- Principle of operation

- Upper combustion boilers

- What is pyrolysis

- Efficiency

- Device classification

- The best solid fuel boilers for long burning

- Zota Carbon

- Candle

- Stropuva S

- Classification

- According to the material of the heat exchanger

- By type of fuel

- By way of submission

- By loading direction

- According to the method of burning

- According to the method of regulation of air draft

- By the number of circuits

- The principle of operation of the pyrolysis boiler

- Instead of an afterword

- What to choose - what is the benefit of a classic boiler

- Popular Models

- Stropuva Mini S8

- Teplodar Kupper Expert-15

- ZOTA Poplar-16VK

- Teplodar Kupper Expert-22

- Stropuva S30

- Conclusions and useful video on the topic

Principle of operation

The boiler is working solid fuel, as a rule, on firewood, peat, lumber waste, special wood briquettes, coal and pellets (granules made from crushed wood, resin, needles, etc.). Especially popular are devices of a universal type, capable of consuming almost all types of solid fuels.

According to the method of heat transfer, boilers are:

- Air.

- Steam.

- Water (most common).

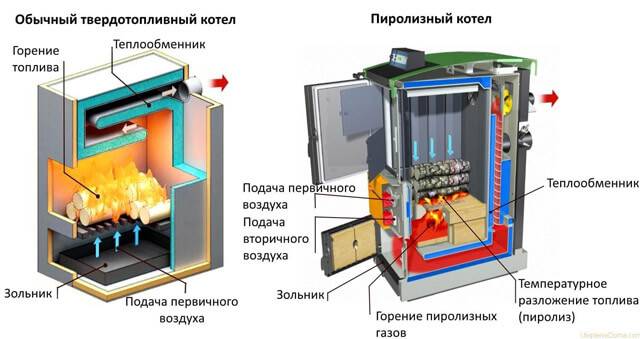

According to the principle of fuel combustion:

- Traditional. They work on wood and coal. The principle of operation is the same as that of a conventional wood-burning stove.

- Long burning.Innovative development in the field of heating equipment. Solid fuel boilers for long burning have the form of an elongated combustion chamber, surrounded on all sides by a water jacket. When burning, the flame does not spread from bottom to top, but from top to bottom, resembling in this respect the process of burning a candle. The principle of operation of the long-burning boiler allows to achieve complete combustion of the fuel. At the same time, the burning interval of one bookmark of fuel increases (up to 7 days). The long-burning boiler operates, as a rule, at a consistently high coolant temperature, which increases its efficiency by an order of magnitude. The uninterrupted and safe operation of such models is achieved by including emergency extinguishing fans, a safety valve and a circulation pump in the design.

- Pellet. Special pellets are used here as fuel. Such boilers are additionally equipped with an automatic pellet feeding system and a fuel storage bin. Thanks to electronic sensors, the presence of fuel inside the furnace is monitored. Such a system requires a stable electrical supply.

- Pyrolysis. Unique equipment, where, along with the energy from the combustion of solid fuel, the heat release of gases is also used. This makes it possible to convert a small amount of fuel into a significant portion of thermal energy. As a result, an increase in the efficiency of the boiler and a decrease in harmful emissions are achieved.

Upper combustion boilers

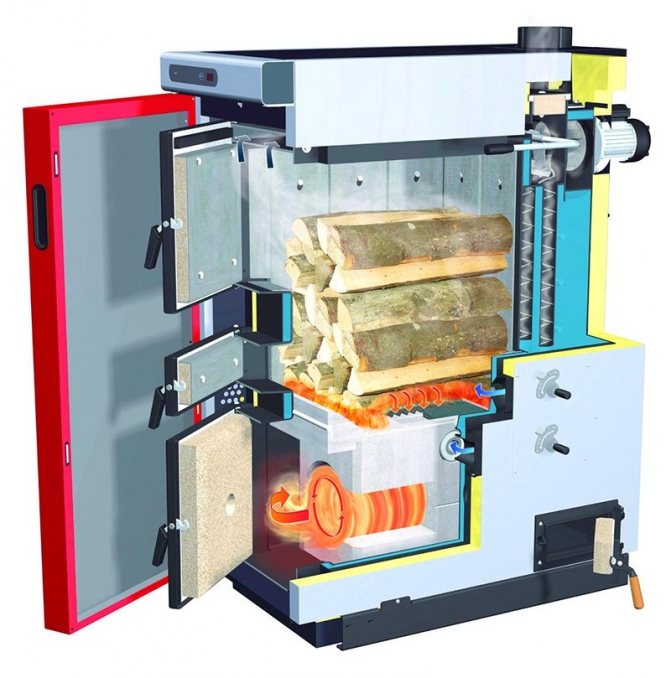

One of the options for a pyrolysis device is an upper combustion boiler. The principle of operation of these two units is very similar.

