- Comparative characteristics of briquettes

- wood briquettes

- Prices for Eurowood Briquettes

- coal briquettes

- Prices for coal briquettes WEBER

- Peat briquettes

- Husk briquettes

- How to make fuel briquettes with your own hands, a simple instruction

- Initial data for calculation

- Advantages and disadvantages of using for heating

- Home packaging of solid fuel

- Applications

- Firewood

- Advantages

- Flaws

- What is better to choose ordinary firewood or euro?

- Choice practice

- What is better to choose ordinary firewood or "euro"?

- Pellets for solid fuel boilers

- Main advantages

- What are briquettes and pellets?

- Is coal the most profitable fuel for a solid fuel boiler?

- Summarizing

Comparative characteristics of briquettes

| Type of fuel | Calorific value, MJ/kg |

|---|---|

| Anthracite | 26,8-31,4 |

| Brown coal | 10,5-15,7 |

| Coal | 20,9-30,1 |

| Gas | 27 |

| Peat (moisture content 20%) | 15,1 |

| Diesel fuel | 42,7 |

| Wood (moisture 40%) | 6-11 |

| Briquettes (from sawdust) | 16-29,5 |

Each type of briquettes has its own characteristics and advantages. And although they are all great for domestic heating, it is still worth familiarizing yourself with their characteristics in more detail in order to choose the best option.

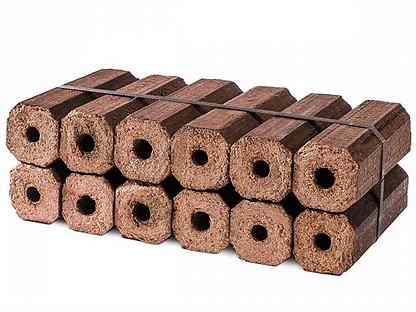

Forms of fuel briquettes

wood briquettes

This type of briquettes is obtained by pressing various wood waste - deadwood, sawdust, shavings, substandard wood.Before pressing, the waste is heated to a certain temperature, as a result of which an adhesive substance, lignin, is released from the cells. Thanks to lignin, briquettes acquire high strength and retain their shape during transportation and storage.

wood briquettes

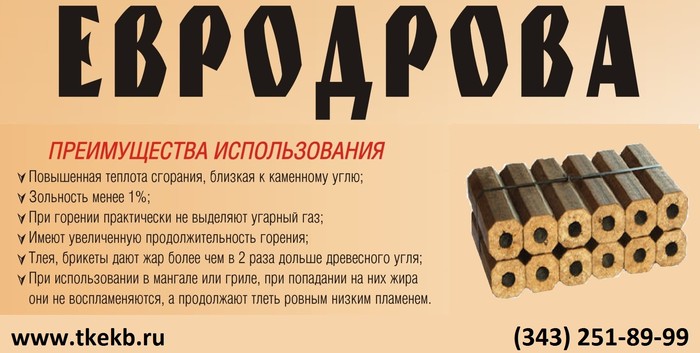

The advantages of briquettes over solid wood are obvious:

- the density of the briquettes is constant and amounts to 1240 kg/m³, the density of the wood depends on the species and ranges from 150-1280 kg/m³;

- maximum humidity of briquettes is 10%, wood - from 20 to 60%;

- when burning a briquette, the volume of ash is 1% of the total mass, wood - 5%;

- when burning, a briquette releases 4400 kcal/kg, a tree - 2930 kcal/kg.

wood briquettes

In addition, wood briquettes have other advantages:

- pressed wood does not spark during combustion and emits very little smoke;

- the boiler is maintained at a constant temperature;

- briquette burning time 4 hours;

- the remaining coals after combustion are great for cooking on an open fire;

- the correct form of briquettes simplifies their transportation and storage.

Such fuel is sold not in cubic meters, like wood, but in kilograms, which is much more profitable.

Prices for Eurowood Briquettes

Eurowood Pini-kay

coal briquettes

coal briquettes

This type of briquettes is obtained from the elimination of hard coal. The screenings are first crushed, mixed with a binder, and then pressed under high pressure.

