- The principle of operation of the long-burning boiler

- Advantages and disadvantages

- Pyrolysis boiler furnace

- Assembly process

- Air supply device

- Housing (furnace)

- Chimney

- We connect the case and the air supply device

- Heat dissipating disc

- convection hood

- Lid

- legs

- What types of gas generating boilers exist

- Features of boilers with a lower combustion chamber

- Features of boilers with an upper combustion chamber

- Finally

- Do-it-yourself pyrolysis boiler: rules and nuances

- Boiler manufacturing

- The peculiarity and peculiarity of the operation of pyrolysis boilers

- Advantages of boilers

- Flaws

- Operation features

- The principle of operation of pyrolysis boilers and their features

- The principle of operation, the pros and cons of the pyrolysis boiler

- Foundation construction

- Preparation stage

- Safety requirements for installing a pyrolysis boiler in a house

- The principle of operation of the pyrolysis boiler

- Determination of dimensions and power

- Conclusions and useful video on the topic

The principle of operation of the long-burning boiler

In conventional solid fuel units, one bookmark is enough for 6-7 hours of burning. Accordingly, if the next portion of resources is not added to the furnace, the temperature in the room will immediately begin to decrease. This is due to the fact that the main heat in the room circulates according to the principle of free movement of gas.When heated by the flame, the air rises and exits.

The thermal resource of a long-burning boiler is enough for about 1-2 days from one laying of firewood. Some models can keep warm up to 7 days.

How is this cost-effectiveness and efficiency achieved?