In the same way, a large amount of low-moisture solid fuel is loaded into the furnace, air is forced in and the fuel is smoldered with a reduced amount of oxygen. The valve that regulates the flow of oxygen is installed in the desired position.

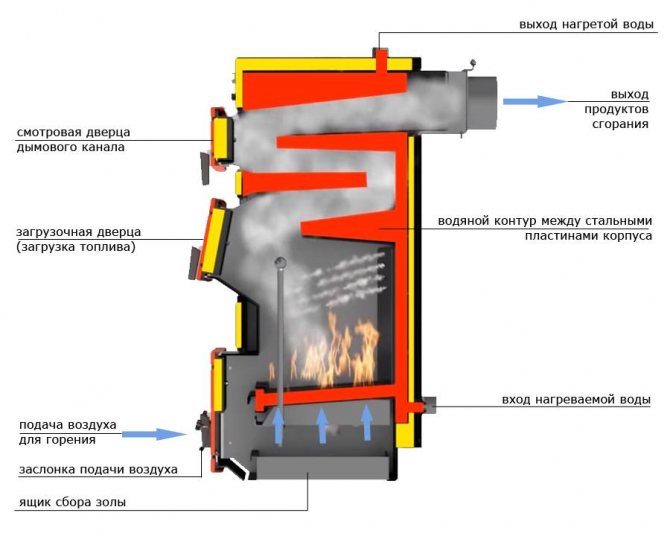

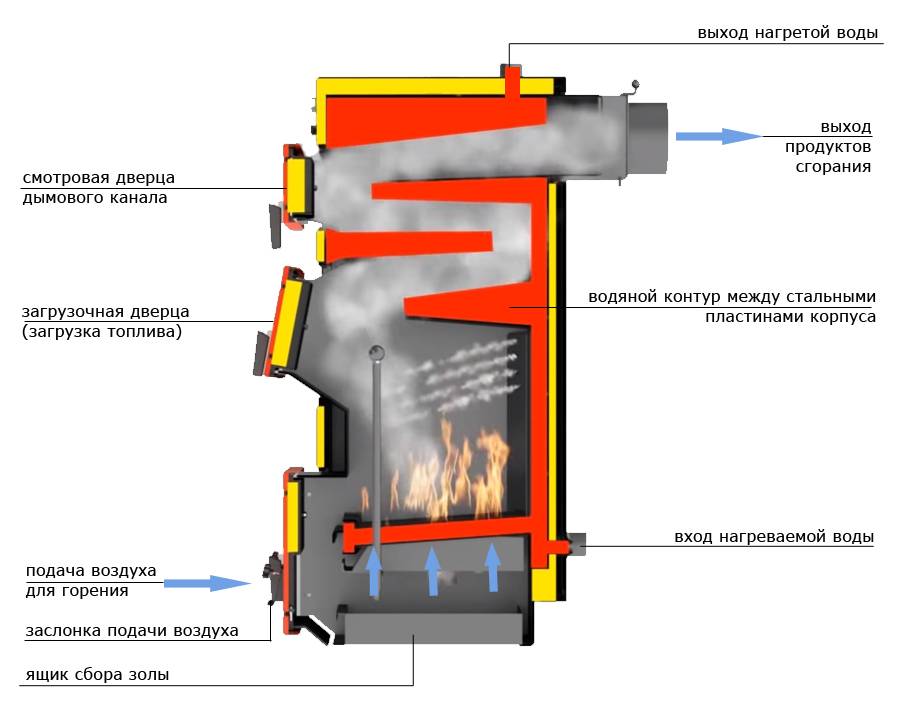

Scheme of the device of the upper combustion boiler. The furnace of such a boiler has a blank bottom, particles of combustion products are removed through the chimney (+)

Scheme of the device of the upper combustion boiler. The furnace of such a boiler has a blank bottom, particles of combustion products are removed through the chimney (+)

But long-burning boilers have neither an ash pan nor a grate. The bottom is a blank metal plate. Such boilers are designed so that the wood burns completely, and the small amount of ash remaining in the furnace is blown out with air.

Such devices are characterized by high efficiency and also operate at temperatures above 1000°C.

The main feature of such devices is that they really provide a long service life when fully loaded. The fuel chamber in such devices is usually made in the form of a cylinder.

Fuel is loaded into it from above, while from above, in the center, the air necessary for combustion is injected.

In top burning boilers, the air injection device is a movable element that falls down as the firewood burns out

Thus, a slow smoldering of the upper layer of fuel is carried out. The fuel gradually burns out, its level in the furnace decreases. At the same time, the position of the device for supplying air to the furnace also changes, this element in such models is movable and it practically lies on the top layer of firewood.

The second stage of combustion is carried out in the upper part of the furnace, which is separated from the lower compartment by a thick metal disk. Hot pyrolysis gases formed as a result of fuel combustion at the bottom expand and move upward.