The main properties of such fuel:

- coal briquettes do not smoke;

- do not emit carbon monoxide;

- burning time in conventional boilers from 5 to 7 hours, with adjustable air supply - 10 hours;

- suitable for domestic use;

- have a compact shape;

- during combustion, 5200k / cal is released and a constant temperature is maintained;

- maximum ash volume - 28%;

- have a long shelf life.

Coal briquettes are the most optimal fuel in severe winters, when pressure drops in domestic gas systems due to low temperatures. Briquettes burn at any temperature, the main thing is that there is a constant flow of air.

Prices on coal briquettes WEBER

Coal briquettes WEBER

Peat briquettes

Peat briquettes

To make briquettes, peat is dried, heated and pressed under high pressure. The result is neat light bricks of dark color. With adjustable air supply, peat briquettes maintain the temperature for 10 hours, which is very convenient for heating the house at night.

Basic properties:

- suitable for all types of ovens;

- heat transfer is 5500-5700 kcal / kg;

- the volume of ash is 1% of the total volume of the briquette;

- affordable price;

- the minimum amount of impurities in the composition.

Peat briquettes

The ash that remains after the combustion of fuel can be used as an effective lime and phosphorus fertilizer. For many owners of private households, this factor is decisive when choosing heating briquettes. Since peat is a flammable substance, it should be stored at a safe distance from open flames and heating appliances. Even dust spilled from the packaging can ignite and cause a fire, so you need to handle the briquettes correctly.

Husk briquettes

Husk briquettes

Sunflower husks, buckwheat and rice husks, rye, oat waste and even straw are widely used to make fuel briquettes. The most common are sunflower husk briquettes, since a large percentage of waste remains during the production of oil.The maximum moisture content of the pressing husk is 8%, which increases the heat transfer and reduces the ignition time.

Sunflower briquettes

Specifications:

- the density of briquettes is 1.2 t/m³;

- heat transfer - 5200 kcal / kg;

- the volume of ash is from 2.7 to 4.5%.

Additional benefits:

- no harmful impurities;

- affordable price;

- long burning time;

- ease of storage and transportation.

How to make fuel briquettes with your own hands, a simple instruction

Recently, it has become fashionable to use not only traditional fuel in the form of firewood for kindling stoves, but also other, alternative options. For example, fuel briquettes, natural materials pressed under high temperature, such as sawdust, sunflower husks, peat, straw, etc., are becoming increasingly popular. Created from biological waste, 100% natural and environmentally friendly, fuel briquettes allow you to effectively and inexpensively drink a house, a bathhouse. In this article we will talk about how to make fuel briquettes with your own hands from improvised materials. To do this, you will need to buy or make suitable waste recycling equipment and learn how to properly make euro firewood. Making fuel briquettes with your own hands will allow you to solve several problems at once:

- get rid of waste;

- obtain efficient and technologically advanced fuel for home heating;

- save money on wood.

Initial data for calculation

The calculation of the consumption of solid fuel per boiler in a season depends on many parameters: the area of \u200b\u200bthe house and the height of the ceilings, the average temperature in the cold season, the duration of winter, the quality of the thermal insulation of the walls, the heat transfer of the fuel and the efficiency of the equipment.

It will not be possible to take into account all variables, but we can calculate the average value for different types of fuel so that you can compare and choose the option that is right for you.

- Let us take the duration of the cold season for 111 days, from November 27 to March 13.

- The area of the room is 100 square meters.

- The amount of heat for heating 1 square meter is 100 W per hour.

- Accordingly, there are 24 hours in a day and an average of 30 days in a month.

If necessary, you can substitute in the formula the actual area of the house for you, the duration of the cold season, depending on the region of residence.

Advantages and disadvantages of using for heating

Positive properties of eurofirewood compared to conventional firewood:

- Scheme of pressing fuel briquettes from soaked paper pulp High combustion temperature, almost 2 times more. Heat transfer from wood is about 2500-2700 kcal / kg, and eurofirewood gives off about 4500-4900 kcal / kg.

- Low degree of humidity. The smaller it is, the greater the heat transfer coefficient. For firewood, subject to proper storage, it is in the range of 15-20%, and for briquettes - 4-8%.