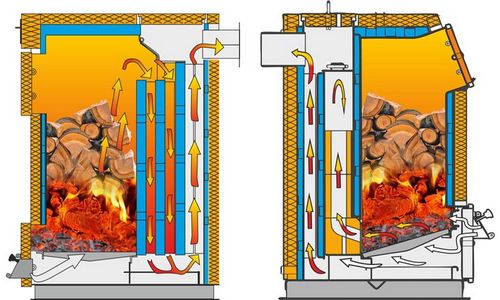

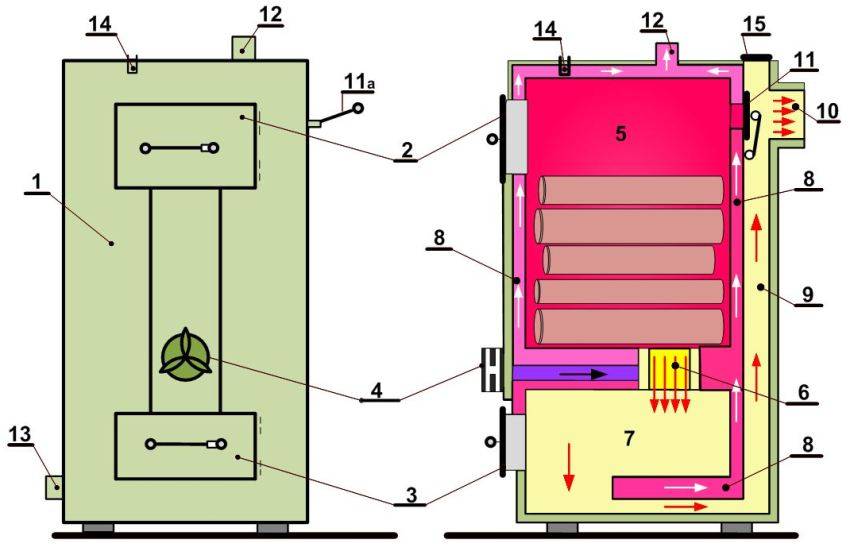

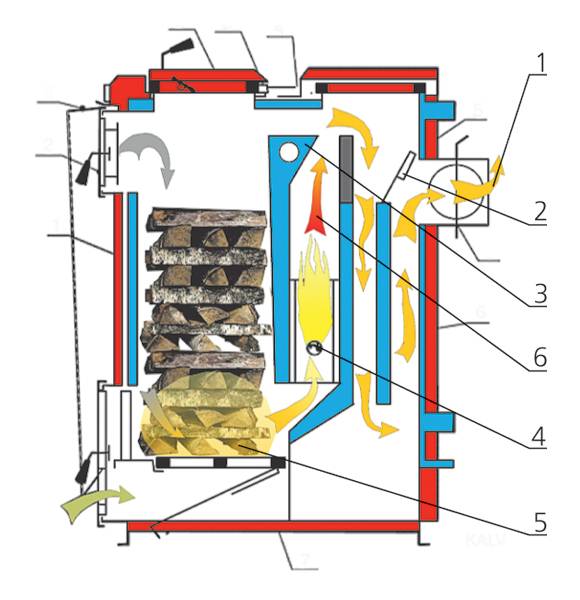

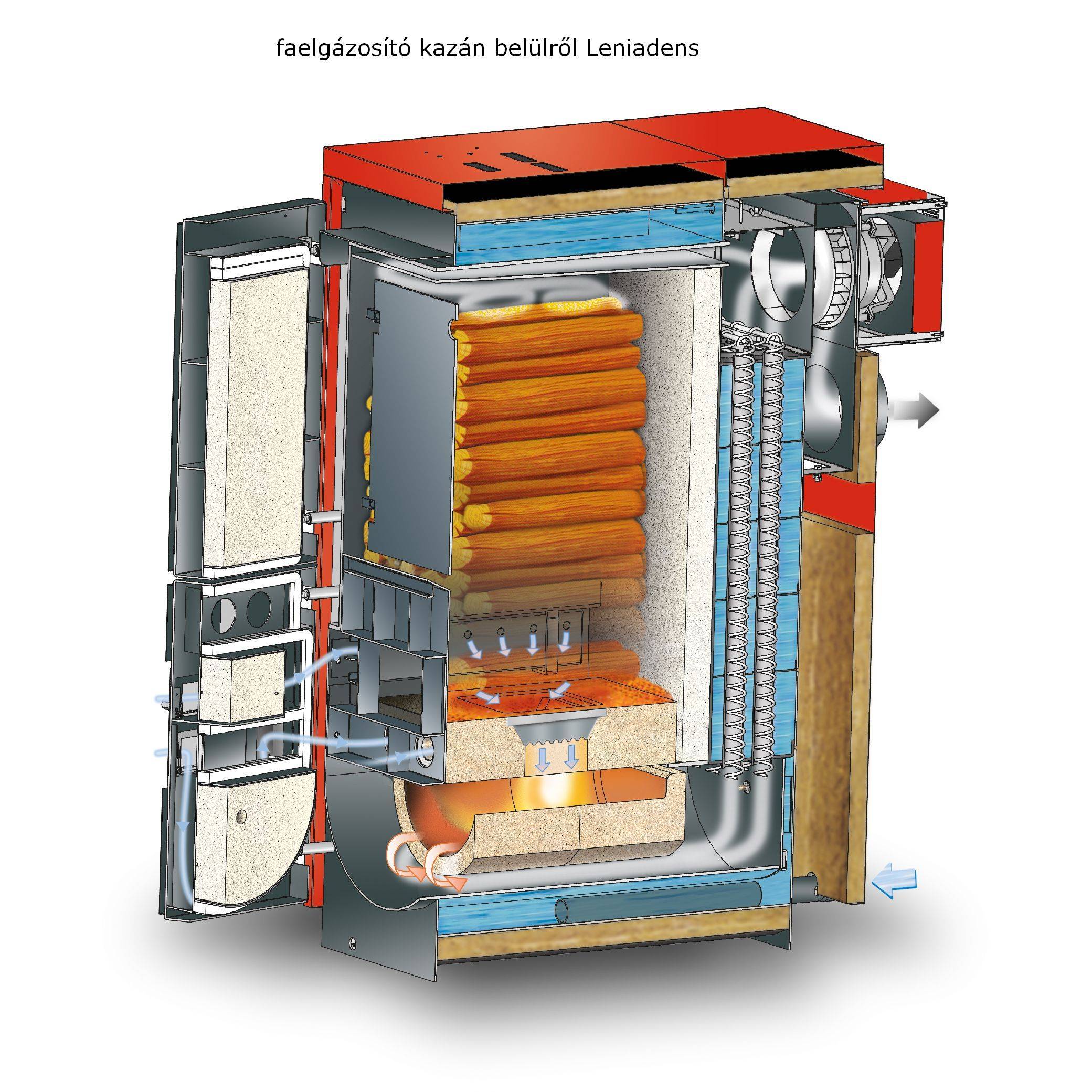

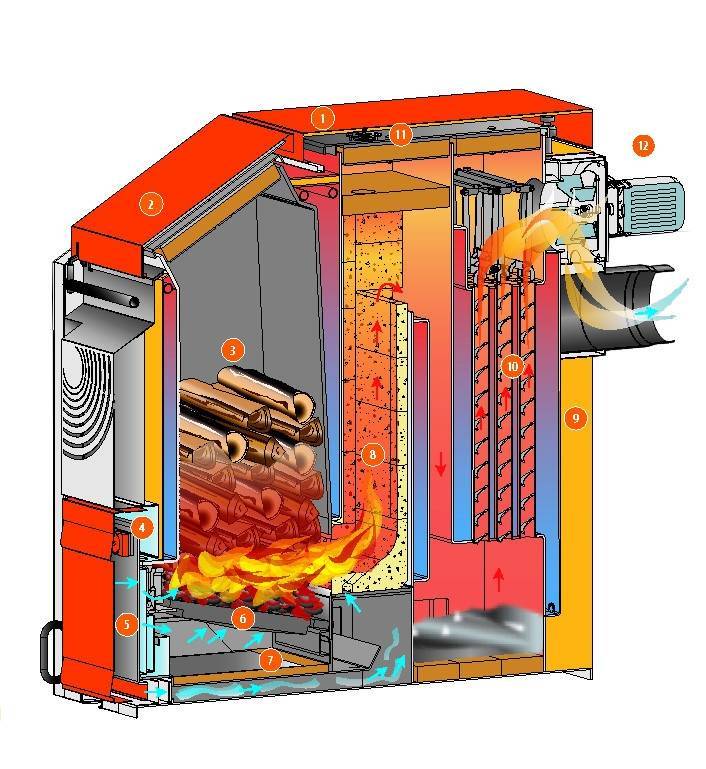

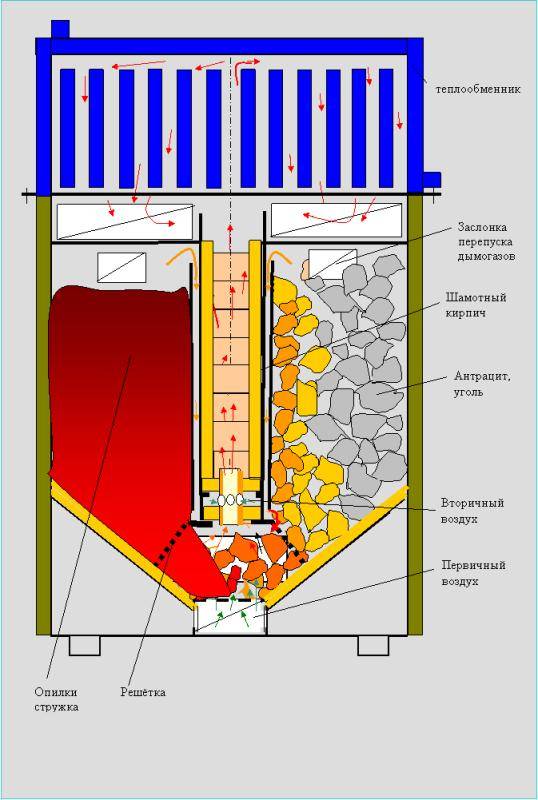

Boiler operation scheme

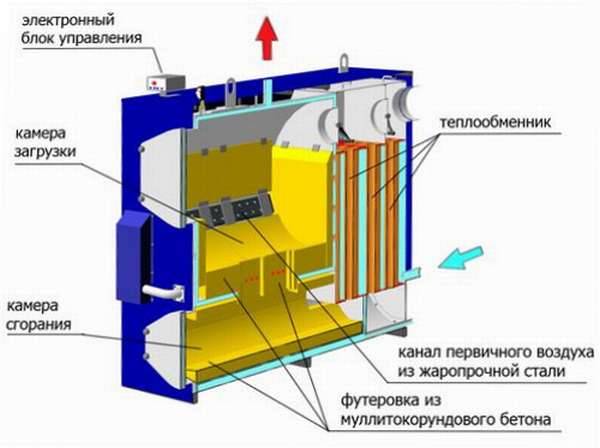

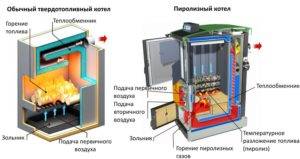

From a conventional boiler, a TT long-burning boiler is distinguished by the presence of two combustion chambers at once. In the first, the fuel itself burns as standard, and in the second, the gases released during this process.

An important role in this process is played by the timely supply of oxygen, which is provided by the fan.

This principle has been implemented relatively recently. In 2000, the Lithuanian company Stropuva presented this technology for the first time, which immediately gained respect and popularity.

Homemade long-burning boiler

Today, this is the cheapest and most practical way to heat a country house, where gasification is not provided and there are power outages.

Such units operate on the principle of burning top fuel. As a standard, in all furnaces, the firebox is located at the bottom, which allows you to take cold air from the floor, heat it up and lift it up.

The principle of operation of this boiler is somewhat similar to pyrolysis. The main heat here is released not from the combustion of solid fuel, but from the gases released as a result of this process.

The combustion process itself takes place in a closed space. Through a telescopic tube, the released gas enters the second chamber, where it is completely burned and mixed with cold air, which is pumped up by the fan.

TT long-burning boiler (diagram)

This is a continuous process that occurs until the fuel burns out completely.The temperature during such combustion is reached very high - about 1200 degrees.

As mentioned above, this boiler has two chambers: the main one is large and small. The fuel itself is placed in a large chamber. Its volume can reach 500 cubic meters.

Any solid fuel can act as a resource for combustion: sawdust, coal, firewood, pallets.

A constant air supply is carried out by a built-in fan. The advantage of this method is that solid fuel is consumed extremely slowly.

This significantly increases the efficiency of such a heater. Why does firewood burn out so slowly compared to a standard stove?

The bottom line is that only the top layer burns out, since air is blown by a fan from above. Moreover, the fan adds air only after the top layer has completely burned out.

There are many models on the market today that work on the same principle, but, depending on the dimensions, material of execution, additional options, have different efficiency and economy.

Universal TT boilers operate on absolutely any fuel, which will greatly simplify their operation for the owners. A more budget option is a wood-fired TT long-burning boiler. It works exclusively on wood and cannot be used with any other fuel option.

Advantages and disadvantages

Application advantages:

- during the combustion of firewood, it is impossible to obtain such a high temperature as in the process of combustion of pyrolysis gas (especially if the firewood contains a lot of moisture);

- with the help of a control controller, we can automate the operation of the pyrolysis boiler without much difficulty, since the process of burning pyrolysis gas is easy to control and regulate;

- much more secondary air is needed to burn wood or coal than to burn wood gas. Therefore, with the same volume of secondary air, the efficiency of combustion of wood gas, the duration and temperature of combustion will be greater;

- the emission of harmful substances from pyrolysis boilers into the atmosphere is minimized, so the pyrolysis boiler is practically an environmentally friendly source of heat;

- solid fuel boilers of pyrolysis combustion need to be cleaned of ash extremely rarely;

- pyrolysis boilers can work for a very long time (up to 15 hours) on one tab of firewood, despite the fact that conventional solid fuel boilers need to be reloaded every 3-4 hours.

If we talk about the disadvantages of this type of unit, then, in addition to the price, which is the price for increased efficiency, and a more complex design, because pyrolysis boilers are 30-35% heavier than usual ones, since more metal is required for their manufacture, other "cons" insignificant.

For maximum efficiency, the moisture content of firewood should be no more than 20%. If the wood is damp, when it burns, steam is formed, which reduces gas emission and leads to the deposition of tar and soot. As a result, the efficiency of the boiler drops, and it becomes necessary to clean it.

Most pyrolysis units are electronically controlled.

Therefore, it becomes necessary to use electricity to operate the controller that controls the fan and smoke exhauster.

Natural draft pyrolysis boilers exist, but they require a very high and powerful chimney, so such models are unpopular.

The need to fill the furnace by 50-100% - only in this case will the high efficiency of the boiler be maintained.

Long-burning pyrolysis solid fuel boilers, although twice as expensive as a conventional solid fuel boiler, are distinguished by the possibility of economical use of fuel with maximum efficiency, which is much higher than from the combustion of coal and wood in conventional units.

Pyrolysis boiler furnace

The furnace provided for by the design of a home-made pyrolysis boiler can be used for the disposal of rubber and polymers, which will not lead to air pollution.

No matter how high-quality the firewood is, nevertheless, during their combustion, the maximum possible temperature is significantly lower than that which can be maintained when burning wood gas.

It is also important that the need for secondary air to create conditions for gas combustion is much less. This allows you to achieve an increased temperature, as a result of which the combustion becomes more efficient and longer.

Also, during the combustion of pyrolysis gas, it is not necessary to solve serious problems in order to control this process.

Assembly process

The process of creating a boiler includes several stages. In the manufacture of each element, it is worth considering the special operating conditions of the manufactured product.

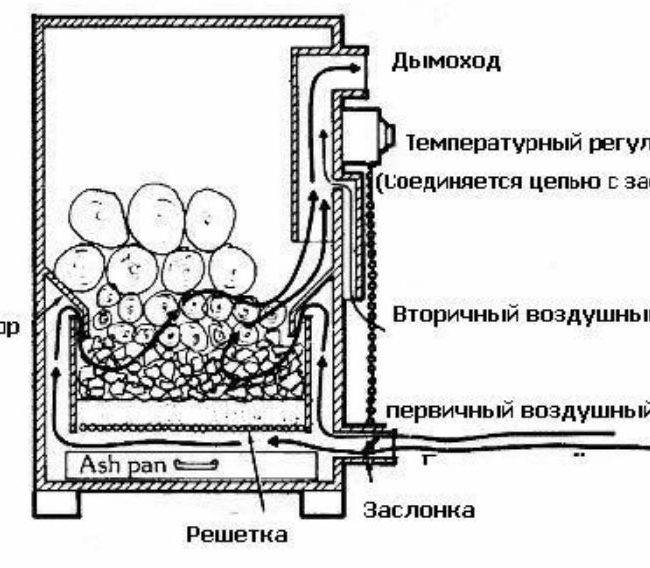

Air supply device

We cut off a segment from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the furnace. Weld a bolt to the bottom. From the steel sheet we cut out a circle of the same diameter as the pipe or larger.We drill a hole in the circle, sufficient for the passage of a bolt welded to the pipe. We connect the circle and the air pipe by screwing the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed with a freely moving metal circle. During operation, this will allow you to regulate the intensity of burning firewood and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical cuts in the pipe with a thickness of approximately 10 mm. Through them, air will flow into the combustion chamber.

Housing (furnace)

The case requires a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a steel thick-walled cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

Chimney

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which exhaust gases will be removed.

The length of the pipe is selected depending on the design considerations.

We connect the case and the air supply device

In the bottom of the case, we cut a hole with a diameter equal to the diameter of the air supply pipe. We insert the pipe into the body so that the blower goes beyond the bottom.

Heat dissipating disc

From a metal sheet with a thickness of 10 mm, we cut out a circle, the size of which is slightly smaller than the diameter of the case.We weld to it a handle made of reinforcement or steel wire.

