- Self Assembly Options

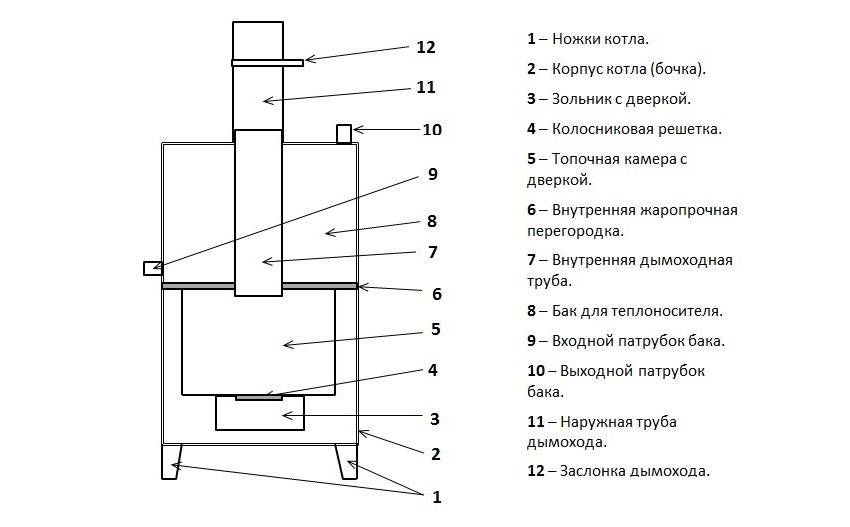

- from brick

- From a gas bottle

- The principle of operation of pyrolysis boilers and their features

- Features of a long burning stove

- Foundation construction

- The device of pyrolysis furnaces

- Advantages and disadvantages

- Base Assembly Order

- Advantages and disadvantages of the pyrolysis oven

- Existing principles of laying a pyrolysis oven

- Manufacturing instructions

- Pros and cons of gas generators

- Fuel for pyrolysis oven

- The essence of the pyrolysis process

- The principle of operation of the pyrolysis boiler

- How to make a metal pyrolysis oven with your own hands

- What you need to make

- Necessary calculations

- Preparatory actions on the spot

- Manufacturing process

- Features of operation and rules of the PPB

- Do-it-yourself pyrolysis oven: manufacturing process

Self Assembly Options

The pyrolysis oven is quite expensive, so many owners are thinking about how to do it themselves.

Home structures can be made from a variety of materials such as gas bottles, cylinders, barrels, bricks, and more.

Depending on the material of production, all furnaces are conditionally divided:

Of course, recently such designs have undergone some changes that have significantly increased their efficiency. As for metal furnaces, they are especially popular.The fact is that they can even be made from an old gas cylinder.

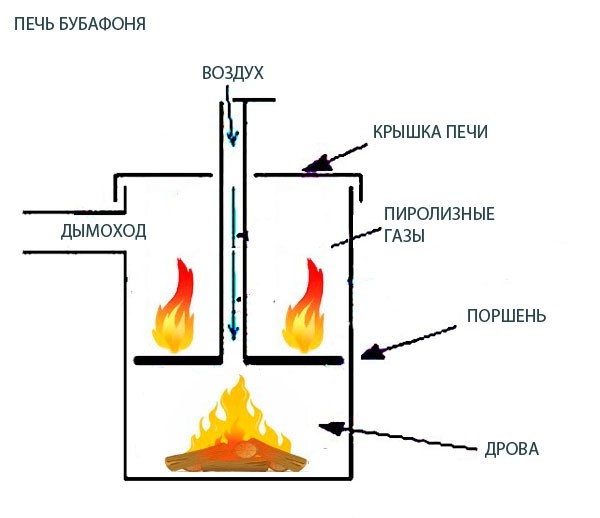

B Depending on the principle of operation, the fuel and material used, all furnaces are divided into these types of furnaces: a furnace operating on treated oil; Kuznetsov's oven; Girl from Lachin; boolean oven; Bubafon.

The principle of operation of all these structures is the same - the afterburning of the gas ejected from the fuel. However, when choosing an industrial design, it is necessary to take into account some specific features of each type.

For example, waste oil stoves are undesirable for use in bathrooms and other residential areas. They are ideal for heating garages and other non-residential premises.

Of course, it should be borne in mind that small furnaces running on waste oil have high productivity. You only need one cup of oil to work.

from brick

We have to build a furnace:

Ceramic and fireclay bricks; Steel sheets; Cast iron grates; 300 W fan; fire chamber door and exploding door; welding machine; an exercise; Bulgarians and others.

With these materials and tools, you can build your own oven. Of course, do not forget some of the nuances on which the strength and efficiency of the heating structure will depend.

If you have chosen a brick oven, then the construction process is as follows:

All work is carried out in accordance with a predetermined plan, which is better agreed with a specialist.

If necessary, the design can be decorated. For this, facing stones, stones and other materials that can withstand high temperatures are often used.

From a gas bottle

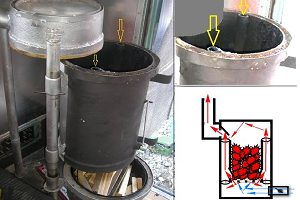

A feature of the Boubafon oven is that it can be used to cook various types of fuel.

Tools are needed in order to make such a design with your own hands:

hammer; Bulgarian; Welding machine and electrodes; Pliers.

The manufacturing process of the Bubafonya furnace is carried out in this order:

Cut off the top bulge of the tank.

Caution: Cut off the top of the cylinder below or above the weld, as the weld is reinforced from the inside with a metal plate, which can make cutting difficult. A channel opens in the center. There is a hole for the chimney in the upper part of the tank body

Make a gas-dispersing device with a tube through which oxygen is supplied to the second chamber. Weld the chimney

In the upper part of the tank body there is a hole for the chimney. Make a gas-dispersing device with a tube through which oxygen is supplied to the second chamber. Weld the chimney

A channel opens in the center. In the upper part of the tank body there is a hole for the chimney. Make a gas-dispersing device with a tube through which oxygen is supplied to the second chamber. Weld the chimney.

As you can see, it is easy to build a stove with your own hands from a gas cylinder.

But you should pay special attention to trimming the tank. Before working with a Bulgarian woman, make sure that there are no gas residues in the tank, the tank is completely filled with water

The principle of operation of pyrolysis boilers and their features

By creating pyrolysis boilers with their own hands, people tend to save money in their wallet.If gas equipment is quite cheap, then solid fuel units are simply amazing at their price. A more or less decent model with a capacity of 10 kW will cost 50-60 thousand rubles - it is cheaper to conduct gas if a gas pipeline passes nearby. But if it is not there, then there are two ways out - to purchase factory equipment or make it yourself.

It is possible, but difficult, to make a long-burning pyrolysis boiler with your own hands. Let's first understand why pyrolysis is needed at all. In conventional boilers and stoves, wood is burned in the traditional way - at high temperature, with the release of combustion products into the atmosphere. The temperature in the combustion chamber is about + 800-1100 degrees, and in the chimney - up to + 150-200 degrees. Thus, a substantial part of the heat simply flies out.

Direct combustion of wood is used in many heating units:

Solid fuel pyrolysis boilers can use several types of fuel, including waste from woodworking and agricultural processing.

- solid fuel boilers;

- Fireplace stoves;

- Fireplaces with water circuits.

