- The choice of elements and calculations of the plastic ventilation system

- Polymer air duct device

- Design of plastic ventilation systems

- Regulatory framework of the Russian Federation

- Legislative acts and GOSTs

- Certification of ventilation equipment

- Why plastic air ducts are relevant

- Pipes for hoods: tips and tricks for choosing

- Shapes and sizes of ventilation pipes: selection rules

- How to calculate the minimum dimensions of a plastic pipe

- Ventilation installation: an alternative to air ducts

- The importance of air duct for the kitchen

- Pros and cons

- Is it always possible to install a hood?

- Is it possible to do without an air duct

- No. 7. What diameter/size of pipe do you need?

- Air duct calculation

- Calculation of the air capacity of the ventilation system

- Method for calculating the cross section of air ducts

- Choose and buy air ducts online

- Summing up

The choice of elements and calculations of the plastic ventilation system

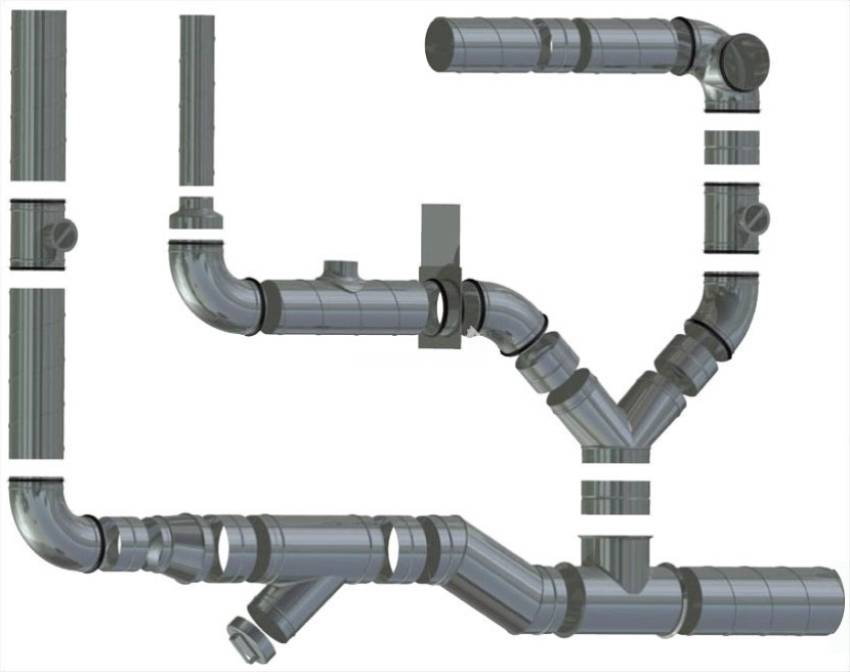

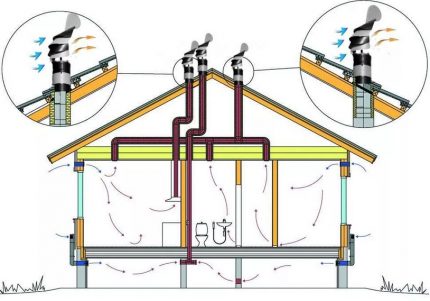

Plastic ventilation has several indisputable advantages: a wide range of components, ease of assembly, good technical characteristics. All these qualities will be fully manifested only in the case of proper assembly.

Before proceeding directly to the installation, it is necessary to draw up a draft of the air duct network, to determine which components will be required.

- plastic ventilation duct;

- backdraft valve;

- details for connecting pipes;

- gratings and plugs;

- optional equipment.

The selection of components depends on the given power of the system and the layout. The number, diameter, cross-section of air ducts can be calculated using a specialized computer program or contact a specialist for this.

When drawing up a diagram, it is important to decide which plastic fittings will be required. Plastic pipes for exhaust hoods in the kitchen are additionally equipped with fittings in the case when the exhaust hood is provided for a general house system or outside

Recirculation models do not require ductwork. According to the type and functionality of shaped elements, there are:

- short straight segments (couplings);

- adapters;

- bends;

- ducks;

- tees.

