- Advantages of polymer wells

- What is a plastic well

- Bottom filter for a well with a wooden shield - step by step instructions

- Making a board shield for a bottom filter

- Laying the shield and backfilling the material of the bottom filter

- Video - Installing a bottom filter

- Advantages of plastic wells

- Kinds

- Design features and production standards

- Selection Tips

- Tips & Tricks

- Manhole structure

- Appointment of sewer wells

- Which well to choose

- Location depending on destination

- Purpose of underground observation chambers

- To summarize: our choice is a sewer plastic well

Advantages of polymer wells

Polymer wells are made by hot pressing from a special polymer sand mixture, the main components of which are plastic as the basis for the future design and sand as a binder.

The polymer sand well is different:

- light weight, which greatly facilitates the transportation and installation of the sewer facility;

- low cost. Depending on the overall dimensions (diameter and height), the prices for wells vary between 5,000 and 50,000 rubles;

- strength.Under the influence of high temperature and pressure, it is possible to make a plastic well, which is not inferior in strength to concrete counterparts;

- resistance to corrosion, chemically active substances;

- resistance to moisture and low temperature. During testing, it was proved that a polymer-sand well, due to minimal interaction with moisture, can withstand up to 500 freezing and defrosting cycles. The well can work uninterrupted at temperatures up to -70ºС.

The average service life of a polymer well is more than 50 years.

What is a plastic well

Sewer wells are devices that collect wastewater that appears during the operation of the sewer. Also, such products keep drains at the correct level. It is they who ensure the correct and free movement of water along special drains and grooves.

To transport a plastic well, freight transport is required

Plastic and polyethylene products can be used for both industrial and domestic sewer systems. They have recently appeared on our markets and are not yet quite confident in competing with their traditional counterparts.

Main elements:

- The shaft is the main part of the device. It is a corrugated or smooth pipe, has a fairly impressive diameter and thick walls. The corrugated version is considered the highest quality.

- The bottom is made of durable and thick layer of propylene. It ensures the tightness of the structure.

- Luke. Its strength depends on what the product is intended for.

If the well is very deep, then it is additionally equipped with a ladder. However, this element is not used in all systems.

Bottom filter for a well with a wooden shield - step by step instructions

As an example, we give the arrangement of a bottom filter for a well with direct backfill and a wooden shield.

Wooden shield for the filter

Bottom filter installation

Making a board shield for a bottom filter

Step 1. Measure the inner diameter of the well. The wooden shield placed on the bottom should be slightly smaller so that during installation there are no problems with moving and laying the product.

Step 2. Choose the type of wood for the shield. Oak has a high durability, but at the same time it will turn the water brown at first. Larch is slightly less resistant to water compared to oak, but cheaper. However, most often for a shield under the bottom the filter for the well use aspen, as it is poorly susceptible to decay under water. Wood should have as few knots and surface defects as possible - its durability depends on this.

Step 3. Knock down a regular square shield from the boards. At the same time, it is not necessary to connect them end-to-end with each other - the presence of gaps is permissible and even necessary. Use only high quality galvanized fasteners.

Step 4. Draw a circle on the surface of the shield, the diameter of which is somewhat smaller than that of the well.

Step 5. Using an electric jigsaw, cut the wooden board around the circumference.

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Step 6. If even taking into account the quicksand, the flow rate in the well is not too large, drill many small holes with a diameter of 10 mm in the shield.

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Laying the shield and backfilling the material of the bottom filter

Now that the plank shield made of aspen, oak or larch is ready, proceed to direct work with the well. Going down there, do not forget about safety - put on a helmet, check the condition of the cable, prepare a lighting device.

Step 1. If the well is up to the moment bottom filter installations has been used for a long time - clean up debris and silt.

Step 2 Install a board shield on the bottom and level it.

Shield ready to install

Installation of a board shield

Step 3. Next, your assistant should lower a bucket of gravel, jadeite or large pebbles. Lay the stones evenly over the surface of the shield. Create a layer of coarse backfill with a thickness of at least 10-15 cm.