Here they mix with air and burn, additionally transferring a substantial portion of thermal energy to the heat exchanger.

The beam holding the disk, which divides the combustion chamber into two parts, like this disk itself, is constantly under the influence of high temperature during the operation of the upper combustion boiler. Over time, these elements burn out, they will have to be replaced periodically.

A draft regulator is usually installed at the outlet of the second part of the fuel chamber. This is an automatic device that determines the temperature of the coolant and, depending on the data obtained, regulates the intensity of the movement of combustible gas. It protects the device from possible overheating.

It should be noted that the external heat exchanger in such boilers reacts to a change in the rate of circulation of the liquid in the heat exchanger, i.e. to temperature fluctuations. A layer of condensate immediately forms on the surface of the device, which causes corrosion, especially when it comes to steel boilers.

It is preferable to take a device made of cast iron, which resists such an effect much better.

Although the fuel in long-burning pyrolysis boilers should burn without residue, in practice this is not always the case. Sometimes the ash sinters, forming particles that are difficult to remove with a stream of air.

If a large amount of such residues accumulate in the furnace, a noticeable decrease in the heat output of the unit can be observed. Therefore, the upper combustion boiler should be periodically cleaned.

A feature of devices of this type is that, as the fuel burns, it can be loaded without waiting for the entire fuel load to burn out. This is convenient when you need to get rid of combustible household waste.

There are also varieties of top-burning boilers that operate not only on wood fuel, but also on coal. There are no complex automatic control units in pyrolysis boilers of this type, so serious breakdowns are extremely rare.

The design of the upper combustion boiler allows you to load the furnace only partially, if necessary. However, in this case, it may not be easy to ignite the top layer of fuel. The fuel itself must be dried, firewood from an open woodpile is not suitable for such a boiler.

Coarse fraction fuel should also not be used for this type of equipment, i.e. firewood will have to be chopped into small pieces.

What is pyrolysis

Firewood is perhaps the very first fuel in human history. Almost everyone knows how quickly they burn out in the open air, and that there is not much heat released. But the situation changes dramatically if other conditions for the combustion process are created.

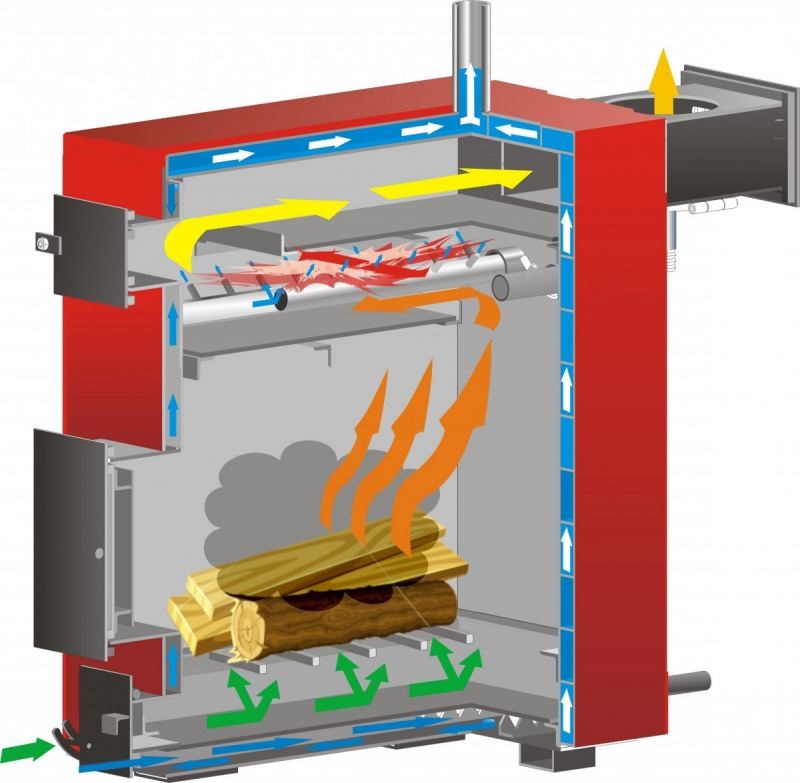

The so-called pyrolysis combustion takes place in closed chambers. Firewood or other solid fuels of a similar type are loaded there: pellets, sawdust, wood production waste, etc.

The fuel is ignited and then the amount of air entering the chamber is reduced.

As you know, during combustion, oxidative processes occur, one of the main participants in which is the oxygen contained in the air. If there is little oxygen, the reaction slows down and the firewood burns slowly, in fact, under such conditions, they simply smolder. In this case, a certain amount of thermal energy, ash and combustible gas are released.

The pyrolysis process does not end there.The gas obtained during the combustion of primary fuel mixes with air masses and also burns. As a result, heat energy is released significantly more than when using standard heat generators.