Adapters are used when connecting parts that differ in diameter. Outwardly, they resemble a truncated cone (for round pipes) or a pyramid (for rectangular products).

You can choose transitions with lateral displacement, a gradual increase or decrease in diameter to install a ventilation system of complex shape.

A branch is used when there is a need to change the direction of air flow at a right angle.

The non-return valve consists of a circuit with a petal that ensures the movement of air in only one direction. Helps prevent cold air from entering the exhaust duct.

Decorative ventilation grilles close the openings of the channels and protect against small debris and insects from getting inside, improve the appearance.

Tees are used to create complex branches in the ventilation system, there are models that allow you to connect parts with different channel diameters.

When assembling the air duct, it is important to remember the low heat resistance of plastic and not to connect heating elements (heaters and recuperators)

Polymer air duct device

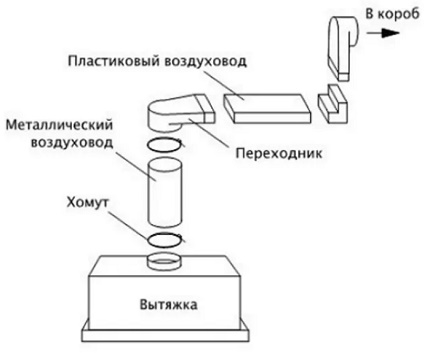

When installing an air duct, it is important to follow a few rules:

- The length of the pipe should not exceed 3 m, otherwise the efficiency of the device will decrease.

- The diameter of the hole through which the pipe is connected to the ventilation shaft cannot be greater than the diameter of the pipe.

- Do not bend the pipe more than 90⁰. This will disrupt the normal flow of air outflow. 4. Special valves must be used to prevent back draft.

- At the point of transition from the hood to the ventilation shaft, it is imperative to install an adapter.

This option is not recommended for implementation when the stove and the hood above it are on the side opposite to the exit to the ventilation shaft. This will significantly increase the length of the pipes and the number of turns, which will reduce the efficiency of the hood to a minimum.

An important parameter when installing the hood is the diameter of the pipe. If it turns out that it is smaller than the size of the outlet, the load on the engine of the hood itself will increase, and the noise level will increase to an uncomfortable perception. This will be followed by breakdowns, additional repair costs.

When installing the hood, a combination of plastic pipes with metal pipes is sometimes used. To connect them, special adapters are used.

Air ducts always try to hide. For this purpose, decorative boxes are mounted, the structure is built into the furniture.A valid option is to install the pipeline above a suspended ceiling. The main thing is not to violate any of the safety rules.

To connect to the equipment, a piece of metal pipe with a diameter of 160 mm is used. From this element, bends are made of plastic pipes. Enhance system efficiency by installing suction or blowers

If it is necessary to connect pipes having different sections, bends, special connectors, adapters are used. The inner surface of these elements must correspond to the external parameters of the duct. The pipe segment is inserted into the connector and sealed using an appropriate sealant.

There is a socket-type mounting connection. It is used when joining pipes of different sections. The smaller diameter pipe is inserted into the wider end of the pipe. Fixation occurs with the help of a thread or a special rubber seal.

Let's analyze the standard sequence for assembling an exhaust duct from plastic pipes:

Design of plastic ventilation systems

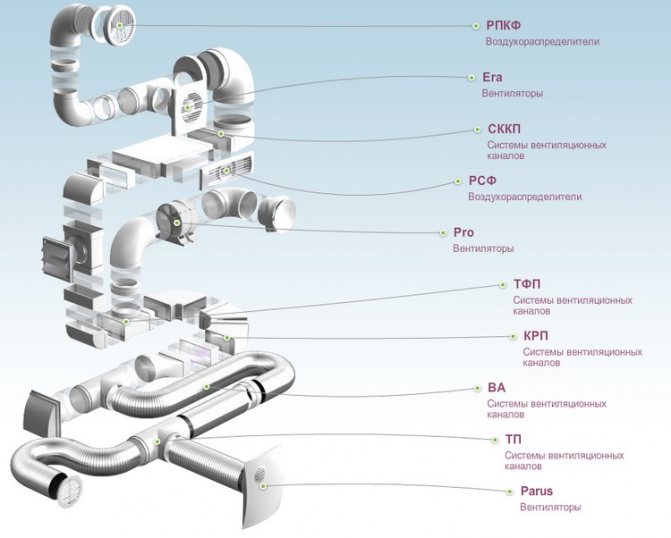

A plastic air duct for ventilation is a great choice for a home. Creating a project for a private apartment or a country house can be done on your own, because the list of technical requirements is not large. If the production workshop is completed, it is better to contact a professional design organization. The order of project development in general cases looks like this:

- production of measurements and preparation of technical specifications;

- calculations taking into account sanitary standards, technical conditions and safety rules;

- system development, primary design (draft);

- aerodynamic and acoustic calculation of the prepared project, adjustment;

- preparation of the final work plan;

- purchase or manufacture of system elements in accordance with the project and installation.

Industrial systems implemented in plastic

Regulatory framework of the Russian Federation

Installation of ventilation systems is mandatory regardless of the type of heating equipment used (p. 9.38 of SNB 4.03.01-98). Installation of heating and ventilation equipment is carried out under the supervision of representatives of gas services.

If, during the commissioning tests, defects in the ventilation system and technical inconsistencies with the design documentation are revealed, the commissioning of the heating system will be refused.

The tasks of the gas service inspector include visual inspection of the equipment, checking the safety functions, control and making control measurements of carbon monoxide. If necessary, the owner of the premises may require the inspector to provide certificates of permission to work with an anemometer or SRO

Ventilation provides a constant intensive supply of fresh air. The functioning of exhaust systems is regulated by a number of regulations.

Legislative acts and GOSTs

The regulatory framework relating to ventilation and air conditioning of gas equipment is quite extensive. These NPAs include:

- Federal Law No. 384;

- Government Decree No. 1521 on mandatory enforcement of 384-FZ;

- Government Decree No. 87;

- Government Decree No. 410 on security measures for the maintenance of gas equipment;

- SNiP (II-35-76, 2.04-05);

- SanPiN 2.2.4.548-96. 2.2.4;

- ABOK standards and recommendations in the field of ventilation, etc.

But legislative acts may change, therefore, when installing ventilation equipment for arranging a gas boiler house, one should follow their latest revisions in official sources.

All standards and regulations that will be applied when checking ventilation equipment can be clarified at the gas service of your locality

Also, all ventilated systems in rooms with boiler equipment must comply with the following GOSTs and SPs:

- GOST 30434-96;

- GOST 30528-97;

- GOST R EN 12238-2012;

- GOST R EN 13779-2007 on air conditioning and ventilation in non-residential buildings;

- GOST 30494-2011 on the microclimate in residential and public buildings;

- SP 7.13130.2013 on requirements for ensuring fire safety;

- GOST 32548-2013 (interstate standard);

- SP 60.13330.2012 (refers to SNiP 41-01-2003), etc.

Based on these regulations, design documentation should be drawn up. So that it does not contradict official requirements and standards, it is necessary to carry out thermal calculations and calculate the main parameters of the exhaust system at the stage of project development.

Certification of ventilation equipment

When buying extractor and fresh air supply devices, check their documents. For ventilation equipment sold on the territory of the Russian Federation, a declaration of conformity is mandatory.

This document confirms that the devices comply with all current requirements of the Customs Union, as set out in the following technical regulations:

- TR TS 004/2011 on the low-voltage equipment used and the safety of its operation;

- TR TS 020/2011 on the electromagnetic compatibility of the equipment used;

- TR TS 010/2012 on the safety of machinery and equipment.

This product declaration is mandatory, but in addition to it, the manufacturer or importer of ventilation equipment can undergo an official voluntary certification procedure for compliance with GOST standards. The presence of such a certificate, obtained on a voluntary basis, indicates the high quality of products and the reliability of the manufacturer.

