- Design features and production standards

- Where to place a drainage well

- Design features and manufacturing standards

- Varieties

- Concrete ring marking

- Kinds

- Recommendations for cleaning reinforced concrete sewer wells

- What should be the pump for pumping drainage water

- Conclusion

- Location depending on destination

Design features and production standards

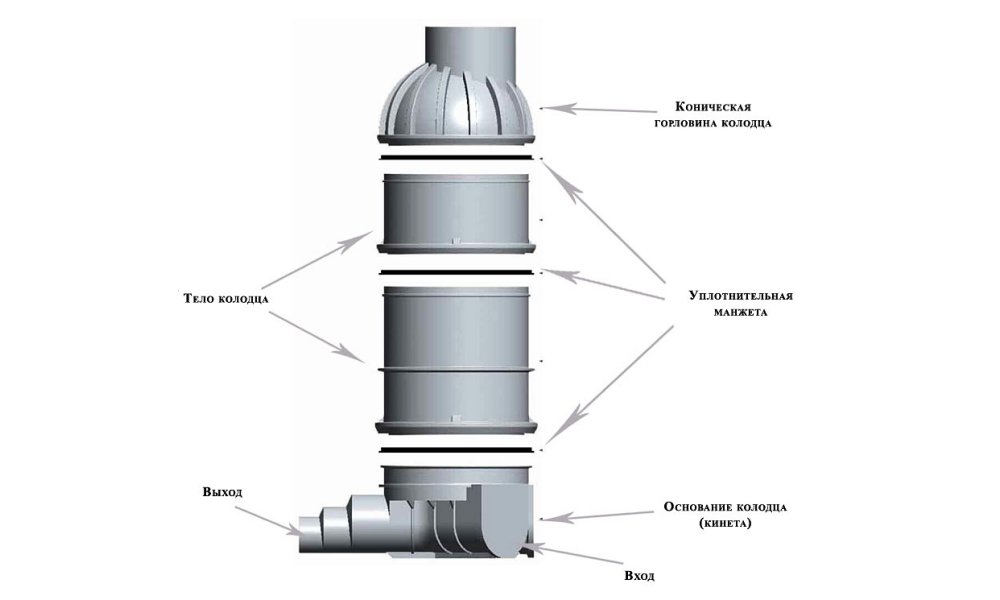

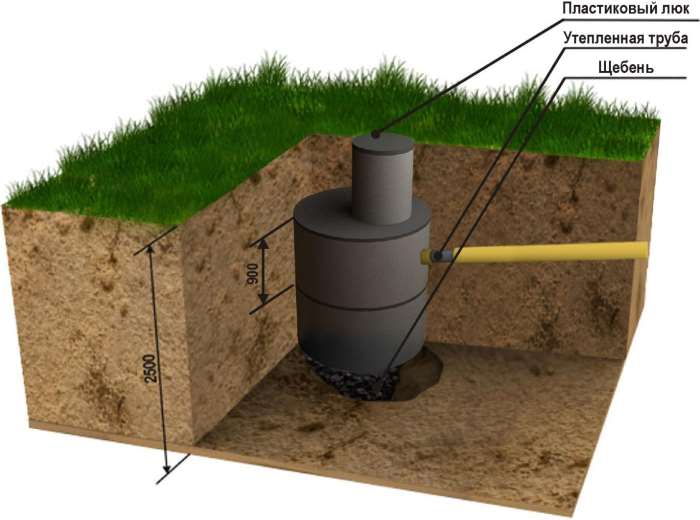

Regardless of the type of material used, the design of sewage wells is the same. The structure is a cylindrical shaft deepened into the ground, at the bottom of which there is a kinet - a tray for two or three pipes with sewage.

One of the prerequisites for the use and arrangement of plastic wells for sewage is to ensure the free movement of water

To regulate the length of the structure allows the use of extension cords and retractable shafts. To gain the required length of the structure, they are joined together, creating a strong and tight connection.