Therefore, pyrolysis boilers demonstrate a very decent efficiency compared to their purely solid fuel “brothers”, and also often provide an opportunity to significantly save on heating.

The advantage of heating equipment of this type is that the principle of its operation and device is relatively uncomplicated. The amount of air entering the combustion chambers is regulated by a conventional mechanical damper. A simple design ensures the reliability of the device; breakdowns for pyrolysis boilers are not a frequent occurrence.

This diagram clearly demonstrates all stages of the pyrolysis combustion process. The temperature inside the device can reach 1200°C (+)

This diagram clearly demonstrates all stages of the pyrolysis combustion process. The temperature inside the device can reach 1200°C (+)

Another “plus” of pyrolysis boilers is a long burning period. Full loading of the device with fuel allows not interfering with the process for several hours, sometimes more than a day, i.e. there is no need to constantly throw firewood into the firebox, as is the case with open burning.

Of course, this does not mean that the pyrolysis boiler can be left unattended. As with other heating technology, there are strict safety regulations.

It is worth remembering that the pyrolysis boiler is not omnivorous - the moisture content of the fuel should be low. Otherwise, part of the precious thermal energy will be spent not on heating the coolant, but on drying the fuel.

Pyrolysis combustion boilers, especially those made of cast iron, have significant physical weight, so they are always represented only by floor models

When implementing pyrolysis combustion, the fuel burns out almost completely, it will be necessary to clean the device much less frequently than when operating a traditional solid fuel boiler. Fine ash obtained after cleaning is used as a fertilizer. The combustion of fuel in such boilers is carried out in the direction from top to bottom.

Therefore, the possibilities for natural air circulation in the furnace are noticeably limited. The use of forced air blowing with a fan significantly improves the efficiency of the device, but at the same time makes the boiler volatile, since the fan requires electricity to operate.

Efficiency

How effective the pyrolysis boiler circuit will be, as well as its operating time, will depend on many factors:

- Fuel type and humidity.

- Thermal insulation of the building.

- Room temperature.

- Air temperature outside.

- Accuracy of design work in relation to the heating system.

Naturally, unlike conventional boilers, gas generating equipment is much more efficient. Since when burning wood it is impossible to obtain such high temperature indicators as in the process of burning wood gas obtained from it. The gas combustion process provides for the use of a smaller volume of air. In this regard, the burning time and temperature increase. It should also be noted that the control of the pyrolysis gas combustion process is much simpler.

Device classification

Boilers are divided into several types according to the type of fuel combustion:

- Pyrolysis - equipped with a pair of combustion chambers. In the first compartment, smoldering takes place and gas is formed, which is mixed with oxygen in the second compartment and burned.Such equipment emits a small amount of pollutants into the atmosphere and is considered environmentally friendly. Also, after the combustion of the fuel, there is little soot left. Automatic models are additionally equipped with a power regulator.

- With the top arrangement of a compartment of burning. Easy to maintain devices, with a minimum of automatic functions required for operation. They can operate autonomously, without access to the mains. But as a result of work, a large amount of ash accumulates, and not all types of fuel are suitable for them. For example, sawdust and small fraction chains cannot be used.

- Pellet - boilers, for the kindling of which special compressed briquettes are used. Such equipment is economical, durable, environmentally friendly and efficient in operation. Disadvantages of devices - high cost, exactingness to the conditions of fuel storage. Pellets are stored only in a dry room.

What solid fuel long-burning boiler is installed in your home?

Pyrolysis Pellet

The best solid fuel boilers for long burning

Zota Carbon

The lineup

This domestic series of solid fuel boilers for long burning is represented by models with a capacity of 15 to 60 kW. The equipment is designed for heating residential and industrial buildings. The boiler is single-circuit and has the following parameters of the coolant: maximum pressure 3 bar; temperature from 65 to 95 ° C. With optimal settings, the efficiency reaches 80%. The boiler is distinguished by its easy loading and the presence of movable grates for ash removal.

Watch product video

Design features

Boilers are completely non-volatile. Management is carried out mechanically. There is protection against overheating of the coolant.The built-in heat exchanger from qualitative steel is installed. The duration of the combustion process is controlled by changing the flow rate of air entering the combustion chamber.

A chimney with a diameter of 180 mm and pipelines of the circulation circuit 2” are connected to the device from the rear wall.

Fuel used. It is recommended to use hard coal fraction 10-50 mm as fuel.

Candle

The lineup

The line of Lithuanian heating equipment Candle includes five long-burning boilers with a capacity of 18 to 50 kW. They are designed for floor installation in residential or industrial premises. The units are designed for autonomous operation as part of a separate heating system. An additional circuit for heating hot water is not provided. The device is designed for a pressure of 1.8 bar and a coolant temperature of 90 ° C.