A voluntary certificate of conformity for air ducts can be requested when purchasing ventilation equipment for a gas boiler house. It contains all technical specifications of the product.

But voluntary certification requires additional investment, so it is often saved on it. In accordance with Federal Law No. 313 and Government Decrees No. 982 and No. 148, mandatory certification of ventilation equipment has been abolished.

Why plastic air ducts are relevant

Such ventilation elements as plastic pipes appeared on the domestic market relatively recently and in the early years were significantly limited in terms of dimensions. The rectangular elements had dimensions of 6-20 cm, while the round ones were only 20 cm. The shaped elements were already included in the original kit. To date, the dimensions of the products have undergone significant changes and have begun to reach dimensions of 90 cm. In the manufacture of special channels, the following polymers can be used:

- polypropylene;

- polyvinyl chloride.

These two materials do not have significant differences, therefore they are almost equally used in the arrangement of ventilation systems. Their alternative is pipes made of galvanized steel. Their advantages:

- affordable pricing policy;

- minimal labor costs during installation;

- resistance to chemicals;

- high service life;

- excellent external performance;

- insignificant weight.

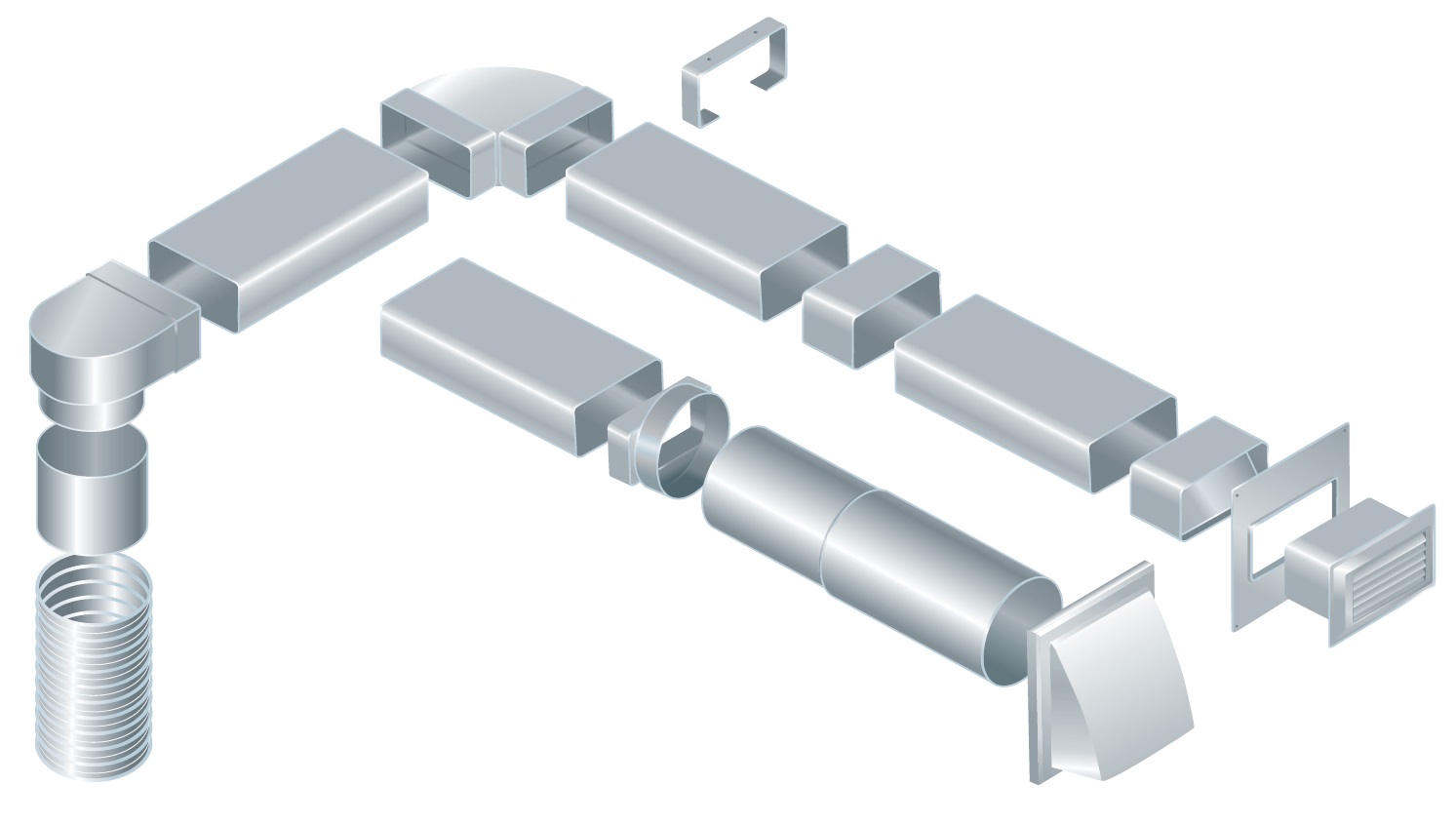

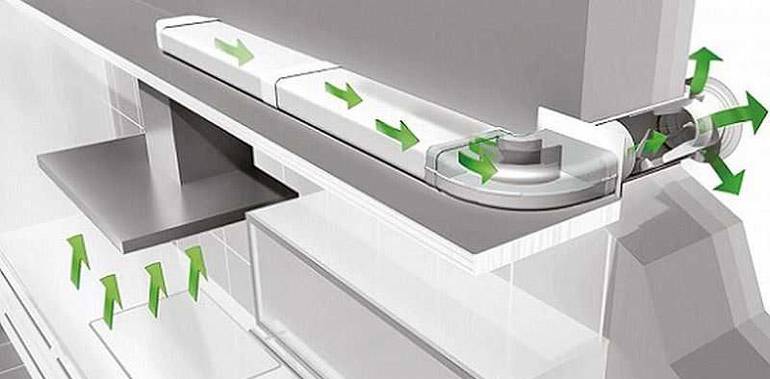

Pipes for hoods: tips and tricks for choosing

When choosing pipes for an air duct, most consumers are primarily guided by aesthetic considerations, which is quite justified. Therefore, before buying, it is recommended to determine exactly how the box will be mounted: outside or behind furniture, behind a false wall or above a false ceiling.

A shiny corrugated pipe definitely spoils the interior of the kitchen, so if we are talking about an open location, then most often they choose smooth plastic pipes that can be painted in a color that matches the design of the ceiling or walls. The most beautifully fits into an open interior is a rectangular or square pipe for the kitchen. A round hood is less aesthetically pleasing, but creates minimal airflow resistance, minimizing noise.