Often, sliding extension models are also used to build up the structure. Acting as connecting elements, in parallel with this they also serve as a continuation of the wall of the structure.

Depending on the operating conditions, sewer pipes can have different shapes, bends and be equipped with various branches.

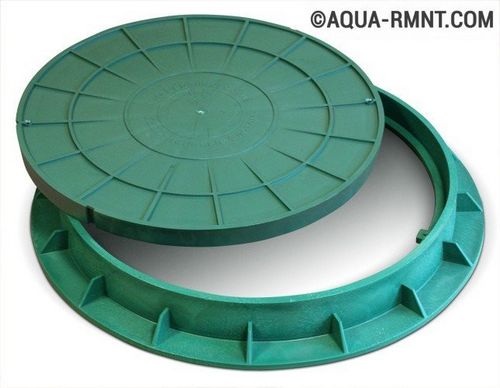

Top of the well equipped with an overlap with a hatch. When installing plastic wells, it is quite logical to choose hatches made of polymers, due to which it is possible to ensure equally long durability of the entire structure.

The dimensions of the plastic models correspond to the dimensions of the cast-iron counterparts. When choosing a hatch, they are guided by its functionality.

Depending on the degree of withstand load, all types of sewer manholes are divided into 4 categories:

- The "A15" standard applies to green areas and walkways. It can withstand up to one and a half tons.

- "B125" is installed on sidewalks and in park areas and parking lots, where the load weight does not exceed 12.5 tons.

- "S250" is used in the construction of sewers, the laying of which is carried out under city roads. Products withstand loads up to 25 tons.

- "D400" the most durable structures, capable of withstanding up to 40 tons, are designed for highways.

Hatches of the A15 standard can be installed directly on the well shaft, and their analogues of the B125, C250 and D400 categories can be installed on the unloading ring or a retractable telescopic pipe.

The manhole cover prevents large construction debris and other foreign objects from entering the mine, making the operation of the facility safer.

The neck is a transitional element between the shaft and the hatch. Its main purpose is to accept and compensate loads from the outside that can damage the mine and the pipes leading to it. For this reason, it is a corrugated or telescopic design.

The telescopic part of the shaft can be extended, taking the most convenient position for inspecting the condition of the wall surface and providing access during repair work. The relief ring is threaded at both ends, making the connection as tight as possible.

Holes are provided in the walls of the structure for supplying the inlet and outlet pipes.

To prevent seepage of groundwater into the cavity of the mine or seepage of sewage from it, the walls of the well are sealed

Depending on the size of the structure, wells are of two types:

- Diameter up to 1 m with unattended shaft. Compact inspection structures are installed when arranging at a shallow depth.

- With a diameter of more than 1 m. The design allows you to easily maintain the equipment and, if necessary, repair the structure.

The well itself is made of the same material that is used in the production of ordinary sewer pipes. It can be structured or two-layer polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP).

Polymers created using modern technologies are chemically resistant materials, and therefore do not pose a danger to the environment.

No less popular are models made of corrugated plastic. This solution simplifies the task of adjusting the height of the tank and allows you to partially compensate for the load on the bottom, thereby significantly extending the service life of the structure.

Both manhole options are available with single or double walls. To resist the compression of the soil from the outside, the products are equipped with stiffeners.

