- Which automation is better - mechanical or electronic

- Mechanical automation

- Electronic automatic control systems

- Electronics or mechanics

- How to calculate the volume and number of cylinders for the boiler

- 1 Equipment description

- How to convert a heating boiler to liquefied gas

- LPG boiler nozzles

- What is the consumption of liquefied gas at the boiler

- Which gas is more profitable to heat - natural or liquefied

- How to connect a gas boiler to a propane tank

- Is it possible to install gas cylinders in the boiler room

- Do I need to reconfigure the boiler for propane?

- What is required to switch the boiler to gas from a cylinder

- Types of products by location

- Option #1: floor equipment

- Option #2: Wall Mounted Devices

- Which automation is better

- german

- Italian automatics

- Russian

- What are the automatic settings?

- Room thermostat

- Thermal head

- Weather-dependent automation

- Why is it beneficial to contact us?

Which automation is better - mechanical or electronic

Devices that control the operation of heating equipment can be mechanical or electronic. In budget models of gas boilers, in most cases, a mechanical, manual control option is used.Despite the fact that the level of technological progress has reached unprecedented heights, mechanics remains a reliable and proven tool. Automatic safety of gas boilers, operating in manual control mode, is an order of magnitude cheaper. The principle of operation of most models of manual boilers is simple and understandable for domestic use.

The automation unit of the mechanical principle of operation is easier to maintain and repair. Dismantling such a unit is quite within the power of a specialist - a heat engineer who carries out a routine inspection of boiler equipment in your home.

Manual, mechanical control of a gas boiler, regardless of the power supply - the owner of the home independently sets the temperature necessary for heating the living space, everything else depends on the laws of physics that underlie the operation of the mechanism.

Mechanical automation

Manual adjustment of domestic gas boilers is provided by the entered settings of the specified range of optimal temperature values. The ignition of the flame wick of the combustion chamber starts the thermostat, which is sensitive to changes in the coolant medium.

Gas boiler burner

The temperature regulator boosts the gas supply to the burner when the water in the heating circuit cools, and shuts off the flow when it is hot enough. The temperature sensor is mounted in the gas pipeline. It is equipped with the following nodes:

- thermoelement;

- group of levers;

- spring pipe;

- core.

The core is a brass tube and an invar rod, a sensitive element that reacts to changes in the state of the coolant. By changing the length, it opens and closes the valve, adjusting the supply of energy to the combustion chamber of the device.

Electronic automatic control systems

The most common type of automation that is used in budget models of boilers is an electronic thermostat.

The device is installed indoors and controls heating based on signals from a remote temperature sensor located in the actual zone of the room. When the temperature drops below the set limit, the boiler is signaled to turn on. When the optimum temperature parameters are reached, the sensors transmit a shutdown signal to the system. Room thermostats have a cable connection with gas boilers.

In this case, the presence of a thermostat ensures the optimal heating temperature of the gas boiler and the economy of blue fuel consumption. To date, several types of thermostats are on sale, differing in functionality, technical characteristics and installation method. Programmable devices ensure that the optimum temperature regime is maintained inside the dwelling for a specified period of time.

Note: some models can automatically control the operation of a gas boiler during the day, other models of equipment are able to control the operating unit during the week. Wireless automatic control devices are also produced, allowing remote control of the operation of the boiler. The range of modern remote control systems, depending on the model chosen, is 25-100 m.

Electronics or mechanics

Modern boiler units, especially of Western production, are equipped with electronic boiler control systems, the cost of which reaches up to 30% of the total cost of the installation. The advantages of such a system are obvious, there is one minus - it is afraid of unstable operation Russian electrical networks. Therefore, it must be operated with reliable stabilizers and autonomous power sources.

The range of regulation and control of the electronic system is practically unlimited: from the pressure and temperature of the coolant to the weather-dependent regulation of the heating unit.

In the security system, the boiler will be cut off from the fuel supply at high / low gas pressure, flame separation, lack of vacuum in the furnace, low / high pressure and coolant T.

Mechanical actuators are also installed - a gas cut-off valve, triggered by unacceptable gas pressure and a safety relief valve that protects the internal circuit of the boiler from high pressure of the medium.

