- Making a tank from plastic pipes

- Manufacturers

- Self-assembly

- The order of laying the drainage system

- Plastic wells for drainage: device, types, classification, installation instructions

- Classification of wells of the drainage system

- Construction of plastic revision and storage tanks

- Plastic drainage well - internal arrangement and installation

- General information

- Plastic drainage well device

- What should be the pump for pumping drainage water

- Conclusion

- What is the height of the insert?

- Calculator for calculating the volume of a septic tank

- Calculator for calculating the height of the septic tank chamber

- Creating wells from concrete rings

- Materials: construction and characteristics

- Concrete

- Plastic

- Advantages and disadvantages of PVC manholes

- Calculation of the number of filter wells on the site

- The purpose of the drainage of the garden plot

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Making a tank from plastic pipes

If a decision is made to make a well out of a plastic container, but it is missing, you can make it yourself. To do this, you should buy a plastic pipe with a diameter of 35-45 centimeters, if you plan to build viewing and turning objects, and a product with a cross section of 63-95 centimeters for absorption and collector structures.

In addition, you will need a round bottom and a plastic hatch, the dimensions of which must match the pipes. You will also need rubber gaskets.

The sequence of manufacturing a plastic container:

- Cut off a piece of plastic pipe of the desired size, which is determined taking into account the depth of the well.

- At a distance of 40-50 centimeters from the bottom, a hole is made for connecting pipelines and equipped with gaskets.

- The bottom is attached to the plastic tank and the resulting seams are sealed with sealant or bituminous mastic. The installation process of a do-it-yourself drainage tank is carried out as described above.

Manufacturers

The drainage structure can be installed with high quality if the parts selected for it meet the established standards and are purchased from trusted manufacturers. In the domestic market, the products of the Dutch corporation Wavin are popular. It produces corrugated products for drainage systems.

The corrugated shape allows the well to move in the direction of the soil and prevents its destruction. The presence of wells with a diameter of 1.0 to 6.0 meters allows you to choose any desired design. In addition to high-quality upper hatches, wells can be equipped with a bottom cover.

The domestic company "Polyplastic" produces drainage systems of various types and purposes. Tanks are made in corrugated and straight shapes.

They have high strength and long service life. The main advantage over foreign analogues is lower cost. The material for mines is polyvinyl chloride and high-strength polyethylene.

"Matline" is another domestic corporation.It produces drainage systems of any design and size, 100% ready for installation. The body of the drainage structure is welded by Leicester extruders.

Self-assembly

For the installation of a drainage well, you can use two options that differ from each other in cost. The first option is more expensive. You can buy a ready-made drive equipped with a tray and holes for drains. It must be installed in the pit, drains connected and sprinkled.

To implement it, you need to purchase the necessary tools and materials, perform installation operations.

From the tools you will need a shovel, a hacksaw, a measuring tool, containers for removing soil and mixing cement.

The list of materials required for the work includes:

- Crushed stone of small fraction.

- Screened sand.

- Cement.

- Corrugated pipe: with a diameter of 35-45 cm - under a plastic inspection well without descending a person, with a diameter of 1.0 meters and above - under a tank into which a person will descend.

- Rubber sealing elements of the required diameter.

- Covers for the bottom and the hatch.

- Mastic.

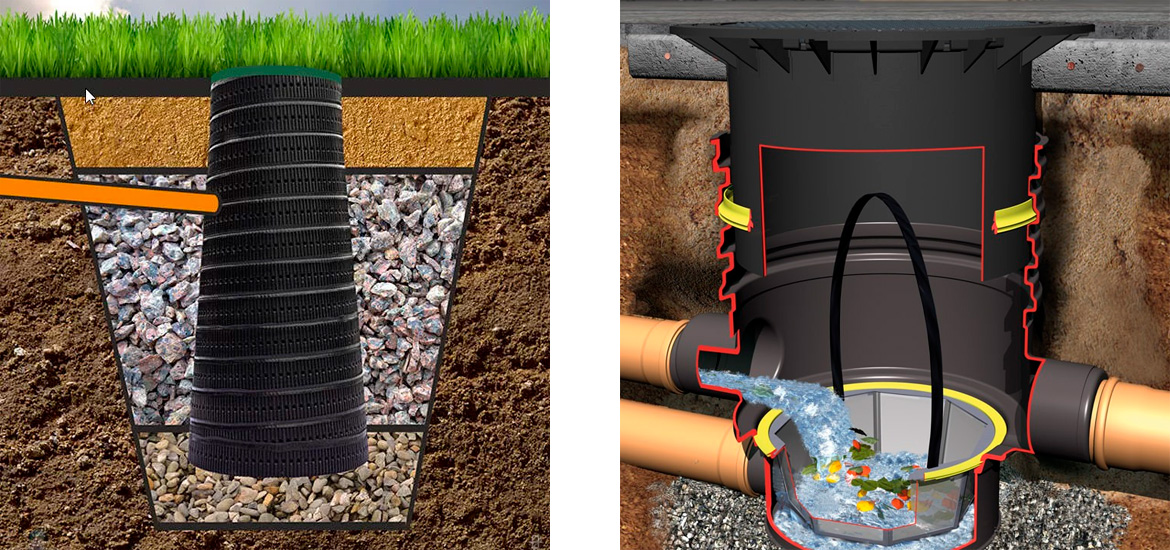

Installation of a drainage well is carried out in accordance with a drawing drawn up in advance, and consists of the following operations:

- The drain pipe must be cut to the correct height. This height should correspond to the future depth of the pit.