Stones are evenly distributed over the surface of the shield

Step 4. Next, place gravel or shungite on top of the first layer. The requirements are the same - to ensure a uniform layer with a thickness of about 15 cm.

Second layer of bottom filter

Step 5. Fill in the last layer of the bottom filter - river sand washed several times.

Step 6. Provide water intake at a depth not reaching the bottom filter with a board shield. To do this, shorten the chain or rope on which the bucket descends into the well. If the water intake is carried out by a pump, raise it higher.

The well can be used 24 hours after the installation of the bottom filter

After some time - usually about 24 hours - the well can be used again. At the same time, monitor the quality of the water coming from there - if after a year or two it has acquired a sweetish taste and an unpleasant smell, this means that the board shield has begun to rot and it needs to be replaced.At the same time, do not forget to regularly wash and change the sand, gravel and shungite used when filling the bottom filter for the well.

Video - Installing a bottom filter

Bottom filter for well

Scheme of a well with a simple gravel pad, which in some cases is capable of performing the tasks of a bottom filter

The rising quicksand not only spoils the water with suspensions and impurities, but also can disable the pump or lead to displacement of the concrete ring of the well

well filter

Sand is filled with water

river sand

large pebble

Medium fraction pebbles

river gravel

rubble

Shungite

Jade

Trimming a board shield

The shield is cut around the circumference

Pruning almost finished

Ready-made shield for the bottom filter of the well. In this case, holes are not required - water will penetrate through the gaps between the boards

Shield ready to install

Installation of a board shield

Large pebbles fall into the well

Second layer of bottom filter

Bottom filter installation

Wooden shield for the filter

Scheme-section of a well with a filter made of wood and stones

Clean water in a well

Aspen shield for bottom filter

In this case, the bottom of the well is formed by clay rocks.

Extraction of river sand

The well can be used 24 hours after the installation of the bottom filter

Advantages of plastic wells

When constructing modern engineering systems for servicing the private sector, the use of plastic sewer wells is the most effective, given the ease of installation and durability of use.

Their distinctive features also include:

- high strength characteristics of the well shaft with the possibility of reinforcement for stability in the event of critical loads;

- high resistance of the tray part to wear;

- smooth outer and inner surface of the well shaft, which ensures a high level of reliability and tightness of the tie-ins, both inlet and outlet pipes;

- the ability to make a well with the necessary dimensions in height;

Well made to order

- complete tightness of all existing connections that are made in the factory;

- a well-established system when carrying out work on organizing the installation of some types of wells in the field where the pipeline is being installed, which leads to a reduction in cost and a reduction in the time for installation of wells with the obligatory provision of the required level of tightness of connections and their reliability;

- high speed of work on the installation of the well; for example, the time spent on the installation of the most structurally complex overflow well is one work shift.

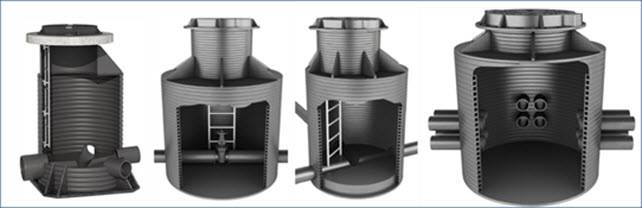

Kinds

Plastic wells for drainage systems are classified by design, purpose and material from which they are made. By design, such plumbing elements are:

- open;

- Closed.

Open ones are characterized by the absence of a bottom, due to which a certain part of the wastewater enters directly into the ground. They are convenient for use in the country or individual consumers (in the summer shower, bath). They also include water intake structures. The main advantage of this design is that they very rarely need to be cleaned.

Closed ones are equipped with a bottom, thanks to which the drains, falling into them, settle and roam.After that, they can be used as technical water for watering plants. Because of this design, these wells need periodic pumping and cleaning. But on the other hand, they do not pollute the environment and are considered the safest for use in a country house or city cottage.

inspection well

Video: what plastic sewer wells look like.

By appointment, plastic sewer wells are:

- Inspection or viewing;

- Water intakes;

- Absorption.