Watch product video

Design features

The design of the open-type furnace and the automatic adjustment of the air supply provide for a long burning mode. The water "jacket" is built into the boiler body. There is an automatic protection against overheating. Flue gas outlet 160 mm. The diameter of the fittings of the circulation circuit is 2”.

Fuel used. Firewood or peat briquettes can be used as fuel.

Stropuva S

The lineup

The line of Lithuanian-made single-circuit long-burning boilers includes models with a capacity of 8, 15, 20, 30 and 40 kW. The buyer can easily choose a suitable unit for heating a private house or a small business. The most productive of them is able to maintain the optimum temperature in a building up to 300 sq.m. Connection to the electrical network is not required.

During operation, the combustion zone smoothly shifts in the furnace from top to bottom. The efficiency reaches 91.6%. Maintenance consists of periodic replacement of fuel, removal of ash and periodic cleaning of the gas path, including the chimney.

Watch product video

Design features

The elongated shape of the housing saves usable space during installation. The volume fire chamber allows to load up to 80 kg of fuel. Precise regulation of the incoming air extends the burning time of one bookmark up to 31 hours. The coolant is heated up to 70o C and circulates with pressure up to 2 bar. On the back side, fittings are provided for connecting a chimney with a diameter of 200 mm and heating water 1 ¼”.

Fuel used. The boiler is designed to use dry firewood as the main source of energy.

Classification

Conventionally, boilers are divided according to their characteristic features.

According to the material of the heat exchanger

1. Cast iron - the structure is assembled from separate sections with threaded connections.

Power depends on the number of sections. Smoke usually exits directly without additional ducts with heat exchangers.

Advantages:

- durability and anti-corrosion properties;

- high thermal stability;

- increase in power by increasing the number of sections;

- maintainability.

Flaws:

- increased fragility;

- instability to sudden changes in temperature;

- the need for a foundation or a solid floor due to the weight of the boiler;

- reduced efficiency.

2. Steel - the structure is welded from sheet elements.

The heat exchanger is a "water jacket" that heats the coolant. Installing additional dampers on the gas outlet paths increases heat transfer and efficiency.

Advantages:

- a large assortment;

- serviceability;

- quick exit to work mode

- shock resistance;

- maintainability.

Flaws:

- susceptibility to corrosion;

- the formation of weakly acidic condensate, which limits the service life;

- the possibility of burnout due to low-quality thin steel;

- power is not adjustable.

By type of fuel

1. On firewood.

The main indicators are the density of wood, the amount of smoke emitted, as well as ash. Suitable Breeds:

- oak - the largest heat release during prolonged burning;

- alder - does not require drying, suitable for cleaning the chimney;

- birch - good heat dissipation with long burning, but short storage;

- aspen - suitable for pipe cleaning;

- ash - maximum calorific value:

- poplar or willow - when there is no longer any firewood;

- pine - gives heat, but quickly burns out, leaving a lot of soot.

2. On the corner.

Boilers use:

- coal;

- weakly caking coke;

- brown coal;

- anthracite.

3. On pellets.

Compressed granules up to 10 mm in diameter and up to 50 mm long. Manufacturers usually indicate suitable dimensions, as exceeding the values increases the load on the components of the boiler, reducing the service life. As raw materials for the manufacture are used:

- wood;

- straw;

- sunflower husk;

- reeds;

- peat;

- corn cobs and buckwheat husks;

- municipal solid waste;

- waste paper;

- coal.

4. On wood chips and sawdust.

An effective way to get rid of woodworking residues.

5. On mixed materials.

Possibility of incineration different types in one boiler.

By way of submission

1. Boilers with manual loading.

Products in which fuel is added as needed or as it burns.A good option for installation in a private house for maximum heat extraction.

2. Semi-automatic units.

Bookmarking is carried out manually, and the combustion process is controlled by automation.

3. Automatic products.

Modern equipment with automatic supply of granulated fuel in the form of pellets. It is characterized by compactness, high efficiency up to 86%, as well as low ash content.

In addition, they are equipped with automated ignition systems, maintaining the set temperature, as well as emergency protection.

By loading direction

- With horizontal (front) loading - for products with cast iron heat exchangers. In the process of work, it is convenient to lay logs of firewood.

- With vertical (top) loading - for models with steel heat exchangers and characteristic combustion at the lower level with simultaneous drying in the upper part. Efficient work requires careful stacking of logs.

According to the method of burning

1. Traditional - differ in the absence of any electronics or elements that depend on the power supply. The entire fuel line is used. The dimensions of the furnace and the principle of combustion determine the frequency of loading the boiler and the regularity of cleaning. The product is a good option for equipping a wooden house or cottage.