This will greatly simplify the subsequent operation of the boiler.

convection hood

We make a cylinder from sheet steel or cut off a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the furnace (body). You can use a pipe with a diameter of 500 mm. We connect together the convection casing and the firebox.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the furnace, if the gap is large enough. With a smaller gap, you can weld the casing to the furnace around the entire perimeter.

Lid

From a steel sheet we cut out a circle of the same diameter as the firebox or a little more. We weld handles to it using electrodes, wire or other improvised means.

Considering that during the operation of the boiler, the handles can become very hot, it is worthwhile to provide special protection from a material with low thermal conductivity.

legs

To ensure long burning, we weld the legs to the bottom. Their height must be sufficient to raise the wood-burning boiler at least 25 cm above the floor. To do this, you can use a different rental (channel, corner).

Congratulations, you have made a wood-burning boiler with your own hands. You can start heating your home. To do this, it is enough to load firewood and set it on fire by opening the lid and the heat-dissipating disk.

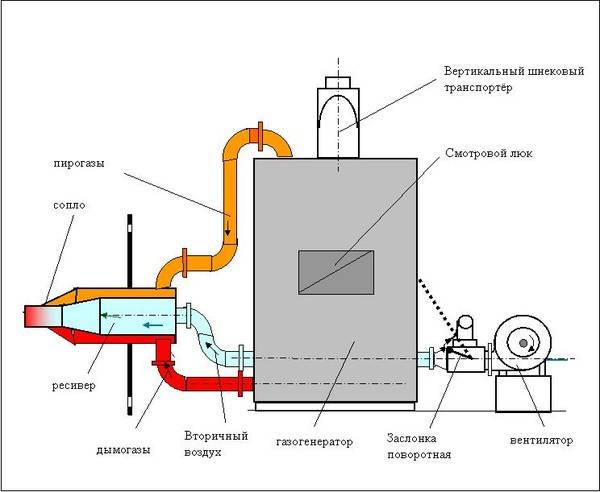

What types of gas generating boilers exist

i http-equiv="Content-Type" content="text/html;charset=UTF-8">d="attachment_2273" style="width: 547px" class="wp-caption aligncenter">

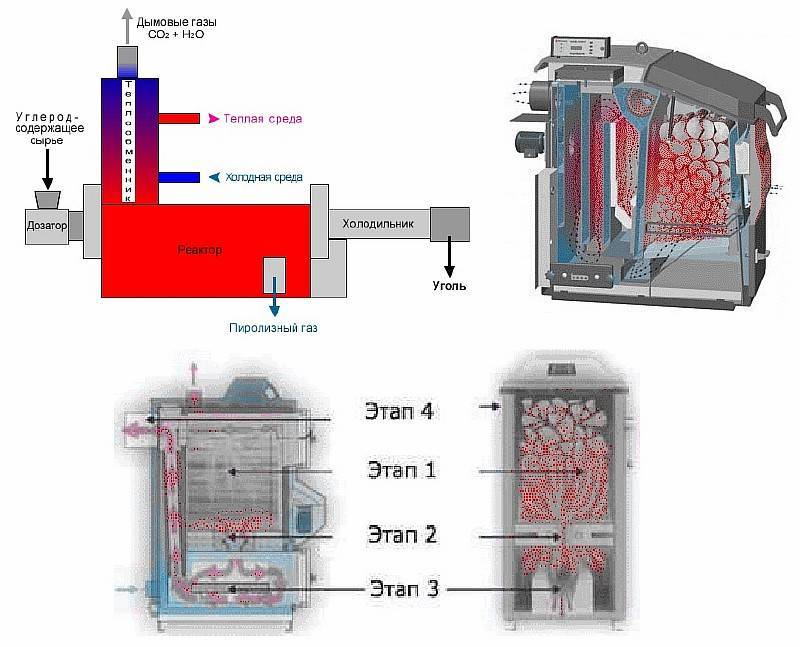

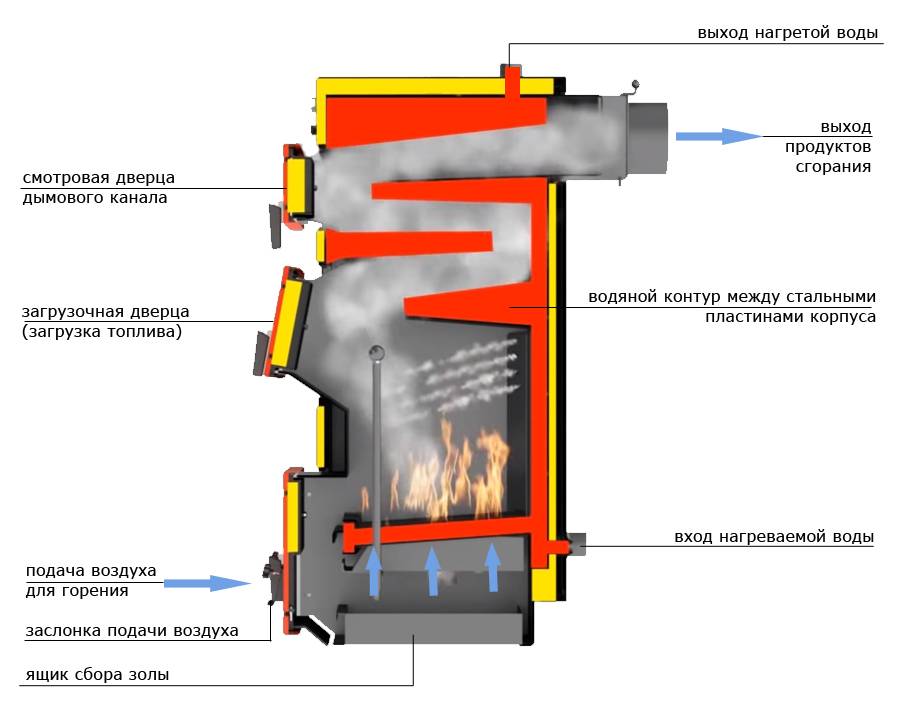

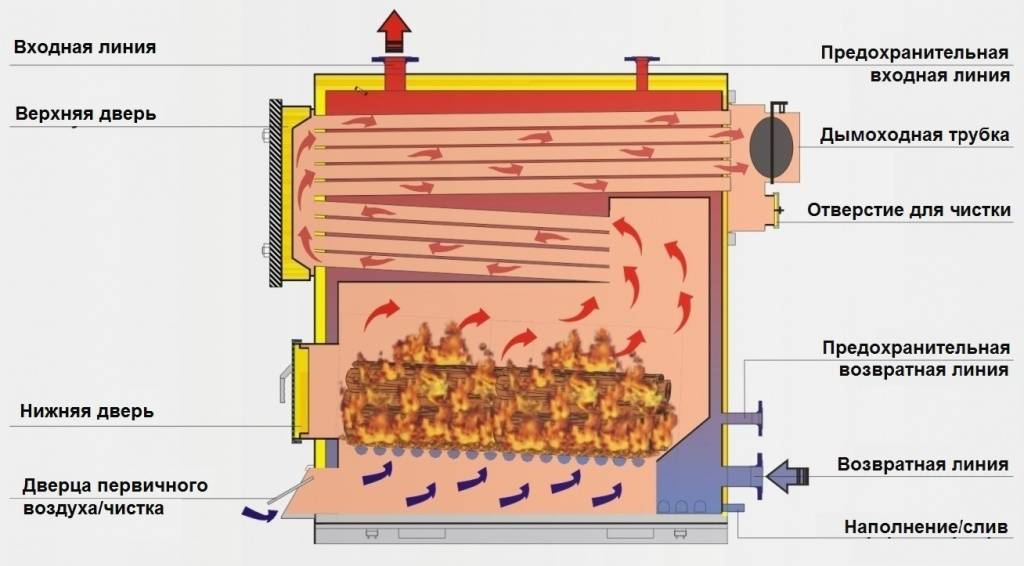

Scheme of a boiler with a lower gas combustion chamber

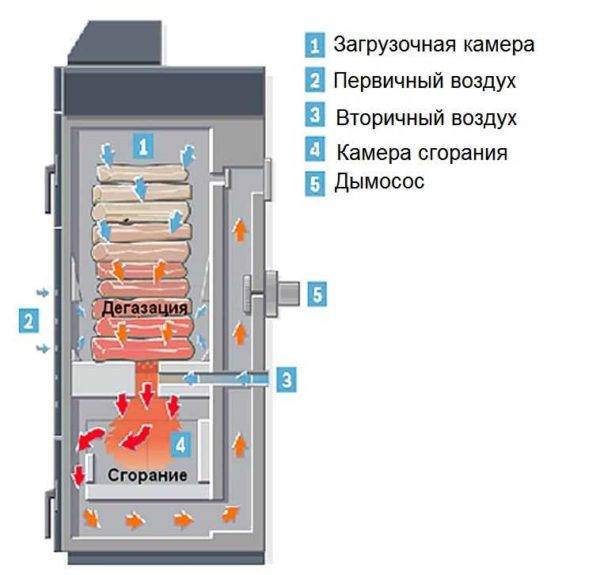

As you already understood, such boilers contain two combustion chambers: the primary combustion chamber (where the wood burns) and the combustion chamber (where the gas burns directly). But, according to their location, fireboxes can be of two types:

- with lower combustion chamber,

- with top combustion chamber.