If we are talking about a hidden laying method, then it is better to give preference to a corrugated metal pipe. It is much easier to mount it, since it does not require the use of adapters and corners. If it is necessary to overcome an obstacle on the way to the ventilation duct, it is enough to simply bend such a pipe. However, additional costs will be required to mask corrugated products. In addition, if access to the duct is required, then the entire conspiracy will have to be dismantled.

Shapes and sizes of ventilation pipes: selection rules

The diameter of the round ventilation pipes must correspond to the cross section of the outlet pipe on the kitchen hood. It should be remembered that it is round boxes that create minimal resistance to air flow.As for the shape, a straight pipe is optimal, however, sharp corners are not allowed during the installation of air ducts.

Plastic pipes with a circular cross section can have a diameter in the range of 10-20 cm

The ideal length of the duct should be no more than 3 m. If this figure is higher, then the fan must be of maximum power. The corrugation diameters used in household ventilation are 10, 12.5 and 15 cm.

The standard sizes of plastic pipes for square and rectangular ventilation are as follows: 8×8, 10×10, 12.5×12.5, 5.5×11, 5×12, 6×20.4 and 9×22 cm. Diameter plastic pipes can be 10, 12.5, 15 and 20 cm.

How to calculate the minimum dimensions of a plastic pipe

The cross-section of square and rectangular plastic ventilation pipes must be equal to the cross-sectional area of the round hood pipe. If the diameter is narrowed, then the performance of the system will deteriorate, the fan will be overloaded, and the noise will increase. As a result, vibration will occur and the fasteners will weaken. The minimum section size is allowed only when a powerful fan is installed in the hood, but it is not used to the maximum.

