- Scope of use

- Advantages of prefabricated plastic wells

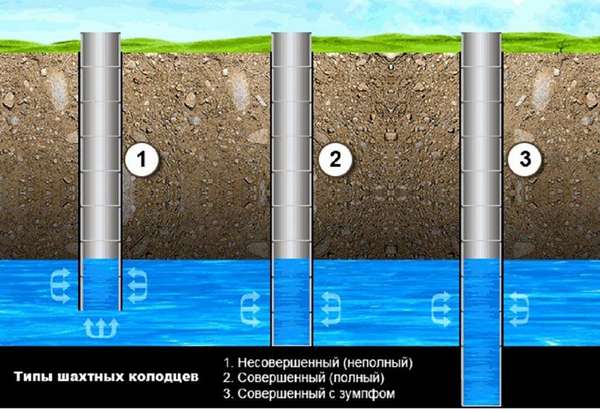

- Classification of wells for sewerage

- Plastic rings for a well: purpose and general information

- Pumping water from a drainage well

- Video: drainage well with water draining outside the site

- Types of filtering facilities

- Absorption well in the drainage system

- Filtration structure in the sewer system

- How to build a plastic well

- Design features

- Conclusions and useful video on the topic

Scope of use

Plastic wells have many advantages. Most importantly, they are airtight, do not enter into a chemical reaction with the environment, and slowly change their properties. Pluses adds a small weight (it can also be a disadvantage). That's just to mount plastic rings for the well is not always easy and they cost a lot.

Shape, size are selected depending on the purpose

Polymer wells can be used for various needs - from the storage of drinking water to the organization of drainage and sewerage. Plastic is used special, according to its characteristics it is selected according to the area of application. So, here's where plastic manhole rings can be used:

- Storm sewer.

- Drainage system:

- viewing;

- differential;

- prefabricated.

- Sewerage (storage and filtration wells).

- Plumbing systems.

- For the construction of cable ducts. Cable plastic wells allow access to power and communication cables laid in the ground.

Well ring polymer sand h-200mm d-1000mm

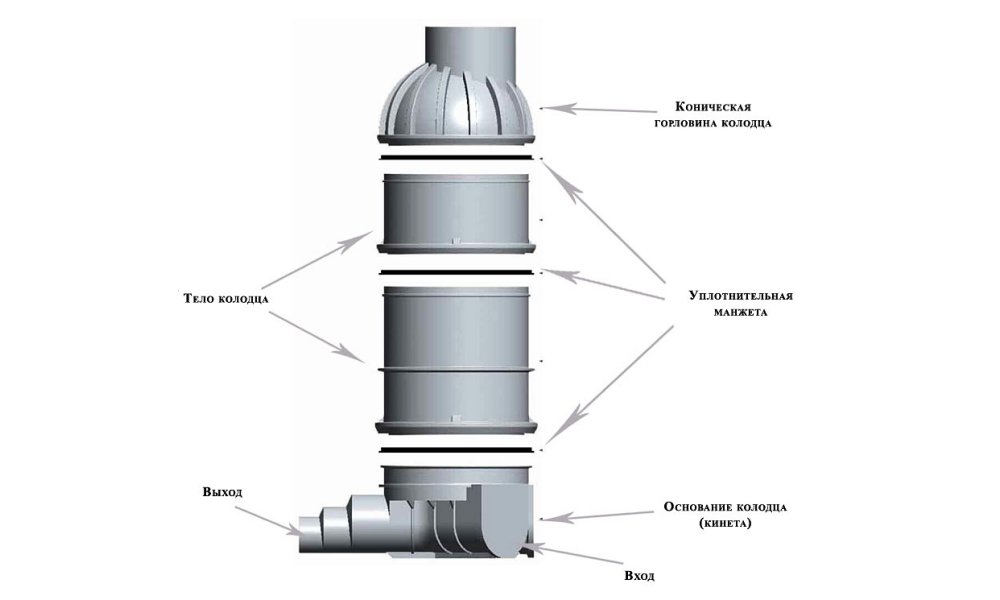

The principle of assembling a sealed plastic well. In addition to the rings, the kit includes the bottom, cone and hatch

What can be counted among the advantages of using plastic for wells? The first is that moisture in any form does not get inside the one-piece case. This is true for drinking water.