Features of boilers with a lower combustion chamber

In this case, pyrolysis gas from the primary furnace is supplied by artificial injection using a turbine. This makes the operation of the installation dependent on electricity.

| Advantages | Flaws |

| Convenient loading of fuel into the chamber | The need to clean the ash from the gas combustion chamber |

| Convenient maintenance | Higher price due to complex design |

| Higher efficiency due to larger heat exchanger chamber |

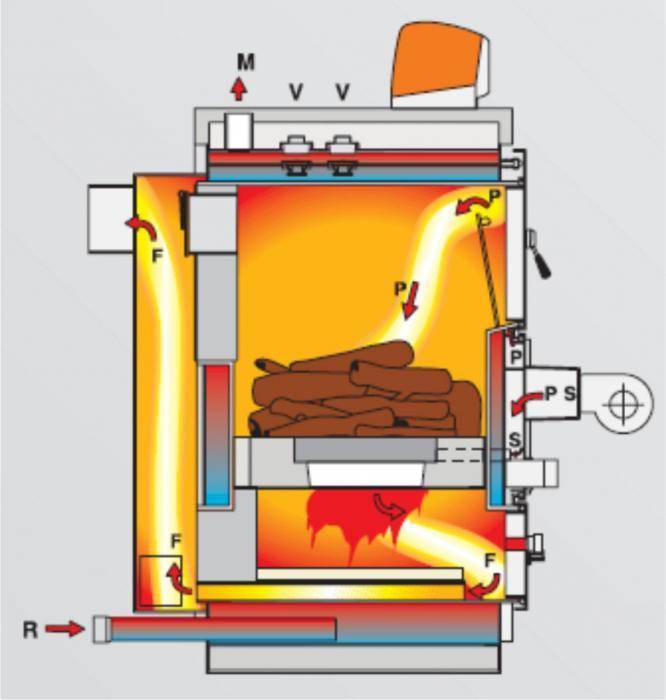

Features of boilers with an upper combustion chamber

Combustion chamber from above

In this case, firewood burns in the lower chamber, and the generated gas rises to the upper one, where it is burned.

| Advantages | Flaws |

| Gas enters the chamber naturally | Slightly lower efficiency |

| The chamber needs to be cleaned less often | |

| Exhaust gases escape due to natural draft |

A little theory from the effectiveness of this equipment

According to many manufacturers, fuel consumption per 100 m² of premises with a height of up to 3 m is no more than 10 kg per day. As firewood, it is recommended to use birch or maple. Conifers are less effective because resin remains in the emitted gases.

Finally

If you decide to install and use a solid fuel boiler, such an option as pyrolysis will be the most rational. Despite its high cost, it will pay off quite quickly due to its high efficiency.In addition, it will save you time during operation and maintenance.

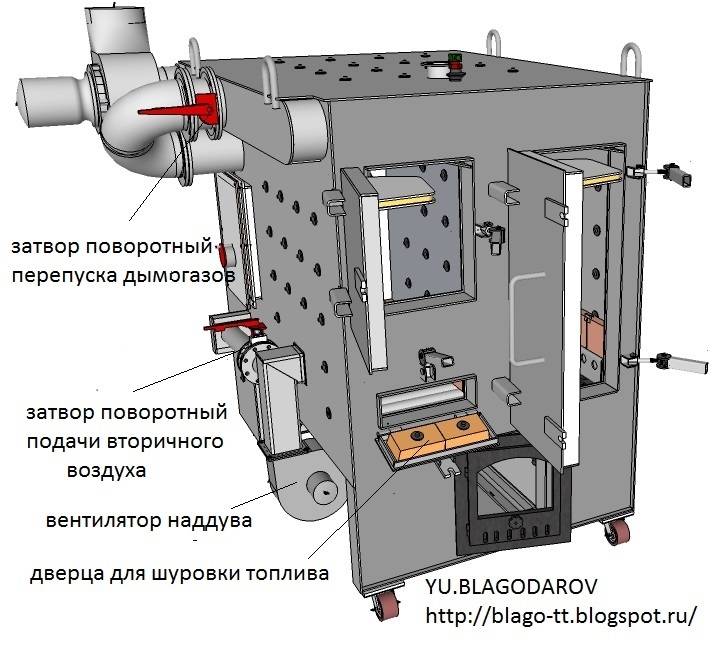

Do-it-yourself pyrolysis boiler: rules and nuances

Do-it-yourself pyrolysis boiler

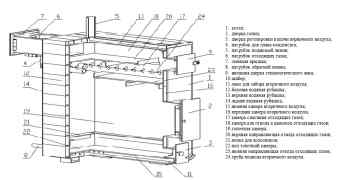

In order to install a pyrolysis boiler with your own hands, while maintaining all its working qualities, it is necessary to rely on accurate drawings and calculations. An incorrectly assembled boiler, mounted according to an incompetent scheme, will not only perform its functions poorly, but also pose a threat to the safety of the environment and you in the first place.

Do-it-yourself pyrolysis boiler assembly rules:

- Your first priority, before starting the assembly, is the mandatory familiarization with the drawings, plans and diagrams. They will help determine the amount of material needed for work, as well as save you from possible emergencies;

- Check for the presence of fundamental elements, without which it is impossible to assemble the pyrolysis boiler with your own hands. These are: regulators, air openings, smoke channels, pipes for water drainage, a combustion chamber, pipes for water supply, and a fan;

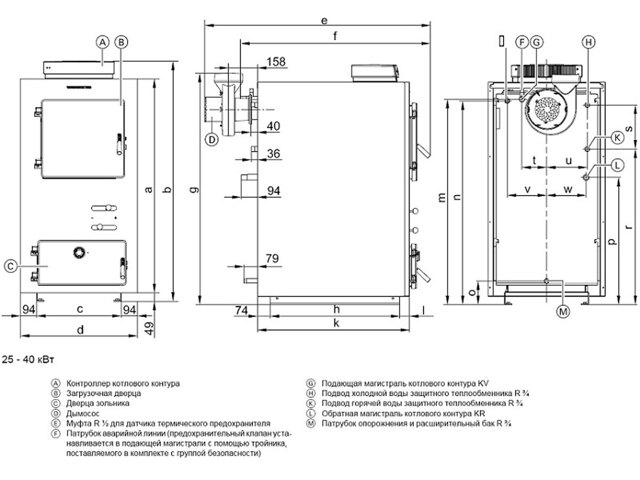

- Please note that if you are supposed to heat a standard country house, a pyrolysis boiler with a capacity of 40 kW is quite suitable for you, and if you are the owner of a very small cottage, then a 30 kW boiler is enough. It makes no sense to install super powerful boilers, since a small device will perfectly insulate the premises, while huge units will cost a lot of money and will require significant costs;

- It will not be superfluous to prepare the necessary tools for installing the boiler. So that you do not have to run to the hardware store once again, prepare everything you need right away.To install a pyrolysis boiler with your own hands, you will need such a toolkit: a grinder, grinding wheels, a welding machine, an electric drill, pipes of various diameters, electrodes, a fan, steel strips, a temperature sensor, metal sheets

Please note that assembling a pyrolysis boiler with your own hands is a long and painstaking process, so be prepared for possible difficulties. However, by carefully preparing for the process, you greatly reduce the risk of unexpected problems.

After all the rules are followed, the desired scheme is selected, it's time to proceed with the direct assembly. When assembling the device in stages, follow the following nuances:

- Unlike conventional boilers, the hole for putting firewood into the firebox should be located slightly higher;

- Be sure to check the presence of a restrictor that fixes the air supply to the boiler. Its optimal dimensions are 70 ml in cross section and a length exceeding the dimensions of the case;

- The disk welded to the limiter must be made of stainless steel and located at the bottom of the entire structure;

- The solid fuel inlet is best desired to be rectangular in shape. For a pyrolysis boiler, this form is optimal;

- The door must close tightly and securely; a special lining is needed that will tightly fix the closure;

- Provide in advance, and then do not forget to make a special hole with which you will remove the accumulated ash;

- The pipe for the coolant should not be straight, but slightly curved. This form is necessary to increase heat supply;

- The location of the valve must be convenient and accessible. Thanks to it, you will control the process of air entering the furnace;

- First start. After you have finished assembling and installing the pyrolysis boiler with your own hands, conduct a test run of the device. Using special equipment, check the error-free operation at all stages, and make sure that carbon monoxide does not accumulate in the boiler. Only after that, you can fully put the boiler into operation.

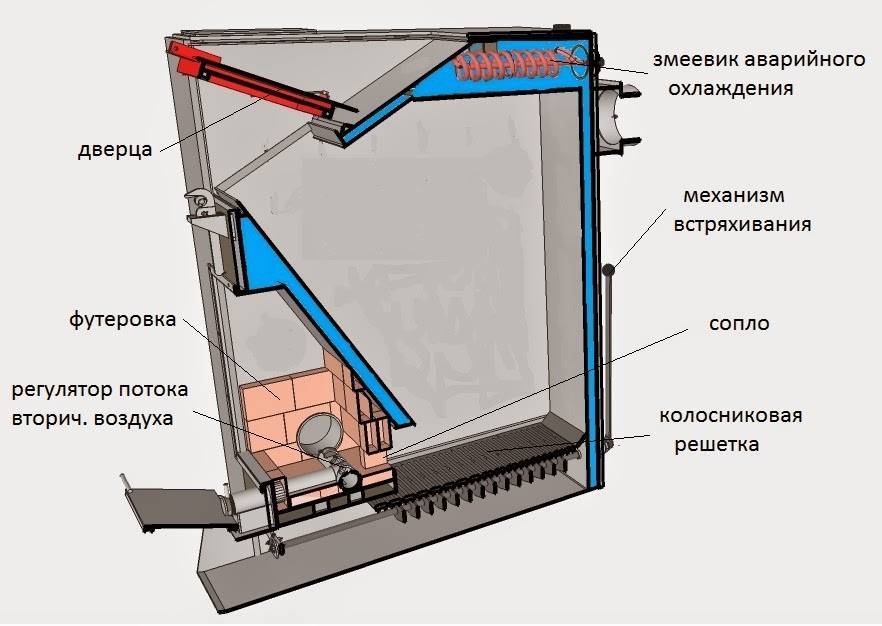

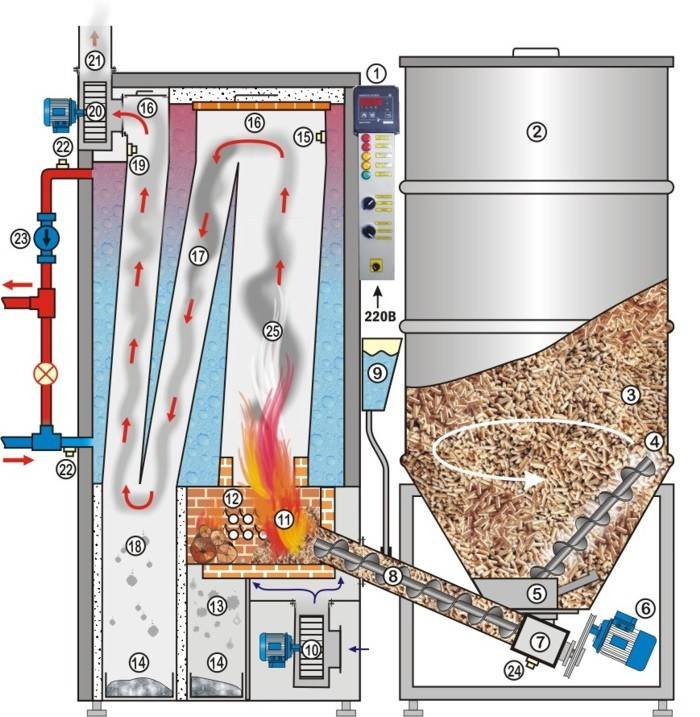

Boiler manufacturing

The pyrolysis boiler is manufactured in the following sequence:

- If a used gas cylinder will be used for the manufacture of the device, then it is necessary to bleed off the remaining gas, unscrew the bolts that hold the neck of the cylinder, and drain the gasoline. After that, the gas cylinder must be filled with water and kept for several days.

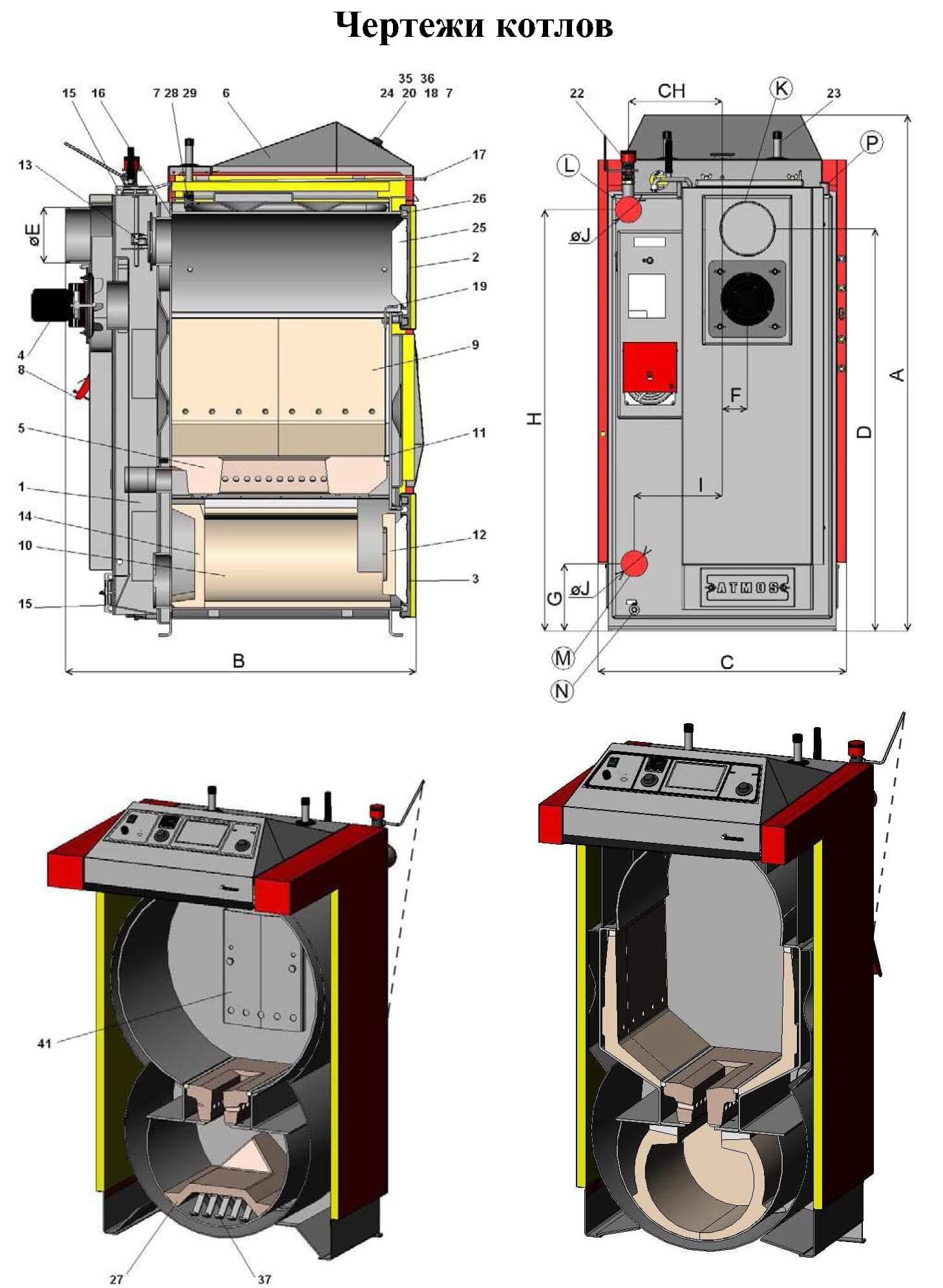

- Then, with a grinder, the balloon is sawn across a little above the weld. Thus, a perfectly even metal cylinder with a length of more than 130 cm will be obtained. Pyrolysis combustion of wood will occur inside this cylinder, but the heat released during this process must be transferred to the coolant. The coolant will be in a jacket, which will be “dressed” on a cylindrical combustion chamber.

- To make a shirt, it is necessary to cut 6 plates from sheet steel: 2 rectangular plates 60 * 60 cm in size, and 4 plates 120 * 60 cm. In plates 60 * 60 cm in size, round holes should be cut exactly in the middle of the square. The diameter of these holes should be equal to the outer diameter of the cylinder made from the gas cylinder.

- To make the holes ideal for placing a propane tank in them, place the cut end of the tank on the plate exactly in the middle and circle it with a marker.Then, according to the outlined pattern, cut a hole with a gas cutter.

- When the manufacture of holes in the lower and upper faces is completed, a container 120 cm high and 60 cm wide is welded from all previously prepared plates. The slotted faces will be located respectively in the upper and lower parts of the tank.

- When the shirt for the cylinder is ready, it is placed inside a rectangular tank so that there is about 5 cm indent from the plane of the shirt from above.

- Then the cylinder is carefully welded to the plane of the jacket. Two pipes are welded to the water jacket.

- One at the bottom of the tank, it will be used to enter the cooled coolant, the other at the top of the jacket, through which the heated liquid will be taken. Both nozzles have a pipe diameter of 28 mm.

- When the water jacket is completely made, a demarcation plate is made from the metal “pancake”, which was formed when cutting holes for the cylinder. This plate will protect the burning pyrolysis gas from the fuel located inside the cylindrical combustion chamber. On the one hand, a corner of 50 * 50 mm is welded to the “pancake”.

- The corner must be installed crosswise. Thus, a constant gap between the baffle and the smoldering fuel will be maintained.

- From the upper part of the cylinder, which has been sawn off, a lid is made to load fuel into the pyrolysis boiler, as well as to remove wood combustion products into a chimney specially mounted for such a furnace.

- In order for the lid to close the combustion cylinder from above tightly enough, it is necessary to weld a strip of metal 1 mm thick and 50 mm wide around the circumference of the sawn-off lid. A hole is made in the upper part of the cover with a cutter and a pipe segment with a diameter of 112 mm and a length of 0.5 meters is welded.

- In the lower part of the cylinder, a hole is made to fit the size of the ash pan door, which is then welded by electric welding. The door must have a reliable locking device in its design, which excludes spontaneous opening during operation of the heater.

- To adjust the intensity of fuel combustion, a pipe with a diameter of 28 mm is welded next to the ash pan door, on which a thread is cut and a water tap with a worm locking mechanism is installed. Thus, it will be possible to completely block the flow of air into the combustion chamber, which will lead to a decrease in the intensity of burning wood, and this process will continue for at least 8 hours.

The peculiarity and peculiarity of the operation of pyrolysis boilers

Advantages of boilers

- When burning fuel, there is no release of soot, soot and other combustion wastes. Pyrolysis furnaces are one of the most environmentally friendly types of furnace equipment.

- Any dry fuel can be used as fuel, for example, sewing waste. Good quality fuel can ensure the continuous operation of the boiler based on the pyrolysis furnace for 12 hours. That is, the loading of firewood can be performed twice a day.

- The use of such a furnace allows you to reduce the cost of heating utilities by 50-60% per year.The use of pyrolysis technology makes it possible to automate the furnace control processes, and this accordingly increases the safety of the device as a whole.

Flaws

Meanwhile, boilers of this type have certain disadvantages.

To buy a finished boiler and put it into operation, you will need to invest a certain amount, but it is worth noting that the efficiency of this device will be visible almost immediately.

Operation features

In some cases, a pump powered by electricity is used to pump air, then the operation of the equipment becomes dependent on electricity.

This information must be borne in mind when proceeding with the independent manufacture of the boiler.

The principle of operation of pyrolysis boilers and their features

By creating pyrolysis boilers with their own hands, people tend to save money in their wallet. If gas equipment is quite cheap, then solid fuel units are simply amazing at their price. A more or less decent model with a capacity of 10 kW will cost 50-60 thousand rubles - it is cheaper to conduct gas if a gas pipeline passes nearby. But if it is not there, then there are two ways out - to purchase factory equipment or make it yourself.