2. Pyrolysis - differ in the use of the principle of separate combustion of materials and gases generated during combustion. Heat is released in large quantities when mixed with incoming oxygen. Waste in the form of ash and soot is practically not formed, and the efficiency of the device is very high. It is imperative to comply with increased requirements for the moisture content of firewood, which should not exceed 15 percent.

3.Long burning - simple devices with loyal requirements for humidity and the possibility of maintenance once or twice a day. There are:

- single-circuit;

- double-circuit;

- combined.

According to the method of regulation of air draft

- Non-volatile - mechanical adjustment of the air flow.

- Volatile - the use of a blower controlled by an electronic unit.

By the number of circuits

- Single-circuit - only for the heating system.

- Double-circuit - provide space heating and hot water supply.

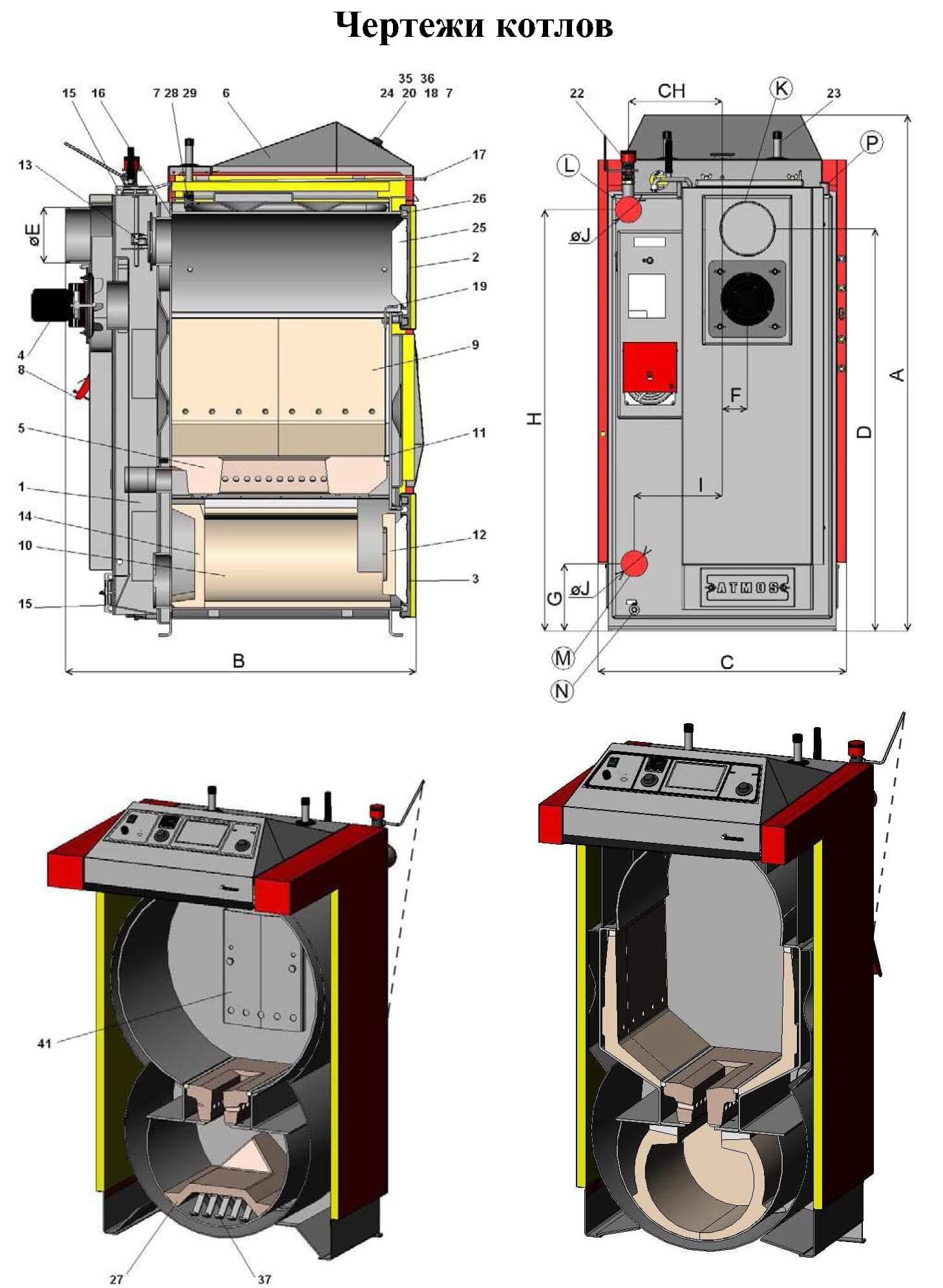

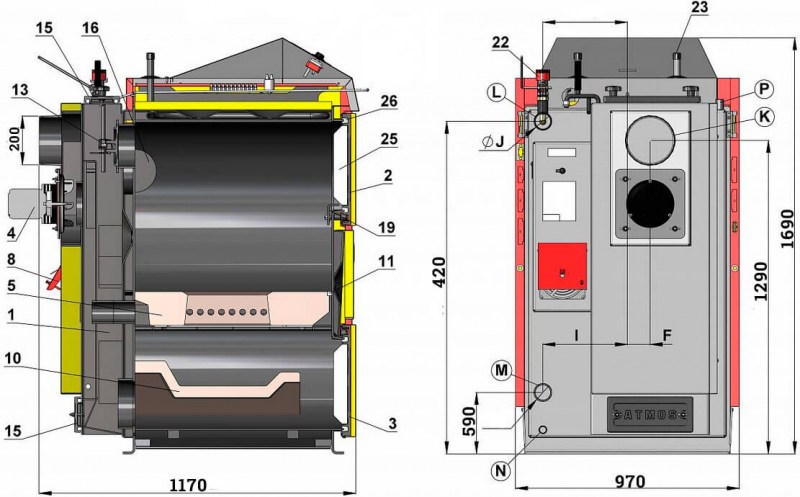

The principle of operation of the pyrolysis boiler

Pyrolysis is a process with a powerful exotherm, in which complex organic matter (in our case, coal, wood, peat, biofuel in the form of pellets, etc.) decomposes into a simpler composition - solid, liquid and gaseous phases. For the decomposition process, it is necessary to provide a temperature and limit the supply of oxygen, which is carried out in a gas-generating boiler. To load into the furnace section of the boiler, you need fuel that has characteristics that meet the manufacturer's recommendations, otherwise there will be no expected effect. Combustion occurs at high temperatures, but simultaneously with oxygen deficiency. Wood or coal fuel under such conditions does not burn with a flame, but rather sinters with pyrolysis decomposition, with a release of energy much greater than during conventional combustion in air. The main products are solid and volatile fractions (coke oven gas).

The unit has two chambers, the upper chamber is used to implement the exothermic reaction of fuel pyrolysis at a temperature of 300⁰С to 800⁰С. The chambers are structurally independent and are separated by grates and regulators - gate valves.The upper gasification chamber, into which the fuel is loaded, is sealed and oxygen is in short supply in it. There is solid fuel on the grate, it creates an obstacle to heat removal, down into the second chamber, only air passes, and its flow is weak. The result is a slow smoldering and decomposition process, or pyrolysis. And the result of pyrolysis is charcoal and pyrolysis, or coke oven gases, CO and, in a small part, carbon dioxide.