- It is necessary to retreat from the lower edge of the pipe, and make holes according to the diameter of the inserted drains. The height of the holes depends on the depth of the drains.

- Using mastic, it is necessary to attach the bottom to the base of the pipe and make sure the connection is tight.

- When the barrel is ready, it is necessary to dig a pit for it.The diameter of the pit should be 30-40 cm larger than the diameter of the pipe.

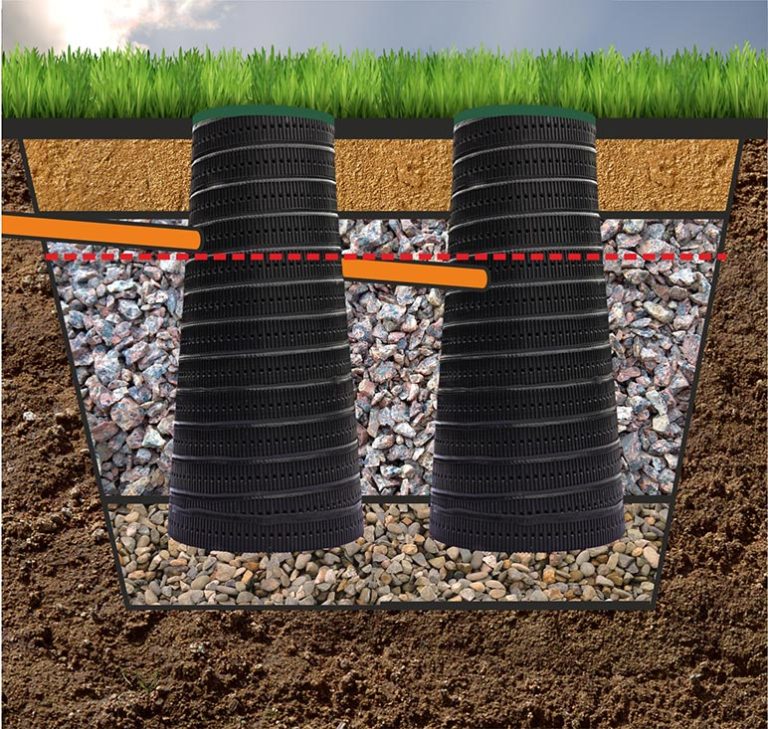

- The bottom of the pit is rammed and covered with rubble to a height of 20-25 cm.

- Crushed stone is poured with cement mortar, 10-15 cm high.

- After the solution hardens, the bottom and walls of the pit are covered with geotextiles.

- A storage or manhole for drainage is installed at the bottom of the pit and connected to the drains. The places where drains enter the mine are sealed with mastic.

- If necessary, a suction pump is installed in the shaft.

- The space between the tank and the walls of the pit is filled with rubble.

- The cover is installed. It should tightly cover the top opening of the tank.

- The top layer is decorated with turf.

The order of laying the drainage system

In order to save money, many homeowners plan to do all the installation work associated with installing a drainage system with their own hands. For such home craftsmen, the following is a step-by-step instruction for self-laying drainage in a summer cottage or in the private sector.

Mounting sequence

At the initial stage, marking and digging of trenches intended for pipe laying is carried out.

Here it is important to strictly comply with the requirements of the project documentation, if any.

The next step is tamping the bottom and side surface of the trenches. To perform this simple operation, you can use a simple device that is easy to make on your own.

For greater efficiency, sandy soils can be slightly moistened.

Next - laying on the bottom and side walls of the trench a pillow of sand and gravel and its careful tamping.

The tamped surface is covered with a geotextile sheet in such a way that a web residue of at least 0.5 m is formed on both sides of the trench.

The next step is washing and laying gravel on the bottom of the trench. Typically, a gravel pad has a thickness of 200 to 250mm.

Perforated drainage pipes are wrapped with geotextile.

Next, the pipe is laid on a gravel bed and connected using specially designed couplings.

In those places where three or more pipes are joined, a special drainage well is installed. In addition, such wells should be installed every 50-55 m.

After assembling the structure, the trench is covered with a layer of gravel 25-30 cm thick.

After that, the trench is completely covered with soil. To improve the aesthetic characteristics, layers of turf can be laid on top.

It is advisable to use the water collected in drainage wells for irrigation of beds or other domestic needs.

It is very difficult to ensure the removal of excess moisture from the site. Before starting the installation of the drainage system, you need to carefully study the landscape of the site, soil features, and accurately determine the depth of the aquifers. Based on these data, independently, or with the help of specialists, draw up a draft drainage system. Only after that you can start installation work.