Fiberglass manholes (Wavin) are an essential part of any pipeline. With their help, the operation of the system is monitored, necessary repairs and other operations where it is necessary to be introduced into the work of the sewer. They differ in large diameter and hatch. When opening the hatch, a certain part of the pipeline is visible, for example, the junction of several pipes. If necessary, a certain treatment plant or even a worker is launched into the hole.

Cable polyethylene well

A water intake well is necessary for the accumulation of wastewater. It can be used for storm sewers, drains from baths, showers and other consumers, as well as a drainage accumulator. It is necessary so that the water in it is settled and used (or diverted). They can be either fecal or just water. In the first case, pumping out is mandatory, in the second, the accumulated liquid can be used as a technical one (just after preliminary cleaning).

plastic storage

Plastic absorption wells (Pragma) are used when it is not possible to organize wastewater pumping on the site.By their design, they are an analogue of a septic tank without pumping. They do not have a bottom, and the walls are additionally reinforced with stiffeners. Thanks to them, the structure is protected from deformation. The bottom is covered with crushed stone or sand (river), the depth of immersion of the tank should be below the groundwater level. The Abyssinian well is installed in the same way. When runoff enters it, it diverts them into the deep layers of the soil.

absorption well

It should be noted that in addition to standard drives, there are also plastic rings for a well or wells. These are universal pads that are used to protect concrete or metal containers from water damage. The production of these rings involves melting PVC and pouring it under high pressure into certain containers. They are seamless, which guarantees complete tightness. Between the individual rings (their height rarely exceeds 90 mm) welds are made.

Plastic sewer wells are made:

- From PVC. The most common type of containers. They are lightweight, durable, resistant to aggressive environments, and have good strength indicators. But, at the same time, they can collapse from sudden changes in temperature and can be deformed under the influence of pressure from the soil masses;

- Rubber. Another popular option. Such waste tanks are necessarily placed in a metal casing to protect against pressure and earth impact. They do not tolerate chemical waste, so they are mainly used only as viewing models;

- Polyethylene. These models are produced for installation in prefabricated casings. The most famous are Corsis.

It should be noted that some plastic prefabricated wells can be used as drinking wells.

Design features and production standards

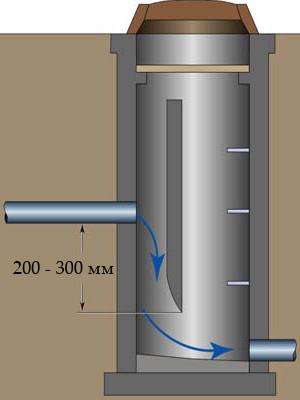

Regardless of the type of material used, the design of sewage wells is the same. The structure is a cylindrical shaft deepened into the ground, at the bottom of which there is a kinet - a tray for two or three pipes with sewage.

One of the prerequisites for the use and arrangement of plastic wells for sewage is to ensure the free movement of water

To regulate the length of the structure allows the use of extension cords and retractable shafts. To gain the required length of the structure, they are joined together, creating a strong and tight connection.

Often, sliding extension models are also used to build up the structure. Acting as connecting elements, in parallel with this they also serve as a continuation of the wall of the structure.

Depending on the operating conditions, sewer pipes can have different shapes, bends and be equipped with various branches.

The upper part of the well is equipped with an overlap with a hatch. When installing plastic wells, it is quite logical to choose hatches made of polymers, due to which it is possible to ensure equally long durability of the entire structure.

The dimensions of the plastic models correspond to the dimensions of the cast-iron counterparts. When choosing a hatch, they are guided by its functionality.

Depending on the degree of withstand load, all types of sewer manholes are divided into 4 categories:

- The "A15" standard applies to green areas and walkways. It can withstand up to one and a half tons.

- "B125" is installed on sidewalks and in park areas and parking lots, where the load weight does not exceed 12.5 tons.

- "S250" is used in the construction of sewers, the laying of which is carried out under city roads. Products withstand loads up to 25 tons.

- "D400" the most durable structures, capable of withstanding up to 40 tons, are designed for highways.

Hatches of the A15 standard can be installed directly on the well shaft, and their analogues of the B125, C250 and D400 categories can be installed on the unloading ring or a retractable telescopic pipe.

The manhole cover prevents large construction debris and other foreign objects from entering the mine, making the operation of the facility safer.

The neck is a transitional element between the shaft and the hatch. Its main purpose is to accept and compensate loads from the outside that can damage the mine and the pipes leading to it. For this reason, it is a corrugated or telescopic design.

The telescopic part of the shaft can be extended, taking the most convenient position for inspecting the condition of the wall surface and providing access during repair work. The relief ring is threaded at both ends, making the connection as tight as possible.

Holes are provided in the walls of the structure for supplying the inlet and outlet pipes.

To prevent seepage of groundwater into the cavity of the mine or seepage of sewage from it, the walls of the well are sealed

Depending on the size of the structure, wells are of two types:

- Diameter up to 1 m with unattended shaft.Compact inspection structures are installed when arranging at a shallow depth.

- With a diameter of more than 1 m. The design allows you to easily maintain the equipment and, if necessary, repair the structure.

The well itself is made of the same material that is used in the production of ordinary sewer pipes. It can be structured or two-layer polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP).

Polymers created using modern technologies are chemically resistant materials, and therefore do not pose a danger to the environment.

No less popular are models made of corrugated plastic. This solution simplifies the task of adjusting the height of the tank and allows you to partially compensate for the load on the bottom, thereby significantly extending the service life of the structure.

Both manhole options are available with single or double walls. To resist the compression of the soil from the outside, the products are equipped with stiffeners.

Selection Tips

In order not to make a mistake with the choice, you need to consider the following points:

- if the daily volume of wastewater does not exceed one cubic meter, then there is no point in spending money on expensive multi-chamber models. A cheap single-chamber sump will quite cope with such a task;

- for non-permanent residence in a country house or in the country, small septic tanks can be used. During the absence of the owners, wastewater will have time to self-clean;

- for a cottage with permanent residence, the most technically advanced models are best suited. Equipment costs will be fully offset by the ease of maintenance and reliability of the entire system.

Tips & Tricks

- If it is necessary to achieve high tightness and install a sewer well in a place with significant temperature fluctuations, it is better to opt for products made of polyethylene, as it withstands ground pressure in the cold season. For soft soil, where the probability of loading is high, it is better to choose polypropylene. It has high ductility and wear resistance. In addition, such structures are easy to weld if necessary.

- It is not recommended to save and purchase the cheapest models, because this can adversely affect the performance of the entire sewer system, and soon you will not only have to do repairs, but also spend a lot of money to fix problems and replace parts that are out of order.

The manufacturing process of plastic sewer wells and a good example in the following video.

Manhole structure

All manholes have a similar structure, no matter where it is located. Each well consists of the following elements:

- the main part in the form of a corrugated pipe;

- working chamber;

- tray;

- neck;

- Luke.

Materials for the manufacture of wells use different. Most often, concrete or plastic is used. It is more difficult to build a well from brick and rubble stone. Somewhat less commonly, cast iron or steel is used.

In some cases, it is not practical to spend money on heavy materials. To protect plastic wells from possible deformation, they are wrapped in metal mesh casings.

The most popular material for a private house is reinforced concrete. The material does not deform from mechanical impact, does not require large financial costs, its service life is approximately 20 years.Just like brick, concrete, after two decades, begins to collapse under the influence of effluents.

In multi-storey buildings, cast-iron manholes are used. The material is durable, but without professional builders, such a structure cannot be installed.

Observation buildings also differ in shape. They are:

- round;

- rectangular;

- polygonal.

A reinforced concrete slab is laid as a base, under it there must be a layer of crushed stone

Much attention is paid to the tray. This part must be strong and reliable, so it is also made of monolithic concrete.

In the process of self-manufacturing of the tray, formwork is used. Next, the concrete surface of the tray is rubbed by cementing or ironing.

There are times when the tray is not installed and the bottom remains smooth. After some time, large contaminants begin to accumulate, the water passes worse.

Directly into the tray part is a pipeline that passes wastewater. If the manhole is of a linear type, then the tray will also be straight, and the lower part will be vertical. The height of the tray must be equal to or greater than the dimensions of the widest pipe.

The height of the working chamber is 180 cm, and the diameter is calculated individually. If the pipe diameter is 60 cm, then the working chamber is 100 cm; with a pipe diameter of 80-100 cm, the working chamber will be 150 cm; if the pipe diameter is 120 cm, then the working chamber is 200 cm.

The manhole has standard neck dimensions, its size is 70 cm. If the pipe diameter is 60 cm, the neck is constructed in such a way that cleaning devices, in particular balls and cylinders, can enter it.

Ladders and brackets for descent are installed on the neck and working chamber. A hatch is installed outside.

There are also standards by which hatches are installed. If the well exits in the green zone, then the hatch should be 7 cm above ground level, if the territory is not built up, then it can be 20 cm above the ground. If the coating on the site is not provided, then a blind area is installed around the hatch to drain the liquid.

The hatch can also be made from various materials. Polymer materials, cast iron are used, both are strong and durable. With less mechanical impact from the outside, it is recommended to install plastic hatches, they are lighter and cheaper.

The hatch is necessary to protect the well from the ingress of clogging particles into it, and also so that a person does not fall into it due to negligence

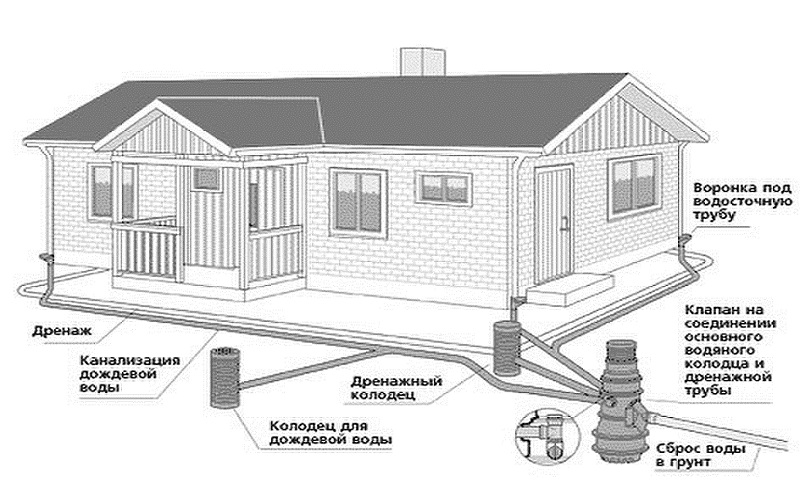

Appointment of sewer wells

This device is a rectangular or cylindrical shaft, at the bottom of which there are channels for draining wastewater. It is designed to monitor the operation of the sewerage system and its subsequent repair. On top of this shaft is a hatch. Now, mainly polyethylene sewer wells are being built, as they have a number of advantages over old concrete structures.

According to the principle of construction and use, sewer wells are of the following types:

- linear wells;

- viewing devices;

- nodal, differential and rotary wells;

- control buildings.

Viewing devices must be installed:

- in places of branches of the pipeline;

- at pipe bends;

- with changes in pipe diameters and slopes;

- on a straight section through certain distances, which depend on the diameter of the pipes.

Work on the installation of sewer wells provides for a relatively large volume and cost of materials.

Which well to choose

What to choose: reinforced concrete devices or polyethylene sewer wells? Let's consider each of them in more detail.

Concrete wells can be installed at any available depth. An employee can be in them and carry out various work. Their price is comparable to plastic products. They are reliable and durable. However, they have significant disadvantages:

- a large mass requires the use of special equipment and large labor costs;

- the difficulty of installing pipes due to the lack of standard holes at the bottom;

- tightness is insufficient and can be broken as a result of ground movements;

- pressure from above the soil is transferred to the pipeline, which can lead to accidents;

- changing the height of a device or structure entails large expenditures of effort and money;

- a limited range of products in sizes from 0.7 to 1.5 meters.

concrete well

Sewer wells made of plastic have many advantages:

- high level of tightness;

- the reliability and durability of the structure is explained by the fact that these products are not subject to rotting and corrosion;

- bacteria do not grow on the internal surfaces of the plastic device;

- light weight saves money on transportation and installation;

- the telescoping system ensures simultaneous oscillation of the hatch with the ground without damage;

- the lower tray of the well is integrated for a different arrangement of pipes of different diameters;

- if necessary, you can easily change the design;

- the cost is comparable to concrete products, however, along with installation, plastic wells are cheaper.