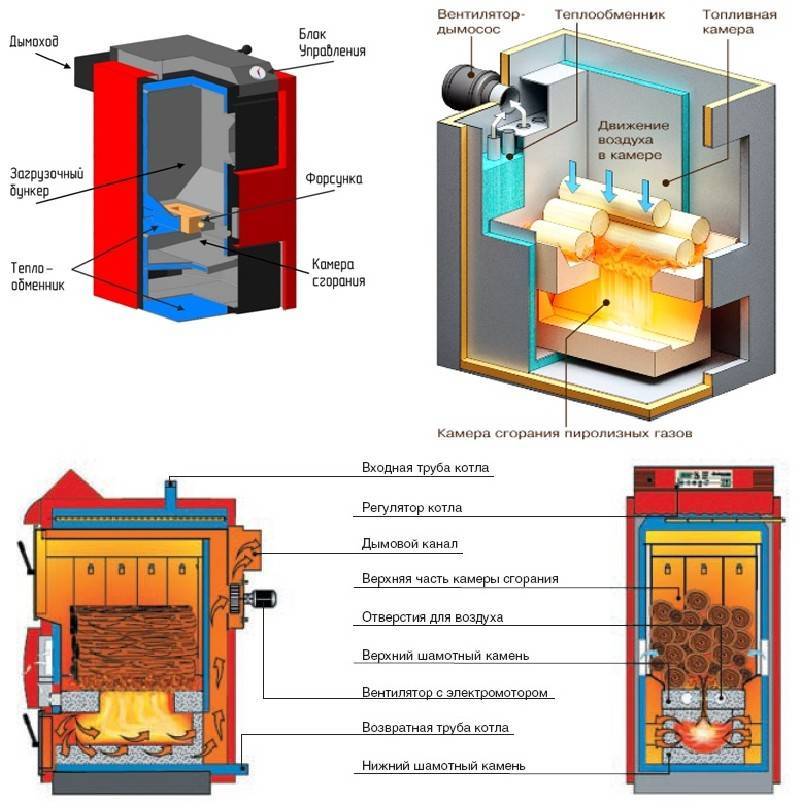

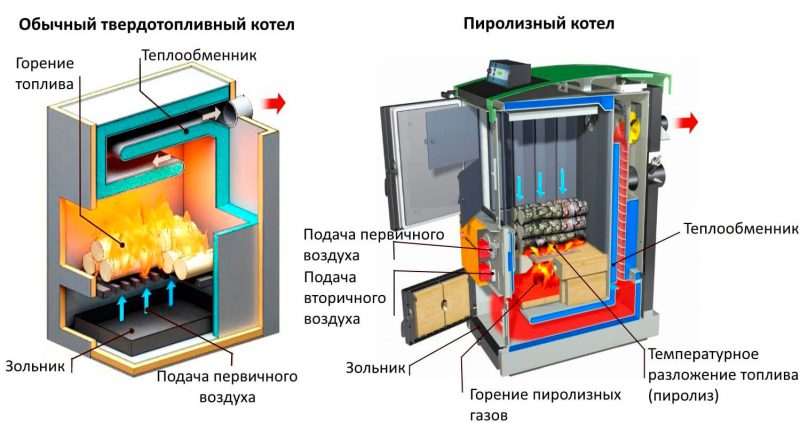

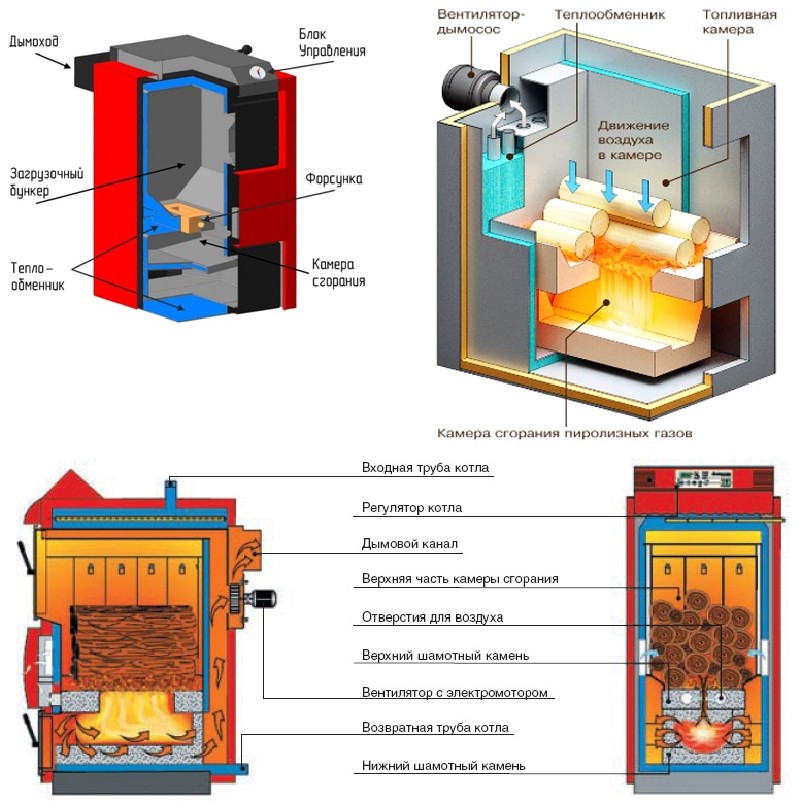

It is possible, but difficult, to make a long-burning pyrolysis boiler with your own hands. Let's first understand why pyrolysis is needed at all. In conventional boilers and stoves, wood is burned in the traditional way - at high temperature, with the release of combustion products into the atmosphere. The temperature in the combustion chamber is about + 800-1100 degrees, and in the chimney - up to + 150-200 degrees. Thus, a substantial part of the heat simply flies out.

Direct combustion of wood is used in many heating units:

Solid fuel pyrolysis boilers can use several types of fuel, including waste from woodworking and agricultural processing.

- solid fuel boilers;

- Fireplace stoves;

- Fireplaces with water circuits.

The main advantage of this technique is that it is simple - it is enough to create a combustion chamber and organize the removal of combustion products outside the equipment. The only regulator here is the blower door - by adjusting the clearance, we can adjust the intensity of combustion, thereby affecting the temperature.

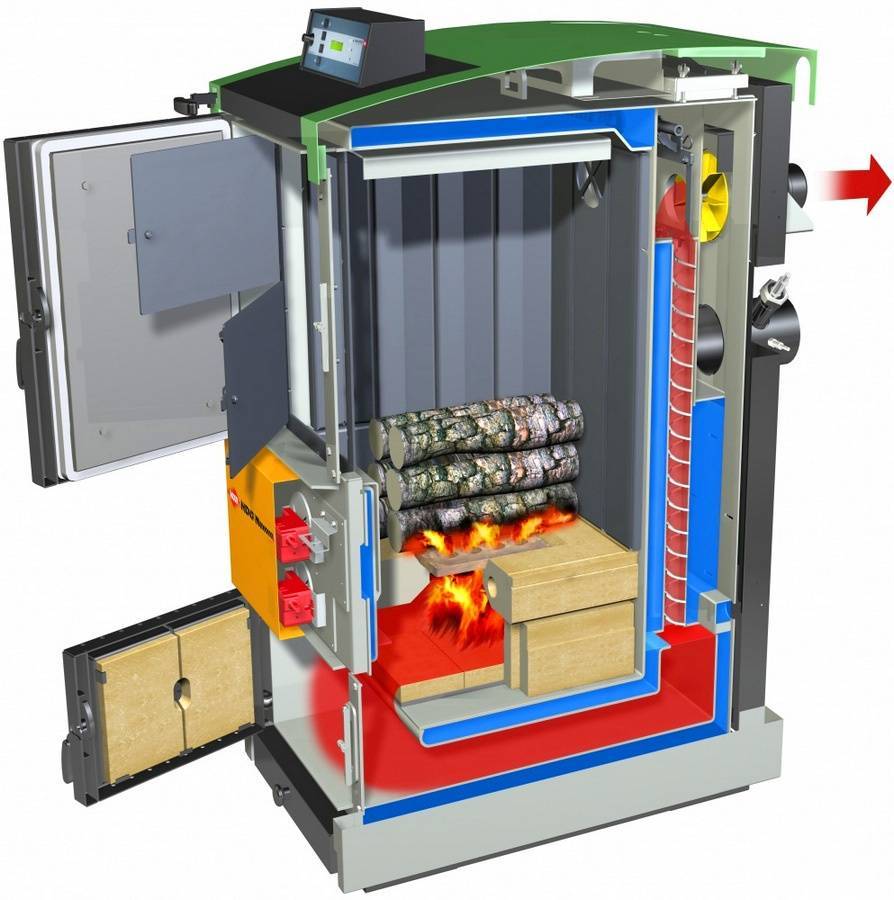

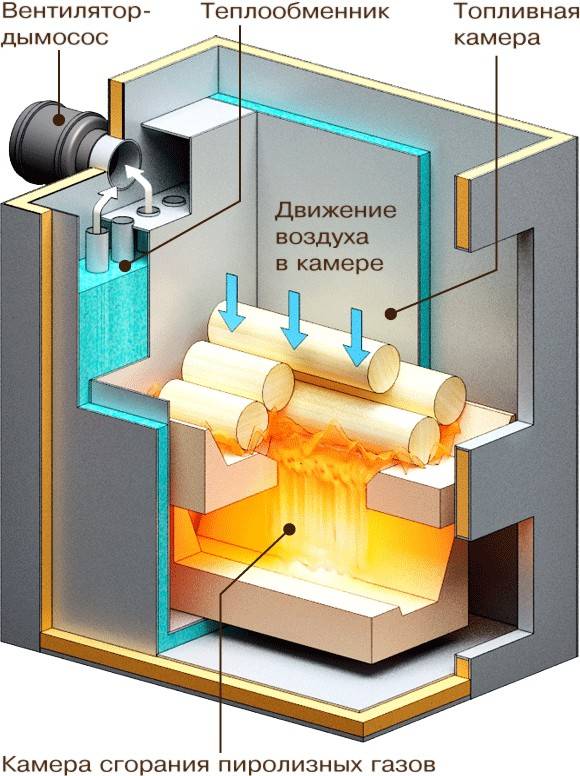

In a pyrolysis boiler, assembled with your own hands or bought in a store, the process of fuel combustion is somewhat different. Firewood is burned here at a low temperature. We can say that this is not even burning, but a slow smoldering. Wood at the same time turns into a kind of coke, while releasing combustible pyrolysis gases. These gases are sent to the afterburner, where they burn with the release of a large amount of heat.

