

These measures will not save the fuel source from subsequent freezing, but they can help out in an emergency.

Car and HBO

Gas systems are gaining great popularity among motorists. This is due to their economic benefits when compared with the use of gasoline.

However, such equipment often explodes. And the most common causes of a gas cylinder explosion in a car are:

- Weak tightness. This can cause fuel leaks and fires. As a rule, powerful blows violate the tightness, for example, in an accident.

- Corrosion and microscopic cracks.

- Overheat. It leads to expansion of the gas, a powerful increase in pressure in the cylinder and subsequent gloomy results.

- Rapid temperature fluctuations. A typical example of this - the driver operated the car in the cold, then put it in a warm garage, and the vessel was under a powerful strong thermal effect.

- Filling the balloon "to the eyeballs".

- Installation of low-quality technology and illiterate system setup. This is purely an error of service workers.

To avoid explosions, many drivers today install modern LPG, given its advantages:

- Corrosion resistance. There are no tanks and pipes made of metal in the system.

- The presence of a multivalve.It disables refilling if the vessel is 80% full.

- The system works without problems in the temperature range of -40 - +650 degrees.

Why is there a "splash" of water in the container?

This can be heard in winter. Know that this is not water, but the butane component of SPBT. At the slightest frost, butane ceases to be converted into a vaporous fraction. It is she who "splashes" in the form of a liquid inside.

Butane component of SPBT in a gas cylinder

In the warm season, this problem does not arise: almost the entire propane-butane mixture is used. In order to avoid this in cold weather, it is recommended, when filling the tank, to ask the refueller about the availability of a passport for the used SPBT. This document must contain information that the mixture contains at least 80 percent propane, which passes from liquid to vapor during cold weather. If you use such a dressing, then there should be no problems.

Safety Compliance

It is very important to follow the basic safety rules in order to prevent tragic consequences. Working with gas equipment is extremely dangerous, so it is not recommended to connect or change the structural elements of the equipment yourself

If gas equipment is used incorrectly, a cylinder explosion can occur, which in most cases leads to a severe fire with tragic consequences.

If gas equipment is used incorrectly, a cylinder explosion can occur, which in most cases leads to a severe fire with tragic consequences.

Before connecting the cylinder to the stove or taking any action to repair it, it is best to contact a gas equipment specialist. If gas installations are mishandled or operating conditions are violated, the gas cylinder may explode and cause a fire.

To date, a lot of tragic cases have been recorded, including fatal ones. Therefore, we strongly recommend that you take a responsible attitude to the performance of work related to gas, as well as during the use of the equipment.

Safety Compliance

It is very important to follow the basic safety rules in order to prevent tragic consequences. Working with gas equipment is extremely dangerous, so it is not recommended to connect or change the structural elements of the equipment yourself

If gas equipment is used incorrectly, a cylinder explosion can occur, which in most cases leads to a severe fire with tragic consequences.

To date, a lot of tragic cases have been recorded, including fatal ones. Therefore, we strongly recommend that you take a responsible attitude to the performance of work related to gas, as well as during the use of the equipment.

Actions in case of freezing of the container

If you notice that your equipment began to work intermittently, then you should pay attention to the surface of the gas cylinder. She's probably covered in frost.

To resume the correct functioning of the equipment, it is necessary to create optimal conditions for this. If this is not done on time, then the gas appliance may completely stop working.

The first step is to determine why freezing occurs. If this is due to weather conditions, then you need to create the optimal temperature regime for the container, how to do this will be written further.

If cooling occurs due to intensive gas consumption, then the consumption must be reduced. This can be done by installing an additional cylinder, you can have several. Depending on the amount of fuel consumption. Connection of several cylinders is carried out using a special unifying ramp.

To connect several cylinders to the gas system, a special metal ramp is used, to which a certain number of gas cylinders are connected, a valve and a pressure gauge are installed on the ramp

To connect several cylinders to the gas system, a special metal ramp is used, to which a certain number of gas cylinders are connected, a valve and a pressure gauge are installed on the ramp

A pressure compensation valve and pressure gauge should be installed in the rail to monitor the fuel level in the combined system.

Where does the ice on a propane tank come from?

The occurrence of frost is explained by certain physical processes that occur inside the vessel when it is connected to a gas receiver: a heating boiler or a column, a heater or a gas stove.

At this moment, there will be an energetic consumption of blue fuel, which means that significant volumes of liquefied gas will be converted into a vapor form.

This phenomenon is accompanied by excessive consumption of thermal energy, in connection with which the metal walls of the propane vessel become much colder than the air temperature in the room.