Plastic wells for drainage: device, types, classification, installation instructions

The drainage system provides for the construction of wells for various purposes. Previously, they were made of concrete rings, but recently, structures made of polymeric materials have become more and more used.The latter have a lot of advantages over concrete counterparts: plastic drainage wells are light in weight and easy to install.

Installation work is simple, you just need to correctly select this plastic product.

Classification of wells of the drainage system

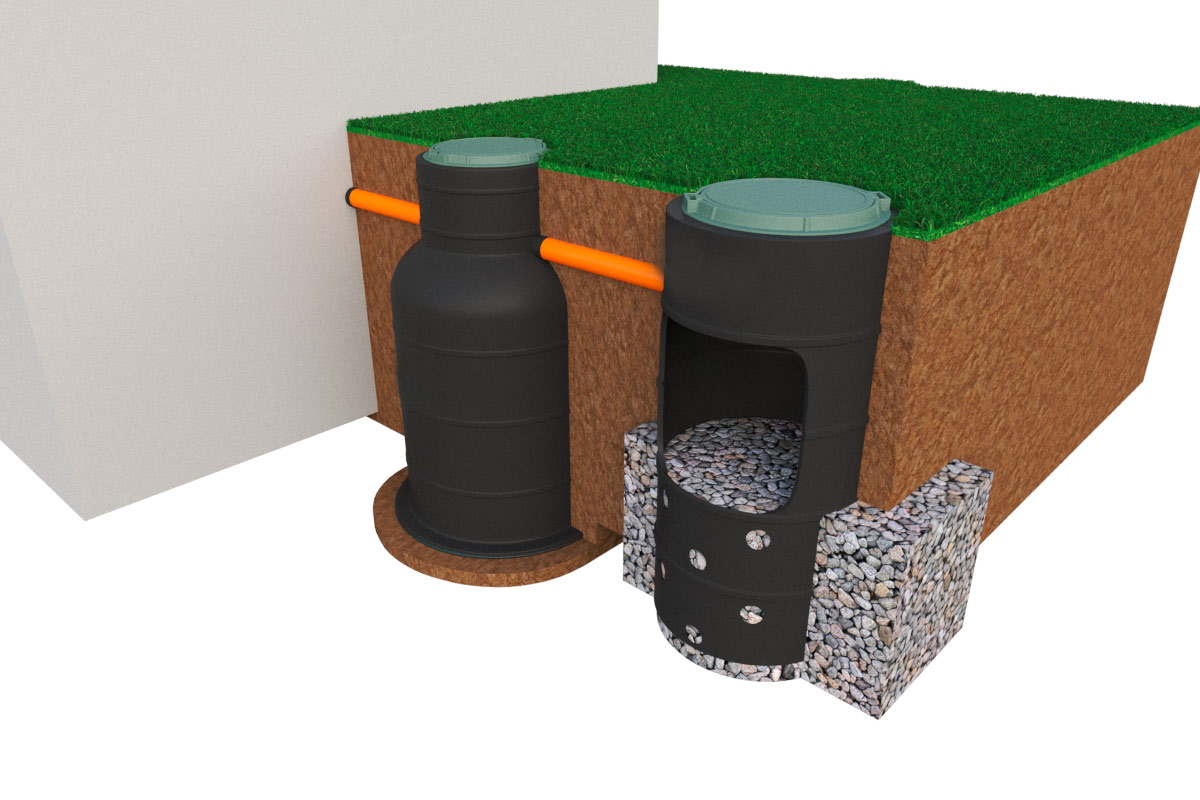

To rid the territory of rain and melt water, it is not enough to install drainage pipes and trays on the site. The same applies to moisture in the soil, drains alone will not be enough, because. the liquid collected by him must be diverted somewhere. For this, a system of drainage pipelines is created, an integral part of which are plastic wells.

There are several different types of such structures, each with its own purpose. They have different sizes and number of inputs, they can be with or without a sealed bottom. And all this variety of devices is now made of plastic.

Types of structures by functionality

In drainage systems, six types of plastic wells with different functional purposes are used:

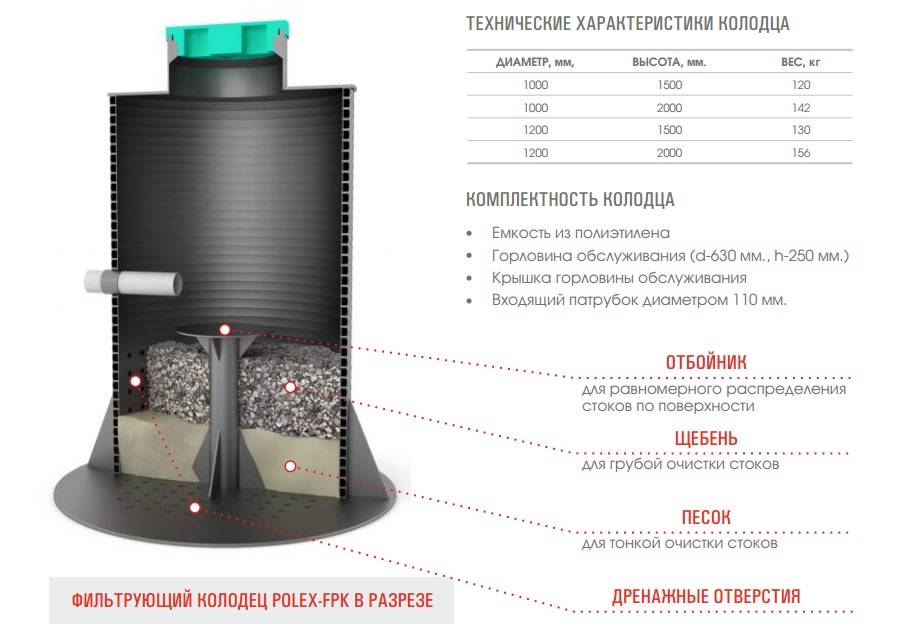

- Collector. In suburban areas, one collector well is arranged to receive wastewater from all types of sewer systems. If there is a need to stimulate the movement of wastewater, it is equipped with a pump. If it is planned to unload the system into the underlying layer, they are constructed without a bottom according to the type of filtration.

- Lookouts. Arranged for system audit and periodic cleaning. They are located at turning points, forming nodes or connecting to central highways.

- Variable. Are established in places of the joining of the pipelines laid at different depth. They are also used when it is necessary to reduce the speed of gravity or when crossing any underground structures.They are practically not used in drainage systems.

According to the type of access to system maintenance, wells are divided into serviced and inspection wells. The first type provides access to the sections of the network passing in the well for maintenance, the second provides for the performance of repair and other operations from the surface of the earth.

The functionality of the wells is different, but they are structurally similar. In general, this is a vertically oriented reservoir in the ground, which has two or more outlets and inlets. Often one well combines a number of significant functions. But in most cases, each of them is mounted for any one role.

Inspection well structures are designed for inspection and maintenance of the entire system. On the one hand, they allow you to monitor the condition and throughput of pipes, controlling the level of clogging, and on the other hand, pipelines are cleaned from them.

Plastic wells for drainage: device, types, classification, installation instructions How is a drainage well made of plastic. All types of well structures for drainage. Instructions for installing a plastic well drainage system.

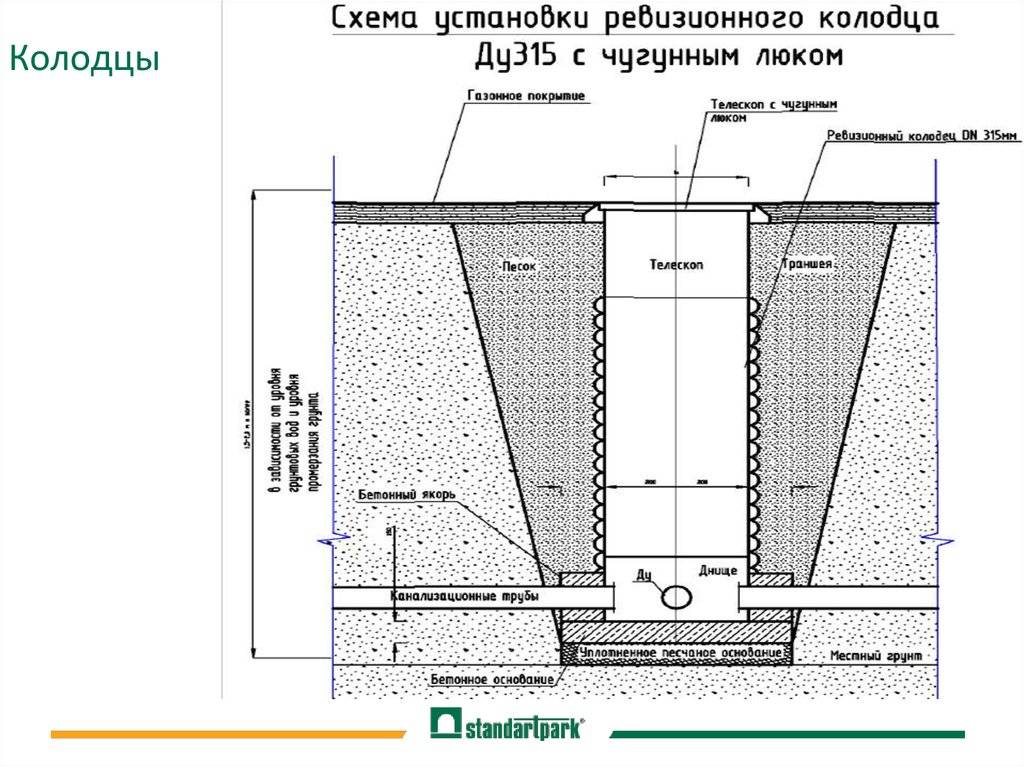

Construction of plastic revision and storage tanks

If a plastic container for a drainage well is purchased, it will only need to be correctly installed on a pre-made base. The installation of these two types of structures is almost the same. The difference may lie in the number of outlet pipes, the parameters of the wells and their different arrangement, which can be vertical or horizontal.