Where to place a drainage well

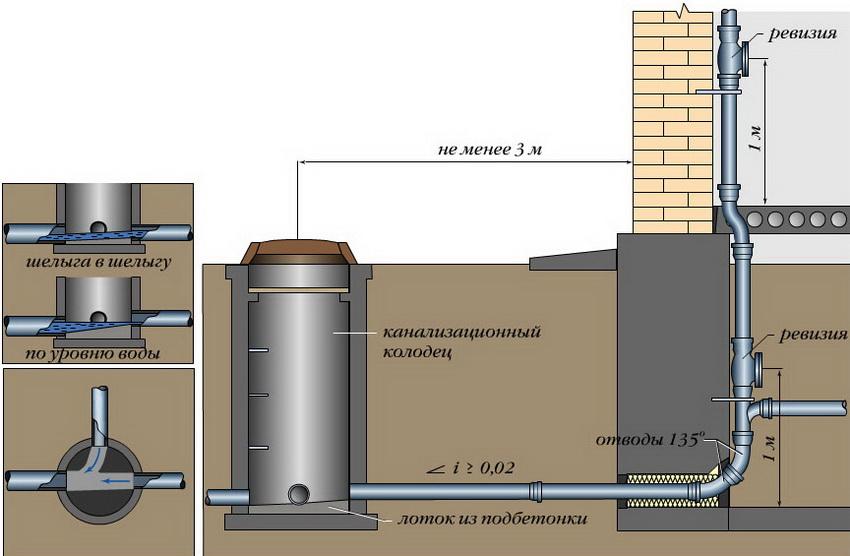

As for the manhole, it is usually located a couple of meters from the lower (or conditionally lower) corner of a residential building, which is surrounded by drainage pipes. In such a well, three tie-ins for pipes are most often obtained: two drainage and one drain (this pipe can drain water into a sewer, a reservoir, into loose soil down a slope, or into another type of drainage well). It can be very small, and then to check its condition it is enough to have a tiny removable hatch and a sludge dipstick (like an automobile, which measures the oil level).

The volume of the collector well should not be small

A grout well is usually equipped after a septic tank, if there is no sewerage or other drain nearby, and the volumes of household or washing waste drain are small (about 1 m³ per day). Concrete for such a design is practically unsuitable - it is better to take a composite, metal, plastic. Before backfilling, such a well is lined with soft material, protecting it from damage by blocks of stones and rubble, and after backfilling, it is perforated by drilling holes in the lower part from the inside.

Design features and manufacturing standards

Ordinary polymer wells are a cylindrical vertical shaft, to the bottom of which a wastewater tray (kinet) is attached. Depending on the operating conditions, these trays are made with a bend, with several branches, or in the form of a combination of branches and a bend. Also, in the well make holes for inlet and outlet pipes, and also provide it with an overlap with a hatch. The well itself is often made of corrugated plastic, since it is easier to adjust in length.In addition, this creates some compensation for the load on the bottom, which increases the life of the well.

Such designs are successfully used for household and industrial and storm sewer structures. You can adjust the length of the shaft using a special part - an extension cord. They must be connected to each other until the required length is reached. The use of sliding extension models can also be quite acceptable.

A hatch for a plastic sewer well must be selected taking into account the standard

You should also pay attention to hatches for plastic wells, which differ depending on the load that they can withstand.

- The A15 standard can withstand up to 1.5 tons and is suitable for installation on footpaths as well as in green areas.

- The B125 standard is designed for areas such as parking lots, parks and sidewalks, as it can withstand loads up to 12.5 tons.

- The C250 standard, which can withstand loads up to 25 tons, is used in the construction of sewers that run under city roads

- Standard D400 (load up to 40 tons) is designed for highways.

Light hatch A15 standard can be installed directly on the mouth of the well. Under the other hatches it is necessary to use a special unloading ring or a retractable telescopic tube. When using wells made of polymeric materials, it is possible, if necessary, to change the height of the structure, for example, if the road surface is being replaced. When using concrete rings, it is almost impossible to increase the length of the well.

Varieties

Classification:

- hatch "Garden" - type LM;

- polymer hatch - type L (light);

- hatch "Road" - type C (medium).

Plastic garden light small-sized:

- Load class: A15.

- Total weight: 11 kg.

- Load: 1.5 tons.

- Dimensions: 540*540*80.

- Purpose: Installed in park areas for manholes, in the yards of cottages and houses.

- Price: 1600 rubles.

- Service life: 50 years.

Green lightweight plastic:

- Load class: A15.

- Total weight: 10 kg.

- Load: 1.5 tons.

- Dimensions: 750*750*80.

- Purpose: observation wells of various communications located in parks, squares, in adjacent territories.

- Price: 1980 rubles.

- Service life: 20 years.