The main advantage of this technique is that it is simple - it is enough to create a combustion chamber and organize the removal of combustion products outside the equipment. The only regulator here is the blower door - by adjusting the clearance, we can adjust the intensity of combustion, thereby affecting the temperature.

In a pyrolysis boiler, assembled with your own hands or bought in a store, the process of fuel combustion is somewhat different. Firewood is burned here at a low temperature. We can say that this is not even burning, but a slow smoldering.Wood at the same time turns into a kind of coke, while releasing combustible pyrolysis gases. These gases are sent to the afterburner, where they burn with the release of a large amount of heat.

If it seems to you that this reaction will not give a special effect, then you are deeply mistaken - if you look into the afterburner, you will see a roaring flame of bright yellow, almost white color. The combustion temperature is slightly above +1000 degrees, and more heat is released in this process than with standard wood combustion.

In order for a self-assembled pyrolysis boiler to be able to show maximum efficiency, firewood with a low moisture content is needed. Wet wood will not allow the equipment to reach its full capacity.

The pyrolysis reaction is familiar to us from the school physics course. In a textbook (and maybe in a laboratory room), many of us saw an interesting reaction - the wood was placed in a sealed glass flask with a tube, after which the flask was heated over a burner. After a few minutes, the wood began to darken, and pyrolysis products began to come out of the tube - these are combustible gases that could be set on fire and watch the yellow-orange flame.

Do-it-yourself pyrolysis boiler works in a similar way:

On one load of fuel, pyrolysis boilers operate for about 4-6 hours. So a large and steadily replenished supply of firewood should be taken care of in advance.

- Firewood is kindled in the firebox until a steady flame appears;

- After that, the access of oxygen is blocked, the flame goes out almost completely;

- The blower fan starts - a high-temperature flame appears in the afterburner.

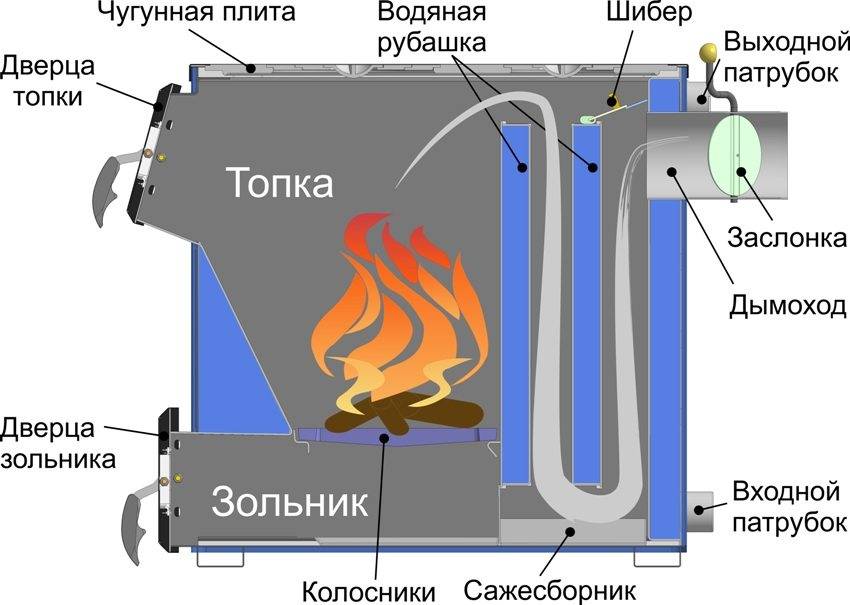

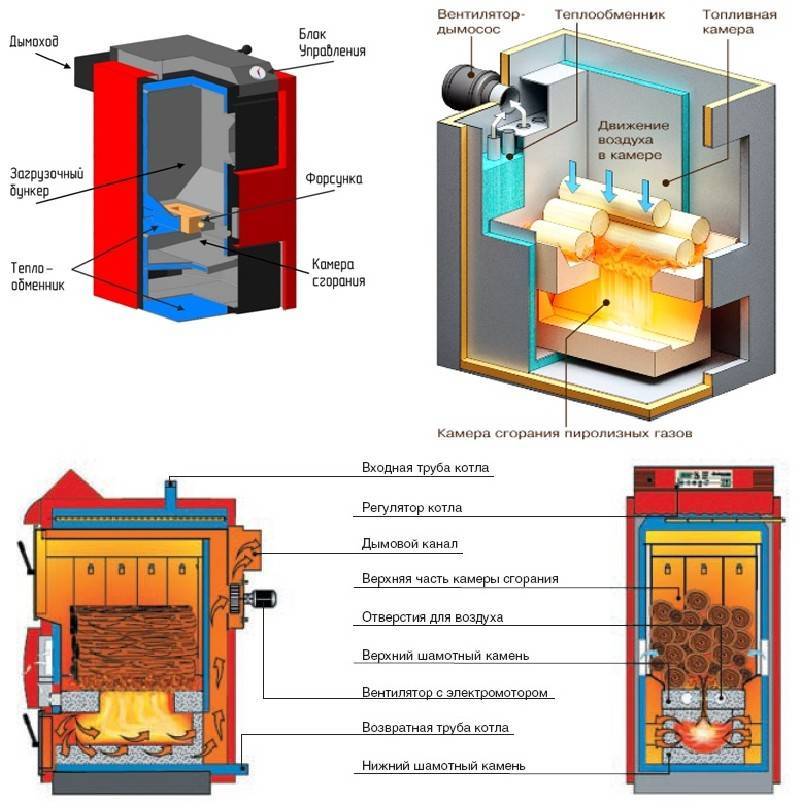

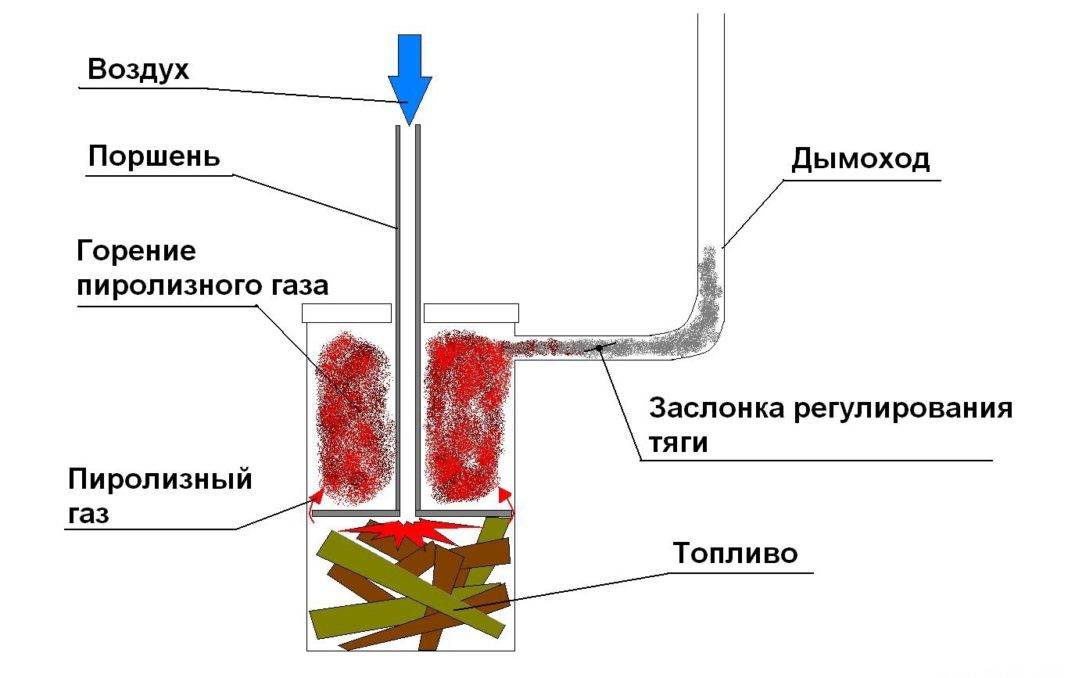

The device of the pyrolysis boiler is quite simple.The main elements here are: a combustion chamber in which firewood is stored, and an afterburner chamber in which pyrolysis products are burned. Heat is transferred to the heating system through a heat exchanger