The process of condensate formation on the walls of the vessel begins, followed by the transformation of moisture into frost. This is a completely natural phenomenon, with which absolutely nothing needs to be done.

In general, propane freezes at -40 degrees Celsius, butane at -1 degrees.

In addition, absolutely all experiments to use artificial thermal insulation lead to a violation of fire safety standards during the operation of gas equipment, disrupt the process of heat exchange of the cylinder with the environment, which greatly affects the gas supply regime.

If the gas stove burner does not work well enough during icing, then after such “insulation” it will stop working altogether

In this case, you need to pay attention to the operating mode of the equipment and fill the vessel with a propane mixture with parameters corresponding to the summer and winter operating modes.

Types of insulation

The most difficult chimneys for insulation are brick. There are 3 main ways to insulate them (which can be used to insulate chimneys and from other materials):

- Insulating plaster is applied. A special solution is made, which is placed in a thick layer - min. 4 cm per pipe. According to the recommendations of experts, it is necessary to apply from 5 to 7 plaster layers.

- Warming takes place with special basalt mines. wadded or asbestos-cement slabs. The minimum thickness of such a plate should be 5-6 cm. The fastening is made with a facing mixture. A reinforcing mesh is laid on top of the insulation. After these works, plastering is carried out.

- The easiest way to insulate is with wooden shields. It is carried out in stages: for a start, a special building is being built. wooden frame around the perimeter of the pipe (can be made from timber); a gap is left between the materials of 15-17 cm; the frame is sheathed with flat slate; gaps are filled with slag or sand, periodically ramming their mass; at the end, a decorative framing of the frame is made with colored prof.sheets, which are fastened with roofing screws.

Achieving security

By knowing the causes and consequences of a gas cylinder explosion, better safety can be achieved. For this you need:

Properly store and operate gas containers.

Take the utmost care when handling them.

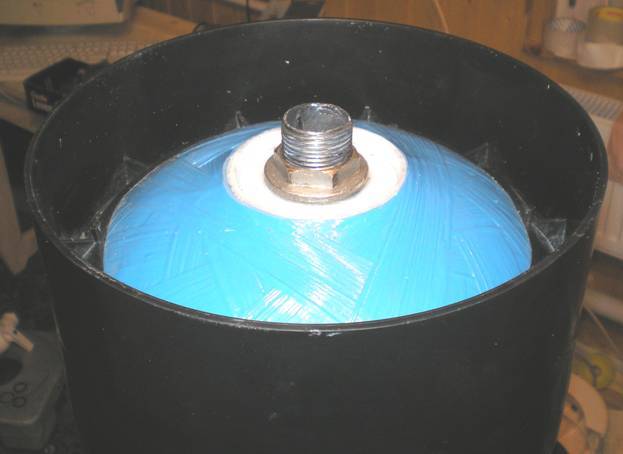

Use composite-polymer versions.

The products indicated in clause 3 have the following advantages:

- Corrosion resistance.

- Gas permeability of walls at elevated temperature.

- Modest mass.

- High strength. This eliminates the appearance of cracks and breaks.

- Resistance to aggressive influences and powerful loads.

- transparent structure. The user can see the fuel filling level.

- Existence of the valve for throwing off of excess pressure in capacity. The valve can be used multiple times.

- A lead valve that protects the vessel from explosion in a situation of overheating. It can only be used once.

- The presence of a polymer casing for easy carrying.

The smallest version (12.5 liters) costs about 7,000 rubles. Model for 30 l. - at least 10,000 rubles.

What condenses in a gas cylinder?

You can often notice that the gas in the cylinder is over, and at the bottom something continues to splash. Some people think that there is still some liquefied gas left, just for some reason it does not come out and does not light up, but this is not so. In fact, after using all the gas in the cylinder, condensate remains - a residue that does not go into a gaseous state at room temperature, and therefore does not go out under pressure and does not provide combustion. To understand why condensation forms in your gas cylinder, let's look at what it consists of.

The liquid that remains at the bottom of the cylinder after all the gas has been used up usually consists of several components.

Among them may be:

- Gasoline is a non-volatile refined product, a cross between butane and gasoline.

- An odorant is a flavoring gas.

- Non-combustible impurities are not uncommon when using insufficiently purified gas or refueling from an almost empty tank.

- Water is the rarest, but also the most dangerous component in this case.

- Butane - if the cylinder was used in the cold.

Propane at normal pressure turns into a gas already at a temperature of -30 degrees, and butane - at 1 degree below zero.