The mixture of pyrolysis gas and air is also sent to the lower section of the combustion chamber, where the temperatures are much higher - up to 1200⁰С, and during combustion it releases heat that is incomparable in quantity with heat transfer from the combustion of solid fuel in air. The lower compartment of the second combustion chamber is nothing more than a nozzle type device made of heat-resistant ceramics or fireclay bricks. Aerodynamics in such a firebox gives high resistance, so the draft is forced by turning on the smoke exhauster. The heat from the combustion of gas is used for efficient heating of housing. In fact, pyrolysis boilers do not work on wood or coal, but on the gas emitted. Gas combustion processes are easier to control, so the automation of gas generating units is more perfect.

The solid phase burns very slowly, with a constant release of thermal energy. Volatile coke oven gas also burns, and the heat transfer from this process is somewhat greater than during the combustion of the solid fraction. The efficiency from the use of firewood and coal increases significantly.

The gas generating unit, for all the simplicity of its design, can be compared with a home laboratory complex that extracts gas from firewood, peat briquettes, coal, and other fuels for subsequent combustion with much greater heat transfer.

The scheme of the pyrolysis unit is considered simple, which attracts home craftsmen. For the construction of the boiler, special equipment is not required, the main conditions are the body with the necessary parameters, ensuring tightness in the combustion chamber and a strict dosage of incoming air.

With the advent of pyrolysis boilers, classic wood-burning boilers began to be considered obsolete, despite their prices - half the price of pyrolysis boilers with a similar power. One load of firewood into the pyrolysis unit gives the combustion time and heat supply many times greater than for a conventional solid fuel boiler. New units pay off in a short time. Double-circuit boilers provide even greater savings, since hot water, unlike heating, is required for housing not seasonally, but all year round. Also called such a plus as the ability to use wet material for the firebox (up to 40-50% moisture). But dried firewood is more efficient and economical. Wood-burning pyrolysis boilers have gained recognition, among other things, because in many regions and settlements, dry wood material is inexpensive, and often free. Drying damp wood during the summer season is also not a problem, and the consumption for a pyrolysis boiler is very economical.

Instead of an afterword

Whatever the solid fuel boiler, the cost of firewood or coal in Russia will always be higher than with gas heating. But if the private sector is not gasified, then long-burning solid fuel boilers are more profitable to install than conventional ones. And the difference this year from year will be felt more and more.