In the scheme of the pyrolysis boiler, special attention is paid to it

The thing is that heat exchangers in do-it-yourself pyrolysis boilers are arranged differently than in gas equipment. Combustion products with air pass here through many metal pipes washed by water. To increase efficiency, boiler water washes not only the heat exchanger itself, but also all other nodes - a kind of water jacket is created here, which takes away excess heat from the hot elements of the boiler unit.

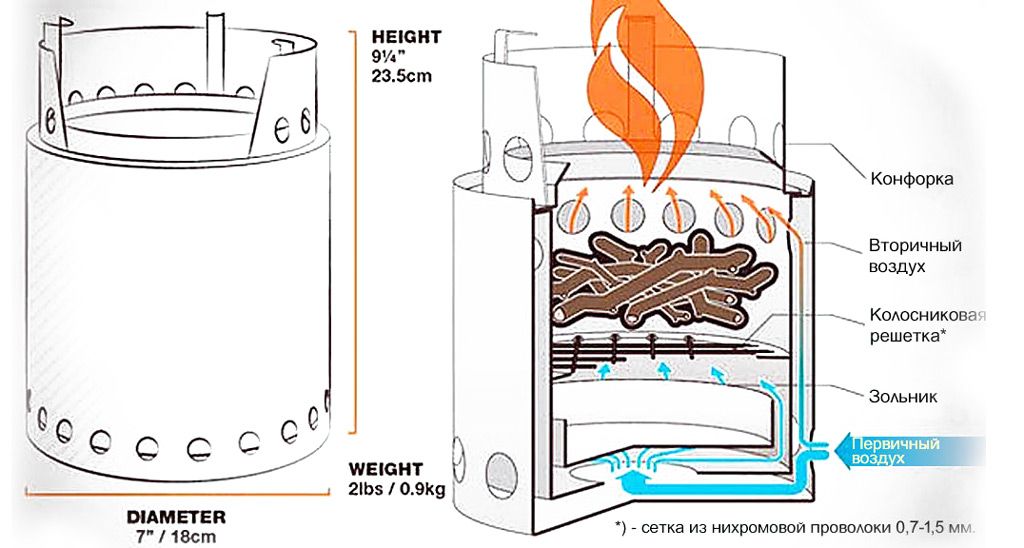

Features of a long burning stove

The first step is to understand what happens during the burning of firewood. For the appearance of a flame, the temperature of the wood must be brought to approximately +150 degrees, using an external heating source for this. Usually, a piece of paper lit from an ordinary match is enough for this. After that, the process of slow carbonization of the material begins, which, after reaching the mark of +250 degrees, turns into decay into simple chemical elements. The composition of the white smoke that appears when the flame is ignited includes gas and water vapor: they exude heated wood. The ignition of the released gaseous components is observed when heating reaches +300 degrees: as a result, the thermochemical reaction is significantly accelerated.

The breakdown of organic matter into simpler elements is called pyrolysis.Practice shows that during the combustion of wood, part of the energy potential embedded in it remains unused. This is expressed in a significant amount of waste remaining after the extinction of the flame. In pyrolysis furnaces, fuel is used much more efficiently, which is achieved by separate combustion of the gases released during the combustion of the fuel. At the same time, the rate of smoldering of the wood itself is very small, which contributes to an increase in the duration of the furnace on one tab. The Bubafonya stove, which is a type of pyrolysis heater, guarantees almost complete combustion of all fuel.

Foundation construction

The foundation for the Bubafonya stove is laid in this way:

- The first step is to dig a square hole. Its approximate dimensions are 150x150 cm, with a depth of 20-30 cm.

- The bottom of the trench is covered with a crushed stone pillow and poured with a concrete solution. To level its surface, a trowel is useful. When the flooded area seizes, it is necessary to check the horizontalness of its surface using the building level. If necessary, additional adjustments are made.

- On top of a completely dried concrete stand, refractory bricks are laid in several rows. Usually 2-3 layers are enough.

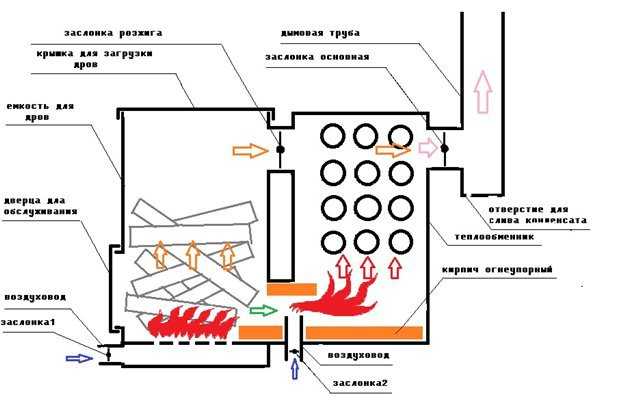

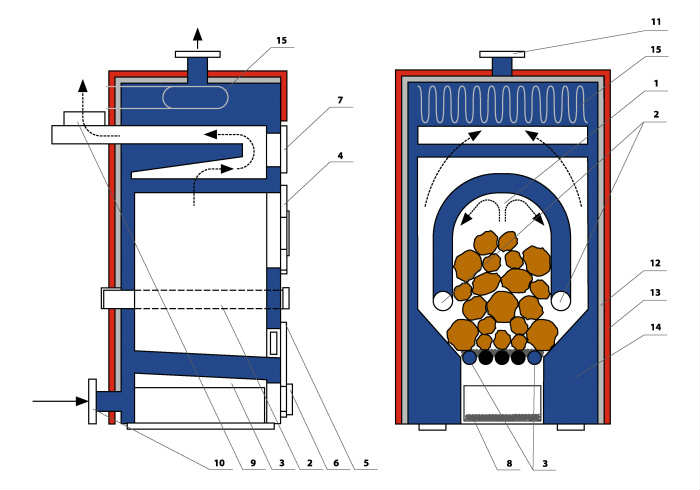

The device of pyrolysis furnaces

The design provides for two compartments: in the first, solid fuel is laid and the process of its slow oxidation takes place. When firewood smolders, a large amount of combustible gases are released, which enter the compartment above and burn out. So that the fuel does not flare up, but smolders, the supply of oxygen is strictly regulated. By and large, pyrolysis devices operate on gas, which is produced in the unit itself.

Scheme of the pyrolysis furnace

Scheme of the pyrolysis furnace

The operation of a long-term combustion plant provides the maximum amount of thermal energy with significant savings in fuel resources. This is due to the fact that the fuel is processed almost completely, as a result, soot and ash are almost not formed, and there is also no smoke.

Advantages and disadvantages

The pyrolysis type device has an extensive list of advantageous characteristics. Let's focus on the key ones:

- high efficiency is achieved due to the complete burnout of the fuel. One loading cycle allows for much longer heat transfer, in comparison with analogues.