For example, the start of the Buderus boiler unit is performed by squeezing the washer of the gas valve, while it opens and gas is supplied to the igniter. It heats up the thermocouple, which generates enough current to drive an electromagnet to hold the valve open.

Next, the power of the boiler is set by the regulator, which passes gas in the required volume with the working pressure, and the heating process is controlled by a thermostat.

How to calculate the volume and number of cylinders for the boiler

As practice shows, for a house of 100 m², gas consumption will be approximately 2 cylinders per week. Accordingly, for a house of 200 m², the consumption will increase to 4 units. Per month gas heating boiler consumes 9 (100 m²) -18 (200 m²) propane tanks, depending on the total heated area. The calculation of the required number of containers is performed taking into account this coefficient.

So, gas boiler installation in a house on propane cylinders per 100 m², it will require at the same time to connect at least 4 cylinders (2 working and 2 reserve), per 200 m² 8-10. To ensure maximum ease of use, the connection kit must include a ramp.

You can accurately calculate the need for a bottled gas boiler using the technical documentation provided by the manufacturer. At least, European concerns in the instructions for the equipment indicate the consumption of LPG after the conversion of the unit.

Refueling of gas cylinders propane must be carried out after emptying the tank by 90%. Full gas production is not allowed.

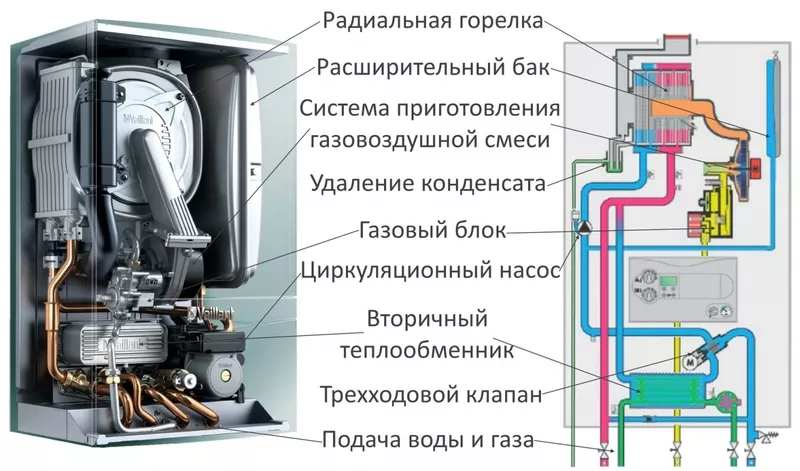

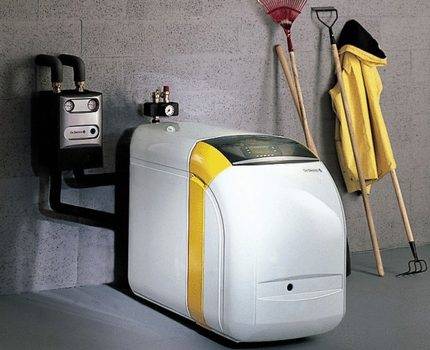

1 Equipment description

Propane boilers, in their design, resemble installations designed for a main gas pipeline. Such equipment consumes a minimum of fuel, and the entire operation of the burner is controlled by automation.

Built-in modules and computer units monitor various parameters of the boiler, ensuring its maximum possible safety. The design of the boiler consists of:

- combustion chambers with a burner;

- water jacket;

- smoke exhaust systems;

- control automation.

Subsequently, heated water or antifreeze is sent to the heating circuit with radiators, which allows you to quickly raise the temperature in the room. The difference between such boilers and classic installations designed to work with gas is the ability to operate in a low-pressure system, organizing the supply of propane from small-capacity cylinders.