We hope that the information presented in today's article will be useful to our reader.If you still have questions after reading, our team will be happy to answer them in the discussion below. We ask you to share your experience of such an acquisition, manufacture or installation. This information may help other readers.

And finally, another interesting video on today's topic:

What to choose - what is the benefit of a classic boiler

A conventional natural draft boiler is distinguished by the fact that it can immediately work with maximum oxygen supply without breakdowns, always, with any firewood. Such reliability cannot but attract. At the same time, the ash remains where it is supposed to be - in the ash pan, and does not pour on people's heads - ash content is a physical characteristic of wood that cannot completely burn out.

But it can also perform the functions of a pyrolysis - a chain from a tuned thermostat controls the air damper in modern models, the boiler switches to smoldering, with secondary air supplied. At the same time, the price among heating equipment is the most democratic.

To reduce the number of approaches to a classic boiler for its maintenance to 1 - 2 per day, there are several methods to increase the accumulation of generated heat. The most effective is the introduction of a heat accumulator, or the construction of heat-intensive massive structures. At the same time, the unit itself is desirable to use a slightly more powerful one, with a greater return on accumulation for one furnace.

Popular Models

The most famous suppliers of solid fuel units are the brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and OOO TK TeploGarant.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

Power independent unit serving up to 80 sq. m. Works with three types of fuel, stands out in small sizes. It is supplied with a convenient vertical door of a fire chamber.

The special design of the ash pan reduces the need to clean it up to twice a month. One bookmark is enough for daily heating, pellets burn out in 48 hours.

Advantages:

- high efficiency;

- construction quality;

- safety;

- the presence of a thermometer.

Flaws:

- big weight;

- The rough coating of the door makes it difficult to clean.

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. Consumes little fuel, heats the house well, does not form soot. The only downside is that it's heavy." | “A small convenient barrel, the device is immediately ready for use, there is no need to assemble and screw anything. The door handles are of high quality and reliable, they do not open spontaneously. It is heated for a long time, it can burn up to 20 hours. |

Teplodar Kupper Expert-15

Russian model with the possibility of installing a burner. An air outlet is located in the upper half of the housing. Compatible with firewood, coal and briquettes. Three air inlet zones and top combustion ensure long heat retention.

Russian model with the possibility of installing a burner. An air outlet is located in the upper half of the housing. Compatible with firewood, coal and briquettes. Three air inlet zones and top combustion ensure long heat retention.

At the bottom there is a reservoir with water, which prevents excessive heating of the floor. A steel plate protects the door from heat. You can optionally attach a draft regulator.

Advantages:

- the possibility of mounting a pellet or gas burner;

- convenient door, placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

| Oleg Yegorin: | Semyon Ivin: |

| “A convenient boiler, you can buy an additional burner, it works for a long time and even after turning off the house remains warm.” | “A good unit, enough for almost a day of heating, but consumes a lot of fuel. Convenient door design for bookmarking. |

ZOTA Poplar-16VK

The device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the life of the device. Firewood, coal and pellets can be used to fuel the boiler.

The model differs in a capacious fire chamber and a possibility of the top and side bookmarks of fuel.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

low efficiency.

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, it can be cleaned without problems, it is possible to load different types of fuel, both briquette and conventional.” |

Teplodar Kupper Expert-22

The device is small in size, capable of operating in 4 modes: fast warm-up, classic, medium and maximum. Burning from top to bottom ensures uniform and longer burning of the material and good heat transfer.

The device is small in size, capable of operating in 4 modes: fast warm-up, classic, medium and maximum. Burning from top to bottom ensures uniform and longer burning of the material and good heat transfer.

The upper cleaning hatch is protected by a steel screen to prevent burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

| Evgeny Zherdev: | Ivan Alaev: |

| “Thoughtful regulation of heating, you can adjust the duration of burning from 30 minutes to a day. Easy to clean, there are special cleaning accessories included.» | “A high-quality model, the design allows you to connect heating pipes from any side. A heating element and a thermomanometer are supplied with the device. |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It features high efficiency, is independent of power supply and is compatible with a variety of fuel material.

The device has compact dimensions, environmentally friendly. The duration of burning firewood is up to 30 hours, briquettes can smolder up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

high price.

Conclusions and useful video on the topic

Tips for choosing boilers for your home:

Boilers that support combustion for a long time are an excellent alternative to units that operate on rising fuel prices.

Yes, they can not boast of compactness, as well as ease of use. But the equipment of this class is highly efficient, which allows you to save your time and a significant amount of money. But only under the condition of competent design of the heating system.

Share your opinion about the operation of boilers and useful information not mentioned in the article. It is possible that you have valuable information at your disposal that will be useful to site visitors. Please leave comments, ask questions, post photos in the block below.