Polymer lightweight with locking device:

- Load class: A15.

- Total weight: 46 kg.

- Load: 1.5 tons.

- Dimensions: 780*789*110.

- Purpose: roads, pedestrian and park areas, planting areas, inspection shafts and wells.

- Price: 1370 rubles.

- Service life: 20 years.

Polymer lightweight small-sized:

- Load class: A15.

- Total weight: 25 kg.

- Load: 1.5 tons.

- Dimensions: 730*730*60.

- Purpose: parks, squares, sidewalk paths, observation wells.

- Price: 680 rubles.

- Service life: 20 years.

Plastic lightweight:

- Load class: A15.

- Total weight: 44 kg.

- Load: 3 tons.

- Dimensions: 750*630*115.

- Purpose: observation wells of various communications located in parks, squares, in adjacent territories.

- Price: 1350 rubles.

- Service life: 20 years.

Plastic road medium:

- Load class: B-125.

- Total weight: 50 kg.

- Load: 12.5 tons.

- Dimensions: 780*780*110.

- Purpose: installed on park roads, sidewalks, parking lots.

- Price: 1340 rubles.

- Service life: 50 years.

The choice of hatches is carried out depending on the purpose of their installation site and on the type of communication networks. Depending on their installation, they are selected according to the class of mechanical load.

Concrete ring marking

In order to use concrete elements, it is necessary to understand their special marking. It is worth knowing that, according to the state standard, the marking of ZhB rings is made using alphanumeric values using a separating hyphen.

So, first, using letters, the type of the element is indicated:

- Prefabricated ring;

- Dobornoe;

- with bottom;

- With lid;

- With lock.

As a result, the marking may look like this - KS "wall ring", or KSD "wall additional ring", etc. Further, two digital values follow in the marking. The first is the diameter of the product, indicated in decimeters, and the second is the height of the element (also in decimeters).

The first numerical value after the indicated letters is the diameter of the ring, indicated in decimeters. For example, KS-15 means "wall ring with a diameter of 1.5 m." The second number is the height of the product. It may or may not be standard. The last in the marking of the rings are the special purposes of the elements. For example, a support ring for a well will be marked as KO. And the ring with the floor slab is PP, etc. Specialists at specialized points of sale will always help you to select the required number of concrete elements for the well.

Kinds

Plastic wells for drainage systems are classified by design, purpose and material from which they are made. By design, such plumbing elements are:

- open;

- Closed.

Open ones are characterized by the absence of a bottom, due to which a certain part of the wastewater enters directly into the ground. They are convenient for use in the country or individual consumers (in the summer shower, bath). They also include water intake structures. The main advantage of this design is that they very rarely need to be cleaned.

Closed ones are equipped with a bottom, thanks to which the drains, falling into them, settle and roam. After that, they can be used as technical water for watering plants. Because of this design, these wells need periodic pumping and cleaning. But on the other hand, they do not pollute the environment and are considered the safest for use in a country house or city cottage.

inspection well

inspection well

Video: what plastic sewer wells look like.

By appointment, plastic sewer wells are:

- Inspection or viewing;

- Water intakes;

- Absorption.

Fiberglass manholes (Wavin) are an essential part of any pipeline. With their help, the operation of the system is monitored, necessary repairs and other operations where it is necessary to be introduced into the work of the sewer. They differ in large diameter and hatch. When opening the hatch, a certain part of the pipeline is visible, for example, the junction of several pipes. If necessary, a certain treatment plant or even a worker is launched into the hole.