How to convert a heating boiler to liquefied gas

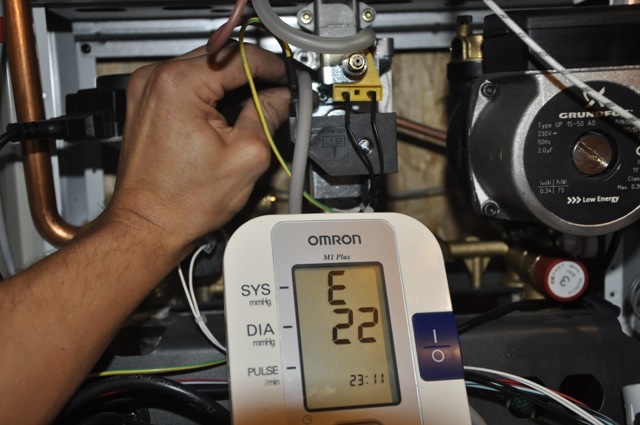

The main difference between natural gas and liquefied gas is that the former is supplied and burned at a higher pressure. Automation of conventional equipment is configured for indicators equal to 6-12 atm. When the indicators decrease, a pressure sensor is activated that turns off the burner.

The operation of a heating boiler on a propane-butane mixture requires a change in configuration and parameters:

- It is necessary to change the flow rate of the gas-air mixture.

- You will need to install a set of jets for liquefied gas.

- Adjust automation to other operating parameters.

Modern single-circuit and double-circuit heating boilers are designed to operate on liquefied and main gas. Re-equipment requires replacement of nozzles and switching the boiler to another mode.

The technical conditions for the use of liquefied gas in individual boilers that are not designed for this type of fuel differ significantly. In addition to replacing jets, a complex reconfiguration of automation and control valves will be required.

It is difficult to correctly adjust the gas supply to the boiler when switching to liquefied gas, set the minimum pressure limit and perform other work on your own, without special skills. According to current regulations, all work must be performed exclusively by licensed specialists.

In the technical documentation of heating equipment, the minimum pressure at which the burner continues to work is indicated. The lower this indicator, the more propane-butane mixture it will be possible to use from a filled fuel tank. Usually, 15-30% of the total volume remains in the container.

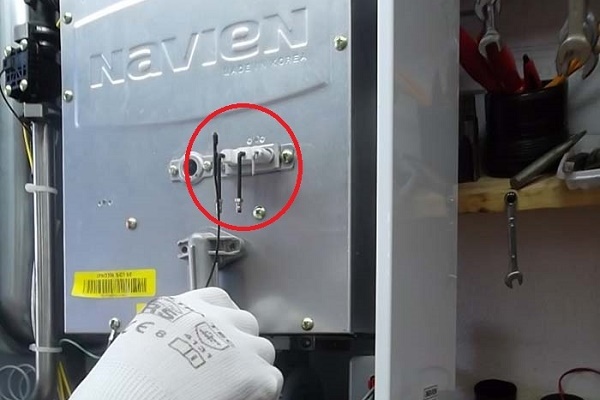

LPG boiler nozzles

In the section on how to transfer the heating boiler to the consumption of a gas boiler on liquefied gas, it was mentioned that it is necessary to replace jets or nozzles. Refurbishment is required for several reasons:

-

The difference between nozzles for liquefied and main gas lies in the different diameters of the outlet. As a rule, jets for propane-butane mixture are narrower.

- After installing a set of nozzles to transfer the heating boiler from natural gas to liquefied gas, the pressure in the system slightly increases.

- The reduced diameter of the jet leads to a decrease in the flow rate of the gas-air propane-butane mixture. For normal operation of a 10 kW unit, it is required that the pressure is no more than 0.86 kg / h.

Nozzles or jets are sold in sets. Some manufacturers, in the basic configuration, make all the fittings necessary for conversion. In other cases, the kit will have to be purchased separately.

What is the consumption of liquefied gas at the boiler

The volume of consumption of liquefied gas in gas heating boilers is indicated in the technical documentation provided by the manufacturer. For all models, it is different and depends on several factors:

- Performance.

- Burner type.

- Equipment setup.

The technical characteristics of the consumption of liquefied gas are also affected by how the selected model is adapted for this type of fuel. On average, for a 10-15 kW unit, it will take 2 per week and per month, 9 cylinders.