For wastewater collection, this is also important, as is the fact that the contents also do not fall into the surrounding soil in any form. If we talk about storm water and drainage, it is important that the walls of the container are smooth and easy to clean. And yet - plastic does not react with either the contents or the environment.

And yet - plastic does not react with either the contents or the environment.

For the organization of sewage on the site, it is more convenient to use a prefabricated plastic sewer well

Another area where plastic rings for the well will be useful is restoration. The task is difficult and dangerous. Working in a dilapidated well, when the logs are almost rotted or the concrete rings have moved, is the height of recklessness. Restoring it is much safer and easier with plastic inserts food grade plastic rings. The disadvantage of this solution is the high price and a decrease in usable volume. After all, the insert should be of a smaller diameter, plus they are made with stiffeners.

Advantages of prefabricated plastic wells

Each of the polymers used for the production of well rings has its own characteristics.However, almost all options have common positive characteristics that should be highlighted. This may include the following:

Ease of installation of the well structure, when compared with reinforced concrete rings. In particular, there is no need to involve heavy lifting equipment, since literally two or three people (depending on the chosen well option, of course) can easily cope with this work.

Structural durability - plastic does not crumble and does not collapse as quickly as concrete rings under the influence of moisture.

The smooth walls of plastic shafts are less prone to contamination, build-up, silt or algae

They are easier to wash if necessary.

No corrosion, as the design does not include metal elements.

Resistance to low temperatures (not all polymers - this was discussed above).

Inert to chemicals that may be in soil moisture or collected effluent.

Shock resistance, which, by the way, is important during installation.

The tightness of the connections is easily achieved.

After sealing the connecting nodes, the structure does not require additional waterproofing either from the outside or from the inside.

As you can see, the benefits are significant, and it fully justifies the purchase and use of such kits. Despite the fact that their selling price is much higher than that of "classic" concrete rings.

Classification of wells for sewerage

Structures related according to technical terminology to sewer wells are divided into several varieties.

The division is made depending on what classifying features we will use. For example, wells can be divided according to the material of manufacture, according to their purpose, or according to the method of their construction.

There are the following classifying features and their corresponding types of modern sewer wells. The first is carried out according to the environment, the transportation of which is carried out by the sewer system.

Drainage networks on which sewer wells are installed are designed to move effluents of various composition and degree of aggressiveness, these are:

- Household. These include waters that have changed their composition as a result of mixing with waste and garbage. Depending on the contaminants included in the composition, they are divided into household and fecal.

- Industrial. These include waters that have changed their mechanical and chemical composition as a result of pollution by industrial waste.

- Atmospheric. These include waters formed as a result of the active melting of winter precipitation, flood and rain water.

In addition to the listed types of wastewater, the sewerage system receives flows collected by the drainage system, the task of which is to drain the territory or drain groundwater from underground building structures.

Wells of sewer systems are divided according to the material of manufacture into:

- Brick. Once upon a time, brick was a commonly used material for the manufacture of wells, but over time, brick structures are becoming less and less.

- Concrete. Concrete structures are today the traditional material for a sewer well.

- Plastic.Obviously, polymer-based compounds are the material of the future, it is he who will someday replace both brick and concrete.

Plastic or composite prefabricated well structures attract with lightness, easy to install. Pleased with resistance to chemical influences during prolonged contact with aggressive environments. They are well tolerated by sharp and smooth temperature fluctuations, they do not pass or absorb water at all.

Sewer systems are divided into floating and export. The former move effluents to treatment plants, facilities or discharge fields. The latter only collect wastewater for subsequent pumping and removal. The wells included in both types of systems perform both the same and different functions.

According to their functional responsibilities, they are divided into:

- Cumulative. Used to accumulate wastewater for subsequent extraction and removal. Naturally, they are built in the export sewer networks.