If it seems to you that this reaction will not give a special effect, then you are deeply mistaken - if you look into the afterburner, you will see a roaring flame of bright yellow, almost white color. The combustion temperature is slightly above +1000 degrees, and more heat is released in this process than with standard wood combustion.

In order for a self-assembled pyrolysis boiler to be able to show maximum efficiency, firewood with a low moisture content is needed. Wet wood will not allow the equipment to reach its full capacity.

The pyrolysis reaction is familiar to us from the school physics course.In a textbook (and maybe in a laboratory room), many of us saw an interesting reaction - the wood was placed in a sealed glass flask with a tube, after which the flask was heated over a burner. After a few minutes, the wood began to darken, and pyrolysis products began to come out of the tube - these are combustible gases that could be set on fire and watch the yellow-orange flame.

Do-it-yourself pyrolysis boiler works in a similar way:

On one load of fuel, pyrolysis boilers operate for about 4-6 hours. So a large and steadily replenished supply of firewood should be taken care of in advance.

- Firewood is kindled in the firebox until a steady flame appears;

- After that, the access of oxygen is blocked, the flame goes out almost completely;

- The blower fan starts - a high-temperature flame appears in the afterburner.

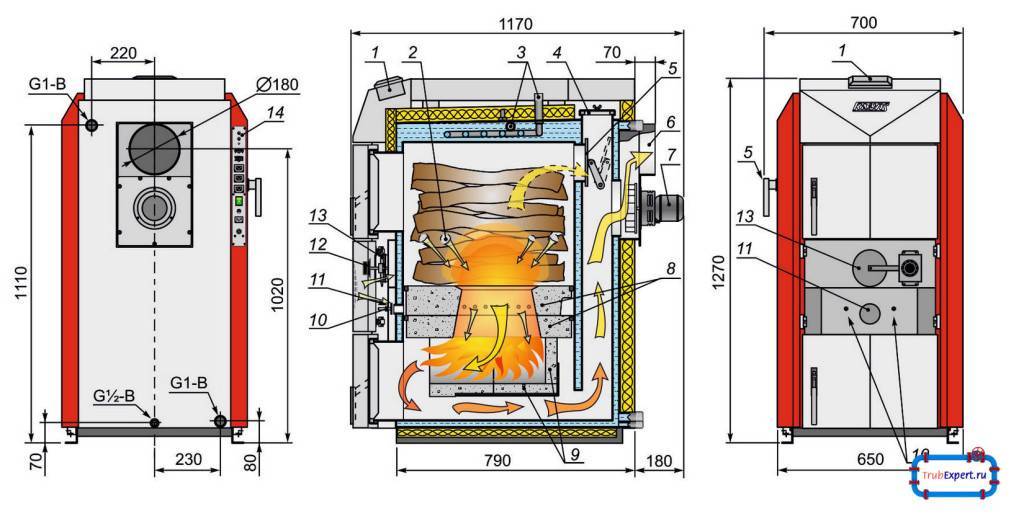

The device of the pyrolysis boiler is quite simple. The main elements here are: a combustion chamber in which firewood is stored, and an afterburner chamber in which pyrolysis products are burned. Heat is transferred to the heating system through a heat exchanger

In the scheme of the pyrolysis boiler, special attention is paid to it

The thing is that heat exchangers in do-it-yourself pyrolysis boilers are arranged differently than in gas equipment. Combustion products with air pass here through many metal pipes washed by water. To increase efficiency, boiler water washes not only the heat exchanger itself, but also all other nodes - a kind of water jacket is created here, which takes away excess heat from the hot elements of the boiler unit.

The principle of operation, the pros and cons of the pyrolysis boiler

You can understand the principle of operation based on the diagrams and drawings. But for self-production, you will need to delve more into the principle of operation of the device. The burner works thanks to dry distillation. When the temperature reaches 500-600 degrees, the decomposition of the tree begins. The result is combustible gas and natural coke.

Combustible gas is mixed with air. This is what becomes the trigger for the start of combustion. But for the correct process, the optimum temperature must be maintained in the chamber.

The long-burning device allows maximum use of solid fuel. The result is very little waste. The potential of wood is revealed better, more heat is released and large areas can be heated.

Pyrolysis refers to exothermic processes. This is the general name of the class, as a result of which heat is generated. But this heat is used for heating and drying fuel.

Advantages of pyrolysis boilers:

- A stable temperature is maintained for a long time;

- Capacity of the loading bunker;

- High efficiency;

- Can be used to recycle wood products.

But homemade pyrolysis has its drawbacks. Among the minuses are the large size of the structure, dependence on electricity and fuel selectivity. When buying a ready-made system, they note the high cost of equipment. Damp wood should not be used to heat a house. High humidity will make pyrolysis difficult.

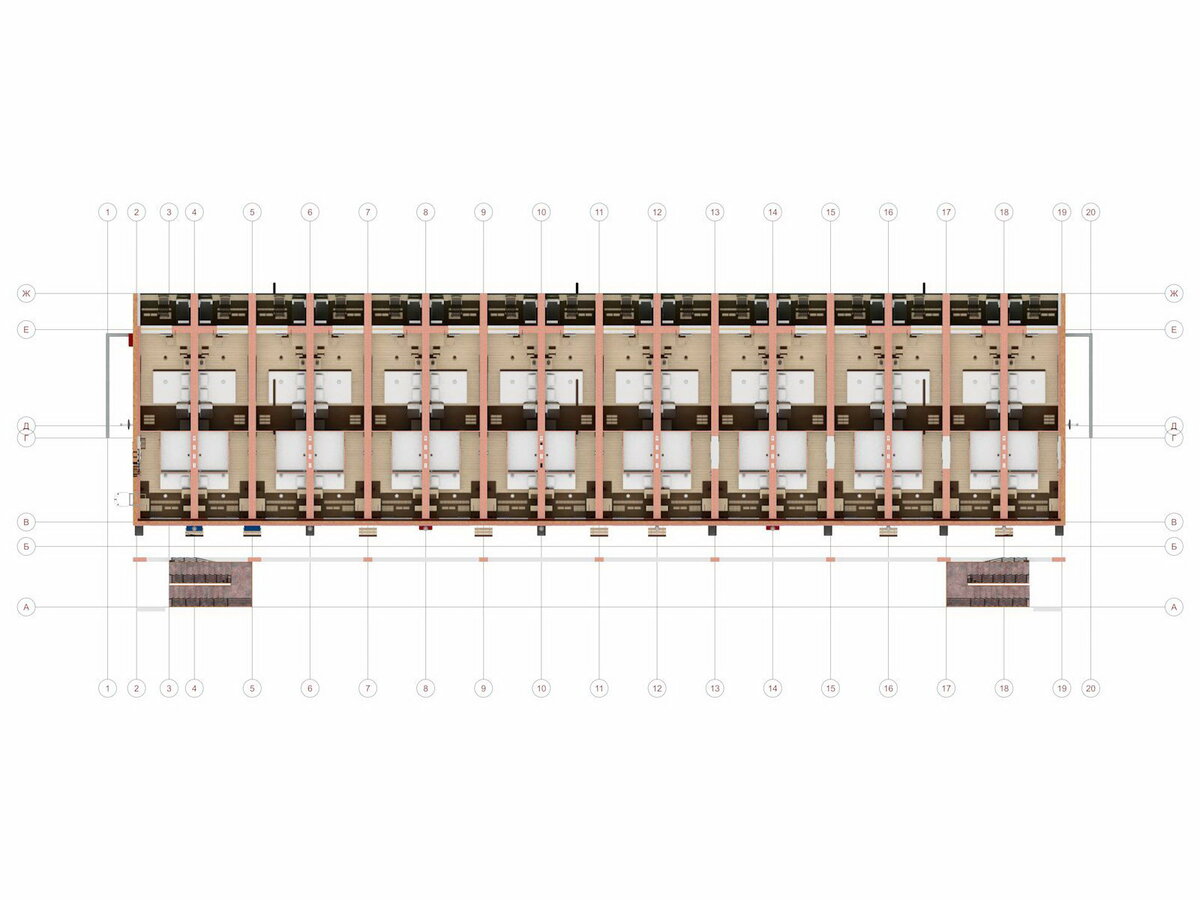

Foundation construction

The foundation for the Bubafonya stove is laid in this way:

- The first step is to dig a square hole. Its approximate dimensions are 150x150 cm, with a depth of 20-30 cm.

- The bottom of the trench is covered with a crushed stone pillow and poured with a concrete solution. To level its surface, a trowel is useful. When the flooded area seizes, it is necessary to check the horizontalness of its surface using the building level. If necessary, additional adjustments are made.

- On top of a completely dried concrete stand, refractory bricks are laid in several rows. Usually 2-3 layers are enough.

Preparation stage

At the preparatory stage, it is important to correctly calculate the required power of the device, as well as choose the model that will be used to heat the house. According to the rules for the operation of these devices, for the installation of a pyrolysis boiler, a separate room with high ceilings, with free air access, should be equipped, but it is not recommended to stay in such a room for a long time, and even more so to stay overnight.

According to the rules for the operation of these devices, for the installation of a pyrolysis boiler, a separate room with high ceilings, with free air access, should be equipped, but it is not recommended to stay in such a room for a long time, and even more so to stay overnight.