Observation structures, as a rule, are created in a vertical position, and accumulative ones are equipped both in vertical and horizontal versions. In addition, collector wells are equipped with drainage pumping equipment, and pipes are drained into a water collector.

The installation of the well is carried out in stages:

- On a personal plot, in the area allocated for the installation of the structure, the soil is deepened by about 40 centimeters from the level of pipe laying.

- Pour and compact layers of sand and gravel.

- Prepare a concrete solution at the rate of 3 parts of sand and 1 part of cement and fill the bottom with it.

- After the foundation has hardened, when it is completely prepared, which takes about two days, a layer of geotextile is laid.

- The container is placed on a concrete sole and pipes are connected to the outlets.

At the final stage, a hatch is installed on top and the structure is covered from all sides with rubble and soil.

Plastic drainage well - internal arrangement and installation

Not so long ago, builders had no choice when arranging drainage communications. A reinforced concrete product has always been used as a moisture distributor and accumulator.

However, in our time, a much more profitable solution has appeared - a KDN plastic drainage well.

Drainage plastic well

General information

It should be said right away that, contrary to the prevailing opinion about the unreliability of plastic products, the strength characteristics of such a well even exceed those of a reinforced concrete device. In addition, due to the prefabricated structure, the versatility of the product is achieved.

Advantages

Experts recommend using plastic wells for drainage, and there is a reasonable explanation for this:

- Space saving. Plastic structures are much smaller than concrete counterparts, which is especially important for owners of small plots.

- Maintenance savings. The service life of such structures is up to 50 years, while reinforced concrete usually serves 5-7 years, after which it begins to deteriorate intensively. As a result, it is necessary to deal with its reconstruction or the construction of new wells.

- Savings on installation work and transportation. The plastic product weighs very little and is completely ready for use, it is enough just to connect the pipes. For the implementation of reinforced concrete structures, it will be necessary to involve equipment, respectively, the price of the product will increase.

- Plastic products do not react with chemicals.

- Possibility of operation in any climatic conditions. Their operating temperature ranges from -60 to +50 degrees Celsius.

- The material is not affected by microorganisms.

- Products are not afraid of hydraulic and dynamic loads.

- If necessary, you can quickly change the height of the shaft.

Thus, the choice in favor of plastic structures is obvious.

Advice! When choosing a product, it is necessary to pay attention to the quality, including the thickness of the walls, which should not be too thin. Otherwise, the container may deform under the pressure of the soil. Drainage well device

Drainage well device

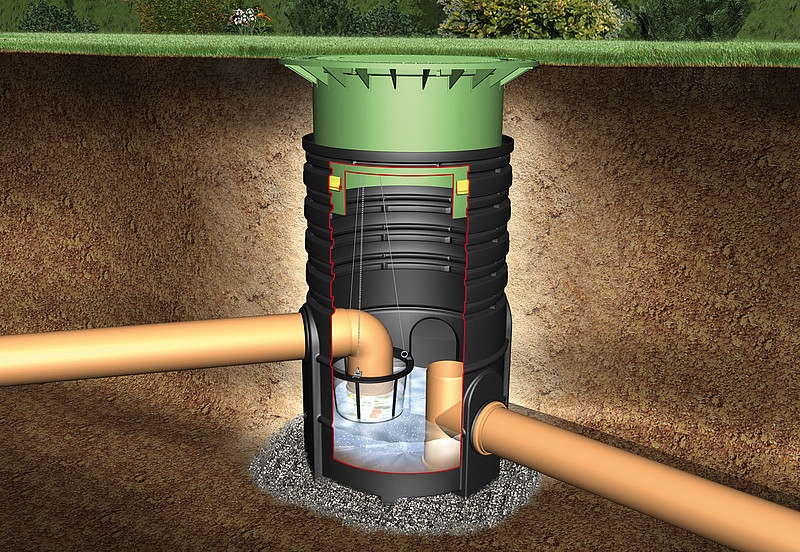

Plastic drainage well device

The drainage well consists of several main elements:

- Well body.

- Bottom.

- Cast iron or plastic hatch for the well (selected depending on the place where the drainage system is located).

Externally, the device resembles a tall glass, which is hermetically sealed from above with a lid. In its lower part, at a distance of at least 40 cm from the bottom, there are holes for drainage pipes.

Hatches of various types

Sand particles linger in the bottom space of the well. This area of the mine is called the sandbox. In addition, a drainage pumping station can be located inside the structure.

Drainage pipes are usually fixed with rubber cuffs. The height of the well and the number of outlets depends on the depth of the pipeline.