Properly selected pipe size affects the quality of the hood

It is best to take a pipe whose cross section will be slightly larger than the diameter of the nozzle. If the diameter of the pipe significantly exceeds the cross-sectional area of the fitting, then this will entail additional costs and problems with its masking.

It is not necessary to calculate the size of the section of the hood hood. It should be equal to the diameter of the outlet pipe. If the hood has a certain power reserve, but is not used at full capacity, then the cross section can be slightly narrowed. To calculate its minimum value, the formula will help:

Smin=Sp*(Qr*Qmax), where:

Smin is the minimum cross-sectional index;

Sp is the section of the branch pipe indicated in the product passport;

Qp is the volume of air to be removed;

Qmax - the maximum indicator of the volume of air to be removed, it is indicated in the passport of the hood.

Qr is calculated using a different formula: Qr = Vkitchen * 12 * 1.3 m³. Vkitchen is the area of the room. According to sanitary standards, 12 is an indicator of air exchange, that is, the air in the kitchen should change 12 times per hour. 1.3 is the power loss factor in the duct and ventilation shaft.

The size of a plastic pipe can be calculated using a special formula

Ventilation installation: an alternative to air ducts

The ventilation system is an important condition for creating comfortable conditions in a country house. Depending on the project of the house, it can have a rather complex device, additional functions and a decent cost. The last point brings to life an understandable desire to save money by replacing part of the air ducts with sewer pipes. To understand whether such a decision will lead to the expected result, the following facts should be considered:

- Size difference. The dimensions and cross-sections of sewer and ventilation pipes most often do not match, so it will not work to assemble a combined system. There is a chance if the installation is carried out from scratch.

- Environmental friendliness of the material. For ventilation products, plastic is used that does not impair the quality of incoming air. Sewer pipes are not environmentally friendly, which is explained by the specifics of the application.Given these features, sewer elements in the ventilation system can only be used in the exhaust part.

One of the ways to mask the ventilation pipe from the hood

- material feature. During production, air ducts are treated with antistatic agents, so that the surface of the products remains clean. Unlike sewer counterparts, on the outer walls of which dirt will inevitably accumulate, and dust accumulations will form inside and all kinds of microorganisms will feel comfortable. Weekly dust removal from the surface is not difficult, the question is how to deal with the internal content.

- The weight. Sewer pipes are much heavier than air ducts; when installing hinged ventilation, they will require reinforced fastening.

- Appearance. The design of sewer elements loses in presentability. It is much easier to choose the right ventilation pipes for the design of the room.

These facts cast doubt on the advisability of using sewer pipes for organizing home ventilation. A compromise that has the right to exist is their use in non-residential premises (for example, a garage) or for arranging a hood.

Properly selected elements of the ventilation system will fit into any interior

The importance of air duct for the kitchen

The existing general ventilation does not remove the products of combustion and evaporation directly from the stove, it serves to replace the air in the entire volume of the room.

Modern housewives are not satisfied with this situation. We want high-quality and durable repairs in the kitchen; a working woman does not have time to regularly wash walls, ceilings and furniture.Demand gives rise to supply - local ventilation installations appeared above the kitchen stoves - hoods. But polluted air must be removed outside the premises, and this function is performed by air ducts.

Pros and cons

There is only one plus of the air duct: it is impossible to remove carbon dioxide, water and soot without it.

Cons of air ducts:

- They take up space.

- They ruin the interior of the kitchen.

- In case of poor-quality installation, the noise of the fan is increased.

- Require regular washing outside and periodic cleaning inside.

Is it always possible to install a hood?

There are situations when the installation of the hood is prohibited rules for the operation of gas appliances.

If there is a gas water heater (column) or a gas heating boiler with an open combustion chamber in the same room with the hood, the hood with air removal (circulation) cannot be installed. Removal of combustion products from the boiler occurs without forced inducement; when the fan of the exhaust device is turned on, the draft may tip over and toxic combustion products are thrown into the room.