- Rapid warm-up of the device. This ensures efficient heating of the room in a short time.

- The level of efficiency reaches 85%.

- The use of environmentally friendly materials in production, as well as to ensure operation that does not emit substances harmful to human health and the environment when heated. The oven is virtually smokeless.

- The power range is adjustable depending on the needs of the user - 5-100%.

- The viewing device can be paired with a heating circuit.

- The pyrolysis device does not require constant monitoring. Loading bio-fuel is carried out once a day, and the cleaning process is performed once a week, without the need to turn off the machine.

- The device is universal, which allows the use of different types of fuel - liquid or solid composition. Samples operating on used oil are also presented.

Photo 3 Staged processes of heat generation.

Despite the predominance of positive aspects, such designs also have a number of disadvantages:

to ensure a sufficient level of heating, large ovens are required;

Photo 4 An optional device of a design operating on the principle of pyrolysis.

- it is required to equip the site for the placement of fuel materials;

- any combustion process is accompanied by the release of impurities and odors. Despite the fact that the peculiarity of this stove is that there is practically no smoke, it is still necessary to organize a ventilation system in the room where the device is located.

- The escaping gases have a sufficiently low temperature, so condensate accumulates at the outlet. Its presence is noted in the chimney and in the outlet channel. In some factory models, a drive is provided for its collection, which requires periodic cleaning.

Advice! When reproducing the furnace device on its own, it is necessary to choose a chimney with a large diameter. According to the same principle, the exit system is organized, necessarily insulated in the area facing the street. Thus, it is possible to eliminate the problem of freezing, with a decrease in external temperature indicators.

To ensure the most efficient operation, it is required to mount a blower in the device, and a pump is built in for the heating system. All these devices led to the dependence of the entire furnace on the power supply.