To make a pyrolysis boiler with your own hands, you will need the following tools and materials:

- Welding machine. It is best to use an inverter type device.

- Bulgarian.

- Electric drill.

- A hammer.

- Screwdrivers and wrenches

- Gas cylinder from a truck with a volume of 175 liters.

- Steel sheet high carbon 5 mm thick.

- Pipe steel with a diameter of 28 mm.

- Pipe steel with a diameter of 112 mm.

- Marker.

- Corner metal 50 * 50 mm.

- Metal door for the ash pan.

In addition, it is necessary to prepare consumables: electrodes for welding, emery wheels and drills.

Homemade pyrolysis boiler

Safety requirements for installing a pyrolysis boiler in a house

Firewood must not be stored near the boiler

- The pipe through which smoke is removed must rise 40 cm above the roof of the building.

- All parts of the chimney must be hermetically connected, excluding the possibility of smoke leakage.

- The boiler must be located in a non-residential area.

- The distance from the unit to the wall must be at least 70 cm.

- When placing the heater, it is recommended to install it in level, avoiding tilting to the side.

- In front of the combustion chambers, metal sheets should be laid on the floor of the room.

- It is not recommended to heat the boiler for more than 11 hours a day. Even metal parts at constant high temperatures quickly become unusable.

- Extinguishing the fire in the boiler with liquids is prohibited.

- Do not open the boiler doors while the unit is running.

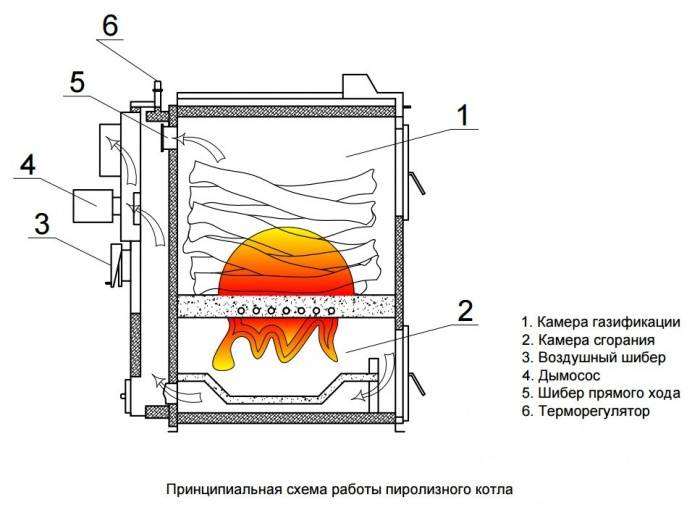

The principle of operation of the pyrolysis boiler

In relation to heating boilers, pyrolysis is the combustion of fuel with an insufficient amount of oxygen. At the same time, the fuel emits a large amount of gases, almost all of which are combustible. These gases are sent to a special combustion and afterburner chamber, where secondary air is supplied. The gas-air mixture ignites, releasing a large amount of heat. Much more thermal energy is released than can be extracted by conventional combustion of wood or coal. The fact is that many of the volatile substances formed during the combustion of fuel have a very high combustion temperature. As a result, pyrolysis boilers extract more heat from the same amount of fuel.

A design feature of pyrolysis boilers is a firebox consisting of two chambers. Fuel is placed in one (often this is the upper part of the furnace), gases are released in it, and therefore this part is called the gas generation chamber. Through a narrow neck, gases enter the second chamber - afterburning. Here they mix with secondary air, flare up and burn out almost without residue.

Pyrolysis boiler with bottom afterburner

On average, the efficiency of pyrolysis plants is above 85%. There are models that can give out 92% and even a little more. But these indicators are possible only and exclusively when using dry fuel. Its humidity should be 5-8%. At 40% moisture content, combustion can completely die out, and at 20% it will simply be inefficient. And this is one of the main disadvantages of this technology: firewood and coal have to be dried beforehand, for example, by making a platform near the chimney. It’s just that firewood dried in a woodshed will not go, like coal taken from a pile on the street.

The video shows a boiler in which the afterburner is at the top. Although boilers of this type have a simpler structure (the resulting gases themselves rise up), do-it-yourselfers prefer a chamber with a lower location of the afterburner (as in the photo above).

Determination of dimensions and power

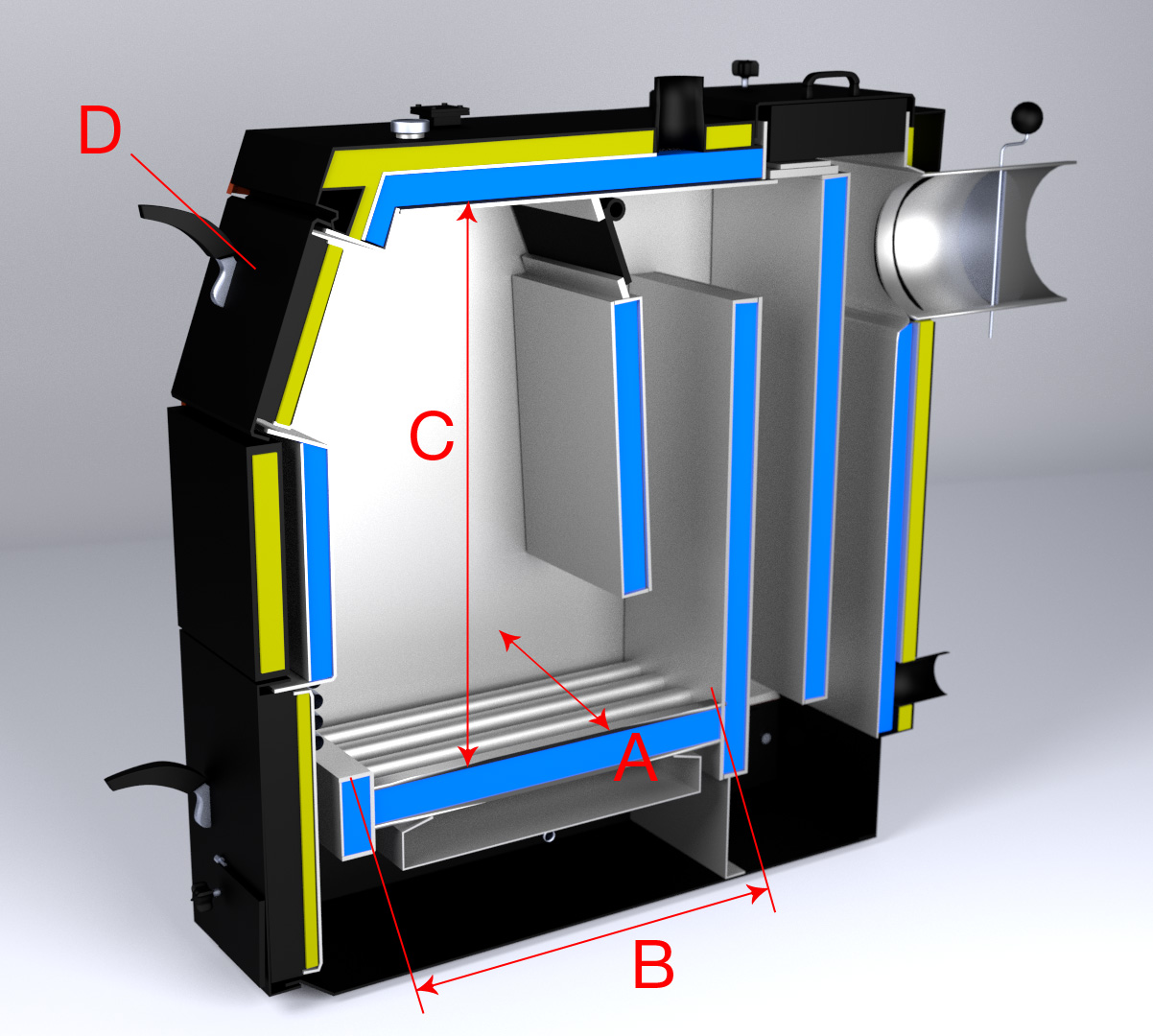

Before proceeding with the manufacture of a pyrolysis boiler, it is necessary to calculate the dimensions of the furnace chambers and additional compartments. The required calorific power is taken as the initial data, determined taking into account the efficiency of a home-made boiler of the order of 75–80%.At home, solid fuel boilers with a power of up to 20–25 kW can be made; more productive units require the use of heat-resistant steels of considerable thickness, which are difficult to weld at home.

The power of the boiler and the duration of its operation are determined by the volume of the gasification chamber. Without taking into account the efficiency, the calorific value of most common wood species is about 4–5 thousand kcal/kg, which approximately corresponds to 4–4.5 kWh of thermal power. These values only apply to wood with a moisture content of 25% or less. The essence of the calculation is simple - determine the required instantaneous power and multiply it by the number of hours of operation. It is worth remembering that pyrolysis boilers, even of perfect designs, have a maximum operating time of no more than a day, but on their own manufactured units should expect a maximum of 12-15 hours of continuous burning.

The volume of the bookmark chamber is determined at the rate of 2 liters per kilogram of firewood. About 30% must be added to the value obtained, because in the pyrolysis boiler, non-split chocks are used, which cannot be laid closely. The size of the gas combustion chamber should be at least 30–40% of the volume of the gasification chamber. The most advantageous is the structure of the boiler, in which two chambers are located one above the other, have the same shape, but differ in height.

Conclusions and useful video on the topic

This video clearly shows the principle of operation of the pyrolysis boiler:

A detailed overview of the operation of the upper combustion boiler can be found here:

Pyrolysis boilers are not cheap, but they fully justify the funds invested in their purchase.With proper installation and maintenance, such devices will provide the house with stable and inexpensive heat.

Are you looking for a pyrolysis boiler for heating your home? Or do you have experience with these units? Please leave comments on the article and share your impressions about the use of pyrolysis boilers. The feedback form is located in the bottom block.