It is allowed to install a flow-through exhaust device only if a boiler with a closed firebox is installed (with a coaxial chimney and combustion air intake from the street).

You can install circulation-type devices with filters that purify the air from grease and soot.

Is it possible to do without an air duct

Hoods produce flow and circulation:

- Flow-through remove the exhaust air from the room.

- Circulation purifies the air without removal from the room.

Circulating hoods are installed above the stove, the air passes through the housing with a carbon filter and is cleaned of grease. These devices do not need air ducts, they are compact and easy to install.But they have other disadvantages - the need for frequent filter changes, insufficient air purification, lack of removal of moisture and carbon dioxide.

No. 7. What diameter/size of pipe do you need?

Calculating ventilation is not an easy task. There are programs where you can upload all the initial data, and then get the recommended values \u200b\u200bof air exchange and duct size. There are specialists who will perform the calculation, taking into account all the features of the premises of the house. The general principle of calculation is as follows.

First you need to find the amount of air that should enter the house and be removed from it per unit hour. In theory, the volume of incoming air = the volume of air removed. How much air must go in and out for us to be comfortable? Everything has already been taken into account in the regulations.

According to SNiP 31-02-2001, air exchange for residential premises is equal to the volume of the room, i.e. in 1 hour, the air should be completely renewed 1 time. For the kitchen, this figure is at least 60 m3 / h, for the bathroom - 25 m3 / h. The volume of a room is easy to calculate.

Design standards "ABOK" 2.1-2008 speak of the following air exchange standards.

Sometimes, according to these standards, slightly different values \u200b\u200bare obtained, it is better to take into account what is larger. For a correct calculation, it is necessary to arm yourself with a house plan, which indicates the parameters of each room. It is convenient to do everything in the form of a table.

From each pair of numbers, choose the larger one and sum them up. In the example, the total air exchange is 430 m3/h. In living rooms, it will be necessary to organize an inflow and exhaust, and in the kitchen and in the bathroom - only an extract. Fresh air will come from neighboring rooms.

Further, when calculating, it is necessary to take into account how the air will be discharged, naturally or forcibly. With the natural method, the speed of the air flow inside the duct will be no more than 1 m / s, with forced - up to 5 m / s, in the branches - up to 3 m / s.

The cross section of the channel is calculated according to the formula S=L/(V 3600) m2, where L is the air exchange and V is the flow rate. You can also use a special chart. In this case, fans are indispensable. If we take the flow velocity as 3 m/s, then we get S = 0.0398 m2, or 398 cm2. It is possible to organize ventilation with one air duct 200*200 mm, two 170*170, or three 150*150. This is all just so that you understand the general calculation scheme. It is safer, of course, to turn to specialists.

Many people treat ventilation too neglectfully. If you don’t want to face microclimate problems later, break walls and ceilings or install pipes for a fine finish, it’s better to think everything through in advance.

Air duct calculation

The calculation of ventilation ducts is one of the most important stages in the design of an air supply system. Before proceeding with the direct selection of the cross-sectional area of the wires, it is necessary to determine the ventilation performance by air.

Plastic air ducts are a high-quality and reliable product with a long service life.

Calculation of the air capacity of the ventilation system

First you need a plan of the object, which indicates the area and purpose of all rooms. Air supply is provided only in those rooms in which people stay for a long time (living room, bedroom, office).Air is not supplied to the corridors, as it gets there from the living rooms, and then to the kitchens and bathrooms. From there, the air flow is discharged through the exhaust ventilation. This scheme prevents the spread of unpleasant odors throughout the house or apartment.

The amount of air supplied for each type of dwelling is calculated using MGSN 3.01.01. and SNiP 41-01-2003. The standard volume for 1 person in each room is 60 m³/h. For a bedroom, this figure can be reduced by 2 times to 30 m³ / h

It is also worth noting that the calculation takes into account only people who are in the room for a long time.

The next step is to calculate the air exchange rate. The multiplicity shows how many times per hour there is a complete renewal of the air in the room. The minimum value is one. This value prevents the atmosphere from stagnating in rooms.