- Collector. Designed to collect wastewater from several sewer branches and direct it to a storage tank, treatment plant or unloading fields. They are arranged both in floating and export branched networks.

- Filtering. Are applied to utilization of liquid fraction of drains in the natural way. They play the role of compact treatment facilities that transport the environment freed from pollution into the ground or into water bodies. Accompany exclusively alloyed varieties of sewage.

- Lookouts. They are built on collector sections longer than 50 m, as well as at all turning points and nodal connection of highways. Necessary for monitoring the operation of the sewer system, for periodic cleaning and repair activities.They are satisfied in both types of sewers.

- Variable. They are arranged in areas with sharp elevation changes. The reasons for the construction include the provision of a buried outlet into the reservoir and the need to slow down the drains on the sections of the pipeline with a large slope. They can be present both in the export and in the floating sewer.

The classification of manholes is much more complex. We will talk about this a little lower, and now we will consider different types of wells in more detail.

Plastic rings for a well: purpose and general information

To begin with, it should be understood that the plastic used for the rings can be different. And it is chosen depending on the subsequent use of the well, the factors of external influence on it and the priorities of the homeowner. The material may be as follows:

- polyethylene - the most resistant to freezing water,

- polypropylene - also resistant to deformation and well welded, which ensures tightness,

- polymer-sand mixture - these rings are quite strong and at the same time have much less weight than concrete ones,

- PVC - ensures the well's resistance to ultraviolet radiation and the effects of aggressive agents.

The latter option is most often used in the construction of septic tanks for sewage. Plastic water wells are usually made of polymer-sand rings or polypropylene. Polyethylene is more often used for inserting into a concrete base.

The main advantage of plastic is its tightness and resistance to destruction due to moisture. Also, the use of plastic rings for the well eliminates the formation of fungus or (as is often the case with concrete or brick) moss on the surface.Of course, the rather high cost of such products is a little embarrassing, but those who already use them have noticed that wells made of plastic rings fully justify it.

Focusnik555, Moscow: At the beginning of summer I bought polymer sand rings for a well. We found a local team that installed all this for us, mounted a house on top and brought a pipe (...). The rings are interconnected very tightly due to the groove, no sealants were used, and by the way, bituminous mastic is generally prohibited for use in drinking wells. My choice in favor of polymer sand rings is due to the fact that they are airtight and do not allow upper rainwater to pass into the well, unlike concrete ones, which work like a sponge and can burst with temperature changes like my neighbors.

Everything shows that the advantage of wells made of plastic rings is growing more and more, while concrete and brick are gradually losing their positions. But let's figure out where and how such material is used.

Pumping water from a drainage well

It is optimal if the drainage well is directly connected to the central sewerage system, but in most cases this cannot be done in summer cottages and suburban areas.

The easiest way to drain water is to bring the sewer pipe outside the site. As the well shaft fills, there will be a natural flow of water into a ravine or reservoir. Before installing the drain, you should contact your local water utility and clarify whether it is possible to mount such a discharge point without the consent of the authorities.

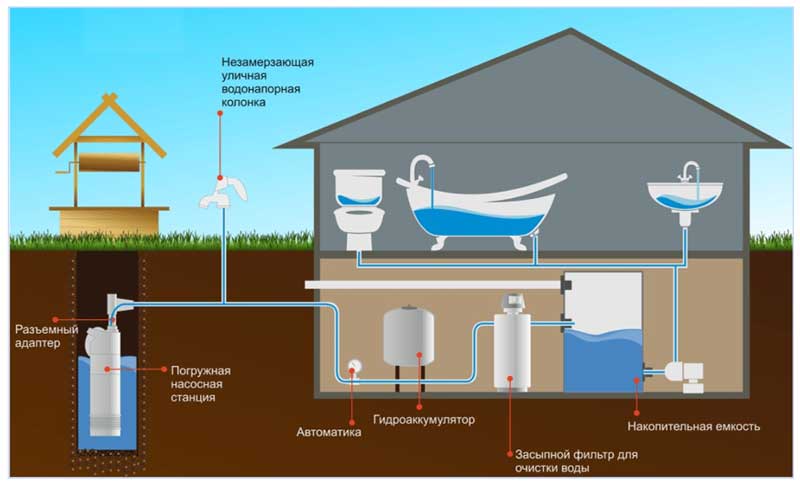

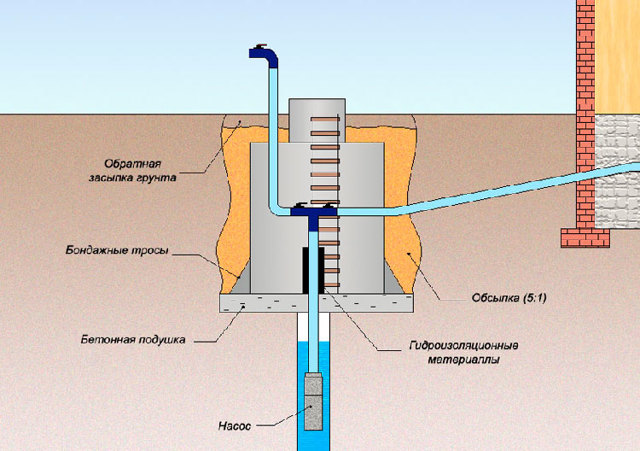

A submersible float pump is used to pump water from storage drainage wells.

A submersible pump is used to force the pumping of water from the well. The unit is connected to the central network, and a special float sensor on a short cable monitors the filling level.

The throughput of the pump depends on its power and the contamination of the wastewater. If the drainage system collects water from storm sewers, large particles of debris up to 50 mm in size may be present in it. This is also taken into account when choosing a pump. To pump out water collected exclusively from the ground, a pump with a permissible solid particle diameter of 5–7 mm is sufficient.

During the operation of the drainage well, the bottom should be washed out with a strong pressure of clean water. As a rule, this is done when the water is completely pumped out of the tank once a month.

Video: drainage well with water draining outside the site

With the proper arrangement of the drainage system, you can not worry about the safety of the materials used for the construction and sheathing of the building, and the crops growing on the site will receive the amount of moisture necessary for their normal functioning.

Types of filtering facilities

There are two types of filtration well structures that operate on the same principle and are installed in a similar way. Their differences are in the field of application. The former are used in the drainage and storm system, the latter in the sewer.

Absorption well in the drainage system

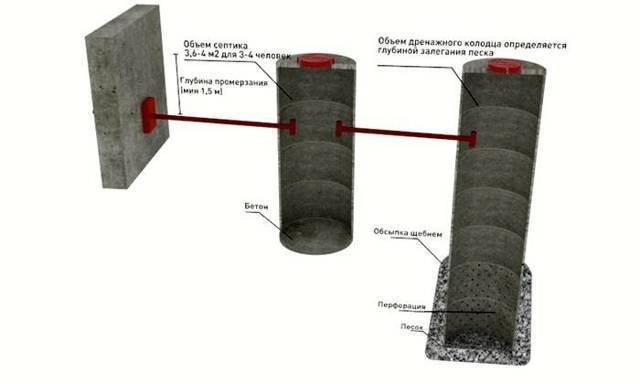

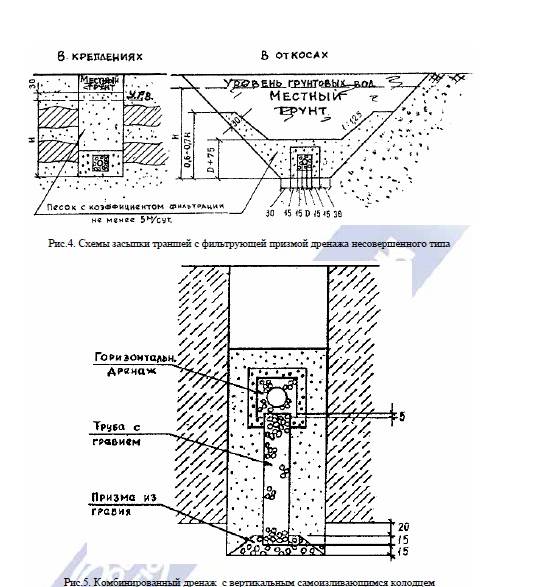

In this case, drainage absorption wells are the end point of a complex drainage system of the site, where groundwater or rainwater rushes through the pipeline, so that later, after passing through a natural filter, it goes into the ground. Its main purpose is to divert water from the house and clean it from silt and sand.

The diagram shows the organization of storm and drainage sewerage of a site with a drive. In soils with a high absorption capacity, instead of a collector, a filtration well is installed

The diameter of such wells, as a rule, is no more than one and a half, and the depth of occurrence is up to two meters. It is allowed to drain both systems into one well. The filter tank is installed at the lowest point of the site so that water flows into it by natural gravity.

Filtration structure in the sewer system

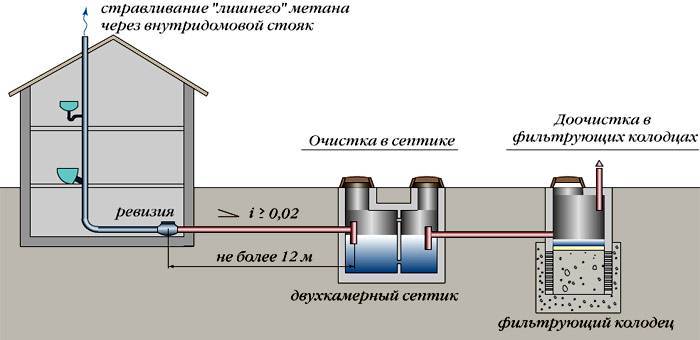

In the sewer system of the site, absorption wells are used for post-treatment of wastewater coming from a hermetically sealed reservoir, in which wastewater undergoes primary biological treatment. The tank is made of concrete rings, brick or rubble stone, or a ready-made septic tank is used.

Scheme of installation of a filtration well with a septic tank, in which sewage flows undergo primary treatment, and then they enter the absorption tank through the pipe and go into the soil through the filter system

The principle of operation of the system is as follows: sewage from the house sewer enters a sealed container, where it is oxidized for two to three days under the influence of anaerobic bacteria living in an airless space.

Then the wastewater enters the filtration well, where other bacteria - aerobes - are already present. Their vital activity is activated under the influence of oxygen.

As a result of double purification, the liquid entering the soil from the absorption well is almost completely rid of harmful microorganisms and organic substances.

Wastewater disposal can be organized in two ways:

- Separate.Water from the kitchen, bath, washing machines goes into the septic tank, and sewage with feces goes into the cesspool.

- Joint. All household waste goes to a septic tank or storage tank.

As a rule, in the first case, gray effluents are sent to different sewer facilities. For example, fecal - into a storage well with subsequent pumping and removal, gray domestic wastewater from kitchen sinks, bathtubs, washbasins, etc. devices - in absorption wells.

In the second case, a septic tank is required, consisting of at least two chambers, in each of which its own cleaning stage is sequentially carried out. Fecal masses settle in the first chamber, from where they are periodically pumped out by a sewage machine.

A single-chamber septic tank is usually installed in individual farms in which a separate sewerage system is organized

The second chamber receives liquid waste without suspended particles with a minimum amount of impurities, where they undergo further purification. After that, the water passes through the pipes into the filtration well, from where, after passing through a natural filter, it goes into the soil.

The second variant of the joint scheme is the complete pumping and removal of wastewater.

How to build a plastic well

Most drinking water sources suffer from surface water pollution, which has prompted the development of effective methods of protection. One of them is to equip the well with a plastic pipe instead of traditional concrete rings.

It is very important to use seamless products for these purposes, which will guarantee against percolation of perched water into the mine. So that the source is not covered with sand, geotextiles are used

An important condition is the most accurate hit in the closest aquifer. Strictly speaking, a plastic pipe well acts as a capping well that accumulates groundwater.

Construction activities for the construction of a plastic well are carried out in the following sequence:

Purchase pipes for a drinking water well of a two-layer type with a diameter of 400 mm: they are specially designed for underground use.

Determine the point on the backyard territory with the maximum pressure of the underground source, which is within the power of a specialist in hydrogeology. For independent search, one of the old-fashioned tricks is usually used, the most common of which is the vine method.

Dig a well shaft using an open method for this. After passing a 2-meter depth, the pit must be given a round shape throughout the rest of the section.

As soon as there are signs of a key, a plastic seamless pipe should be prepared

It must be lowered into the mine carefully, making sure that the product is at the very bottom.

After the pipe is installed, the space between its outer walls and the surface of the mine is filled with sand.

I prepare the pipe, you must take the following steps:

- The fin cavities in a section of 500 mm are equipped with a series of holes, for which a 7 mm drill is used.

- The openings of the hole and the pipe are wrapped with two layers of geotextile.

- To fix the well filter, a wire placed in a plastic sheath is used. With it, the interior of the well will be protected from sand, while water will pass unhindered.

- Usually, about 1 meter of a plastic pipe protrudes above the ground: foam can be used to insulate this segment.

- The buildup of the well is carried out using a submersible pump. In order for the water to be of high quality, it is practiced to fill the lumen of the pipe with shungite or quartz sand.

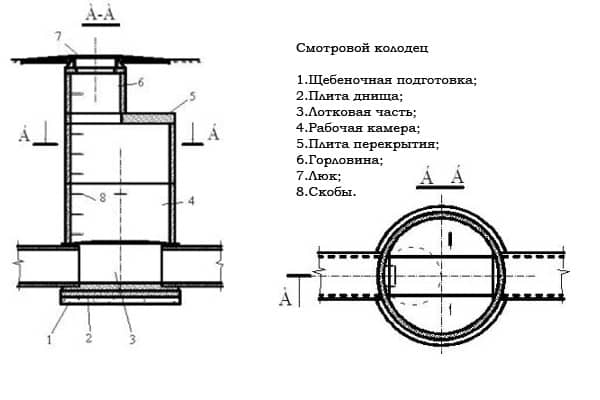

Design features

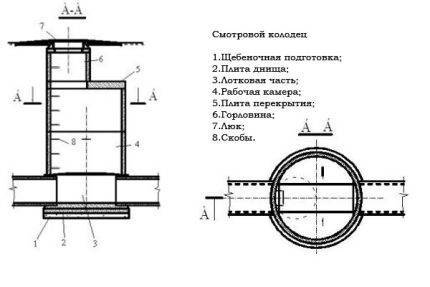

The street manhole is the following design:

- Bottom. All inspection outlets must be of closed type;

- Working part. It can be a wide ring, a curved geometric figure, less often a square or a rectangle. Here, if necessary, a specialist is immersed;

- Lid, GOST 3634-99. A plastic or cast iron hatch for a manhole is an essential component. It protects the sewer from external pollution and guarantees the safety of households. It is recommended to supplement it with a lock.

Linear manhole design

Linear manhole design

Sometimes structures are equipped with a ladder, which allows you to move freely along the well. It is sometimes replaced with shelves. Their drawing is shown below.

Shelf layout example

The principle of the system is simple. The main pipe passes into the observation structure by connecting to the tank. The junction is carefully sealed. In any inspection outlet there is a tray part - the one in which the inspection is carried out, and the working one. Drains from the sewer pass through the working area, so it has a slight slope.

Video: manhole d 300mm from a plastic pipe

Conclusions and useful video on the topic

In this video, plastic modules can be viewed from all sides and even touched:

Video about the assembly of the well from plastic elements at the place of its installation:

A plastic well insert will completely solve three problems: leakage through joints, through cracks and through the walls of concrete rings. However, the cost of such repairs will not be cheap. The cost of a one and a half meter insert segment with a diameter of 950 mm and 5 mm wall thickness is approximately 15,000 rubles. However, decades without sewer "surprises" are worth it.

Are you going to install a plastic insert in a concrete septic tank, but don't know where to start? Or do you have experience doing something like this? Please share your knowledge with our readers - leave comments in the block below.