- The principle of operation of pyrolysis boilers and their features

- How does a boiler work in practice?

- The principle of operation of the long-burning boiler

- Installation and design requirements: recommendations from experts

- Step by step instructions for making

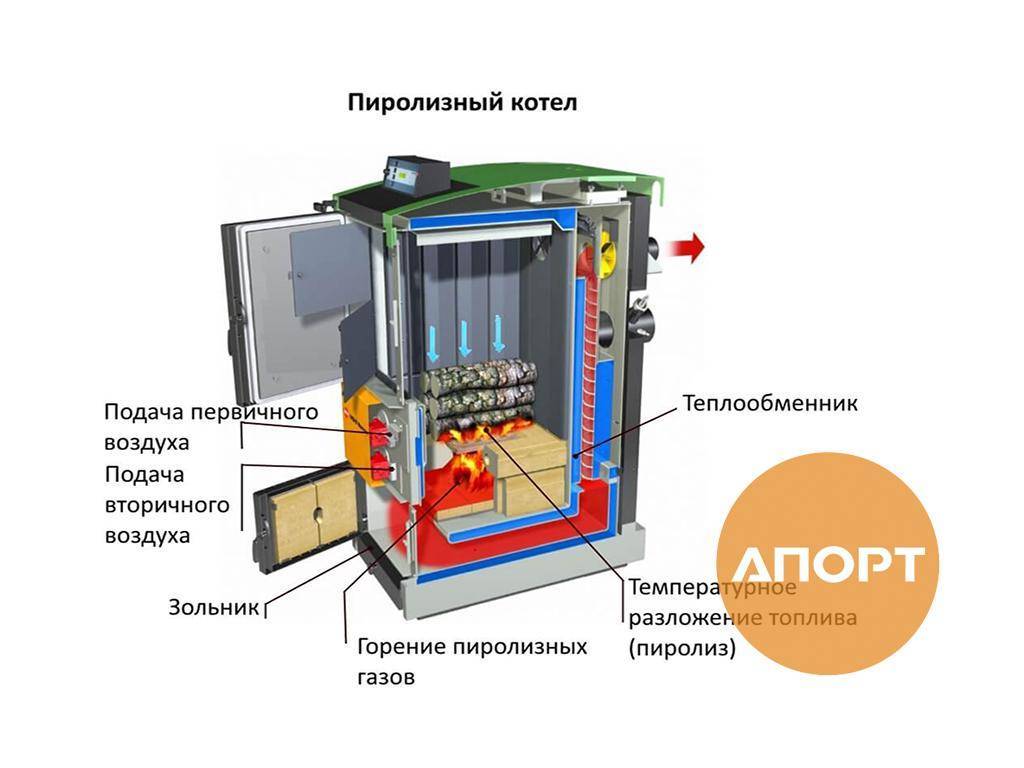

- Description and principle of operation of the pyrolysis boiler

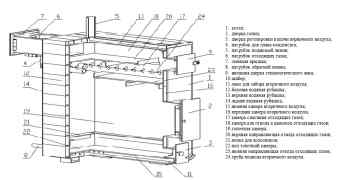

- Boiler device

- Do-it-yourself wood-fired water heating boiler. Welding a wood-burning boiler - self-assembly

- Classification

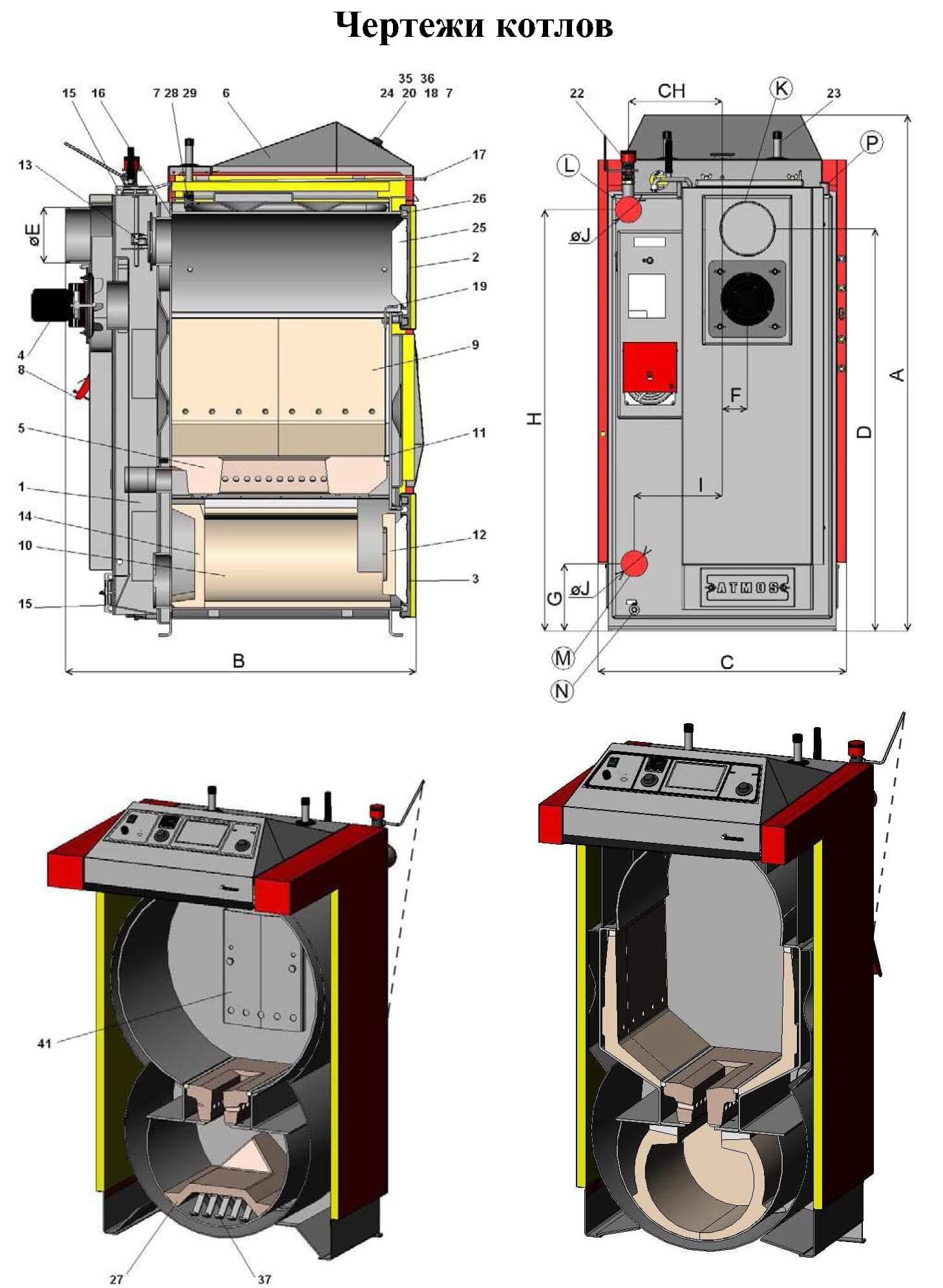

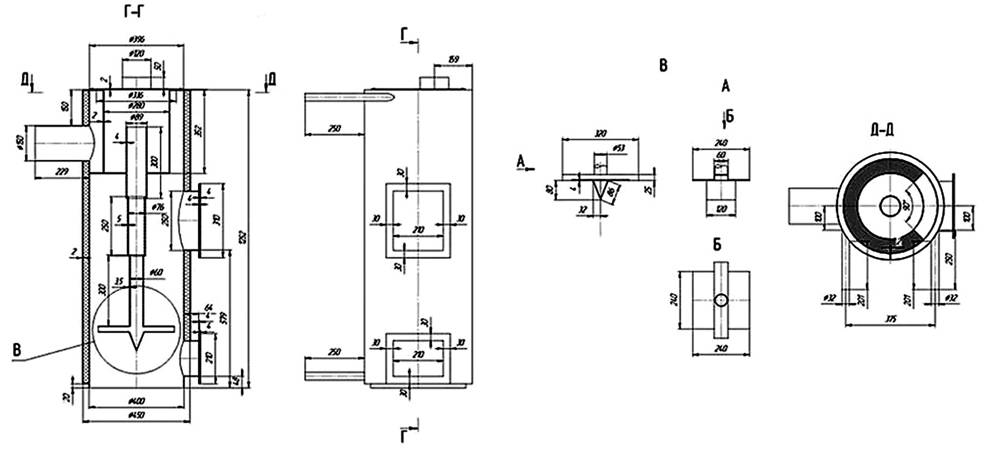

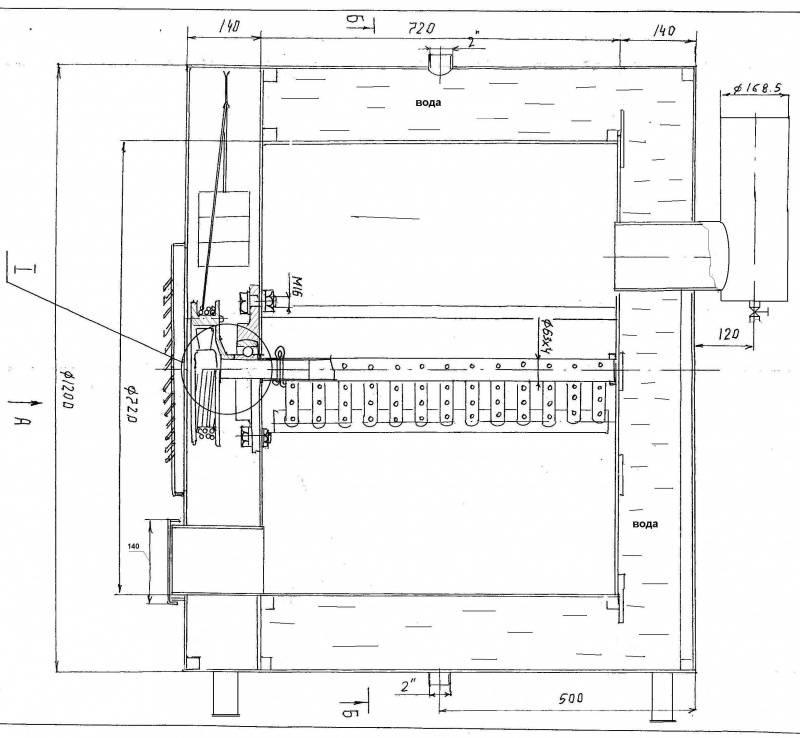

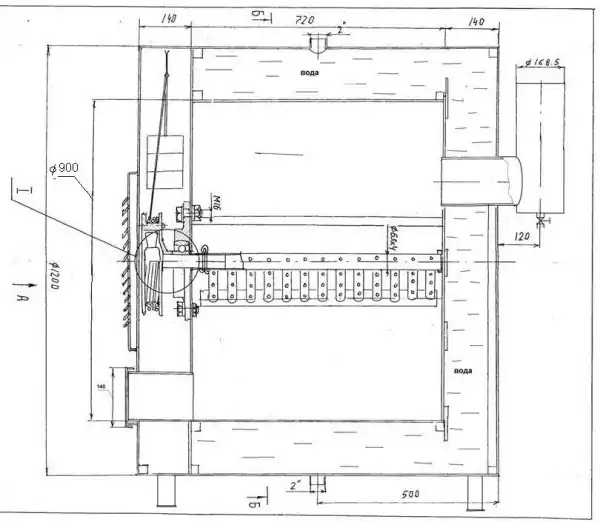

- Drawing: general view, workflow

- Differences of the device from conventional boilers

- Assembly process

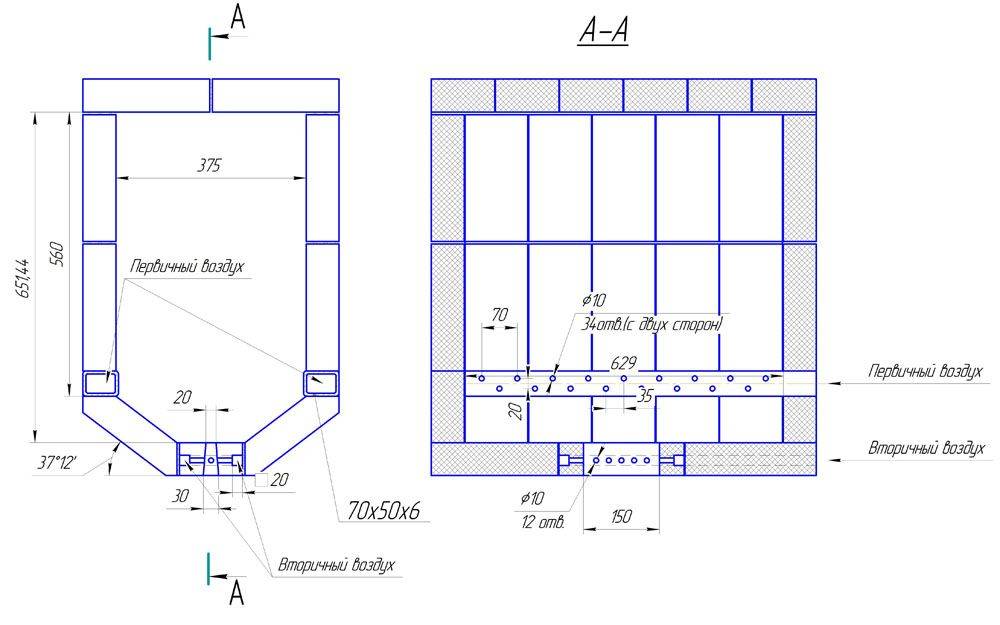

- Air supply device

- Housing (furnace)

- Chimney

- We connect the case and the air supply device

- Heat dissipating disc

- convection hood

- Lid

- legs

- Do-it-yourself pyrolysis boiler: rules and nuances

- Finally

The principle of operation of pyrolysis boilers and their features

By creating pyrolysis boilers with their own hands, people tend to save money in their wallet. If gas equipment is quite cheap, then solid fuel units are simply amazing at their price. A more or less decent model with a capacity of 10 kW will cost 50-60 thousand rubles - it is cheaper to conduct gas if a gas pipeline passes nearby. But if it is not there, then there are two ways out - to purchase factory equipment or make it yourself.

It is possible, but difficult, to make a long-burning pyrolysis boiler with your own hands.Let's first understand why pyrolysis is needed at all. In conventional boilers and stoves, wood is burned in the traditional way - at high temperature, with the release of combustion products into the atmosphere. The temperature in the combustion chamber is about + 800-1100 degrees, and in the chimney - up to + 150-200 degrees. Thus, a substantial part of the heat simply flies out.

Direct combustion of wood is used in many heating units:

Solid fuel pyrolysis boilers can use several types of fuel, including waste from woodworking and agricultural processing.

- solid fuel boilers;

- Fireplace stoves;

- Fireplaces with water circuits.

The main advantage of this technique is that it is simple - it is enough to create a camera combustion and organize the removal of combustion products outside of the equipment. The only regulator here is the blower door - by adjusting the clearance, we can adjust the intensity of combustion, thereby affecting the temperature.

In a pyrolysis boiler, assembled with your own hands or bought in a store, the process of fuel combustion is somewhat different. Firewood is burned here at a low temperature. We can say that this is not even burning, but a slow smoldering. Wood at the same time turns into a kind of coke, while releasing combustible pyrolysis gases. These gases are sent to the afterburner, where they burn with the release of a large amount of heat.

If it seems to you that this reaction will not give a special effect, then you are deeply mistaken - if you look into the afterburner, you will see a roaring flame of bright yellow, almost white color.The combustion temperature is slightly above +1000 degrees, and more heat is released in this process than with standard wood combustion.

In order for a self-assembled pyrolysis boiler to be able to show maximum efficiency, firewood with a low moisture content is needed. Wet wood will not allow the equipment to reach its full capacity.

The pyrolysis reaction is familiar to us from the school physics course. In a textbook (and maybe in a laboratory room), many of us saw an interesting reaction - the wood was placed in a sealed glass flask with a tube, after which the flask was heated over a burner. After a few minutes, the wood began to darken, and pyrolysis products began to come out of the tube - these are combustible gases that could be set on fire and watch the yellow-orange flame.

Do-it-yourself pyrolysis boiler works in a similar way:

On one load of fuel, pyrolysis boilers operate for about 4-6 hours. So a large and steadily replenished supply of firewood should be taken care of in advance.

- Firewood is kindled in the firebox until a steady flame appears;

- After that, the access of oxygen is blocked, the flame goes out almost completely;

- The blower fan starts - a high-temperature flame appears in the afterburner.

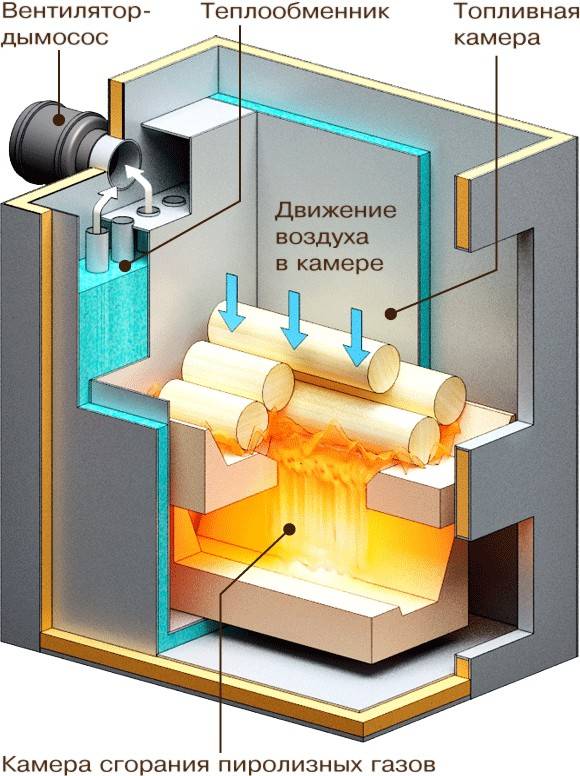

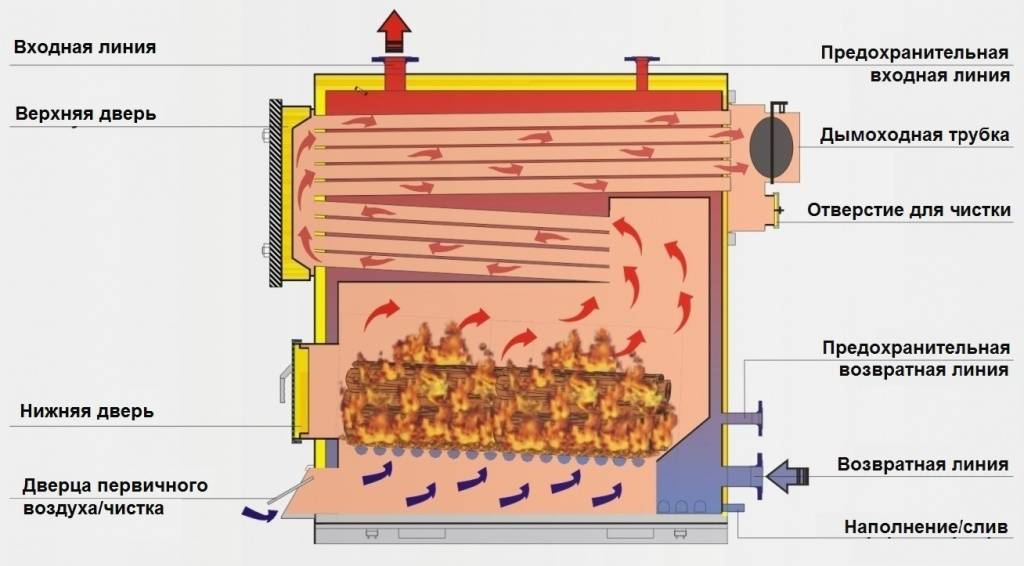

The device of the pyrolysis boiler is quite simple. The main elements here are: a combustion chamber in which firewood is stored, and an afterburner chamber in which pyrolysis products are burned. Heat is transferred to the heating system through a heat exchanger

In the scheme of the pyrolysis boiler, special attention is paid to it

The thing is that heat exchangers in do-it-yourself pyrolysis boilers are arranged differently than in gas equipment.Combustion products with air pass here through many metal pipes washed by water. To increase efficiency, boiler water washes not only the heat exchanger itself, but also all other nodes - a kind of water jacket is created here, which takes away excess heat from the hot elements of the boiler unit.

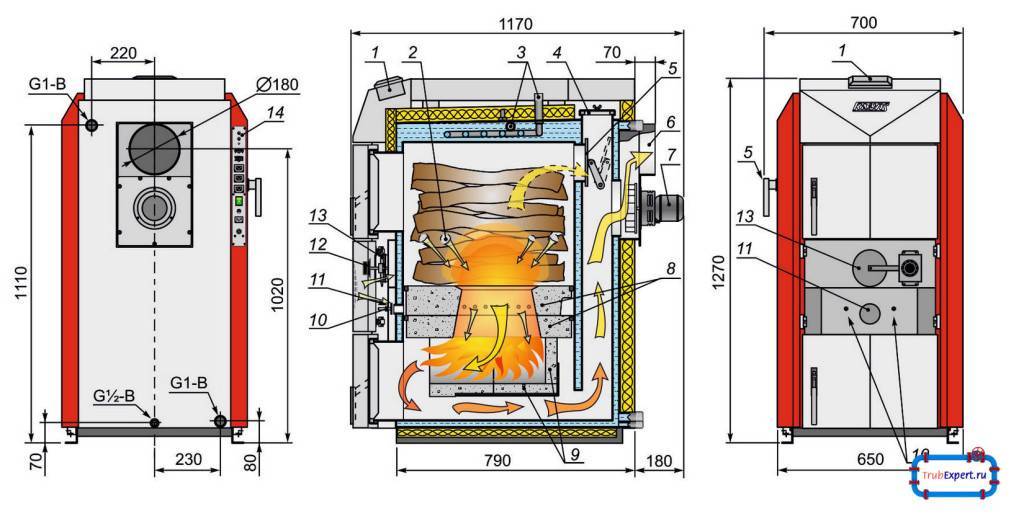

How does a boiler work in practice?

It is convenient to consider the practical use of equipment in a step-by-step process:

- Loading firewood - laying on the grate of the upper area of the chamber.

- Ignition of fuel and start-up of the smoke pump.

- Formation of wood gas at a temperature of 250-850 °C.

- The transition of wood gas to the lower region of the furnace.

- Combustion of wood gas with additional air supply.

Further, the heat received in the lower region of the fuel chamber is used to heat the coolant. The heat carrier can be both water and air.

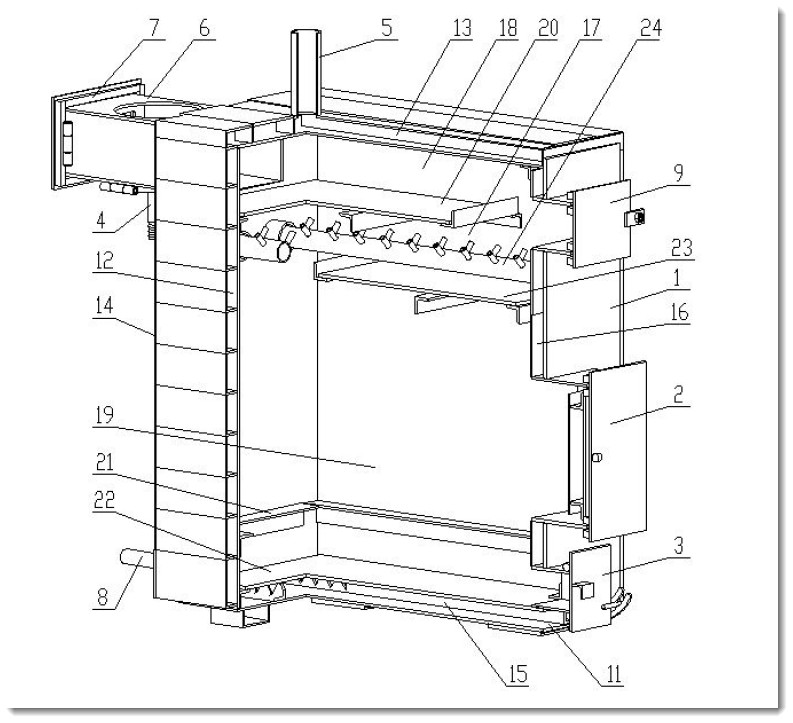

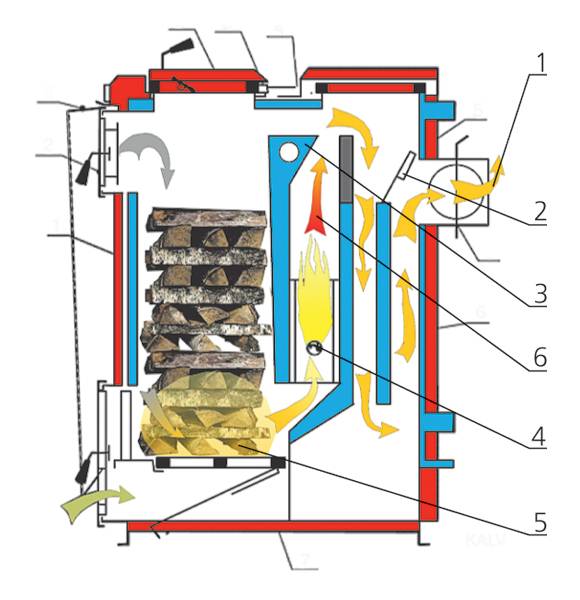

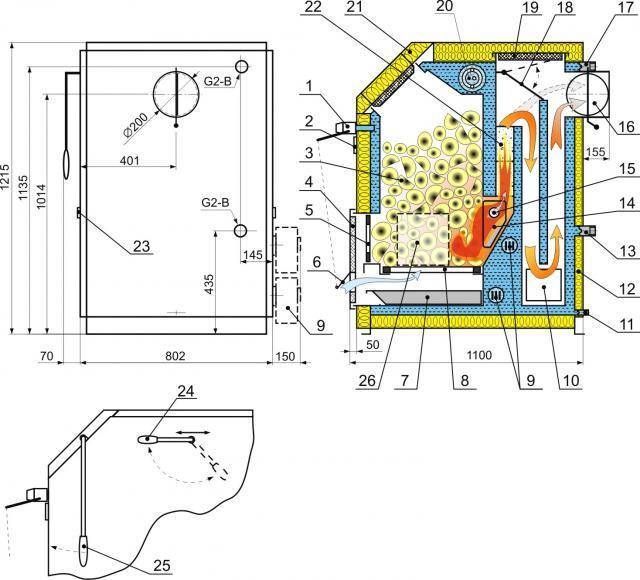

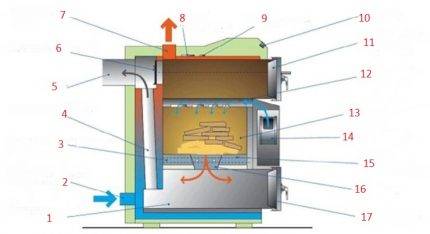

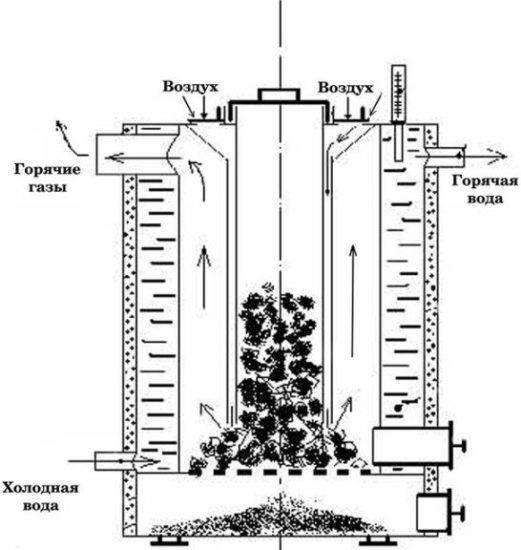

1 – active camera; 2 - water inlet; 3 - secondary air; 4 - chimney; 5 - outlet pipe; 6 - throttle valve; 7 - water outlet; 8, 9 – sensors; 10 - thermostat; 11 – passive chamber door; 12 - primary air; 13 - passive camera; 14 - air pump; 15 - heat exchanger circuit; 16 - nozzle; 17 - active chamber door

1 – active camera; 2 - water inlet; 3 - secondary air; 4 - chimney; 5 - outlet pipe; 6 - throttle valve; 7 - water outlet; 8, 9 – sensors; 10 - thermostat; 11 – passive chamber door; 12 - primary air; 13 - passive camera; 14 - air pump; 15 - heat exchanger circuit; 16 - nozzle; 17 - active chamber door

If you pay attention to all existing designs of domestic solid fuel boilers, the main alternative to the pyrolysis boiler is the traditional design. This is a similar version of a wood-burning boiler, where one undivided firebox operates and the principle of lower air supply to the combustion chamber works.

But such a system is considered less efficient and uneconomical due to the rapid combustion of fuel.

This is a similar version of a wood-burning boiler, where one undivided firebox operates and the principle of lower air supply to the combustion chamber works. But such a system is considered less efficient and uneconomical due to the rapid combustion of fuel.

The pyrolysis boiler is capable of producing an efficiency of 85-95% under the condition of 100% load. However, the efficiency drops sharply if the load is less than 50%. That is why manufacturers of pyrolysis equipment recommend users to operate equipment with maximum load.

A similar approach is also valid for home-made structures, provided that they fully comply with the classical pyrolysis scheme and operating requirements.

For “pyrolysis”, the operating requirements, it should be noted, are quite stringent:

- obligatory equipment with an air pump;

- admissible humidity of fuel is not higher than 25-35%;

- the load on the equipment is not less than 50%;

- return heat carrier temperature not lower than 60 °С;

- loading only with a large fuel array.

It should also be noted the high cost of industrial pyrolysis systems. This is probably why the do-it-yourself option is so popular.

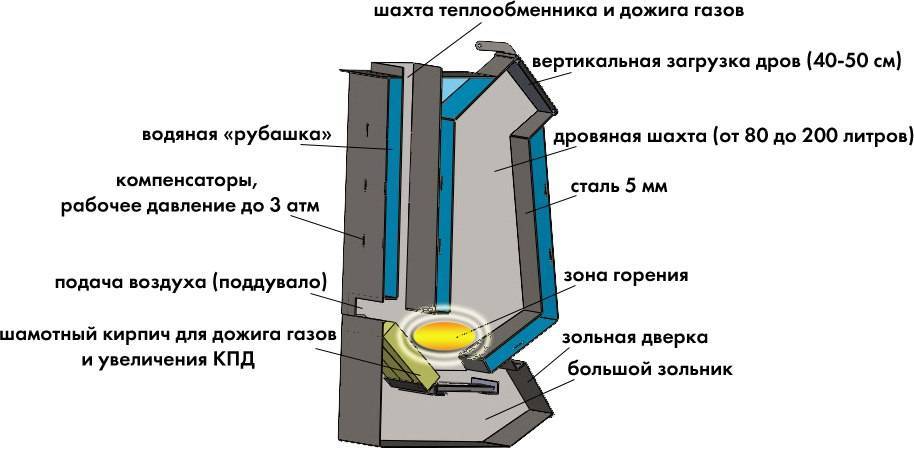

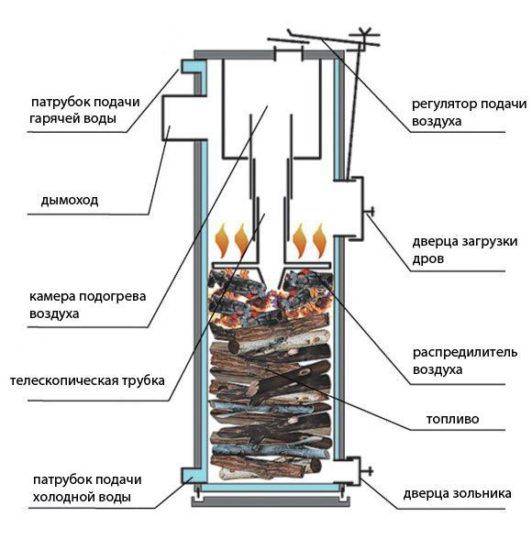

The principle of operation of the long-burning boiler

In conventional solid fuel units, one bookmark is enough for 6-7 hours of burning. Accordingly, if the next portion of resources is not added to the furnace, the temperature in the room will immediately begin to decrease. This is due to the fact that the main heat in the room circulates according to the principle of free movement of gas. When heated by the flame, the air rises and exits.

The thermal resource of a long-burning boiler is enough for about 1-2 days from one laying of firewood. Some models can keep warm up to 7 days.

How is this cost-effectiveness and efficiency achieved?

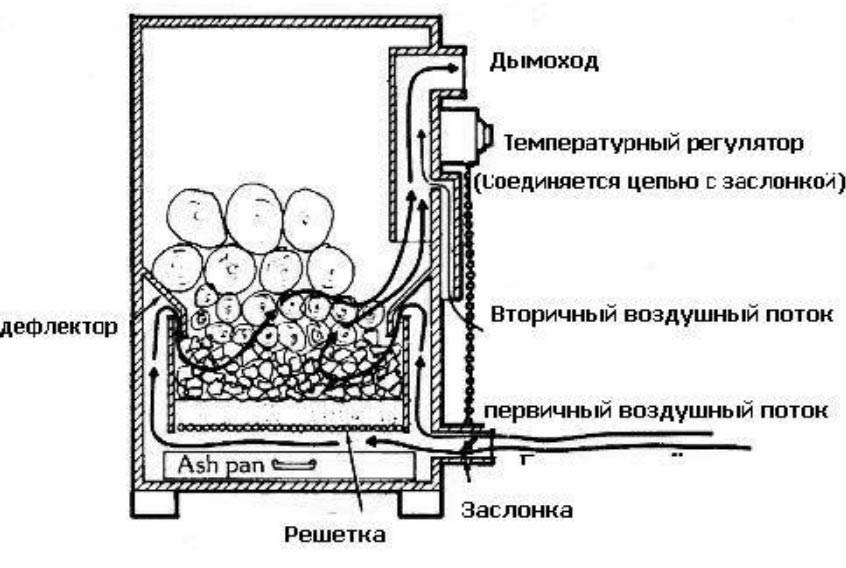

Boiler operation scheme

From a conventional boiler, a TT long-burning boiler is distinguished by the presence of two combustion chambers at once. In the first, the fuel itself burns as standard, and in the second, the gases released during this process.

An important role in this process is played by the timely supply of oxygen, which is provided by the fan.

This principle has been implemented relatively recently. In 2000, the Lithuanian company Stropuva presented this technology for the first time, which immediately gained respect and popularity.

Homemade long-burning boiler

Today, this is the cheapest and most practical way to heat a country house, where gasification is not provided and there are power outages.

Such units operate on the principle of burning top fuel. As a standard, in all furnaces, the firebox is located at the bottom, which allows you to take cold air from the floor, heat it up and lift it up.

The principle of operation of this boiler is somewhat similar to pyrolysis. The main heat here is released not from the combustion of solid fuel, but from the gases released as a result of this process.

The combustion process itself takes place in a closed space. Through a telescopic tube, the released gas enters the second chamber, where it is completely burned and mixed with cold air, which is pumped up by the fan.

TT long-burning boiler (diagram)

This is a continuous process that occurs until the fuel burns out completely. The temperature during such combustion is reached very high - about 1200 degrees.

As mentioned above, this boiler has two chambers: the main one is large and small. The fuel itself is placed in a large chamber. Its volume can reach 500 cubic meters.

Any solid fuel can act as a resource for combustion: sawdust, coal, firewood, pallets.

A constant air supply is carried out by a built-in fan. The advantage of this method is that solid fuel is consumed extremely slowly.

This significantly increases the efficiency of such a heater. Why does firewood burn out so slowly compared to a standard stove?

The bottom line is that only the top layer burns out, since air is blown by a fan from above. Moreover, the fan adds air only after the top layer has completely burned out.

There are many models on the market today that work on the same principle, but, depending on the dimensions, material of execution, additional options, have different efficiency and economy.

Universal TT boilers operate on absolutely any fuel, which will greatly simplify their operation for the owners. A more budget option is a wood-fired TT long-burning boiler. It works exclusively on wood and cannot be used with any other fuel option.

Installation and design requirements: recommendations from experts

The high level of fire hazard of this heat engineering unit implies the fulfillment of a number of requirements for the installation of a pyrolysis boiler:

- Boiler equipment should be placed in a separate room specially designed for it.

- For safe operation, it is necessary to build a ventilation hole with an area of 100 square meters. cm.

- The boiler must be installed on a foundation made of brick or concrete.

- The protection of combustion chambers from sheet steel should be equipped.

- There must be a free space between furniture, walls and the boiler casing of at least 200 mm.

- It is necessary to carry out measures to insulate the chimney. If this condition is not met, heat loss is inevitable. In addition, the lack of reliable thermal insulation will cause increased wear and tear of the device due to the occurrence of carbon deposits and condensation.

pyrolysis boiler

pyrolysis boiler

Step by step instructions for making

The process of creating a heating device is quite simple and takes place in several successive stages.

First, the body of the structure is made:

- Two large diameter pipes (50 and 45 cm) are inserted into each other and connected with a metal ring.

- From a pre-prepared sheet, a circle of metal with a diameter of 45 cm is cut out, with which the bottom of a smaller pipe located inside the structure is welded. As a result, we get a barrel with a diameter of 45 cm, with a welded hot water jacket-contour 2.5 cm wide.

-

A rectangular hole is cut at the bottom of the "barrel". Height - up to 10 cm, width - about 15. It will be used as an ash pan door. A hatch is welded in, a door with attached hinges and a valve is installed.

-

A rectangular hole is cut in the upper part of the circuit for supplying solid fuel. The size is selected individually, the main condition is the convenience of loading firewood. The hatch is welded. A door equipped with hinges and a latch is installed. It is made double: an asbestos layer is laid between the individual metal sheets, the contact points are sealed with an asbestos cord.Thanks to such manipulations, the heat loss of the boiler is reduced.

-

At the top level, an exhaust pipe is equipped that removes exhaust gases into the chimney.

- In two places (top and bottom) of the water circuit, branch pipes with a diameter of 4–5 cm are welded, which are necessary to connect the boiler to a further heating system. A thread is cut, for which a lerka is used.

- Inspection of welding seams, if necessary - elimination of flaws.

After creating the metal body of the solid fuel boiler, you can proceed to the manufacture and installation of the air distributor:

The air distributor can be made in the form of a pancake with welded channels

- A metal circle is cut out. Its diameter should be several centimeters smaller than the internal one on the boiler. A round hole is cut in the center of the circle, corresponding in size to the air distributor pipe (5–6 centimeters).

- A metal tube is inserted into the cut hole.

- From below, channels or corners arranged in the form of blades are welded onto the “pancake”. With a suitable thickness of the blades, an impeller from a fan is sometimes used.

- A small loop is welded on top. It can be used to raise and lower the distributor. It is also equipped with a damper that regulates the intensity of air supply to the fire zone.

-

Mounting the air distributor to the housing. A circle is cut out of a metal sheet, the diameter of which is equal to the outer body. A hole of 6–8 cm is cut in the center. The lower part of the air distributor is inserted into the boiler, the upper part is threaded through the hole made. After that, the circle is welded to the boiler and further functions as a top cover.

This is one of the simplest ways to make a solid fuel boiler.There are complicated circuits used in industrial and household models.

Description and principle of operation of the pyrolysis boiler

A pyrolysis boiler is one of the types of heating sources for a residential building. As fuel for it you can use:

- Ordinary firewood (different types of wood);

- Pressed briquette;

- Lumber waste;

- Wood sawdust (pressed and loose).

Their use is quite popular in many Russian regions, they are increasingly replacing conventional wood-burning boilers.

Despite the similarity with the usual solid fuel boiler, the principle of operation of the pyrolysis boiler is slightly different. Why are they so popular and good, and is it possible to make a pyrolysis boiler with your own hands, let's try to figure it out.

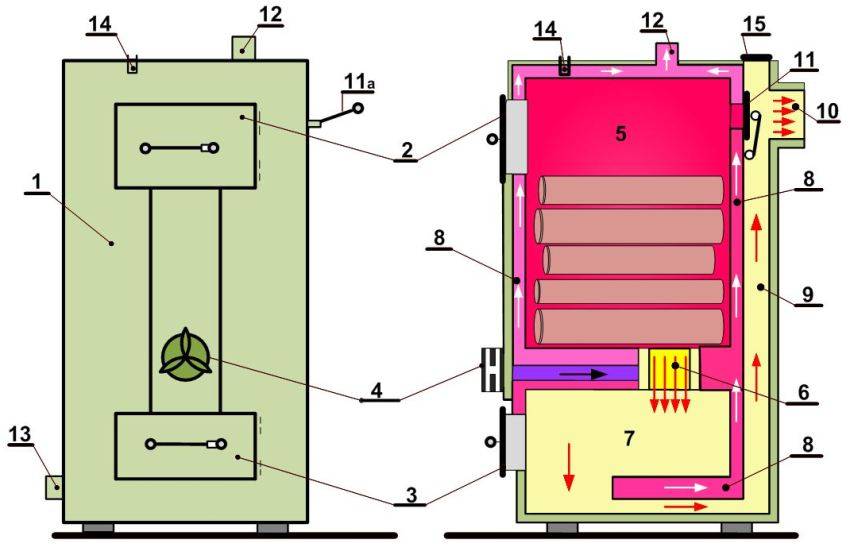

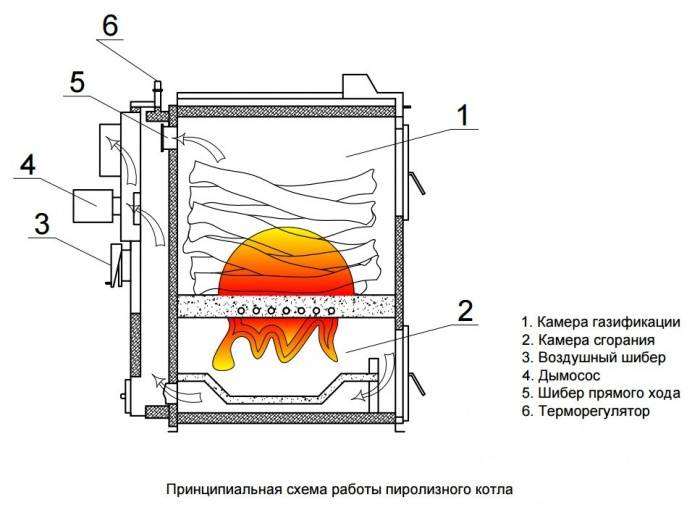

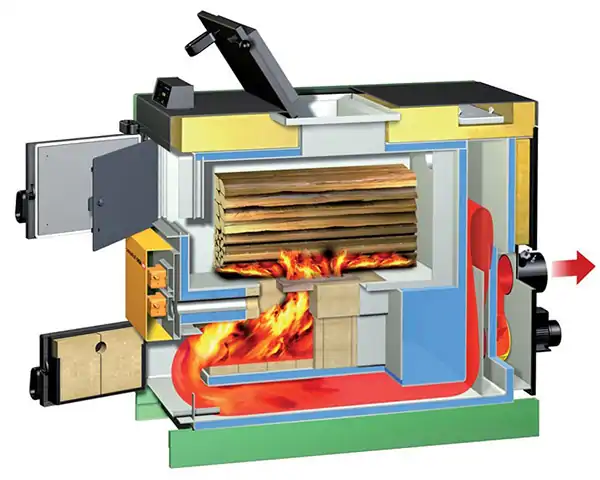

The design of the boiler is quite simple, it is divided into two chambers:

- Firewood loading and burning chamber, where they are pyrolized;

- Chamber burning pyrolysis gases.

Both chambers are separated by a grate, on which firewood is placed on top. The movement of air in the chamber occurs from top to bottom. This method of two-component decomposition of firewood is more efficient, although there are pyrolysis boilers with a gas combustion chamber above.

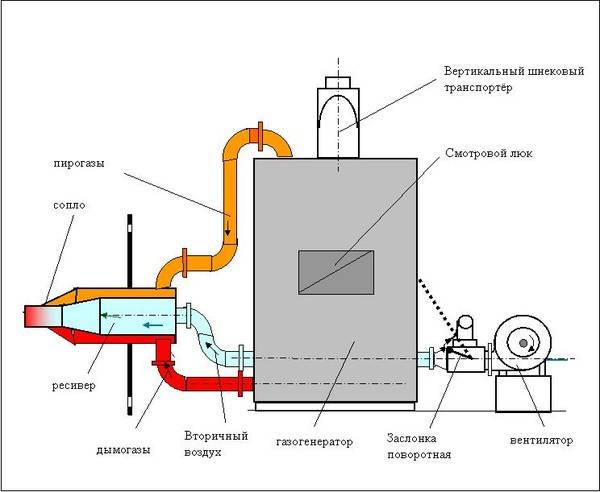

Long-burning pyrolysis boiler - the principle of operation of fuel combustion

Such a boiler works on the principle of pyrolysis fuel combustion. Otherwise, the process can be called dry distillation. At a temperature in the chamber with steam reaching 800 ° -900 ° C, lacking oxygen, the thermal decomposition of firewood into: coal and pyrolysis gas occurs.

- From the first chamber, the resulting gas enters another, where it ignites when mixed with oxygen, bringing the temperature to 1100°-1200°C.

- Combustible gases heat the heat exchanger, from where hot water enters the heating system, and the products of gas combustion exit through the chimney.

Thus, we can say that the main energy for the coolant is obtained not when burning wood, and by burning their gases.

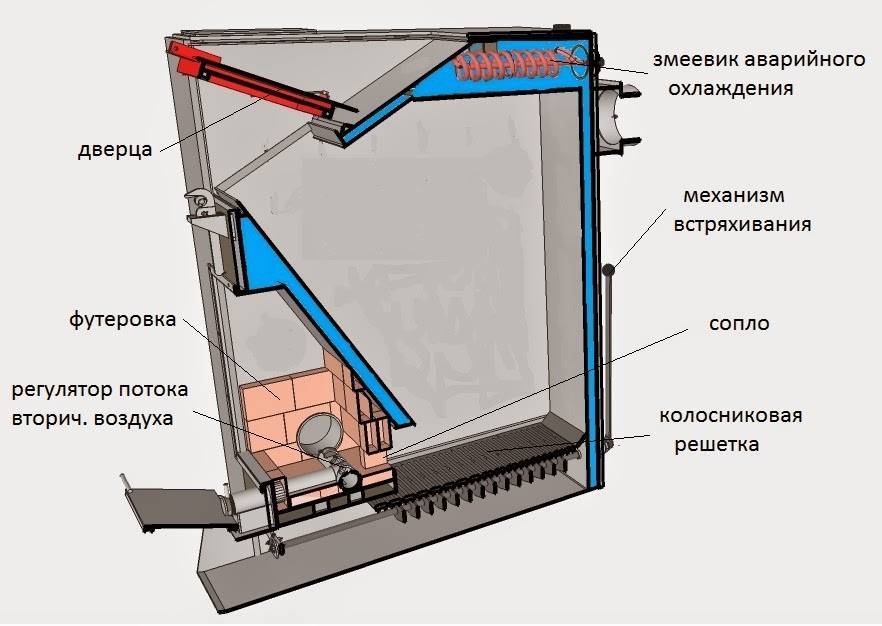

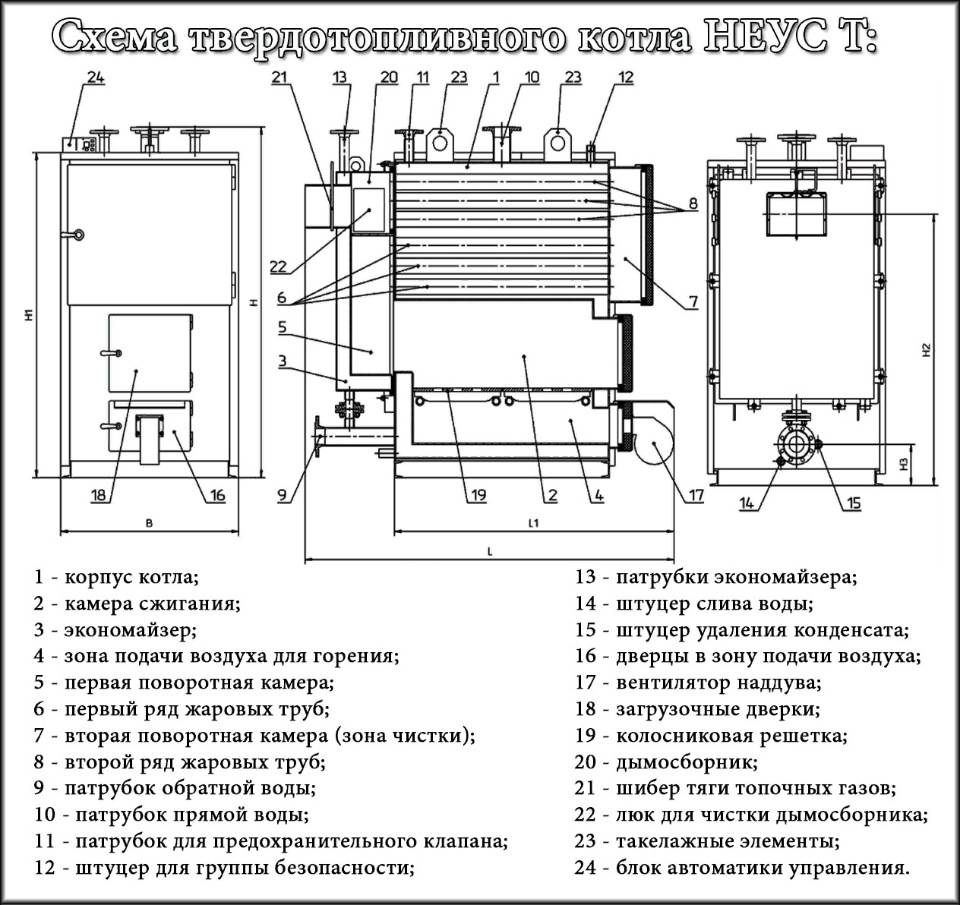

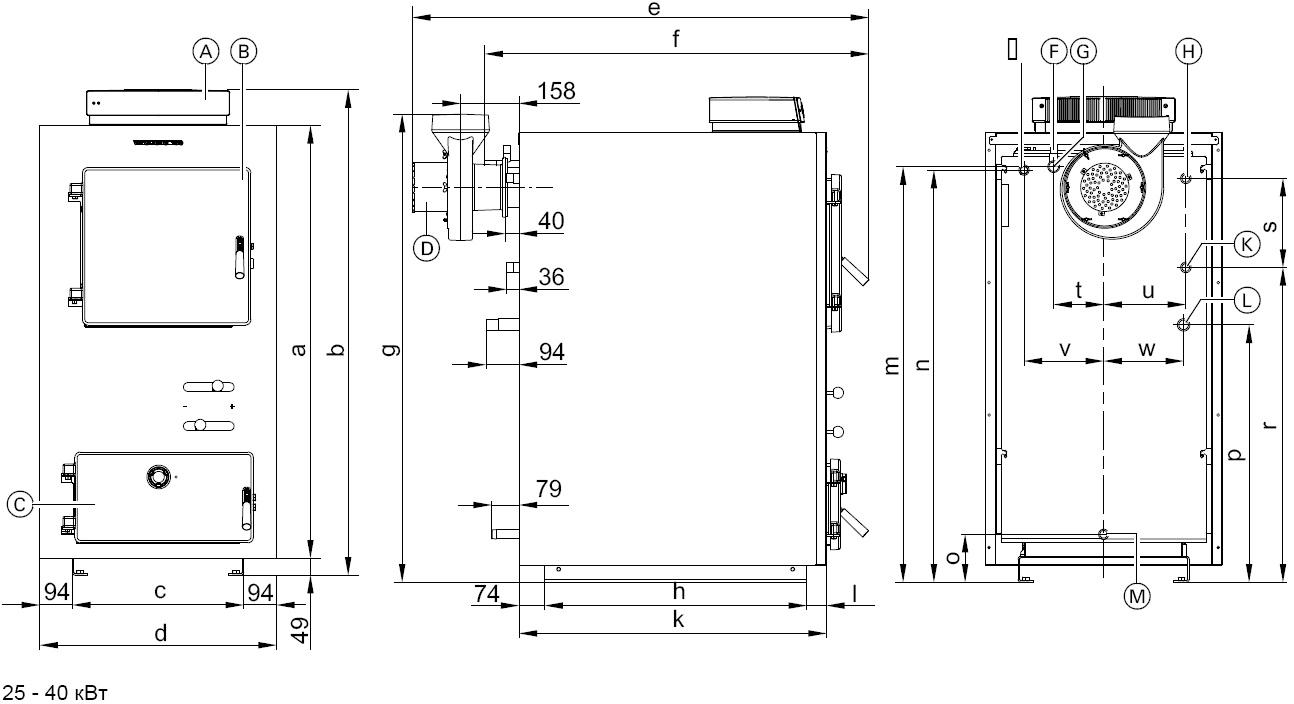

Boiler device

The fundamental difference between a standard and a pyrolysis boiler is that in the first version there is 1 combustion chamber, and in the second - 2, between which there is a grate, the fuel itself and the solid residue burn in the lower one, and pyrolysis gases in the upper one. It is this organization of the combustion chambers that allows you to optimize the process, increase the combustion time of the fuel and maximize efficiency.

Photo 2 Scheme of the device of the pyrolysis boiler

Among the features of the pyrolysis boiler is the increased aerodynamic resistance in the chimney due to the absence of air and the reaction of carbon with pyrolysis gas. Forced draft is provided by an electric fan, in fact, it is for this reason that pyrolysis boilers belong to the category of volatile equipment.

It is interesting: Voltage stabilizer for gas heating boiler - selection, installation

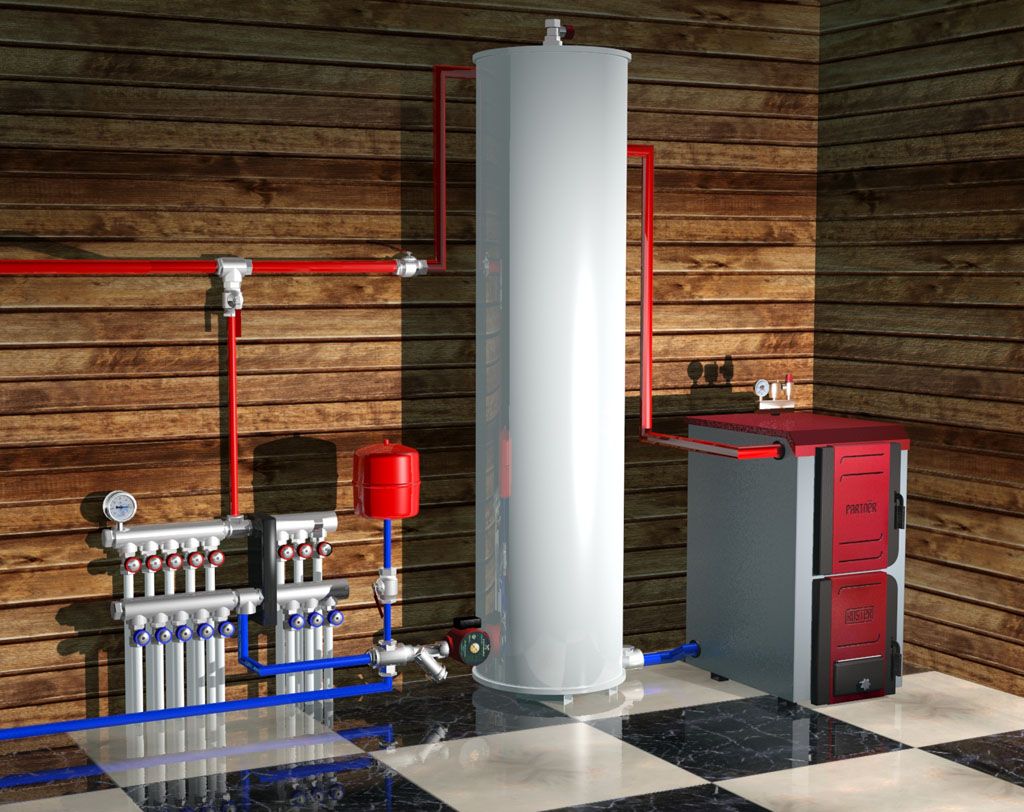

Do-it-yourself wood-fired water heating boiler. Welding a wood-burning boiler - self-assembly

The simplicity of the process also lies in the availability of materials and tools for work. Welding skills required. So what is needed:

- An old fuel barrel or a self-welded box. The containers are preliminarily burned out from the remnants of oils - they are filled with firewood and the future boiler is melted.

The future building must be hermetically sealed - this is checked even at the stage of burning. If there are minor defects in the form of holes, then they are welded and the barrel is filled with water - there should be no leakage.

Sheet, thick-walled metal. A heat exchanger will be made from it. By the way, an alternative replacement for this is old, obsolete cast-iron radiators. Five or six sections will be enough for the case.

Profile pipes. They will be required for the manufacture of the chimney and the assembly of the frame on which the boiler will be mounted. The diameter and thickness of the walls must be impressive in order to support the weight of the boiler filled with fuel and water.

Grates, shutters, doors are purchased. If the room is impressive or the object is two floors, then a circulation pump is required - without it, the carrier will not rise to a height, and there is a risk of the system defrosting in cold weather. It is not bad to install a manometer and a thermometer on the finished boiler in order to control the pressure and temperature of the carrier.

For piping, metal-plastic pipes and radiators will be required - wood-fired heating boilers with a water circuit are unacceptable without this.

Classification

Boilers have differences in the location of the chambers for afterburning gases:

- top position;

- with bottom position.

Boilers with an upper chamber are more bulky, more material is required to assemble the chimney. But they will have to be cleaned much less frequently, because the particles from the burnt fuel do not enter the chamber for afterburning gases.

In boilers with a lower section, the fuel is located in the upper part, and the gases are discharged to the lower part and burn out there. This is convenient, but you will often have to remove small wood particles from the gas recovery chamber.

According to energy dependence, boilers are:

- without the use of electricity: natural draft boilers;

- with forced draft.

Non-volatile boilers imply the inclusion of a high chimney (at least 5-6 meters) in the design to increase traction and ensure sufficient vacuum in the combustion chamber.

The heating efficiency of such boilers will be somewhat lower than that of forced draft boilers.

Devices with forced air are equipped with one or two fans, which can operate in the mode of air injection or exhaust of burnt gases.

In some models of boilers, a combined method is used with the participation of gas-injecting and exhausting devices to increase power.

Reference! Mechanisms that pump out exhaust gases are made of special heat-resistant (austenitic) alloys, their cost is much higher than that of blowers.

Heating method:

- Water heating - water pipelines are connected to the boiler heat exchanger, through which the heated working fluid is distributed to various rooms.

- Air heating - instead of water, air is used, which receives heat through the same heat exchanger and is distributed through air ducts. The efficiency is lower than that of the water method, it is used at production sites, warehouses.

Photo 1. Pyrolysis boiler with a heat exchanger, designed for water heating, runs on wood.

Drawing: general view, workflow

There are many options for the execution of the pyrolysis boiler. The simplest view according to the drawing is arranged in this way.

- Boiler combustion chamber.

- Gasification section.

- Gas afterburning section.

- Grate grates.

- Heat exchanger (inlet/outlet pipes).

- Gas exhaust pipeline (chimney).

- Blow holes.

- The door to the compartment for laying fuel.

Temperature controls can be included in the boiler. sensors and control devices and maintaining normal operating conditions.

As well as the hardware of the boiler to automate the operation of the entire heating complex.

The essence of what is happening inside the pyrolysis boiler is characterized by the following processes:

- The air flow from the outside enters the gasification compartment with the fuel located there.

- Some of the oxygen will support the combustion (smoldering) process. Gases, which are products of combustion, enter the combustion chamber of the boiler through the nozzle and are oxidized there in the presence of secondary oxygen, which enters together with the outside air.

- Part of the pyrolysis gases is reduced in the presence of carbon from the fuel to carbon monoxide and nitrogen oxide, while consuming part of the energy. The mixture passes into the gas afterburning section and is oxidized there with the return of the energy it has taken away.