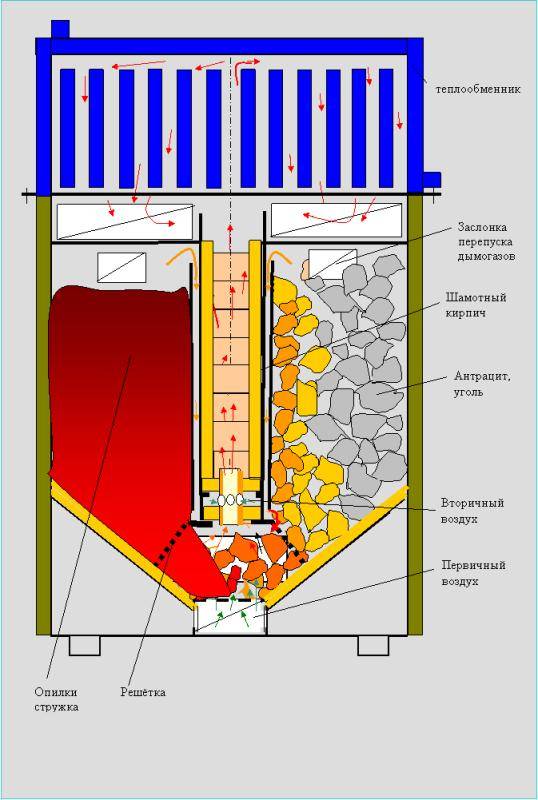

Base Assembly Order

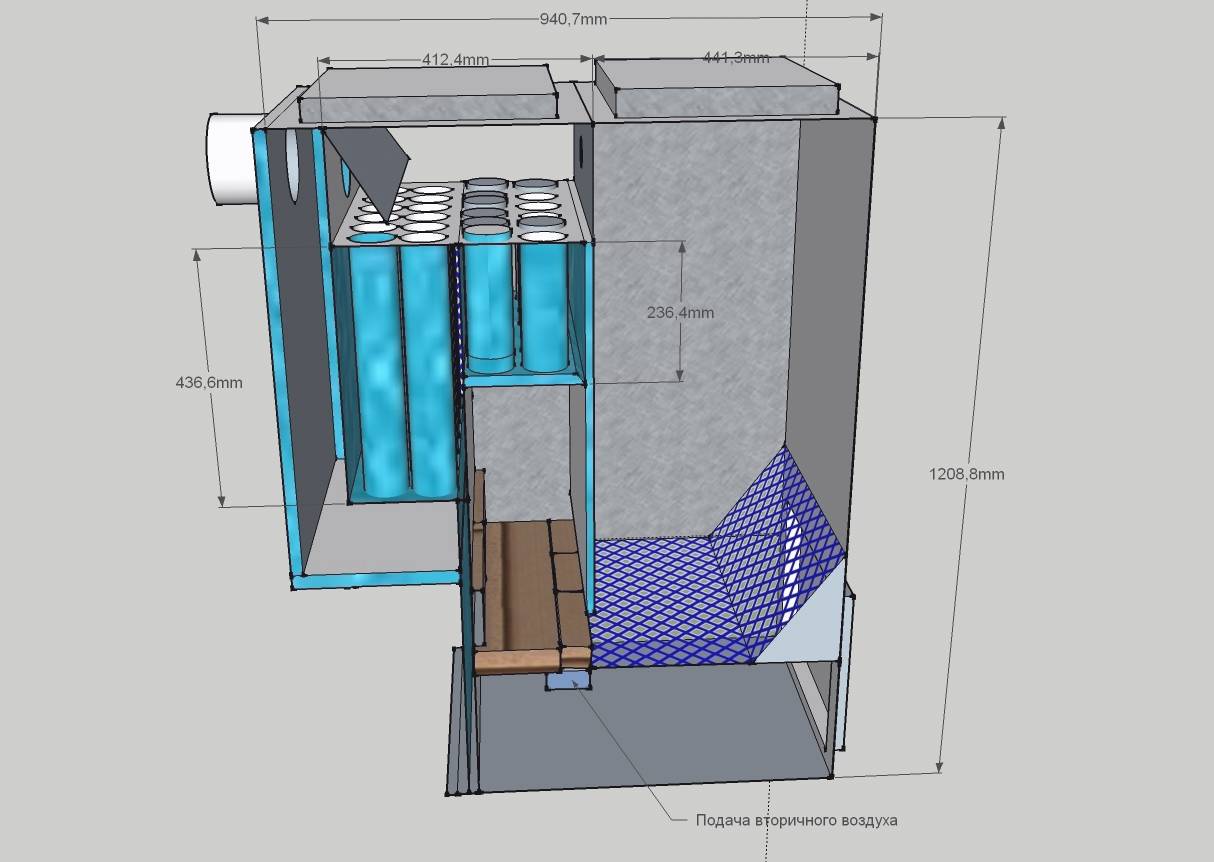

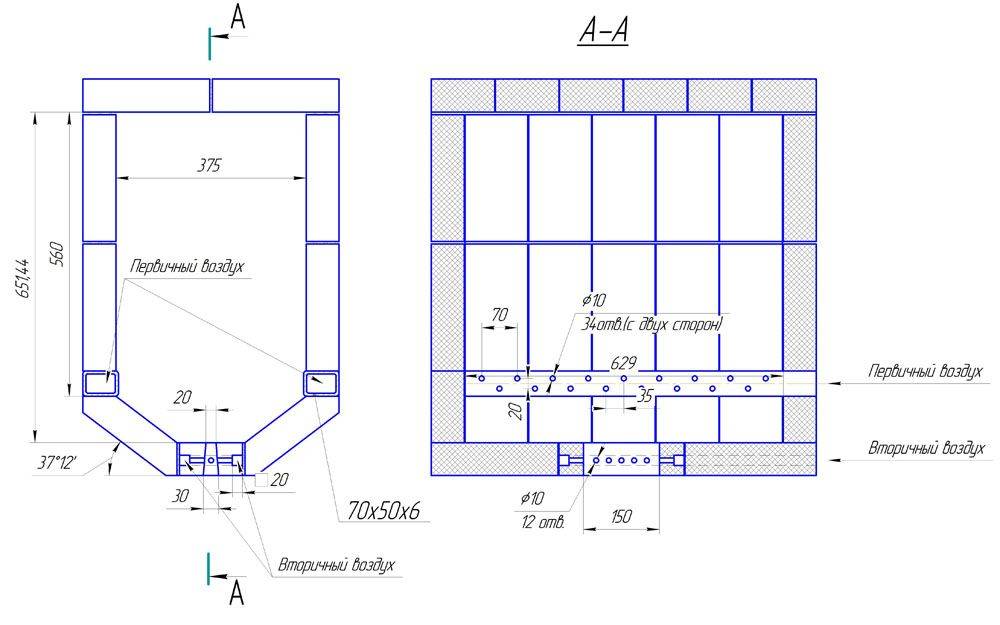

- Since we are trying to consider a design that has the right to be called a pyrolysis furnace, at the first stage, care should be taken to manufacture internal channels, supply primary and secondary air and burner piping. The burner lining is made of fireclay bricks. Actually, heat-resistant nozzles of the nozzle themselves are made from it.

- Further, from sheet metal, you need to cut and weld, the primary gasification chamber - it is also a bunker, and the secondary gas afterburner.It must be well protected from high temperature flames and have an outlet to convection channels.

- In practice, a material with a thickness of 4 mm is used. But it is desirable to use large thicknesses, in order to avoid warping and premature failure due to corrosion.

- Ready - the upper and lower combustion sections are combined by tying nozzles and air heat exchangers are connected according to the Buleryan principle.

- After that, you can proceed to the intermediate stage, welding of fasteners that prevent hydraulic deformations of the outer casing. These are metal pins that will strengthen the internal and external elements of the boiler.

- The shell elements are welded with simultaneous joining of all air channel openings.

- Also, it is necessary to provide holes for levers, chimney dampers and secondary chamber dampers in advance.

- After welding the outer elements of the duct, doors, an external air supply pipe are installed, to which an injection pump and a hatch for cleaning convection chimneys will be attached.

Advantages and disadvantages of the pyrolysis oven

The mini-gas generator, which is found in all devices of this type, has a very advantageous position due to its principle of operation. Its efficiency exceeds 80%. Due to this factor, the operation of the stove is very economical: you can rationally use fuel, adjust the process and the degree of combustion yourself.

The mini-gas generator, which is found in all devices of this type, has a very advantageous position due to its principle of operation. Its efficiency exceeds 80%. Due to this factor, the operation of the stove is very economical: you can rationally use fuel, adjust the process and the degree of combustion yourself.

Such a stove will work on any fuel. For fuel, various waste products from the woodworking industry can be used. It can be firewood, chips, sawdust, small branches and so on.It is acceptable to operate the unit on small household waste, in the form of plastic or small rubber products.

Pyrolysis gas is environmentally friendly and does not harm nature.

The “clean” operation of the stove from a gas cylinder is very important. During the operation of the device, no such dirty substances as, for example, soot or ash appear, due to the principle of operation of the gas generator. This factor greatly facilitates the use of the design: you will not need to spend a lot of time cleaning the stove, eliminating dirt from its surfaces.

Flaws:

- High price. Most often, this stops buyers. The cheapest model for a bath will cost at least 10,000 rubles. If you want a more modern and improved sample, you will have to pay about 17,000 rubles. But high prices fully pay off with good quality and versatility.

- The need for constant power supply. This is necessary to keep the oven running. There are models of stoves that do not need a constant supply of electricity, but they are not popular.

Existing principles of laying a pyrolysis oven

The principles in this case will be the same as when laying any stove. Laying should be carried out evenly, in rows. In the process of laying out each of the rows, it is necessary to check the evenness of the placement of bricks with a building level. Walls and guides should not move apart on the sides.

The masonry mixture must be prepared in advance. In this case, you will need to choose the right proportions of sand and clay, make the mixture elastic and easy to use.

Particular attention should be paid to laying out openings for doors.It is necessary to expose the frame and immediately lay a special basalt-based cardboard between it and the masonry

The metal will expand and contract in case of temperature changes, basalt board is used to level this moment.

The distance between the bricks and the walls of the boiler must be at least 6-7 cm.

At the bottom of the structure, you will need to make several small holes. In the first or second row of masonry, small gaps should be left, approximately in the seam, so that air can be ventilated. Air exchange allows you to quickly warm up the room, since in this case the principle of natural convection will work.

At the base of the foundation, it will be possible to lay out another row with them, after which it is necessary to raise the base of the boiler. This material has a good level of strength, therefore it is recommended to use it.

Thus, a significant amount of money can be saved.

At the next stage, the chimney pipe is installed, after which it is lined with bricks. In this case, you will need to constantly overwrite the inside of the masonry. In this way, problems associated with the appearance of gaps in the seams can be avoided. Every few rows of masonry with a damp cloth, you need to wipe the wall from the inside to wipe all the seams.

It is quite difficult to make a pyrolysis stove with your own hands, therefore, you cannot do without the help of a professional stove-maker.

Manufacturing instructions

Ordering a pyrolysis oven made of bricks

We will use the scheme, perform the markup before proceeding with the construction of a pyrolysis furnace with our own hands.

We make the foundation. We put waterproofing on a solid base. Pour 10 mm of sand on top.We accept the base plate with dimensions of 1200x1000 mm. Height - 100 mm. Mix and pour.

We start laying. The first row is the most important. Be especially careful and careful. Building such a pyrolysis oven with your own hands is not an easy task. We make all corners strictly perpendicular. Focus on the ordering of a conventional brick oven. Carry out laying to the firebox. As a binder, use ready-made mortars for laying furnaces. They are easy to get at any building materials store.

We carry out the device of the firebox

Note that there are 2 cameras here. First carry out the bookmark of fuel

Secondary air and gases enter the second during the pyrolysis process. This is the basic principle in the manufacture of a pyrolysis oven with your own hands. Focus on the dimensions shown in photo No. 1.

Installing the grate. Be sure to leave a small gap as the metal expands when heated.

We install our fan. Its function is to create an additional air flow to activate the convection process. The intensity of combustion will be regulated by a valve in the chimney, which allows you to increase or decrease the draft at your discretion.

We mount the doors on the firebox and blower.

Lay out the rest of the oven. Pay special attention to the chimney

It is important to strictly adhere to the chosen scheme. Any deviations can lead to smoke in the room.

Seal all cracks, joints, etc. carefully.

Now our oven needs to be tested, then dried

Lay a small amount of small firewood. About half an hour of burning. Light it up and watch for the smell of carbon monoxide.For drying - heat the oven for 2-3 hours twice a day for a week.