- High density - 0.95-1 g / cm3. For example, oak logs with a density of 0.81 g/cm3 burn much hotter than poplar logs with a density of 0.4 g/cm3.

The positive qualities of Eurowood include:

- They don't take up much space.

- They do not harm the environment because they are made from waste.

- They smolder much longer, and most importantly, they burn evenly.

- Low soot and less polluted smoke passage due to the dryness of the material.

The disadvantages include:

- Price. Initially, it seems that the cost of briquettes is much higher than firewood. But if we calculate the price per unit of heat that is obtained, the difference will not be so big.

- Moisture resistance. The briquettes need a closed storage area with good ventilation, because the wet material quickly crumbles.

- Marriage. Unfortunately, there are bad briquettes that are made from soft, rotten, very old, low-quality, and chemically treated wood species. They significantly affect the quality of the material.

Home packaging of solid fuel

The process of artisanal briquetting differs from that occurring in the factory by a low level of mechanization and by the fact that instead of drying the original components, they are moistened. For the heating needs of a standard private house, you do not have to organize a grandiose production with serious energy costs and expensive equipment. It is possible to prepare three or four tons of economical solid fuel for the autumn-winter period using old-fashioned methods.

Stages of home briquette production:

- Coal dust is taken in its pure form or with the addition of clay in a ratio of 10:1 and diluted with water until the required density is obtained. A safe clay binder prevents the destruction of finished briquettes, but increases the ash content. High quality of hashing allows to receive use of the construction mixer.

- Prepared forms are filled with a homogeneous solution. For this, both special containers and pots, buckets or used containers are suitable. Briquettes can simply be molded by hand, as they did before.

- Finished products are dried and stacked in storage areas.

Home-made coal briquettes differ from factory ones in disadvantageous qualities.They have an imperfect shape, different levels of humidity and heat transfer, low strength, which makes it difficult to transport products. But this does not prevent home-made coal briquettes from being economical and easy to use, having a low cost and high calorific value. These advantages favorably distinguish them from caked dust.

When creating equipment similar to industrial equipment, a press for the production of homemade bricks is taken as the basis. It will be improved with a loading hopper and a device for forming briquettes in the form of bars, pillows or cylinders. If you provide for the formation of through holes, this will contribute to better combustion and increase the heat transfer of finished products.

Can also be pressed at home

Can also be pressed at home

The technology of artisanal pressing of briquettes looks like this:

- Coal dust and substandard are carefully crushed, the final strength indicators depend on this.

- The raw material is mixed with water and clay until a viscous and sticky consistency is obtained.

- The mass is loaded into the hopper and squeezed out by pressing the lever, filling the form.

- When the lever moves back, the finished briquette is pushed out, removed and spread out in the sun to dry.

The production of a machine for home briquetting of charcoal by extrusion should be entrusted to a professional turner. You will have to pay a considerable amount for materials and work on the manufacture of the body, matrix and screw, but the productivity of such equipment will be higher.

Applications

They can be used to create heat in residential premises, the area of \u200b\u200bwhich is not more than 200 square meters. meters.

For heating systems of industrial and warehouse premises.

For autonomous heating systems of settlements and private buildings

An important advantage is that uniform heating is guaranteed.

For heating the railway transport sector.

It is actively used when traveling outside the city - bonfires, barbecues.

This type of fuel is suitable for stoves, saunas and Russian baths, as the briquettes meet all the necessary standards in terms of ecology and sanitation. Moreover, the heating rate increases up to two times. In fact, the practical use of this type of fuel proves its clear advantage not only in terms of price, but also ease of operation, transportation and storage.

In fact, the practical application of this type of fuel proves its clear advantage not only in terms of price, but also ease of use, transportation and storage.

Firewood

Firewood is the most environmentally friendly and natural type of fuel. In addition, they have been used for space heating since ancient times. Firewood has a high heat capacity, thanks to which it heats up the stove quickly and is able to maintain heat for a long time.

However, specific combustion parameters (including, for example, heat transfer or the height of the flame columns) largely depend on the type of wood used for firewood. For example, poplar burns quickly and gives little heat; linden flares up very poorly, but gives a lot of heat; birch burns well, but it is very poorly stored and after a couple of years it can crumble into dust.

In general, regardless of the variety, firewood is characterized as follows:

- A source of hot fire with clearly visible flames and smoke.They are suitable for use both in stoves - as fuel for heating systems - and in fireplaces, where their burning has a more decorative than practical function;

- Little sensitive to wetness. Of course, wet firewood burns poorly and is not stored very well, as various pests begin to attack them, however, they can be placed under sheds or even in the open air (but only in extreme cases);

- They have different sizes and geometries. Therefore, folding them is not very convenient. To simplify the storage of firewood, woodpile is used - special devices that protect the trunks from rolling and getting wet;

- The quality of combustion depends on the type of wood. Worst of all, willow and poplar are suitable for heating - they burn out quickly and give very little heat. Best of all - birch and oak, but the first is poorly stored, and the second is too valuable a species of wood to use for firewood.

But, regardless of the type of wood, on average, it takes 1-2 hours to burn a log. Of course, for some breeds this period may be shorter, for others it may be longer. But in the vast majority of varieties, firewood burns out in 1-2 hours.

Advantages

- Relatively low price, which can be practically zero at all with hand-made harvesting;

- Do not require special storage conditions. Although, of course, it is better to keep them in a dry, ventilated place, protected from moisture. But you can even store it in the open air - but then they can partially or significantly lose their qualities or crumble under the influence of pests;

- Suitable for burning in fireplaces, as they create a beautiful flame;

- Easily survive shocks, shocks and other mechanical damage.

Flaws

- The quality of combustion depends on the type of wood, storage conditions, drying time and many other external factors;

- They smoke a lot, so they need a well-cleaned chimney;

- They can have different diameters, shapes, sizes and other geometric parameters, as a result of which it is better to use woodpile for storage - they will not allow the firewood to roll.

A good hood (ventilation, chimney) is necessary in any case. When burned, wood emits carbon dioxide, which has a harmful effect on the human body. And cumulative.

What is better to choose ordinary firewood or euro?

Fuel briquettes are no different from other products on the market, and they also have both advantages and disadvantages. If we compare briquettes with firewood, then the first one can distinguish the following positive aspects:

- Longer burning time compared to wood. They take 4 times longer to burn completely than conventional wood. Therefore, such briquettes are very economical.

- After the combustion of fuel briquettes, a very small amount of ash is formed relative to the initial weight - no more than 1%. Firewood, on the other hand, differs in this respect - if you heat the stove with them, then after combustion, coal is formed, which is about 20% of the initial volume of the material. Some owners use the ash received after the combustion of eurofirewood for their own benefit. This is an excellent fertilizer for the soil. As a result of its introduction to the site, the growth of seedlings is improved due to an increase in the content of potassium.

- Eurowood provides more thermal energy - about 2 times.

- Modern fuel briquettes emit heat during almost the entire combustion process.In the case of conventional firewood, the heating power never remains constant and decreases over time. After about 15 minutes, the coals are completely extinguished. Eurowood until they are completely converted into ash emit the same amount of heat, and even when they turn into coals, they burn for about 1 hour more. This fuel is ideal for those people who often go outdoors with a barbecue.

- If you heat the stove with briquettes, then you will not get sparks, smoke and an unpleasant smell. Therefore, the use of eurofirewood does not harm the environment, as well as people who sit next to a heat source.

- The process of burning eurofirewood is not accompanied by the formation of substances hazardous to human health. This is explained by the presence of fungi and mold in ordinary firewood, which are not found in fuel briquettes. Microorganisms cannot withstand high temperatures and die, creating toxic smoke in the process.

- When using eurofirewood, soot is not formed, so the walls of the chimney remain clean.

- The small sizes of eurofirewood. Thanks to this quality, they can be rationally placed in a small area, saving a lot of free space. They are offered to customers in the form of neatly folded stacks. Unlike them, firewood has a different shape and size, so folding them neatly with all your desire will not work. Everyone is familiar with the situation when firewood is delivered to the customer: they are simply dumped from the truck into any free space on the site. Then everything depends entirely on you - you will have to spend more than one hour to transfer them to the barn and put them in the order you need.

Even despite the fact that fuel briquettes have a lot of advantages, the main one should be considered as efficiency.Although for some buyers, other useful qualities of eurofirewood will not be of last importance. This includes cleanliness and order. In the case of ordinary firewood, which many owners use to heat stoves, a large amount of dust, chips and other debris is often generated. When using briquettes, the owner solves all these problems at once. However, is it right only for this reason to make a choice in favor of briquettes?

Choice practice

Studying the issue of using such alternative fuel, wants to learn more about how to choose fuel briquettes. It turns out that there are some nuances here.

Budget campfire from suitable raw materials

Usually, the cost directly reflects the quality of euro briquettes, which can be ordinary or high. High-quality fuel briquettes have a high density, about 1400 kg per m3. The dense structure without cracks and chips allows them to burn perfectly, giving off a large amount of heat and leaving almost nothing behind.

Standard briquettes have a lower density, about 1000 kg per m3. Usually they consist of several layers, which can break off under mechanical stress. The heat transfer from such products is less, they burn faster and leave more ash.

The difference in the quality of eurobriquettes inexorably affects their price, distributing products by cost. However, the price of even the highest quality briquettes is 2-3 times less than that of ordinary firewood. Eurobriquettes are solid fuel available to everyone without exception.

Note that fuel briquettes can be made at home using wood, clay and water. There are plenty of recipes for preparing such fuel.

Summing up, it should be said that fuel briquettes burn for a long time, emit a lot of heat, do not leave debris and ash behind, and are cheaper than ordinary firewood. At the same time, firewood allows you to create an amazing atmosphere of warmth and comfort, solely due to its smell and cod, and you can heat a house or a bathhouse with their help as quickly as possible.

When choosing a suitable solid fuel for yourself, it is worth evaluating not only its technical characteristics, but also the possibility of application, as well as the final result.

What is better to choose ordinary firewood or "euro"?

Fuel briquettes, like any manufactured product, has both its positive and negative aspects. Compared to firewood, briquettes boast the following advantages:

- They burn on average 4 times longer than conventional firewood, which allows them to be consumed in much smaller quantities.

- They literally burn to ash, leaving behind it in the amount of 1% of the initial mass of the material. By the way, after the combustion of firewood, coal remains, which is about 20% of the initial amount of material. By the way, the ash from the burnt eurowood can be used as a fertilizer for the soil: seedlings in this place will grow better due to the increased amount of potassium.

- The heat transfer of euro-dvrs is much higher than that of conventional ones: the difference is 2 times.

-

- Able to maintain heat literally throughout the entire combustion process. That is, if for ordinary firewood the heating power decreases as it burns, and the coals die out within 15 minutes, then for eurofirewood the level of heat transfer does not change even when only coals are left from the briquette, which continue to burn for another hour. This property is extremely useful for those who like to go outdoors with a barbecue.

- The fire from burning briquettes does not spark, practically does not emit smoke and smell. Thus, eurofirewood does not harm the environment and does not cause discomfort when being near them.

- When burned, Eurowood does not emit substances that are harmful and dangerous to human health. The fact is that ordinary firewood contains fungi and mold, which die during combustion, but create toxic smoke.

- As a result of the combustion of fuel briquettes, soot does not form on the walls of the chimney.

Ignition temperature table of fuel materials

The compactness of the briquettes allows you to significantly save on space: they are delivered in the form of neatly stacked stacks. Firewood can be of different shapes and sizes, which almost eliminates the possibility of stacking them neatly. Moreover, firewood is usually “dumped” from the truck to any free place on the site, after which you will have to transfer it yourself to the barn and spread it out there.

In general, all the positive aspects of fuel briquettes could be summed up in one word: cost-effectiveness. Although, there are several points that distinguish fuel briquettes from ordinary firewood that are not related to price. For example, one of the very big advantages is cleanliness and order. From ordinary firewood there is a lot of dust, chips and other debris. Briquettes do not have such difficulties. However, does this mean that briquettes are definitely better than firewood?

Pellets for solid fuel boilers

By analogy with briquettes, pellets are compressed granules from various woodworking wastes and economic activities. The fuel is also environmentally friendly, has a homogeneous structure, but the calorific value is equal to that of coal.Pellets serve as fuel for pellet boilers, which are widely used throughout Europe.

Pellets for solid fuel boilers

The characteristics of pellets are similar to the characteristics of briquettes, however, they have such an indicator as humidity, which is no more than 10%. For comparison, freshly cut firewood has this indicator in the range of 50%. In order to maintain a low moisture content of pellets, they must be stored exclusively in a dry place, otherwise, with an increase in humidity, the calorific value of the pellets decreases. By the way, about storage: 1 ton of pellets occupies a space equal to 1m (in width), 1.1m (in length) and 1.6m (in height). It is preferable to store pellets in plastic bags.

For example, we can give the characteristics of pellets from sunflower husks:

You can buy pellets in Moscow for 5,500 rubles/t. both in big bags and in 25 kg bags. To find out in detail the cost of goods, you need to use the price lists for pellets, where, in addition to the cost, the conditions for delivery to consumers are indicated.

Main advantages

Fuel briquettes are a modern type of alternative fuel. They can be used in any stoves, fireplaces, boilers, barbecues, barbecues. Eurobriquettes are cylindrical blanks resembling firewood, or rectangular bricks. Small dimensions allow to place them in furnaces of any size.

What are briquettes made of? Most often, wood is used (sawdust, shavings, dust), but straw, paper, peat, coal, seed or nut husks, and even manure are also used. The composition of the eurobriquette can vary significantly, depending on which technology is used in the production.

A home-made eurobriquette can be used to kindle a sauna stove or heat a house. Since the raw material is compressed quite strongly and the amount of moisture is minimal, the fuel briquette burns for a long time, constantly releasing a large amount of heat. An interesting point was noticed by people who are already actively using such fuel: if you melt your barbecue with eco-wood and fry food on it, it does not ignite if it gets on the briquettes of fat.

For solid fuel stoves, boilers and fireplaces, sawdust briquettes are an excellent option. They slowly flare up, but after burning for a long time and emit a large amount of heat. This is explained by the high density of the pressed wood product. The heat transfer from briquettes significantly exceeds the level of heat obtained by burning even the driest firewood, the storage and drying of which took at least a year.

Humidity of fuel briquettes is 8-9%, dry firewood, in turn, has an indicator of 20%. It turns out that a briquette made from the same wood burns better than the wood itself. This effect is formed due to the fact that during combustion, fuel briquettes do not need to evaporate a large amount of moisture.

The briquette burns with a stable fire, without splashes, sparks, cod, and the amount of smoke emitted during combustion can be described as small. It is extremely convenient to lay such fuel in the furnace, since all products have the same regular shape.

Like any product, fuel briquettes are not without disadvantages:

- First of all, it is worth noting that they are very vulnerable to moisture, therefore they are sold in cellophane packaging.

- Briquettes are not able to withstand mechanical stress, especially products made using the RUF technology that are not fired on the outside.

- If you want to set up the manufacture of such things at home, it will cost you a pretty penny, although there will certainly be a benefit in the long run. The fact is that you will have to purchase a grinding plant, a dryer and a press machine in order to carry out the entire cycle of work with raw materials. With the right equipment, it will be possible to set up handicraft production of fuel briquettes even in your own garage.

What are briquettes and pellets?

Briquettes are larger than pellets. The range of their application is very similar to coal and wood. Due to its high density, transportation and storage of this material is not difficult. The production requires a small area and one press, which creates a briquette for heating from chips, dry sawdust and small reject waste.

Compared to pellets, briquettes are produced with lower quality requirements. This raw material is used for heating boiler houses, power plants, railway transport and boilers, which do not have such a large capacity. Of course, such material can be safely used to heat a residential building.

One of the main differences is the use of briquettes in solid fuel boilers.

Pellets are made from high quality raw materials, which are carefully pre-treated. They do not require special conditions for storage. The main thing is that the room is dry and well ventilated. Their operation pleases in that the presence of a person during heating is not mandatory, because the materials are completely burned in the boiler. In European countries, the use of this method has already been widely developed for the operation of municipal, industrial boiler houses, as well as for heat in private homes.