Note! Of great importance for the well is a plastic lid, which must be tightly closed. In this case, the system will be protected from overloads resulting from the ingress of rainwater into it. Drainage well in section

Drainage well in section

Materials for a drainage well

To date, manufacturers most often make plastic drainage wells from the following materials:

- polyvinyl chloride (PVC),

- Polyethylene (PE),

- Polypropylene (PP).

Note! If a person is supposed to descend into the well, then its diameter should be at least one meter. PVC construction. PVC construction

PVC construction

In addition, fiberglass products have recently appeared on the market.

Plastic drainage well - internal arrangement and installation Plastic drainage well: video instruction for do-it-yourself installation, features of KDN products, photo

What should be the pump for pumping drainage water

The pump is a common attribute of wells of all types.For pumping out drainage water, both stationary and periodically used pumps are used. For permanent operation, a pump of small capacity, but sufficient power, such as a submersible drainage, drainage float, is selected.

A submersible pump for a well will help you easily pump out liquid from an overflow tank

Pumps suitable for removing deposits are called differently: mud pump, submersible pump, fecal pump, centrifugal pump, sand pump, hydraulic pump - the question is not in the principle of operation or name, but in that this device is intended for pumping precisely deposits, including silt, sand and even small pebbles.

In principle, any pump according to the “drainage” data sheet must pump out accumulated deposits, but for this it may not have enough power (say, the “Kid” pump) or steam. Two pumps are usually used for cleaning deposits. Also, a container of the order of 200 - 300 liters may be required. The sequence of work is as follows:

- A mud pump pumps water from a drainage well.

- A water-type pump supplies, if possible with a powerful jet, clean or settled water from a container or other source.

- A mud pump (for example, Pumpex of the SK series, Makita, Karcher, Grandfos), switched on with the start of a jet of water, pumps out the turbid water, carrying away deposits.

- Another option for cleaning deposits: the team scoops out deposits with buckets, trowels, shovels by hand.

Manual cleaning is the cheapest, but not the cleanest.

In any case, drainage storage wells provide for maintenance with the help of pumps (water must still be pumped out before manual cleaning).

An example of arranging a drainage well in the video:

Conclusion

Despite the apparent simplicity of the drainage well manufacturing technology, this work is best entrusted to specialists. For the reliable functioning of the drainage system during installation, it is necessary at least to correctly set the slopes of the pipes, and not everyone will be able to do this without special tools, especially if there are certain elevation differences on the site. In addition, it is necessary to provide systems for protecting against the reverse flow of water, and to choose the right pump so that its power is enough to lift a column of water from the bottom of the well.

What is the height of the insert?

It is clear that the septic tank is obliged to cope with its task - the timely cleaning of household wastewater entering it.

In accordance with the requirements of SNiP 2.04.03-85 “Sewerage. External networks and structures" the septic tank should be designed based on three times the average daily flow of effluents (with a total daily volume of discharges up to 5 m³). This requirement is valid for the annual maintenance (pumping out) of the primary chambers.

Naturally, there is a constant gradual decrease in volume due to the settling of insoluble sediment - sludge. In addition, it is desirable to have some kind of “technological reserve” in case of an increase in water consumption - permanent, due to an increase in the number of families, or temporary, but abrupt, for example, the arrival of guests. For all these circumstances, you can add about 30% more to the estimated volume.

To calculate what volume of a septic tank will be optimal for specific conditions, the proposed online calculator will help.

Calculator for calculating the volume of a septic tank

Now we are solving the question - into how many chambers this volume should be divided.

There are also recommendations for this. With daily volumes of wastewater up to 1 m³, one chamber can be dispensed with, up to 10 m³ - two chambers can be provided, and more than 10 m³ - three.

At the same time, the share of the first settling chamber should be in a two-chamber septic tank - 75% of its volume, in a three-chamber - 50% with a uniform distribution of the remaining 50%.

True, if the septic tank is made from the glands of concrete rings, that is, our version, then it is recommended that the chambers be made of the same volume.

These are, so to speak, dry numbers. And if you read the opinions of experts on this matter, then there are somewhat different recommendations:

Never stop at one chamber, even with small volumes of wastewater, up to 1 m³. The quality of cleaning will not be the same ...

The more chambers, the cleaner the water at the outlet, that is, the less overgrowth of underground drainage tunnels or perforated pipes of irrigation fields. This means that the less often they will have to be cleaned, and this is also not an easy task, taking into account the volume of earthworks. As already mentioned, a three-chamber septic tank is able to bring water to a state where it can be reused for irrigation or fearlessly drained.

Therefore, there is such a recommendation - regardless of the calculated volume, build a three-chamber system if possible. And at the same time, do not “split” the calculated three-day volume into three chambers - only into two, according to the ratio indicated above. And the third chamber is already of arbitrary volume, for example, equal to the second. Or even go deeper if necessary to reach the filter layers of the soil.

This option is also possible - two isolated chambers of equal volume and the last one, with a draining bottom, enlarged to reach the desired soil layers.