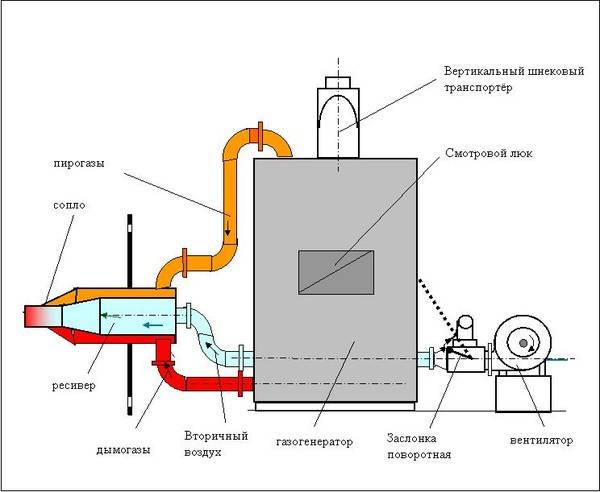

Pros and cons of gas generators

Pyrolysis combustion units are highly efficient and have a lot of competitive advantages:

- high performance - efficiency up to 95%,

- environmental friendliness - minimal smoke, no soot,

- comfortable service - they load fuel 1-2 times a day, depending on the model, there is no need for constant monitoring of the fuel supply,

- fuel variability - pyrolysis is able to work on any solid fuel resource. It can be various materials, including peat, pellets, wood, coal. Sawdust, husks, cardboard and other types of industrial waste are also used.

Another plus in the piggy bank is the availability of self-assembly and installation of the factory model of the gas generator and the possibility of making a pyrolysis furnace with your own hands.

The main disadvantage of long-burning units is the high cost of the product. Depending on the power, the models are sold in the range from 30 to 100 thousand rubles or more. Therefore, many are attracted by the idea of \u200b\u200bself-manufacturing a pyrolysis oven for the home from inexpensive materials.

Among the disadvantages of operating pyrolysis devices, fuel quality requirements are also noted. Firewood must be stored under proper conditions to ensure optimum moisture levels. Otherwise, the efficiency of the unit is reduced, since the presence of wet vapors adversely affects the process of gas processing.

Fuel for pyrolysis oven

Thus, there is nothing particularly difficult in self-laying a brick pyrolysis oven - the laying is carried out in the same way as in the case of most other stoves, and the differences are present only at the stage of arranging the firebox.

However, it is not enough to simply lay out such an oven. You still need to figure out how to heat it.

Fuel briquettes

The best fuel option for long-burning brick kilns is dry wood and its processed products (pellets, bars, etc.). The drier the fuel, the more thoroughly you compact it when loading, the more efficient and economical the operation of the furnace will be.

Fuel briquettes from sunflower husks

For comparison: when using fuel with a moisture content of up to 20%, a medium-sized pyrolysis furnace can safely produce about 4 kW of thermal energy from 1 kg of load, and when the wood moisture content increases to 50%, the performance indicator, other things being equal, decreases by more than 2 times. That is, you will have to spend 2 times more fuel, which means that heating costs will also increase 2 times.

Fuel briquettes-evrodrov from linden

Therefore, the fuel must be as dry as possible. Wet loading is not able to give out enough heat, because the pyrolysis process may simply not start. In addition, when using wet wood, a lot of smoke with harmful impurities will be released. Raw firewood will negatively affect the condition and functioning of the stove as a whole.

Pellets (granules)

In the absence of a sufficient amount of suitable fuel, it is possible to mix the available wood with a variety of construction waste - chipboard residues, plastics, rubber products, etc.This will allow you to dispose of waste and further save on heating.

But you shouldn’t get too carried away either - to ensure the high efficiency of the furnace, wood materials should account for at least 70% of the total load.

Now you will not have any problems with the self-construction of a long-burning brick oven. Follow the instructions, carry out the laying in accordance with the chosen order, remember the main features of pyrolysis fireboxes and everything will definitely work out.

Successful work!

The essence of the pyrolysis process

In pyrolysis boilers for solid fuels, such types of organics are used, which, during thermal decomposition, give a large yield of volatile combustible substances. Such boilers work not only on wood (and all types of fuel from wood, such as pellets or fuel briquettes), but also on coal, up to coking grades, the combustion temperature of which reaches very high values!

smoldering fuel

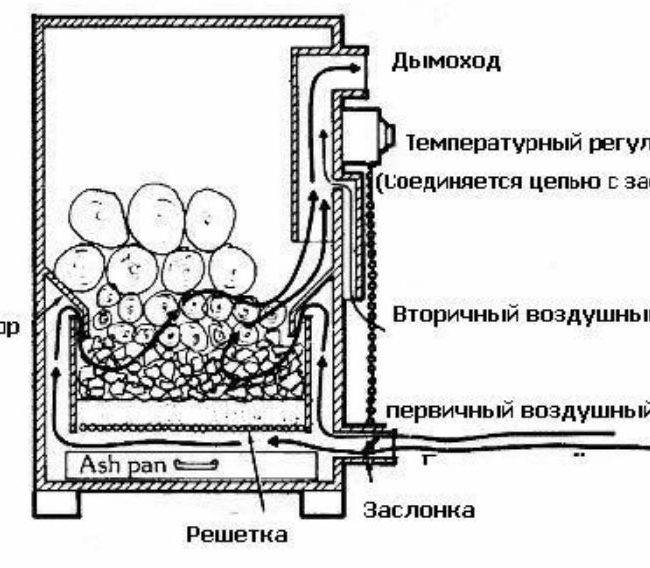

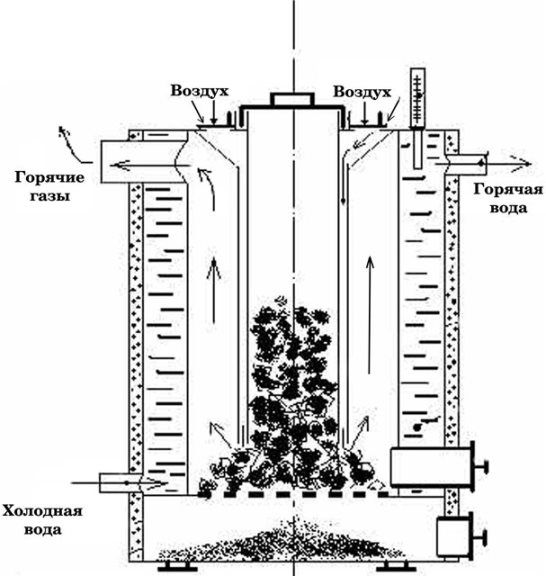

Fuel in pyrolysis boilers is placed on the grate. After igniting the loaded batch of fuel, the tight door closes and the smoke exhauster starts to work. As a result, a high temperature rises in the combustion chamber, up to 800 degrees, but there is no oxygen from the air for normal intensive combustion. Instead, fossil fuels smolder and char, releasing volatile gases, predominantly hydrocarbons.

Under the action of convection, volatile combustible gas enters the grate space. Together with them, nitrogen also migrates, which is in the primary air in the furnace. Under the grate of the grate, oxygen from the secondary air supply circuit is mixed with the gas mixture. The resulting mixture already has the ability to burn.It burns out, performing a useful function (for example, heating water in a heat exchanger), and in addition, the released heat goes back to the fossil fuel and supports the smoldering process.