Even in coolness, both components - propane and butane - actively evaporate, filling under pressure all the space of the cylinder free from liquid, and look for opportunities to break out

However, there are other products of oil refining, the boiling point of which is much higher: 30 - 90 degrees and above. That is, when heated to a sufficient temperature, they will behave in the same way as propane and butane - only heating a gas cylinder is very dangerous. And at room temperature, and even at elevated pressure inside the cylinder, they remain in a liquid state, forming condensate.

These non-volatile fractions under normal conditions are called gasoline, and the better the gas at the gas station, the lower the percentage of their content.

In addition to gasoline, propane-butane technical mixture, which is filled with household gas cylinders, always contains an odorant. This is a special substance, ethyl mercoptan, with an extremely strong pungent odor: it is added in order to notice the leak in time and to have time to prevent the accumulation of gas in the room.

Without the addition of an odorant, the gas mixture would have no odor - just like purified propane, pure butane, and natural gas do not. The odorant is also non-flammable, so it remains in the condensate. Its volume is negligible, because according to the norms, 6-9 ml of flavoring per 100 kg of liquefied gas are added. However, after using the cylinder, it almost completely remains in the condensate, due to a decrease in the total mass of substances, its concentration increases.

Drained condensate has a very strong, pungent and persistent odor that does not disappear for quite some time - do not do this in the yard

Water and non-combustible impurities should normally not be in the gas. However, when refueling at unverified stations, anything happens, so we named these components of the condensate. Water in a gas cylinder is dangerous because it provokes corrosion of the inner surface of the metal. The cylinder is not painted from the inside, and therefore easily rusts, and it is impossible to control this process. Such rust is detected only when it eats through the metal - and this is already too late and extremely dangerous.

If you used bottled gas in late autumn or winter, especially if it was filled in summer, try bringing the bottle indoors after the gas stops flowing. Most likely, after its contents warm up to room temperature, you can use it for some more time.

Do not worry about the appearance of condensate on the outside of the cylinder: these droplets of moisture, or even frost, indicate only the temperature difference between the air and the liquid in the cylinder

Nothing needs to be done with condensate or frost on the outside of the cylinder, this moisture can only harm the container on which the paint layer is damaged: with prolonged and regular exposure, the steel of the cylinder may begin to rust, and corrosion can lead to leakage, fire and even explosion of the gas cylinder .

We offer you to familiarize yourself with How to clean the blockage in the sink at home

However, this will take quite a long time, so the task of the user is limited to maintaining a uniform and high-quality color.

Errors when installing ceilings

Stretch ceilings are beauty, refined style and grace. Their installation is ordered quite often. But the work involves a serious risk, because they use dangerous gas appliances.

In a different situation, there is a dilemma - why do gas cylinders explode during the installation of stretch ceilings? The explanations for this are as follows:

- Illiterate employees. This reason is inherent in companies that do not instruct employees on safety aspects. As a result, people without the proper skills and qualifications go to work. They may carelessly handle gas appliances, increasing the risk of an explosion. In high-level firms, production training has been established. There, the staff regularly pass exams on safety standards, and receive permission to work with gas guns and cylinders.

- Faulty vessel. Each cylinder is subject to recertification. In this procedure, experts decide whether it is serviceable. The date of the next test is always reflected on the cylinder. And until the specified period, its use is safe. Using an expired option increases the possibility of an explosion, even if safety measures are observed in the work.

- Refueling with errors.Often negligent employees fill the cylinders not at special points, but at ordinary gas stations. In this case, the vessel is filled to the limit. And liquefied gas is deprived of the freedom to expand. In the cold, it occupies less volume, and at room temperature it increases in volume and presses on the walls of the cylinder. And since an indicator of the order of +40 degrees is kept in the room for stretching the ceiling, ideal conditions are created for the explosion of an oversaturated gas tank.

- Cylinder hit by a stream released by a thermal gun. So the container gets very hot. And if you don’t notice it in time, its explosion is not ruled out.

- Employee negligence. The cause is much rarer than the others. It manifests itself in the fact that even workers who are trained and well aware of safety regulations violate it. For example, they are trying to remove frost from the tank with a gas gun. It also happens that workers deliberately block the button that supplies fuel. As a result, in case of severe overheating, the system does not turn off automatically and the risk of an explosion increases significantly.

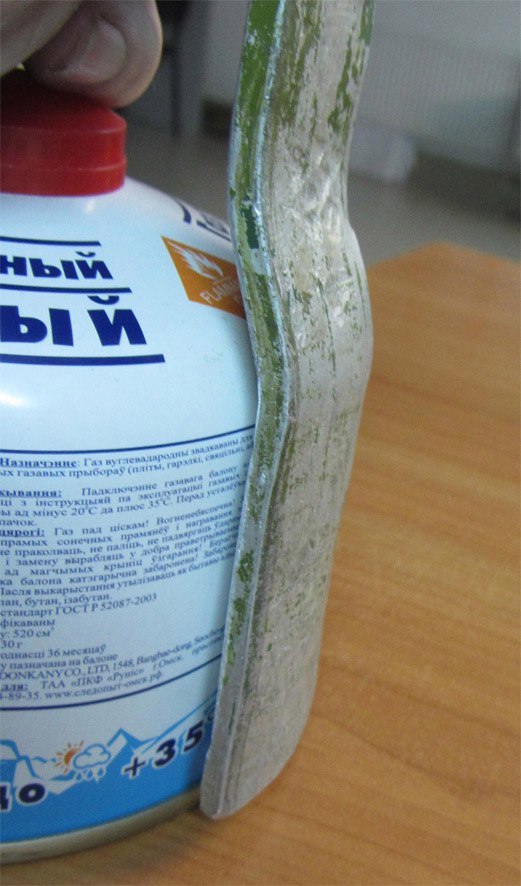

Why does the gearbox freeze on carbon dioxide?

Many people have asked this question at least once! As a rule, it occurs in those who work with carbon dioxide as a protective gas. There aren't many reasons...

- Poor quality gas

- Old or defective gearbox

- High gas flow rate set

The first cause of freezing of the gearbox is the low quality of carbon dioxide. Yes, that's right. As a rule, this means that there is moisture in the gas. It can be formed in the gas at the stage of its production.And also, it can get directly into the gas cylinder if you consume gas to the last drop ... (To avoid this, before giving the cylinder to the gas station, do not consume the gas completely, leave 1 - 1.5 atmospheres).

I personally worked with such a gearbox ... Photo. There were difficult times

We advise you to read - How to cook semiautomatically for dummies. This article has already made it easier for many beginners to get acquainted with semi-automatic welding ...

The second reason lies in the gearbox itself. This means that either the gearbox is old and not designed for large amounts of work, or it is not working. In any case, if this reason is identified, the gearbox must be replaced with a new one.

The next reason is the high flow rate. That is, the welder set a high working pressure, which is the reason for the freezing of the carbon dioxide cylinder reducer.

Safety measures to become a habit when using city gas

You always need to remember about the safety rules that must be followed at a subconscious level.

Before lighting a gas stove, it is necessary to ventilate the room at least for a short time.

Follow the sequence of turning on gas appliances: first light a match, and then turn on the gas supply.

Before turning on the oven, it must be ventilated.

The gas should burn with a uniform blue flame. If there are yellow tongues in the flame, then the burner is clogged. Still the flame can break away from the burner. This indicates the intake of a large amount of air. In both cases, you need to call a wizard who will fix the problem.

Each user of gas equipment must conclude a contract for professional maintenance of appliances and renew it in a timely manner.

Homeowners should regularly check vents and outlets during the heating season for blockages and ice build-up.

Do not leave working gas appliances unattended if they do not have the appropriate automation and are not designed for continuous operation.

Constantly check the ventilation draft and / or keep the vents in the rooms where gas appliances are installed open.

Preschool children may not be allowed near gas appliances. As well as persons who do not give control to their actions and have not been pre-instructed.

It is forbidden to use gas appliances for other purposes: for drying things, heating the room, etc.

It is forbidden to sleep and rest in a room with working gas appliances.

At the end of the use of gas, it is necessary to close the taps on gas appliances, the valves in front of them, and when using cylinders, the valves of the cylinders.

It is advisable to place gas cylinders (working and spare) for household gas appliances outside buildings (in annexes, basement and basement floors) at a blank wall at a distance of no closer than 5 m from the entrances to the building

Outbuildings must be made of non-combustible materials.

To detect the presence of household gas leaks, a soapy solution is used, but not an open flame.

All work related to gas equipment or gas pipelines is carried out by special licensed organizations.

When leaving for a long time, you need to close all the valves on the gas pipe.

Be attentive to elderly neighbors who may forget to turn off the gas, and be wary of dysfunctional neighbors ... Although in which case this will not help much, unless, of course, you live in a communal apartment.

Timely checking of equipment significantly reduces the likelihood of dangerous situations (boilers and columns are checked once a year, and stoves - once every three years.

although if the plates are old, it is better to check every year).

The hose connecting the gas line to the stove must not be pinched by an object standing on it or stretched, bent, twisted. It is best to fix it with safety clips above the floor. Please note that the hose connecting the gas line to the stove must be specially made for this type of operation and be marked accordingly. In domestic conditions, as a rule, red hoses (with a red stripe) of class I are used. The hose for supplying oxygen to the gas appliance is marked in blue and belongs to class III. Extended information about the purpose of the hose is indicated in the product specifications.

Make sure the flexible hoses are tight on the faucet. The recommended length of such a hose is up to 2 meters, the service life is up to 4 years (optimally 2 years), after which it should be replaced.

After each use of the gas stove, it is recommended to close the valve on the pipe, blocking the gas supply.

Very good advice - if possible, set up an alarm against gas leaks. In the event of a leak, it will sound an alarm. And some will be able to turn off the gas.

Its disadvantage is the price and the need to periodically check and maintain.

Install the analyzer in the immediate vicinity of a window or ventilation duct, avoid installation in places where the sun's rays constantly fall. Exposure to high temperatures may cause the gas analyzer to become unusable. However, if there is no other suitable place, then sun protection must be installed on the device. An important condition for the operation of the gas detector is its constant cleanliness. Because even a slight contamination of the sensors can lead to unstable operation of the device.

The frequency of draining condensate from the cylinder

But when should the condensate be drained? This question is very individual and depends on the quality of the fueled gas, operating conditions.

Many users of gas cylinders have not encountered such a need at all, while others do this before each refueling. Both of these extremes are normal behavior under certain conditions, and to determine which is closer to you, we will consider these conditions in more detail.

Option # 1 - refueling at a specialized substation

If you fill the cylinder at a specialized substation, you may not encounter condensate at all, for several reasons at once. Firstly, the “correct” gas is filled there, with a high propane content, and not just cheap butane, as at car gas stations.

Secondly, their gas quality control is much stricter, so the degree of gas purification is higher, and there are practically no foreign impurities.

Thirdly, at most such substations, cylinders are exchanged, and before refueling, they are inspected and serviced, discarding excessively worn ones, and after refueling, safety and tightness control is carried out.In particular, substation workers drain condensate if it has accumulated in a cylinder.

Even if you insist on refueling your particular cylinder, it will not be performed without first making sure that the unit is in good condition and safe. The fact is that specialized substations work officially, observing the norms and technical requirements for filling cylinders, and are responsible for the safety of each client.

Option # 2 - refueling at the gas filling station

Cylinders filled at car filling stations, but used for domestic purposes, are much more prone to the formation of condensate.

A little about tent insulation

Not only by heating it is possible to exclude the freezing of gas in the cylinder. As you know, ordinary single-layer tents keep heat “so-so”. But they are easy to hem from the inside with a padding polyester and another layer of fabric. After that, the tent will warm up faster and keep warm many times longer, but it will become heavier.

In addition to the walls of the tent, a significant part of the heat is also absorbed by the ice. The thermal conductivity of frozen water is much higher than that of liquid water, and at -20 °C is actually equal to the thermal conductivity of granite (2.4 W/m*K). It's funny, but it turns out that snow can play the role of a heat insulator here, because its thermal conductivity is approximately equal to the thermal conductivity of wood (0.15 W / m * K). Therefore, if the ice is covered with a layer of snow, heat loss in the tent will decrease.

However, snow always has a negative temperature, so you should not rely on its heat-insulating properties. It is better to equip the tent with a homemade floor, which can be cut from a dense isolon one and a half centimeters thick. This will not only insulate the angler's shelter, but also eliminate the melting of ice and snow under it.

Where does frost come from

Indeed, sometimes after the delivery of a gas cylinder from a cold street, its lower part is covered with frost. But it will melt much faster if you do not wrap the container with anything, but simply leave it warm for a while. This phenomenon is quite simply explained by a number of physical phenomena that occur inside the vessel when the consumer is connected. During active gas consumption, the liquefied medium quickly evaporates. The process of vaporization is accompanied by the absorption of a large amount of heat. As a consequence, the lower part of the cylinder, in which the liquefied gas remains, cools rapidly and becomes colder than the surroundings.

Again, according to the laws of physics, moisture from warmer air begins to settle on a cold surface. Condensation appears on the cylinder, which, upon further cooling, turns into frost. These are natural processes that do not need to be fought at all. In addition, all attempts to insulate the vessel on their own are a direct violation of the requirements for safe operation. Blankets and other covers interfere with the normal heat exchange of the container with the environment and affect the characteristics of the contents. For example, if an intense flame was not observed in the burner before, then after wrapping the cold cylinder it may not burn at all.