In a word, there is something to think about - how to distribute the estimated volume of the septic tank and what additions to make. It remains only to recalculate how this volume will be expressed in the number of rings (if the septic tank is built initially) and in the height of the polymer insert (when building a new or reconstructing an old septic tank), since the insert is always smaller than the diameter of a standard reinforced concrete ring.

The following online calculator will help us with this.

Calculator for calculating the height of the septic tank chamber

Please note that whatever calculation option is chosen, the result will show the working height of the camera. What is meant?

This means that the chamber itself from the bottom to the neck can be (and will be) larger. Only the volume that can be filled with water (sewage) is taken into account. For a single-chamber septic tank, this is limited by the height of the sewer pipe entering it. For cameras with overflow - even less, that is, up to the level of this very overflow. This circumstance should be borne in mind in order not to make mistakes and not subsequently encounter unpleasant “discoveries” that the volume of the septic tank suddenly begins to be lacking.

If the calculation of the chamber with an insert is selected, then an additional data entry field will open, in which you must specify the inner diameter of this insert. If there is no such data in the technical documentation for the product (only the outer diameter is indicated), then double the wall thickness of the liner should be subtracted from the outer one.

By the way, the calculation for a chamber with an insert will allow you to compare how much higher (or, if you like, deeper) it should be in the end compared to a tank made simply of concrete rings. Sometimes such a difference makes you wonder whether the volume of the septic tank will be enough after its reconstruction, and whether it will be necessary to organize an additional chamber.

Creating wells from concrete rings

When it is necessary to provide drainage on a personal plot - a storage well or another type of such a structure, it can be assembled from reinforced concrete rings. They are made from moisture-resistant concrete. The size and diameter of the products depends on the purpose of the object being constructed. But at the same time, the depth of their installation should be at least two meters.

Manufacturers make concrete rings of different sizes. Their height can be from 10 to 100 centimeters, and the diameter is from 70 to 200 centimeters, so it will not be difficult to choose products of the required parameter.

There are two ways to install a heavy structure:

- If the diameter of the ring allows a person to fit inside it, the product is lowered to the installation site and the soil begins to be removed from the inside. Since it has a large mass, due to its own weight, it will exert pressure on the ground and, as the soil is dug out from under it, it will gradually begin to subside. Using this technology, all used rings are installed one on top of the other and fastened together with metal brackets.

- First of all, they dig a pit, in which the width will be approximately 40 centimeters greater than the diameter of the rings.If the soil is soft, a layer of gravel 15–20 centimeters thick should be poured onto the bottom, and only then concrete rings should be lowered into it successively.

If the installation is performed in the second way, then when creating a storage or revision well, it is better that the lowest ring has a blank bottom. If it is missing, then it is done independently. To do this, in the lower part, a base with reinforcement is poured from a concrete solution.

After the installation is completed, a trench is dug from it for laying pipes, but they are not placed there until holes are made in the concrete in order to connect the water drain from the drainage well. For this laborious work, a perforator with victorious or diamond crowns is used. They come in different diameters, so choosing the required size is not difficult, but their cost is high.

If the home craftsman does not have crowns for concrete work at his disposal, another cheaper method can be used. In the place where it is planned to equip the outlet, a pipe is applied and outlined with a pencil. As a result, a circle of the desired diameter will remain on the concrete.

Through holes are drilled along the contour of the prepared line with a perforator with a step of 1-2 centimeters, and one of them is placed in the center of the circle. Scrap is sent to the central hole and slowly begin to break it. After the hole becomes larger, take a sledgehammer or a large hammer and complete this process.

Now you can start piping. Rubber seals are put on them and inserted into the hole made. The entry points are treated with bitumen. Then the cover is installed.

A well of concrete elements is covered on all sides with a layer of rubble about 50 centimeters high, and then clay is poured to the top and carefully rammed. A clay pad created in this way will protect the structure from water seepage and extend the life of the well.

Materials: construction and characteristics

Most often, drainage wells are made from two types of raw materials.

Concrete

This design is equipped with concrete pipes of different lengths and diameters. The most common structures for the drainage system are products made of reinforced concrete rings.

Concrete wells are distinguished by the following positive features.

- High level of strength - prefabricated structures made of concrete rings provide the entire structure with similar properties due to the specific qualities of the raw materials.

- Long service life, which is determined by the resistance of the material to environmental factors. That is why, despite the large selection of various building materials of the latest generation, concrete remains a popular and sought-after raw material for creating drainage wells.

But the work on arranging a well from concrete elements differs in a number of difficulties. This is due to the impressive mass of structures, as a result of which the help of specialized equipment may be needed. Therefore, it will be quite difficult to do such work with your own hands.

To create a drainage well from concrete, two technologies for performing work are used: in the first case, the master is inside the ring and digs a hole; during the work, the product gradually sags.

Plastic

A drainage well made of plastic (KDN) has a number of positive features, among which the following are worth highlighting:

- simple installation, the design does not require the involvement of trucks to perform work;

- the cost of plastic products is several times less than the price of reinforced concrete rings;

- the design already contains all the necessary distribution elements for water drainage, including rainwater, as well as the necessary outlets for storm sewers;

- The service life of plastic drainage wells is about half a century.