Is coal the most profitable fuel for a solid fuel boiler?

If we compare the specific heat of combustion of 1 kg of coal, for example, anthracite (6700 kcal, 7.8 kWh) with fuel briquettes (4500 - 5000 kcal), then one might think that coal, as a fuel for a TT boiler, is out of competition. In regions where it is mined, and where there is little forest and no alternative, this is true. But coal can be different - low-grade (it burns poorly, gives little heat), brown, coal with a large inclusion of rock, coking (it clogs the furnace with sintered mass).

Pechnik62User

I once bought coal. So it did not burn until I put the building dryer into the blower. I want to try long-burning coal pellets, and coal "tablets" made from coal dust. And in terms of costs, I conducted such an experiment. For kindling, to the operating temperature, I need: 1 bucket of coal, or 6 fuel briquettes "bricks", or 3 bundles of firewood from the store, or 6 euro-"cylinders".

Of the advantages of coal, we note:

- Ease of storage. Unlike firewood, it is enough to pour coal on the street and cover it with a banner from precipitation. The main thing is that the coal does not freeze to the ground. Then it will have to be broken to collect in a bucket.

- Less humidity than firewood and approximately the same as fuel briquettes.

- It is easier to heat a TT boiler with coal. It burns long and hot.

But, not everyone will like the dirt and coal dust in the boiler room. To heat a house with coal, you need to adapt to it.

alexggrUser

I heat my house with coal. So far, only the first floor, with an area of 70 sq. m. Boiler power 26 kW. My method of kindling - first I throw firewood into the firebox. Aspen or birch. When the firewood burns down to coals in 1.5 hours, I pour a layer of coal on them. When the coal flares up to red, then I pour a whole bucket on it. The boiler heats up to 80-85 °C.Experience shows that good coal produces much more heat. About 20 liters of coal fit into the boiler furnace. This is enough for 8-9 hours of operation of the heat generator.

Summarizing

As mentioned above, there is no ideal or universal type of fuel. Each case must be considered individually, based on their region of residence, availability and price of fuel, boiler design, and the degree of insulation of the house.

- In the firewood asset, we write down the relative availability and low price. But firewood needs to be dried, and not to heat the boiler “from wheels” with it. When delivering, for example, chopped firewood in bulk, negligent suppliers can easily deceive the customer and bring a smaller amount of fuel. Firewood must be stored somewhere. To saw. Prick. Carry. Put in a firewood. Throw in the furnace more often.

One so-called. firewood storage meter (1 firewood storage meter approximately = 0.7 cubic meters of wood) weighs about 300 - 350 kg.

- Fuel briquettes are more expensive, but due to strictly specified geometric dimensions, humidity and density, their real weight and the amount of thermal energy that they release during combustion are easily calculated. Eurowood is easier to store when unloading on pallets with a manipulator. They are less dirty. Briquettes burn longer and hotter than firewood, but unscrupulous manufacturers come across.

- Coal is the most caloric fuel. But, not all regions have this fuel at an affordable price. Not everyone wants to deal with dragging and storing coal, mud or inhaling coal dust. Often, when heating with coal, firewood is needed for the initial kindling of the boiler.

Conclusion - always consider the economic feasibility of using a particular type of fuel + the convenience of its use. Your time is also worth something.Give a comparative analysis of various types of solid fuels, bringing it to a common denominator - kilograms.

Everything about comparing different types of solid fuels in the topic: "Firewood, coal or fuel briquettes?".

Recommended articles:

Homemade goats for sawing firewood and a wood splitter: drawings, design, experience of use.

The material contains 5 types of goat for sawing firewood and 3 options for spring wood splitters.

Cheap heating of a country house with electricity.

If you do not want to be a stoker, and there is no main gas on the site, then find out how to heat a cottage with an area of 180 square meters. m, electricity in winter, spending only 1,500 rubles a month.

Heating without gas: do-it-yourself engineering communications, or how to organize a heating system based on a home-made solid fuel boiler with automation.

Source