Which gas is more profitable to heat - natural or liquefied

The comparative consumption of natural and liquefied gas during the operation of a heating boiler shows that it is more profitable to heat a house when the boiler equipment is connected to the mains.It is worth heating with a propane-butane mixture only in the following cases:

- Changes in the design and reconfiguration of the boiler when using liquefied gas are temporary. It may take about six months from the start of registration and ordering a project for the installation of heating equipment connected to the main gas pipeline. During this period, it is not economically feasible to heat the room with electric or solid fuel heating equipment specially purchased for this purpose. The cost of converting a conventional boiler to liquefied gas ranges from 500-1000 rubles.

- Connecting a gas tank - in this case, the cost of using the mixture is more profitable than heating with wood, electricity or diesel fuel. The only condition is that the pressure of liquefied gas, adjust the operation of the automation, should be reported by a qualified specialist. Incorrect settings lead to an increase in flow, approximately 15%.

The economic component, operational safety, the possibility of switching back to natural gas - all these factors make it expedient to use boilers running on liquefied gas.

How to connect a gas boiler to a propane tank

Installing a gas boiler for autonomous heating using bottled gas is much easier than using main fuel. There are several rules regarding fire safety, equipment reconfiguration and power calculation that must be strictly observed.

Unauthorized installation is not recommended. It is better to invite a specialist.Subject to competent connection and qualified conversion of the boiler, installation work will take only a few hours.

Is it possible to install gas cylinders in the boiler room

The norms and rules for installing the cylinder are regulated by the requirements of the industrial security. In particular, it states that containers with liquefied gas cannot be located in the same room as heating appliances.

- Cylinders should be taken to an adjacent room or outside, installed in a special cabinet.

Store empty gas cylinders outside the building. Ideally, if the containers are immediately refueled.

If cylinders installed in a cabinet on the street freeze, the storage walls should be insulated with non-combustible thermal insulation. It is strictly forbidden to heat containers or a cabinet with an open flame.

The gas cylinder can be installed from the boiler heating at a distance at least 2 m.

Store compressed gas cylinders near the boiler room is prohibited. It is possible to store containers only in a specially equipped room located no closer than 10 meters, as well as equipped with ventilation and without pits, and a basement. This requirement is due to the fact that propane is heavier than air and accumulates at floor level when it leaks. In the presence of pits or a basement, the concentration of gas will become critical, which is enough for an explosion.

Operation of cylinders - full production of LPG from the tank is not allowed. Every 4 years, it is required to certify the tightness of the cylinders and the integrity of their walls.

Do I need to reconfigure the boiler for propane?

A conventional boiler from gas cylinders works only if certain conditions are met and a conversion is performed.It is not necessary to reconfigure the equipment, but it will be necessary to install additional fittings to stabilize the gas pressure.

Not every boiler is able to work on LPG

You should pay attention to the technical documentation. An essential requirement is the ability of the unit to operate at a reduced gas pressure of 3-4 mbar

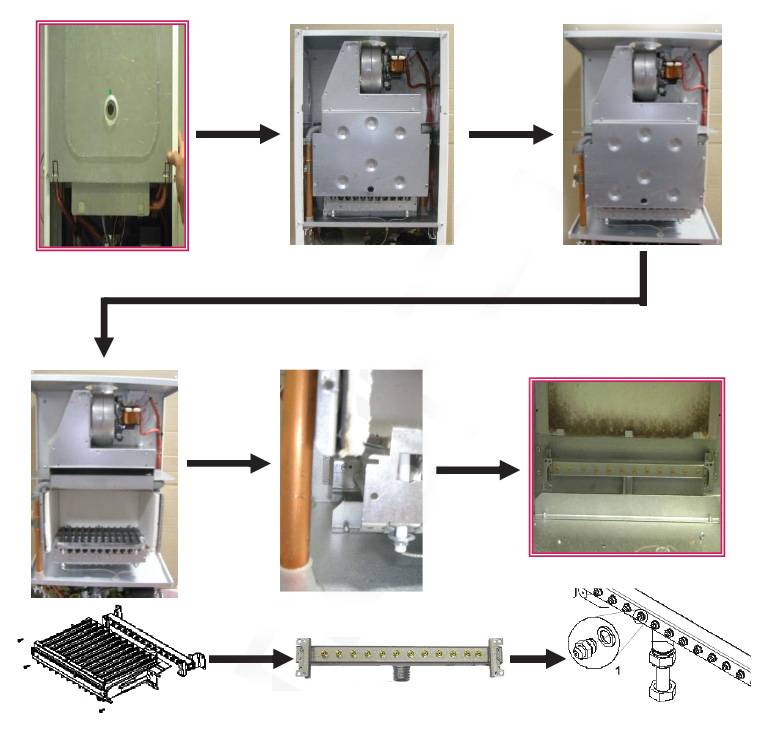

What is required to switch the boiler to gas from a cylinder

For the normal operation of the LPG boiler, several important conditions will need to be met:

- Replacing nozzles or burners. Gas-balloon water-heating equipment designed to operate exclusively on LPG is not produced. Some manufacturers make universal units equipped with an electronic processor. To switch from main gas to cylinders, you simply need to change the cartridge. But more often, conversion will require the replacement of nozzles or the entire burner.

Gearbox installation. Liquefied gas is pumped into cylinders under pressure, which leads to the transformation from a gaseous to a liquid state. To transform it back, you need to lower the pressure. For this purpose, a gearbox is designed.

Gas valve - in some models, connection and operation of a household gas boiler on bottled gas possible only when replacing this node.

A conventional gas reducer is not suitable for conversion. A gas heating boiler can operate from ordinary bottled gas only when installing a unit with a flow rate of 1.8-2 m³ / h.

Types of products by location

Equipment in operation on liquefied fuel, happens floor and hinged. Each option has specific characteristics that make it attractive and practical under certain conditions.

With this information in hand, the owners can independently determine which device is most suitable for them, and then purchase it in a specialized store.

Option #1: floor equipment

Floor-standing devices are the most widely used. These are high-power units capable of providing comfortable heat and hot water not only to standard residential buildings, but also to large country cottages.

The main operating element of the devices is a pressurized gas burner. It has a good degree of efficiency and is characterized by high heat dissipation.

Floor-standing devices show stability in operation even with a strong drop in gas pressure in the system and reliably serve in intensive operation from 15 to 25 years, depending on the manufacturer

The boilers are equipped with a cast iron or steel heat exchanger. The cast iron element is heavy and has a long service life. A steel object is much lighter, but exhibits brittleness, sensitivity to mechanical damage and shock, and lasts for a shorter period of time.

In addition to the basic elements, progressive modules have all kinds of auxiliary equipment that increases operational safety. These are sensors for controlling the level of thrust, the volume of the coolant and the presence of a flame, as well as thermostats that block operation in case of an emergency high level of heating of the working fluid

The device, depending on the manufacturer, is equipped with a piezo or electronic ignition system. In the first variant, the device is started manually by pressing a button.

In the second case, activation occurs automatically, and the boiler does not consume excess fuel during operation, since there is no igniter in the system with a flame burning in a constant mode.

Detailed information on selection and installation floor gas boilers featured in articles:

- Floor-standing gas heating boilers: types, how to choose, an overview of the best brands

- Do-it-yourself installation of a floor-standing gas boiler in accordance with technical installation standards

Option #2: Wall Mounted Devices

Boilers designed for wall mounting are distinguished by their compact size and modern appearance. They occupy a minimum amount of space and are suitable for placement in small-sized rooms of complex layout.

The installation of a mounted boiler is always carried out by a master with experience in such a plan. The equipment must be installed in accordance with the safety requirements for domestic gas systems.

Functionally, mounted gas units are no different from floor-standing ones, however, they have slightly less power and are not very suitable for use in large, spacious houses. But they economically consume a fuel resource, while providing a high level of comfort in a residential area.

Which automation is better

Today, the market for boiler equipment is oversaturated with proposals for the automation of boilers, coming from both imported and domestic manufacturers.

The former are very expensive and capricious, they do not tolerate the working conditions of Russian engineering networks, the latter are less functional.The best automation for a boiler is always its own, that is, produced in a single configuration by the manufacturer.

It is there on the stands that she gets the correct setting with the operating modes of the unit. An equally important factor in boiler room automation is the manufacturer's warranty obligations, which must guarantee its operation for at least a year free of charge and replace the unit in case of failure.

german

German automation for Vaillant, Honeywell, AEG, Bosch boilers is quite popular in the Russian market, due to its excellent consumer quality, durability and reliability. High level of automation and protection. Recently, German manufacturers have set up automation of condensate boilers that provide efficiency. almost 100%.