Photo 2. A drawing of a long-burning pyrolysis boiler, a device assembled from it can heat a large house.

The gas mixtures involved in the pyrolysis reaction are discharged outside through the chimney, bypassing the boiler heat exchanger.

Attention! Since the operation of pyrolysis boilers is associated with a large amount of energy generated inside the equipment and the possible release of various kinds of harmful gases, it is recommended to build boilers on your own only with a full understanding of all the physical and chemical processes that occur during its operation. Temperature phases:

Temperature phases:

- drying, pyrolysis of wood - 450 ° C;

- combustion of wood gas and secondary air - 560 ° C;

- flame blowing and heat recovery - 1200 °C;

- removal of the remaining combustion products - 160 °C.

Differences of the device from conventional boilers

Including wood (firewood), special fuel briquettes (pellets) and industrial waste. One of the main differences between boilers is the use of various types of solid fuel, almost any substance that can burn.

The duration of the fuel combustion process is much longer than that of conventional boilers. 8-10 hours or more. There are models of boilers with a large compartment for firewood, the duration of continuous operation is up to 24 hours. This means that the combustion chamber is replenished with new portions of fuel 1–2 times a day.

Important! Due to the almost complete decomposition of solid materials, pyro-boilers are less harmful to the environment.

Assembly process

The process of creating a boiler includes several stages. In the manufacture of each element, it is worth considering the special operating conditions of the manufactured product.

Air supply device

We cut off a segment from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the furnace. Weld a bolt to the bottom. From the steel sheet we cut out a circle of the same diameter as the pipe or larger. We drill a hole in the circle, sufficient for the passage of a bolt welded to the pipe. We connect the circle and the air pipe by screwing the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed with a freely moving metal circle. During operation, this will allow you to regulate the intensity of burning firewood and, consequently, the temperature in the room.

With the help of a grinder and disc for metal we make vertical cuts in the pipe with a thickness of approximately 10 mm.Through them, air will flow into the combustion chamber.

Housing (furnace)

The case requires a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a steel thick-walled cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

Chimney

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which exhaust gases will be removed.

The length of the pipe is selected depending on the design considerations.

We connect the case and the air supply device

In the bottom of the case, we cut a hole with a diameter equal to the diameter of the air supply pipe. We insert the pipe into the body so that the blower goes beyond the bottom.

Heat dissipating disc

From a metal sheet with a thickness of 10 mm, we cut out a circle, the size of which is slightly smaller than the diameter of the case. We weld to it a handle made of reinforcement or steel wire.

This will greatly simplify the subsequent operation of the boiler.

convection hood

We make a cylinder from sheet steel or cut off a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the furnace (body). You can use a pipe with a diameter of 500 mm. We connect together the convection casing and the firebox.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the furnace, if the gap is large enough.With a smaller gap, you can weld the casing to the furnace around the entire perimeter.

Lid

From a steel sheet we cut out a circle of the same diameter as the firebox or a little more. We weld handles to it using electrodes, wire or other improvised means.

Considering that during the operation of the boiler, the handles can become very hot, it is worthwhile to provide special protection from a material with low thermal conductivity.

legs

To ensure long burning, we weld the legs to the bottom. Their height must be sufficient to raise the wood-burning boiler at least 25 cm above the floor. To do this, you can use a different rental (channel, corner).

Congratulations, you have made a wood-burning boiler with your own hands. You can start heating your home. To do this, it is enough to load firewood and set it on fire by opening the lid and the heat-dissipating disk.

Do-it-yourself pyrolysis boiler: rules and nuances

Do-it-yourself pyrolysis boiler

Do-it-yourself pyrolysis boiler

In order to install a pyrolysis boiler with your own hands, while maintaining all its working qualities, it is necessary to rely on accurate drawings and calculations. An incorrectly assembled boiler, mounted according to an incompetent scheme, will not only perform its functions poorly, but also pose a threat to the safety of the environment and you in the first place.

Do-it-yourself pyrolysis boiler assembly rules:

- Your first priority, before starting the assembly, is the mandatory familiarization with the drawings, plans and diagrams. They will help determine the amount of material needed for work, as well as save you from possible emergencies;

- Check for the presence of fundamental elements, without which it is impossible to assemble the pyrolysis boiler with your own hands.These are: regulators, air openings, smoke channels, pipes for water drainage, a combustion chamber, pipes for water supply, and a fan;

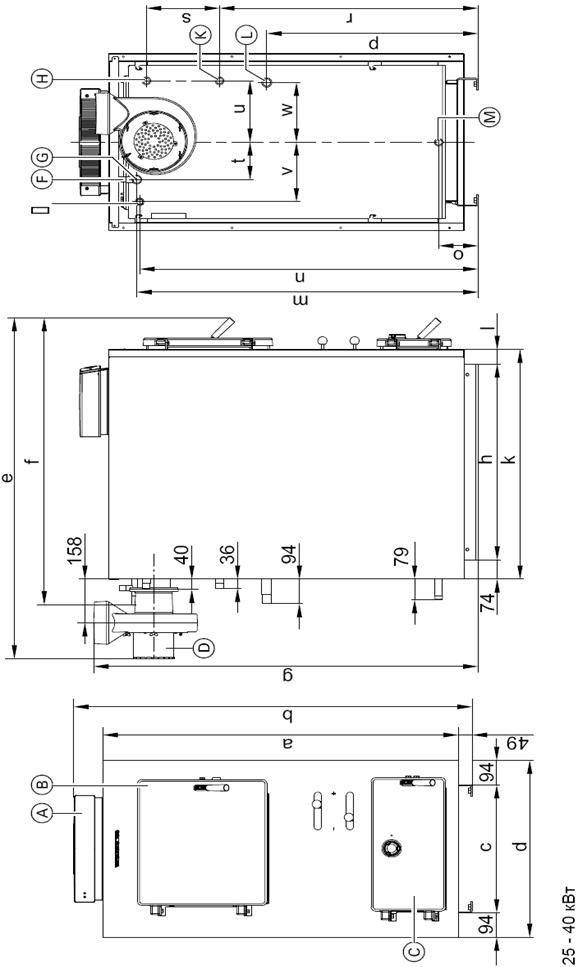

- Please note that if you are supposed to heat a standard country house, a pyrolysis boiler with a capacity of 40 kW is quite suitable for you, and if you are the owner of a very small cottage, then a 30 kW boiler is enough. It makes no sense to install super powerful boilers, since a small device will perfectly insulate the premises, while huge units will cost a lot of money and will require significant costs;

- It will not be superfluous to prepare the necessary tools for installing the boiler. So that you do not have to run to the hardware store once again, prepare everything you need right away. To install a pyrolysis boiler with your own hands, you will need such a toolkit: a grinder, grinding wheels, a welding machine, an electric drill, pipes of various diameters, electrodes, a fan, steel strips, a temperature sensor, metal sheets

Please note that assembling a pyrolysis boiler with your own hands is a long and painstaking process, so be prepared for possible difficulties. However, by carefully preparing for the process, you greatly reduce the risk of unexpected problems.

After all the rules are followed, the desired scheme is selected, it's time to proceed with the direct assembly. When assembling the device in stages, follow the following nuances:

- Unlike conventional boilers, the hole for putting firewood into the firebox should be located slightly higher;

- Be sure to check the presence of a restrictor that fixes the air supply to the boiler. Its optimal dimensions are 70 ml in cross section and a length exceeding the dimensions of the case;

- The disk welded to the limiter must be made of stainless steel and located at the bottom of the entire structure;

- The solid fuel inlet is best desired to be rectangular in shape. For a pyrolysis boiler, this form is optimal;

- The door must close tightly and securely; a special lining is needed that will tightly fix the closure;

- Provide in advance, and then do not forget to make a special hole with which you will remove the accumulated ash;

- The pipe for the coolant should not be straight, but slightly curved. This form is necessary to increase heat supply;

- The location of the valve must be convenient and accessible. Thanks to it, you will control the process of air entering the furnace;

- First start. After you have finished assembling and installing the pyrolysis boiler with your own hands, conduct a test run of the device. Using special equipment, check the error-free operation at all stages, and make sure that carbon monoxide does not accumulate in the boiler. Only after that, you can fully put the boiler into operation.

Finally

Gas-fired boilers are rather complex structures. In order to make them with your own hands, you need to have some skills in the manufacture of such units and, in addition, detailed drawings of a particular design. The schemes of pyrolysis boilers presented here reflect only the general principles of their design and can be used as the basis for drawing up such drawings with your own hands, based on calculations of their parameters, taking into account the required power, burning time and other criteria. But it is not so easy to do so.It is best to find and use ready-made drawings of home-made pyrolysis boilers operating according to one or another scheme that interests you. Some of them we will try to consider in the following articles of this section.