Cable polyethylene well

Cable polyethylene well

A water intake well is necessary for the accumulation of wastewater. It can be used for storm sewers, drainage from the bath, shower and other consumers, as well as a drainage accumulator. It is necessary so that the water in it is settled and used (or diverted). They can be either fecal or just water. In the first case, pumping out is mandatory, in the second, the accumulated liquid can be used as a technical one (just after preliminary cleaning).

plastic storage

plastic storage

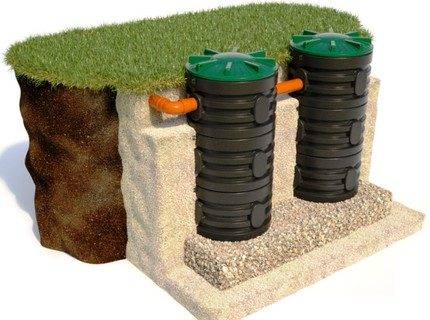

Plastic absorption wells (Pragma) are used when it is not possible to organize wastewater pumping on the site. By their design, they are analogous septic tank without pumping. They do not have a bottom, and the walls are additionally reinforced with stiffeners. Thanks to them, the structure is protected from deformation. The bottom is covered with crushed stone or sand (river), the depth of immersion of the tank should be below the groundwater level. The Abyssinian well is installed in the same way. When runoff enters it, it diverts them into the deep layers of the soil.

absorption well

absorption well

It should be noted that in addition to standard drives, there are also plastic ones. well rings or wells. These are universal pads that are used to protect concrete or metal containers from water damage. The production of these rings involves melting PVC and pouring it under high pressure into certain containers. They are seamless, which guarantees complete tightness. Between the individual rings (their height rarely exceeds 90 mm) welds are made.

Plastic sewer wells are made:

- From PVC. The most common type of containers. They are lightweight, durable, resistant to aggressive environments, and have good strength indicators.But, at the same time, they can collapse from sudden changes in temperature and can be deformed under the influence of pressure from the soil masses;

- Rubber. Another popular option. Such waste tanks are necessarily placed in a metal casing to protect against pressure and earth impact. They do not tolerate chemical waste, so they are mainly used only as viewing models;

- Polyethylene. These models are produced for installation in prefabricated casings. The most famous are Corsis.

It should be noted that some plastic prefabricated wells can be used as drinking wells.

Recommendations for cleaning reinforced concrete sewer wells

Even with all modern devices, sewer wells are often cleaned manually. It happens like this:

- One of the workers descends into the tank in order to push the wire in the direction of the blockage that has formed.

- The second group of workers, who are at the top, diligently rotate its opposite end.

There is another classification of wells, which affects the difference in:

- Depth of laying, as well as dimensions. According to these criteria, objects are divided into 2 types - serviced and inspection. The first category requires immersion inside the service personnel. The process of fulfilling the set tasks is fraught with significant difficulties. But inspection wells provide for the possibility of monitoring the performance and technical condition directly from the daylight surface.

- Regarding the dimensions, the dimensions of the serviced containers were determined in such a way that a person would not only fit in the treatment facility in question, but could also work normally there. Accordingly, the transverse size of the structure should be at least 700 mm. The most commonly used standards are one thousand, one and a half and 2 thousand mm in diameter. Adjusted for the listed standards, round slabs are used as a base.

Regarding the available structural components, from the point of view of cleaning the sewer well, it is customary to distinguish:

- The base or bottom, which may look like a circle or a rectangle;

- Rings that are part of the mine;

- The upper floor with a round hole made in it, intended for a hatch;

- Manhole cover, which may consist of cast iron or polymer material.

The preference for a round shape can be attributed to the fact that a structure with just such a geometry provides the best possible resistance to the surrounding soil. After all, the manufacturer does not have information on where and how precast concrete elements will be used, so they are made in a standardized, even form. Moreover, they are supplied with embedded parts only - hinges, which are necessarily used during the installation process.

In order to bring the pipeline into the well, it is necessary to make a hole in the lower ring, and create a tray of the required shape on the lower plate.

This design underlies manholes and overflow wells - in the latter case can be carried out minor modernization of devices, adjusted for the features of a single design model.The height of the object is determined by the number of standard and additional rings - they are the main structural components used in the process of its construction. In order for the installation of each subsequent ring to be carried out as close as possible to the previous one, it is necessary to remove all unnecessary mounting loops. Be sure to monitor the quality of sealing cracks with cement. This will reduce pollution of the surrounding soil by sewage, as well as the intensity of groundwater intrusion, which will enter the reservoir and contribute to its overflow.