Before installing the pipes of the ventilation system, the necessary measurements are made and a technical design is drawn up

Based on the foregoing, to determine the air flow, it is required to calculate two parameters of air exchange: by the multiplicity and by the number of people, from which the larger value is selected.

Calculation by the number of people:

L = N x Lnormal, where

L – supply ventilation power, m³/h;

N is the number of people;

Lnormal - normalized value of air consumption per person (typical - 60 m³ / h, in a state of sleep - 30 m³ / h).

Calculation by air exchange rate:

L = b x S x H, where

L – supply ventilation power, m³/h;

b - air ratio (residential premises - from 1 to 2, offices - from 2 to 3);

S is the area of the room, m²;

H - vertical dimensions of the room (height), m².

After calculating the air exchange for each room, the obtained values are summarized for each method. More will be the required ventilation performance. For example, typical values are:

- rooms and apartments - 100-500 m³ / h;

- cottages - 500-2000 m³ / h;

- offices – 1000-10000 m³/h

Ventilation hoses are light weight and highly flexible

Method for calculating the cross section of air ducts

To calculate the area of air ducts, it is necessary to know the volume of air that must flow through them over a period of time (according to the previous calculation stage) and the maximum flow rate. The design values of the cross section decrease with increasing air velocity, however, the noise level increases. In practice, for cottages and apartments, the speed value is selected within 3-4 m / s.

It should be noted that the use of low-speed wires with large dimensions is not always possible due to the complexity of placement in the overhead space. It is possible to reduce the height of the structure using rectangular air ducts, which, with a similar cross-sectional area, have smaller dimensions compared to a round shape. However, mounting round flexible ducts is faster and easier.

Computer modeling of internal engineering networks of ventilation

The calculation of the duct area is made according to the formula:

Sc \u003d L x 2.778 / V, where

Sc - the estimated size of the wire section, cm²;

L – air consumption, m³/h;

V is the air velocity in the wire, m/s;

2.778 is a constant for converting different dimensions.

Calculation of the actual cross-sectional area of a circular duct is made according to the formula:

Calculation of the actual area of rectangular plastic air ducts is carried out according to the formula:

S = A x B / 100, where

S – actual air duct area, cm²;

A and B are the cross-sectional dimensions of the rectangular air duct, mm.

The quality of the outflow of polluted air depends on how correctly the ventilation system is calculated.

Calculations start from the main canal and are carried out for each branch. The air speed in the main channel can be increased up to 6-8 m/s. It should be added that in domestic ventilation systems, as a rule, round ducts with a diameter of 100-250 mm or rectangular ones with a similar cross-sectional area are used. It is very convenient to use the Vents catalogs for choosing plastic air ducts for ventilation.

Choose and buy air ducts online

We have agreed on DISCOUNTS for our readers in the LEROY MERLIN store.

The range of air ducts at Leroy Merlin is huge - more than 70 varieties. You won’t see such a quantity in a regular store - there won’t be enough time or energy.

Buying online is cheaper than in the store (online price is lower)! It is very profitable, convenient and safe: you can buy goods without leaving your home and without visiting the store. All purchases will be delivered to your home. And if something does not fit, you can issue a return of the goods.

In addition, in the online store on each product page you can find the exact characteristics and real customer reviews.

Summing up

Someone may say that it makes no sense to install a ventilation system in the kitchen, which may well be enough for the mine provided by the builders without additional devices. Well, let it remain on their conscience. But still, a good ventilation system that provides a normal supply of fresh air and the removal of polluted air is a guarantee of human health.And the steam from the cooking surfaces, settling on the surfaces, will quickly nullify all efforts to repair the apartment. And therefore, the installation of ventilation pipes is a necessary thing, and sometimes even necessary.

And it's pretty easy to attach.

And it's pretty easy to attach.

We hope that the information presented today was useful to the reader. And if you have any questions about the topic, you can always ask them in the discussions. And finally, I would like to offer a short informative video on the installation of an air duct for an exhaust hood: