- Malfunction of electrical appliances and heating elements

- What will the repairman do?

- Shocks the body of the equipment

- Other interesting questions and answers

- What to do when you get electric shock from tap water?

- Why does tap water jolt when the washing machine is on?

- The water from the tap is electric ... but only me! Why?

- Ground loop device

- Features of gasification of residential buildings

- Causes of the malfunction

- Electric ignition does not work on only one burner

- Zero is electric and the indicator is on: reasons

- How to solve the problem with a "bad" zero

- Gasification of the house in stages

- Theft of electricity or unscrupulous neighbors

- Possible causes of problems and solutions

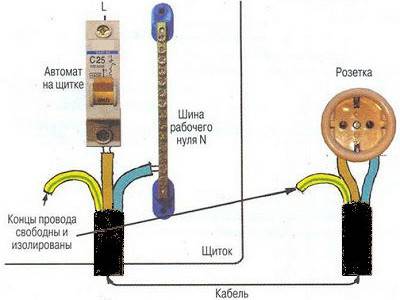

- No grounding

- A breach in isolation

- Breakdown of the heating element

- Capacitor problems

- Shielding

- Liquid

- Causes of malfunctioning burners

Malfunction of electrical appliances and heating elements

But most often, electric shocks are possible due to a malfunction of such simple household appliances as a washing machine, a titanium boiler, instantaneous water heaters, and a dishwasher.

If they do not have a protective ground, any of them, sooner or later, starts to beat with current. At the same time, it is enough to simply plug them into the outlet and not even start them.And when you touch the surface of this device or just water, you will begin to “pinch” in a significant way.

With a small leak, a slight vibration of the device will be felt.

If the tap water itself beats with current (usually the pipes are plastic), then the cause is most likely damage to the water heaters through which this same water enters.

Here, all the blame lies with the heating element. Its insulation is destroyed, cracks appear, the heating coil is exposed and begins to come into direct contact with water. Hence the electric shocks.

Here, all the blame lies with the heating element. Its insulation is destroyed, cracks appear, the heating coil is exposed and begins to come into direct contact with water. Hence the electric shocks.

If this is one small microcrack, then when the heating element is heated, it will open and the current will beat stronger. When the titanium is turned off, the heating element cools down and the crack closes, as it were, hiding the spiral. The tingling may be subtle or disappear altogether. As the heating element is destroyed, the voltage on the tap water will be constant.

To find out, you need to “ring out” the heating element with an indicator screwdriver or a multimeter.

Moreover, it should be especially noted that water can be electrocuted even if the water heaters are faulty not with you, but with your neighbors.

It's very easy to find out. Disconnect the machine or plug from the heater outlet and check for voltage. If it has not disappeared, then go to the neighbors and ask them to do the same. When the power is turned off from a faulty water heater, the potential on the pipes with water will also disappear.

What will the repairman do?

The specialist will first carry out diagnostics using a megaohmmeter and other professional tools

It is important not only to find the "leakage" of the current, but also to check all the details for serviceability. Further:. Establish the cause of the breakdown, prescribe it in the receipt

This is an official document and conclusion.

Check the socket for grounding. Often there is a yellow-green wire in the outlet (the universal color for marking "ground"), but you need to check if it is working.

Ground the device

Establish the cause of the breakdown, prescribe it in the receipt. This is an official document and conclusion.

Check the socket for grounding. Often there is a yellow-green wire in the outlet (the universal color for marking "ground"), but you need to check if it is working.

Ground the device

Important: the plate is grounded only if the house already has a grounding element. If the device is located in a building where there is no grounding structure, it is better to contact an electrician for help.

It will restore the insulation of the circuit, clean the contacts from dust and grease drops. Food particles often get on the contacts and wires of the electric stove, form a plaque that conducts electricity perfectly

To avoid problems, you need to clean these elements regularly.

Will replace a broken part: heater, capacitor, wires, etc. Our company uses only original spare parts of brands Gefest, Electrolux, Gorenje, Kaiser, Indesit, Zanussi, Hansa and others.

Provides warranty on all labor and parts.

Food particles often get on the contacts and wires of the electric stove, form a plaque that conducts electricity perfectly. To avoid problems, you need to clean these elements regularly.

Will replace a broken part: heater, capacitor, wires, etc. Our company uses only original spare parts of brands Gefest, Electrolux, Gorenje, Kaiser, Indesit, Zanussi, Hansa and others.

Provides warranty on all labor and parts.

Shocks the body of the equipment

Touching the body of the unit can also lead to pain due to the action of electric current. Firstly, a damaged contact or abrasions and cracks in the wire insulation can act as a factor in the leakage of electricity. Violations of the integrity of the insulating coating are often caused by excessive vibration due to a rotating drum. During washing and spinning, the wires rub against each other, resulting in the destruction of their outer sheath.

First, turn off the power to the equipment and open the case by removing or folding the top cover. Then, carefully inspect the wires inside, located in close proximity to the housing surface. As a rule, frayed wiring can be seen with the naked eye.

The next most frequent factor is the use of a washing machine in a room with a high level of humidity. The optimal solution is to dismantle the device and install it in a dry room. If this is not possible, the device will need to be properly grounded. This will protect you from "breakdowns" during operation.

The last reason is the breakdown of the heating element or the electric motor. If it's the heating tube, purchase a similar element from the store and insert it in place of the old one. If the motor fails, you can try to repair it alone, if it fails, replace it with an analogue.

Other interesting questions and answers

What to do when you get electric shock from tap water?

Guest2

If you do not wish to endure electric shocks from a faucet, you will have to do the following:

-

Replace all sockets in the kitchen, bathroom and toilet with special models with a moisture protection class of at least IP44 or IP54. They will protect you from accidental breakdown on the socket housing.

-

Examine the wiring with an ohmmeter or a detector to search for hidden breaks. Increased resistance in the area or a detector signal will indicate the location of the breakdown.

-

Replace all problem areas of wiring, and even better - replace the entire line that runs into the bath, kitchen or toilet, using a special, moisture-resistant cable.

-

Call the master and ask to replace the heater on the washing machine and dishwasher, as well as on the boiler. Unless, of course, water-heating electrical appliances are the source of the problem.

Vladimir1

The reason that the jet of water is electric may be the lack of grounding at the washing machine, water heater or other electrical appliance that is connected to the outlet in the bathroom / kitchen, or is located next to it. It can also mean that the wiring is faulty, the wire is twisted somewhere, or the wires are damaged. It happens that your neighbors have errors in the grounding of the water heating system, but it is shocked by water from your tap. If you make sure that the problem is not in your apartment, then you need to look for neighbors in a common riser to solve the problem. If in your bathroom or kitchen all sockets and all wiring are adapted to humidity, there are no problems with grounding and damage to the electrical wiring and the appliances themselves, then contact the Housing Office / DUK in order to check neighboring apartments for malfunctions. To determine the problem with you, call a specialist, it is better not to mess with electricity on your own, and this should be done as soon as possible. The electrician will carry out diagnostics, if necessary, replace problem areas of wiring, switches and sockets, indicate a malfunction of the water heating system and electrical appliances.Well, if an electrician is attached to your home, he may already be familiar with the problem, if it is not an isolated one. In addition, the prices for services from electricians of the ZhEK are lower than those of specialists from third-party firms. Natalia K.3

Why does tap water jolt when the washing machine is on?

There are no intersections, they just stand side by side. Leaks too. It hits little by little, barely noticeable on small wounds on the hands.

iris3

Or there or there is a bad ground. Also, there is an isolation breach somewhere. Let's say that in a washing machine, the insulation in some place is not good enough and a “bridge” has formed, along which electricity hits the body. If at the same time the ground is connected incorrectly or is absent, but there is a slight voltage on the case. Water pipes, on the contrary, are well grounded and the resulting current goes into the ground. In this case, if you hold on to the washing machine with one hand and the water pipe with the other, then you just close the electrical circuit. Wounds on the arm, as the most sensitive place, feel a small current. This can be dangerous because in a damp room the effect of the current is only increased due to poorer insulation. You need to take a device (for example, an ammeter) and check where the problem comes from. Of course, it may turn out that everything is in order with your washing machine, and a small current flows from the side of the water supply system through some faulty electrical appliance.

Sveta17082

The water from the tap is electric ... but only me! Why?

Before, everything was fine, but now ... I’ll get into the spirit, wash normally, and two seconds before turning off, the faucet gives me a shock! I turn off the faucet already and it sucks again! And the battery is hanging there. And after that, if I turn on the sink in the bathroom or in the kitchen for half an hour, the water beats with electricity there. And only me! Grandmother neighs and says that you need to sit less with the phone ... But if it was the phone, then it would beat right away and constantly like ... Alena .4

So some smart guy made grounding on the water pipe. Serezha3

Ground loop device

The end point of any man-made grounding system is the circuit of the main grounding conductors. It connects the protective conductor system to the nearest aquifer, in which moisture is saturated with ions and, in fact, is an excellent electrolyte.

To ensure low electrical resistance between the top conductor and the protective conductor, a sufficient contact area and low resistance of the conductors are required. The main grounding conductors are most often represented by rolled products made of grade 3 steel or metal parts of underground utilities. In the latter case, the admissibility of using natural grounding conductors as such is determined by the PUE.

The grounding system can be mounted in a driving way or arranged with concomitant earthworks. In the first case, rolled metal with stiffening ribs is used: angle steel, channel, Taurus. Such products can be hammered vertically down without deformation, moreover, they have a well-developed outer surface.When digging in grounding, a steel sheet, a strip, and in general any metal objects that are massive enough to exist in the soil layer for several decades can be used.

Installation of the grounding system can be done independently, however, the calculation of the number, degree of immersion and cross section of the main electrodes must be carried out by specialists. The calculation method is based both on the type and resistivity of the soil, and on the location of the main circuit and its operating conditions. But you can go in a simpler way: start with 3–4 electrodes that pierce the watershed by 50–70 cm, and then add them if, according to the measurement results, the contact resistance of the circuit is not low enough.

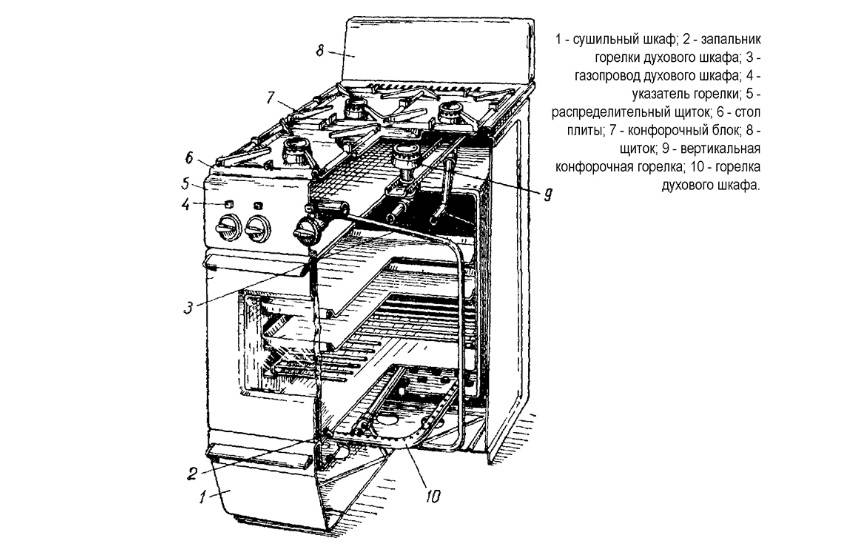

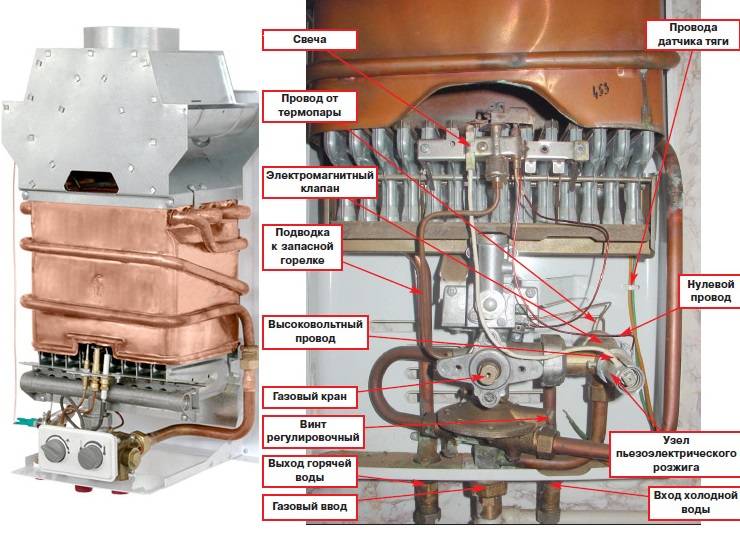

Features of gasification of residential buildings

With the help of gas in the house, you can successfully organize heating, hot water heating, and cooking.

Gas equipment is reliable and diverse, and the cost of blue fuel is usually lower than the use of electricity, solid or liquid fuel for the same purposes.

In addition, gas lines fail extremely rarely, but power outages are common. Stocks of firewood, coal, diesel fuel and other similar energy carriers have to be constantly replenished.

The main problem with natural gas is its danger to human health and its ability to explode. Even a small leak can lead to poisoning or an explosion.

That is why the requirements for the installation of gas communications are very high, you should not even think about doing all the work yourself.

In order to properly introduce gas into a private house, a special unit is used, which is called a reducer for reducing gas pressure.

To begin with, experts do not recommend saving on materials or system elements. Pipe laying of dubious quality and unprofessional installation are unacceptable.

Gas pipes almost always need to be laid in an open way (except for underground sections of the highway). They cannot be hidden under any decorative elements to improve the interior.

It is not recommended to introduce a gas pipe into the house through the thickness of the foundation; for this purpose, a hole is made in the outer wall and a sleeve is inserted into it for protection

It is recommended to avoid plug connections whenever possible. All places where pipes are connected must be located in such a way that at any time the point of contact can be examined and repaired if necessary.

Do not lay gas pipes inside the walls or in the thickness of the foundation. This rule also applies to other elements such as architraves, door frames, window frames, partitions, etc.

In some cases, it is allowed to lay a gas pipe in a wall niche, but this point must be clearly reflected and justified in the project. Special requirements are also imposed on the slope of the pipes.

Horizontally, the position of the line is allowed to deviate by only 3 mm towards gas appliances.

Vertically, no deviations are allowed, but the riser may have a slight slope: no more than 2 mm per meter. It should not pass through living quarters, through a toilet or bathroom.

The gas riser should be located in the stairwell, often through the kitchen.

You will also have to carefully monitor the installation of shut-off valves. So, the position of the central axis of the plug must be strictly parallel to the wall along which the pipe runs.

When choosing the position of the valve, make sure that the position of the locking device is not blocked by the wall. From the ceiling and from the walls, the gas pipe should be located at a distance of 100 mm.

Gas pipes are fixed along the wall not close, but at a short distance so that communications remain available for routine inspection and repair

The gap between the wall and the pipe can vary from the size of the pipe radius to a limit value of 100 mm. This clearance is necessary so that the structure can be easily examined.

A distance of 2.2 m should be maintained from the floor. Gas pipes are placed on special strong supports, sagging of the structure is unacceptable.

Therefore, it is necessary to make sure that there are no gaps between the bracket and the pipe. All these important points are taken into account in the project, which must be preliminarily drawn up by specialist engineers.

Gas pipes should be laid at least 30 cm from the electrical panel, and at least 25 cm from open wiring. From the hidden cable should retreat at least five centimeters.

Causes of the malfunction

No grounding. According to the technical requirements, the electric stove must be connected to a grounded socket, it must have 3 wires: zero, phase and earth. The latter is needed just in order to protect you from electric shock. Modern houses usually have a grounding conductor. But in Soviet-built buildings, the sockets are two-phase, there is no grounding factor there.

wear of insulation. The entire electrical network inside the device is built on wires and contacts.

The most important thing here is that each element is isolated.To do this, all wires are covered with a layer of PVC. This is a fragile plastic layer that can be damaged during transportation.

And over time, the isolation itself can collapse. If a live wire comes into contact with the metal parts of the system, voltage will be transmitted to the case. When touched with wet hands, you will feel a small discharge.

Broken TEN. The heating elements are located in all heating parts: in the burners and in the oven (there are from 1 to 4 heaters). Any tubular electric heater consists of a conductive filament and an insulator around it that transfers heat but not current. If the insulating material is damaged, the electric stove will generate electricity and heat up even when it is turned off.

Water got in. If the tile is next to the sink or the soup boils out of the pot frequently, liquid can enter the system and complete the circuit on the metal case of the appliance. The good news is that the fluid can be removed and the system sealed. There are no serious holes in the wiring. But if, after water gets in, when you turn on the burner, it knocks out plugs, you need to call the master and check the entire structure.

Electrical defects. If you dismissed all the previous reasons, but it is still easy to get hit from the body of the plate, it is possible that the phase and neutral wires were mixed up when connecting. You won't be able to fix it on your own.

This is a fragile plastic layer that can be damaged during shipping. And over time, the isolation itself can collapse. If a live wire comes into contact with the metal parts of the system, voltage will be transmitted to the case. When touched with wet hands, you will feel a small discharge.

Broken TEN.The heating elements are located in all heating parts: in the burners and in the oven (there are from 1 to 4 heaters). Any tubular electric heater consists of a conductive filament and an insulator around it that transfers heat but not current. If the insulating material is damaged, the electric stove will generate electricity and heat up even when it is turned off.

Water got in. If the tile is next to the sink or the soup boils out of the pot frequently, liquid can enter the system and complete the circuit on the metal case of the appliance. The good news is that the fluid can be removed and the system sealed. There are no serious holes in the wiring. But if, after water gets in, when you turn on the burner, it knocks out plugs, you need to call the master and check the entire structure.

Electrical defects. If you dismissed all the previous reasons, but it is still easy to get hit from the body of the plate, it is possible that the phase and neutral wires were mixed up when connecting. You won't be able to fix it on your own.

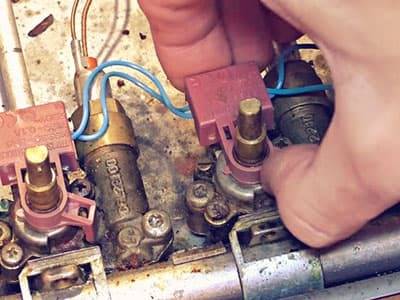

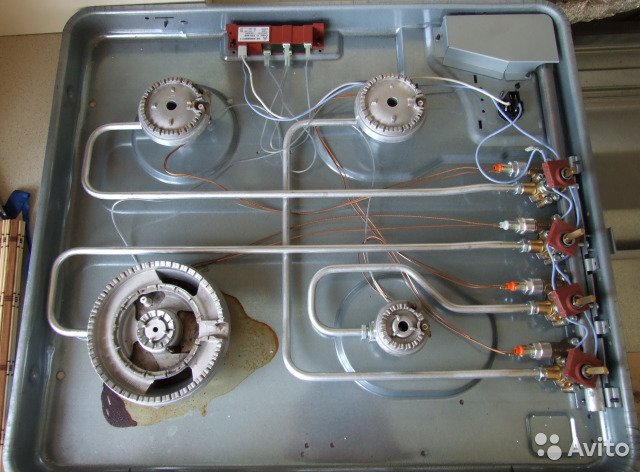

Electric ignition does not work on only one burner

If you cannot turn on only one burner using auto ignition, the first thing to check is if the spark plug is dirty. You may have spilled something on it, or the spark plug shows signs of oxidation. To clean, use WD-40 spray or just wipe it with a sponge. Did it not help or does the candle look perfect? Then it's a malfunction.

| signs | Breaking | Repair or replacement |

| There is no spark on one burner, the electric ignition works on the rest. | Faulty burner ignition plug. The power cord that goes from the ignition unit to the candle fails: the wire itself is damaged, the contacts are oxidized. |

In some stoves, when food gets on the power cord, it sticks to the case, and it is punched through this dirt onto the case.

It is necessary to replace the power cord along with the spark plug (as a rule, they are assembled).

A stuck power cord is enough to “unstick” from the case. To do this, it is necessary to disassemble the plate and remove contamination.

In a gas stove with auto-ignition buttons built into the handles of the burners, when you press the handle of one of the burners, there is no spark. The other hotplates light up as usual.

The handle of a burner with an inoperative ignition is pressed differently than others (softer, harder, etc.).

Auto ignition button failure. Modern gas stove models medium and high price categories, as a rule, have ignition buttons built into the burner handle. When the button on the burner handle fails, it stops lighting, while the rest of the burners light up normally.

Button failure is usually caused by mechanical damage or oxidation of the contacts.

AT contact oxidation they are being cleaned up. If the button mechanism is damaged, replace it.

Zero is electric and the indicator is on: reasons

Before climbing to repair the outlet, be sure to make sure that both conductors (phase and zero) are de-energized. However, in old houses, there is only one introductory machine on the electricity meters, which cuts off only the phase

Therefore, the first thing you need to pay attention to is whether the phase and zero are mixed up in places

Things are completely different when, when checking the phase and zero with an indicator screwdriver, both conductors are highlighted. There may be several reasons for this:

- Poor contact of the working zero at the substation or in the shield;

- The insulation in the electrical wiring is broken, which causes current leakage;

- Phase shift.

By itself, the neutral conductor (zero) cannot shock. However, dangerous voltage can pass through it, and when checked with an indicator screwdriver or when contact is made with the ground, zero can be shocked. Most often, such a problem is related to the fact that current leakage occurs through the phase wire, and touching the working zero, the circuit closes, due to which zero can be shocked.

Also, this often happens due to network overload or when the resistance of the neutral conductor becomes too large.

How to solve the problem with a "bad" zero

A radical solution to this problem is to replace the old electrical wiring. If the whole point is precisely in it, then finding a place where current leakage occurs is not so simple as it might seem at first glance.

Grounding in the house will also help, without which it is impossible to connect some electrical appliances at all. These, first of all, include a water heater, a washing machine and some others.

It will not be superfluous to check if the phase is mixed up with zero at the input, and also to make sure that there is no breakdown in electrical appliances. If such a breakdown is in phase, and it falls on the body of the electrical appliance, then a dangerous voltage may turn out to be at zero.

Often the reasons why zero is shocking turn out to be completely banal:

- In strong winds, wires are thrown onto tree branches;

- Someone steals electricity in the house by connecting a working zero to radiators, gas pipes and plumbing;

- There are many twists in the wiring, as well as wires made of different metals, different cross-sections of conductors, etc.

Some problems, in general, cannot be solved on their own. One of these is a bad zero on the CTP itself or its partial burnout. In this case, you must definitely contact the company supplying electricity to the house for help.

Gasification of the house in stages

- They begin to gasify the house with the registration of the relevant specifications, which are issued by the regional department of the gas service. According to the law, you will be provided with this documentation within 10 working days, free of charge, on a first-come, first-served basis;

- Next, it is necessary to draw up a project of gasified premises and buildings, and this work should be left to professionals - design bureaus with the appropriate specifics;

- Having received the technical specifications from the gas service, the owner of the house concludes an agreement with her to draw up a project for gas supply;

- The finished project documentation is coordinated with the technical department of the regional gas service, then an agreement is concluded for the pipeline and gas supply to the house.

Theft of electricity or unscrupulous neighbors

The first and most common reason that people sin is unscrupulous neighbors. Suspicions immediately arise that they are trying to steal some electricity and save extra kilowatts. This may be due to their capital repairs of the apartment and the heavy loads associated with this connection - welding machines, electric heat guns, etc.

The first and most common reason that people sin is unscrupulous neighbors. Suspicions immediately arise that they are trying to steal some electricity and save extra kilowatts. This may be due to their capital repairs of the apartment and the heavy loads associated with this connection - welding machines, electric heat guns, etc.

Or in winter, when the temperature of the central heating batteries is insufficient, very often they begin to use powerful heaters and heaters.Naturally, you can try to connect all this by illegally throwing wires to the wiring in addition to the meter.

True, neighbors can not always be consciously to blame! Therefore, do not rush to immediately accuse them of stealing electricity.

True, neighbors can not always be consciously to blame! Therefore, do not rush to immediately accuse them of stealing electricity.

In old buildings with a TN-C earthing system, there is no separate earth conductor. But many lately, still carry out wiring with three-core cables.

And on the one hand, this is correct. The house will fall under reconstruction, the grounding system will change to TN-C-S, and everything will be ready for you. But until this moment, do not rush to connect such a conductor.

However, some, without waiting for reconstructions, simply use the risers of the nearest water supply as grounding conductors. And immediately connected to it, that same third ground wire. Which, in turn, is connected to the body of the electrical appliance.

And if this device breaks through the insulation, then the phase will just get through the pipes into neighboring apartments.

Possible causes of problems and solutions

No grounding

Despite the fact that the design of the electric stove was originally designed in such a way as to exclude any current leakage, voltage on the case can still occur. As a rule, the current on the walls of the stove appears due to the lack of external grounding.

Each socket has outputs to three wires, which are called "zero", "phase" and "ground". There were no such standards in Soviet-built houses, so there is no grounding there. At the same time, in some modern houses, grounding is available only according to documents, but in fact it is absent or does not work correctly.

The main causes of grounding problems:

intense ultraviolet radiation;

too high temperature;

oxidation of ground terminals;

To check the ground loop, you need a multimeter, with which you need to find a wire with a phase in the outlet, and then, in the resistance measurement mode, determine whether the power is grounded. The phase on the case may appear due to unreliable ground contact of the electrical outlet with the stove power cord plug. Remember: an electrician should deal with grounding problems.

A breach in isolation

One of the possible reasons for the appearance of current on the surface of the plate is the broken insulation of wires and contacts. Its integrity can be checked with a tester. To do this, you need to “ring out” all the contacts of the plug and all panels of the case with an indicator screwdriver in order to localize the problem. So you can check the voltage and determine which structural element needs to be replaced. Never try to touch the surface of the stove if it is not insulated.

Breakdown of the heating element

The appearance of current on the body of the stove can be provoked by an electric heating element in which a hole has appeared. In this case, it is necessary to de-energize the unit, call the master and replace the heating element. The stove is the first element of the stove design, which begins to “pinch” in the event of a breakdown in the heating system. If the electric stove is electric, and the surface temperature rises even with inactive burners, urgently call the master.

Capacitor problems

The rarest reason for the appearance of a phase (operating voltage) is a failure in the operation of a capacitor that suppresses impulse noise. It is usually installed next to switching power supplies and power components. The current escaping from the capacitor to the case is usually safe (less than 110 volts), but unpleasant sensations will certainly arise when contacting it.

Shielding

If the floor on which the stove is placed is equipped with a heating function, shielding may occur. In this case, it makes sense to remove the underfloor heating controller and disconnect all conductors from it. After that, you need to find out the cause of the potential difference between the body of the electric stove and the floor heating elements.

Liquid

We all know that water is an excellent conductor of electricity. This knowledge can be useful to us during the diagnosis of problems associated with the electric stove. Sometimes the liquid gets on the metal contacts and conductors, closing the circuit on the case, which is why the latter beats with current. The hand working with the stove must always be dry and clean to minimize the possibility of contamination of the device.

If your electric stove continues to shock you and your relatives with current, do not rush to throw it away and buy a new one, because, most likely, the problem can be solved. Before starting repairs, the most important thing is to localize the problem and determine the root cause of its appearance, and not every owner can handle this. One way or another, grounding the device and repairing the heating element are not the easiest tasks that a professional should perform.

It often happens that when you touch the body of the gas stove, there is a “tingling” sensation. This is unpleasant, but the worst thing is that such minor annoyances often develop into grandiose problems and breakdown of gas equipment. And no one needs such a development of the situation, right?

Causes of malfunctioning burners

The very name of the electric stove suggests that the principle of its operation is based on the use of electrical energy.If the stove stops heating or heats up weakly, it means that a breakdown has occurred in some place in the electrical circuit. Before contacting the master, check the operability of the socket, plug, and cord. Perhaps they are the cause of the malfunction. If everything is in order with them, then you need to look for other reasons for the breakdown. And there may be several:

- Long period of operation at maximum power. With this method of operation, natural wear of parts occurs. One or more heating elements may burn out, a fuse may blow, terminal contacts may oxidize, etc. The master will be able to detect the breakdown and fix it.

- Faulty power switch. This could happen when water gets on the switch contacts or as a result of mechanical wear of the part.

- The control board is not working. To decide whether the board can be repaired or whether it will have to be replaced should be a service center specialist.