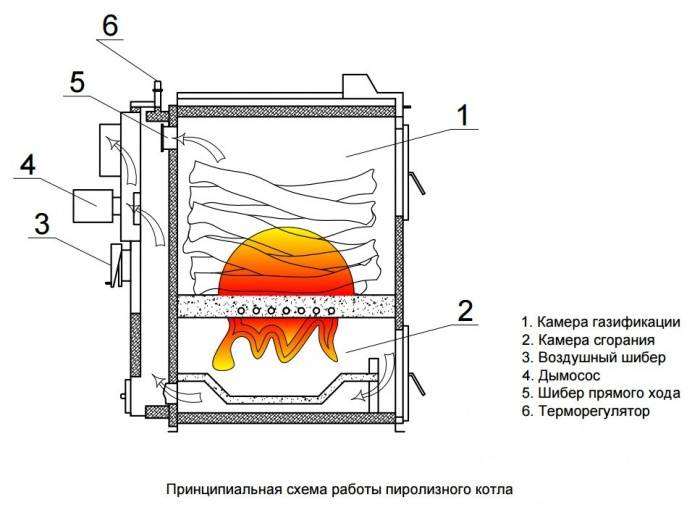

The principle of operation of the pyrolysis boiler

In relation to heating boilers, pyrolysis is the combustion of fuel with an insufficient amount of oxygen. At the same time, the fuel emits a large amount of gases, almost all of which are combustible. These gases are sent to a special combustion and afterburner chamber, where secondary air is supplied. The gas-air mixture ignites, releasing a large amount of heat. Much more thermal energy is released than can be extracted by conventional combustion of wood or coal. The fact is that many of the volatile substances formed during the combustion of fuel have a very high combustion temperature. As a result, pyrolysis boilers extract more heat from the same amount of fuel.

A design feature of pyrolysis boilers is a firebox consisting of two chambers. Fuel is placed in one (often this is the upper part of the furnace), gases are released in it, and therefore this part is called the gas generation chamber. Through a narrow neck, gases enter the second chamber - afterburning. Here they mix with secondary air, flare up and burn out almost without residue.

Pyrolysis boiler with bottom afterburner

On average, the efficiency of pyrolysis plants is above 85%. There are models that can give out 92% and even a little more. But these indicators are possible only and exclusively when using dry fuel. Its humidity should be 5-8%. At 40% moisture content, combustion can completely die out, and at 20% it will simply be inefficient.And this is one of the main disadvantages of this technology: firewood and coal have to be dried beforehand, for example, by making a platform near the chimney. It’s just that firewood dried in a woodshed will not go, like coal taken from a pile on the street.

The video shows a boiler in which the afterburner is at the top. Although boilers of this type have a simpler structure (the resulting gases themselves rise up), do-it-yourselfers prefer a chamber with a lower location of the afterburner (as in the photo above).

How to make a metal pyrolysis oven with your own hands

As you know, all metal pyrolysis furnaces are very mobile and can be moved in space. Therefore, many choose this type of stove.

To date, a large number of schemes for their manufacture have been presented, therefore, creating your own highly efficient heating unit is no longer problematic.

When designing a homemade pyrolysis oven, it must be taken into account that the pyrolysis process is not regulated, so you should pay due attention to the choice of materials: they must be of sufficient quality. With the right materials, a do-it-yourself pyrolysis boiler can serve its owners for a long time

With the right materials, a do-it-yourself pyrolysis boiler can serve its owners for a long time.

A metal furnace is made from durable and high-quality steel sheets, usually 2 walls are formed in the furnace. Between them the space is filled with water or sand.

The blower fan is an essential component of the stove, in which the gas chamber is located below, and provides such an element for supplying these gases downward, where the process of afterburning the gas residue takes place. Also, pyrolysis furnaces from gas cylinders are no less popular.

What you need to make

It is possible to make a pyrolysis oven from improvised materials without resorting to the purchase of expensive elements. To create a pyrolysis oven, you need a basic set of tools, as well as the main components of the oven itself.

Among them:

- Drill.

- Metal thickness 4-7 mm.

- Fan.

- Sensor.

- Welding machine and electrodes.

- Bulgarian, grinding and cutting wheels.

- Refractory brick (for long-burning brick boilers).

- Grids.

- Pipes of various sections (rectangular and round).

- Steel strip.

- Two small doors.