With the use of modern sewer repair and maintenance technologies, plastic devices can be manufactured with a smaller diameter. Now the presence of a person is not always required below, most of the work is done by equipment.

Location depending on destination

According to the SNiP standards, there are points for the mandatory installation of revision cameras:

- in places of turns and slopes, when changing the direction of the linear pipeline;

- at the points of connection to the central line of additional outlets;

- in areas where pipe diameters change.

The entrances of private sewer networks to the central system (or collector) are also equipped with viewing chambers.

The diameter of the pipes directly depends on the length of the linear section. For example, a pipeline up to 35 m long consists of elements with a diameter of 150 mm, a hundred-meter section - from pipes with a diameter of 700 to 900 mm, the maximum possible 300-meter line - from pipes whose diameter can be more than 2 m.

The dependence is inverse, that is, if the diameter of the pipeline is 150 mm, then after 35 meters it is necessary to install a well.

The main location of viewing facilities on a private suburban area is a line connecting storm water inlets with a sump, collector or filtration field

The most difficult section is selected and the revision chamber is mounted. Most often, this is a place for inserting an additional sleeve, for example, coming from a bathhouse.

Inspection wells for private use may differ from industrial counterparts in size or number of branch pipes, but they do not have a fundamental difference.

This is interesting: Do-it-yourself electric floor heating - we are studying the issue

Purpose of underground observation chambers

Inspection chambers are arranged in more critical sections of the sewer network. This is done, as a rule, on rather long sections with a large number of nodes, intersections, turns, as well as level differences. With the help of control points, it is possible to check the operability of a pipeline lying at depths of up to two meters and, in case of faults, carry out repair work in a timely manner. The shut-off and control valves, which are part of the inspection chambers, are located in plain sight, so it will not be difficult to trace and replace structural elements that have served their purpose.

Nowadays, there are many documents that regulate the construction of such facilities, and their features are reflected in documents of the SNiP or GOST type. The requirements set out in them are dictated by the experience of previous generations since the appearance of the first communication systems for moving water. As an example of regulation of construction by the regulatory framework, one can cite paragraph 2.04.03-85 (SNIP) entitled “Sewerage. External networks and structures”, which contains the rules for constructing manholes. You can make a cable transitional manhole for water supply and sewerage with your own hands and independently inspect the condition of the systems. You can select a typical project that consists of a specific schema. And it is also necessary to designate such parameters as height, plumbing dimensions and the distance of double-walled structures.

To summarize: our choice is a sewer plastic well

When deciding on the installation of communications (household, drainage), it is most reliable to use plastic sewer wells. This choice in modern times is the most practical. Its advantages include the following properties and characteristics:

- lightness of structural elements

- feasible installation of the system, ease of transportation, ease of storage

- excellent sealing performance

- resistance to mechanical damage, resistance to aggression of chemical environments on internal and external surfaces

- plasticity of the material

- long service life

- built-in additional elements (ladders, necks, etc.)

- practical solutions to the problems of the tray part of the system

- adjustment of elements in depth during installation and disassembly of the structure

- it is possible to install a small well

A significant circumstance is that polymer hatches covering wells provide protection for the sewer system no worse than their cast-iron counterpart. If desired, the hatch can be additionally equipped with constipation and other additions. In addition, a synthetic hatch will not be stolen for the benefit of scrap metal.

In the vast market for sewer wells, there is a variety of modified models from various numerous manufacturers. Systems are made of polyethylene, polypropylene, PVC. These synthetic materials are able to implement special design solutions to problems of any complexity.

Plastic sewer wells video