Remember - sewerage systems (in fact, like all other structures) need systematic and professional maintenance. Their condition must be carefully monitored: to maintain the specified operating functions, periodically making routine repairs. If the system becomes clogged, then emergency intervention may be necessary. So, one of the purposes of sewer tanks is to ensure the possibility of implementing all the processes listed above.

And once again, attention should be paid to the advantage of reinforced concrete wells - only due to their reliability, durability and ease of installation, which does not require much effort. They still remain competitive in the market, and also hold a leading position.

Experts in the field of construction and arrangement of sewers authoritatively state that it is unlikely that in the near future there will be a “worthy rival” to reinforced concrete wells, because the shortcomings of polymer analogues are too significant.Especially often they make themselves felt in regions with cold winters - it is rare that a plastic well regularly serves more than 3-4 seasons.

What should be the pump for pumping drainage water

The pump is a common attribute of wells of all types. For pumping out drainage water, both stationary and periodically used pumps are used. For permanent operation, a pump of small capacity, but sufficient power, such as a submersible drainage, drainage float, is selected.

A submersible pump for a well will help you easily pump out liquid from an overflow tank

Pumps suitable for removing deposits are called differently: mud pump, submersible pump, fecal pump, centrifugal pump, sand pump, hydraulic pump - the question is not in the principle of operation or name, but in that this device is intended for pumping precisely deposits, including silt, sand and even small pebbles.

In principle, any pump according to the “drainage” data sheet must pump out accumulated deposits, but for this it may not have enough power (say, the “Kid” pump) or steam. Two pumps are usually used for cleaning deposits. Also, a container of the order of 200 - 300 liters may be required. The sequence of work is as follows:

- A mud pump pumps water from a drainage well.

- A water-type pump supplies, if possible with a powerful jet, clean or settled water from a container or other source.

- A mud pump (for example, Pumpex of the SK series, Makita, Karcher, Grandfos), switched on with the start of a jet of water, pumps out the turbid water, carrying away deposits.

- Another option for cleaning deposits: the team scoops out deposits with buckets, trowels, shovels by hand.

Manual cleaning is the cheapest, but not the cleanest.

In any case, drainage storage wells provide for maintenance with the help of pumps (water must still be pumped out before manual cleaning).

An example of arranging a drainage well in the video:

Conclusion

Despite the apparent simplicity of the drainage well manufacturing technology, this work is best entrusted to specialists. For the reliable functioning of the drainage system during installation, it is necessary at least to correctly set the slopes of the pipes, and not everyone will be able to do this without special tools, especially if there are certain elevation differences on the site. In addition, it is necessary to provide systems for protecting against the reverse flow of water, and to choose the right pump so that its power is enough to lift a column of water from the bottom of the well.

Location depending on destination

According to the SNiP standards, there are points for the mandatory installation of revision cameras:

- in places of turns and slopes, when changing the direction of the linear pipeline;

- at the points of connection to the central line of additional outlets;

- in areas where pipe diameters change.

The entrances of private sewer networks to the central system (or collector) are also equipped with viewing chambers.

The diameter of the pipes directly depends on the length of the linear section. For example, a pipeline up to 35 m long consists of elements with a diameter of 150 mm, a hundred-meter section - from pipes with a diameter from 700 to 900 mm, the maximum possible 300-meter line - from pipes whose diameter can be more than 2 m.

The dependence is inverse, that is, if the diameter of the pipeline is 150 mm, then after 35 meters it is necessary to install a well.

The main location of viewing facilities on a private suburban area is a line connecting storm water inlets with a sump, collector or filtration field

The most difficult section is selected and the revision chamber is mounted. Most often, this is a place for inserting an additional sleeve, for example, coming from a bathhouse.

Inspection wells for private use may differ from industrial counterparts in size or number of branch pipes, but they do not have a fundamental difference.

This is interesting: Do-it-yourself electric floor heating - we are studying the issue