Experts identify the main distinguishing characteristic of such wells - the design includes perforated pipes, which ensure the stability and rigidity of the structure in the ground. For the manufacture of plastic drainage wells, manufacturers use the following types of raw materials: polyvinyl chloride, polyethylene, polypropylene.

Advantages and disadvantages of PVC manholes

For several years now, plastic products have been at the forefront of water supply and sanitation, including stormwater and drainage systems. This is determined by a whole range of positive qualities of plastic products.

- One of the main advantages is the relatively light weight. Installation and transportation does not require the use of special equipment and the organization of an entrance to the installation site. The container is very easy to install by 2-3 people.

- Plastic is a sealed material that is not subject to corrosion. The service life of such products is about 50 years, and no maintenance is required.

- Resistant to aggressive media and low temperatures.

- High-quality PVC does not emit toxic substances into the soil, so drainage containers from it will not harm the ecological condition of the site.

Another often mentioned disadvantage is the high price.But if you remember that when installing a plastic tank, there is no need to hire special equipment, and the service life is several decades, it becomes clear that the cost will quickly pay off.

Calculation of the number of filter wells on the site

The number of filtration wells depends on the daily water consumption in the house. One septic tank is usually installed from two to four absorption wells. In turn, the volume of the septic tank should be three times the daily flow rate of water effluents.

Based on the fact that one person in a private house has 250 liters per day, then four family members need a septic tank with a volume of at least 3 cubic meters. meters.

Load per 1 sq. m. area of the absorption well is calculated based on the type of soil. (sandy - up to 80, super sandy - up to 40 l) If the distance from groundwater to the bottom of the well is more than two meters, the load can be increased by 20%. It is also permissible to increase the load in summer cottages, where the well is used only in the summer.

The purpose of the drainage of the garden plot

Land reclamation measures, in accordance with the norms (SNiP 2.06.15), are carried out in forest and agricultural lands so that the soil becomes as suitable as possible for growing fruit trees, cereals and vegetables.

For this, an extensive system of open ditches or closed pipelines is formed, the main purpose of which is to drain overly wet areas.

The ultimate goal of collecting water through branches and sleeves of various types is artificial or natural reservoirs (if conditions permit), special drainage ditches, absorbing wells or storage tanks, from which water is pumped out for irrigation and maintenance of the territory.

Often, pipes buried in the ground, if the relief allows, are replaced by external structures - ditches and trenches. These are open-type drainage elements, through which water moves by gravity.

According to the same principle, a pipeline network is designed for a summer cottage, regardless of its area - 6 or 26 acres. If the area suffers from frequent flooding after rain or spring floods, the construction of catchment facilities is mandatory.

Accumulation of excess moisture is facilitated by clay soils: sandy loam and loam, because they do not pass or very weakly pass water into the underlying layers.

Another factor that encourages thinking about a drainage project is the elevated level of groundwater, the presence of which can be found out even without special geological surveys.

If on the territory of the dacha a pit was dug for a cesspool or a septic tank, and it was filled with water, then the aquifers are located in close proximity to the surface of the earth. When arranging a well by a drilling organization, you will receive data on the location of water horizons from specialists.

Even if the foundation stands, there is no guarantee of maintaining a comfortable environment inside basements and basements: dampness, premature corrosion, fungus and mold may appear.

Over time, damp concrete and brick foundations become covered with cracks that are difficult to repair. On the contrary, they continue to grow, provoking movements of buildings. To prevent destruction, even at the stage of building construction, it is necessary to think about the device of effective drainage.

Excess moisture in the soil is always a danger to the integrity of the foundation of building objects: houses, baths, garages, outbuildings

Conclusions and useful video on the topic

Video #1 Technology of tapping into the plastic casing of the pipeline using a coupling:

Video #2 Overview of drainage wells from different manufacturers:

Video #3 Step-by-step installation of a plastic well structure:

A plastic well designed for use in a drainage system is a practical, durable and easy-to-install product. To install it, you do not have to involve construction equipment.

A variety of prefabricated and standard sizes of monoblock structures makes it possible to arrange drainage systems of any complexity. It is only necessary to correctly select their model in accordance with the functional purpose.

Please write your comments in the box below. Here you can also ask a question or tell us about your own experience in installing plastic wells. Share interesting facts and photographs on the topic of the article.

Conclusions and useful video on the topic

Video #1 Technology of tapping into the plastic casing of the pipeline using a coupling:

Video #2 Overview of drainage wells from different manufacturers:

Video #3 Step-by-step installation of a plastic well structure:

A plastic well designed for use in a drainage system is a practical, durable and easy-to-install product. To install it, you do not have to involve construction equipment.

A variety of prefabricated and standard sizes of monoblock structures makes it possible to arrange drainage systems of any complexity. It is only necessary to correctly select their model in accordance with the functional purpose.

Please write in the box below. Here you can also ask a question or tell us about your own experience in installing plastic wells.Share interesting facts and photographs on the topic of the article.