Italian automatics

EuroSIT 630 is considered the best Italian automatic system for gas boilers in the world. It is produced in full compliance with EU standards, but at the same time they have a lower price than German systems.

Automation boilers EuroSIT 630 covers all parameters of the boiler, but is very sensitive to the parameters of the gas line and the power grid. For this system, the mandatory installation of input voltage stabilizers.

Russian

Recently, more and more boilers are purchased with Russian automation systems, since they provide a good protection system and reliable boiler control at the lowest price level.

The experience gained with the automation of processes in industrial boilers has been successfully integrated into the operation of domestic boilers using the latest technologies and developments of European manufacturers.Among the large number of Russian companies, especially, the most popular are Neva-Transit and Lemax.

What are the automatic settings?

At the moment, the market presents the consumer with a wide range of control devices. Therefore, it is necessary to know what kind of automation for home heating systems generally exist, what to give preference to.

Room thermostat

According to the installation criteria, there are:

- Wired thermostats. The advantage of this type is the ability to conduct power up to approximately 50 meters through wires.

- Wireless thermostats. The advantage is that it is not necessary to create a hole for the wires. However, they have a significant drawback - reinforced concrete walls reduce the signal strength.

By functionality, they distinguish:

- simple thermostats. They keep the right level of warmth.

- Programmable thermostats. Such devices are able to set a certain number of degrees for a whole week in advance (the period depends on the model) with a maximum accuracy of seconds. The advantages can also be counted as cost savings due to weekly programming.

There are also thermostats:

- Electronic thermostats. The kit contains three components: temperature sensor, signal transmitter, relay. The main advantage of the device is the maximum accuracy of the equipment. Don't forget ease of use.

- Mechanical thermostats. The basis of the devices is the ability to change properties under the influence of the temperature level. Due to temperature changes in the gas membrane, the circuit closes or opens, forcing certain mechanisms to work.

- Electromechanical thermostats. The mechanism of the device is much simpler than electronic. The main element is the relay.The node looks like a tube, which is filled with a special substance that reacts to temperature. If the cauldron heats up, then the substance expands; similarly, the cauldron cools down - the substance contracts. And the substance-dependent drive, thanks to the electrical circuit, regulates the temperature.

Connection can be made to:

- boiler;

- pump;

- Servo drive;

Thermal head

This is a thermostatic element that, under the influence of the external environment, slightly opens or closes the radiator. Inexpensive type of automation for home heating. A significant plus is that the thermal head is very convenient for local heating, and there are also significant cost savings. Of the minuses: firstly, the adjustment takes place by the standards, consisting of abstract numbers, not degrees. Secondly, the sensor measures the degree of heat around the installation, but not the room, which reduces the accuracy of the device.

Weather-dependent automation

The design of weather-dependent automation for heating a house is simple: the weather outside decreases, the temperature of the coolant increases. However, the weather-dependent installation has a very significant drawback - the system sometimes does not have time to adapt to the temperature, and, therefore, the effect is delayed. Especially the mentioned minus is manifested if an addition is connected - heated floors. The disadvantages include the fact that the devices do not work quite correctly, approximately, so the change is noticeable only with a seasonal change in climate. It is worth noting that the prices for the unit are relatively high. But the units will be very convenient in production, large-scale houses (over 500 square meters).

Why is it beneficial to contact us?

The company's staff has experience in equipping boiler rooms in residential buildings and industrial enterprises. We will find the right solution for any given task. High-quality equipment with proven equipment guarantees the timely response of tracking devices to a dangerous signal and the prevention of an emergency situation.

We offer a range of services: selection of equipment, professional installation, adjustment, subsequent maintenance with performance monitoring. Automatic equipment is individually selected for each object. We guarantee that we will take into account the maximum wishes.

The complex of services is offered at attractive prices. Experience allows us to find profitable solutions for each client. To view the proposed rates and discuss the terms of the contract, call us. Be sure that after the conclusion of the contract, the employees will soon cope with the task. Take advantage of the offer today to get the desired result at a reasonable cost!