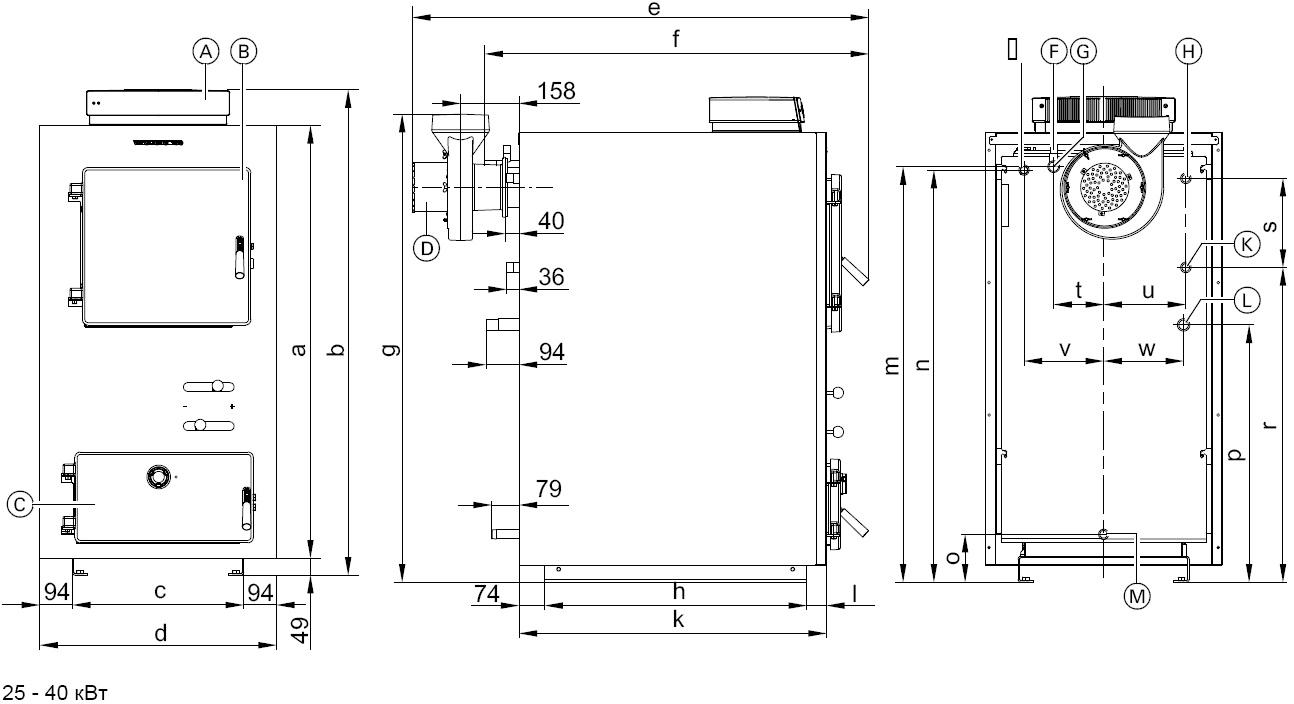

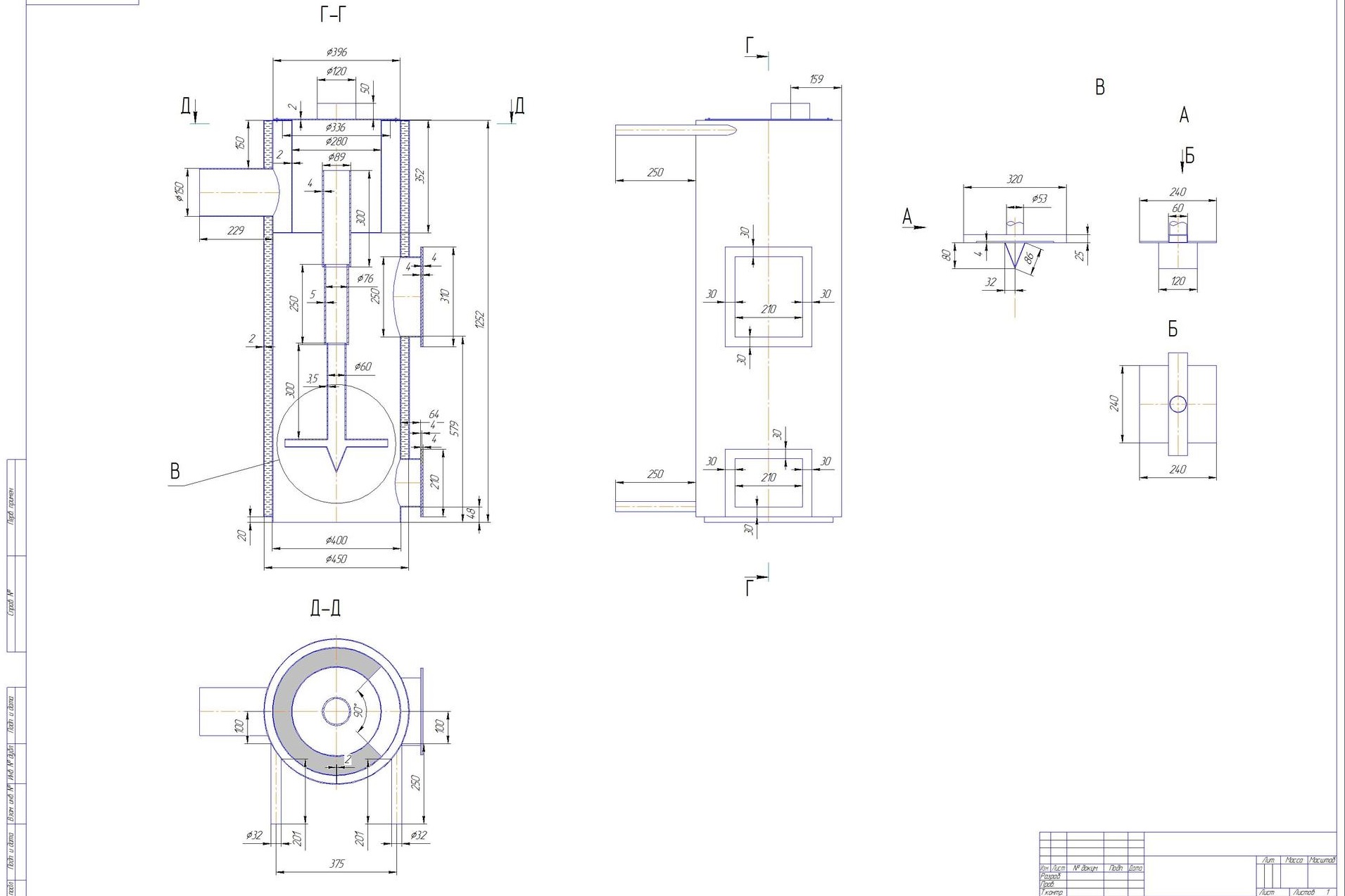

Necessary calculations

In the process of creating an efficient pyrolysis furnace, one of the main points is a well-drawn drawing and diagram of the future design.

To this end, it is necessary to determine in advance the desired size of the unit, the shape of the body, as well as options for the location of the cameras. Also, you need to calculate the required power of the device.

To do this, there are various formulas by which you can determine its effectiveness.

First of all, it is worth determining the amount of energy needed to heat the entire room.

Next, select the desired fuel and determine the volume of the fuel bookmark.

This value is calculated by the formula: M \u003d amount of heat / (15.5 * 0.8 * 0.5) (given that only 80% of the fuel burns out completely, and the efficiency of a home-made stove is approximately 50%). Next, the required volume of solid fuel combustion is calculated.

Preparatory actions on the spot

Usually, the assembly of the furnace itself takes place already at the place where it will stand in the future.

Therefore, it is important to prepare the installation site well.

The stove itself should be located at least 0.8 m from each nearest wall. At the place of its installation, a base is laid out of bricks or other non-combustible material, such as a sheet of iron, about 0.15 cm thick. In addition, the area of \u200b\u200bthis base should be chosen so that it is an order of magnitude larger than the stove itself.

Manufacturing process

For the manufacture of a pyrolysis furnace, first of all, it is necessary to make special metal blanks. By welding all the details, they get the frame of the stove.

After that, its walls are made, in which special holes for the firebox and an ash hole are made.

Also, in one of the side walls it is necessary to make a gap, which will act as a blower with a damper. It is made of a pipe with a round cross section and its diameter is 5-6 cm.

To connect the stove to the chimney, it is necessary to attach a branch with a diameter of about 11-12 cm to the opening of the lid, to which a bur is attached - a damper that delays the exit of gases from the afterburner, ensuring their combustion in full.

Features of operation and rules of the PPB

It is very easy to operate such a sauna stove:

- they collected thick and long firewood;

- filled them with the entire volume of the furnace;

- they opened the damper and the ash pan, made sure that the draft was good and lit the firewood.

Everything, as the firewood burns out, the stones heat up, the water heats up. You can call friends, take brooms and a supply of herbal decoction or just kvass and splash a few bowls on the stones, enjoy the fragrant and hot steam and conversation with loved ones.

During operation, it is important to follow the rules for the safe use of the oven. There are few of them and they are very simple:

- be sure to check the condition of the chimney. At the first sign of its malfunction or a decrease in traction, you will immediately need to fix all the problems. It is recommended to clean the chimney at least once a month;

- after the firewood starts burning, the ash pan door should be closed;

- the firebox door is opened only for laying firewood and controlling its combustion. All the rest of the time when the fuel is burning, the door must be securely locked;

- do not try to heat the oven by touching the sides with bare hands - this will lead to burns of the hands. The level of heating can be felt by the amount of steam from the stones when you splash water from the ladle on them.

Do-it-yourself pyrolysis oven: manufacturing process

The order of laying the furnace.

It is quite difficult to build such a furnace with your own hands from brick. If a complete set of necessary technical support is available, there will be a large number of nuances in connection with which you need to get advice from a specialist with relevant work experience.

You will need to work with a high combustion temperature and comply with existing sealing requirements, which is quite difficult to do yourself. You should be aware that such a design does not need to be connected to the heating system, since this device will simply heat the air in the rooms.

To enhance the moment of heat transfer from the inside, it is necessary to line the stove with special fireclay bricks; from the outside, the structure is lined with refractory bricks.

To build such a boiler, you will need not only to have the skills to work with a grinder and measurement tools, but also to be able to weld metal.

It should be understood that the manufacture of a pyrolysis stove consists not only in laying bricks, but also in installing or constructing a boiler, which is the main element of the entire fixture.

The easiest way is to purchase a ready-made boiler, and then overlay it with bricks. Thus, it is possible to obtain a brick structure, which only needs to be installed and connected.